Similar presentations:

Carnelian Р416

1.

ai

l

e

n

r

a

C n

6

1

PDP Training Manual

2.

Agenda1. Introduction to PDP

2. Manufacturing & Structure of Panel

3. PDP Driving Characteristics

4. CARNELIAN Training

5. Trouble shooting

6. CIRCUIT DIAGRAM

3.

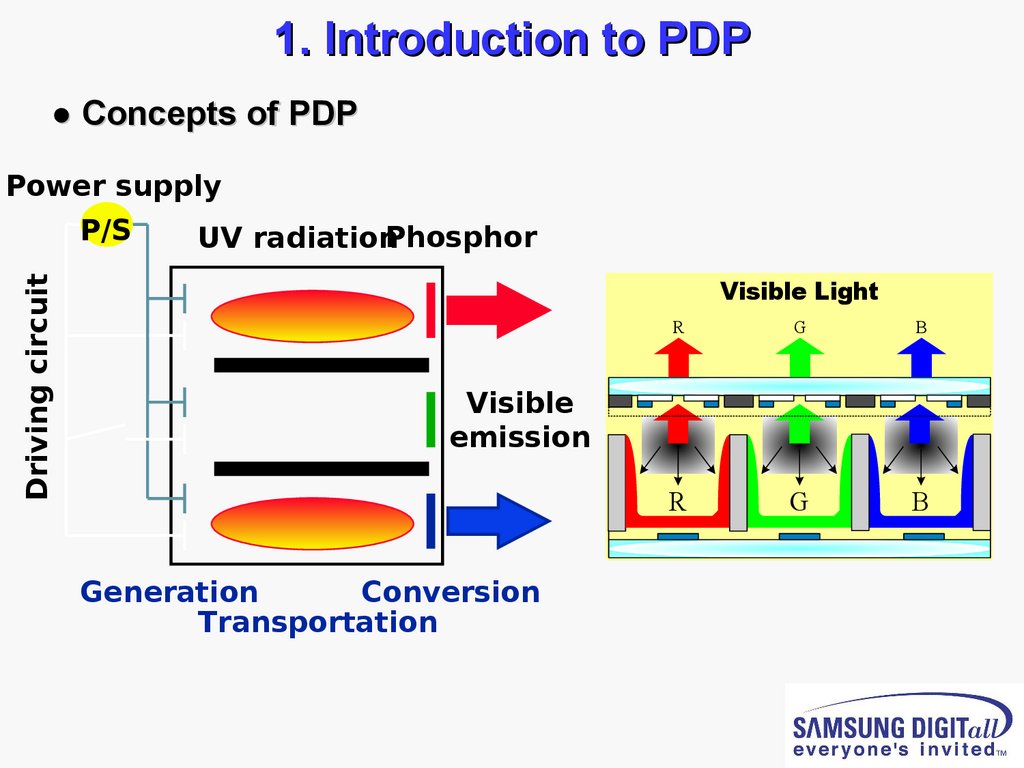

1. Introduction to PDP● Concepts of PDP

Power supply

Driving circuit

P/S

UV radiationPhosphor

Visible Light

R

G

B

R

G

B

Visible

emission

Generation

Conversion

Transportation

4.

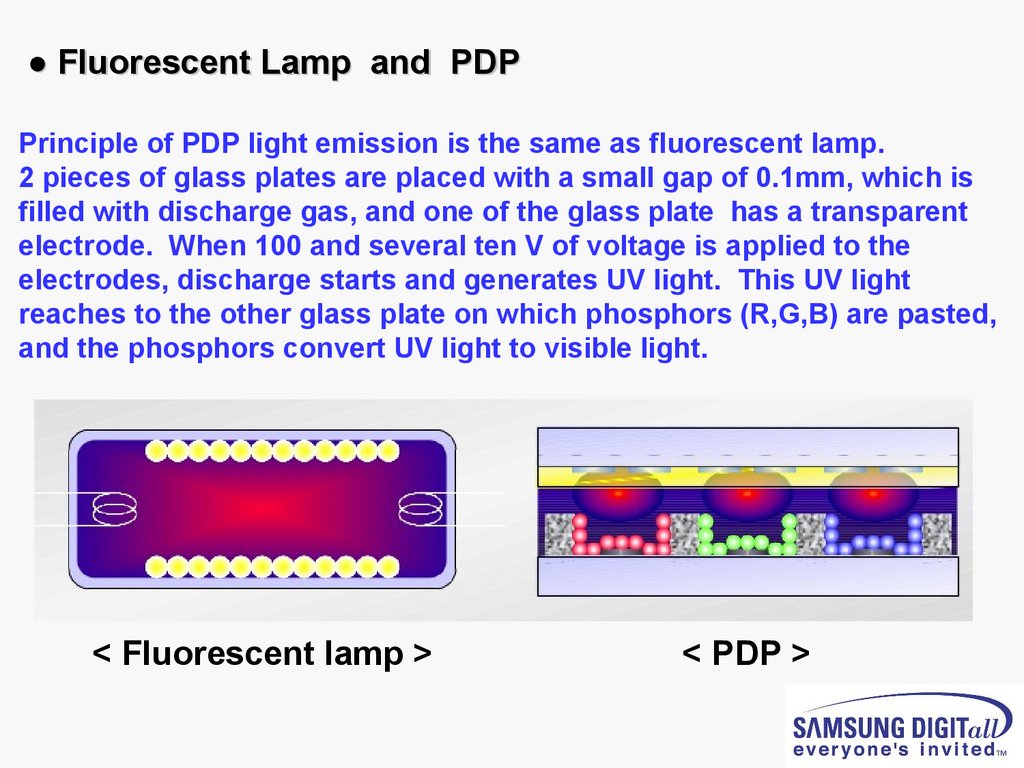

● Fluorescent Lamp and PDPPrinciple of PDP light emission is the same as fluorescent lamp.

2 pieces of glass plates are placed with a small gap of 0.1mm, which is

filled with discharge gas, and one of the glass plate has a transparent

electrode. When 100 and several ten V of voltage is applied to the

electrodes, discharge starts and generates UV light. This UV light

reaches to the other glass plate on which phosphors (R,G,B) are pasted,

and the phosphors convert UV light to visible light.

< Fluorescent lamp >

< PDP >

5.

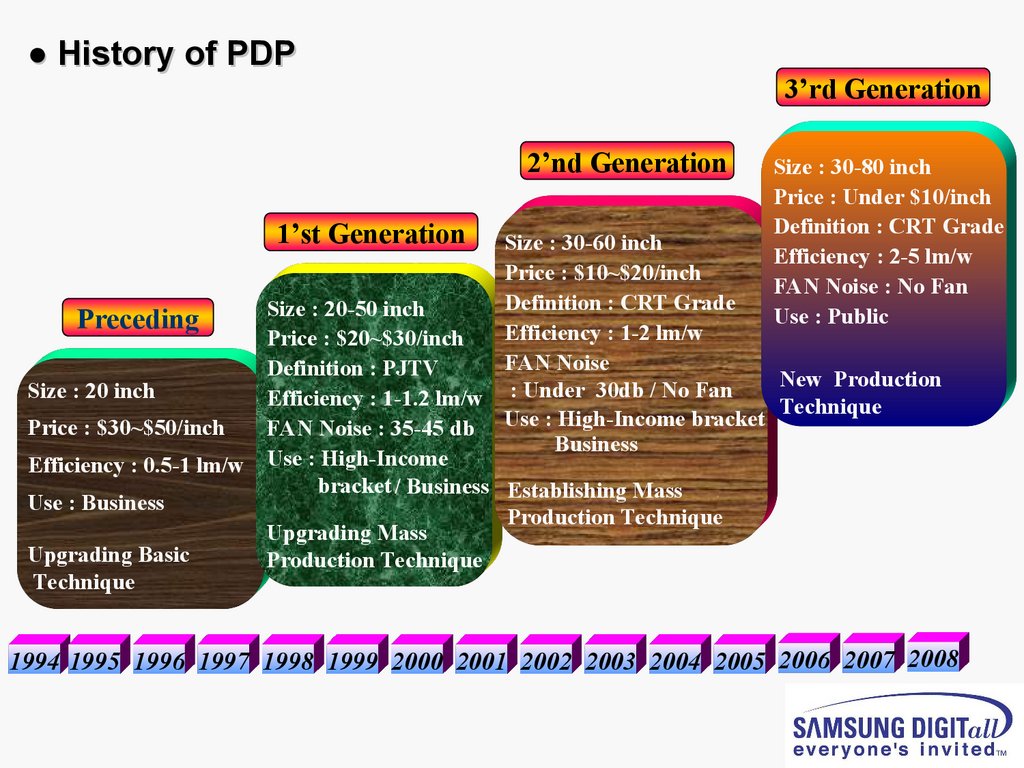

● History of PDP3’rd Generation

2’nd Generation

1’st Generation

Size : 30-80 inch

Price : Under $10/inch

Definition : CRT Grade

Efficiency : 2-5 lm/w

FAN Noise : No Fan

Use : Public

Size : 30-60 inch

Price : $10~$20/inch

Definition : CRT Grade

Size : 20-50 inch

Preceding

Efficiency : 1-2 lm/w

Price : $20~$30/inch

FAN Noise

Definition : PJTV

New Production

:

Under

30db

/

No

Fan

Size : 20 inch

Efficiency : 1-1.2 lm/w

Technique

Use

:

High-Income

bracket

Price : $30~$50/inch

FAN Noise : 35-45 db

Business

Use

:

High-Income

Efficiency : 0.5-1 lm/w

bracket / Business Establishing Mass

Use : Business

Production Technique

Upgrading Mass

Upgrading Basic

Production Technique

Technique

1994 1995 1996 1997 1998 1999 2000 2001 2002 2003 2004 2005 2006 2007 2008

6.

● Merits & Demerits of PDP< Merits

Merits >

>

<

<

< Demerits

Demerits >

>

ThinType

TypeTV

TV

--Thin

LargeScale

Scale::80”

80”possible

possible

--Large

--High

HighPower

PowerConsumption

Consumption

--Low

LowBrightness

Brightness

LightWeight

Weight(42”

(42”Scale)

Scale)

--Light

PDP30kg

30kg//CRT:

CRT:over

over100kg

100kg

::PDP

--High

HighCost

Cost

--Low

LowLighting

LightingEfficiency

Efficiency

LCD40”

40”32Kg

32Kg

::LCD

WideAngleview

Angleview

--Wide

--Image

ImageRetention

Retention

--Operation

OperationTemperature

Temperature

HighDefinition

Definition

--High

cellpitch

pitch0.1mm

0.1mm

::cell

--Acoustic

AcousticNoise

Noiseof

ofDriving

Driving

Not-Sensitiveto

toMagnetic

MagneticField

Field

--Not-Sensitive

Full-color

--Full-color

GoodNon

Nonlinerity

linerity

--Good

Noneed

needfor

forTFT

TFTlike

likeLCD

LCD

::No

7.

Manufacturing &Structure of Panel

8.

2. Manufacturing & Structure of Panel● Cell Structure of Panel

Bus electrode

Front panel

Dielectric

MgO layer

Barrier

Address

Electrode

ITO electrode

Phosphors

Back panel

9.

● Cell Structure of Panel10.

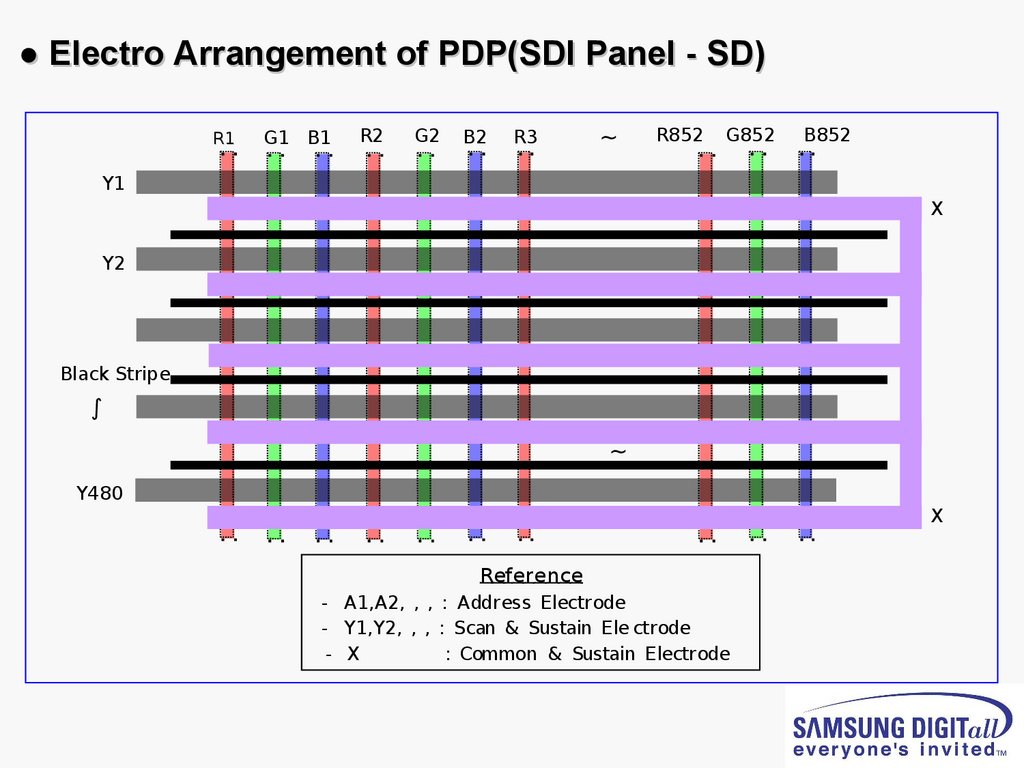

● Electro Arrangement of PDP(SDI Panel - SD)R1

G1 B1

R2

G2

B2

R3

∼

R852

G852

B852

Y1

X

Y2

Black Stripe

∫

∼

Y480

X

Reference

- A1,A2, , , : Address Electrode

- Y1,Y2, , , : Scan & Sustain Ele ctrode

- X

: Common & Sustain Electrode

11.

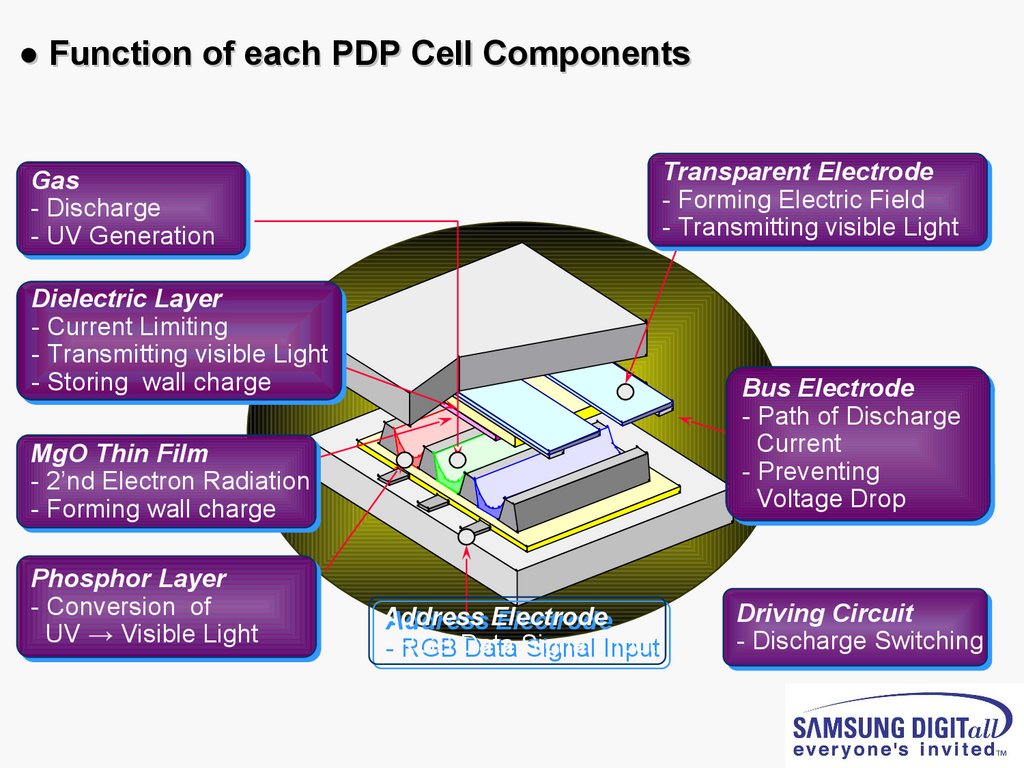

● Function of each PDP Cell ComponentsTransparent

Transparent Electrode

Electrode

-- Forming

Forming Electric

Electric Field

Field

-- Transmitting

Transmitting visible

visible Light

Light

Gas

Gas

-- Discharge

Discharge

-- UV

UV Generation

Generation

Dielectric

Dielectric Layer

Layer

-- Current

Current Limiting

Limiting

-- Transmitting

Transmitting visible

visible Light

Light

-- Storing

Storing wall

wall charge

charge

Bus

Bus Electrode

Electrode

-- Path

Path of

of Discharge

Discharge

Current

Current

-- Preventing

Preventing

Voltage

Voltage Drop

Drop

MgO

MgO Thin

Thin Film

Film

-- 2’nd

2’nd Electron

Electron Radiation

Radiation

-- Forming

Forming wall

wall charge

charge

Phosphor

Phosphor Layer

Layer

-- Conversion

Conversion of

of

UV

UV →

→ Visible

Visible Light

Light

Address

Address Electrode

Electrode

-- RGB

RGB Data

Data Signal

Signal Input

Input

Driving

Driving Circuit

Circuit

-- Discharge

Discharge Switching

Switching

12.

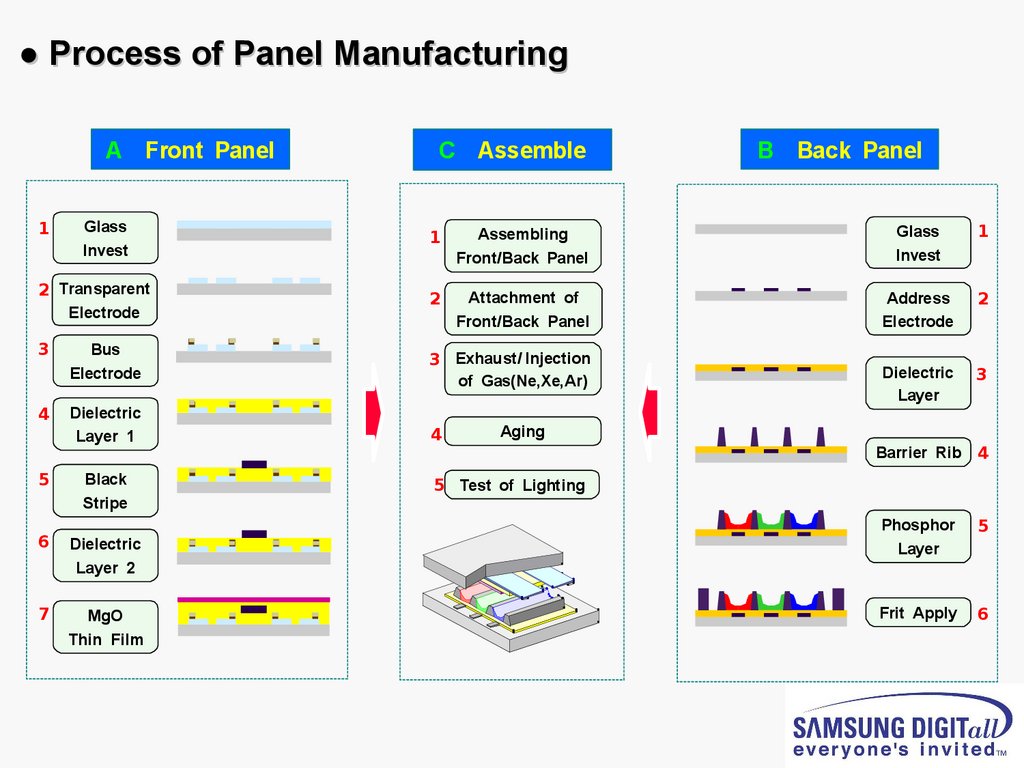

● Process of Panel ManufacturingA Front Panel

1

Glass

Invest

2 Transparent

Electrode

3

4

C Assemble

1

Assembling

Front/Back Panel

Glass

Invest

1

2

Attachment of

Front/Back Panel

Address

Electrode

2

Dielectric

Layer

3

Bus

Electrode

3 Exhaust/ Injection

of Gas(Ne,Xe,Ar)

Dielectric

Layer 1

4

5

Black

Stripe

6

Dielectric

Layer 2

7

MgO

Thin Film

B Back Panel

Aging

Barrier Rib 4

5 Test of Lighting

Phosphor

Layer

5

Frit Apply

6

13.

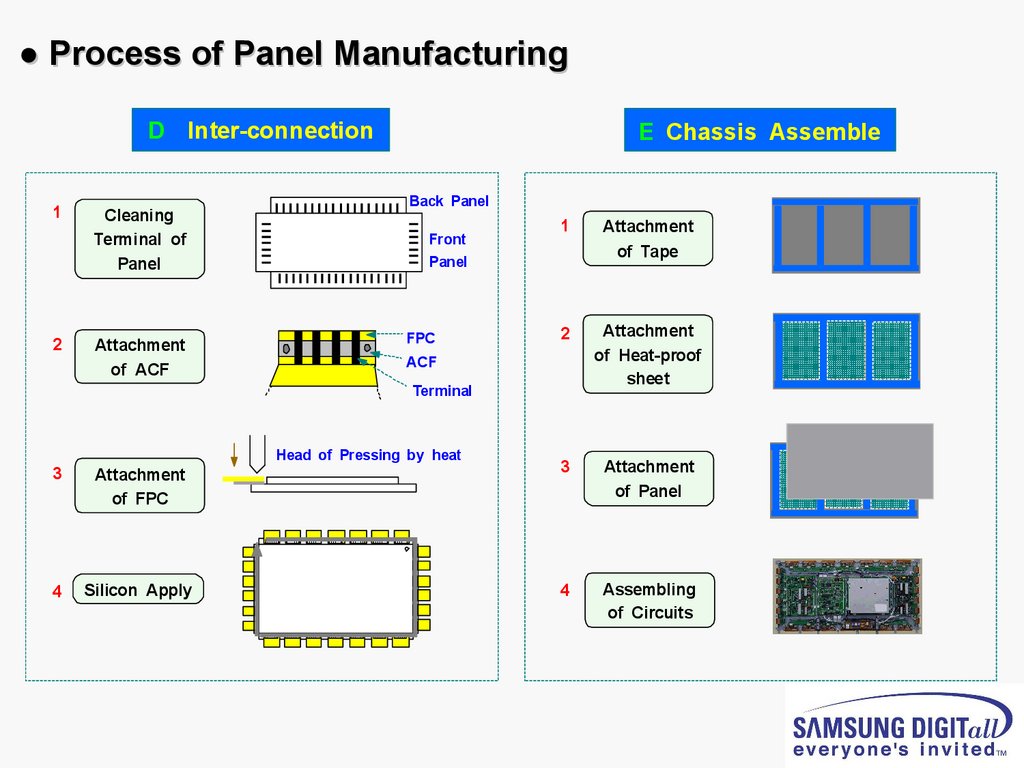

● Process of Panel ManufacturingD Inter-connection

1

2

Cleaning

Terminal of

Panel

Attachment

of ACF

E Chassis Assemble

Back Panel

Front

1

Attachment

of Tape

2

Attachment

of Heat-proof

sheet

Panel

FPC

ACF

Terminal

Head of Pressing by heat

3

Attachment

of FPC

3

Attachment

of Panel

4

Silicon Apply

4

Assembling

of Circuits

14.

PDP DrivingCharacteristics

15.

3. General PDP Driving Characteristics● Function Description by board - 1

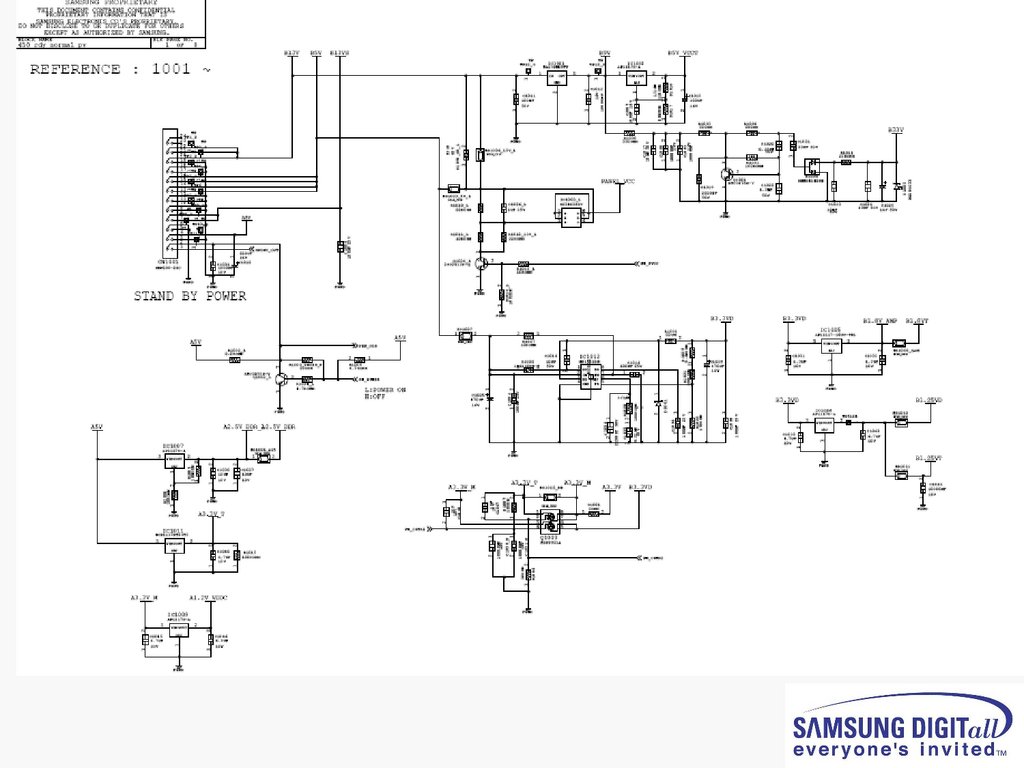

■.SMPS(Switching Mode Power Supply)

: It is the supplier to provide voltage and current to work the drive voltage and panel in each board.

■.X-MAIN BOARD

: It makes the drive wave form by switching FETs to Timing Controlle coming from logic-board and

supplies X electrode of panel with the drive wave form via connector.

■.Y-MAIN BOARD

: It makes the drive wave form by switching FETs to Timing Controller coming from the logic-board

and provides Y electrode of panel with the drive wave form via Scan Driver IC on Y buffer board

in order.

■.LOGIC MAIN BOARD

: It process image signal and performs buffering of the logic-main board (to create XY drive signal

and output) and the address driver output signal.

Then it supplies the output signal to the address driver IC(COF Module).

16.

● Function Description by board - 2■.LOGIC BUFFER(E,F) : It delivers the data signal and control signal to the COF.

■.AC Noise Filter

: It has functions to remove noise(low frequency) coming from AC LINE and prevent surge.

It gives serious effects on the safety regulations (EMC, EMI) according to AC filter.

■.COF (Chip on Flexible)

: It impress the Va pulse to the address electrode in the address section and forms the

address discharge by electric potential difference with scanning pulse to be dismissed

by the Y electrode. It is made in the form of COF and one COF consists of 4 Data Drive IC

(STV7610A :96 Output), otherwise single scan is made of 7 COF.

17.

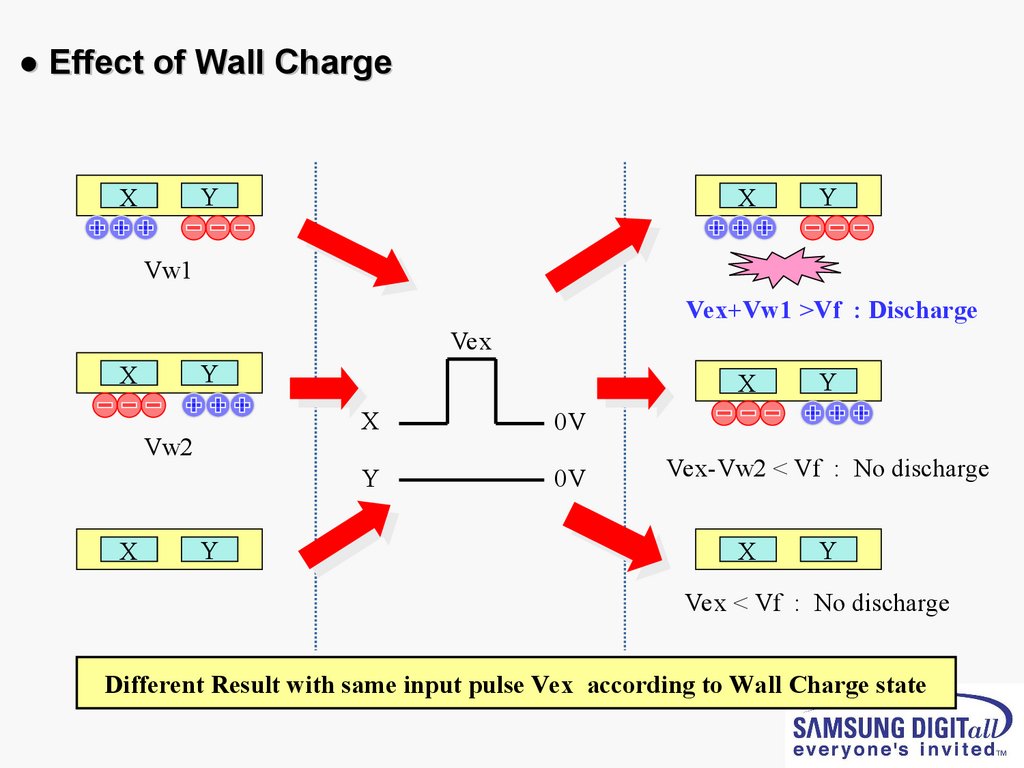

● Effect of Wall ChargeY

X

X

Y

Vw1

Vex+Vw1 >Vf : Discharge

Vex

Y

X

Vw2

X

Y

X

X

0V

Y

0V

Y

Vex-Vw2 < Vf : No discharge

X

Y

Vex < Vf : No discharge

Different Result with same input pulse Vex according to Wall Charge state

18.

● 1 Sub-Field Image Process(ADS – Address Data Separate)Reset

Function

Function

••Sustain

SustainErase

Erase

••Wall

WallCharge

ChargeSet

Set

Issue

Issue

••Operation

Operationmargin

margin

••Contrast

Contrast

••Short

ShortTime

Time

Address

Sustain

Function

Function

••Select

SelectOn

OnCell

Cell

Function

Function

••Discharge

DischargeOn

OnCell

Cell

Issue

Issue

••High

HighSpeed

Speed

••Low

LowVoltage

Voltage

••Low

LowFailure

Failure

Issue

Issue

••High

HighEfficiency

Efficiency

••Low

LowVoltage

Voltage

••ERC

ERCPerformance

Performance

19.

● Driving Waveform Specification (P3 Alexander)Reset

Address

Sustain

Y rising

Y sustain

Ramp

Pulse

Y falling

Ramp

Y scan

Pulse

X sustain

Pulse

Address

Pulse

A1,2.....

X

Y1,2....

Address(=Data) Electrode

Vs

85V

Ve

110V

Common & Sustain Electrode

Vset

95V

Va

79V

Scan & Sustain Electrode

Vscan

85V

20.

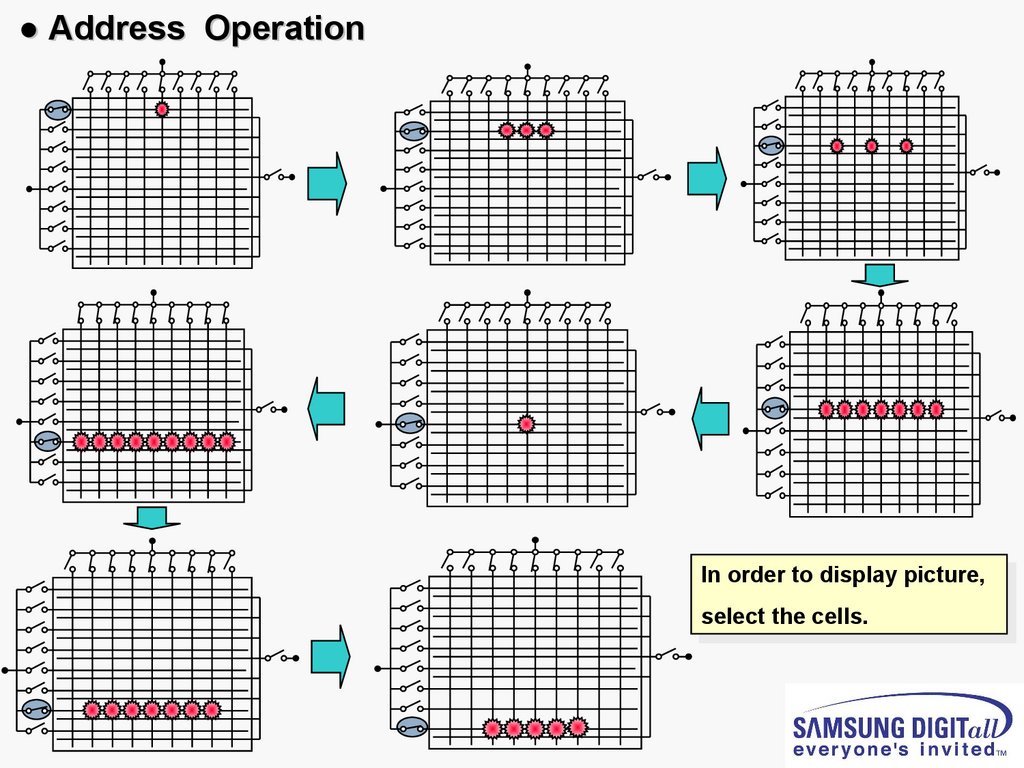

● Address OperationIn

Inorder

orderto

todisplay

displaypicture,

picture,

select

selectthe

thecells.

cells.

21.

● Sustain OperationDisplay

Displaycells

cellsthrough

throughstrong

strong

Sustain

Sustaindischarge.

discharge.

22.

● Combination of R,G,B Light1 - Pixel

Level of Luminance

RED 4096 Levels

Green 4096 Levels Blue 4096 Levels

68.7 Billion Colors

23.

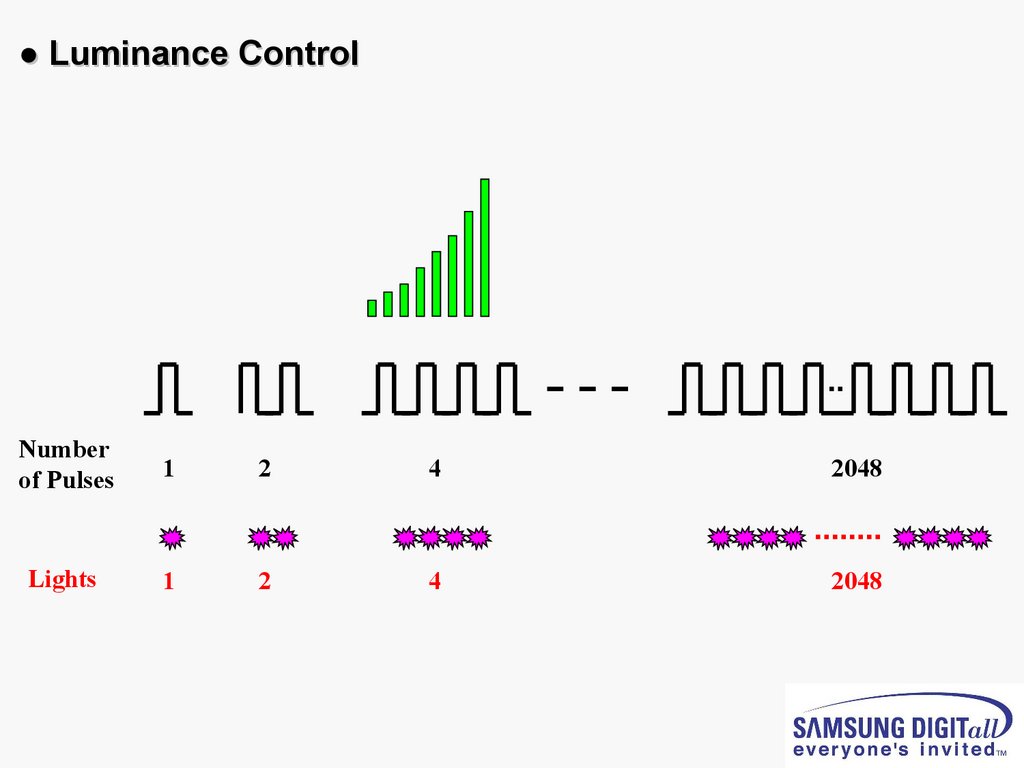

● Luminance ControlNumber

of Pulses

1

2

4

2048

Lights

1

2

4

2048

24.

● 1 Picture Structure by 12 Sub-Field - 125.

● 1 Picture Structure by 12 Sub-Field - 226.

● 1 Picture Structure by 12 Sub-Field - 327.

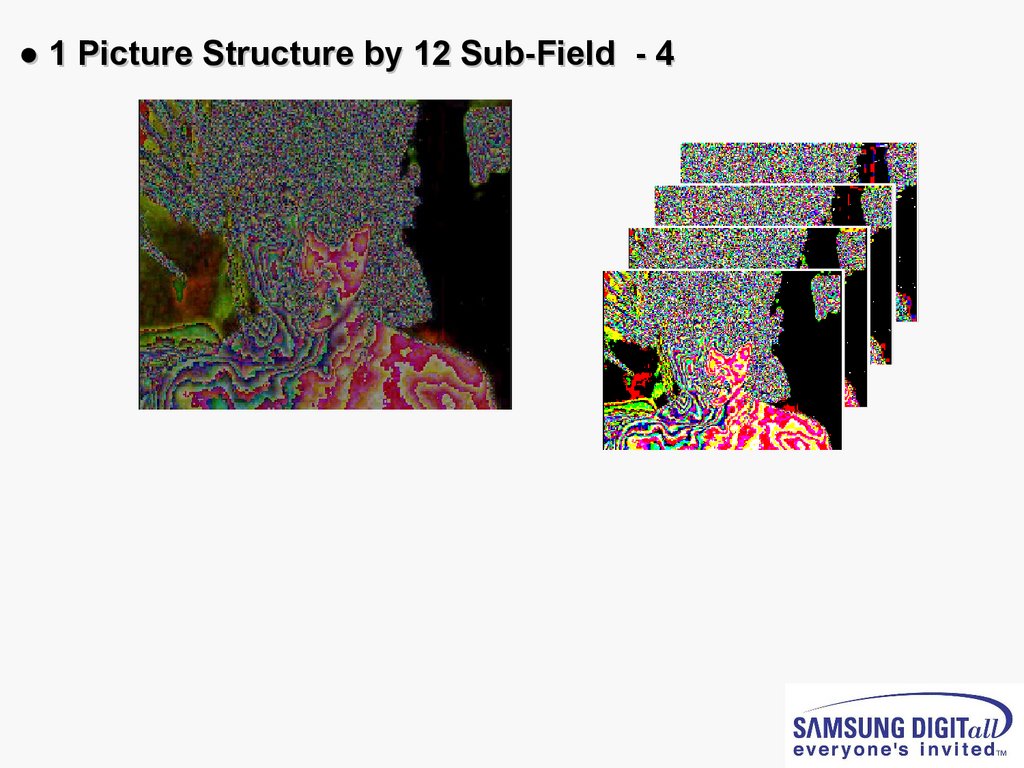

● 1 Picture Structure by 12 Sub-Field - 428.

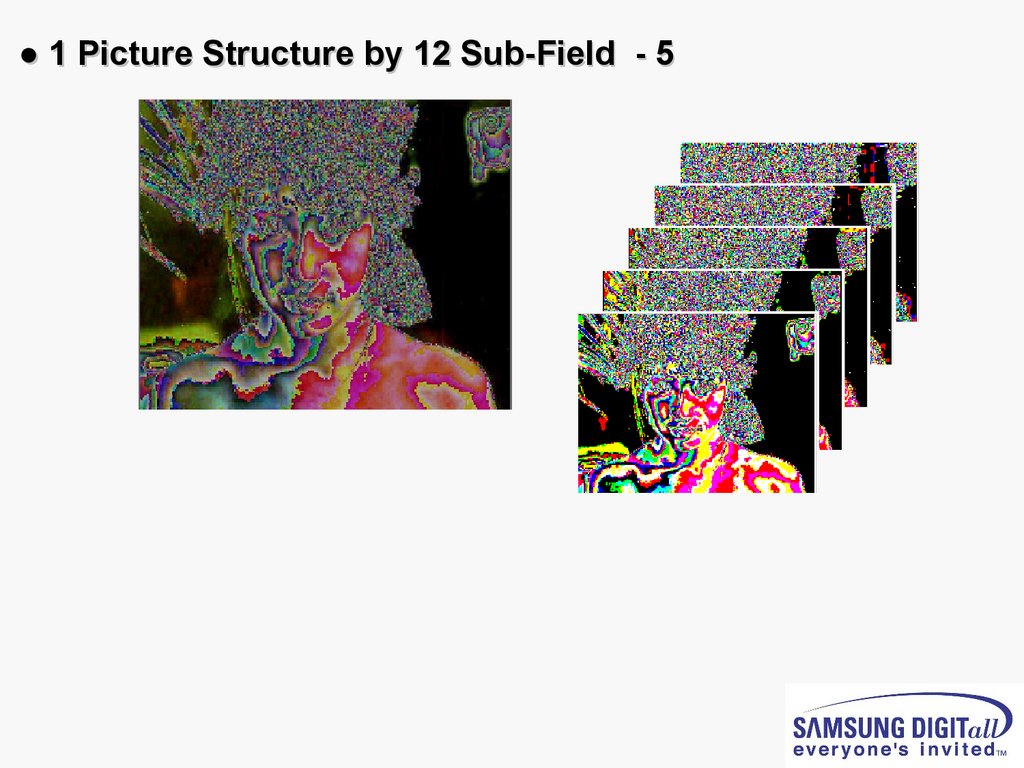

● 1 Picture Structure by 12 Sub-Field - 529.

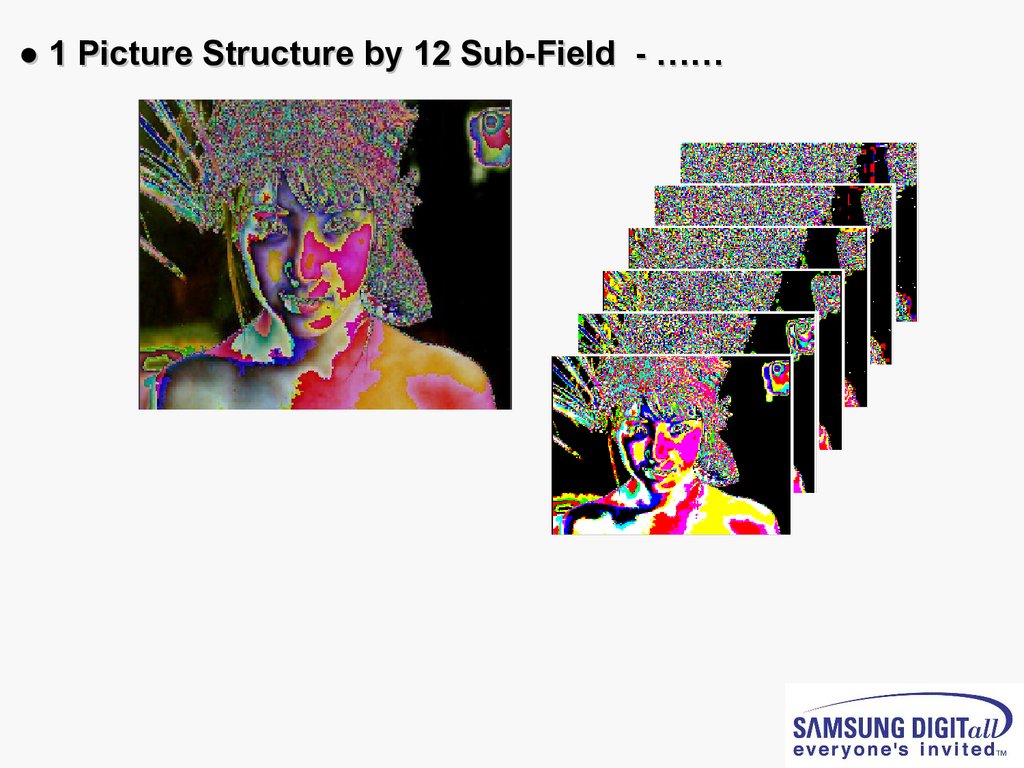

● 1 Picture Structure by 12 Sub-Field - ……30.

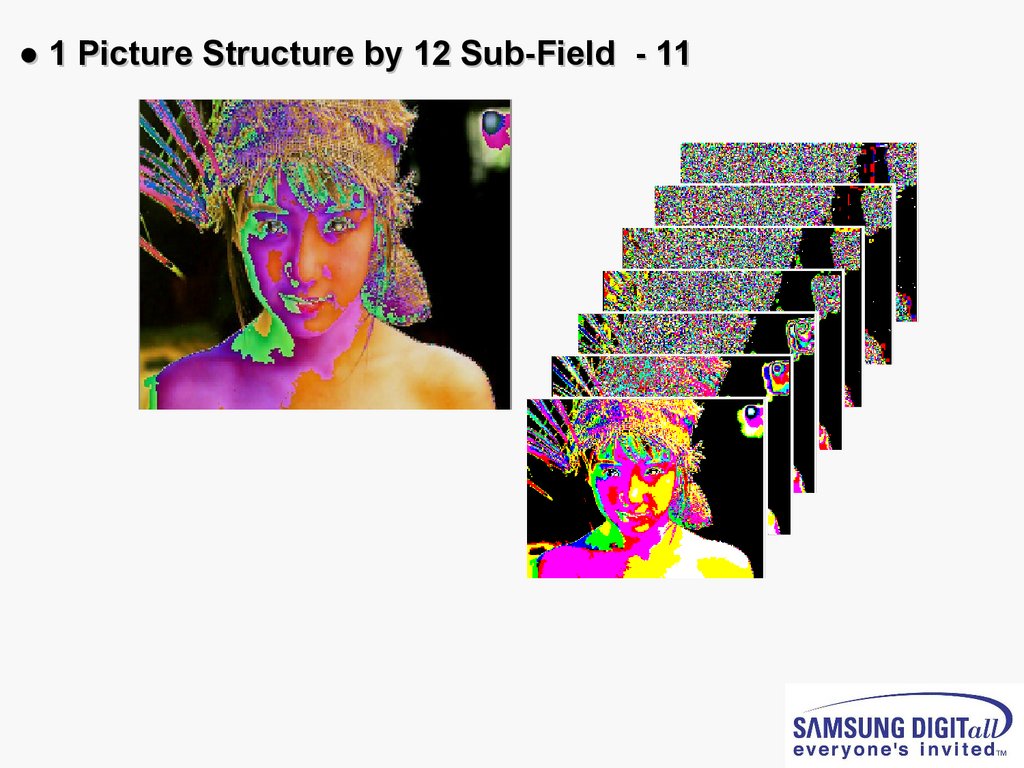

● 1 Picture Structure by 12 Sub-Field - 1131.

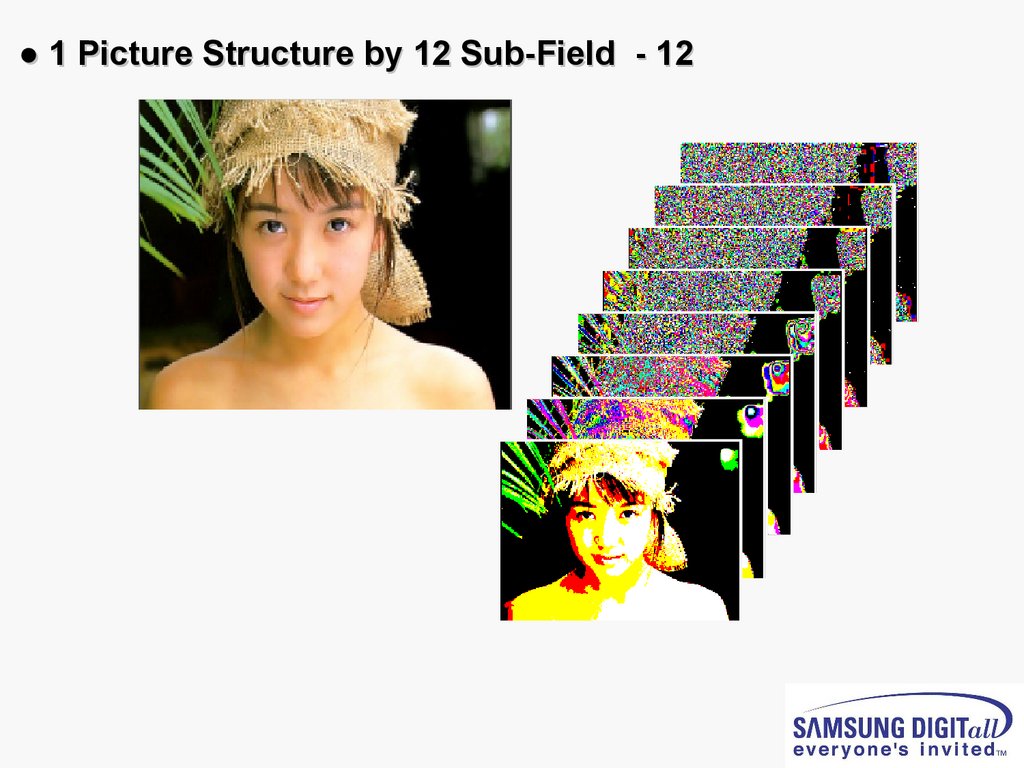

● 1 Picture Structure by 12 Sub-Field - 1232.

3. CARNELIAN Training33.

● Comparison with other ModelsProject

LILY2 (W2A)

CARNELIAN (W3)

Brightness

1500cd/m2

1500cd/m2

Contrast ratio

10000:1

15000:1

Tuner

1 Nim Tuner

1 Nim Tuner (Slim)

Audio out

10W x 2

10W x 2

Sound

SRS Tru Surround XT

SRS Tru Surround XT

Speaker

Included

Included

Video input

-

1Side

S-Video input

-

1Side

Component

Input

1Rear

1Rear

Side Input

-

CVBS,S-Video, Headphone

HDMI

1Rear

2Rear

Power

Consumption

42” : 350W

50” : 450W

42” : 380W

50” : 480W

Etc.

-

-

Design

34.

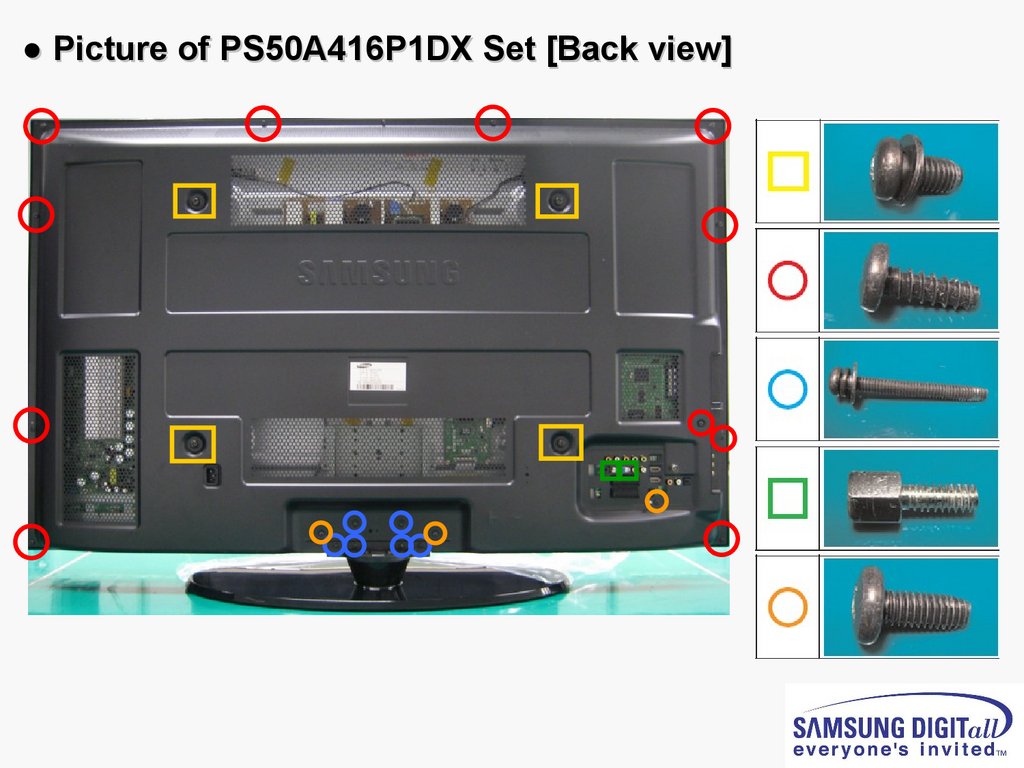

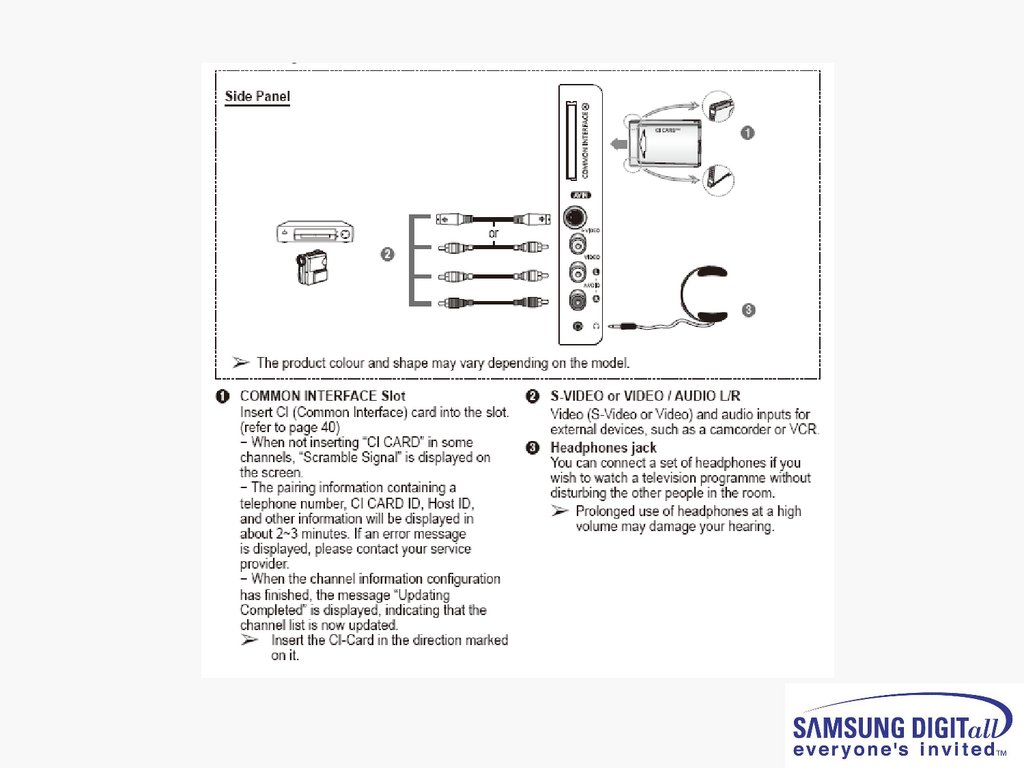

● Picture of PS50A416P1DX Set [Back view]35.

● Picture of CARNELIAN 50” W3 PDP Module [Back view]36.

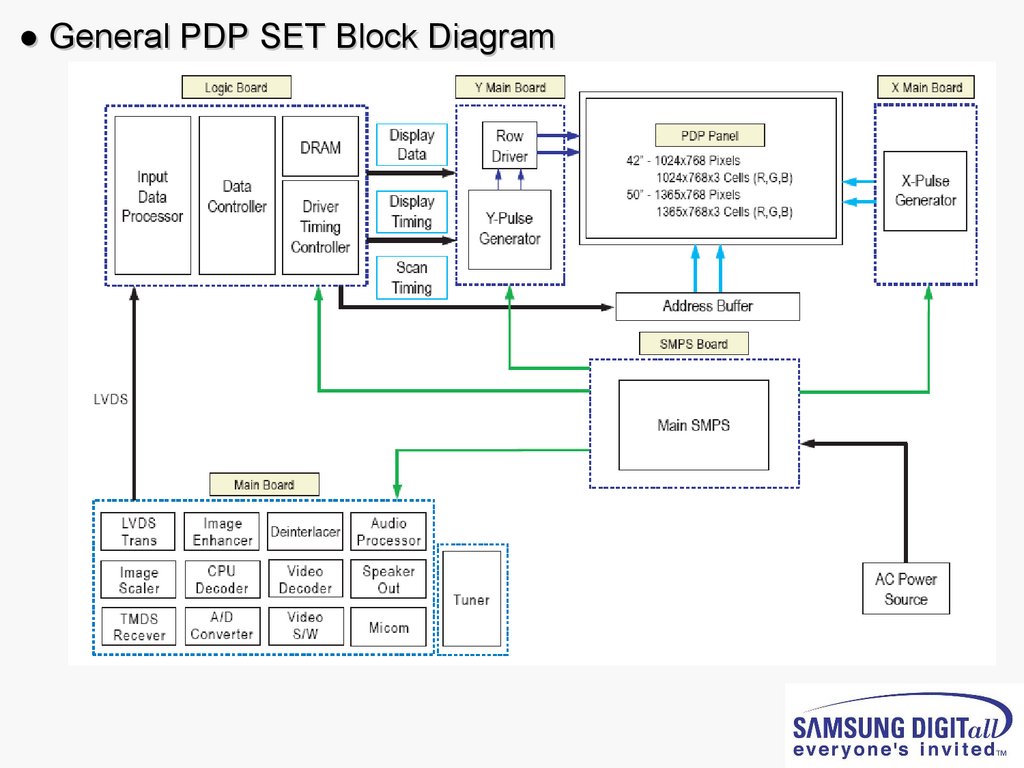

● General PDP SET Block Diagram37.

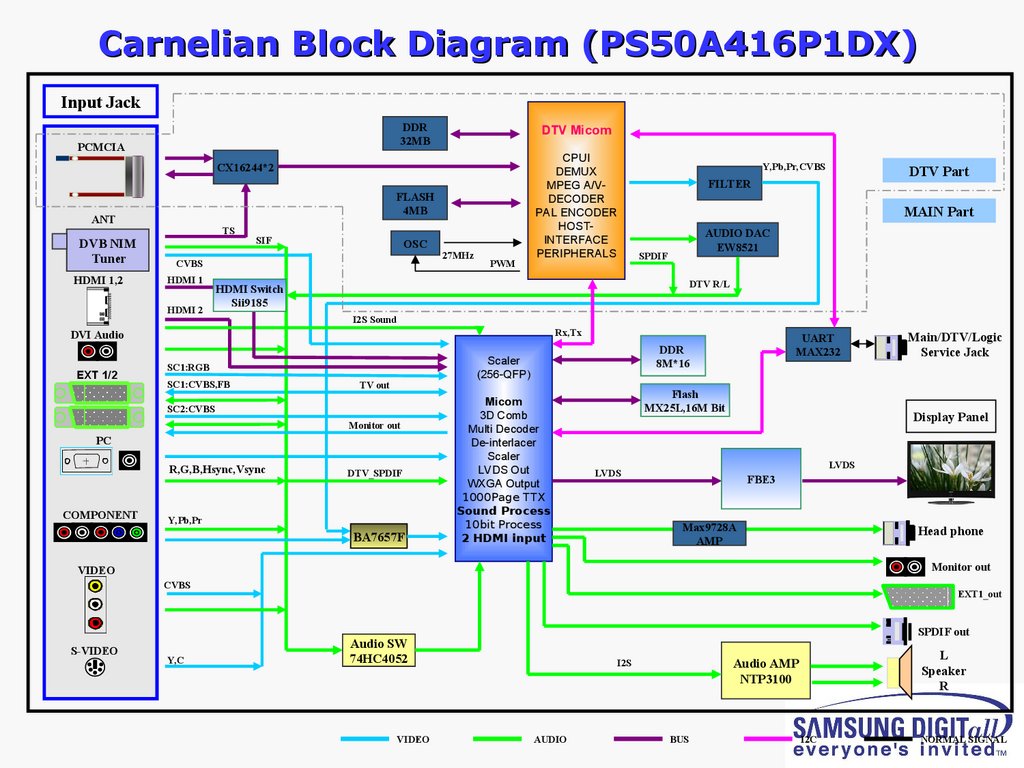

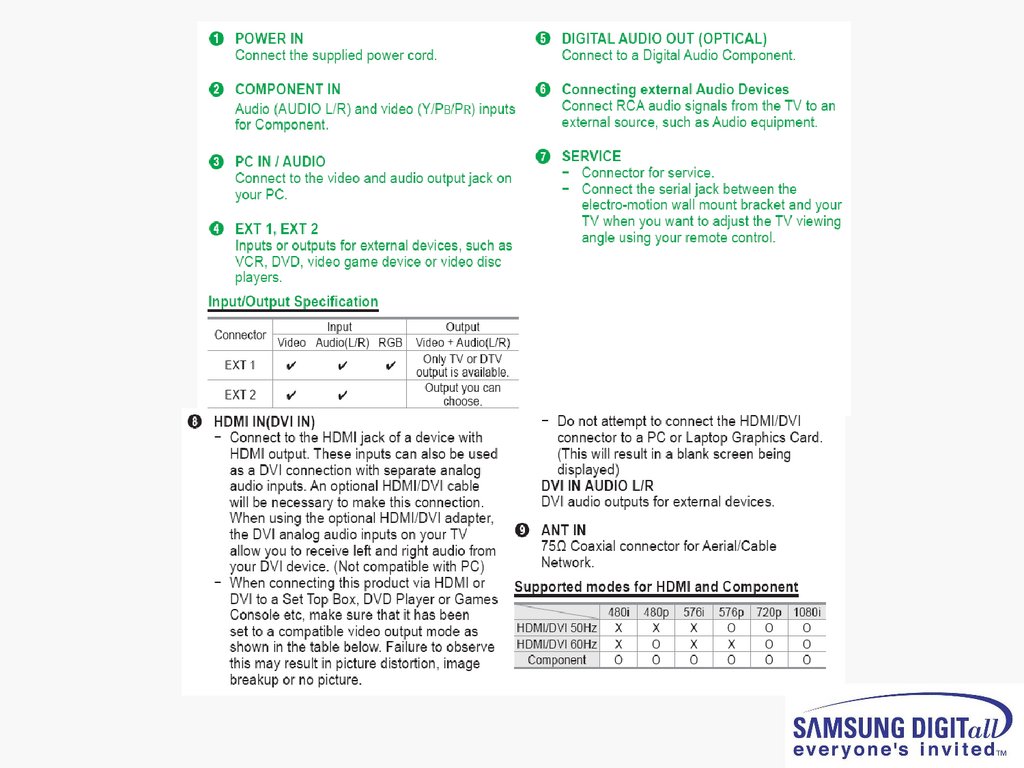

Carnelian Block Diagram (PS50A416P1DX)Input Jack

DDR

32MB

DTV Micom

FLASH

4MB

CPUI

DEMUX

MPEG A/VDECODER

PAL ENCODER

HOSTINTERFACE

PERIPHERALS

PCMCIA

CX16244*2

ANT

DVB NIM

Tuner

HDMI 1,2

TS

SIF

OSC

CVBS

HDMI 1

HDMI 2

27MHz

PWM

SPDIF

DTV R/L

I2S Sound

TV out

Monitor out

PC

R,G,B,Hsync,Vsync

DTV_SPDIF

Y,Pb,Pr

BA7657F

UART

MAX232

DDR

8M*16

Scaler

(256-QFP)

SC1:RGB

SC2:CVBS

COMPONENT

MAIN Part

AUDIO DAC

EW8521

Rx,Tx

SC1:CVBS,FB

Micom

3D Comb

Multi Decoder

De-interlacer

Scaler

LVDS Out

WXGA Output

1000Page TTX

Sound Process

10bit Process

2 HDMI input

Flash

MX25L,16M Bit

Main/DTV/Logic

Service Jack

Display Panel

LVDS

LVDS

FBE3

Max9728A

AMP

Head phone

Monitor out

VIDEO

CVBS

S-VIDEO

DTV Part

FILTER

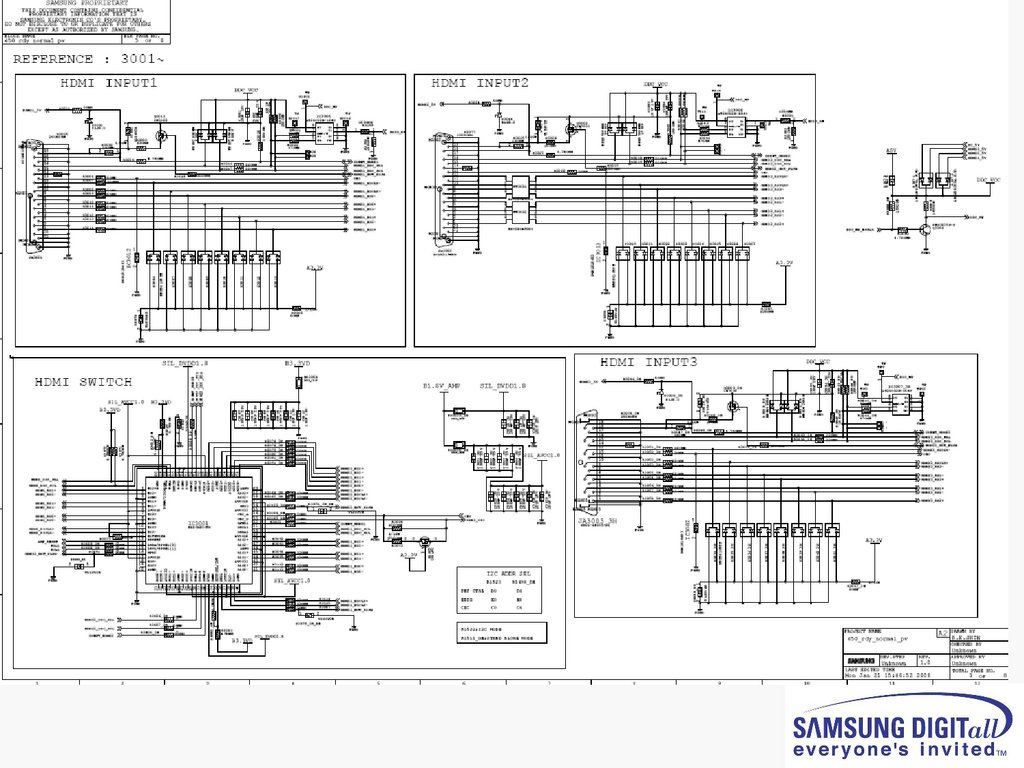

HDMI Switch

Sii9185

DVI Audio

EXT 1/2

Y,Pb,Pr,CVBS

Y,C

EXT1_out

SPDIF out

Audio SW

74HC4052

VIDEO

AUDIO

L

Speaker

R

Audio AMP

NTP3100

I2S

BUS

I2C

37

NORMAL SIGNAL

38.

● Picture of PS50A416P1DX Chassis - TopLVDS

3.DTV

Micom

6.DRAM

2.FBE3

7.Sound AMP

5.DDR

1.Scaler

4.HDMI

switch

39.

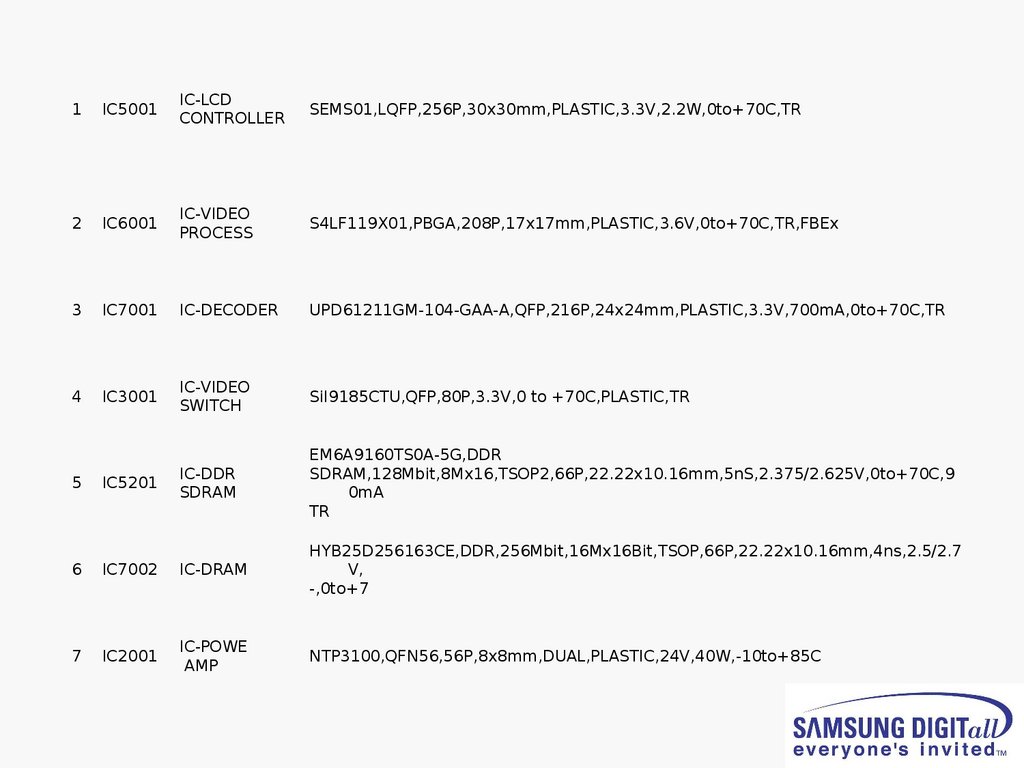

1IC5001

IC-LCD

CONTROLLER

SEMS01,LQFP,256P,30x30mm,PLASTIC,3.3V,2.2W,0to+70C,TR

2

IC6001

IC-VIDEO

PROCESS

S4LF119X01,PBGA,208P,17x17mm,PLASTIC,3.6V,0to+70C,TR,FBEx

3

IC7001

IC-DECODER

UPD61211GM-104-GAA-A,QFP,216P,24x24mm,PLASTIC,3.3V,700mA,0to+70C,TR

4

IC3001

IC-VIDEO

SWITCH

SiI9185CTU,QFP,80P,3.3V,0 to +70C,PLASTIC,TR

IC-DDR

SDRAM

EM6A9160TS0A-5G,DDR

SDRAM,128Mbit,8Mx16,TSOP2,66P,22.22x10.16mm,5nS,2.375/2.625V,0to+70C,9

0mA

TR

5

IC5201

6

IC7002

IC-DRAM

HYB25D256163CE,DDR,256Mbit,16Mx16Bit,TSOP,66P,22.22x10.16mm,4ns,2.5/2.7

V,

-,0to+7

7

IC2001

IC-POWE

AMP

NTP3100,QFN56,56P,8x8mm,DUAL,PLASTIC,24V,40W,-10to+85C

40.

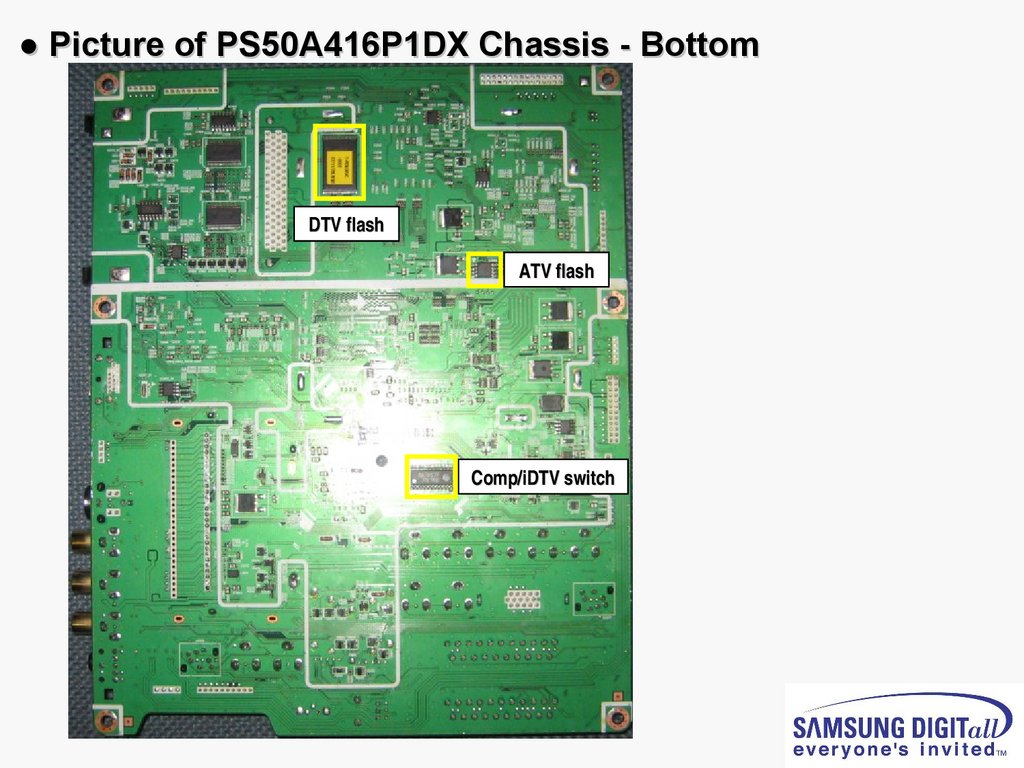

● Picture of PS50A416P1DX Chassis - BottomDTV flash

ATV flash

Comp/iDTV switch

41.

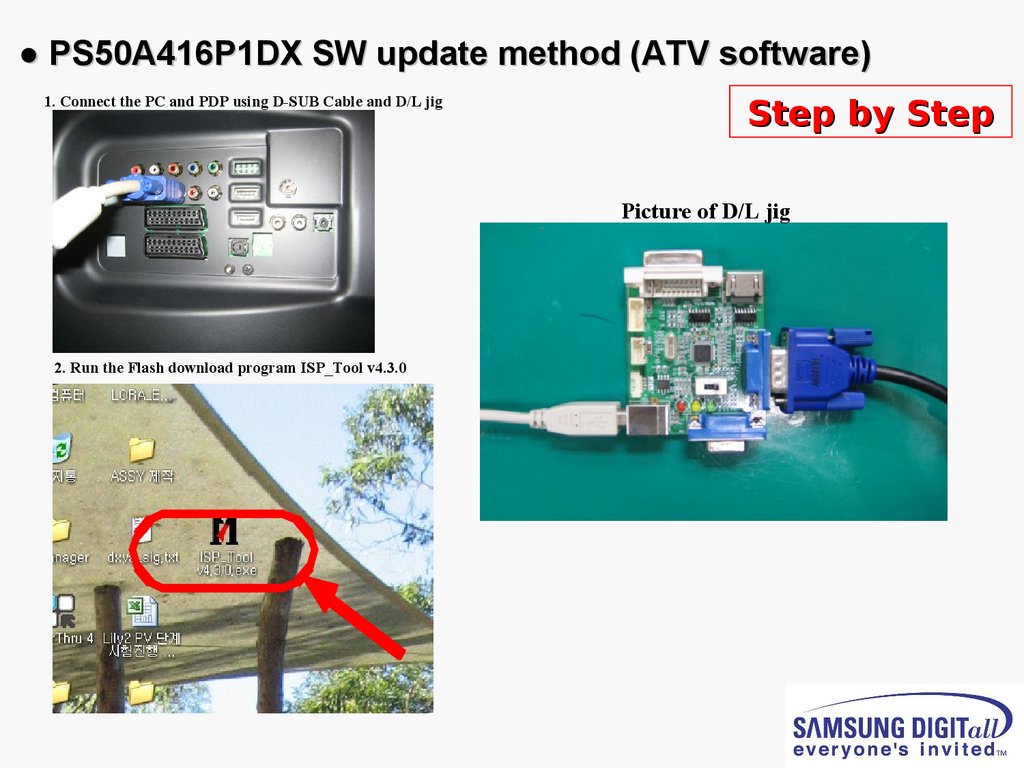

● PS50A416P1DX SW update method (ATV software)1. Connect the PC and PDP using D-SUB Cable and D/L jig

Step by Step

Picture of D/L jig

D-SUB Cable

2. Run the Flash download program ISP_Tool v4.3.0

42.

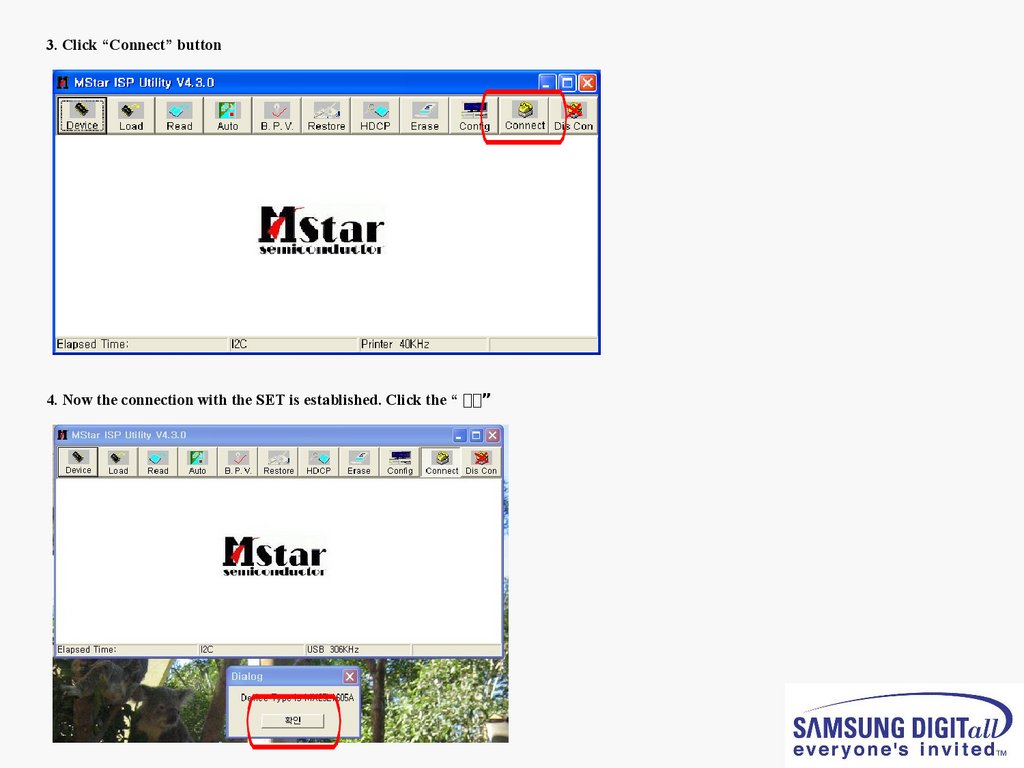

3. Click “Connect” button4. Now the connection with the SET is established. Click the “ 확인”

43.

5. Connect the Power cord and click “Read”①

②

6. Click the new “Read” button

44.

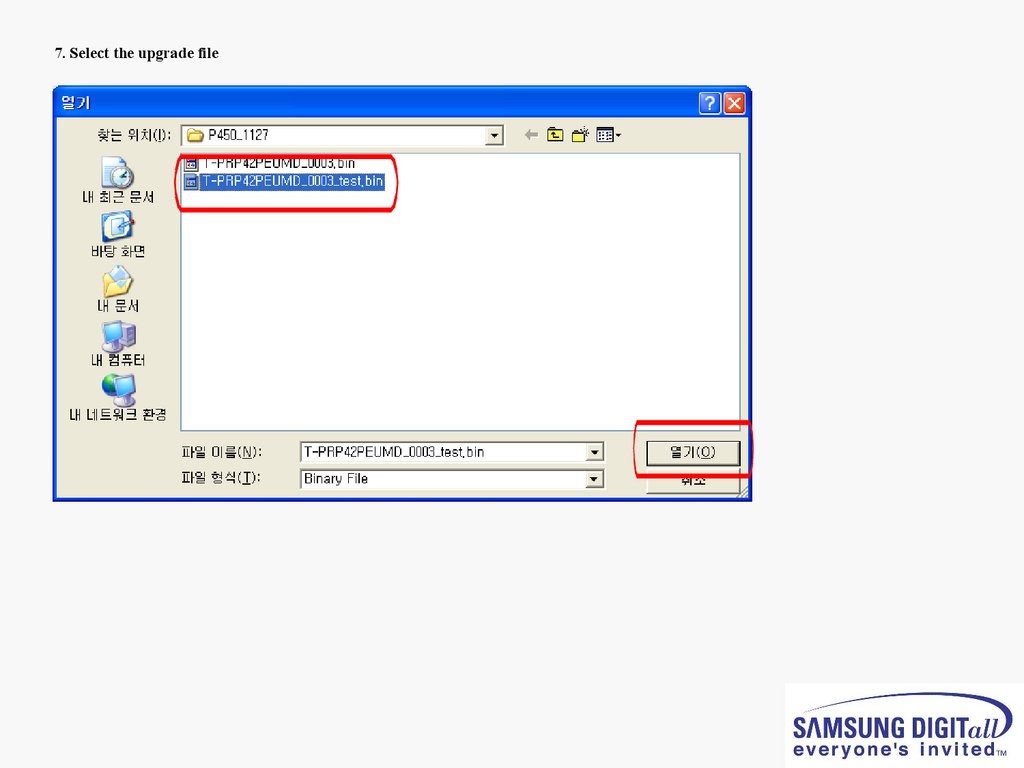

7. Select the upgrade file45.

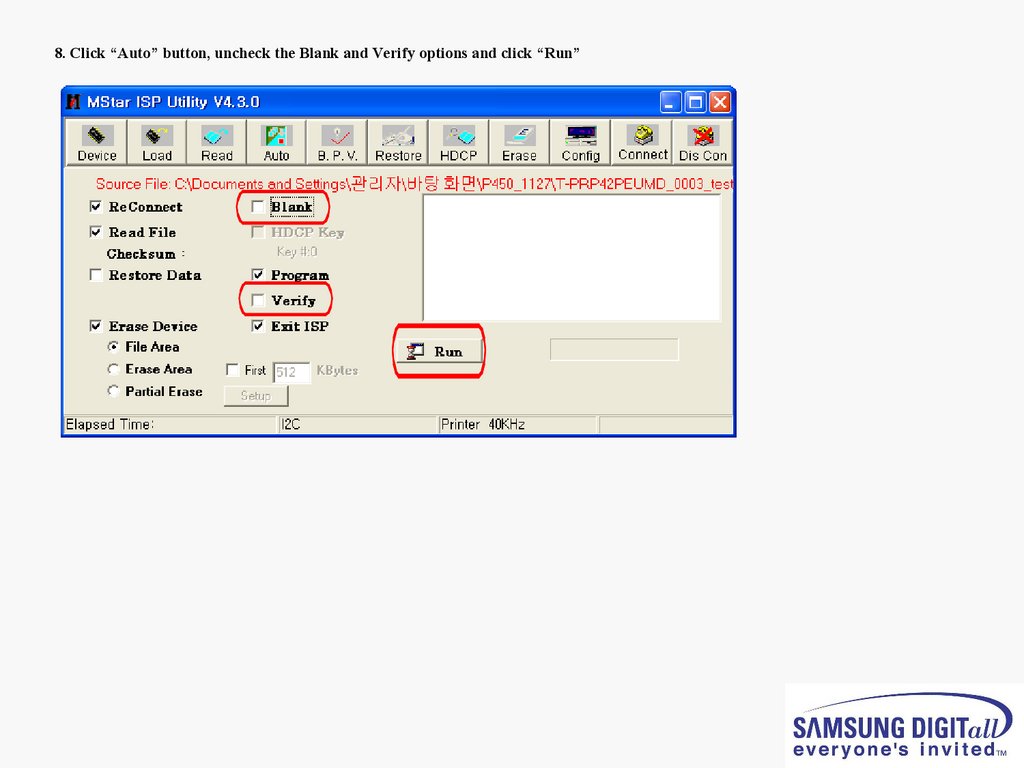

8. Click “Auto” button, uncheck the Blank and Verify options and click “Run”①

46.

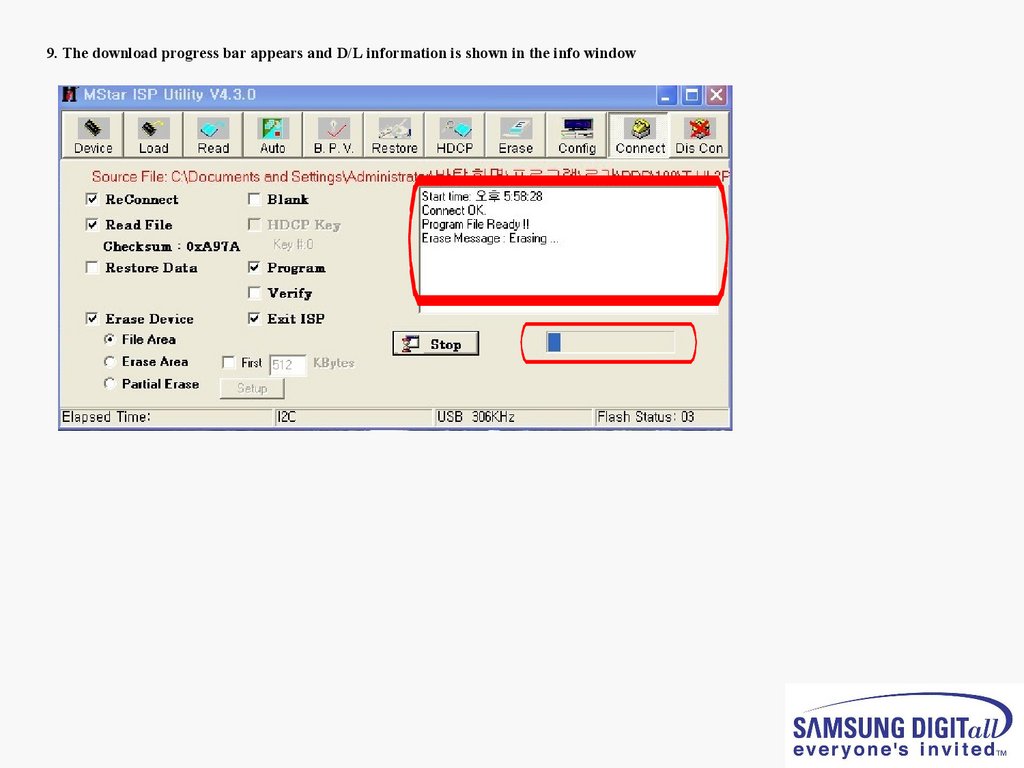

9. The download progress bar appears and D/L information is shown in the info window47.

PS50A416P1DX SW update method (DTV software)Step by Step

1. Connect the serial D/L cable to the SET and execute the D/L program

2. Click the “Browse…” button to select the upgrade file and click “Next

>”

3. Select the appropriate COM port and click “Next >”

4. After a short port scan the communication should be established

Click “Next >” to continue

5. Click “Next >” to continue

48.

PS50A416P1DX SW update method (DTV software)6. The upgrade file is transferring to the SET

You can check the transfer progress bar and the remaining time

8. Wait the upgrade process to finish

You can check the upgrade progress bar

7. After the file was transferred the upgrade process will start

automatically

9. After a successful upgrade the following window appears

Click “OK” to close the program

49.

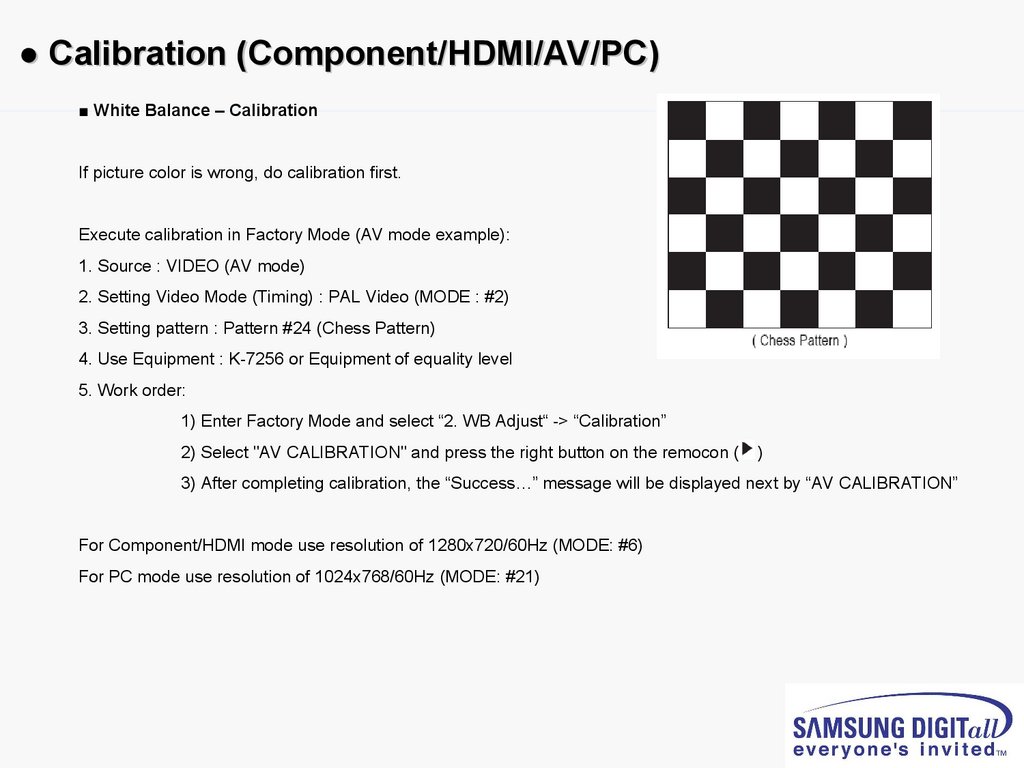

● Calibration (Component/HDMI/AV/PC)■ White Balance – Calibration

If picture color is wrong, do calibration first.

Execute calibration in Factory Mode (AV mode example):

1. Source : VIDEO (AV mode)

2. Setting Video Mode (Timing) : PAL Video (MODE : #2)

3. Setting pattern : Pattern #24 (Chess Pattern)

4. Use Equipment : K-7256 or Equipment of equality level

5. Work order:

1) Enter Factory Mode and select “2. WB Adjust“ -> “Calibration”

2) Select "AV CALIBRATION" and press the right button on the remocon (

)

3) After completing calibration, the “Success…” message will be displayed next by “AV CALIBRATION”

For Component/HDMI mode use resolution of 1280x720/60Hz (MODE: #6)

For PC mode use resolution of 1024x768/60Hz (MODE: #21)

50.

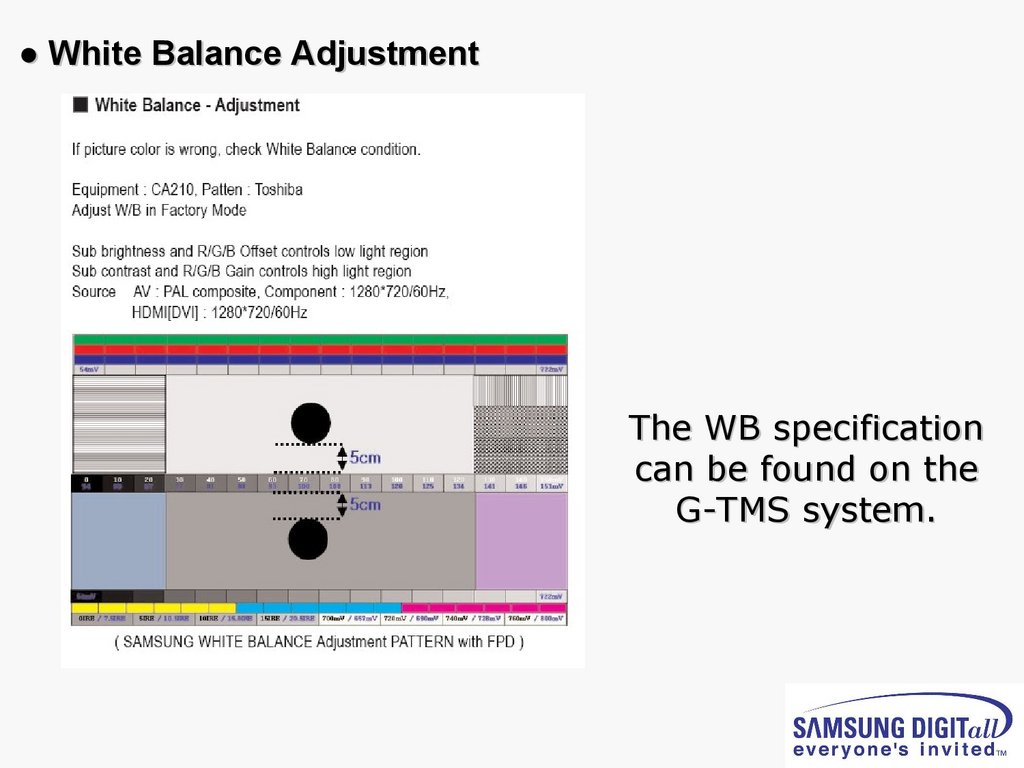

● White Balance AdjustmentThe WB specification

can be found on the

G-TMS system.

51.

● Picture condition in Factory mode / during WB adjust● Factory mode OSD

52.

53.

54.

55.

56.

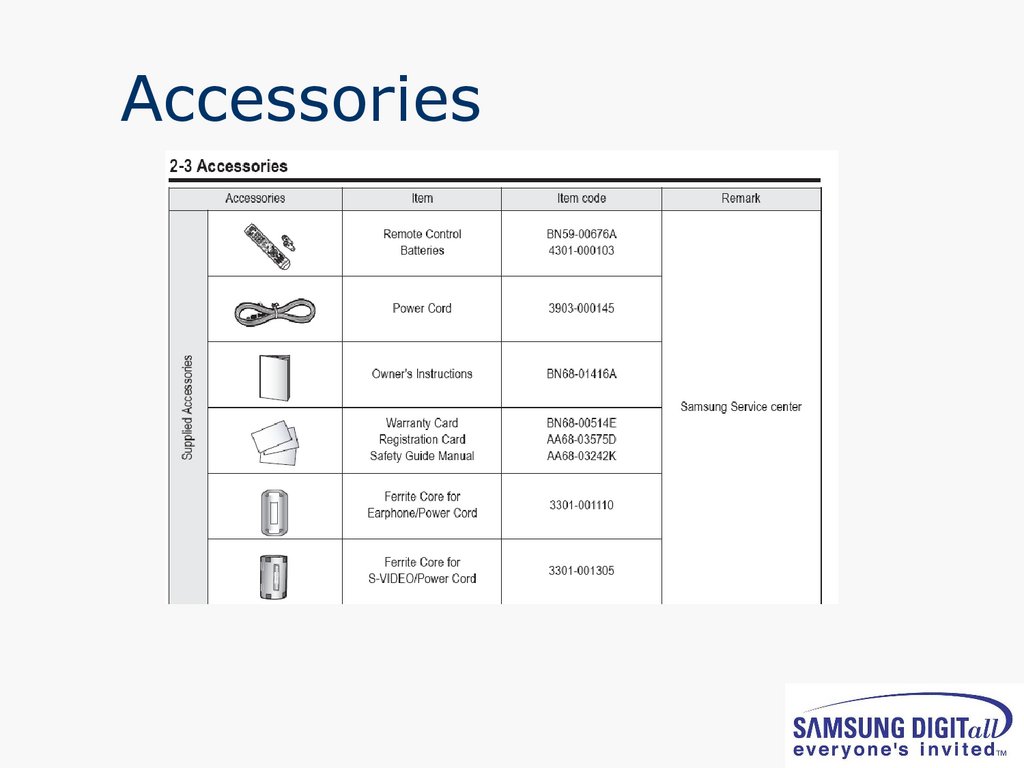

Accessories57.

5. Trouble shooting58.

● Check List in advance■. Each cable connection condition check

- Cable is connected correctly ?

■.Check Voltage

- SMPS Video main Board, SMPS X,Y Drive board, SMPS Logic board

■. The chart below shows abnormal condition

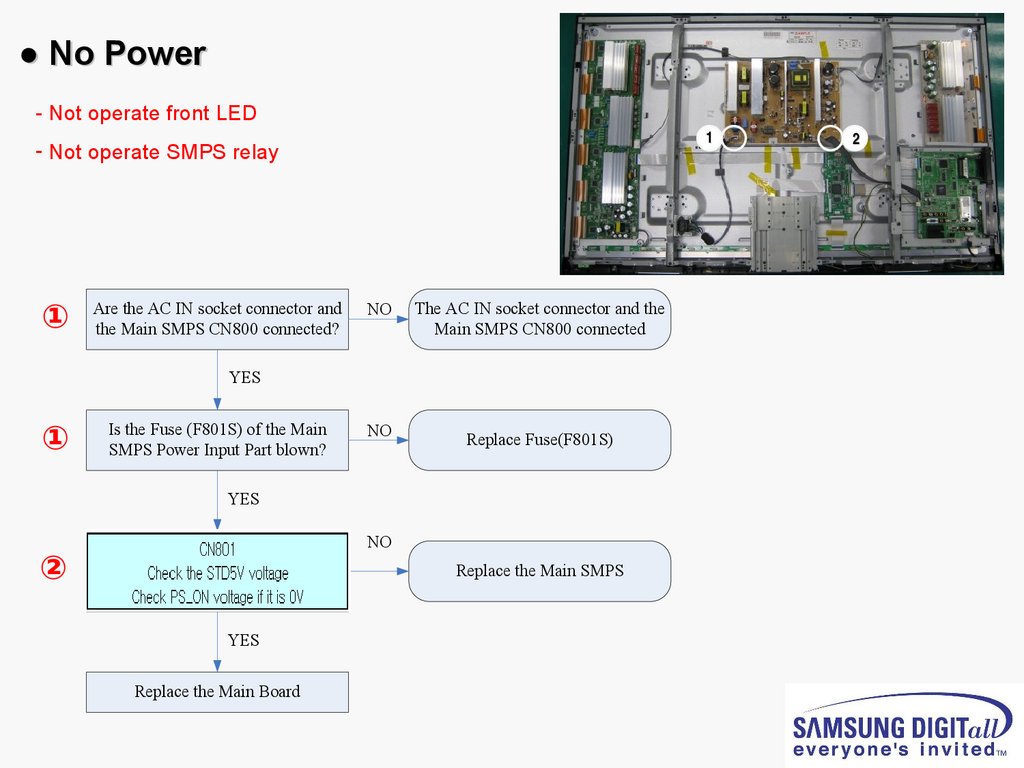

59.

● No Power- Not operate front LED

1

- Not operate SMPS relay

①

Are the AC IN socket connector and

the Main SMPS CN800 connected?

NO

The AC IN socket connector and the

Main SMPS CN800 connected

YES

①

Is the Fuse (F801S) of the Main

SMPS Power Input Part blown?

NO

Replace Fuse(F801S)

YES

②

Main SMPS CN804-1

Pin 3:STB 5V

Pin 8 PS-ON: Check to see If

it is 0V

YES

Replace the Main Board

NO

Replace the Main SMPS

2

60.

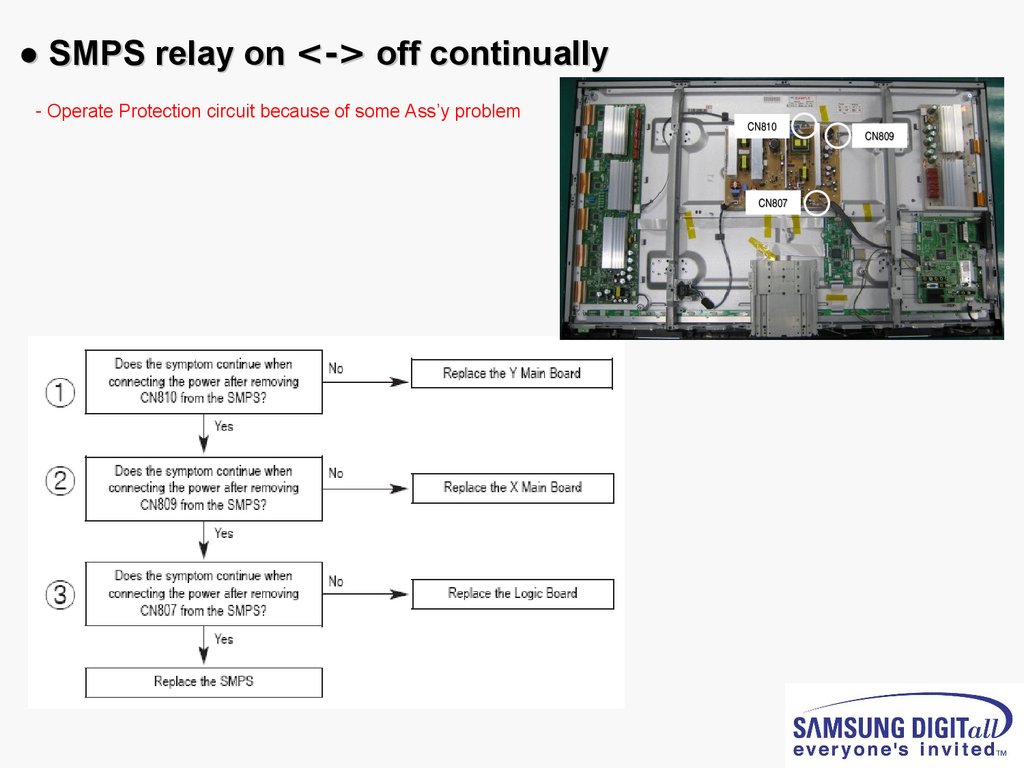

● SMPS relay on <-> off continually- Operate Protection circuit because of some Ass’y problem

CN810

CN807

CN809

61.

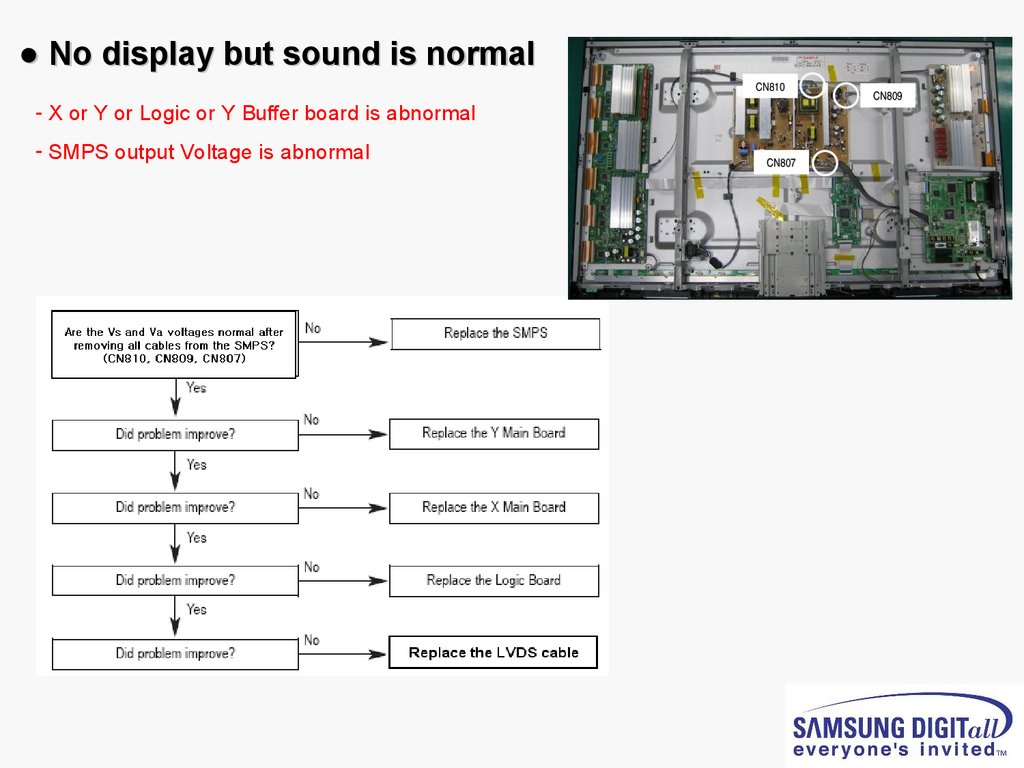

● No display but sound is normalCN810

- X or Y or Logic or Y Buffer board is abnormal

- SMPS output Voltage is abnormal

CN807

CN809

62.

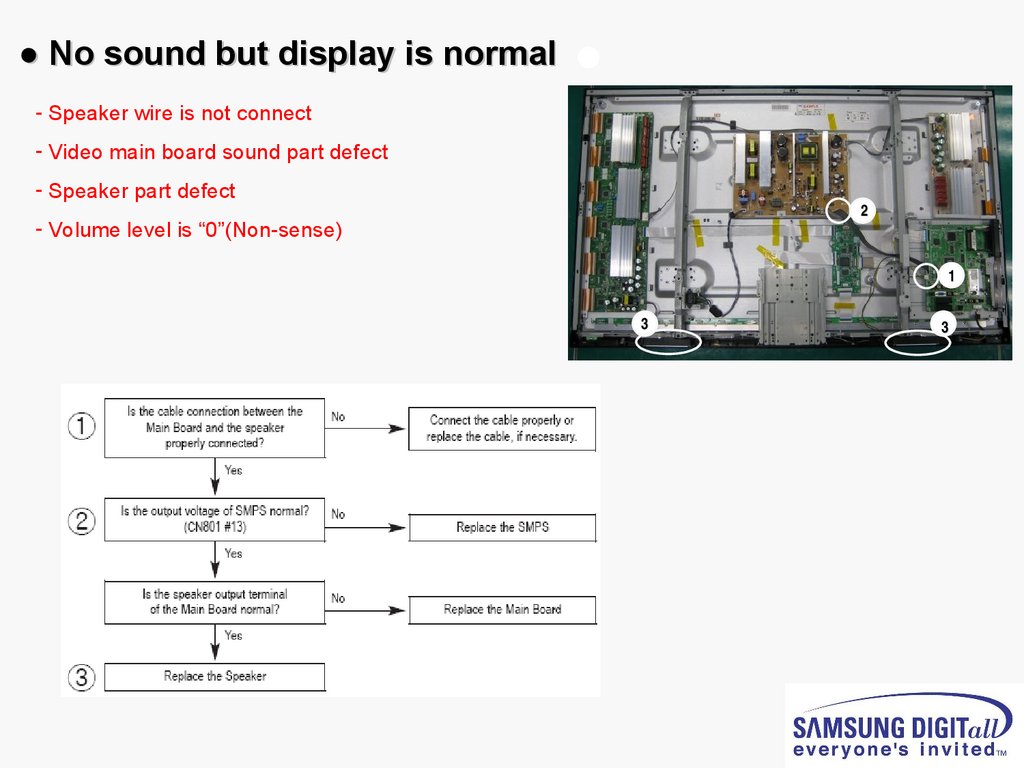

● No sound but display is normal- Speaker wire is not connect

- Video main board sound part defect

- Speaker part defect

2

- Volume level is “0”(Non-sense)

1

3

3

63.

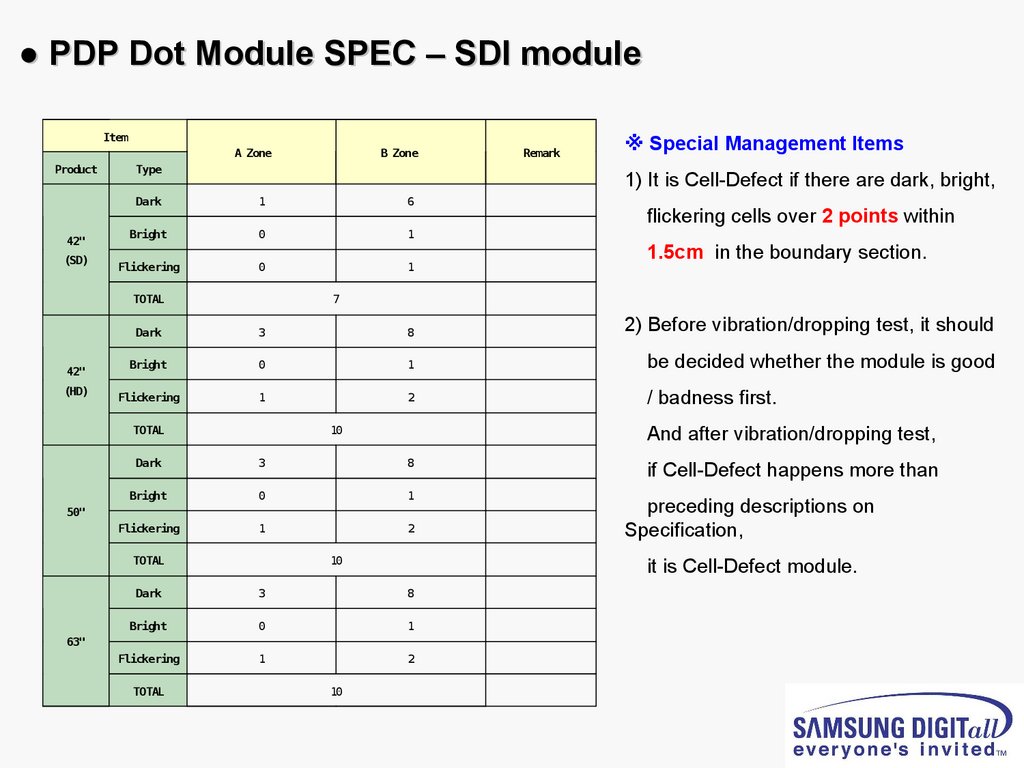

● PDP Dot Module SPEC – SDI moduleItem

A Zone

Product

42"

(SD)

Type

(HD)

Remark

※ Special Management Items

1) It is Cell-Defect if there are dark, bright,

Dark

1

6

Bright

0

1

Flickering

0

1

TOTAL

42"

B Zone

flickering cells over 2 points within

1.5cm in the boundary section.

7

Dark

3

8

2) Before vibration/dropping test, it should

Bright

0

1

be decided whether the module is good

Flickering

1

2

/ badness first.

TOTAL

And after vibration/dropping test,

10

Dark

3

8

Bright

0

1

Flickering

1

2

50"

TOTAL

10

3

8

Bright

0

1

Flickering

1

2

63"

10

preceding descriptions on

Specification,

it is Cell-Defect module.

Dark

TOTAL

if Cell-Defect happens more than

64.

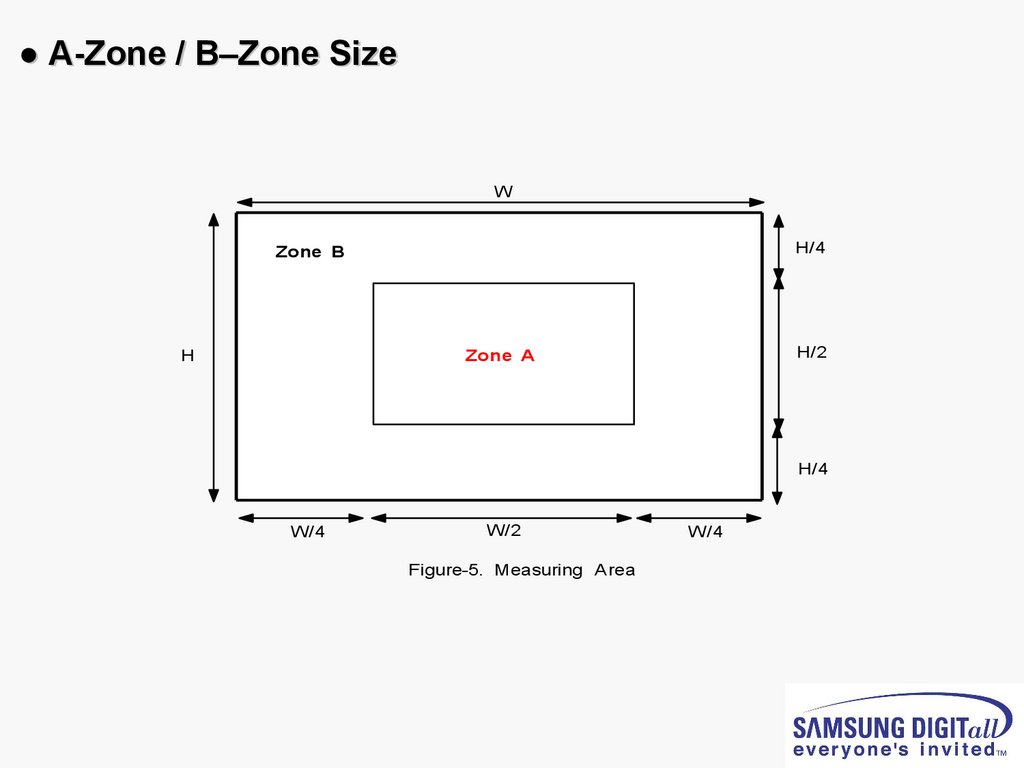

● A-Zone / B–Zone SizeW

H/4

Zone B

H

H/2

Zone A

H/4

W/4

W/2

Figure-5. Measuring Area

W/4

physics

physics