Similar presentations:

Ball Charge Design and Management

1. Ball Charge Design and Management

2.

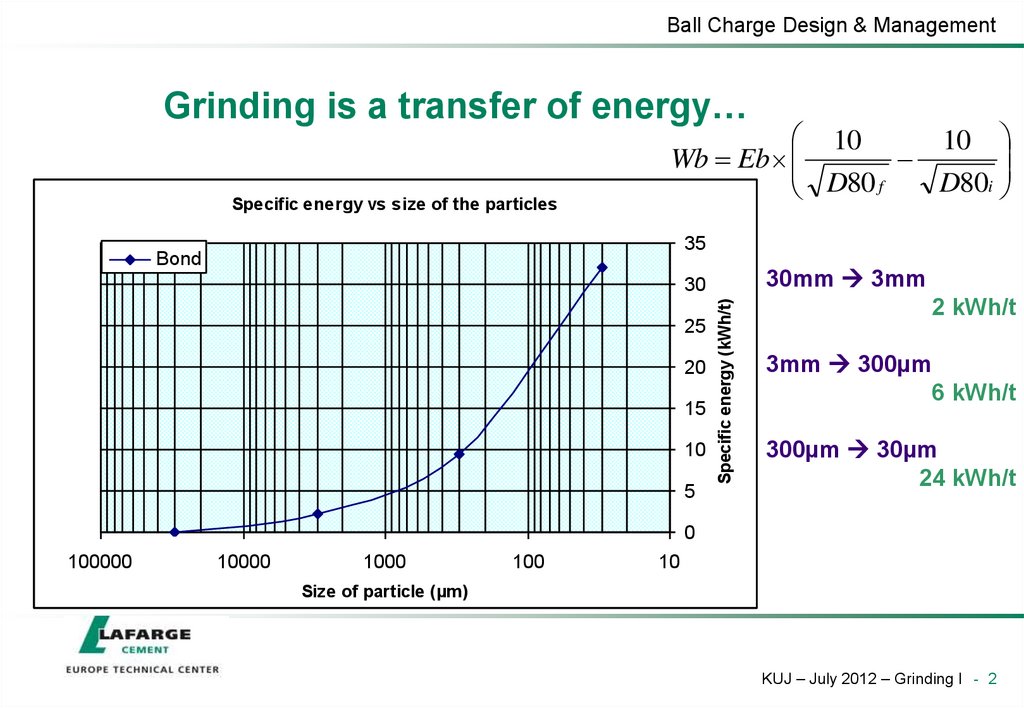

Ball Charge Design & ManagementGrinding is a transfer of energy…

Specific energy vs size of the particles

10

10

Wb Eb

D80i

D80 f

35

Bond

30mm 3mm

25

20

15

10

5

Specific energy (kWh/t)

30

2 kWh/t

3mm 300µm

6 kWh/t

300µm 30µm

24 kWh/t

0

100000

10000

1000

100

10

Size of particle (µm )

KUJ – July 2012 – Grinding I - 2

3.

Mill exitgas&+Management

dust

Ball Charge

Design

… from a mill to particles…

(mill motors = 85% of the power absorbed in the shop)

Mill rotation

Partition wall

Fresh feed +

Rejects

Material

Balls

Venti-

Balls

lation

Compartments

Liners C2

Liners C1

KUJ – July 2012 – Grinding I - 3

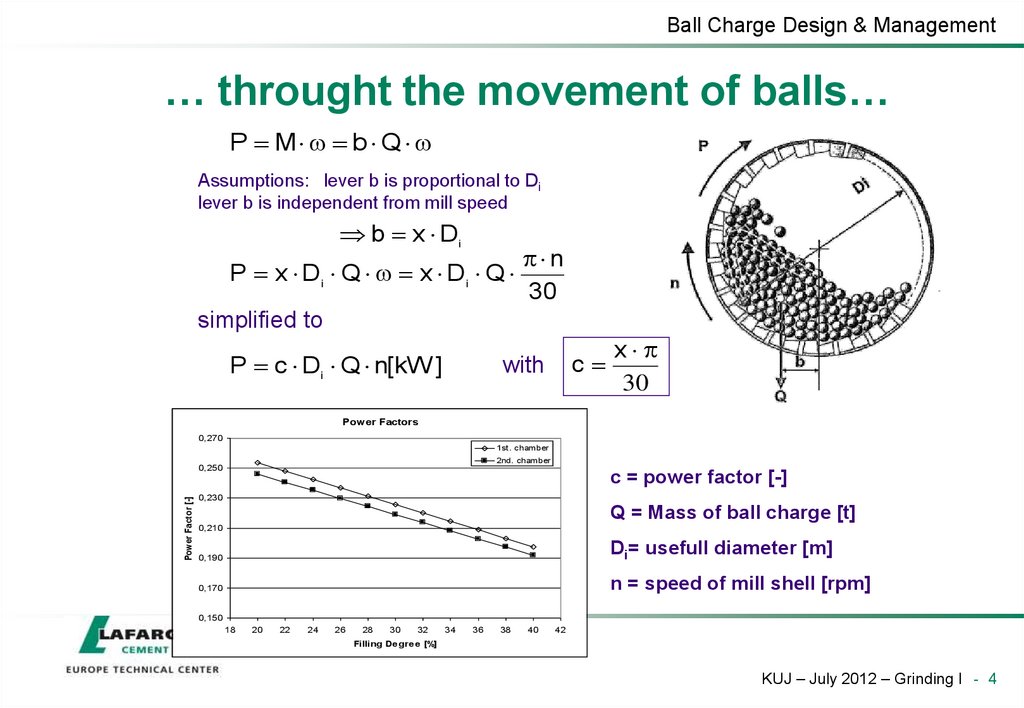

4. … throught the movement of balls…

Ball Charge Design & Management… throught the movement of balls…

P M b Q

Assumptions: lever b is proportional to Di

lever b is independent from mill speed

b x Di

P x Di Q x Di Q

n

30

simplified to

P c Di Q n[kW ]

c

with

x

30

Power Factors

0,270

1st. chamber

2nd. chamber

Power Factor [-]

0,250

c = power factor [-]

0,230

Q = Mass of ball charge [t]

0,210

0,190

Di= usefull diameter [m]

0,170

n = speed of mill shell [rpm]

0,150

18

20

22

24

26

28

30

32

34

36

38

40

42

Filling Degree [%]

KUJ – July 2012 – Grinding I - 4

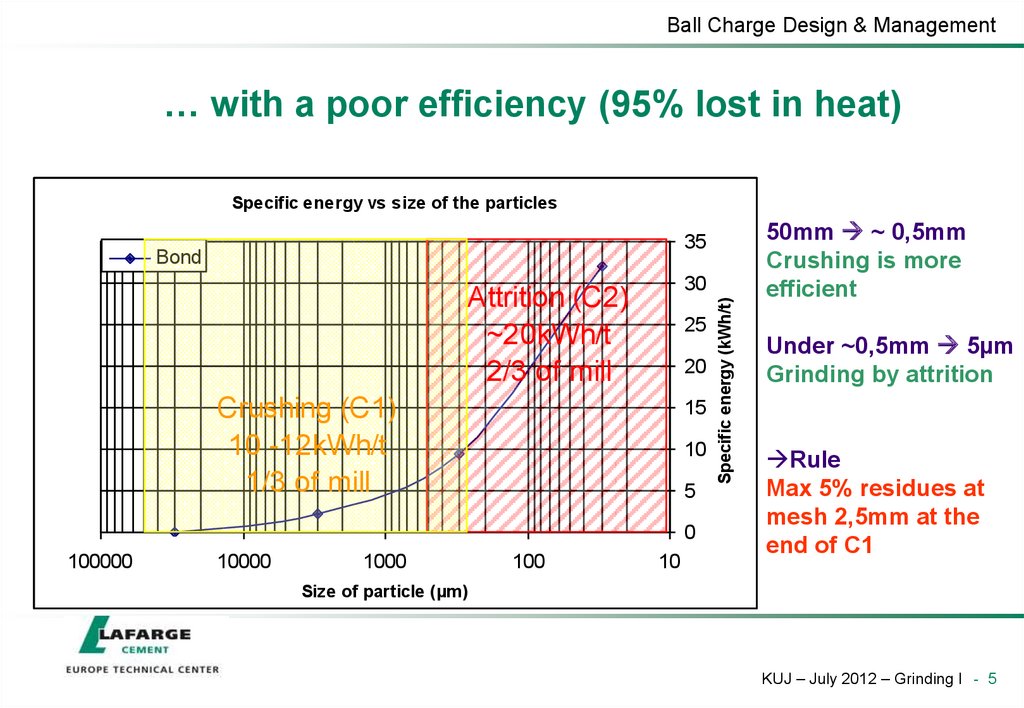

5. … with a poor efficiency (95% lost in heat)

Ball Charge Design & Management… with a poor efficiency (95% lost in heat)

Specific energy vs size of the particles

35

Bond

25

20

Crushing (C1)

10 -12kWh/t

1/3 of mill

15

10

5

0

100000

10000

1000

100

10

Specific energy (kWh/t)

30

Attrition (C2)

~20kWh/t

2/3 of mill

50mm ~ 0,5mm

Crushing is more

efficient

Under ~0,5mm 5µm

Grinding by attrition

Rule

Max 5% residues at

mesh 2,5mm at the

end of C1

Size of particle (µm )

KUJ – July 2012 – Grinding I - 5

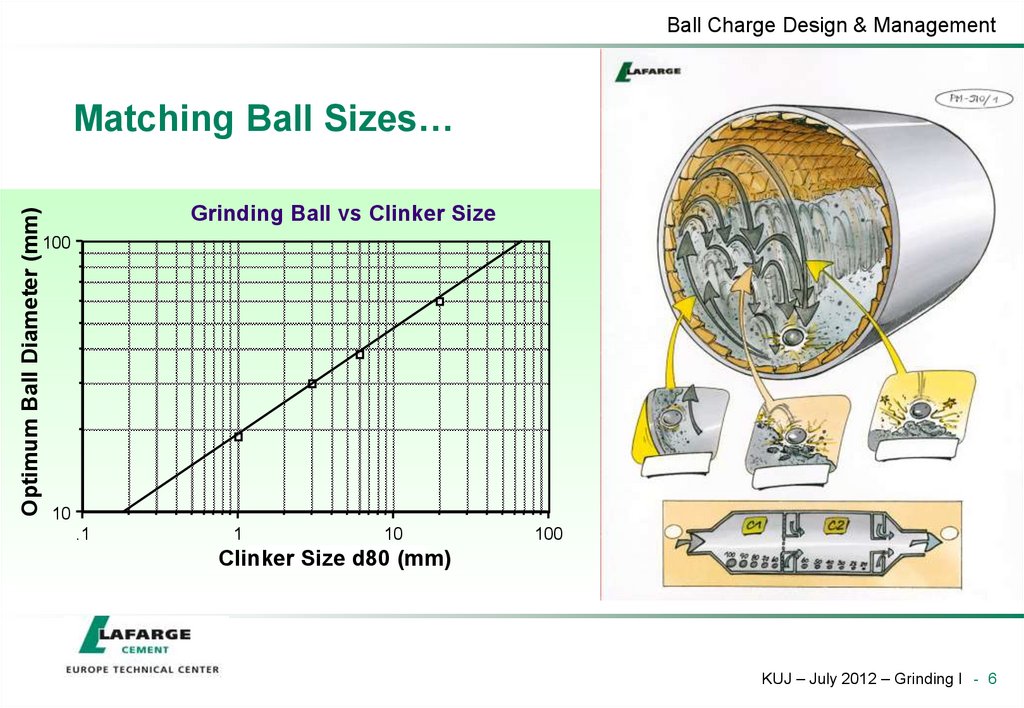

6. Matching Ball Sizes…

Ball Charge Design & ManagementOptimum Ball Diameter (mm)

Matching Ball Sizes…

Grinding Ball vs Clinker Size

100

10

.1

1

10

100

Clinker Size d80 (mm)

KUJ – July 2012 – Grinding I - 6

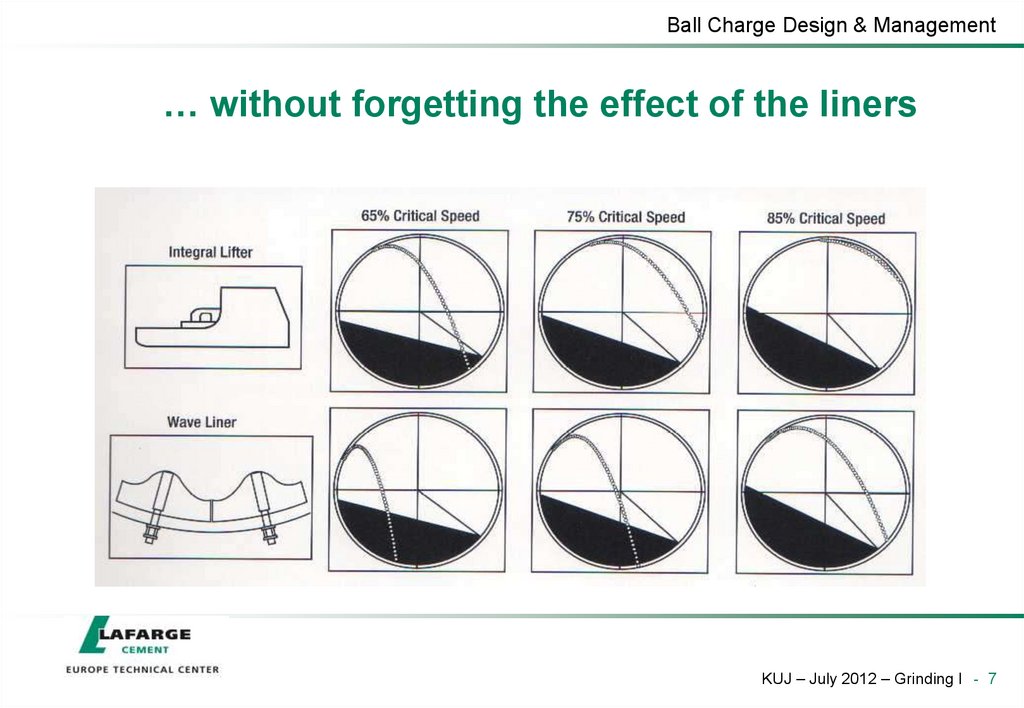

7. … without forgetting the effect of the liners

Ball Charge Design & Management… without forgetting the effect of the liners

KUJ – July 2012 – Grinding I - 7

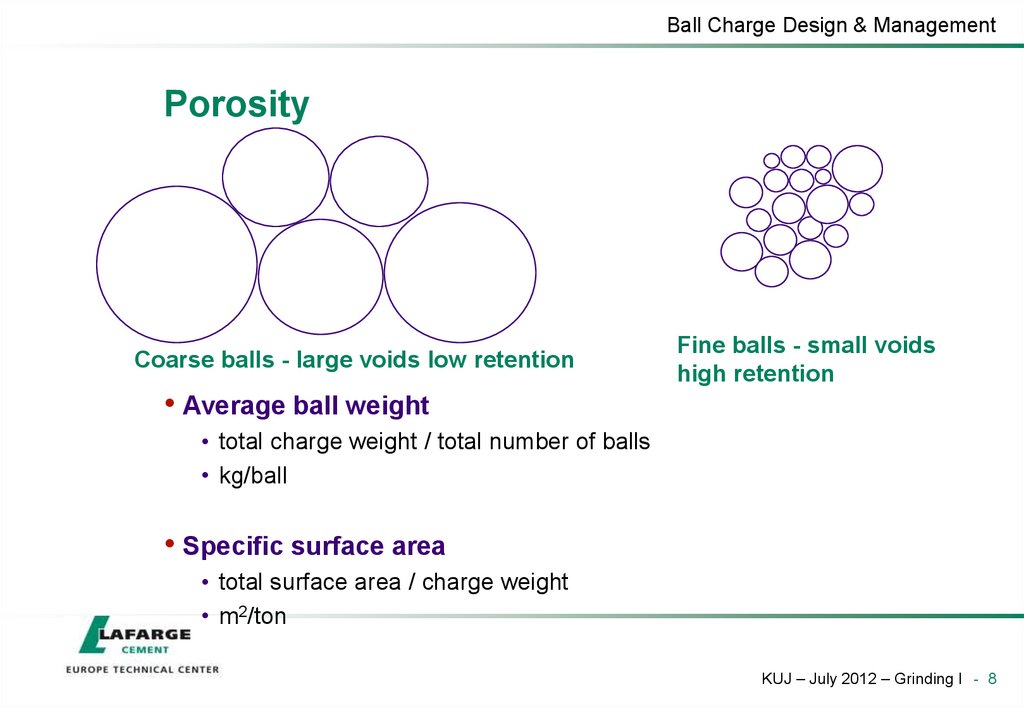

8. Porosity

Ball Charge Design & ManagementPorosity

Coarse balls - large voids low retention

• Average ball weight

Fine balls - small voids

high retention

• total charge weight / total number of balls

• kg/ball

• Specific surface area

• total surface area / charge weight

• m2/ton

KUJ – July 2012 – Grinding I - 8

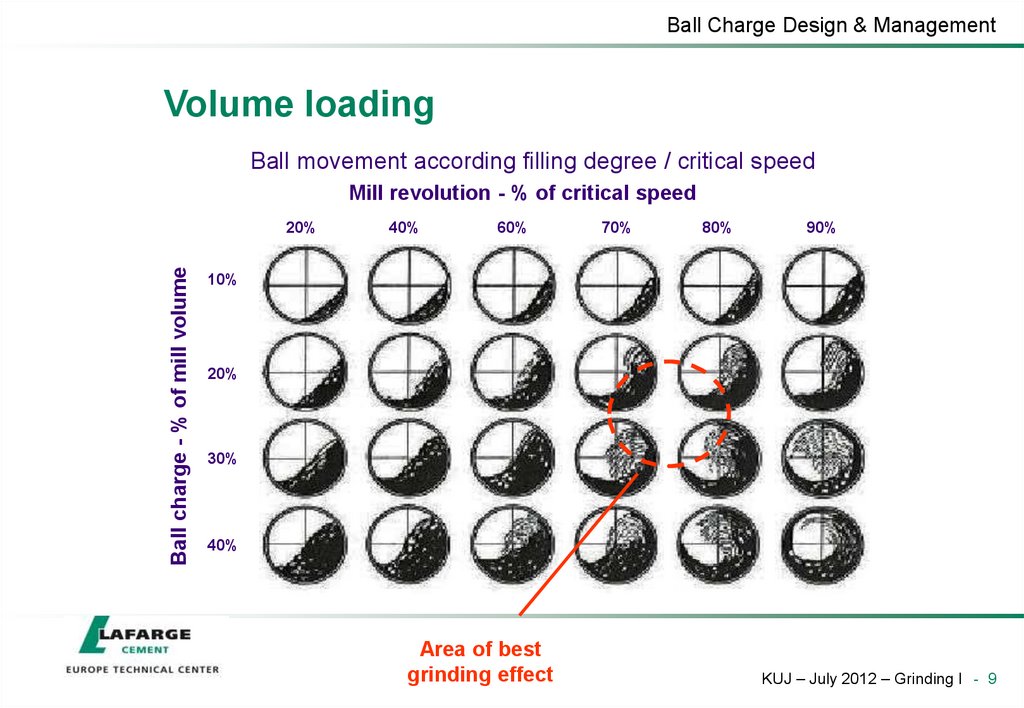

9. Volume loading

Ball Charge Design & ManagementVolume loading

Ball movement according filling degree / critical speed

Mill revolution - % of critical speed

Ball charge - % of mill volume

20%

40%

60%

70%

80%

90%

10%

20%

30%

40%

Area of best

grinding effect

KUJ – July 2012 – Grinding I - 9

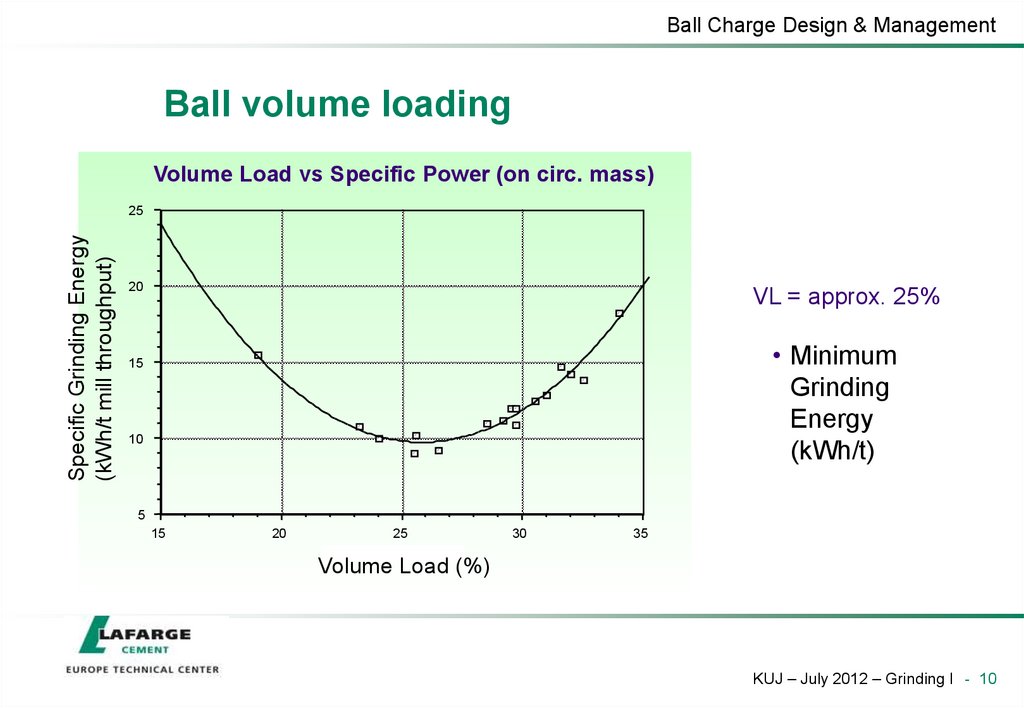

10. Ball volume loading

Ball Charge Design & ManagementBall volume loading

Volume Load vs Specific Power (on circ. mass)

Specific Grinding Energy

(kWh/t mill throughput)

25

20

VL = approx. 25%

• Minimum

Grinding

Energy

(kWh/t)

15

10

5

15

20

25

30

35

Volume Load (%)

KUJ – July 2012 – Grinding I - 10

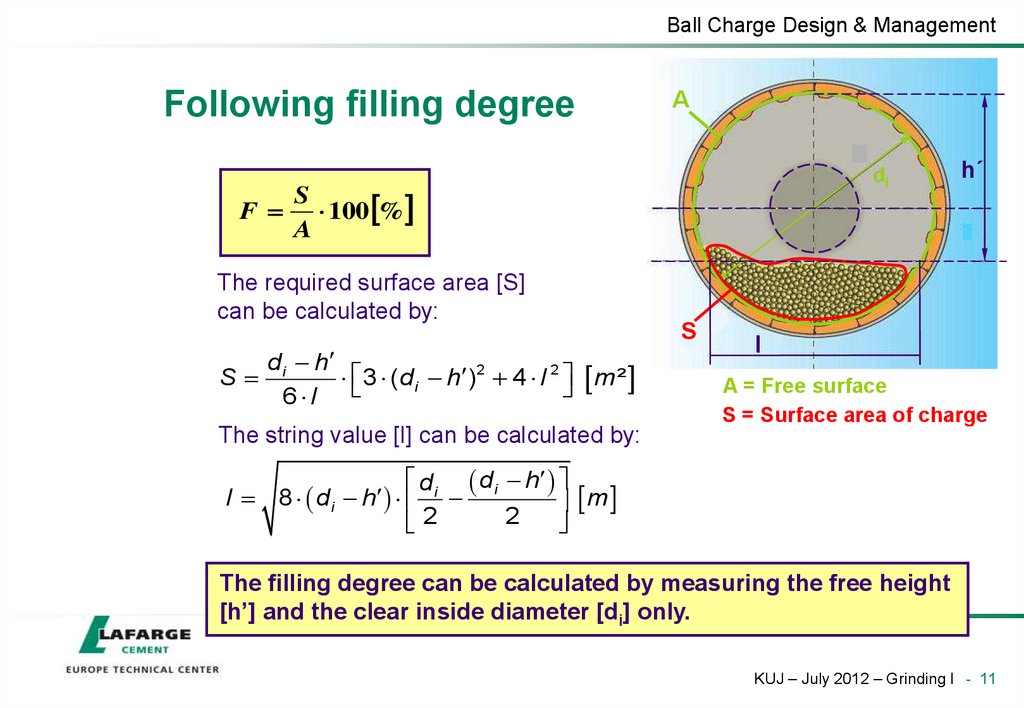

11. Following filling degree

Ball Charge Design & ManagementFollowing filling degree

F

A

di

S

100 %

A

The required surface area [S]

can be calculated by:

d h

S i

3 (di h )2 4 l 2 m²

6 l

The string value [l] can be calculated by:

S

h´

l

A = Free surface

S = Surface area of charge

d i d i h

l 8 di h

m

2

2

The filling degree can be calculated by measuring the free height

[h’] and the clear inside diameter [di] only.

KUJ – July 2012 – Grinding I - 11

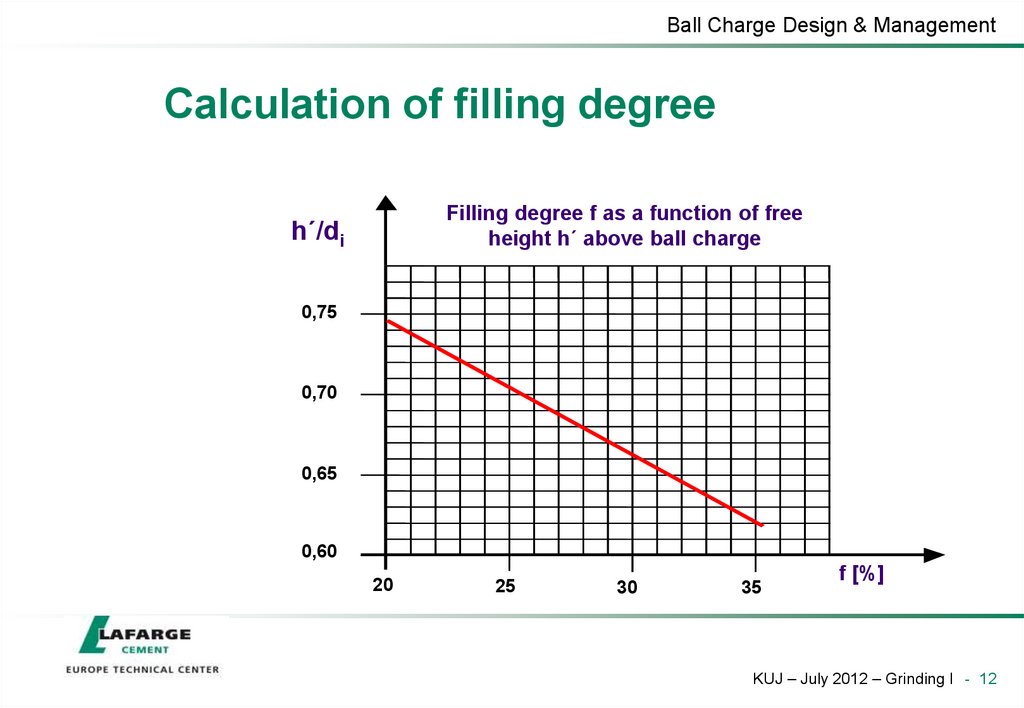

12. Calculation of filling degree

Ball Charge Design & ManagementCalculation of filling degree

Filling degree f as a function of free

height h´ above ball charge

h´/di

0,75

0,70

0,65

0,60

20

25

30

35

f [%]

KUJ – July 2012 – Grinding I - 12

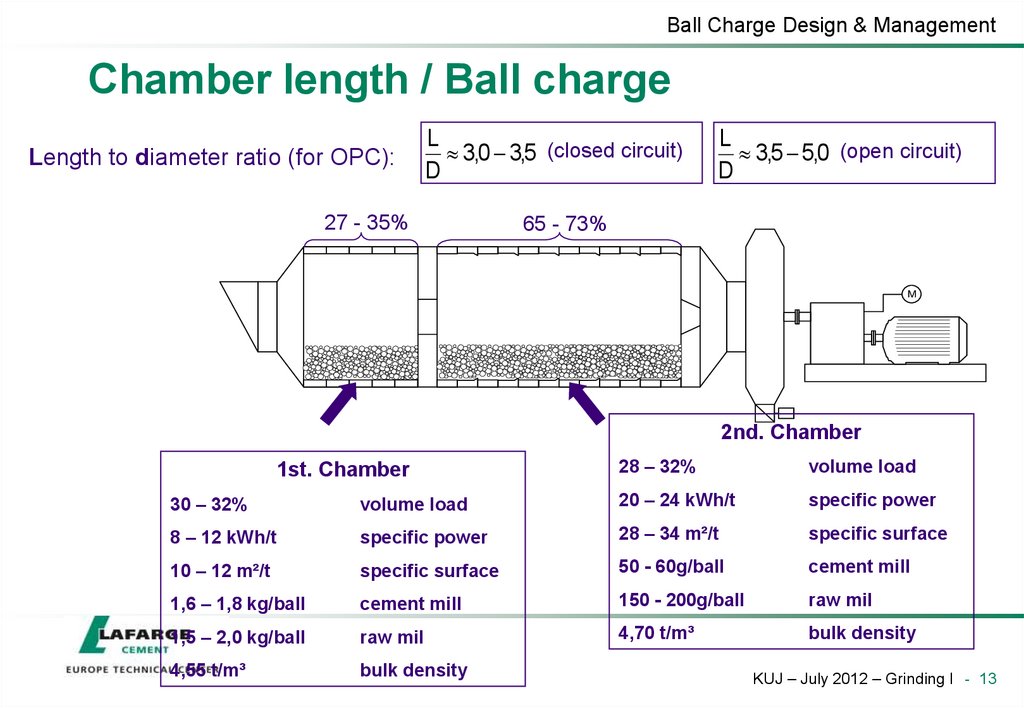

13. Chamber length / Ball charge

Ball Charge Design & ManagementChamber length / Ball charge

Length to diameter ratio (for OPC):

L

3,0 3,5 (closed circuit)

D

27 - 35%

L

3,5 5,0 (open circuit)

D

65 - 73%

M

2nd. Chamber

1st. Chamber

28 – 32%

volume load

30 – 32%

volume load

20 – 24 kWh/t

specific power

8 – 12 kWh/t

specific power

28 – 34 m²/t

specific surface

10 – 12 m²/t

specific surface

50 - 60g/ball

cement mill

1,6 – 1,8 kg/ball

cement mill

150 - 200g/ball

raw mil

1,5 – 2,0 kg/ball

raw mil

4,70 t/m³

bulk density

4,55 t/m³

bulk density

KUJ – July 2012 – Grinding I - 13

14. Ball Charge Fundamentals

Ball Charge Design & ManagementBall Charge Fundamentals

• In a ball mill, the balls grind the material

• Match the charge to the material particle size

• The ball charge has a major effect on material

progression in the tube

• Adjust the mill charge porosity or permeability, to the

amount of circulating load and throughput required

• Adjust the level of charge, or volume loading, to

optimize production and efficiency.

KUJ – July 2012 – Grinding I - 14

15. How to design a ball charge and manage it?

Calculation of a theoretical ball charge(always involve your Technical centre)

Optimisation of a ball charge in an existing mill

(better to involve Technical centre)

Ball charge management and follow-up

16. Theoretical ball charge

Ball Charge Design & ManagementTheoretical ball charge

• Parameters

• Product: type, composition, fineness, throughput…

• the ball charge design must produce the maximum output of

different types of optimum quality cement. The charge should be

adjusted to the type most produced.

• Material characteristics: crushability, grindability, size,

moisture…

• Mill: L/D, power available, internals, speed, ventilation…

• Whenever possible, the design should try to minimise the risk of

metal to metal contact and thereby the wear rate of components

Always take into account possible variations of these parameters

KUJ – July 2012 – Grinding I - 16

17. Design methodology

Ball Charge Design & ManagementDesign methodology

• Numerous attempts to make the process more scientific and

rigorous

• Slegten, Polysius Models

• Lafarge Corp. Mill Grinding Reference

• Effort continues with Best Practices

• Efforts are hampered by lack of

• Raw material testing data

• Crushability, feed size

• Consideration for mill & circuit design/condition

• Liner type & condition, mill sweep, separator type

• Lack of extensive trial & validation programme

… but methods can be a useful guide!

KUJ – July 2012 – Grinding I - 17

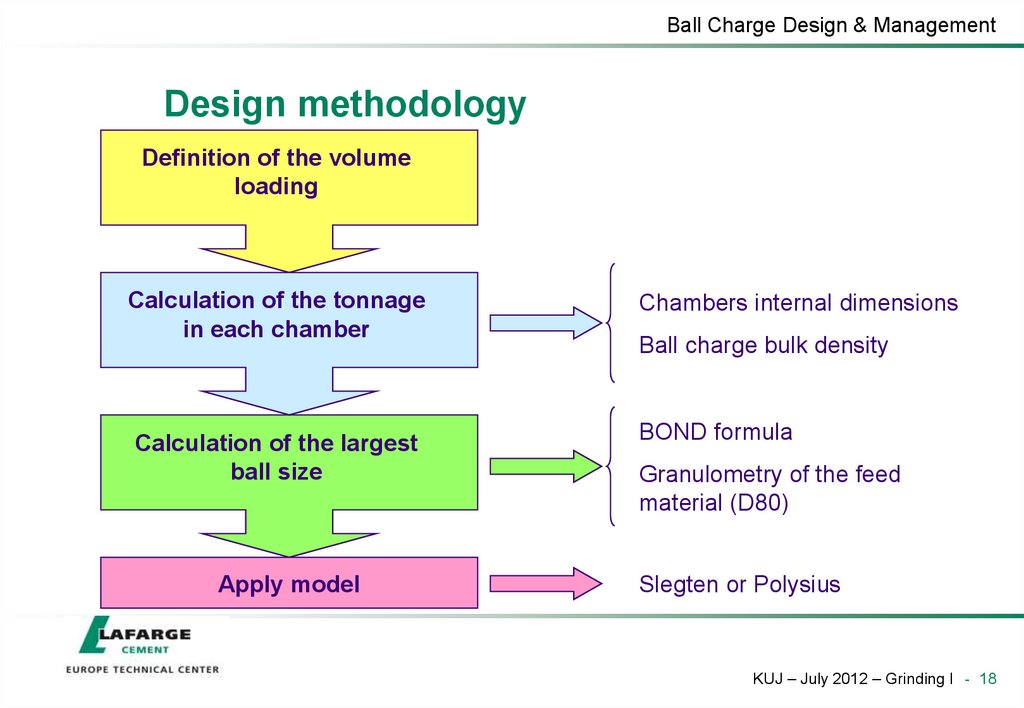

18. Design methodology

Ball Charge Design & ManagementDesign methodology

Definition of the volume

loading

Calculation of the tonnage

in each chamber

Calculation of the largest

ball size

Apply model

Chambers internal dimensions

Ball charge bulk density

BOND formula

Granulometry of the feed

material (D80)

Slegten or Polysius

KUJ – July 2012 – Grinding I - 18

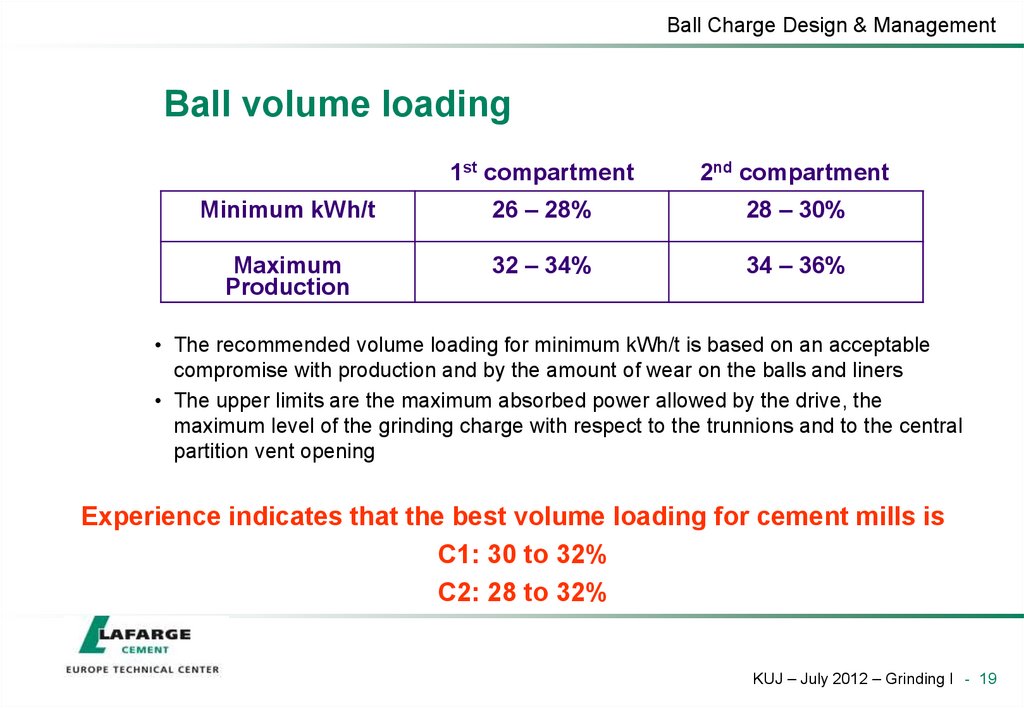

19. Ball volume loading

Ball Charge Design & ManagementBall volume loading

1st compartment

2nd compartment

Minimum kWh/t

26 – 28%

28 – 30%

Maximum

Production

32 – 34%

34 – 36%

• The recommended volume loading for minimum kWh/t is based on an acceptable

compromise with production and by the amount of wear on the balls and liners

• The upper limits are the maximum absorbed power allowed by the drive, the

maximum level of the grinding charge with respect to the trunnions and to the central

partition vent opening

Experience indicates that the best volume loading for cement mills is

C1: 30 to 32%

C2: 28 to 32%

KUJ – July 2012 – Grinding I - 19

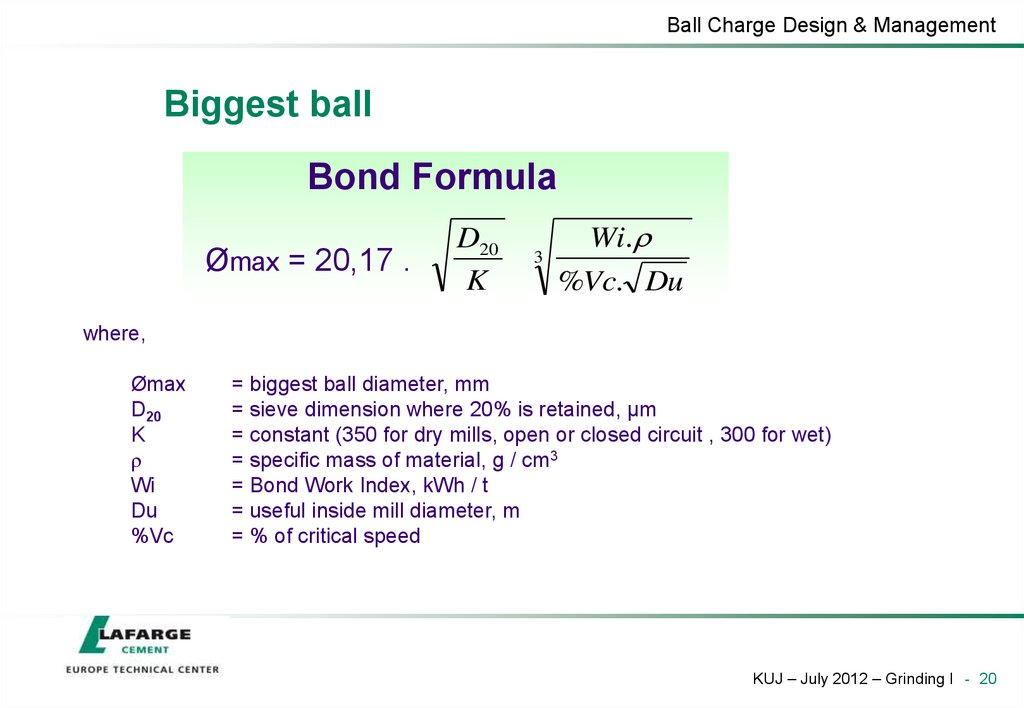

20. Biggest ball

Ball Charge Design & ManagementBiggest ball

Bond Formula

Ømax = 20,17 .

D20

K

3

Wi.

%Vc. Du

where,

Ømax

D20

K

Wi

Du

%Vc

= biggest ball diameter, mm

= sieve dimension where 20% is retained, µm

= constant (350 for dry mills, open or closed circuit , 300 for wet)

= specific mass of material, g / cm3

= Bond Work Index, kWh / t

= useful inside mill diameter, m

= % of critical speed

KUJ – July 2012 – Grinding I - 20

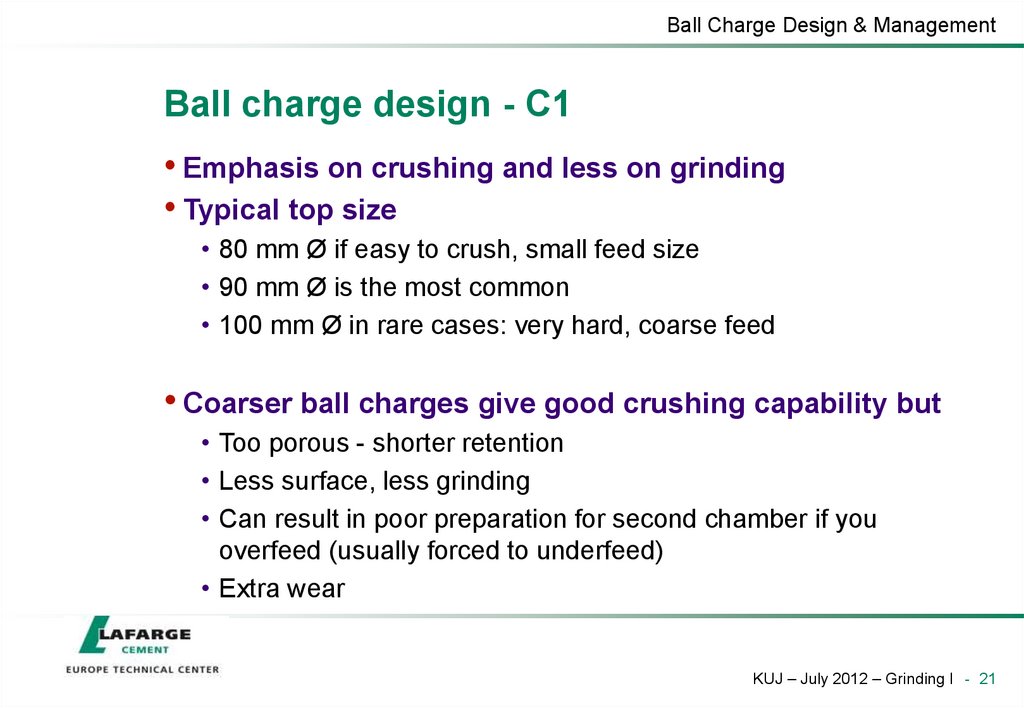

21. Ball charge design - C1

Ball Charge Design & ManagementBall charge design - C1

• Emphasis on crushing and less on grinding

• Typical top size

• 80 mm Ø if easy to crush, small feed size

• 90 mm Ø is the most common

• 100 mm Ø in rare cases: very hard, coarse feed

• Coarser ball charges give good crushing capability but

• Too porous - shorter retention

• Less surface, less grinding

• Can result in poor preparation for second chamber if you

overfeed (usually forced to underfeed)

• Extra wear

KUJ – July 2012 – Grinding I - 21

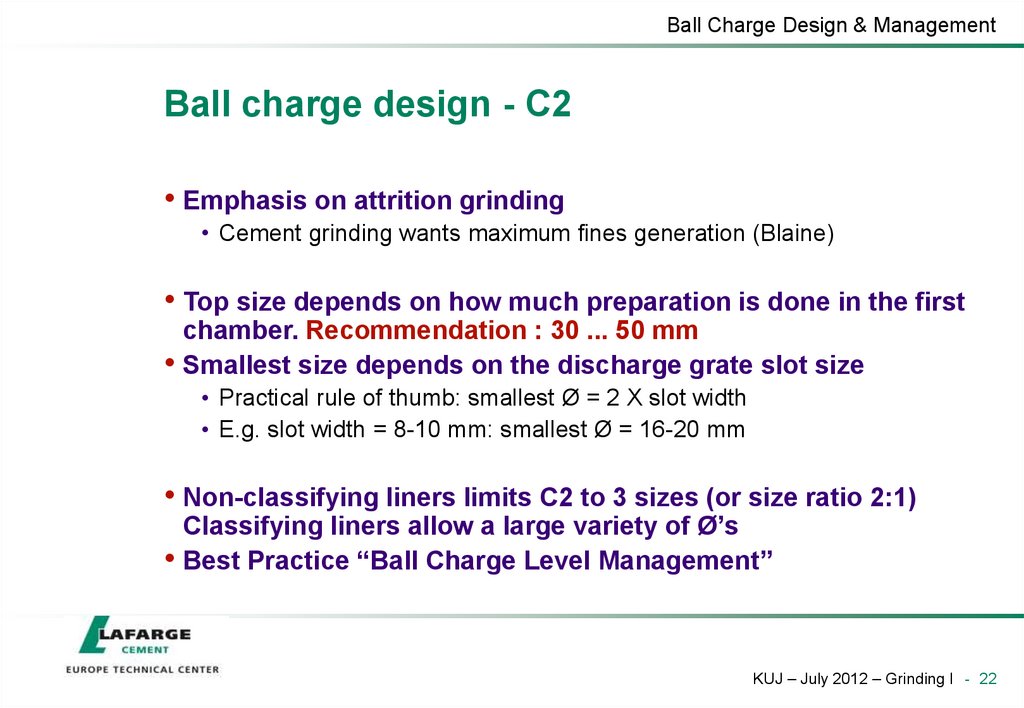

22. Ball charge design - C2

Ball Charge Design & ManagementBall charge design - C2

• Emphasis on attrition grinding

• Cement grinding wants maximum fines generation (Blaine)

• Top size depends on how much preparation is done in the first

chamber. Recommendation : 30 ... 50 mm

• Smallest size depends on the discharge grate slot size

• Practical rule of thumb: smallest Ø = 2 X slot width

• E.g. slot width = 8-10 mm: smallest Ø = 16-20 mm

• Non-classifying liners limits C2 to 3 sizes (or size ratio 2:1)

Classifying liners allow a large variety of Ø’s

• Best Practice “Ball Charge Level Management”

KUJ – July 2012 – Grinding I - 22

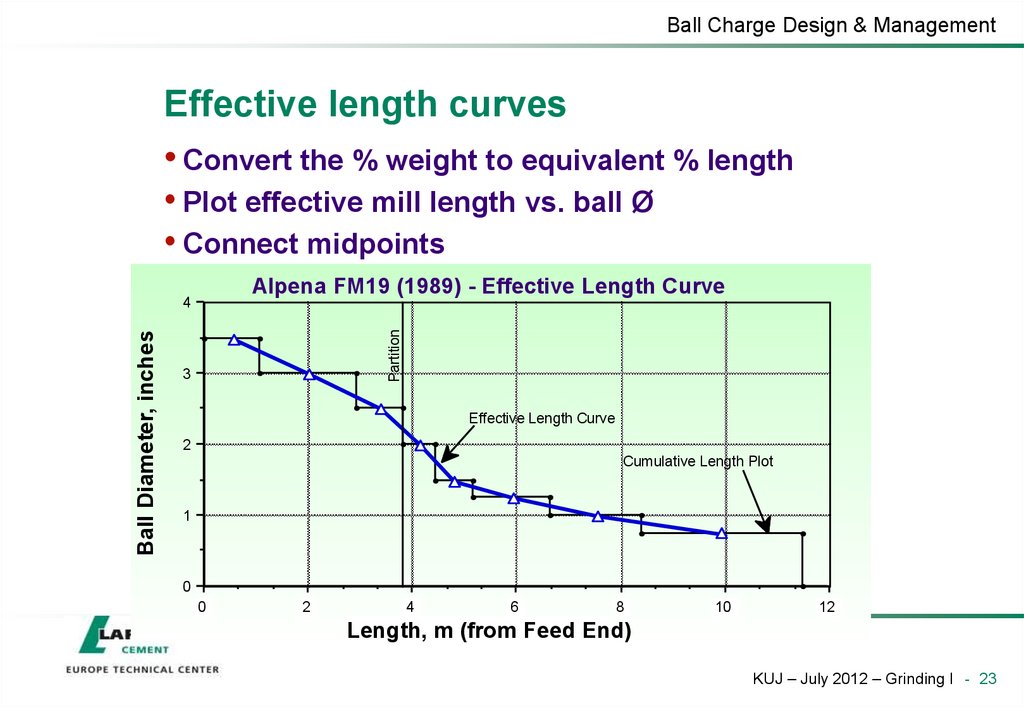

23. Effective length curves

Ball Charge Design & ManagementEffective length curves

• Convert the % weight to equivalent % length

• Plot effective mill length vs. ball Ø

• Connect midpoints

Alpena FM19 (1989) - Effective Length Curve

Partition

Ball Diameter, inches

4

3

Effective Length Curve

2

Cumulative Length Plot

1

0

0

2

4

6

8

10

12

Length, m (from Feed End)

KUJ – July 2012 – Grinding I - 23

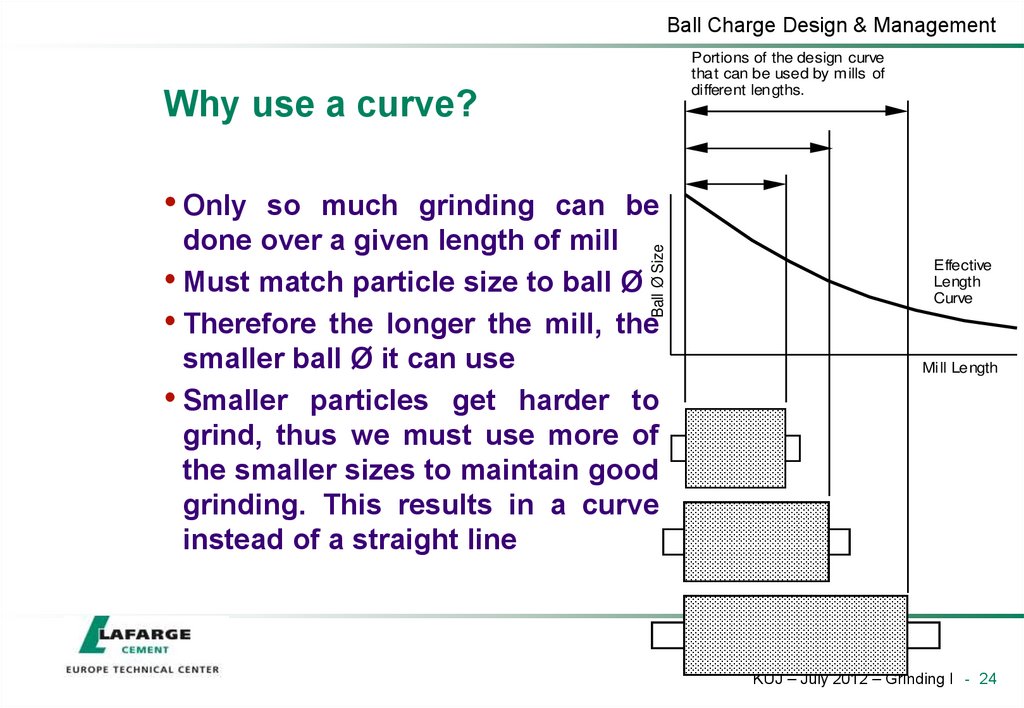

24. Why use a curve?

Ball Charge Design & ManagementPortions of the design curve

that can be used by mills of

different lengths.

Why use a curve?

• Only

Ball Ø Size

so much grinding can be

done over a given length of mill

• Must match particle size to ball Ø

• Therefore the longer the mill, the

smaller ball Ø it can use

• Smaller particles get harder to

grind, thus we must use more of

the smaller sizes to maintain good

grinding. This results in a curve

instead of a straight line

Effective

Length

Curve

Mill Length

KUJ – July 2012 – Grinding I - 24

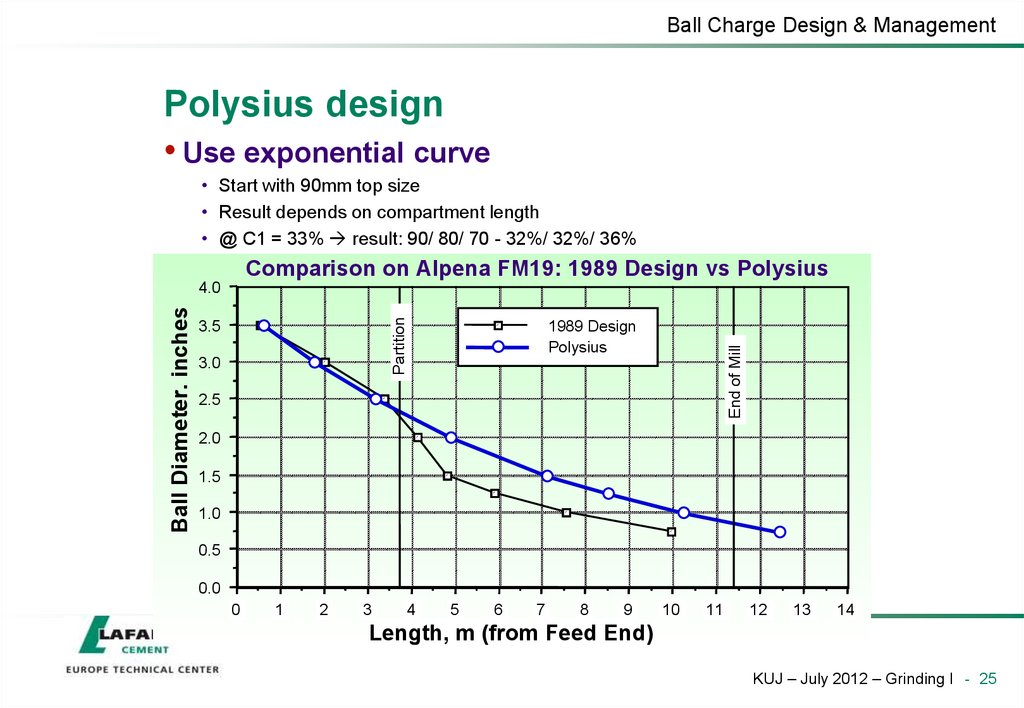

25. Polysius design

Ball Charge Design & ManagementPolysius design

• Use exponential curve

• Start with 90mm top size

• Result depends on compartment length

• @ C1 = 33% result: 90/ 80/ 70 - 32%/ 32%/ 36%

Comparison on Alpena FM19: 1989 Design vs Polysius

Partition

3.5

3.0

1989 Design

Polysius

End of Mill

Ball Diameter. inches

4.0

2.5

2.0

1.5

1.0

0.5

0.0

0

1

2

3

4

5

6

7

8

9

10

11

12

13

14

Length, m (from Feed End)

KUJ – July 2012 – Grinding I - 25

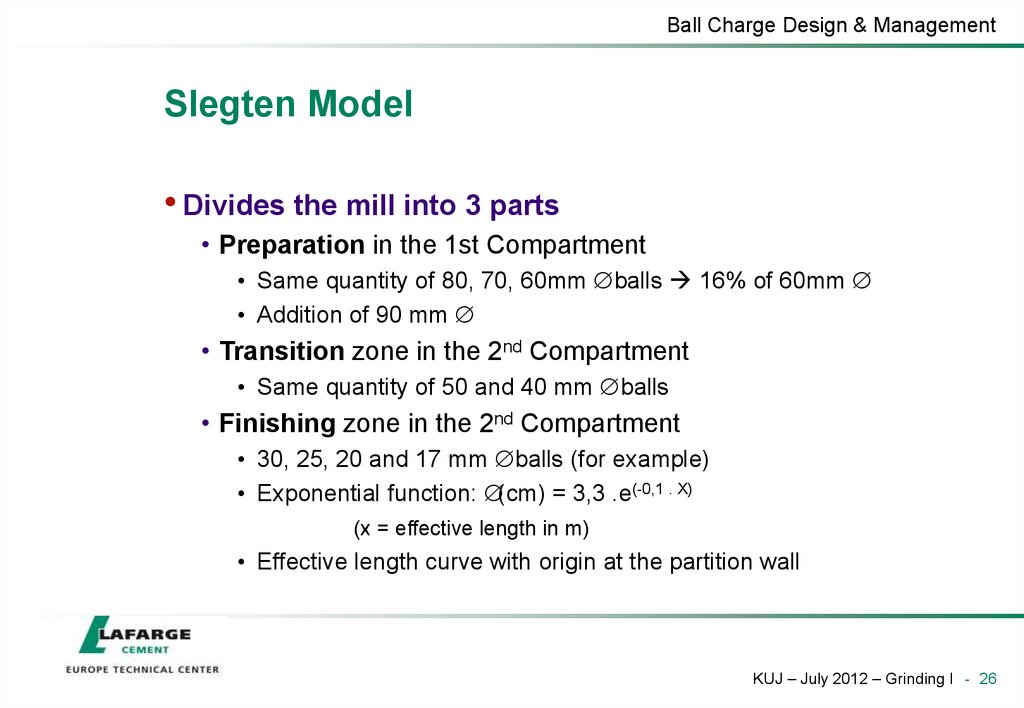

26. Slegten Model

Ball Charge Design & ManagementSlegten Model

• Divides the mill into 3 parts

• Preparation in the 1st Compartment

• Same quantity of 80, 70, 60mm balls 16% of 60mm

• Addition of 90 mm

• Transition zone in the 2nd Compartment

• Same quantity of 50 and 40 mm balls

• Finishing zone in the 2nd Compartment

• 30, 25, 20 and 17 mm balls (for example)

• Exponential function: (cm) = 3,3 .e(-0,1 . X)

(x = effective length in m)

• Effective length curve with origin at the partition wall

KUJ – July 2012 – Grinding I - 26

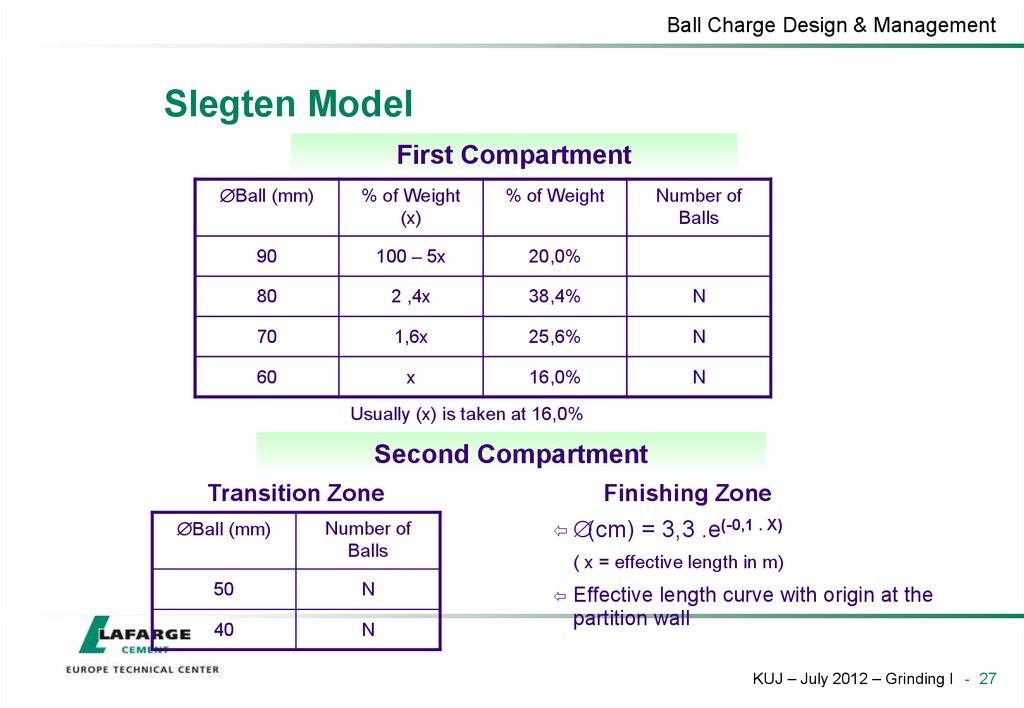

27. Slegten Model

Ball Charge Design & ManagementSlegten Model

First Compartment

Ball (mm)

% of Weight

(x)

% of Weight

90

100 – 5x

20,0%

80

2 ,4x

38,4%

N

70

1,6x

25,6%

N

60

x

16,0%

N

Number of

Balls

Usually (x) is taken at 16,0%

Second Compartment

Transition Zone

Ball (mm)

Number of

Balls

50

N

40

N

Finishing Zone

(cm)

= 3,3 .e(-0,1 . X)

( x = effective length in m)

Effective length curve with origin at the

partition wall

KUJ – July 2012 – Grinding I - 27

28. Slegten model example calculation

Ball Charge Design & ManagementSlegten model example calculation

• Material characteristics

Clinker

D80 = 15 mm

Wi = 13,49 kWh/t

= 3,09 g/cm3

KUJ – July 2012 – Grinding I - 28

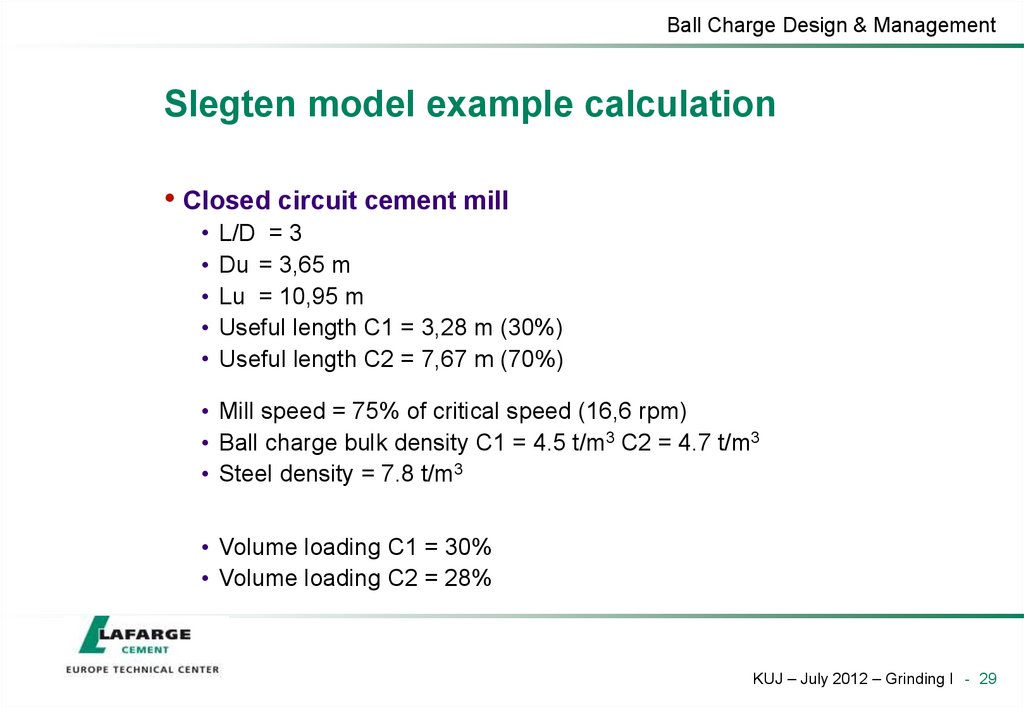

29. Slegten model example calculation

Ball Charge Design & ManagementSlegten model example calculation

• Closed circuit cement mill

L/D = 3

Du = 3,65 m

Lu = 10,95 m

Useful length C1 = 3,28 m (30%)

Useful length C2 = 7,67 m (70%)

• Mill speed = 75% of critical speed (16,6 rpm)

• Ball charge bulk density C1 = 4.5 t/m3 C2 = 4.7 t/m3

• Steel density = 7.8 t/m3

• Volume loading C1 = 30%

• Volume loading C2 = 28%

KUJ – July 2012 – Grinding I - 29

30. Excercise

Ball Charge Design & ManagementExcercise

• Calculate biggest ball

• Remember

Ømax = 20,17 .

D20

K

3

Wi.

%Vc. Du

• Propose a ball charge (Slegten)

KUJ – July 2012 – Grinding I - 30

31. Ball charge optimization (existing mill)

Ball Charge Design & ManagementBall charge optimization (existing mill)

• Calculate theoretical ball charge as a reference

• Perform a mill audit to assess critical points

Axial test: grinding efficiency of the charge, presence of nibs…

Partition condition: slot width, broken plates…

Condition of ball charge and liners

Coating, temperature, water injection…

• Adjust ball charge according to conclusions

When several products are made with the same mill,

check conditions for all of them

KUJ – July 2012 – Grinding I - 31

32. Ball charge management

Ball Charge Design & ManagementBall charge management

• Having a well-designed ball charge is one thing…

… but you need to keep it this way in time

Wear

Balls can break, lose their shape

Pollution by foreign bodies

Partition liners can break balls get mixed

• Object of ball charge management

• Top-ups

• Ball charge sorting

• Wear calculation

KUJ – July 2012 – Grinding I - 32

33. Top-ups

Ball Charge Design & ManagementTop-ups

• Follow-up at least every month

• Check mill power consumption (same product every time)

• Free height measurement on purged mill

• Top-up decision

• Ratio should be known

• 10 kW ~ 1 t of balls

• Or 1% filling level ~ x t of balls

• Rules to be established for each plant: when to add balls

• Usually add only bigger balls

• Methods

• Mill stopped:through doors

• Mill in operation: through inlet trunnion (possible with feed, but not

recommended)

• Always record date, ball size and quality, weight…

KUJ – July 2012 – Grinding I - 33

34. Ball charge sorting

Ball Charge Design & ManagementBall charge sorting

• Objective

• Eliminate scrap, broken and undersize balls

• scrap = foreign metallic elements polluting the ball charge (bolts,

pieces of liners, …)

• Go back to optimal ball charge

• Minimal frequency

• C1

• Every year or 7500 to 8000 hours

• C2 (and C3)

• Every 2 years or 15000 to 16000 hours

• More often when necessary (very high wear, wet mills…)

KUJ – July 2012 – Grinding I - 34

35. Sorting method

Ball Charge Design & ManagementSorting method

• Purge mill, take everything out of the compartment

• Sort, weigh and record

• By size classes for still usable balls (ex: 75 – 85 mm = 80 mm

class)

• Undersized balls (not suitable for the compartment)

• Broken, out-of-shape balls (not reusable)

• Scrap

• Sorting machine recommended

• When a plant has several mills, it can be easier to have

an extra charge ready to put in the mill gives more

time for sorting

KUJ – July 2012 – Grinding I - 35

36. Wear calculation

Ball Charge Design & ManagementWear calculation

• Can be done only if proper records of charges, top-ups

and sorting are kept

• Major indicator = wear rate in g of metal / ton of product

• By compartment or globally

• Count only worn metal from balls (not scrap)

• Other indicators can be calculated if specific needs

• Example

KUJ – July 2012 – Grinding I - 36

industry

industry