Similar presentations:

Development of air conditioning

1.

EDUCATION MANUAL- 06R INVERTER RAC -

2006.05

System Appliances Division

Air Conditioning R&D Team

Inverter TF

2.

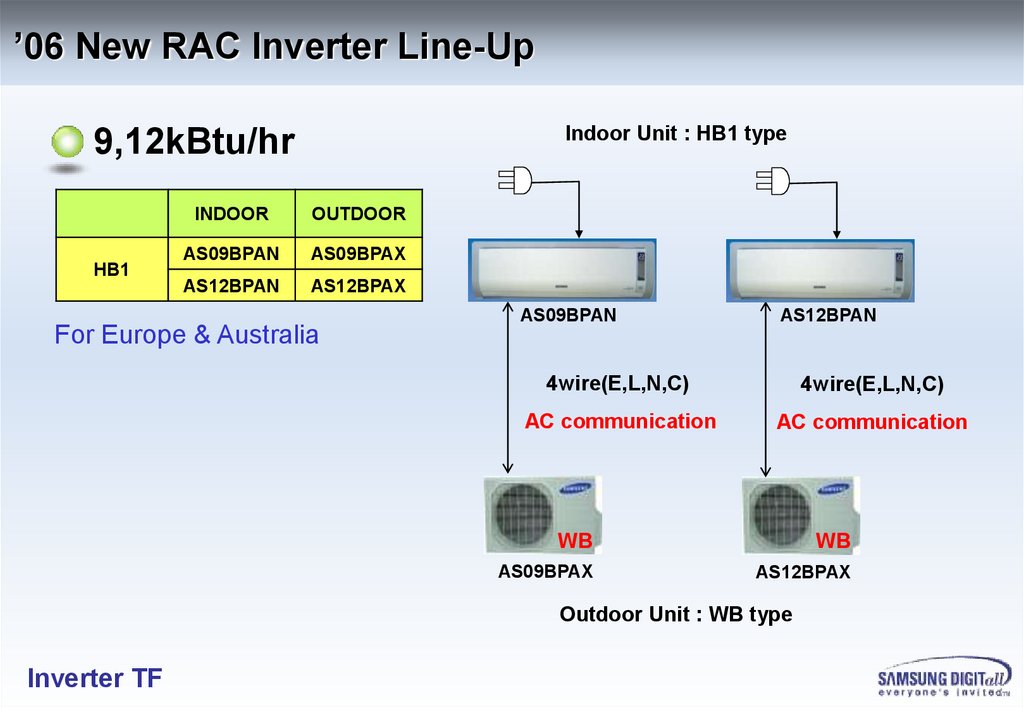

’06 New RAC Inverter Line-UpIndoor Unit : HB1 type

9,12kBtu/hr

HB1

INDOOR

OUTDOOR

AS09BPAN

AS09BPAX

AS12BPAN

AS12BPAX

For Europe & Australia

AS09BPAN

AS12BPAN

4wire(E,L,N,C)

4wire(E,L,N,C)

AC communication

AC communication

WB

WB

AS09BPAX

AS12BPAX

Outdoor Unit : WB type

Inverter TF

3.

’06 New RAC Inverter Line-UpIndoor Unit : WW1 Premium type

9,12kBtu/hr

WW1

AQB09JJWC/KCV

INDOOR

OUTDOOR

AQB09JJWC

UQB09JJWC

AQB12JJWC

UQB12JJWC

For United States

3wire (E,L,N)

3wire (E,L,N)

+ 2Wire(F1,F2)

+ 2Wire(F1,F2)

485 communication

485 communication

WB

UQB09JJWC/KCV

Inverter TF

AQB12JJWC/KCV

WB

UQB12JJWC/KCV

4.

’06 New RAC Inverter Line-Up18,24kBtu/hr

HB2

G3_P

WW2

INDOOR

OUTDOOR

AS18BPAN

AS18BPAX

AS24BPAN

AS24BPAX

SH18BP6

SH18BP6X

SH24BP2

SH24BP2X

SH18BW6

SH18BW6X

SH24BW2

SH24BW2X

AS18BPAN

AS24BPAN

SH18BP6

SH24BP2

SH18BW6

SH24BW2

3wire (E,L,N)

+ 2Wire(F1,F2)

485 communication

3wire (E,L,N)

+ 2Wire(F1,F2)

485 communication

For Europe & Australia

Q

P

AS18BPAX

SH18BP6X

SH18BW6X

Inverter TF

AS24BPAX

SH24BP2X

SH24BW2X

5.

’06 New RAC Inverter Line-UpIndoor Unit : WW2 Premium type

18,24kBtu/hr

WW2

AQB18J6WC/KCV

INDOOR

OUTDOOR

AQB18J6WC

UQB18J6WC

AQB24J2WC

UQB24J2WC

For United States

AQB24J2WC/KCV

3wire (E,L,N)

3wire (E,L,N)

+ 2Wire(F1,F2)

+ 2Wire(F1,F2)

485 communication

485 communication

Q

P

UQB18J6WC/KCV

UQB24J2WC/KCV

Inverter TF

6.

Comparison of Inverter Line-UpDaikin:●, Mitsubishi:●, Samsung ’06:

Capacity

9kBtu/hr

12kBtu/hr

18kBtu/hr

24kBtu/hr

Wall mounted

(RAC)

●●

●●

●●

●●

Europe

HB1

G2-P

WW1

HB1

G2-P

WW1

HB2

G3-P

WW2

HB2

G3-P

WW2

Australia

HB1

G2-P

HB1

G2-P

-

HB2

G3-P

US

WW1

WW1

WW2

WW2

China

HB1

G2-P

WW1

China Deluxe

HB1

G2-P

WW1

China Deluxe

-

-

SAMSUNG

Model

Type

Inverter TF

7.

FEATURES - High Energy EfficiencyEnergy Grade

Sales Area

Capacity

Model Name

Remarks

Cooling

Heating

9kBtu/hr

AS09BPAN

A

A

A/A

12kBtu/hr

AS12BPAN

A

A

A/A

AS18BPAN

A

B

-

SH18BP6

A

B

-

SH18BW6

A

B

-

AS24BPAN

B

D

-

SH24BP2

B

D

-

SH24BW2

B

D

-

9kBtu/hr

AS09BPAN

6.0 ★

5.0 ★

TESAW 2006

12kBtu/hr

AS12BPAN

5.0 ★

4.0 ★

TESAW 2006

24kBtu/hr

AS24BPAN

3.5 ★

2.0 ★

-

9kBtu/hr

AQB09JJWC

SEER 20.0

HSPF 10.0

Energy Star

12kBtu/hr

AQB12JJWC

SEER 19.0

HSPF 9.0

Energy Star

18kBtu/hr

AQB18J6WC

SEER 17.0

HSPF 8.0

-

24kBtu/hr

AQB24J2WC

SEER 15.5

HSPF 7.8

-

18kBtu/hr

EUROPE

24kBtu/hr

AUSTRALIA

UNITED

STATES

Inverter TF

8.

FEATURES - Wider Performance RangePerformance

Sales Area

Capacity

Model Name

Remarks

Cooling

Heating

9kBtu/hr

AS09BPAN

2.5 (0.99~3.5)

3.5 (0.85~5.0)

kW

12kBtu/hr

AS12BPAN

3.5 (0.99~4.2)

4.0 (0.85~5.5)

kW

AS18BPAN

5.0 (1.6~6.0)

6.0 (1.5~9.0)

kW

SH18BP6

5.0 (1.6~6.0)

6.0 (1.5~9.0)

kW

SH18BW6

5.0 (1.6~6.0)

6.0 (1.5~9.0)

kW

AS24BPAN

6.8 (1.9~8.0)

8.0 (1.7~10.5)

kW

SH24BP2

6.8 (1.9~8.0)

8.0 (1.7~10.5)

kW

SH24BW2

6.8 (1.9~8.0)

8.0 (1.7~10.5)

kW

9kBtu/hr

AS09BPAN

2.5 (0.99~3.5)

3.5 (0.85~5.0)

kW

12kBtu/hr

AS12BPAN

3.5 (0.99~4.2)

4.0 (0.85~5.5)

kW

24kBtu/hr

AS24BPAN

6.8 (1.9~8.0)

8.0 (1.7~10.5)

kW

9kBtu/hr

AQB09JJWC

9.0 (3.1~11.9)

12.0 (3.1~17.0)

kBtu/hr

12kBtu/hr

AQB12JJWC

12.0 (3.1~14.3)

13.6 (3.1~18.7)

kBtu/hr

18kBtu/hr

AQB18J6WC

18.0 (5.5~21.0)

20.5 (5.1~30.7)

kBtu/hr

24kBtu/hr

AQB24J2WC

24.0 (6.5~27.0)

27.0 (5.8~35.0)

kBtu/hr

18kBtu/hr

EUROPE

24kBtu/hr

AUSTRALIA

UNITED

STATES

Inverter TF

9.

FEATURES – Specification (HB)MODEL

DIV.

AS09BPAN

AS09BPAX

AS12BPAN

AS12BPAX

Power

S

I

Z

E

W

E

I

G

H

T

S

P

E

C

AS24BPAN

AS24BPAX

1ph, 220~240V, 50Hz

INDOOR

NET

mm

950x268x165

OUTDOOR

NET

mm

790x548x285

kg

9.0 / 10.5

kg

35.5 / 38.0

INDOOR

1099x315x200

880x638x310

880x798x310

13.0 / 16.0

NET/

GROSS

OUTDOOR

50.0 / 53.0

57.0 / 61.0

Performance

C/H

kW

2.5 / 3.5

3.5 / 4.0

5.0 / 6.0

6.8 / 8.0

Consumption

C/H

kW

0.61 / 0.9

1.03 / 1.105

1.56 / 1.76

2.26 / 2.85

Current

C/H

A

3.0 / 4.4

5.0 / 5.3

7.0 / 8.0

10.6 / 13.0

IN

dB

40 ↓

41 ↓

48 ↓

48 ↓

OUT

dB

51 ↓

53 ↓

58 ↓

60 ↓

Liquid

Inch (mm)

Gas

Inch (mm)

3/8 (9.52)

1/2 (12.7)

5/8 (15.88)

g

1,000

1,450

1,650

Noise

E

X

AS18BPAN

AS18BPAX

Piping OD

Refrigerant (R410A)

Inverter TF

1/4 (6.35)

10.

FEATURES – Specification (G3P_WW2)MODEL

DIV.

SH18BP6

SH18BP6X

SH24BP2

SH24BP2X

Power

S

I

Z

E

W

E

I

G

H

T

S

P

E

C

SH24BW2

SH24BW2X

1ph, 220~240V, 50Hz

INDOOR

NET

mm

OUTDOOR

NET

mm

INDOOR

1080x315x205

880x638x310

kg

1065x298x218

880x798x310

880x638x310

13.0 / 16.0

880x798x310

13.0 / 16.0

NET/

GROSS

OUTDOOR

kg

50.0 / 53.0

57.0 / 61.0

50.0 / 53.0

57.0 / 61.0

Performance

C/H

kW

5.0 / 6.0

6.8 / 8.0

5.0 / 6.0

6.8 / 8.0

Consumption

C/H

kW

1.56 / 1.76

2.26 / 2.85

1.56 / 1.76

2.26 / 2.85

Current

C/H

A

7.0 / 8.0

10.6 / 13.0

7.0 / 8.0

10.6 / 13.0

IN

dB

48 ↓

48 ↓

48 ↓

48 ↓

OUT

dB

58 ↓

60 ↓

58 ↓

60 ↓

Liquid

Inch (mm)

Gas

Inch (mm)

1/2 (12.7)

5/8 (15.88)

1/2 (12.7)

5/8 (15.88)

g

1,350

1,500

1,450

1,650

Noise

E

X

SH18BW6

SH18BW6X

Piping OD

Refrigerant (R410A)

Inverter TF

1/4 (6.35)

11.

FEATURES – Specification (WW1_WW2)MODEL

DIV.

AQB09JJWC

UQB09JJWC

AQB12JJWC

UQB12JJWC

Power

S

I

Z

E

W

E

I

G

H

T

S

P

E

C

AQB24J2WC

UQB24J2WC

1ph, 208~230V, 60Hz

Indoor

NET

inch

32.5x11.2x7.4

Outdoor

NET

mm

31.1x21.6x11.2

lb

17.0 / 20.3

kg

78.3 / 83.8

Indoor

41.9x11.7x8.6

34.6x25.1x12.2

34.6x31.4x12.2

28.0 / 34.6

NET/

GROSS

Outdoor

110.0 / 116.8

125.7 / 134.5

Performance

C/H

kBtu/hr

9.0 / 12.0

12.0 / 13.6

18.0 / 20.5

24.0 / 27.0

Consumption

C/H

kW

0.65 / 0.95

1.05 / 1.13

1.70 / 1.85

2.60 / 2.80

Current

C/H

A

3.0 / 4.4

4.9 / 5.3

7.5 / 8.2

12.0 / 13.0

IN

dB

41 ↓

43 ↓

48 ↓

48 ↓

OUT

dB

51 ↓

53 ↓

58 ↓

60 ↓

Liquid

Inch (mm)

Gas

Inch (mm)

3/8 (9.52)

1/2 (12.7)

5/8 (15.88)

lb

2.2

3.2

3.6

Noise

E

X

AQB18J6WC

UQB18J6WC

Piping OD

Refrigerant (R410A)

Inverter TF

1/4 (6.35)

12.

FEATURES - Longer Max. Piping Length & HeightDiv.

Standard Pipe Length

Maximum Pipe Length

Maximum Height Difference

Additional Refrigerant Charged

Inverter TF

Unit

9kBtu/hr

12kBtu/hr

18kBtu/hr

m

7.5

ft

24.6

24kBtu/hr

m

15.0

30.0

ft

49.2

98.4

m

8.0

15.0

ft

26.2

49.2

g/m

oz/ft

Charge-less

20

15

0.21

0.16

13.

FEATURES - Wider Operation Temperature RangeCooling

Heating

43℃

24℃

21℃

Conventional

0℃

- 5℃

New

Inverter TF

Conventional

- 10℃

New

14.

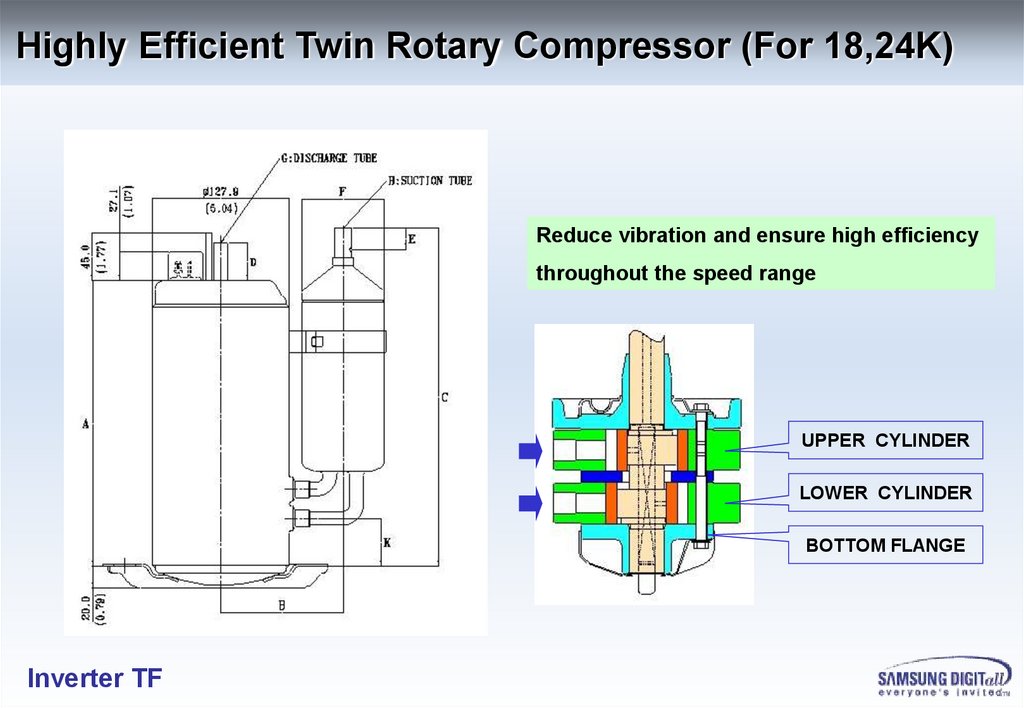

Highly Efficient Twin Rotary Compressor (For 18,24K)Reduce vibration and ensure high efficiency

throughout the speed range

UPPER CYLINDER

LOWER CYLINDER

BOTTOM FLANGE

Inverter TF

15.

Highly Efficient Wide Fin40% of heat transfer area is increased

Preventing clogging, the Initial high efficiency is maintained

throughout the unit’s long lifespan

Conventional Fin

Inverter TF

Wide Fin

16.

Accessory (HB1)Inverter TF

17.

Accessory (WW1)Inverter TF

18.

Accessory (HB2)Inverter TF

19.

Accessory (G3P)Inverter TF

20.

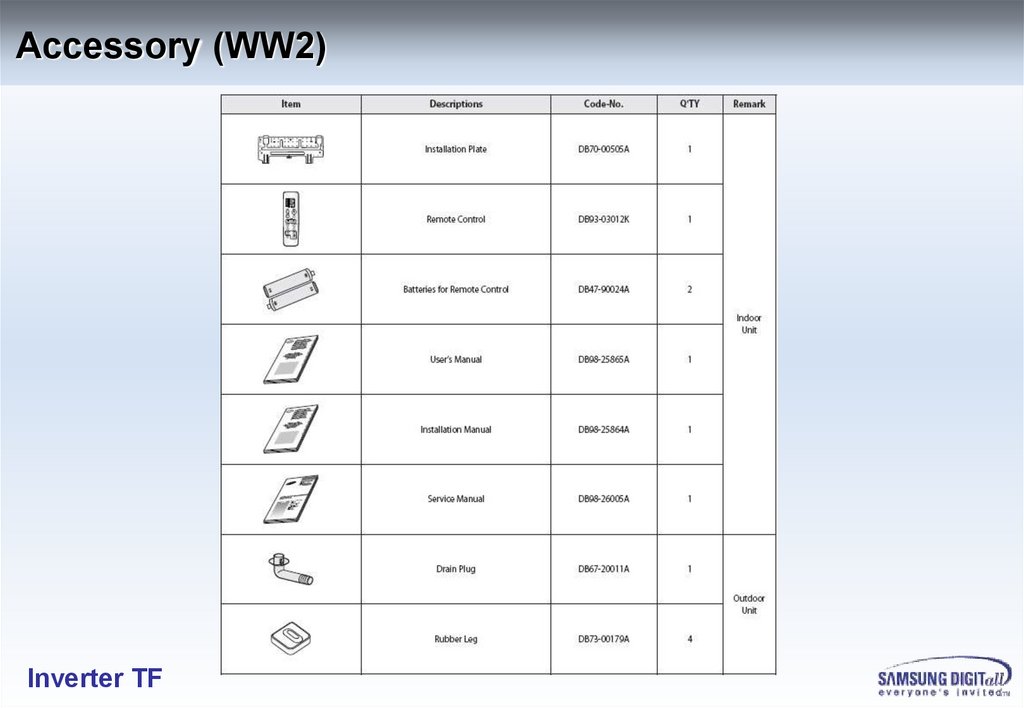

Accessory (WW2)Inverter TF

21.

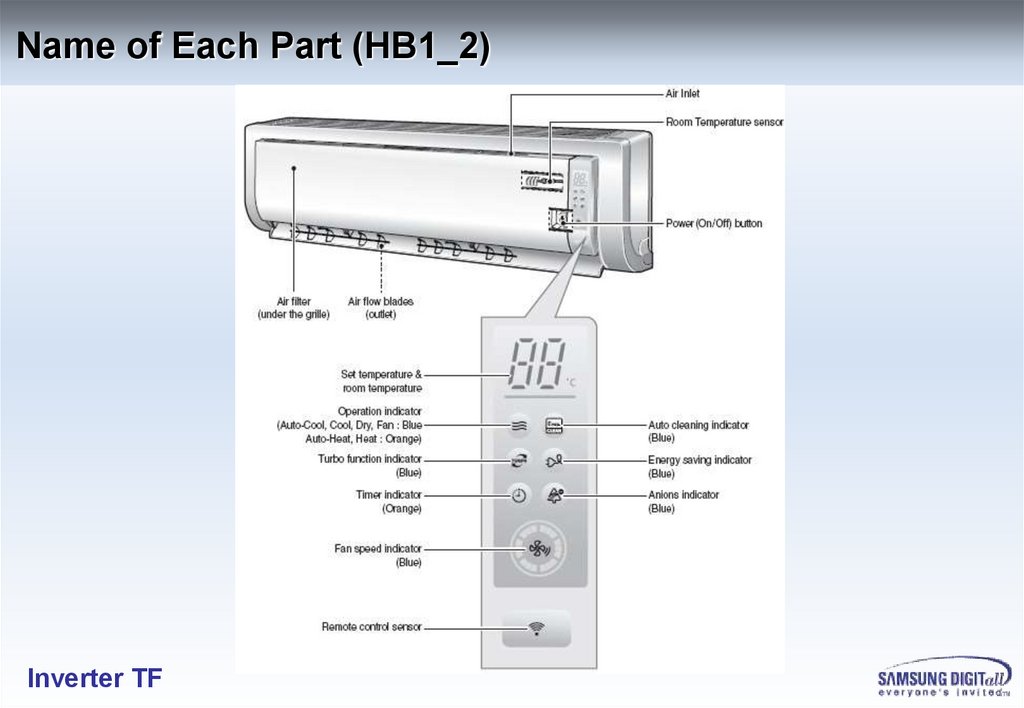

Name of Each Part (HB1_2)Inverter TF

22.

Name of Each Part (WW1_2)Inverter TF

23.

Name of Each Part (G3P)Inverter TF

24.

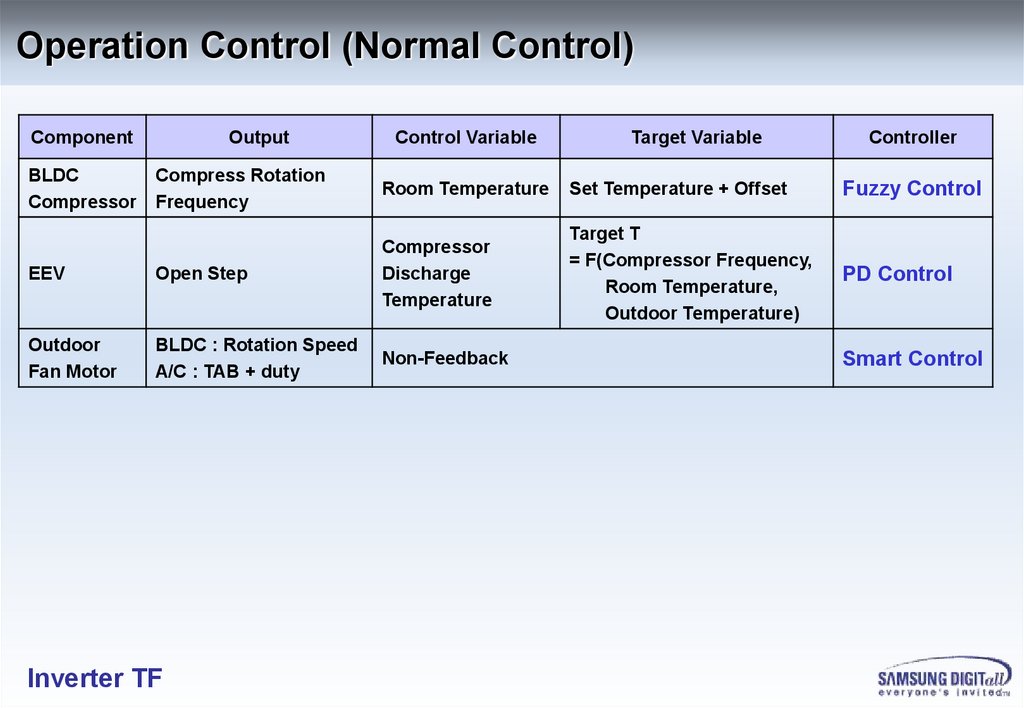

Operation Control (Normal Control)Component

BLDC

Compressor

Output

Control Variable

Target Variable

Controller

Compress Rotation

Frequency

Room Temperature

Set Temperature + Offset

Fuzzy Control

EEV

Open Step

Compressor

Discharge

Temperature

Target T

= F(Compressor Frequency,

Room Temperature,

Outdoor Temperature)

PD Control

Outdoor

Fan Motor

BLDC : Rotation Speed

A/C : TAB + duty

Non-Feedback

Inverter TF

Smart Control

25.

Start ControlCompressor Rotation Frequency

Frequency

Start Frequency

Case 3

Fuzzy Control

2nd Holding Time

= 1minute

2nd Hold

Frequency

Fuzzy Control

1st Hold

Frequency

Start Frequency

Case 2

Fuzzy Control Interval

= 1 minute

Fuzzy Control

Start Frequency

Case 1

1st Holding Time = 1minute

Electric Expansion Valve Open Step (4 minutes)

EEV Open Step = A * Compressor Frequency + B

Inverter TF

Time

26.

Disassembly & Reassembly (HB1 & HB2_INDOOR)Inverter TF

27.

Inverter TF28.

Disassembly & Reassembly (WW1 & WW2_INDOOR)Inverter TF

29.

Disassembly & Reassembly (WW1 & WW2_INDOOR)Inverter TF

30.

Disassembly & Reassembly (G3P_INDOOR)Inverter TF

31.

Disassembly & Reassembly (G3P_INDOOR)Inverter TF

32.

Disassembly & Reassembly (9&12K_OUTDOOR)Inverter TF

33.

Disassembly & Reassembly (9&12K_OUTDOOR)Inverter TF

34.

Disassembly & Reassembly (18K_OUTDOOR)Inverter TF

35.

Disassembly & Reassembly (18K_OUTDOOR)Inverter TF

36.

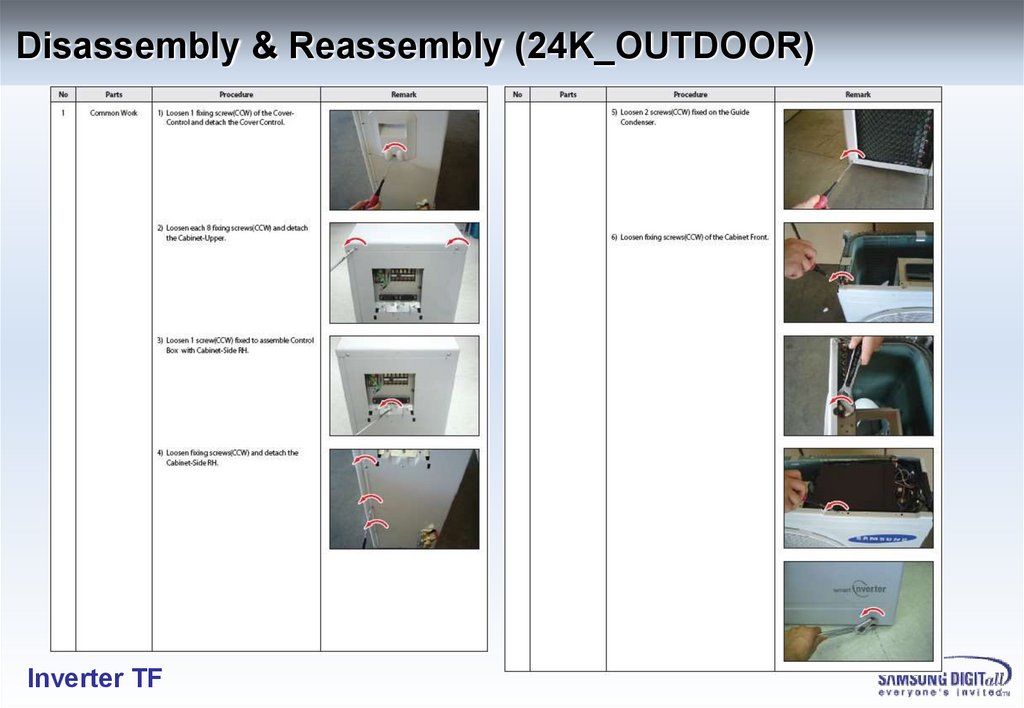

Disassembly & Reassembly (24K_OUTDOOR)Inverter TF

37.

Disassembly & Reassembly (24K_OUTDOOR)Inverter TF

38.

Disassembly & Reassembly (24K_OUTDOOR)Inverter TF

39.

Exploded Views & Part List (HB1_INDOOR)Inverter TF

40.

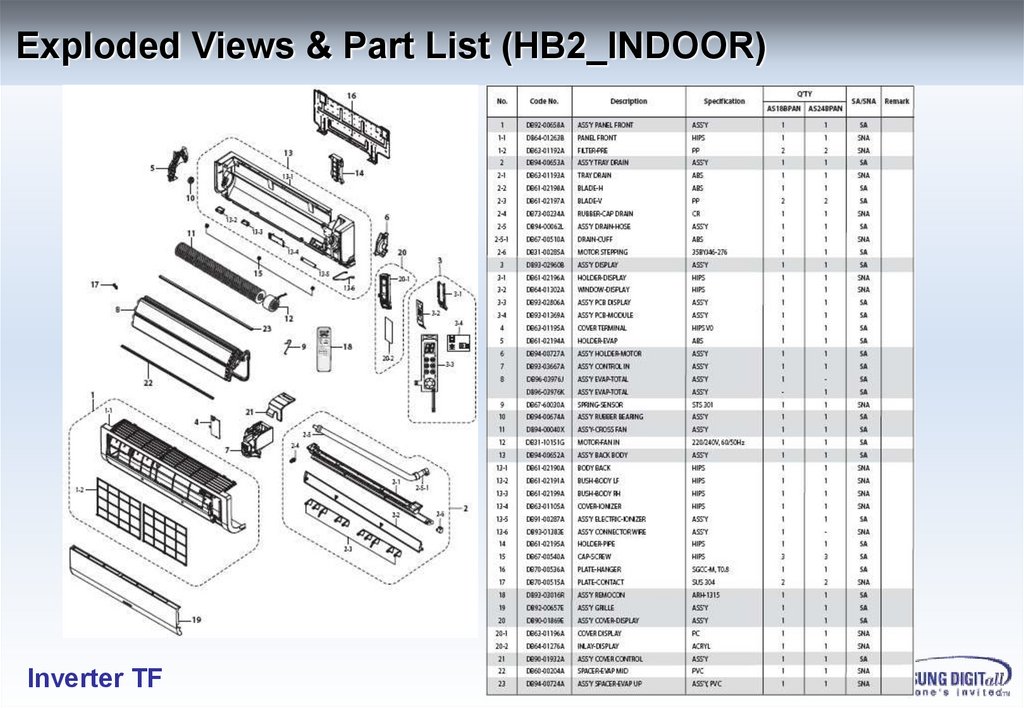

Exploded Views & Part List (HB2_INDOOR)Inverter TF

41.

Exploded Views & Part List (G3P_INDOOR)Inverter TF

42.

Exploded Views & Part List (WW1_INDOOR)Inverter TF

43.

Exploded Views & Part List (WW2_INDOOR)Inverter TF

44.

Exploded Views & Part List (9&12K_OUTDOOR)Inverter TF

45.

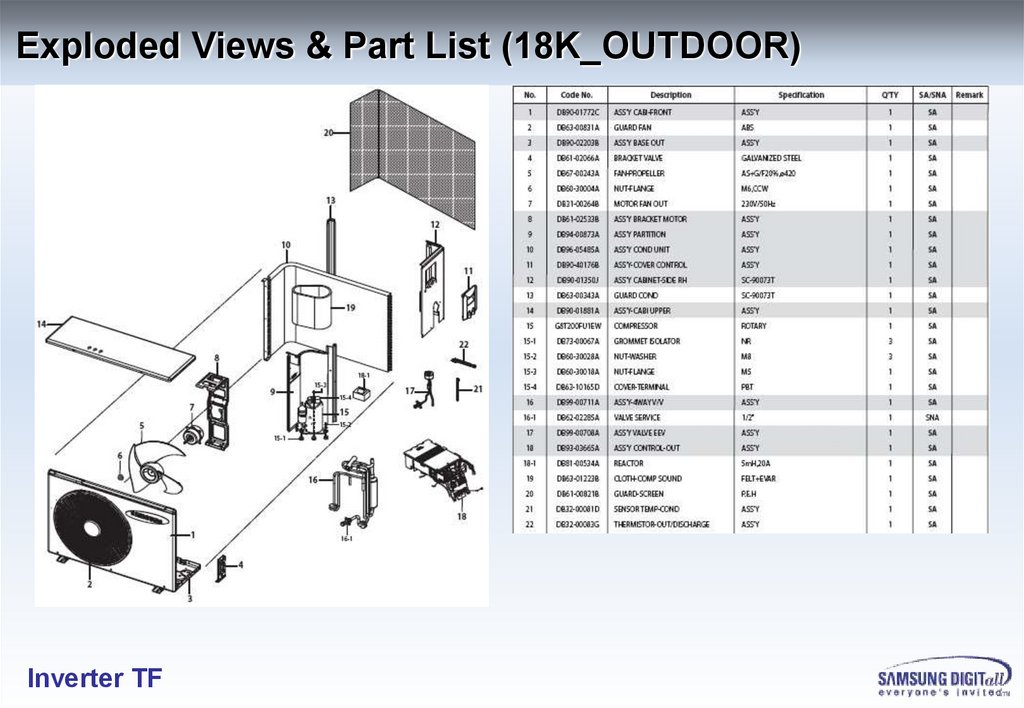

Exploded Views & Part List (18K_OUTDOOR)Inverter TF

46.

Exploded Views & Part List (24K_OUTDOOR)Inverter TF

47.

Exploded Views & Part List (9&12K_Control Out_AC)Inverter TF

48.

Exploded Views & Part List (9&12K_Control Out_485)Inverter TF

49.

Exploded Views & Part List (18&24K_Control Out_485)Inverter TF

50.

Wiring DiagramAC Serial

Inverter TF

485 Serial

- 50 -

51.

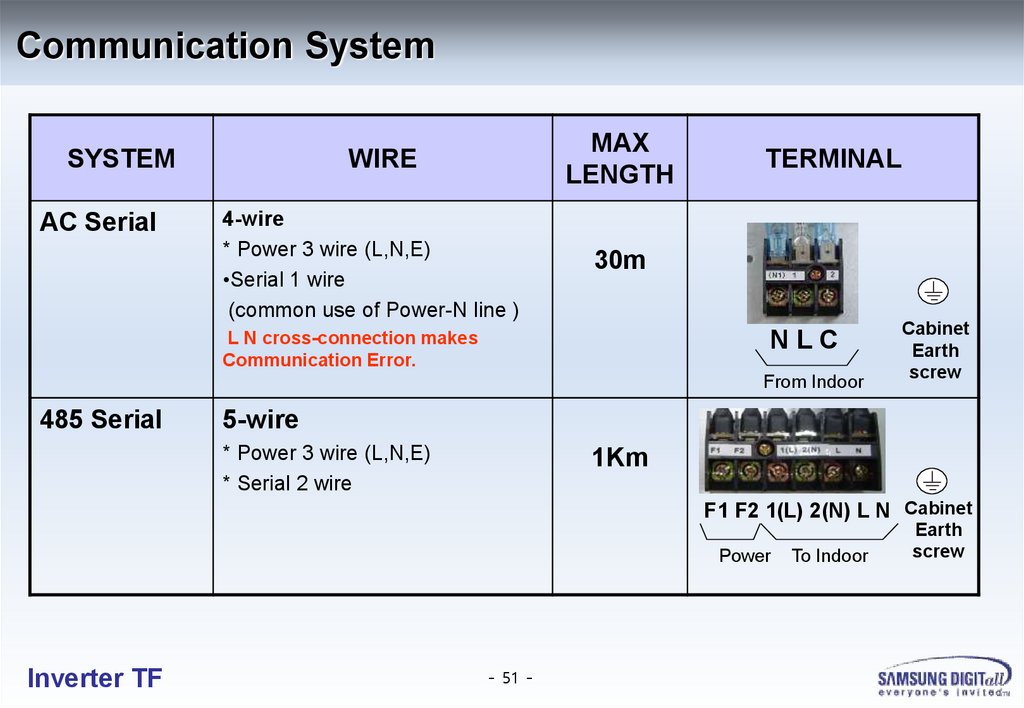

Communication SystemSYSTEM

AC Serial

MAX

LENGTH

WIRE

4-wire

* Power 3 wire (L,N,E)

•Serial 1 wire

(common use of Power-N line )

TERMINAL

30m

NLC

L N cross-connection makes

Communication Error.

From Indoor

485 Serial

Cabinet

Earth

screw

5-wire

* Power 3 wire (L,N,E)

* Serial 2 wire

1Km

F1 F2 1(L) 2(N) L N Cabinet

Power

Inverter TF

- 51 -

To Indoor

Earth

screw

52.

Inverter Controller9/12K BTU (AC)

9/12K BTU (485)

18/24K BTU

2 PCBs

3 PCBs

2 PCBs

Figure

Terminal

Error

Display

Inverter TF

MAIN

Board

Display PCB

- 52 -

53.

Inverter Controller PCB (9/12K OUT_AC)Inverter TF

- 53 -

54.

Inverter Controller PCB (9/12K OUT_485)Inverter TF

- 54 -

55.

Inverter Controller PCB (18/24K OUT)Inverter TF

- 55 -

56.

Inverter Controller (Block Diagram_9/12K AC)Outdoor

Discharge

Defrost

090

COMP

Reactor

BLDC

FAN

IPM

pos.ZC

PFC

IGBT / ZC

FAN

DRIVE

EEPROM

INVERTER

MICOM

R G

LED

AC

COMM.

COM

L

N

Y

AC

RELAY

4way

Inverter TF

POWER

RELAY

INDOOR

- 56 -

Driver

MAIN PCB

EMI FILTER PCB

EEV

57.

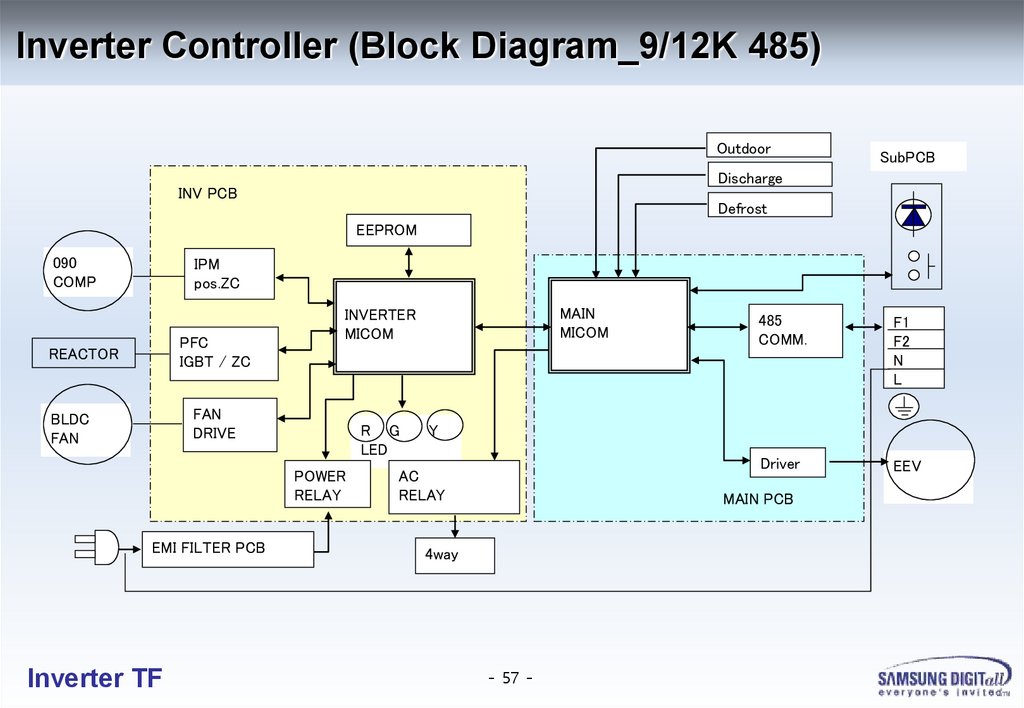

Inverter Controller (Block Diagram_9/12K 485)Outdoor

SubPCB

Discharge

INV PCB

Defrost

EEPROM

090

COMP

IPM

pos.ZC

PFC

IGBT / ZC

REACTOR

FAN

DRIVE

BLDC

FAN

R G

LED

POWER

RELAY

EMI FILTER PCB

Inverter TF

MAIN

MICOM

INVERTER

MICOM

485

COMM.

F1

F2

N

L

Driver

EEV

Y

AC

RELAY

MAIN PCB

4way

- 57 -

58.

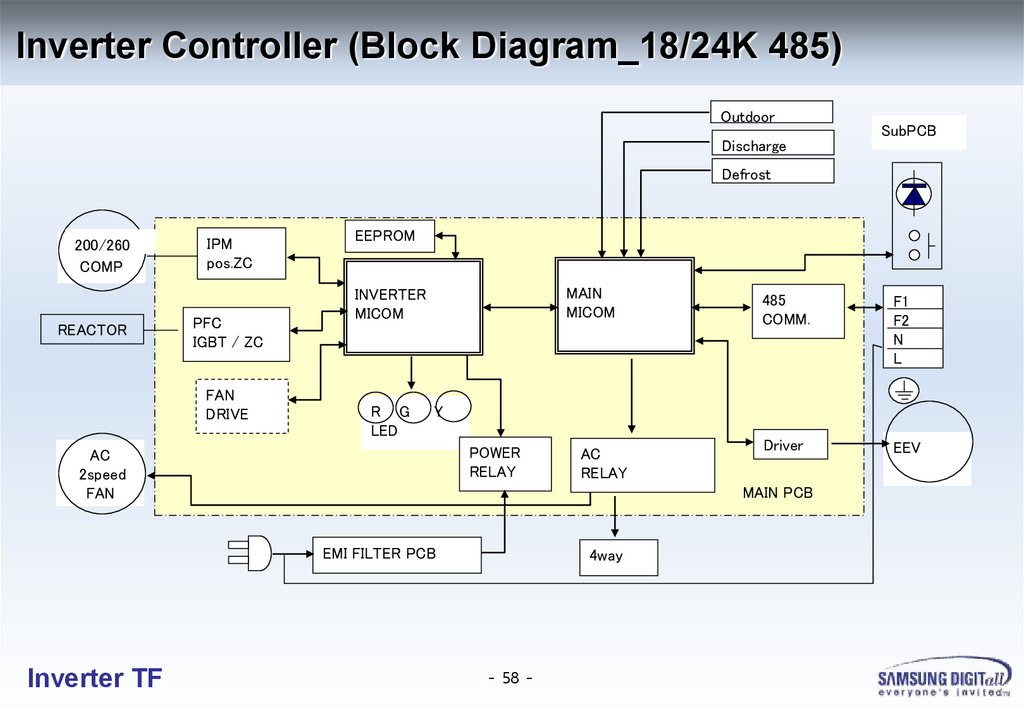

Inverter Controller (Block Diagram_18/24K 485)Outdoor

Discharge

SubPCB

Defrost

200/260

220/260

COMP

REACTOR

IPM

pos.ZC

PFC

IGBT / ZC

FAN

DRIVE

EEPROM

MAIN

MICOM

INVERTER

MICOM

R G

LED

F1

F2

N

L

Driver

EEV

Y

POWER

RELAY

AC

2speed

FAN

AC

RELAY

MAIN PCB

EMI FILTER PCB

Inverter TF

485

COMM.

4way

- 58 -

59.

Inverter Electronics230Vac

50Hz

Power

Pulg

CONVERTER part

310Vdc

RECTIFIERS

Filter

RFI FILTER &

SURGE

SUPPLESSION

Reactor & PFC

INVERTER part

IPM

CAPACI

TOR

0-310V

6600rpm max

Compressor

BLDC

Motor

INDOOR

Unit

Communication

INVERTER & PFC

CONTROLLER

Cycle Controller

Driver

SMPS

EEV

Fan

Motor

Temperature

Sensor

Block Diagram of Outdoor Unit Inverter Controller

Inverter TF

- 59 -

Sensorless

Rotor

Position

Detector

60.

Intelligent Temperature ControlRobust Fuzzy Control

Rapid Temperature Response

High Stability

High Reliability

Inverter TF

61.

A S 12B P A N R e s id e n tia l T e s t F o r C o o lin g40

5000

Inverter

AS12BPAN

35

4500

4000

27℃ S e ttin g

30

25℃ S e ttin g

23℃ S e ttin g

25

3000

20

2500

Non Inverter

AS12HPA

15

2000

1500

10

1000

5

500

0

0

0

60

120

180

240

300

T im e(M in)

R o o m T e m p _A S 12B P A N

P o w e r In p u t_A S 12B P A N

P o w e r In p u t_A S 12H P A

Inverter TF

R o o m T e m p _A S 12H P A

In te g P o w e r In p u t_A S 12B P A N

In te g P o w e r In p u t_A S 12H P A

360

P ow er Input(W )

R oom Tem p.(℃)

3500

62.

A S 12B P A N R e s id e n tia l T e s t fo r H e a tin g5000

30

Inverter

AS12BPAN

4500

4000

3500

20

3000

Non Inverter

AS12HPA

15

2500

2000

10

1500

1000

5

500

0

0

60

180

120

240

300

T im e (M in )

R o o m T e m p _A S 12B P A N

P o w e r In p u t_A S 12B P A N

P o w e r In p u t_A S 12H P A

Inverter TF

R o o m T e m p _A S 12H P A

In te g P o w e r In p u t_A S 12B P A N

In te g P o w e r In p u t_A S 12H P A

0

360

P o w er In p ut(W )

R o o m T em p .(℃)

25

63.

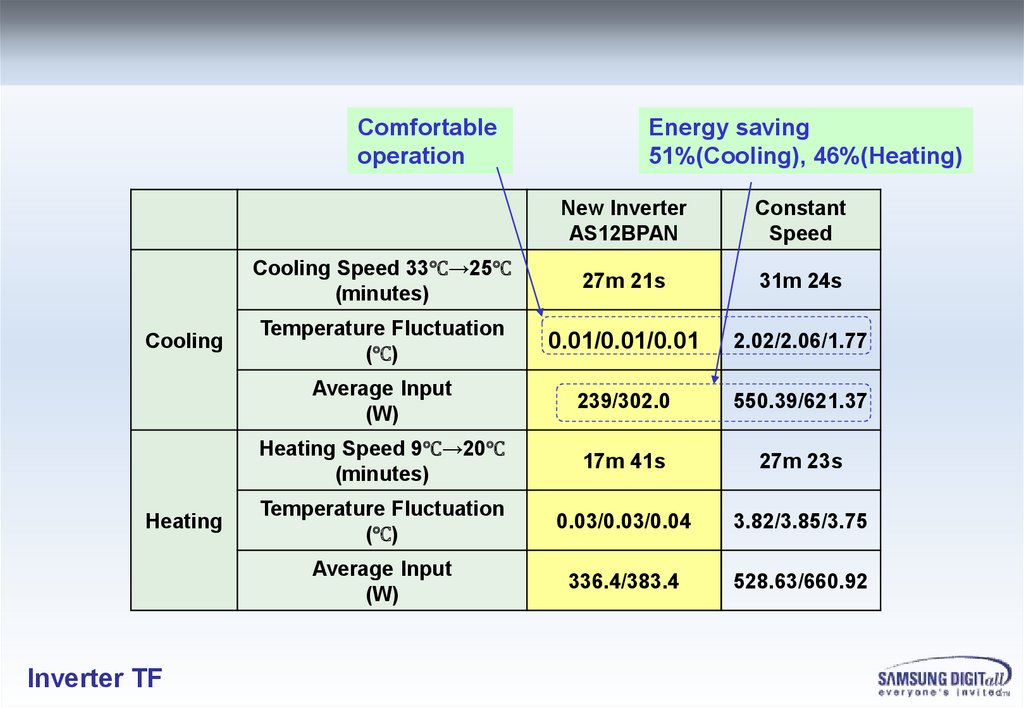

Comfortableoperation

Cooling

Heating

Inverter TF

Energy saving

51%(Cooling), 46%(Heating)

New Inverter

AS12BPAN

Constant

Speed

Cooling Speed 33℃→25℃

(minutes)

27m 21s

31m 24s

Temperature Fluctuation

(℃)

0.01/0.01/0.01

2.02/2.06/1.77

Average Input

(W)

239/302.0

550.39/621.37

Heating Speed 9℃→20℃

(minutes)

17m 41s

27m 23s

Temperature Fluctuation

(℃)

0.03/0.03/0.04

3.82/3.85/3.75

Average Input

(W)

336.4/383.4

528.63/660.92

64.

ROTARY COMPRESSOR APPLICATION SHEETNo

1

Items

Operational standards and limits

Operating frequency range

15 ~ 110 rps (15 ~ 85Hz)

Quantity of refrigerant charge

2000 g (Need to the special discussion when refrigerant

quantity is over than 2000 g.)

Usage range in ordinary load

Discharge pressure : Less than 3.29MPa (33.5 ㎏/㎠)

Discharge temperature : Less than 100℃

Motor coil temperature : Less than 100℃

4

Usage range of pressure

Refer to pressure guarantee range (Page 6~7 )

5

Discharge gas temp.

Max. 115℃

6

Motor winding temp.

Max. 130℃

Bottom shell temperature

Min. 5 ℃ higher than condensing temp.

(Except transient condition)

8

On-Off cycle

Less than 6 cycle/hour => total 200,000 cycles

9

Liquid back operation

No liquid back with current variation and strange noise.

Vibration of tubing

Tubing vibration displacement : Max 0.8mm (±10% of rated voltage)

If the resonance of the pipe can be checked, above condition is not

necessary

Pipe Stress (Operation)

At continuous operation, stress of bottom of discharge part in accumulator

must be below 15MPa (1.5㎏/㎟)

12

Pipe Stress

(Stop starting)

On starting ,stopping and operation, the stress of bottom of discharge part in

accumulator must be below 29.5MPa (3㎏/㎟)

13

Allowable gradient at the time of the

installation

5 degree and below

2

3

7

10

11

Inverter TF

65.

PRESSURE GUARANTEE RANGEACCORDING TO LOW AND HIGH PRESSURE

4.5

4.12

45 90Hz

Pd (MPaG)

4.0

3.43

3.5

3.23

30Hz

110Hz

3.0

2.74

15Hz

2.5

2.0

1.5

A

1.0

0.79

1.03 1.18 1.30 1.42

0.5

0.59

0.0

0

0.2

0.4

0.6

0.8

1

1.2

1.4

Ps (MPaG)

Inverter TF

G8T260 Operating Envelope

1.6

66.

Protection Control – Overload ProtectionIndoor unit

Heat Exchanger

Temperature

T_Trip

T_Down

T_Hold

T_UpRelease

Prevent to Raise

Compressor Frequency

Inverter TF

Compressor Frequency

Down Region

67.

Protection Control – Discharge Temperature Over Heat ProtectionD ischarg e

Tem p erature

T[℃]

C om p

T rip

T_trip

H z D ow n

H z D ow n

T_d o w n

P revent to

raise H z

T_ho ld

10m in

T_U p R elease

stay

시간[s]

Inverter TF

68.

Protection Control – Over Current ProtectionCurrent [A]

Current [

I_ trip

I_ trip

I_D

I_down

own_Heat_10

0.4

2.0A

Id′

Hz Down 1 Hz 2s ec

I_down_cool_30

I_D

Hz Down 1 Hz 2s ec

own_Heat_50

Hz Hold

I_down_cool_50

Hz Hold

Cooling Mode

Inverter TF

Outdoor

Temperature

[℃]

Heating Mode

Outdoor

Temperature

[℃]

69.

Protection Control – Freezing Evaporator Protection1st P ro tectio n S tart

Indo o r

H eat E xchang er

Tem p erature

T_R elease

2 nd P ro tectio n S tart

R elease

T_D o w n

T_C o m p O FF

C om p

9 m in

M inim um

2m in 50sec

S tart F req uency

P ro tectio n

F req uency

O utdo o r Fan

O ff

On

On

O ff

Indo o r Fan

U ser S et A irflo w

U ser S et A irflo w

LL

Inverter TF

70.

Indoor Unit Display For Error Detecting (HB1/2,G3P)Inverter TF

71.

Indoor Unit Display For Error Detecting (WW1/2)Inverter TF

72.

Outdoor LED Error DisplayInverter TF

73.

Error OperationIndoor unit

Error Code

Outdoor unit

Error Cause

Display

Operation OFF

Display

Operation OFF

E102

Indoor/Outdoor Communication Time Out (1 minute)

immediately

immediately

immediately

immediately

E202

60 Packet Over data

immediately

immediately

immediately

immediately

E203

Communication Error between Outdoor Main and Inverter

Micom (Occurred after I minute detection in Main and Inverter)

immediately

immediately

immediately

immediately

E221

Outdoor Temp. Sensor Error (OPEN/SHORT ERROR)

immediately

immediately

immediately

immediately

E237

COND Temp. Sensor Error (OPEN/SHORT ERROR)

immediately

immediately

immediately

immediately

E260

Inverter Compressor Discharge Temp. sensor Error

(OPEN/SHORT ERROR)

immediately

immediately

immediately

immediately

E416

Discharge over temperature (Dual/Single)

3rd detection

3rd detection

immediately

3min restart

3rd detection

E462

I_Trip error / PFC Over current

3rd detection

3rd detection

immediately

3min restart 3rd

detection

E440/441

Operation condition secession

immediately

immediately

immediately

immediately

E460

Outdoor unit-Indoor unit Communication wire Voltage Detection

immediately

immediately

immediately

immediately

E554

Outdoor unit Refrigerant Full Leakage (Gas Leak)

3rd detection

3rd detection

immediately

3min restart

3rd detection

E458

Outdoor door Fan Error

immediately

immediately

immediately

10 min restart

E556

capacity miss match

immediately

immediately

immediately

immediately

Inverter TF

74.

Indoor unitError Code

Outdoor unit

Error Cause

Display

Operation OFF

Display

Operation OFF

E464

IPM Over Current (O.C)

9th detection

9th detection

immediately

3min restart 9th

detection

E461

Comp Starting error

5th detection

5th detection

immediately

3min restart 5th

detection

E473

Comp Lock error

3rd detection

3rd detection

immediately

3min restart 3rd

detection

E466

DC-Link voltage under/over error

immediately

immediately

immediately

immediately

E468

current sensor error

immediately

immediately

immediately

immediately

E465

Comp Vlimit error

9th detection

9th detection

immediately

3min restart 9th

detection

E471

OTP error

immediately

immediately

immediately

immediately

E467

Comp rotation error

3rd detection

3rd detection

immediately

3min restart 3rd

detection

E469

DC-Link valtage sensor error

immediately

immediately

immediately

immediately

E472

AC Line Zero Cross Signal out

immediately

immediately

immediately

immediately

Inverter TF

75.

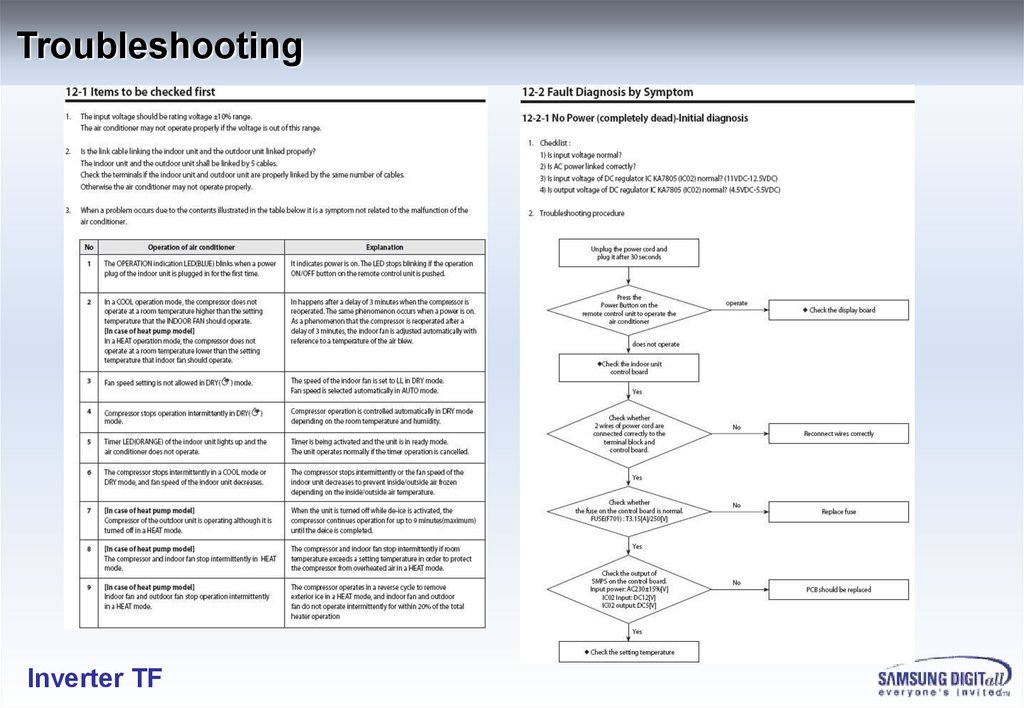

TroubleshootingInverter TF

76.

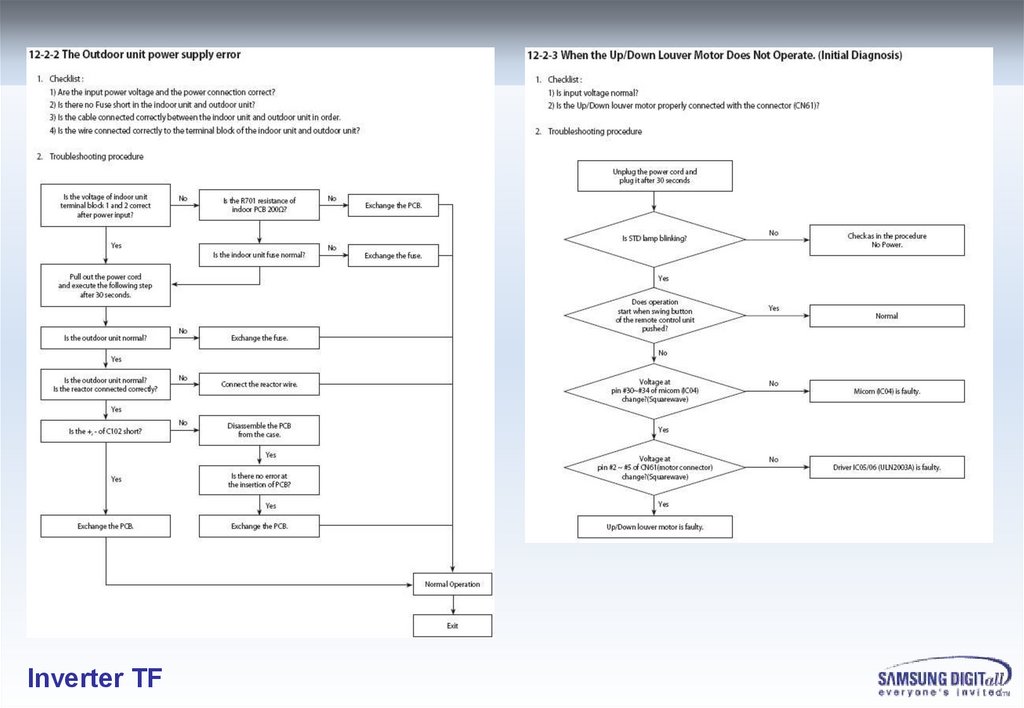

Inverter TF77.

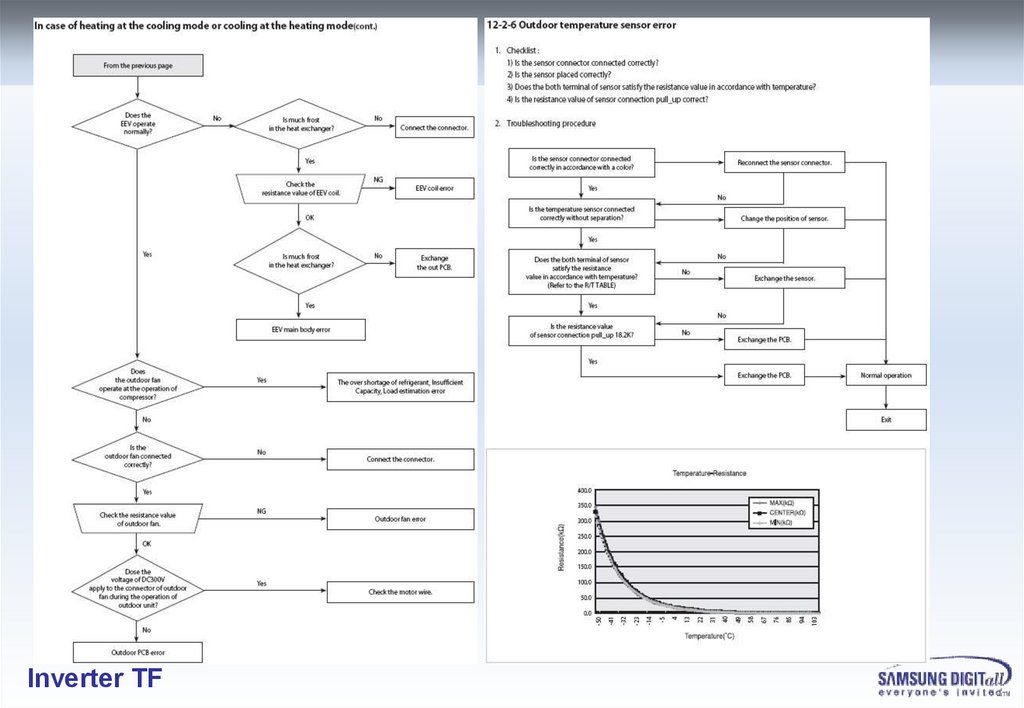

Inverter TF78.

Inverter TF79.

Inverter TF80.

Inverter TF81.

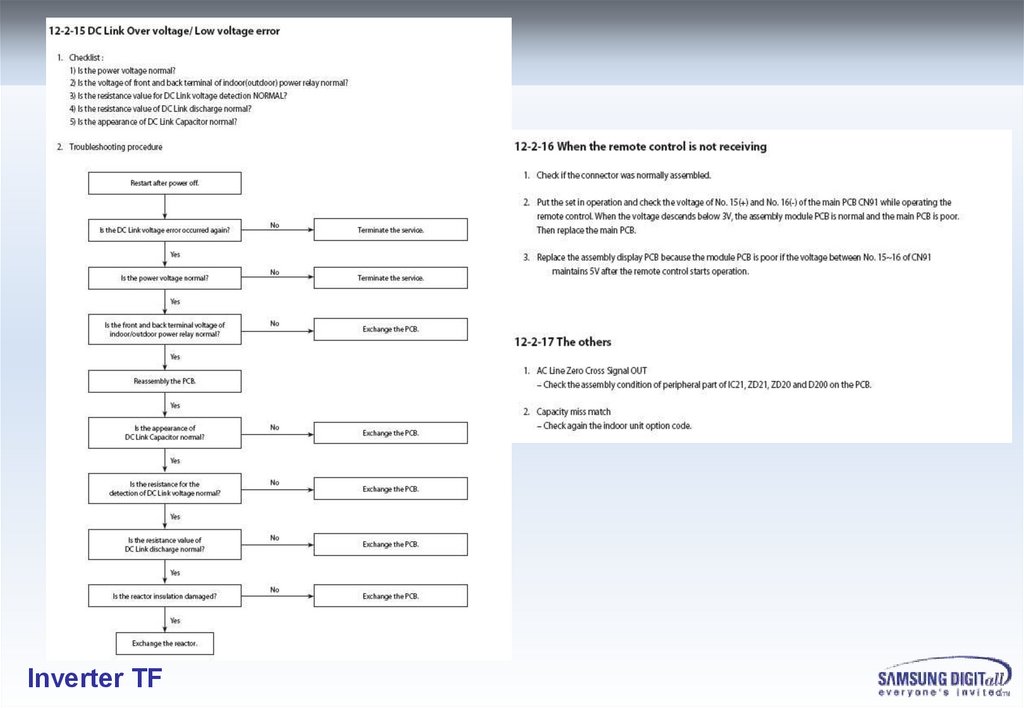

Inverter TF82.

Inverter TF83.

Inverter TF84.

Wiring Diagram (HB1_INDOOR)Inverter TF

85.

Wiring Diagram (HB2_INDOOR)Inverter TF

86.

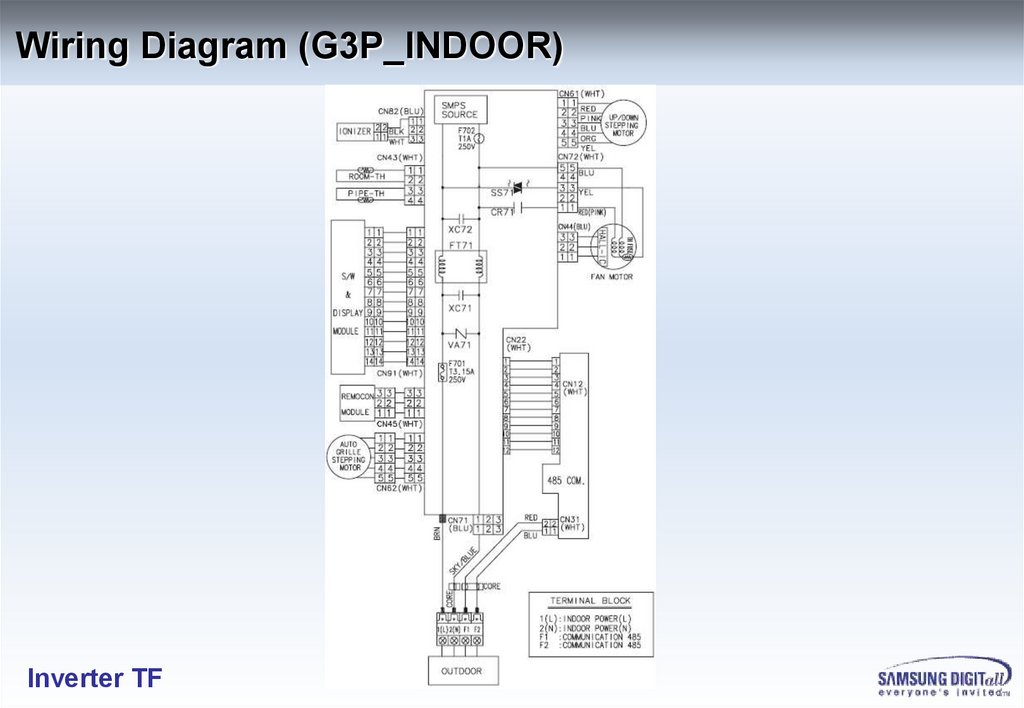

Wiring Diagram (G3P_INDOOR)Inverter TF

87.

Wiring Diagram (WW1/2_INDOOR)Inverter TF

88.

Wiring Diagram (HB1_OUTDOOR)Inverter TF

89.

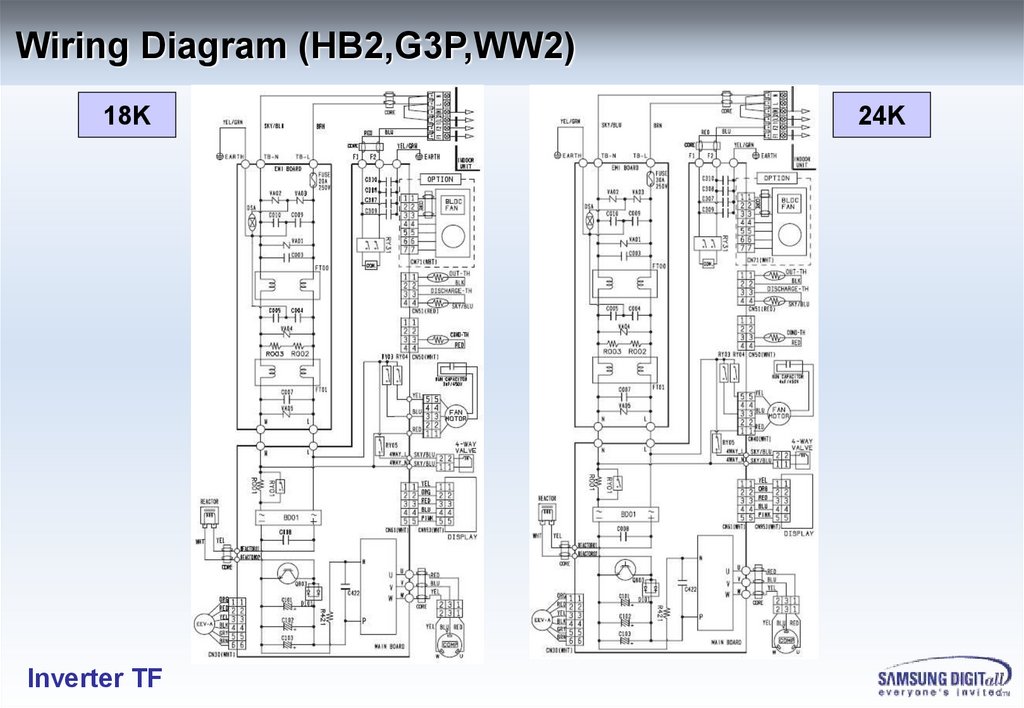

Wiring Diagram (HB2,G3P,WW2)18K

Inverter TF

24K

90.

Check Point In Service1. Temperature sensor off from the holder

Correct temperature detection can control the air conditioner

2. To loosen screws makes controller trouble

,especially Heat-Sink part

Inverter TF

- 90 -

91.

3. Always putting silicon greaseon the surface between Power semicondoctor and heatsink

Also putting insulation mica on non insulated power semiconductor.

4. Confirm POWER OFF and LED OFF

before Connecting / Dis-Connecting BLDC FAN socket.

Connecting / Dis-connecting of BLDC FAN SOCKET can make

Damage to both PCB assy and BLDC FAN MOTOR (9K/12K model).

5. Make sure the tight power wire connection

to the terminal block screw and OUTLET (power plug).

This cause troubles like fire, reset trouble, etc.

Inverter TF

- 91 -

92.

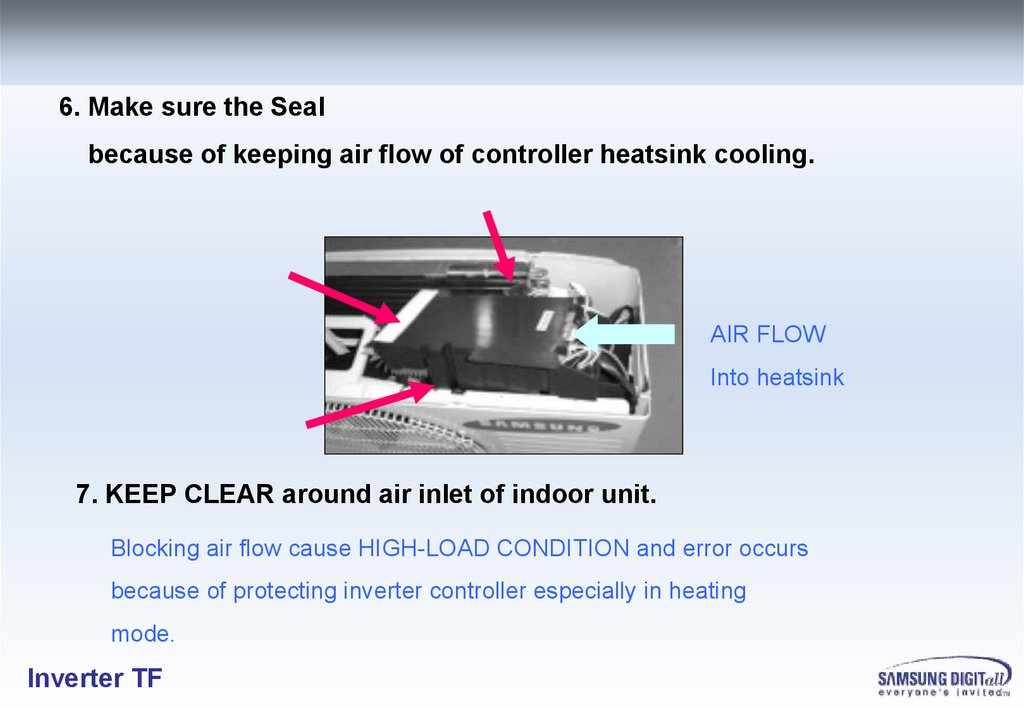

6. Make sure the Sealbecause of keeping air flow of controller heatsink cooling.

AIR FLOW

Into heatsink

7. KEEP CLEAR around air inlet of indoor unit.

Blocking air flow cause HIGH-LOAD CONDITION and error occurs

because of protecting inverter controller especially in heating

mode.

Inverter TF

93.

Thank you.Inverter TF

electronics

electronics