Similar presentations:

Tech Service HTTI HTA Program “Cutting/Marking Routines”

1. Tech Service HTTI HTA Program “Cutting/Marking Routines”

Technical Training InstituteTech Service HTTI

HTA Program

“Cutting/Marking Routines”

Author: JDE

Created 7/15/09

2. Cutting/Marking Routines

Technical Training InstituteOur controllers are used for a variety of

functions – but lets look at the three major

routines.

• Plasma Cutting

• Marking

• Oxyfuel

6/9/2020 10:41 AM

2

3. Cutting/Marking Routines

Technical Training InstituteWhen we look at a “routine” we are going to be

talking about:

• Sequence of operation

• I/O required

• How to configure the CNC system

6/9/2020 10:41 AM

3

4. Cutting/Marking Routines

Technical Training InstituteTypical Oxyfuel Operation:

The Oxyfuel process operates three different gas flows or

stages

One to ignite the flame

One to heat the surface plate

One to cut the plate.

These stages are called Low Preheat, High Preheat (or

Preheat Control), and Cut Gas

6/9/2020 10:41 AM

4

5. Cutting/Marking Routines

Technical Training InstituteTypical Oxyfuel Operation:

The three stages are defined as:

Low Preheat: Low pressure fuel gas used to ignite the flame

High Preheat: High pressure fuel gas with low pressure

Oxygen used to heat the plate to the point where

piercing/cutting can occur

Cut Gas: High pressure Oxygen and fuel gas used to

pierce/cut the plate.

6/9/2020 10:41 AM

5

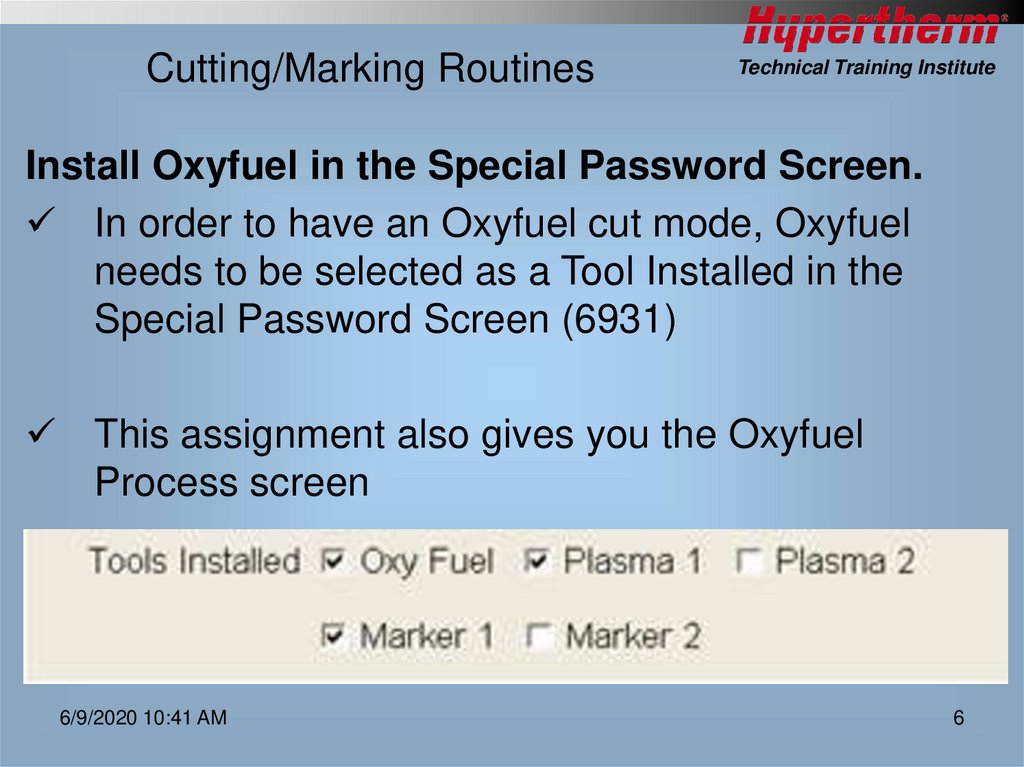

6. Cutting/Marking Routines

Technical Training InstituteInstall Oxyfuel in the Special Password Screen.

In order to have an Oxyfuel cut mode, Oxyfuel

needs to be selected as a Tool Installed in the

Special Password Screen (6931)

This assignment also gives you the Oxyfuel

Process screen

6/9/2020 10:41 AM

6

7. Cutting/Marking Routines

Technical Training InstituteNotice* You do not need to install a OxyFuel torch into

the Station Configuration Screen (4170)

Checking OxyFuel in Special Setups (6931)

will give you the OxyFuel Process settings

6/9/2020 10:41 AM

7

8. Cutting/Marking Routines

Technical Training InstituteTypical Inputs used in the Oxyfuel Routine:

Cut Select:

Manually activates the Cut Control output

Operators use this input to manually adjust the cut oxygen gas

flow.

Input is typically driven by a momentary push button switch

6/9/2020 10:41 AM

8

9. Cutting/Marking Routines

Technical Training InstituteTypical Inputs used in the Oxyfuel Routine:

Low Preheat Select:

Manually activates the Low Preheat output

Operators use this input to manually adjust the low preheat

gas flow.

Input is typically driven by a momentary push button switch

6/9/2020 10:41 AM

9

10. Cutting/Marking Routines

Technical Training InstituteTypical Inputs used in the Oxyfuel Routine:

High Preheat Select:

Manually activates the High Preheat output.

Operators use this input to manually adjust the high preheat

gas flow.

Input is typically driven by a momentary push button switch

6/9/2020 10:41 AM

10

11. Cutting/Marking Routines

Technical Training InstituteTypical Inputs used in the Oxyfuel Routine:

Manual Ignition Select:

Manually activates the ignition output.

Operators use this input to manually activate the igniters'.

Input is typically driven by a momentary push button switch

6/9/2020 10:41 AM

11

12. Cutting/Marking Routines

Technical Training InstituteTypical Inputs used in the Oxyfuel Routine:

Lower Torch:

Activates the Torch Down output

The output is used to signal the Oxyfuel Cutting

Station to lower the torch.

Input is typically driven by a manual toggle switch

6/9/2020 10:41 AM

12

13. Cutting/Marking Routines

Technical Training InstituteTypical Inputs used in the Oxyfuel Routine:

Lower All Torches:

Activates all Torch Down outputs

Used in multiple torch applications.

The input is typically driven by a manual toggle switch

6/9/2020 10:41 AM

13

14. Cutting/Marking Routines

Technical Training InstituteTypical Inputs used in the Oxyfuel Routine:

Raise Torch:

Activates the Torch Up output

The output is used to signal the Oxyfuel Cutting

Station to raise the torch.

Input is typically driven by a manual toggle switch

6/9/2020 10:41 AM

14

15. Cutting/Marking Routines

Technical Training InstituteTypical Inputs used in the Oxyfuel Routine:

Raise All Torches:

Activates the all Torch Up outputs

Used in multiple torch applications.

The input is typically driven by a manual toggle switch

6/9/2020 10:41 AM

15

16. Cutting/Marking Routines

Technical Training InstituteTypical Inputs used in the Oxyfuel Routine:

Torch Down Sense:

De-activates the Torch Down output when active.

This input is used as a lower limit switch in an Oxyfuel

Cutting Station.

Input is typically a limit switch or proximity switch

6/9/2020 10:41 AM

16

17. Cutting/Marking Routines

Technical Training InstituteTypical Inputs used in the Oxyfuel Routine:

Torch Up Sense:

De-activates the Torch Up output when active.

This input is used as a upper limit switch in an

Oxyfuel Cutting Station.

Input is typically a limit switch or proximity switch

6/9/2020 10:41 AM

17

18. Cutting/Marking Routines

Technical Training InstituteTypical Outputs used in the Oxyfuel Routine:

Ignition:

Used to activate the ignitors.

Output is timer driven; timer setting is located

in the Oxyfuel Process screen

6/9/2020 10:41 AM

18

19. Cutting/Marking Routines

Technical Training InstituteTypical Outputs used in the Oxyfuel Routine:

Low Preheat Control:

Used to activate the low preheat gas valves.

The output is timer driven; timer setting is

located in the Oxyfuel Process screen

6/9/2020 10:41 AM

19

20. Cutting/Marking Routines

Technical Training InstituteTypical Outputs used in the Oxyfuel Routine:

High Preheat Control:

Used to activate the high preheat gas valves

Output is timer driven; timer setting is located

in the Oxyfuel Process screen

6/9/2020 10:41 AM

20

21. Cutting/Marking Routines

Technical Training InstituteTypical Outputs used in the Oxyfuel Routine:

Pierce Control:

Output activates during Pierce and remains

active until the Pierce timer is complete.

Pierce Timer is located in the Oxyfuel Process

screen

6/9/2020 10:41 AM

21

22. Cutting/Marking Routines

Technical Training InstituteTypical Outputs used in the Oxyfuel Routine:

Cut Control:

Used to activate the cut oxygen gas valves.

The output activates after the preheat outputs

and remains active until the M08 (cut off)

command is executed in the part program

6/9/2020 10:41 AM

22

23. Cutting/Marking Routines

Technical Training InstituteTypical Outputs used in the Oxyfuel Routine:

Torch Down:

Used to signal the Oxyfuel cutting station to lower the torch.

Output is timer driven; timer setting is located in the Oxyfuel

Process screen.

Output will shut off if the Torch Down timer expires or the Torch

Down Sense input activates

6/9/2020 10:41 AM

23

24. Cutting/Marking Routines

Technical Training InstituteTypical Outputs used in the Oxyfuel Routine:

Torch Up:

Used to signal the Oxyfuel cutting station to raise the torch.

Output is timer driven; timer setting is located in the Oxyfuel

Process screen.

Output will shut off if Torch Up timer expires or the Torch Up

Sense input activates

6/9/2020 10:41 AM

24

25. Cutting/Marking Routines

Technical Training InstituteTypical Outputs used in the Oxyfuel Routine:

Lets look at the OxyFuel process screen and

timing chart

6/9/2020 10:41 AM

25

26. Cutting/Marking Routines

Technical Training InstituteAssign Inputs and Outputs for Oxyfuel in

the I/O setup screen

The I/O assignments for the Oxyfuel system on

the cutting table will depend on the number

of Oxyfuel torches and whether the CNC

will be operating all the torches

independently

6/9/2020 10:41 AM

26

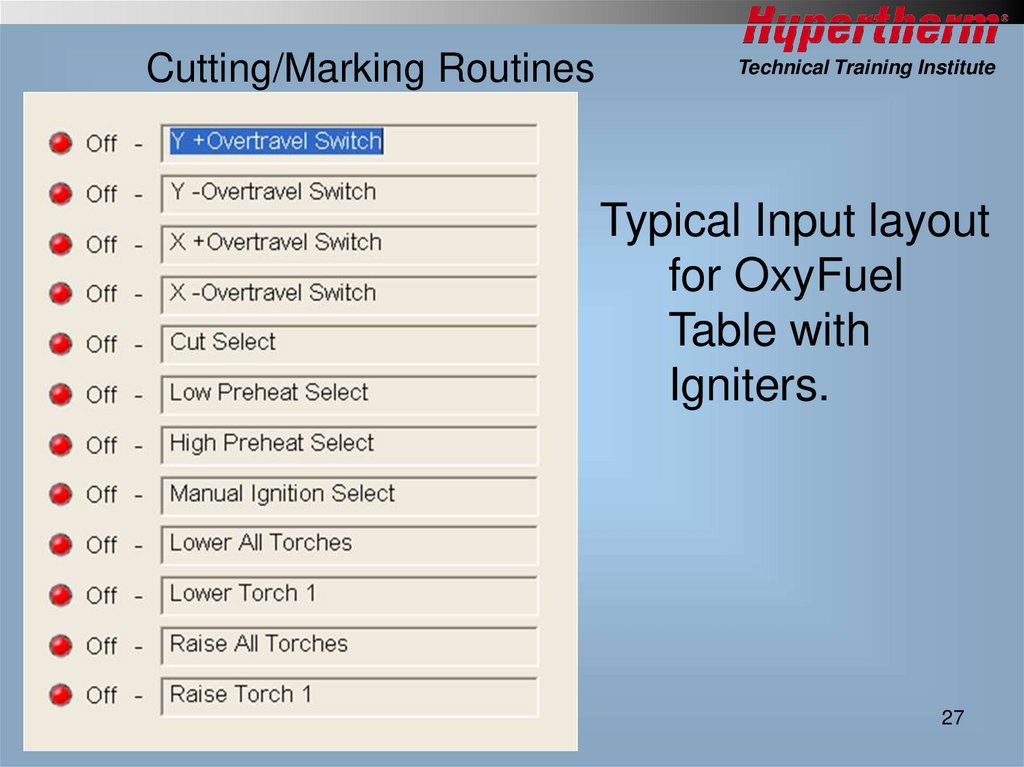

27. Cutting/Marking Routines

Technical Training InstituteTypical Input layout

for OxyFuel

Table with

Igniters.

6/9/2020 10:41 AM

27

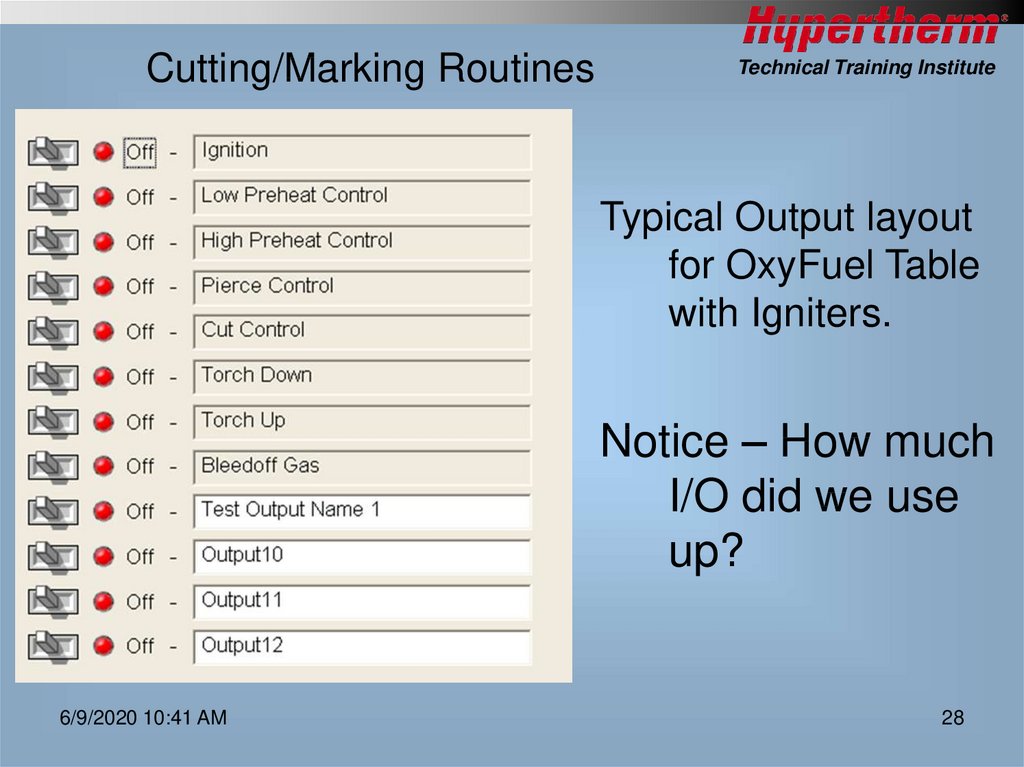

28. Cutting/Marking Routines

Technical Training InstituteTypical Output layout

for OxyFuel Table

with Igniters.

Notice – How much

I/O did we use

up?

6/9/2020 10:41 AM

28

29. Cutting/Marking Routines

Technical Training InstituteSetting Up “Watch” window

The Watch window is a great tool for watching

timing and I/O function.

Lets setup Load Phoenix and Setup a Watch

Windows for Oxyfuel

6/9/2020 10:41 AM

29

software

software industry

industry