Similar presentations:

Two different PCBs, addressing hundreds of applications, with thousands in volume

1.

Two different PCBs, addressing hundreds ofapplications, with thousands in volume...

5802A2XX

1

Title

5802A1XX

2.

Electrical specifications...Small footprint. Big leap in quality and

reliability. Just as 5333.

• RTD or Ohm input

• 2- / 3-wire RTD connection

• -200…+850 degree C

• 0…10kꭥ

• Accuracy: Better than 0.1% of selected range

• Programmable sensor error value

• Output 4...20 mA, with or without M12

connector.

• Programmable via PReset

2

Title

3.

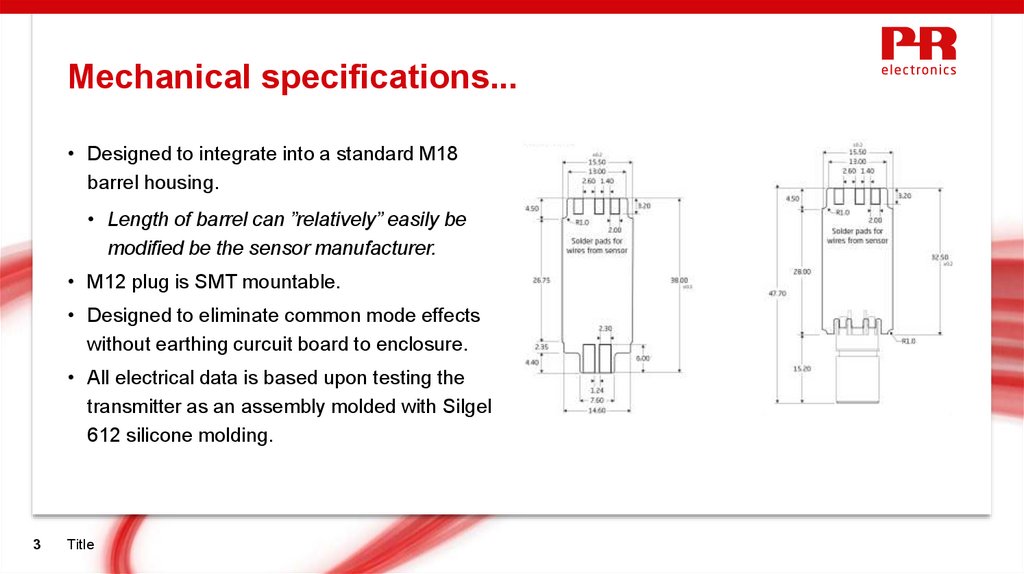

Mechanical specifications...• Designed to integrate into a standard M18

barrel housing.

• Length of barrel can ”relatively” easily be

modified be the sensor manufacturer.

• M12 plug is SMT mountable.

• Designed to eliminate common mode effects

without earthing curcuit board to enclosure.

• All electrical data is based upon testing the

transmitter as an assembly molded with Silgel

612 silicone molding.

3

Title

4.

What components constitute an assembly?5802A2XX

5802A1XX

4

Title

5.

Important installation points...5

5802A2XX Installation:

5802A1XX Installation:

• Handle components with ESD precaution!

• Handle components with ESD precaution!

• Requires mounting the PCB from the inside of

the barrel, with the M12 connector guiding and

”locking” the PCB into the process connection.

• Requires mounting the M12 from the ouside of

the process connection before soldering onto

the PCB soldering patches.

• Silgel 612 silicone molding to fix the PCB and

protect the components, only leaving the 3

input soldering patches exposed.

• Silgel 612 silicone molding to fix the PCB and

protect the components, only leaving the 3

input soldering patches exposed.

• Solder the sensor onto the soldering patches.

• Solder the sensor onto the soldering patches.

• Connect the thermowell with loctite onto the

barrel.

• Connect the thermowell with loctite onto the

barrel.

Title

6.

Where is it being used?• Very robust and accurate electronics for

compact sensors.

• Capable of measuring temperature in a variety

of media with RTD integrated into a standard

thermowell mounted into the process stream.

• Mountable in confined spaces.

• Depending on enclosure, suitable for general

purpose and hygenic applications in ie. life

science, food & beverage and common

industries.

• ”Consumable” product.

6

Title

7.

Where do we differentiate?• Easy programming through PReset.

• Designed to eliminate common mode effects without

establising a connection between curcuit board and

steel enclosure.

• Operates down to -40 degrees.

• Wider and programmable measurement ranges

available within the same unit.

• Supports both RTD and Lin. R. Input type.

• Higher accuracy.

• Lower temperature coefficient.

• Very strong EMC performance.

• Calibration of input/output in PReset.

7

Title

8.

Temperature sensor manufacturers...You know who they are: All 1104 of them. What

could be their counter arguments?

• Size:

• Barrel M18 is standard. Length can be

modified.

• Price on 5802A2:

• We upcharge more than cost of M12 plug

(they know this cost), but also eliminate a

burdensome step in their assembly process.

• We are missing I/O link:

• So is the competition making PCB’s.

8

Title

NB: Do not use the temperature sensor

manufacturers to build a full assembly, that

PR SUBs then re-sells.

9.

How do they program it?9

Title

10.

What are we selling?• MOQ is 40pcs.

10

Title

• Looplink:

5909

• M12 female interface cable:

8509

electronics

electronics