Similar presentations:

Oxyfuel Cutting Routine

1. Oxyfuel Cutting Routine

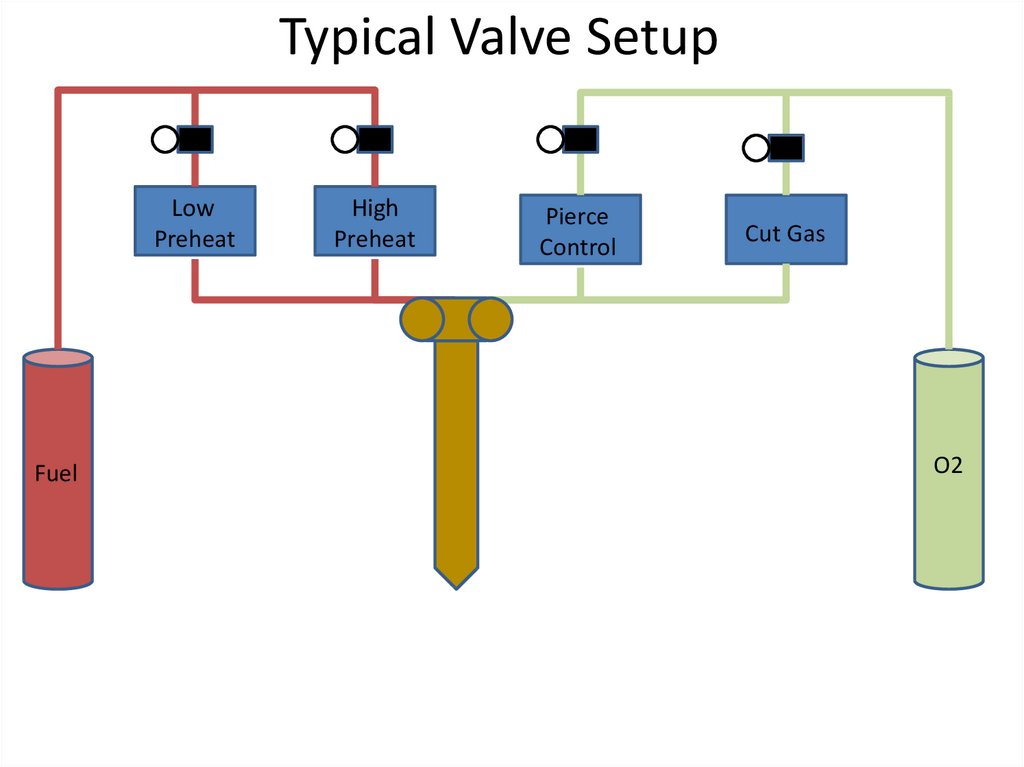

2. Typical Valve Setup

LowPreheat

Fuel

High

Preheat

Pierce

Control

Cut Gas

O2

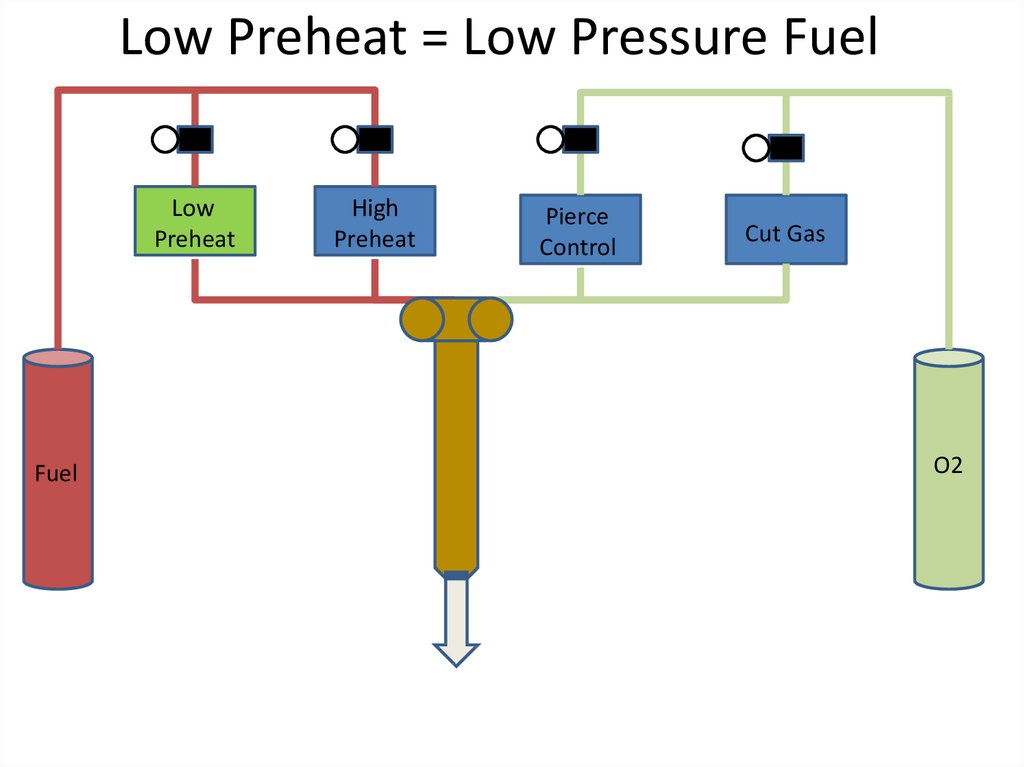

3. Low Preheat = Low Pressure Fuel

LowPreheat

Fuel

High

Preheat

Pierce

Control

Cut Gas

O2

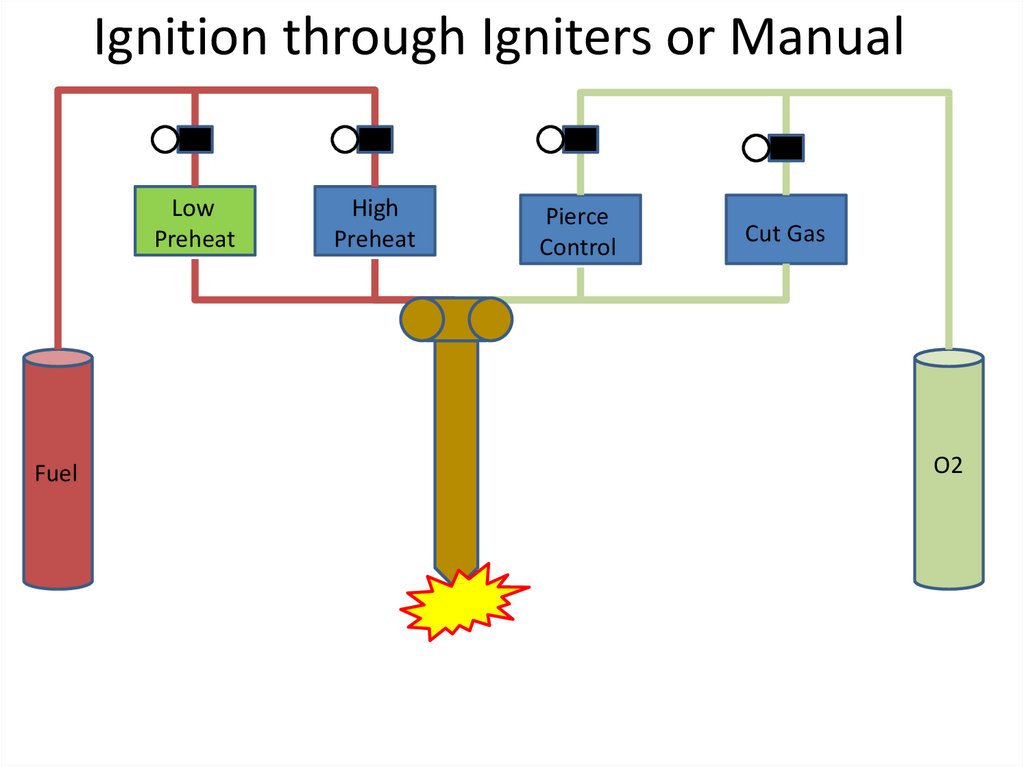

4. Ignition through Igniters or Manual

LowPreheat

Fuel

High

Preheat

Pierce

Control

Cut Gas

O2

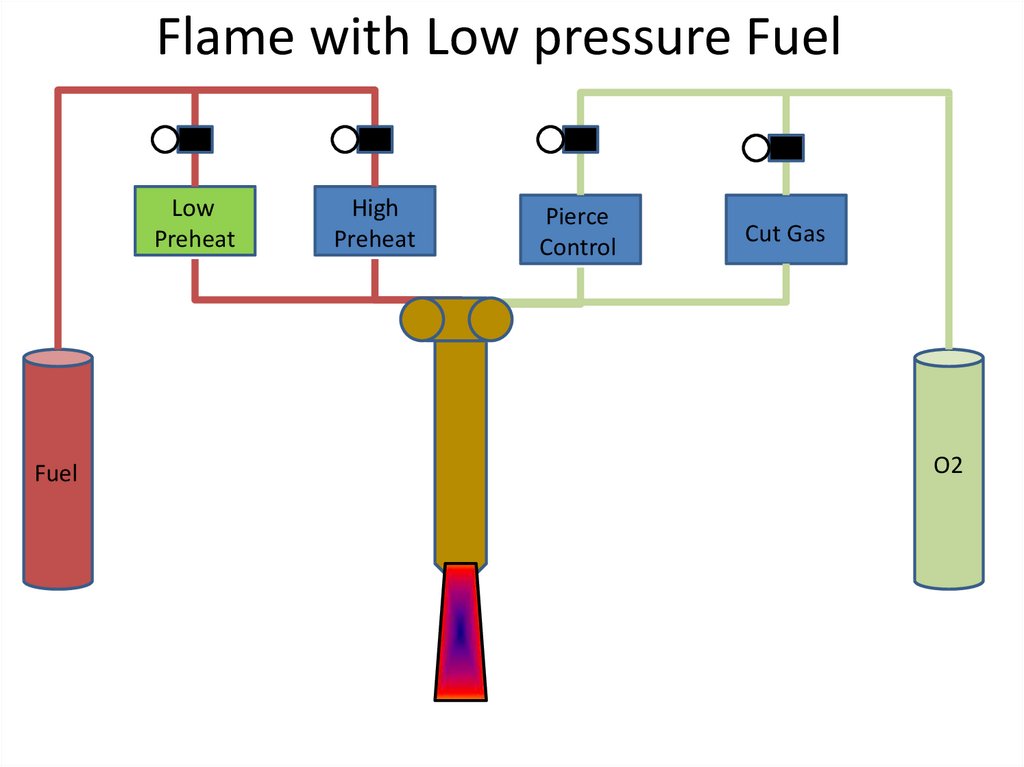

5. Flame with Low pressure Fuel

LowPreheat

Fuel

High

Preheat

Pierce

Control

Cut Gas

O2

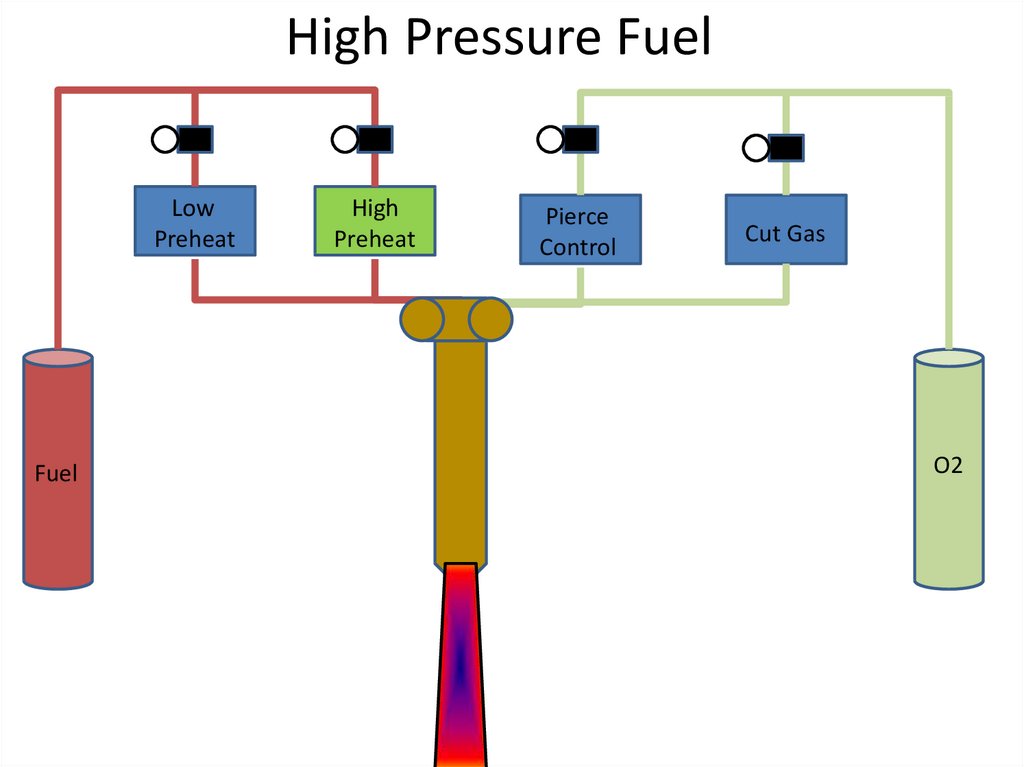

6. High Pressure Fuel

LowPreheat

Fuel

High

Preheat

Pierce

Control

Cut Gas

O2

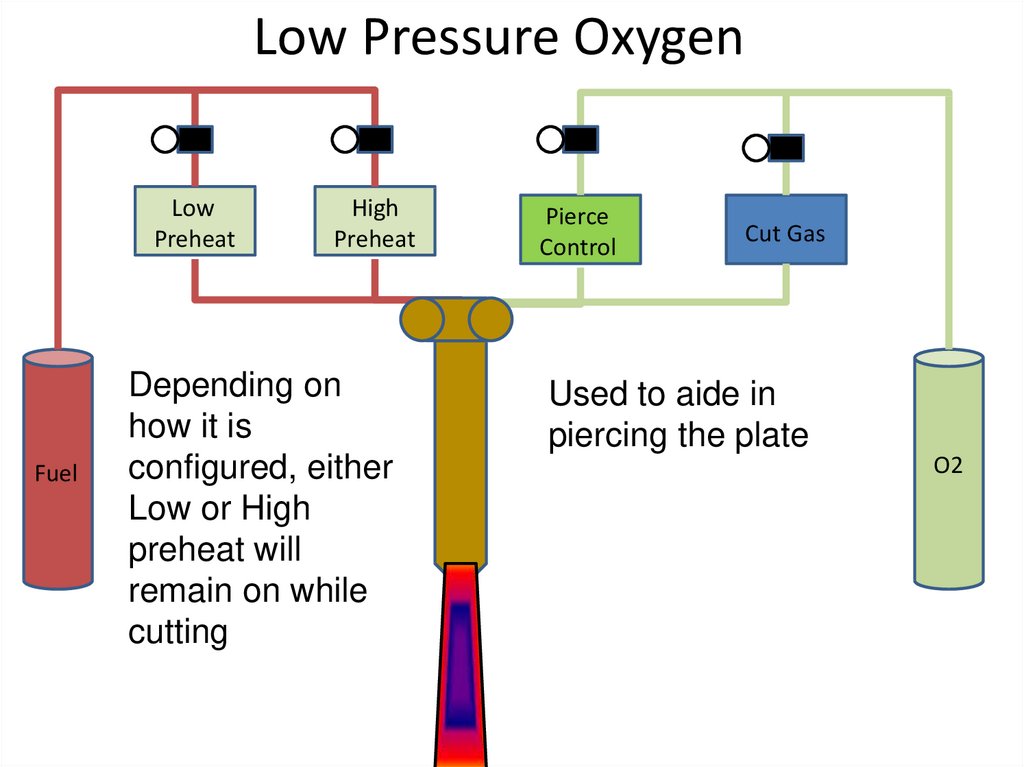

7. Low Pressure Oxygen

LowPreheat

Fuel

High

Preheat

Depending on

how it is

configured, either

Low or High

preheat will

remain on while

cutting

Pierce

Control

Cut Gas

Used to aide in

piercing the plate

O2

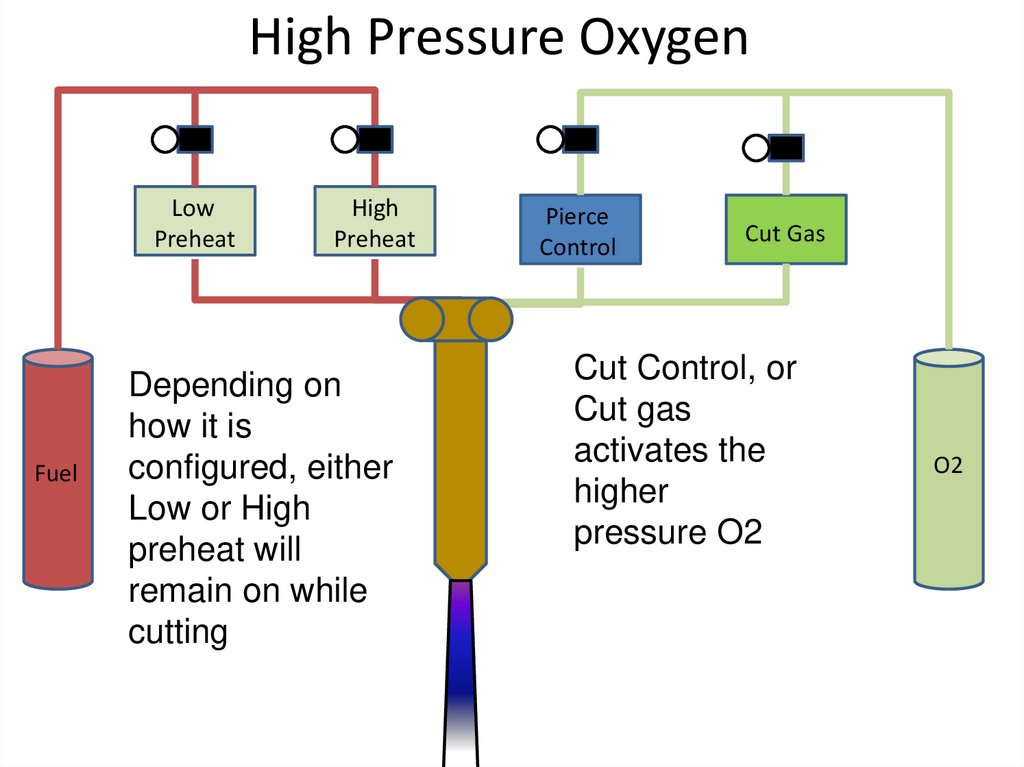

8. High Pressure Oxygen

LowPreheat

Fuel

High

Preheat

Depending on

how it is

configured, either

Low or High

preheat will

remain on while

cutting

Pierce

Control

Cut Gas

Cut Control, or

Cut gas

activates the

higher

pressure O2

O2

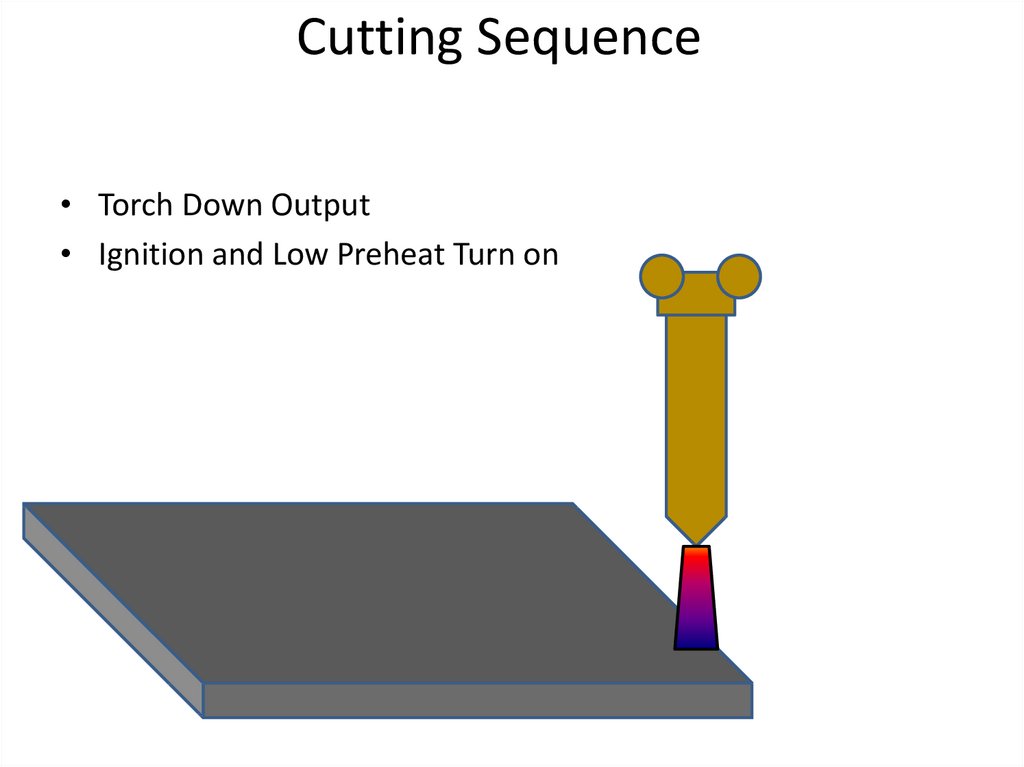

9. Cutting Sequence

• Torch Down Output• Ignition and Low Preheat Turn on

10.

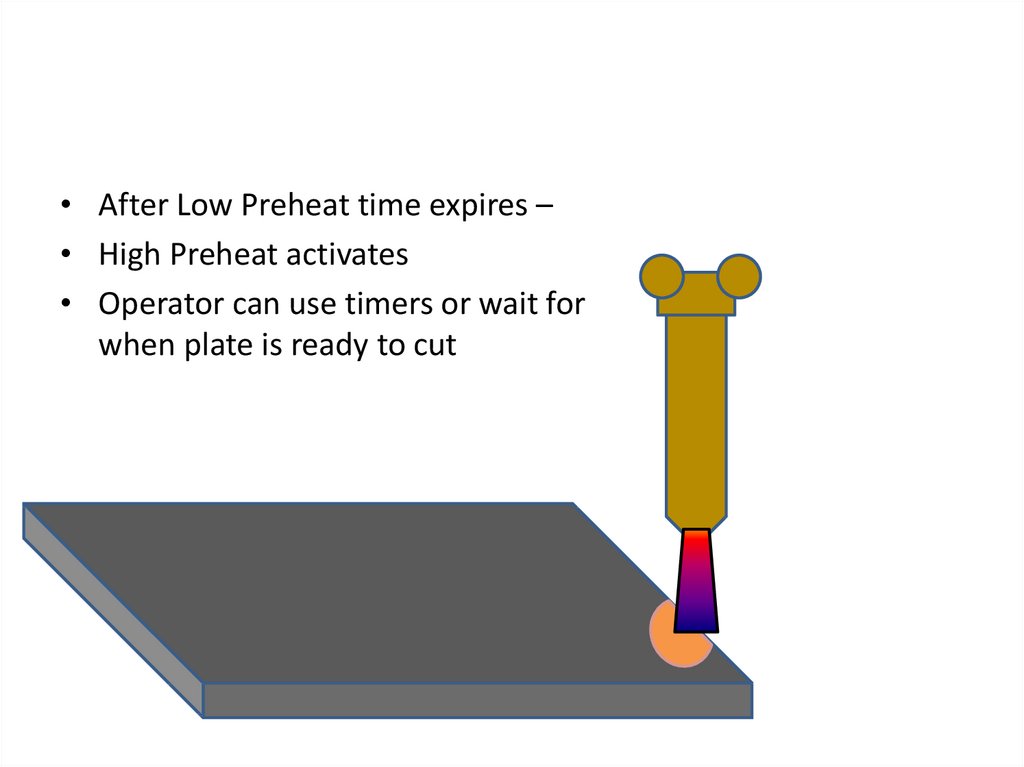

• After Low Preheat time expires –• High Preheat activates

• Operator can use timers or wait for

when plate is ready to cut

11.

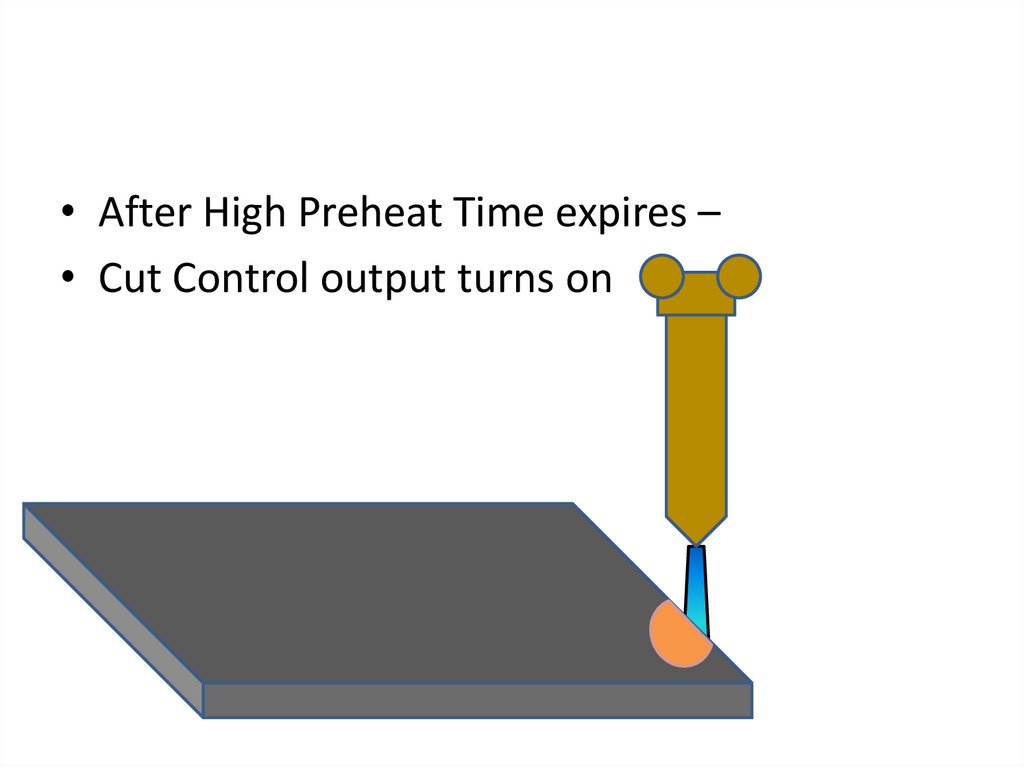

• After High Preheat Time expires –• Cut Control output turns on

12.

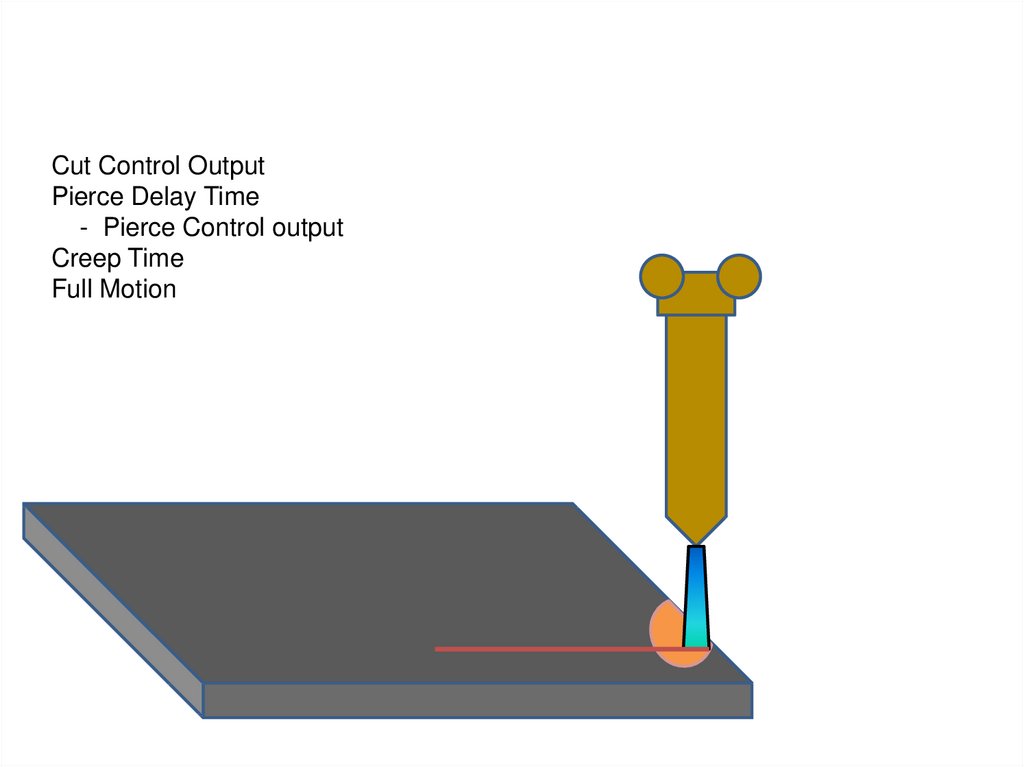

Cut Control OutputPierce Delay Time

- Pierce Control output

Creep Time

Full Motion

software

software industry

industry