Similar presentations:

Service Manual No-Frost

1.

Service ManualNo-Frost

Combi-Refrigerator

Models:

FR-417W

FR-417S

FR-415W

FR-415S

2. CONTENTS

1. SPECIFICATIONS2. EXTERNAL VIEW

3. EXTERNAL PARTS LIST

4. MACHINE ROOM VIEW

5. REFRIGERANT CYCLE

6. TEMPERATURES DIAGRAMS

7. WIRING DIAGRAMS

8. PCB CIRCUIT DIAGRAMS

9. COMPONENTS DISASSEMBLY PICTURES

10. DOOR POSITION CHANGE PROCESS

11. EXPLODE DRAWING

12. PARTS LIST

13. PCB CONTROL FUNCTION

1

3.

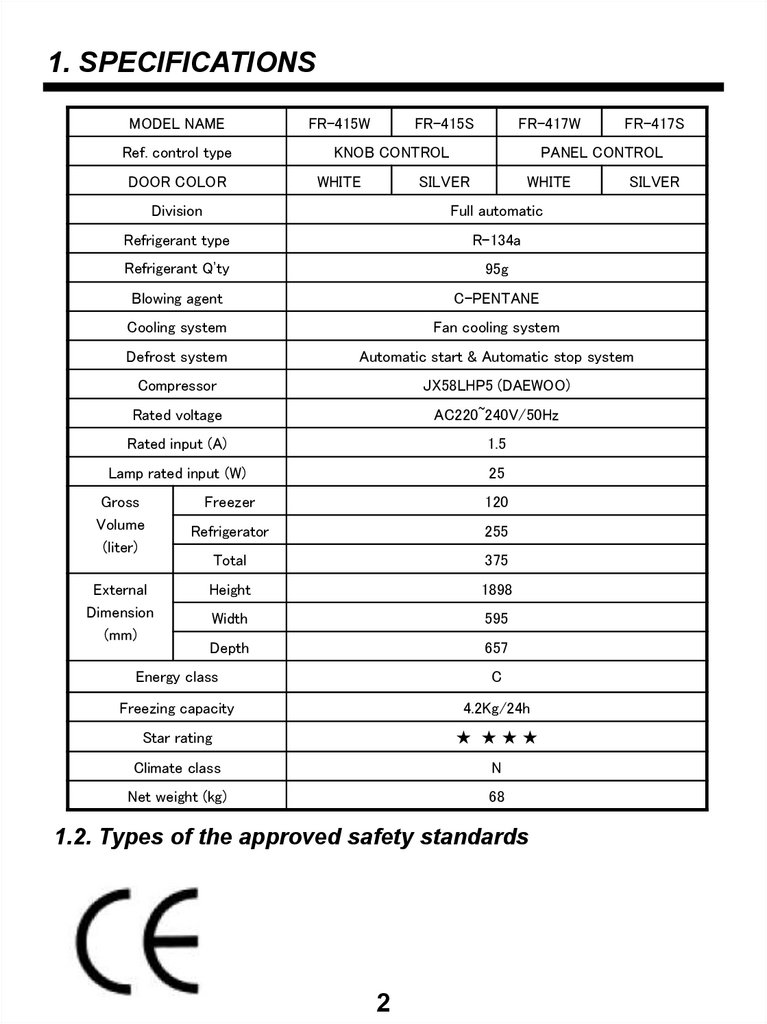

1. SPECIFICATIONSMODEL NAME

Ref. control type

DOOR COLOR

FR-415W

FR-415S

FR-417W

KNOB CONTROL

WHITE

FR-417S

PANEL CONTROL

SILVER

WHITE

SILVER

Division

Full automatic

Refrigerant type

R-134a

Refrigerant Q’ty

95g

Blowing agent

C-PENTANE

Cooling system

Fan cooling system

Defrost system

Automatic start & Automatic stop system

Compressor

JX58LHP5 (DAEWOO)

Rated voltage

AC220~240V/50Hz

Rated input (A)

1.5

Lamp rated input (W)

25

Gross

Volume

(liter)

External

Dimension

(mm)

Freezer

120

Refrigerator

255

Total

375

Height

1898

Width

595

Depth

657

Energy class

C

Freezing capacity

4.2Kg/24h

Star rating

★ ★★★

Climate class

N

Net weight (kg)

68

1.2. Types of the approved safety standards

2

4.

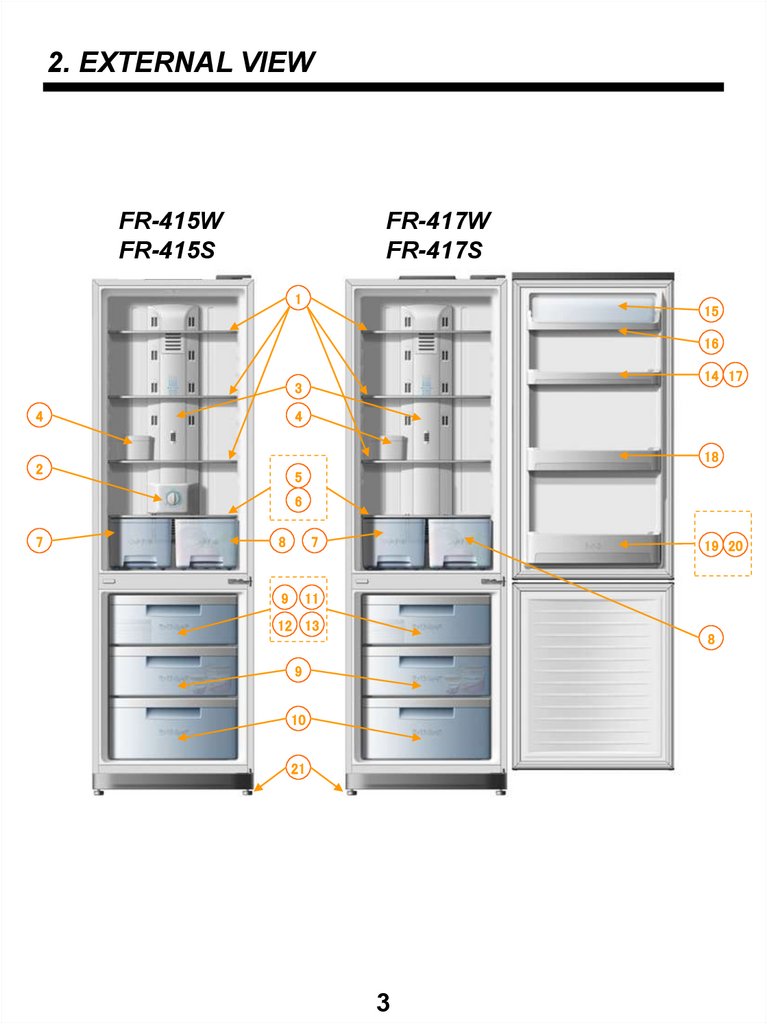

2. EXTERNAL VIEWFR-415W

FR-415S

FR-417W

FR-417S

1

15

16

14 17

3

4

4

18

2

5

6

7

8

7

9

11

19 20

12 13

8

9

10

21

3

5.

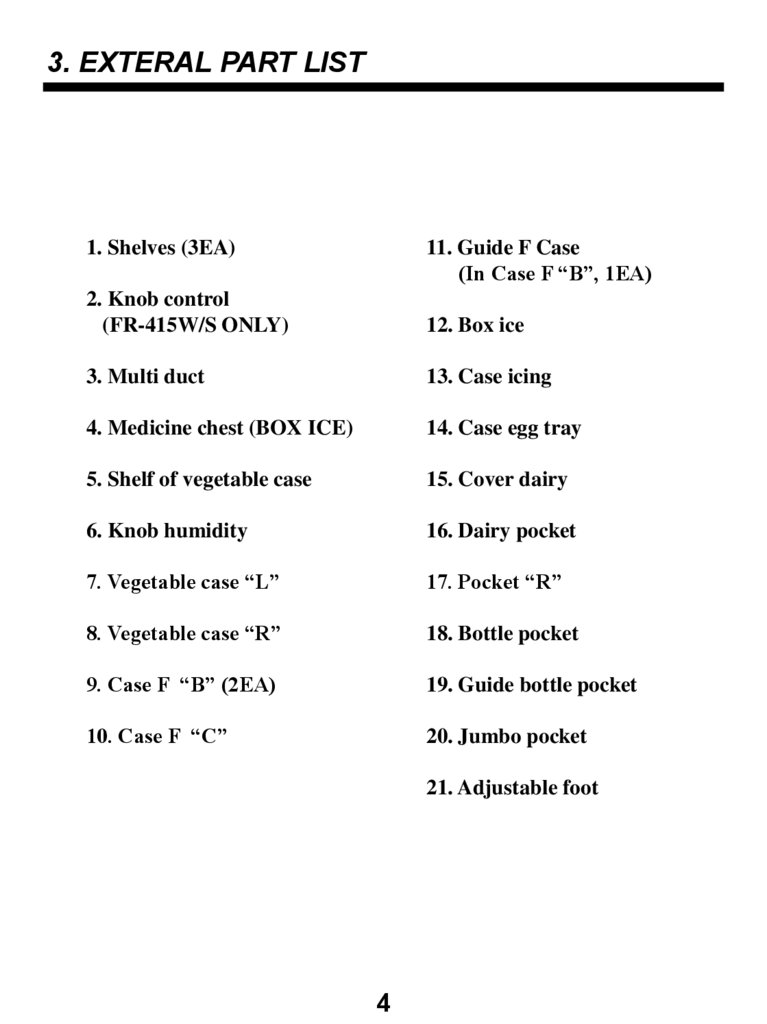

3. EXTERAL PART LIST1. Shelves (3EA)

11. Guide F Case

(In Case F “B”, 1EA)

2. Knob control

(FR-415W/S ONLY)

12. Box ice

3. Multi duct

13. Case icing

4. Medicine chest (BOX ICE)

14. Case egg tray

5. Shelf of vegetable case

15. Cover dairy

6. Knob humidity

16. Dairy pocket

7. Vegetable case “L”

17. Pocket “R”

8. Vegetable case “R”

18. Bottle pocket

9. Case F “B” (2EA)

19. Guide bottle pocket

10. Case F “C”

20. Jumbo pocket

21. Adjustable foot

4

6.

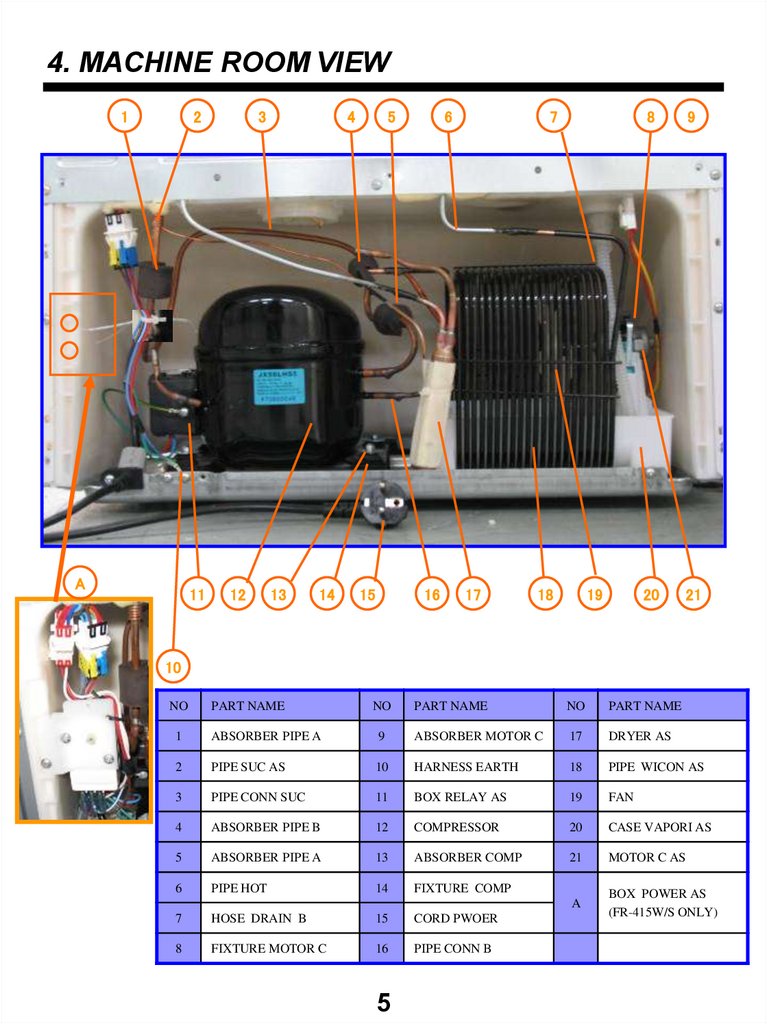

4. MACHINE ROOM VIEW1

2

A

11

3

12

4

13

14

5

15

6

16

7

17

18

19

8

9

20

21

10

NO

PART NAME

NO

PART NAME

NO

PART NAME

1

ABSORBER PIPE A

9

ABSORBER MOTOR C

17

DRYER AS

2

PIPE SUC AS

10

HARNESS EARTH

18

PIPE WICON AS

3

PIPE CONN SUC

11

BOX RELAY AS

19

FAN

4

ABSORBER PIPE B

12

COMPRESSOR

20

CASE VAPORI AS

5

ABSORBER PIPE A

13

ABSORBER COMP

21

MOTOR C AS

6

PIPE HOT

14

FIXTURE COMP

A

BOX POWER AS

(FR-415W/S ONLY)

7

HOSE DRAIN B

15

CORD PWOER

8

FIXTURE MOTOR C

16

PIPE CONN B

5

7.

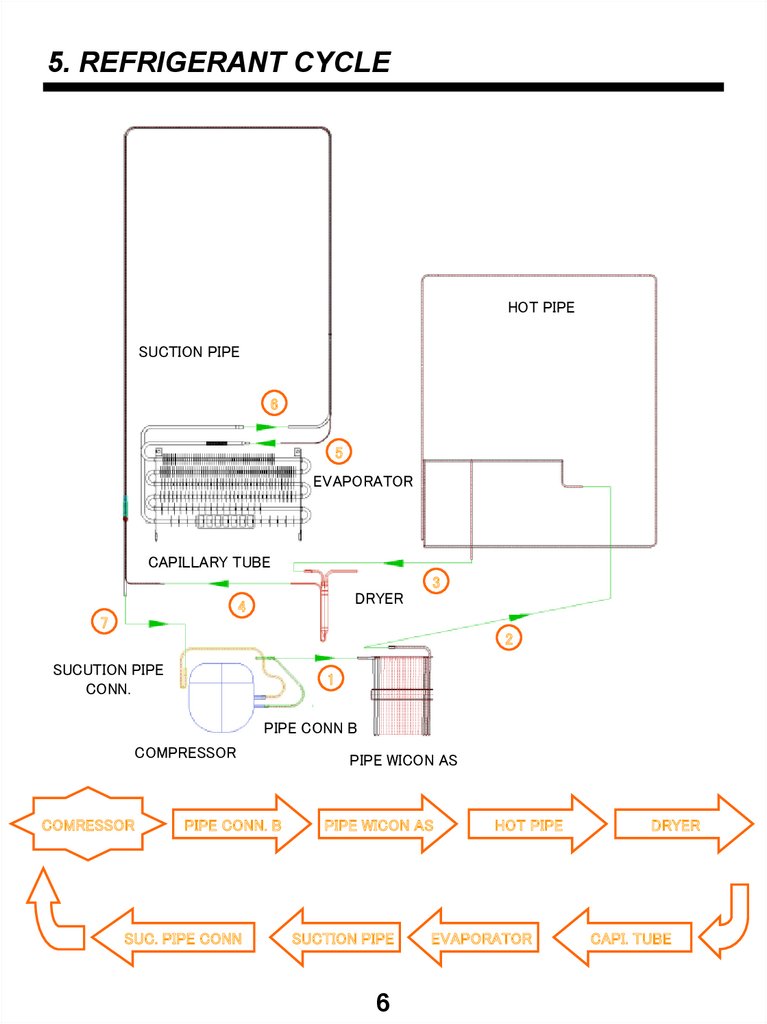

5. REFRIGERANT CYCLEHOT PIPE

SUCTION PIPE

6

5

EVAPORATOR

CAPILLARY TUBE

3

DRYER

4

7

2

SUCUTION PIPE

CONN.

1

PIPE CONN B

COMPRESSOR

COMRESSOR

PIPE CONN. B

SUC. PIPE CONN

PIPE WICON AS

PIPE WICON AS

SUCTION PIPE

6

HOT PIPE

EVAPORATOR

DRYER

CAPI. TUBE

8.

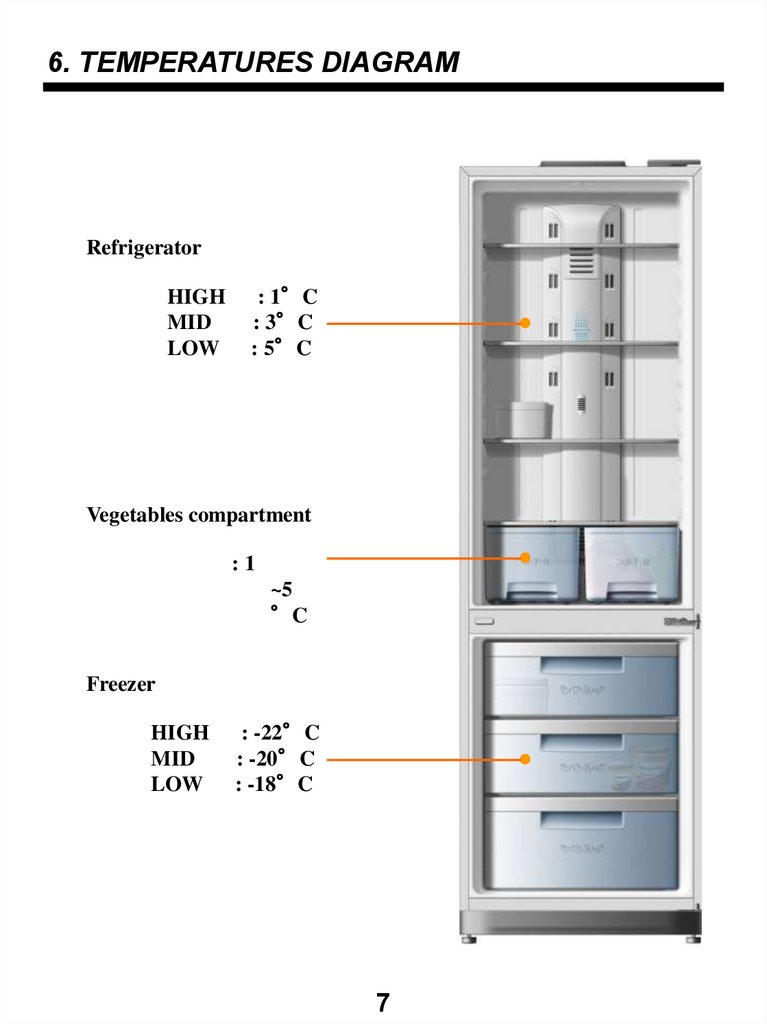

6. TEMPERATURES DIAGRAMRefrigerator

HIGH

MID

LOW

: 1°C

: 3°C

: 5°C

Vegetables compartment

:1

~5

°C

Freezer

HIGH

MID

LOW

: -22°C

: -20°C

: -18°C

7

9.

7. WIRING DIAGRAMS7.1. FR-417W/S

8

10.

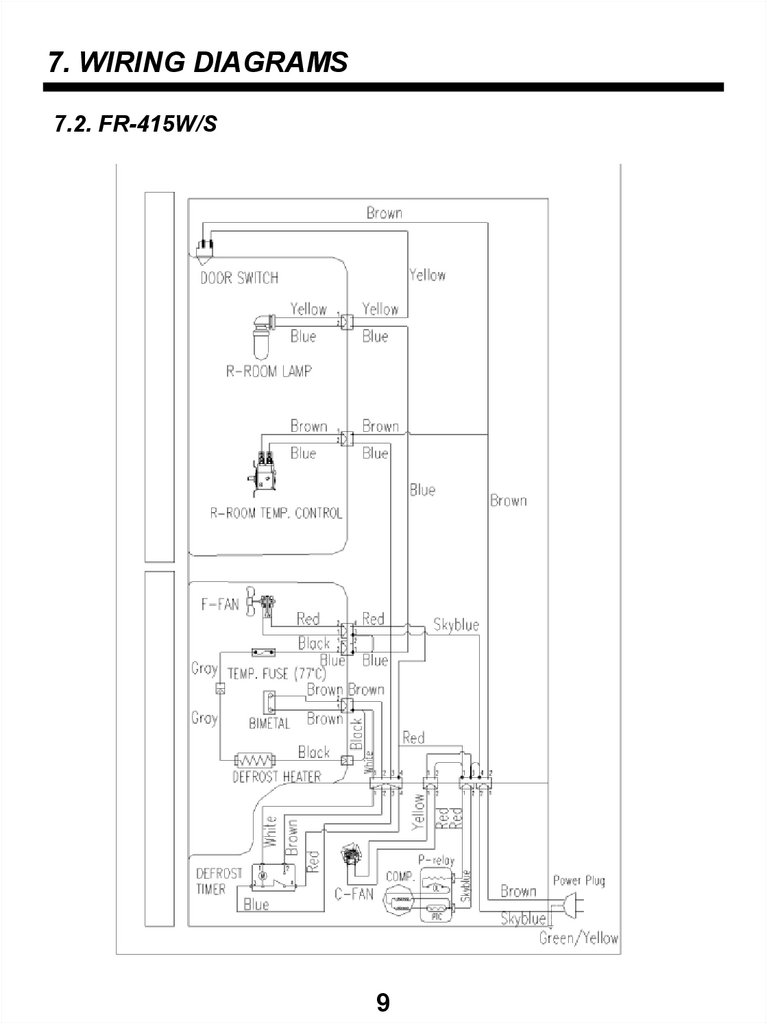

7. WIRING DIAGRAMS7.2. FR-415W/S

9

11.

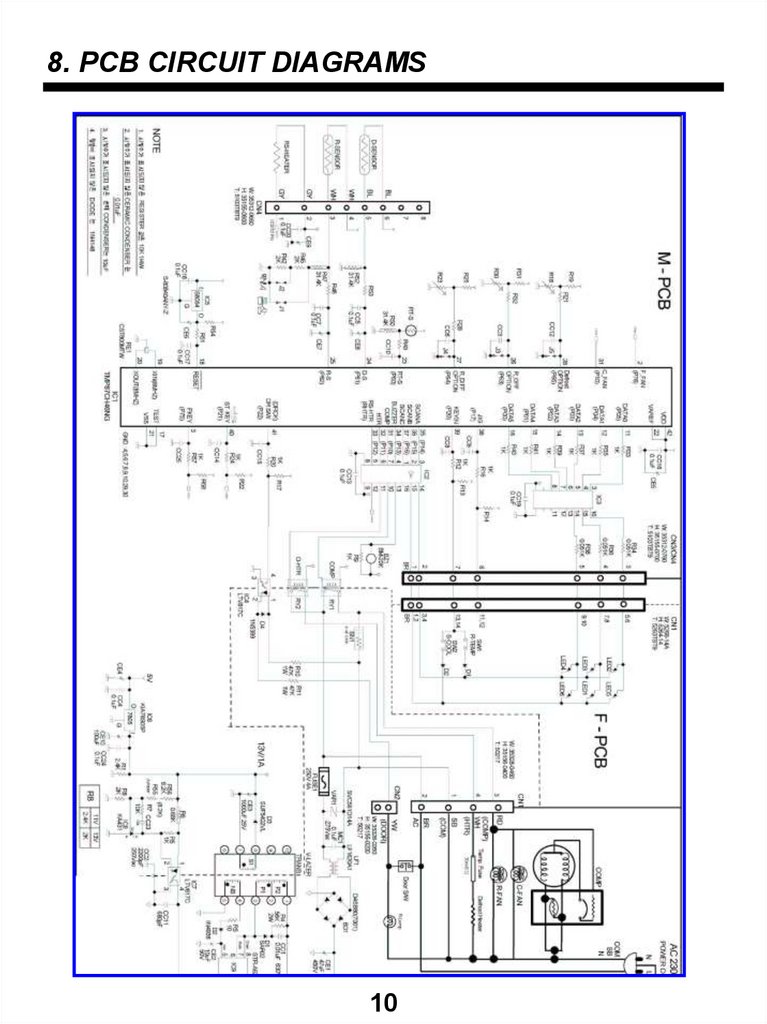

8. PCB CIRCUIT DIAGRAMS10

12.

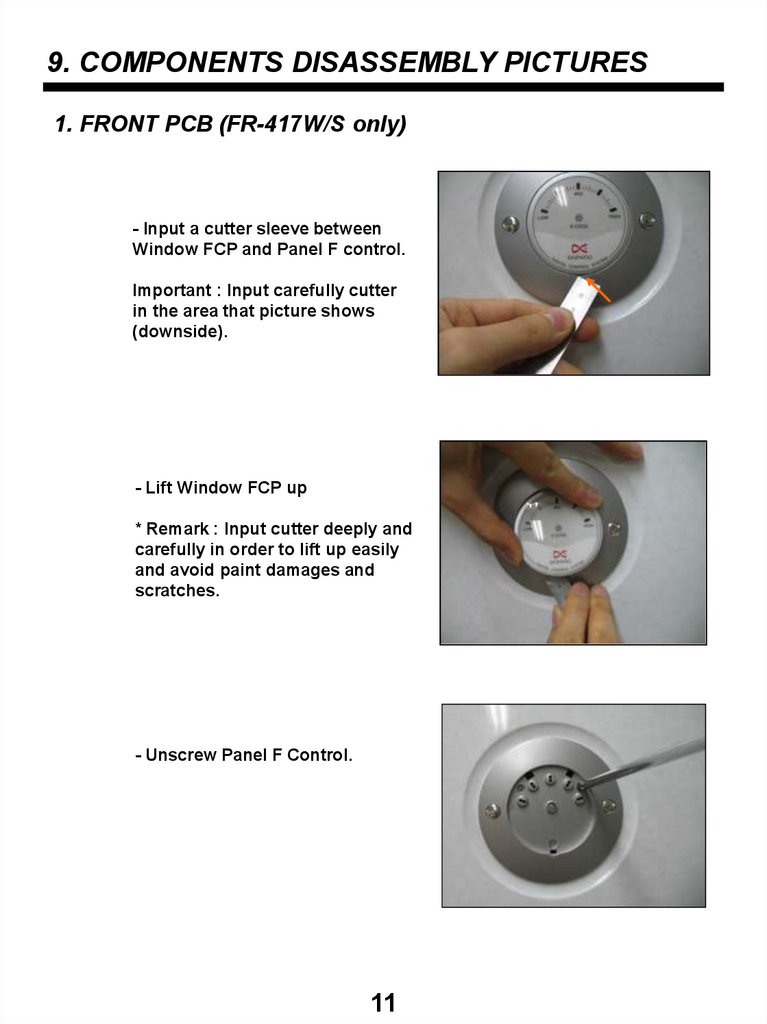

9. COMPONENTS DISASSEMBLY PICTURES1. FRONT PCB (FR-417W/S only)

- Input a cutter sleeve between

Window FCP and Panel F control.

Important : Input carefully cutter

in the area that picture shows

(downside).

- Lift Window FCP up

* Remark : Input cutter deeply and

carefully in order to lift up easily

and avoid paint damages and

scratches.

- Unscrew Panel F Control.

11

13.

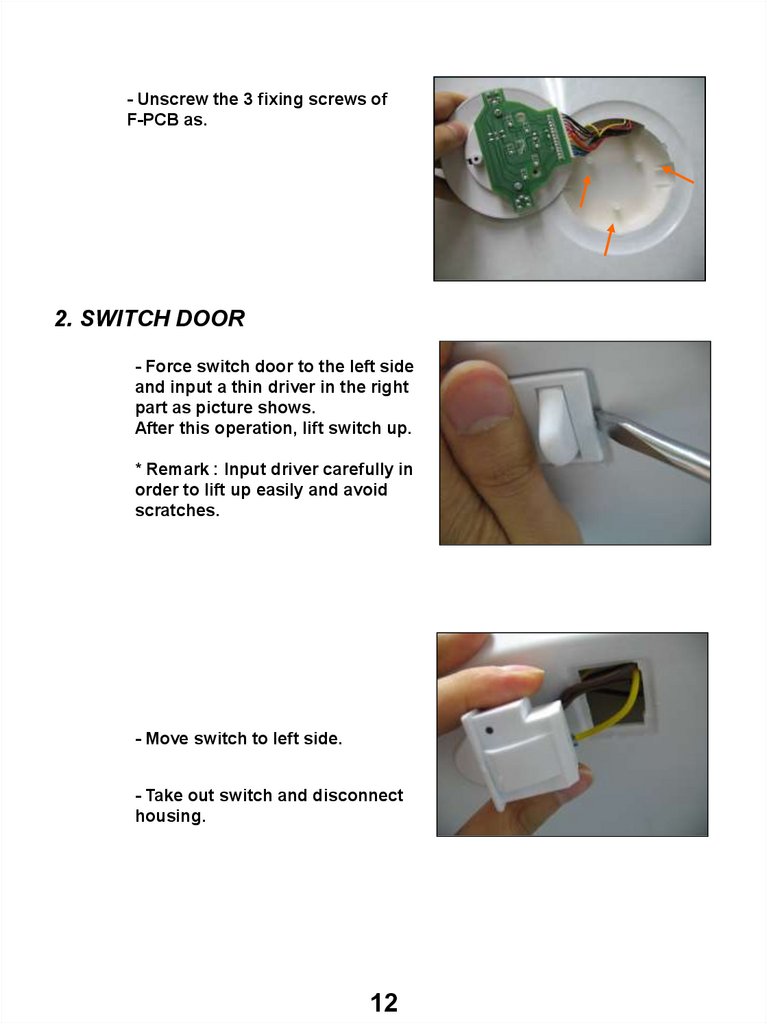

- Unscrew the 3 fixing screws ofF-PCB as.

2. SWITCH DOOR

- Force switch door to the left side

and input a thin driver in the right

part as picture shows.

After this operation, lift switch up.

* Remark : Input driver carefully in

order to lift up easily and avoid

scratches.

- Move switch to left side.

- Take out switch and disconnect

housing.

12

14.

3. M-PCB(FR-417W/S only)- Unscrew the 3 fixing screws of

cover PCB box.

- Disconnect all housings

connectors from M-PCB, and

force plastic locker of PCB box in

order to take out the PCB.

* Remake: In FR-417W/S models

forced defrost button is located in

M-PCB, so PCB box cover must

be disassembled.

4. RELAY BOX COVER

- Press relay box cover stopper

sleeve with a minus driver like

picture shows.

13

15.

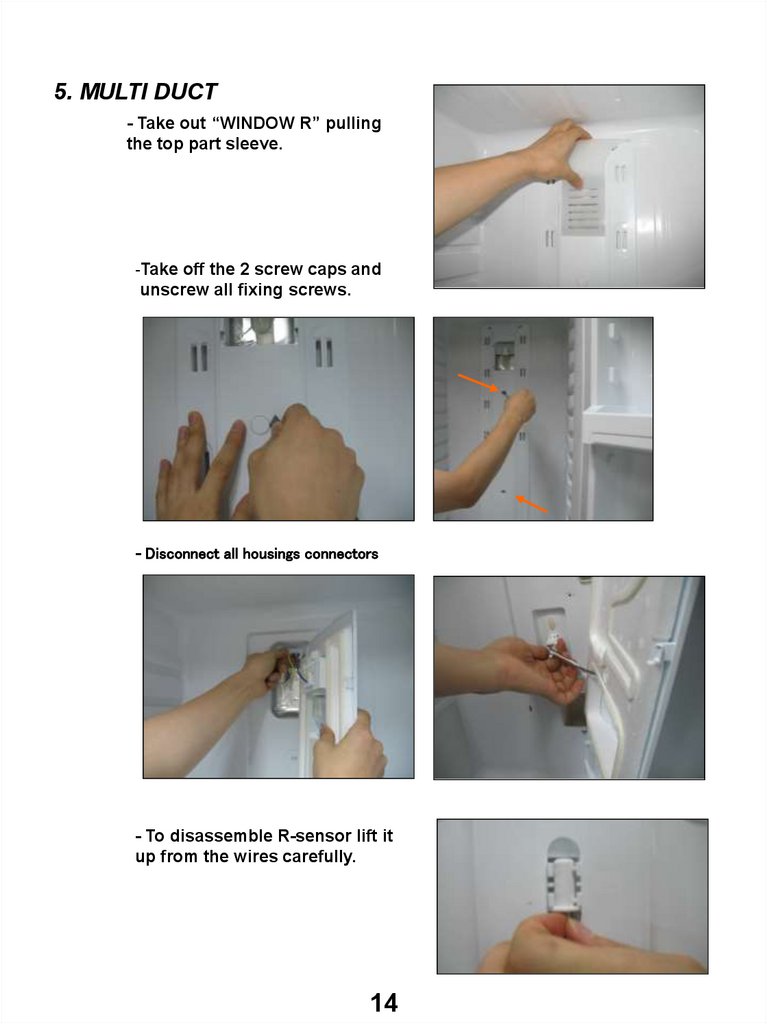

5. MULTI DUCT- Take out “WINDOW R” pulling

the top part sleeve.

-Take off the 2 screw caps and

unscrew all fixing screws.

- Disconnect all housings connectors

- To disassemble R-sensor lift it

up from the wires carefully.

14

16.

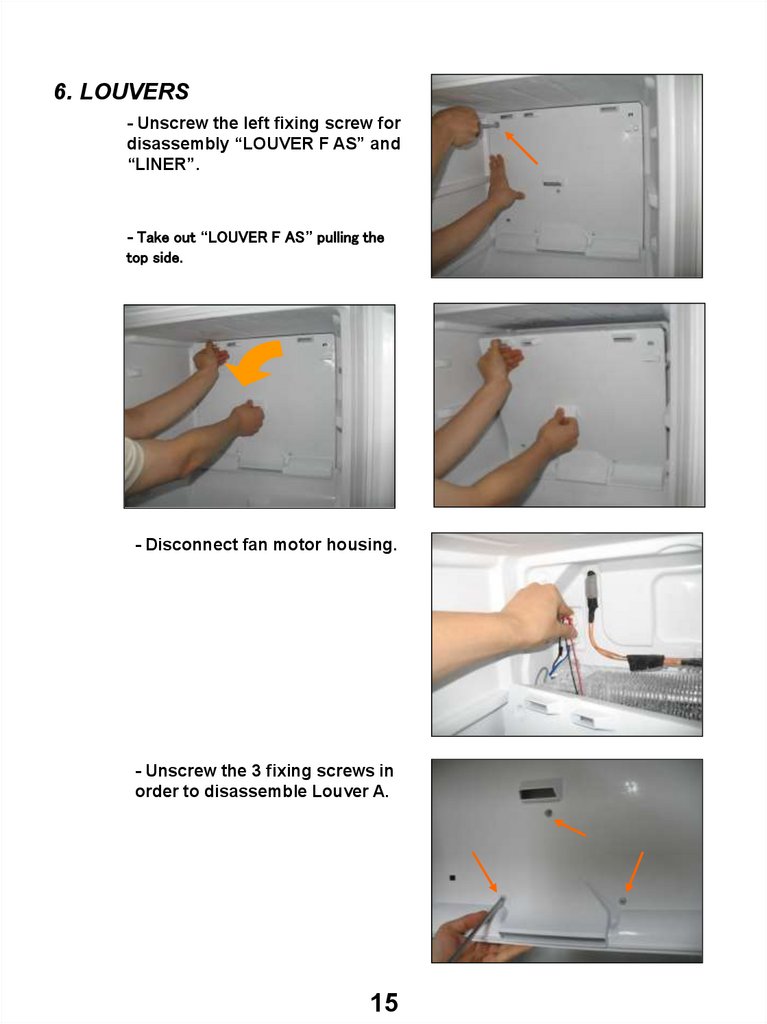

6. LOUVERS- Unscrew the left fixing screw for

disassembly “LOUVER F AS” and

“LINER”.

- Take out “LOUVER F AS” pulling the

top side.

- Disconnect fan motor housing.

- Unscrew the 3 fixing screws in

order to disassemble Louver A.

15

17.

- When louvers are disassembledis very important check Knob F

louver position.

Default position is M

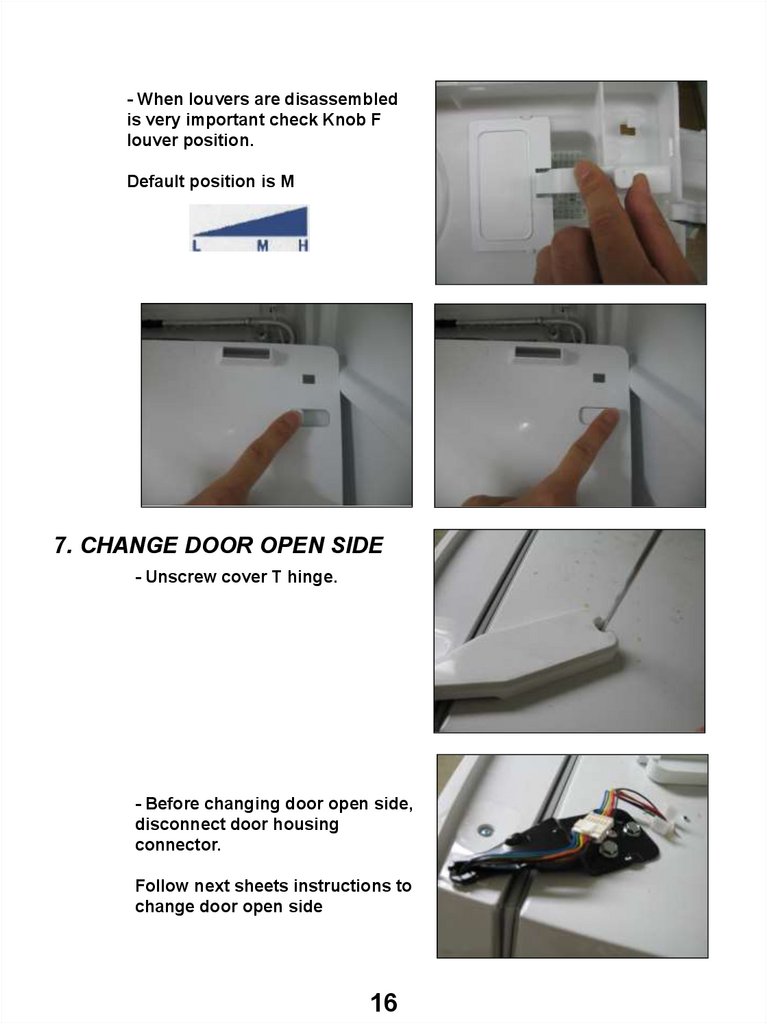

7. CHANGE DOOR OPEN SIDE

- Unscrew cover T hinge.

- Before changing door open side,

disconnect door housing

connector.

Follow next sheets instructions to

change door open side

16

18.

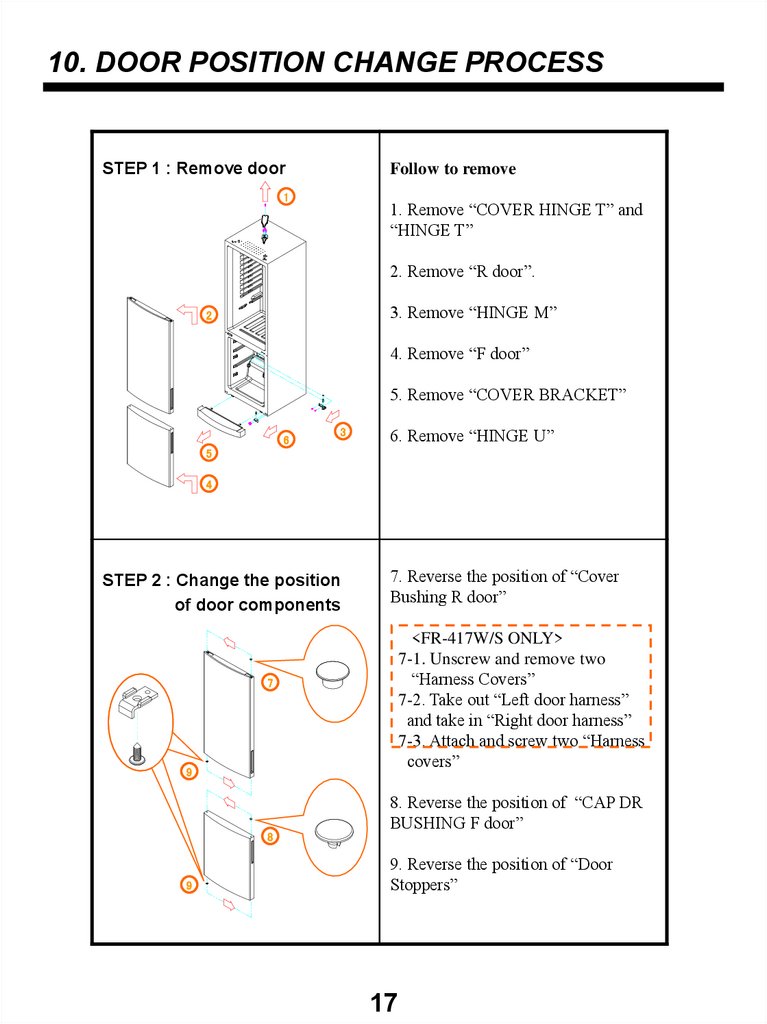

10. DOOR POSITION CHANGE PROCESSSTEP 1 : Remove door

Follow to remove

1

1. Remove “COVER HINGE T” and

“HINGE T”

2. Remove “R door”.

3. Remove “HINGE M”

2

4. Remove “F door”

5. Remove “COVER BRACKET”

6

3

6. Remove “HINGE U”

5

4

STEP 2 : Change the position

of door components

7. Reverse the position of “Cover

Bushing R door”

<FR-417W/S ONLY>

7-1. Unscrew and remove two

“Harness Covers”

7-2. Take out “Left door harness”

and take in “Right door harness”

7-3. Attach and screw two “Harness

covers”

7

9

8

9

8. Reverse the position of “CAP DR

BUSHING F door”

9. Reverse the position of “Door

Stoppers”

17

19.

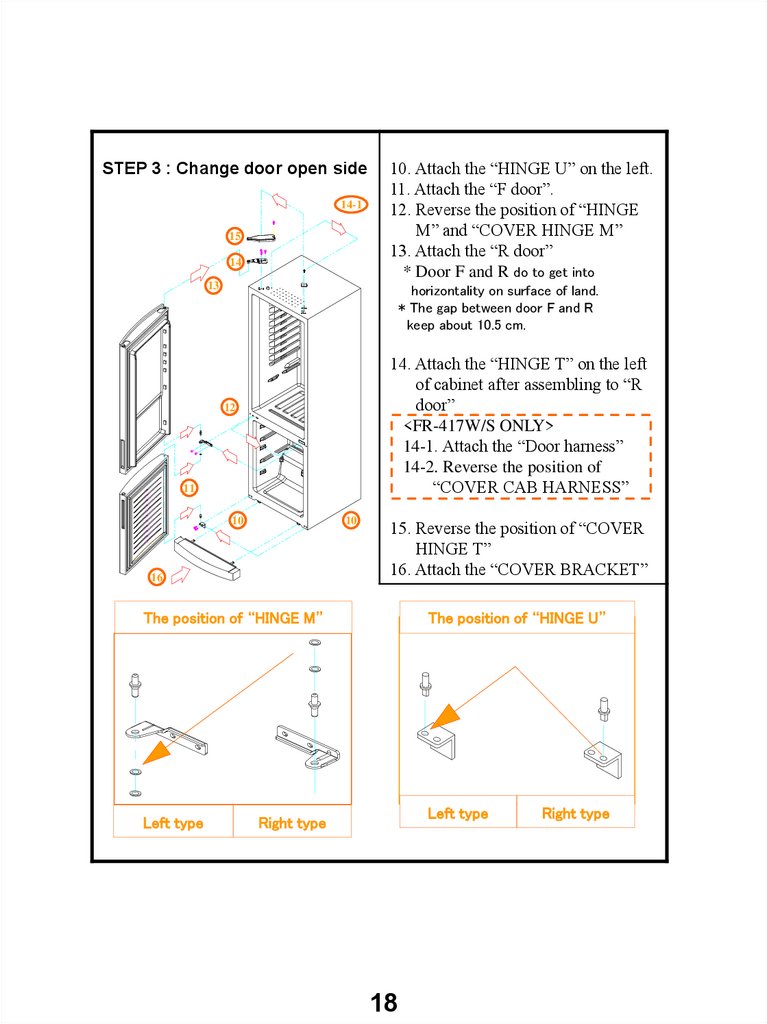

STEP 3 : Change door open side14-1

15

14

10. Attach the “HINGE U” on the left.

11. Attach the “F door”.

12. Reverse the position of “HINGE

M” and “COVER HINGE M”

13. Attach the “R door”

* Door F and R do to get into

13

horizontality on surface of land.

* The gap between door F and R

keep about 10.5 cm.

14. Attach the “HINGE T” on the left

of cabinet after assembling to “R

door”

<FR-417W/S ONLY>

14-1. Attach the “Door harness”

14-2. Reverse the position of

“COVER CAB HARNESS”

12

11

10

10

16

15. Reverse the position of “COVER

HINGE T”

16. Attach the “COVER BRACKET”

The position of “HINGE M”

Left type

The position of “HINGE U”

Left type

Right type

18

Right type

20.

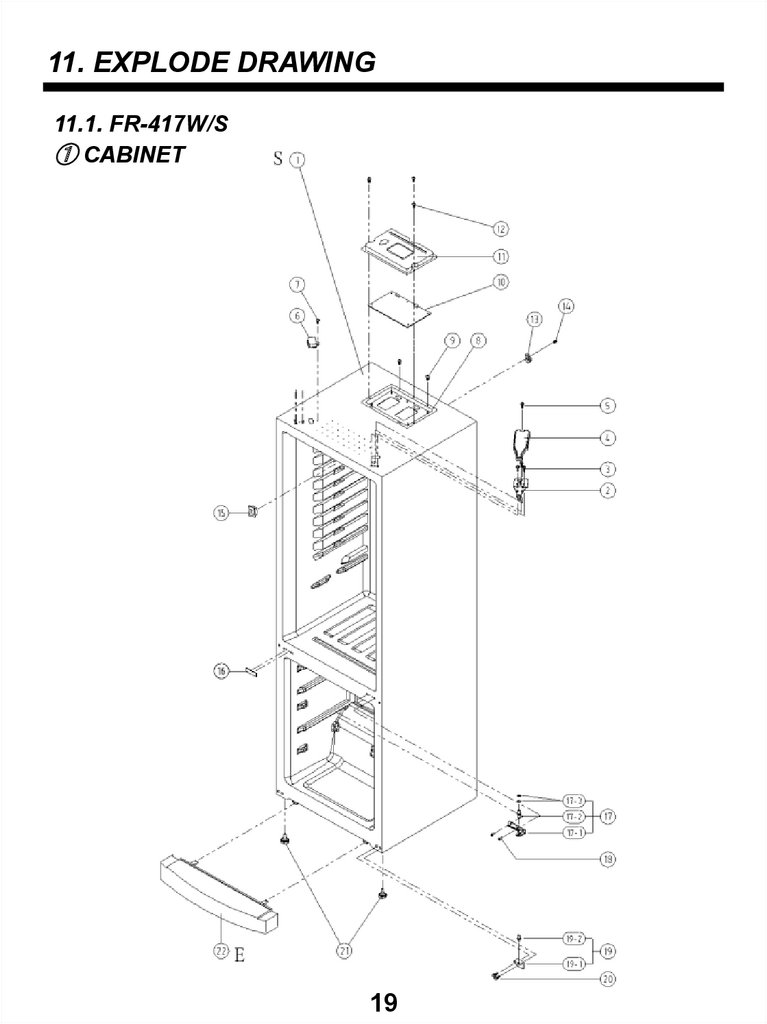

11. EXPLODE DRAWING11.1. FR-417W/S

① CABINET

19

21.

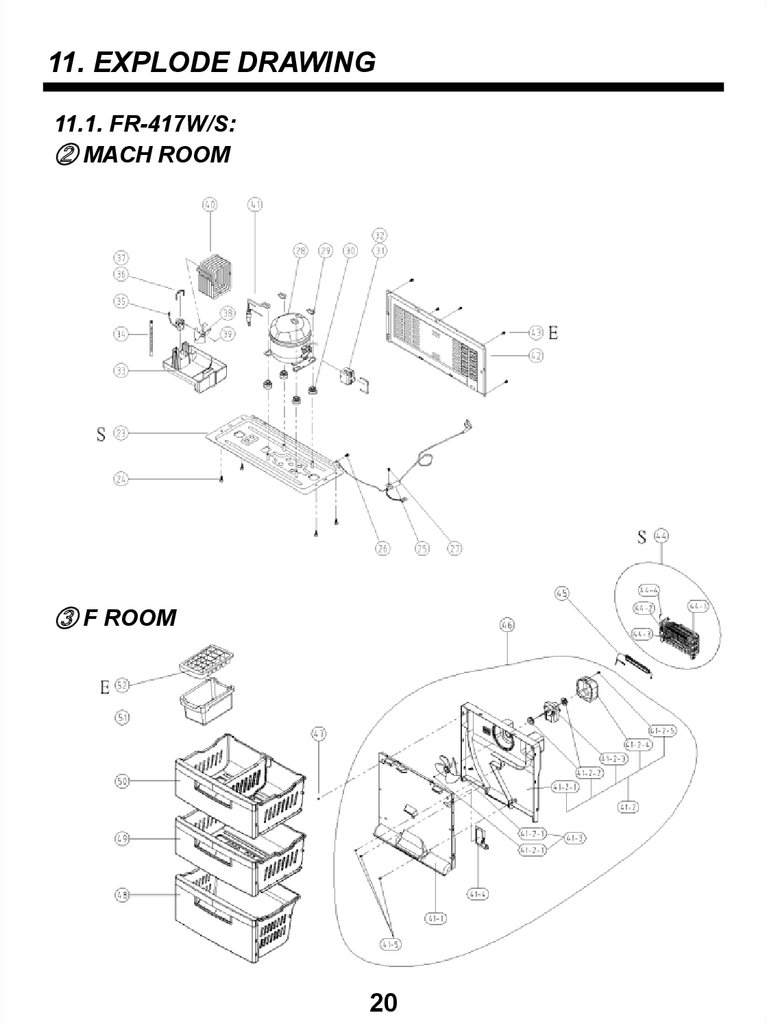

11. EXPLODE DRAWING11.1. FR-417W/S:

② MACH ROOM

③ F ROOM

20

22.

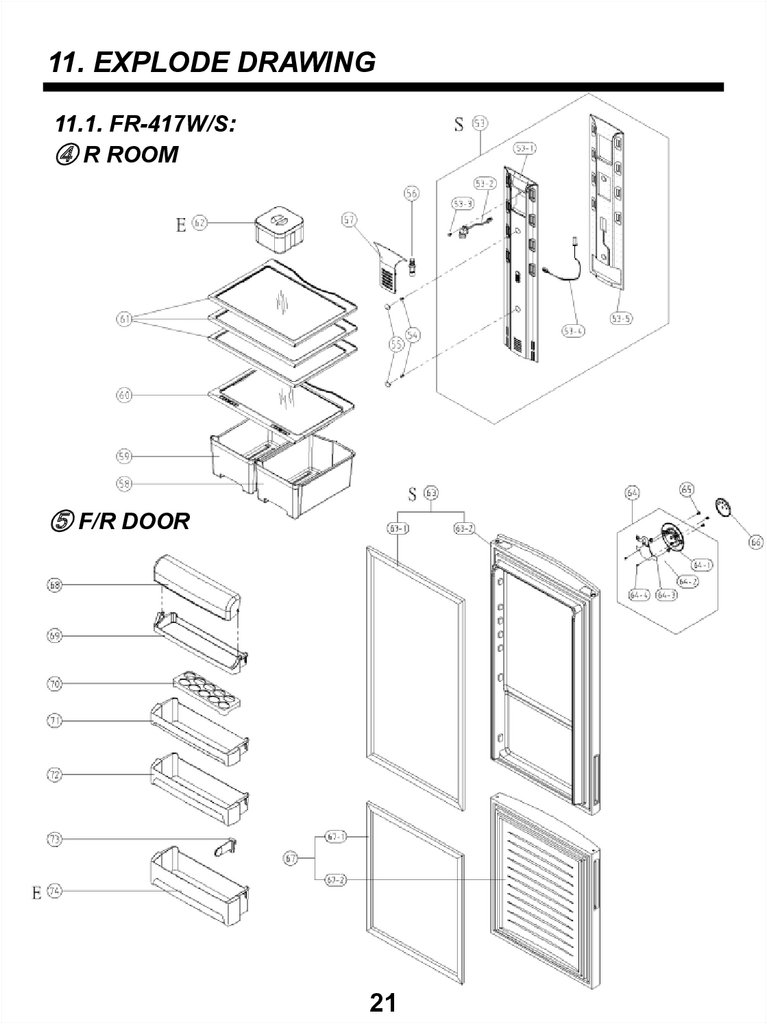

11. EXPLODE DRAWING11.1. FR-417W/S:

④ R ROOM

⑤ F/R DOOR

21

23.

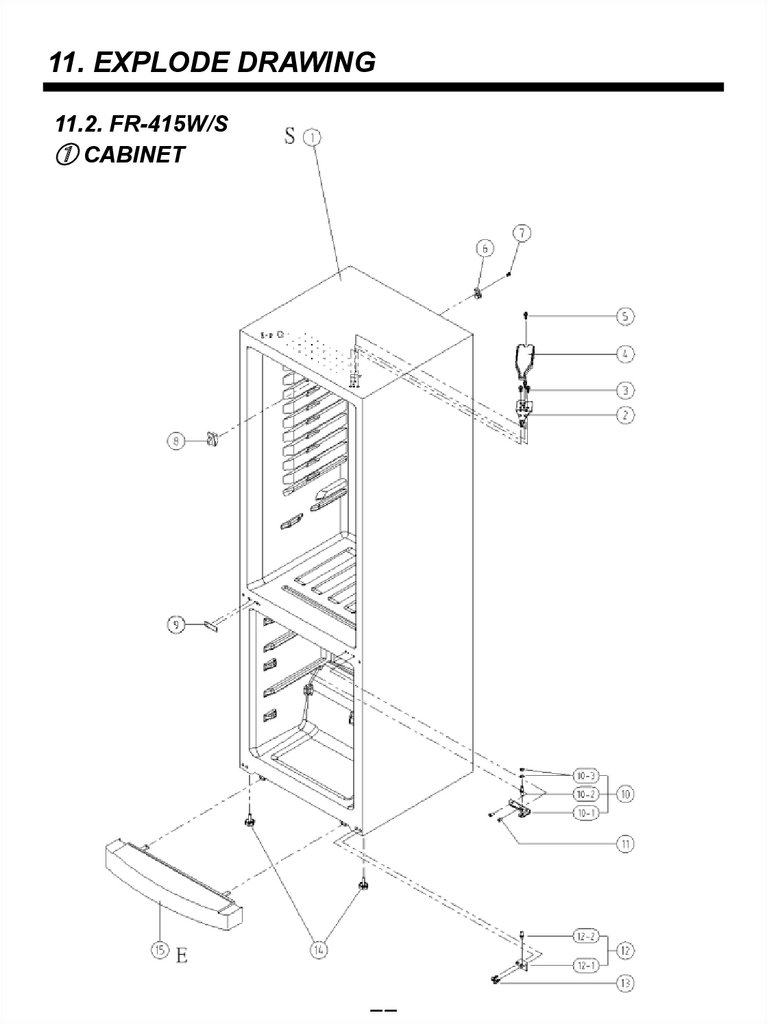

11. EXPLODE DRAWING11.2. FR-415W/S

① CABINET

22

24.

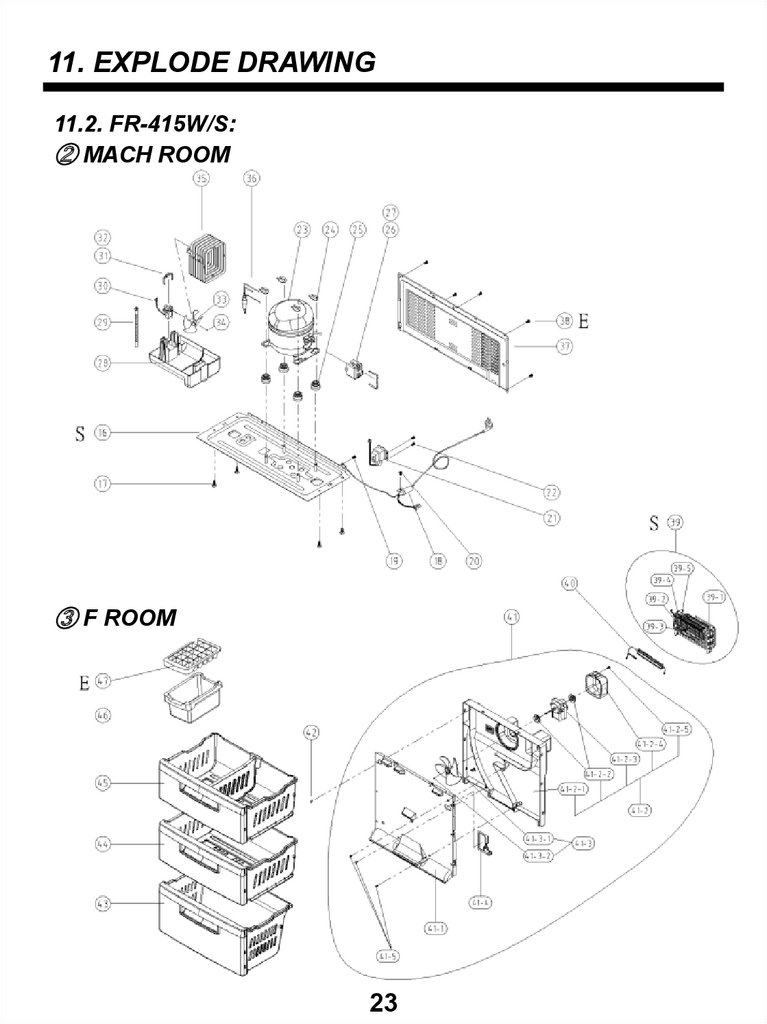

11. EXPLODE DRAWING11.2. FR-415W/S:

② MACH ROOM

③ F ROOM

23

25.

11. EXPLODE DRAWING11.2. FR-415W/S:

④ R ROOM

⑤ F/R DOOR

24

26.

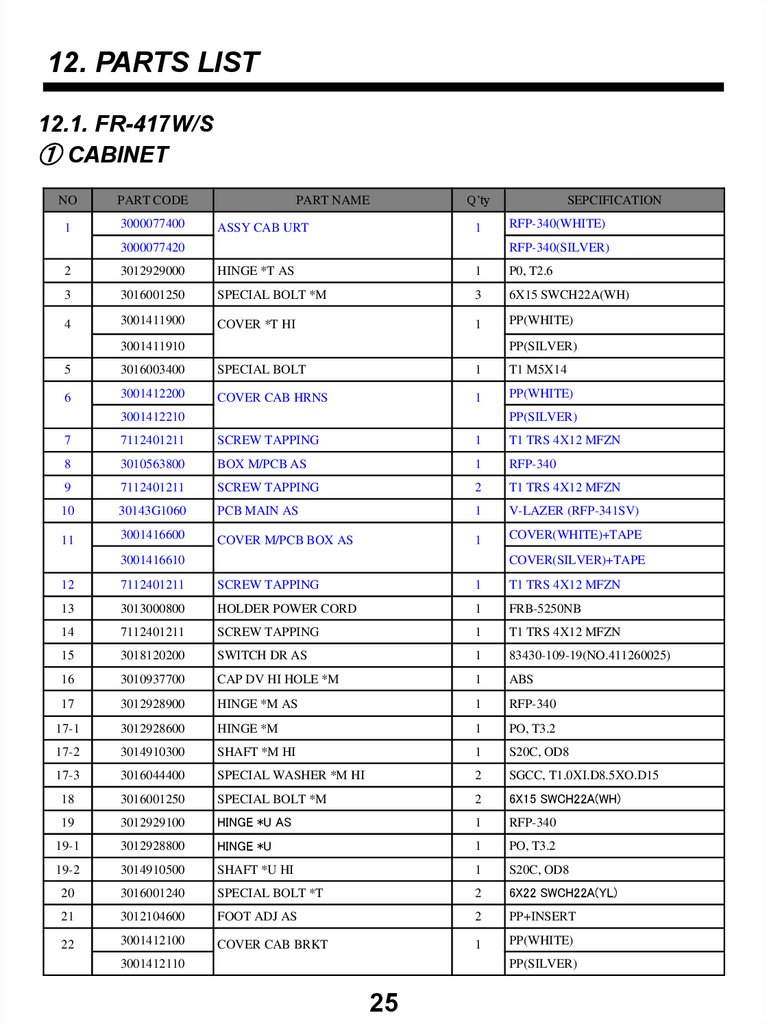

12. PARTS LIST12.1. FR-417W/S

① CABINET

NO

PART CODE

1

3000077400

PART NAME

ASSY CAB URT

Q’ty

1

3000077420

SEPCIFICATION

RFP-340(WHITE)

RFP-340(SILVER)

2

3012929000

HINGE *T AS

1

P0, T2.6

3

3016001250

SPECIAL BOLT *M

3

6X15 SWCH22A(WH)

4

3001411900

COVER *T HI

1

PP(WHITE)

3001411910

PP(SILVER)

5

3016003400

SPECIAL BOLT

1

T1 M5X14

6

3001412200

COVER CAB HRNS

1

PP(WHITE)

3001412210

PP(SILVER)

7

7112401211

SCREW TAPPING

1

T1 TRS 4X12 MFZN

8

3010563800

BOX M/PCB AS

1

RFP-340

9

7112401211

SCREW TAPPING

2

T1 TRS 4X12 MFZN

10

30143G1060

PCB MAIN AS

1

V-LAZER (RFP-341SV)

11

3001416600

COVER M/PCB BOX AS

1

COVER(WHITE)+TAPE

3001416610

COVER(SILVER)+TAPE

12

7112401211

SCREW TAPPING

1

T1 TRS 4X12 MFZN

13

3013000800

HOLDER POWER CORD

1

FRB-5250NB

14

7112401211

SCREW TAPPING

1

T1 TRS 4X12 MFZN

15

3018120200

SWITCH DR AS

1

83430-109-19(NO.411260025)

16

3010937700

CAP DV HI HOLE *M

1

ABS

17

3012928900

HINGE *M AS

1

RFP-340

17-1

3012928600

HINGE *M

1

PO, T3.2

17-2

3014910300

SHAFT *M HI

1

S20C, OD8

17-3

3016044400

SPECIAL WASHER *M HI

2

SGCC, T1.0XI.D8.5XO.D15

18

3016001250

SPECIAL BOLT *M

2

6X15 SWCH22A(WH)

19

3012929100

HINGE *U AS

1

RFP-340

19-1

3012928800

HINGE *U

1

PO, T3.2

19-2

3014910500

SHAFT *U HI

1

S20C, OD8

20

3016001240

SPECIAL BOLT *T

2

6X22 SWCH22A(YL)

21

3012104600

FOOT ADJ AS

2

PP+INSERT

22

3001412100

COVER CAB BRKT

1

PP(WHITE)

3001412110

PP(SILVER)

25

27.

12. PARTS LIST12.1. FR-417W/S

② MACH ROOM

PART NAME

Q’ty

NO

PART CODE

23

3010349300

BASE COMP AS

1

RFP-340

24

3016003300

SPECIAL BOLT

4

T2 M6.5X20

25

3011349300

CORD POWER AS

1

RFP-340

26

7S422X4081

SPECIAL SCREW

1

TT3 TRS 4X8 SE MFZN

27

7112401211

SCREW TAPPING

1

T1 TRS 4X12 MFZN

28

3954158J50

COMPRESSOR

1

JX58LHS5 220V-50HZ

29

3016002500

SPECIAL WASHER

4

SK-5 T0.8

30

3010101600

ABSORBER COMP

4

NBR

31

3018131800

SWITCH P RELAY AS

1

RFP(M)-340

32

3811400503

COVER RELAY

1

PRF(M)-340

33

3011122800

CASE VAPORI AS

1

PP+TAPE ALUMINUM

34

3013202700

HOSE DRN B

1

PP

35

3015918100

MOTOR C AS

1

2100RPM 230V/50Hz

36

3012004400

FIXTURE C MOTOR

1

SUS

37

3010102100

ABSORBER C MOTOR

1

NR FRB-5350NT

38

3011802200

FAN

1

ABS OD3.17XD110

39

3011200510

CLAMP FAN

1

SUS 304 (SPRING)

40

3014469600

PIPE WICON AS

1

41

3016808100

DRYER AS

1

C1220T-M OD19.0XL135

42

3001414000

COVER MACH RM AS

1

ABS

43

7112401211

SCREW TAPPING

1

T1 TRS 4X12 MFZN

26

SEPCIFICATION

28.

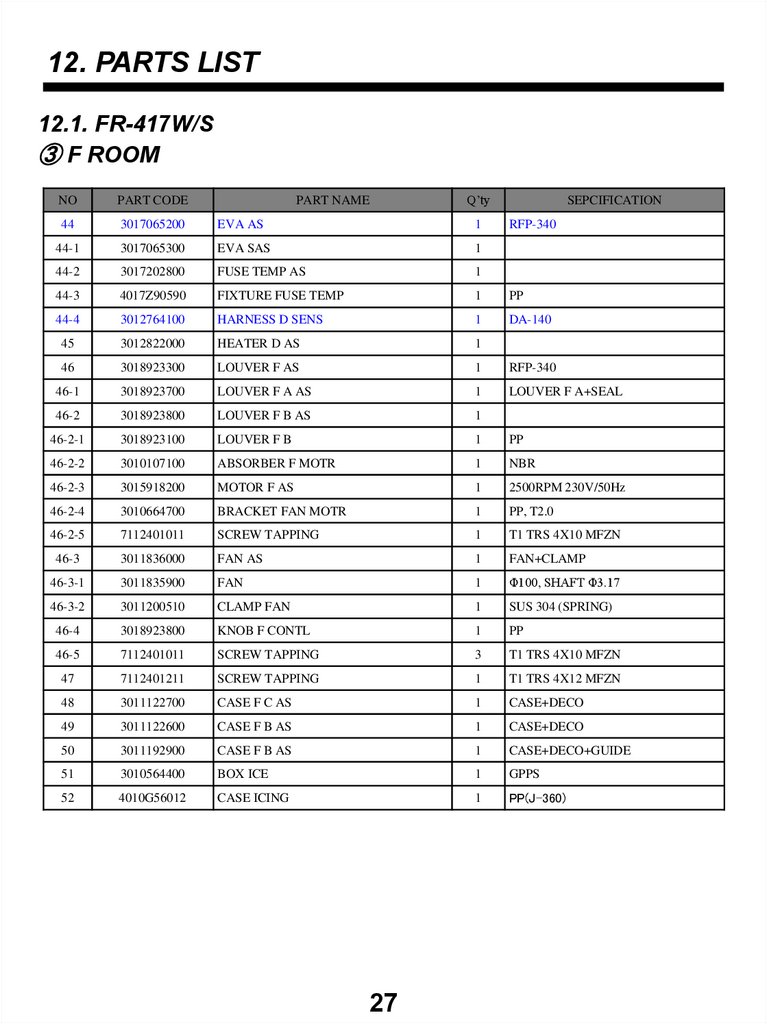

12. PARTS LIST12.1. FR-417W/S

③ F ROOM

PART NAME

Q’ty

NO

PART CODE

44

3017065200

EVA AS

1

44-1

3017065300

EVA SAS

1

44-2

3017202800

FUSE TEMP AS

1

44-3

4017Z90590

FIXTURE FUSE TEMP

1

PP

44-4

3012764100

HARNESS D SENS

1

DA-140

45

3012822000

HEATER D AS

1

46

3018923300

LOUVER F AS

1

RFP-340

46-1

3018923700

LOUVER F A AS

1

LOUVER F A+SEAL

46-2

3018923800

LOUVER F B AS

1

46-2-1

3018923100

LOUVER F B

1

PP

46-2-2

3010107100

ABSORBER F MOTR

1

NBR

46-2-3

3015918200

MOTOR F AS

1

2500RPM 230V/50Hz

46-2-4

3010664700

BRACKET FAN MOTR

1

PP, T2.0

46-2-5

7112401011

SCREW TAPPING

1

T1 TRS 4X10 MFZN

46-3

3011836000

FAN AS

1

FAN+CLAMP

46-3-1

3011835900

FAN

1

Φ100, SHAFT Φ3.17

46-3-2

3011200510

CLAMP FAN

1

SUS 304 (SPRING)

46-4

3018923800

KNOB F CONTL

1

PP

46-5

7112401011

SCREW TAPPING

3

T1 TRS 4X10 MFZN

47

7112401211

SCREW TAPPING

1

T1 TRS 4X12 MFZN

48

3011122700

CASE F C AS

1

CASE+DECO

49

3011122600

CASE F B AS

1

CASE+DECO

50

3011192900

CASE F B AS

1

CASE+DECO+GUIDE

51

3010564400

BOX ICE

1

GPPS

52

4010G56012

CASE ICING

1

PP(J-360)

27

SEPCIFICATION

RFP-340

29.

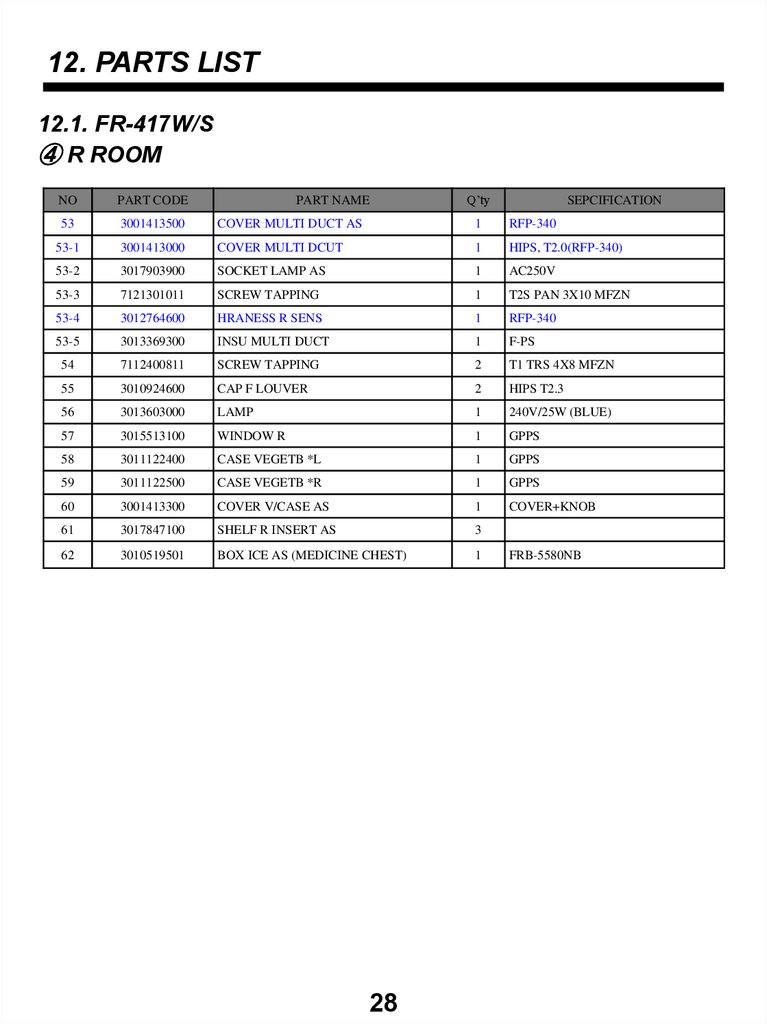

12. PARTS LIST12.1. FR-417W/S

④ R ROOM

PART NAME

Q’ty

NO

PART CODE

53

3001413500

COVER MULTI DUCT AS

1

RFP-340

53-1

3001413000

COVER MULTI DCUT

1

HIPS, T2.0(RFP-340)

53-2

3017903900

SOCKET LAMP AS

1

AC250V

53-3

7121301011

SCREW TAPPING

1

T2S PAN 3X10 MFZN

53-4

3012764600

HRANESS R SENS

1

RFP-340

53-5

3013369300

INSU MULTI DUCT

1

F-PS

54

7112400811

SCREW TAPPING

2

T1 TRS 4X8 MFZN

55

3010924600

CAP F LOUVER

2

HIPS T2.3

56

3013603000

LAMP

1

240V/25W (BLUE)

57

3015513100

WINDOW R

1

GPPS

58

3011122400

CASE VEGETB *L

1

GPPS

59

3011122500

CASE VEGETB *R

1

GPPS

60

3001413300

COVER V/CASE AS

1

COVER+KNOB

61

3017847100

SHELF R INSERT AS

3

62

3010519501

BOX ICE AS (MEDICINE CHEST)

1

28

SEPCIFICATION

FRB-5580NB

30.

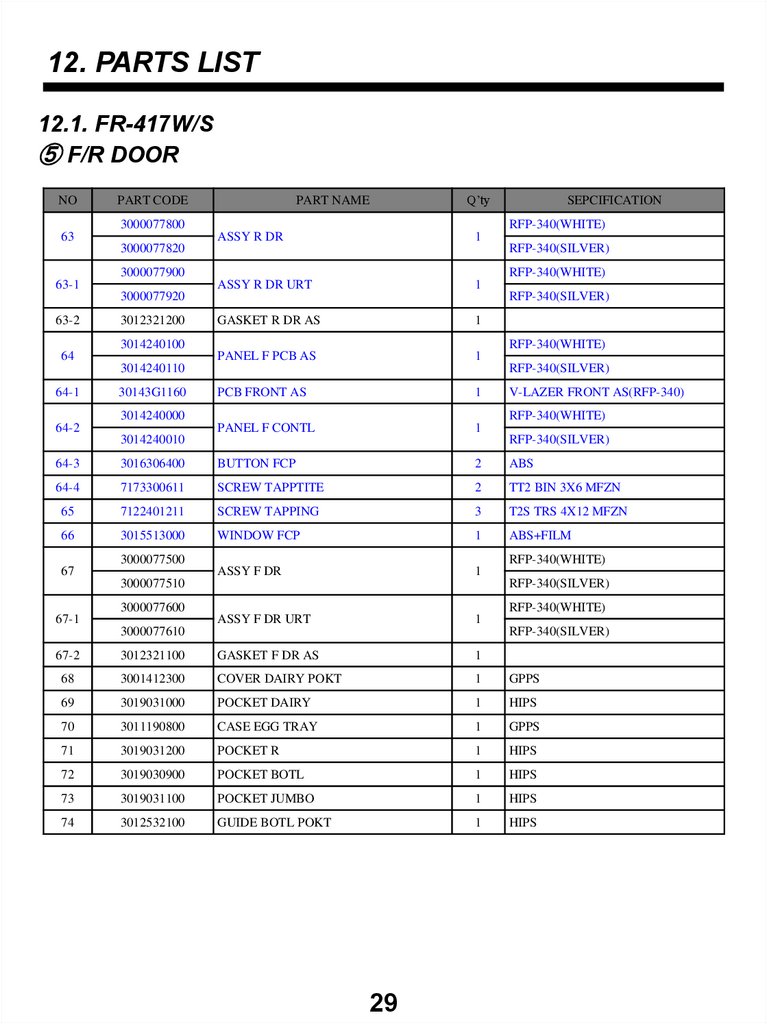

12. PARTS LIST12.1. FR-417W/S

⑤ F/R DOOR

NO

PART CODE

PART NAME

Q’ty

3000077800

63

RFP-340(WHITE)

ASSY R DR

1

3000077820

RFP-340(SILVER)

3000077900

63-1

RFP-340(WHITE)

ASSY R DR URT

1

3000077920

63-2

3012321200

RFP-340(SILVER)

GASKET R DR AS

1

PANEL F PCB AS

1

3014240100

64

RFP-340(WHITE)

3014240110

64-1

30143G1160

RFP-340(SILVER)

PCB FRONT AS

1

PANEL F CONTL

1

3014240000

64-2

SEPCIFICATION

V-LAZER FRONT AS(RFP-340)

RFP-340(WHITE)

3014240010

RFP-340(SILVER)

64-3

3016306400

BUTTON FCP

2

ABS

64-4

7173300611

SCREW TAPPTITE

2

TT2 BIN 3X6 MFZN

65

7122401211

SCREW TAPPING

3

T2S TRS 4X12 MFZN

66

3015513000

WINDOW FCP

1

ABS+FILM

ASSY F DR

1

3000077500

67

RFP-340(WHITE)

3000077510

RFP-340(SILVER)

3000077600

67-1

RFP-340(WHITE)

ASSY F DR URT

1

3000077610

RFP-340(SILVER)

67-2

3012321100

GASKET F DR AS

1

68

3001412300

COVER DAIRY POKT

1

GPPS

69

3019031000

POCKET DAIRY

1

HIPS

70

3011190800

CASE EGG TRAY

1

GPPS

71

3019031200

POCKET R

1

HIPS

72

3019030900

POCKET BOTL

1

HIPS

73

3019031100

POCKET JUMBO

1

HIPS

74

3012532100

GUIDE BOTL POKT

1

HIPS

29

31.

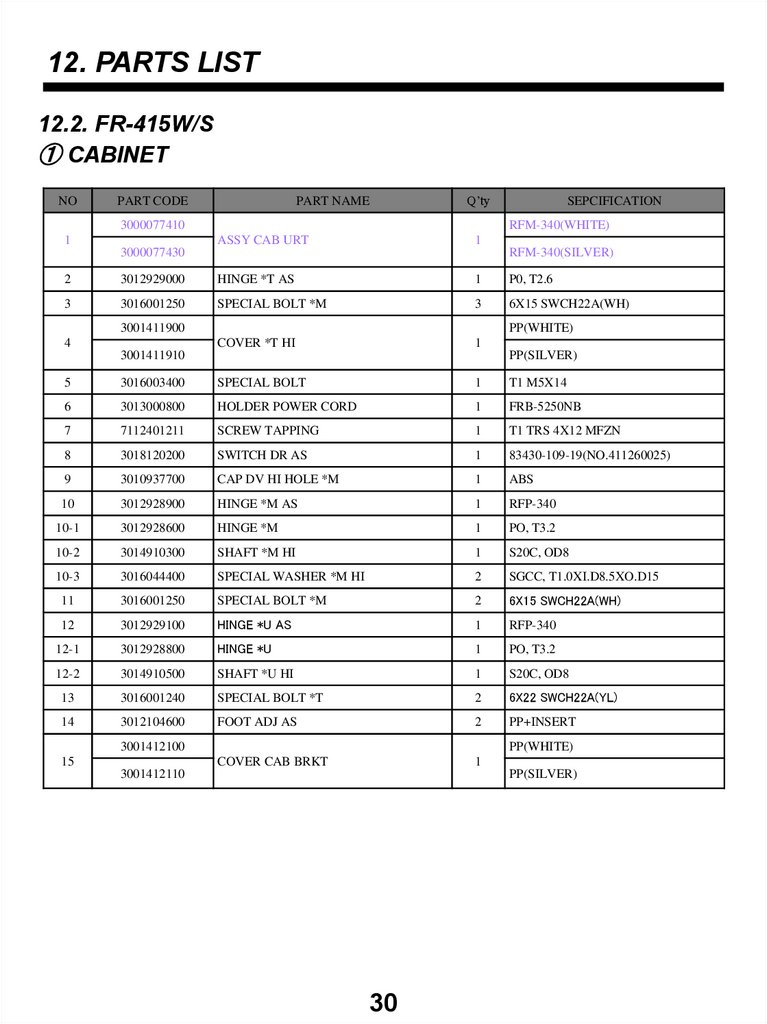

12. PARTS LIST12.2. FR-415W/S

① CABINET

NO

PART CODE

PART NAME

Q’ty

3000077410

1

SEPCIFICATION

RFM-340(WHITE)

ASSY CAB URT

1

3000077430

RFM-340(SILVER)

2

3012929000

HINGE *T AS

1

P0, T2.6

3

3016001250

SPECIAL BOLT *M

3

6X15 SWCH22A(WH)

COVER *T HI

1

3001411900

4

PP(WHITE)

3001411910

PP(SILVER)

5

3016003400

SPECIAL BOLT

1

T1 M5X14

6

3013000800

HOLDER POWER CORD

1

FRB-5250NB

7

7112401211

SCREW TAPPING

1

T1 TRS 4X12 MFZN

8

3018120200

SWITCH DR AS

1

83430-109-19(NO.411260025)

9

3010937700

CAP DV HI HOLE *M

1

ABS

10

3012928900

HINGE *M AS

1

RFP-340

10-1

3012928600

HINGE *M

1

PO, T3.2

10-2

3014910300

SHAFT *M HI

1

S20C, OD8

10-3

3016044400

SPECIAL WASHER *M HI

2

SGCC, T1.0XI.D8.5XO.D15

11

3016001250

SPECIAL BOLT *M

2

6X15 SWCH22A(WH)

12

3012929100

HINGE *U AS

1

RFP-340

12-1

3012928800

HINGE *U

1

PO, T3.2

12-2

3014910500

SHAFT *U HI

1

S20C, OD8

13

3016001240

SPECIAL BOLT *T

2

6X22 SWCH22A(YL)

14

3012104600

FOOT ADJ AS

2

PP+INSERT

COVER CAB BRKT

1

3001412100

15

PP(WHITE)

3001412110

PP(SILVER)

30

32.

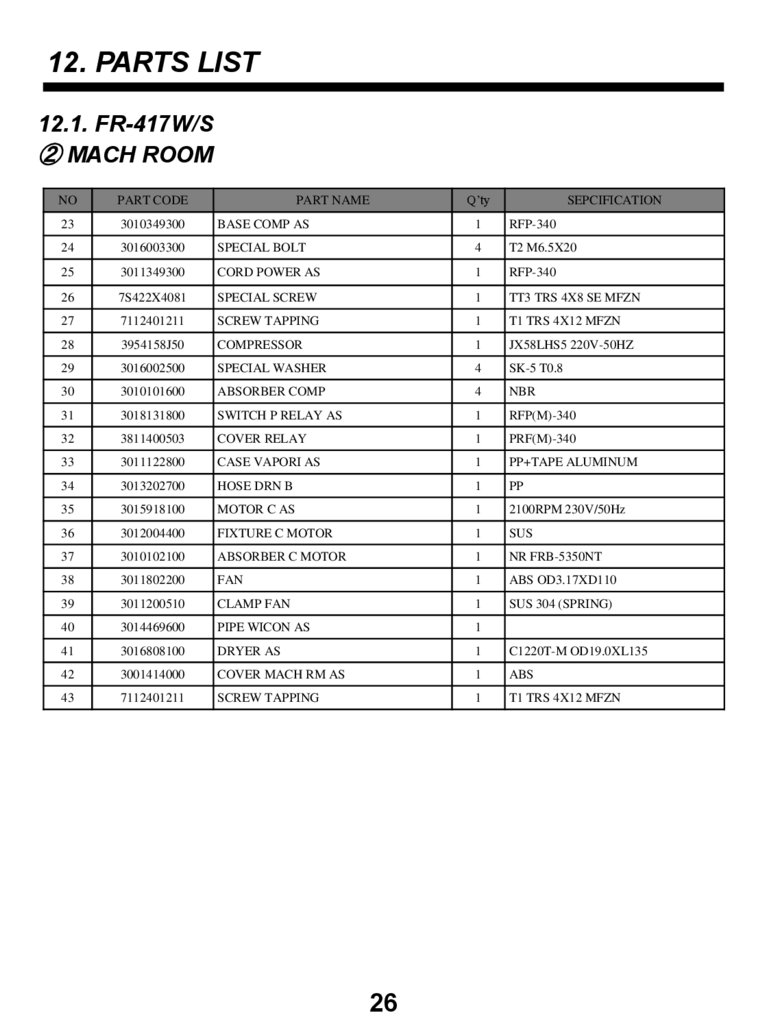

12. PARTS LIST12.2. FR-415W/S

② MACH ROOM

PART NAME

Q’ty

NO

PART CODE

16

3010349300

BASE COMP AS

1

RFP-340

17

3016003300

SPECIAL BOLT

4

T2 M6.5X20

18

3011349300

CORD POWER AS

1

RFP-340

19

7S422X4081

SPECIAL SCREW

1

TT3 TRS 4X8 SE MFZN

20

7112401211

SCREW TAPPING

1

T1 TRS 4X12 MFZN

21

3010563900

BOX POWER AS

1

RFM-340

22

7112401211

SCREW TAPPING

2

T1 TRS 4X12 MFZN

23

3954158J50

COMPRESSOR

1

JX58LHS5 220V-50HZ

24

3016002500

SPECIAL WASHER

4

SK-5 T0.8

25

3010101600

ABSORBER COMP

4

NBR

26

3018131800

SWITCH P RELAY AS

1

RFP(M)-340

27

3811400503

COVER RELAY

1

PRF(M)-340

28

3011122800

CASE VAPORI AS

1

PP+TAPE ALUMINUM

29

3013202700

HOSE DRN B

1

PP

30

3015918100

MOTOR C AS

1

2100RPM 230V/50Hz

31

3012004400

FIXTURE C MOTOR

1

SUS

32

3010102100

ABSORBER C MOTOR

1

NR FRB-5350NT

33

3011802200

FAN

1

ABS OD3.17XD110

34

3011200510

CLAMP FAN

1

SUS 304 (SPRING)

35

3014469600

PIPE WICON AS

1

36

3016808100

DRYER AS

1

C1220T-M OD19.0XL135

37

3001414000

COVER MACH RM AS

1

ABS

38

7112401211

SCREW TAPPING

1

T1 TRS 4X12 MFZN

31

SEPCIFICATION

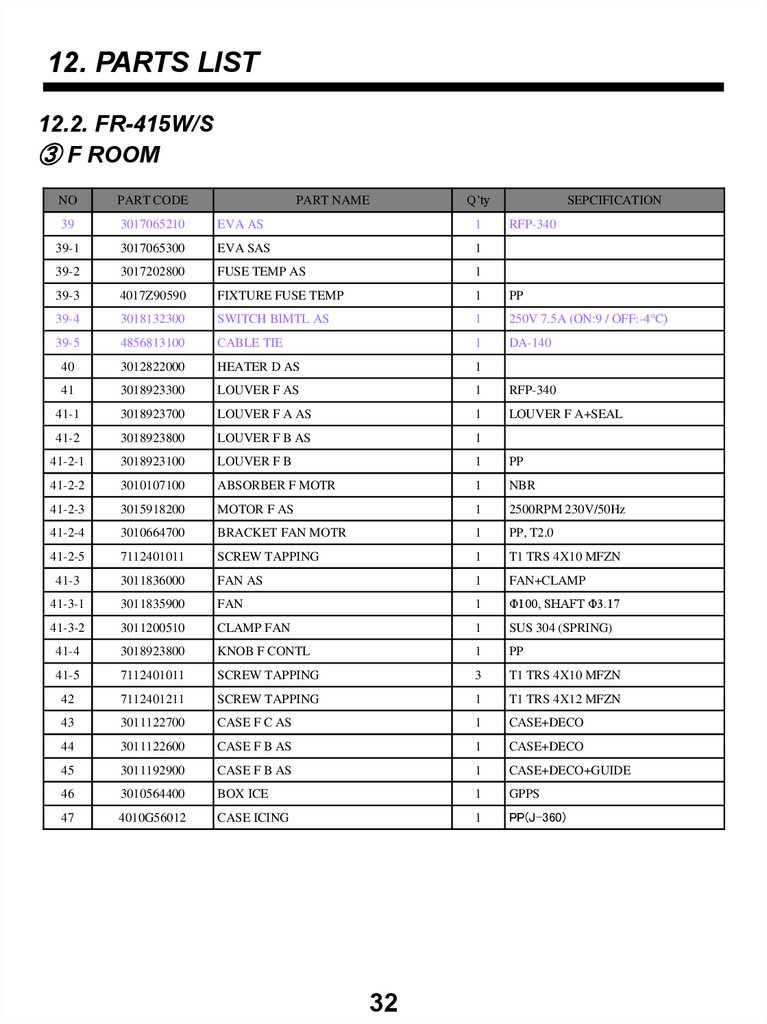

33.

12. PARTS LIST12.2. FR-415W/S

③ F ROOM

PART NAME

Q’ty

NO

PART CODE

39

3017065210

EVA AS

1

39-1

3017065300

EVA SAS

1

39-2

3017202800

FUSE TEMP AS

1

39-3

4017Z90590

FIXTURE FUSE TEMP

1

PP

39-4

3018132300

SWITCH BIMTL AS

1

250V 7.5A (ON:9 / OFF:-4℃)

39-5

4856813100

CABLE TIE

1

DA-140

40

3012822000

HEATER D AS

1

41

3018923300

LOUVER F AS

1

RFP-340

41-1

3018923700

LOUVER F A AS

1

LOUVER F A+SEAL

41-2

3018923800

LOUVER F B AS

1

41-2-1

3018923100

LOUVER F B

1

PP

41-2-2

3010107100

ABSORBER F MOTR

1

NBR

41-2-3

3015918200

MOTOR F AS

1

2500RPM 230V/50Hz

41-2-4

3010664700

BRACKET FAN MOTR

1

PP, T2.0

41-2-5

7112401011

SCREW TAPPING

1

T1 TRS 4X10 MFZN

41-3

3011836000

FAN AS

1

FAN+CLAMP

41-3-1

3011835900

FAN

1

Φ100, SHAFT Φ3.17

41-3-2

3011200510

CLAMP FAN

1

SUS 304 (SPRING)

41-4

3018923800

KNOB F CONTL

1

PP

41-5

7112401011

SCREW TAPPING

3

T1 TRS 4X10 MFZN

42

7112401211

SCREW TAPPING

1

T1 TRS 4X12 MFZN

43

3011122700

CASE F C AS

1

CASE+DECO

44

3011122600

CASE F B AS

1

CASE+DECO

45

3011192900

CASE F B AS

1

CASE+DECO+GUIDE

46

3010564400

BOX ICE

1

GPPS

47

4010G56012

CASE ICING

1

PP(J-360)

32

SEPCIFICATION

RFP-340

34.

12. PARTS LIST12.2. FR-415W/S

④ R ROOM

PART NAME

Q’ty

NO

PART CODE

48

3001413500

COVER MULTI DUCT AS

1

RFP-340

48-1

3001413000

COVER MULTI DCUT

1

HIPS, T2.0(RFP-340)

48-2

3017903900

SOCKET LAMP AS

1

AC250V

48-3

7121301011

SCREW TAPPING

1

T2S PAN 3X10 MFZN

48-4

3018305700

THERMOSTAT

1

RFM-340

48-5

3017903900

HARNESS THERMO AS

1

RFM-340

48-6

3013413600

KNOB R CONTL

1

HIPS

48-7

3013369300

INSU MULTI DUCT

1

F-PS

49

7112400811

SCREW TAPPING

2

T1 TRS 4X8 MFZN

50

3010924600

CAP F LOUVER

2

HIPS T2.3

51

3013603000

LAMP

1

240V/25W (BLUE)

52

3015513100

WINDOW R

1

GPPS

53

3011122400

CASE VEGETB *L

1

GPPS

54

3011122500

CASE VEGETB *R

1

GPPS

55

3001413300

COVER V/CASE AS

1

COVER+KNOB

56

3017847100

SHELF R INSERT AS

3

57

3010519501

BOX ICE AS (MEDICINE CHEST)

1

33

SEPCIFICATION

FRB-5580NB

35.

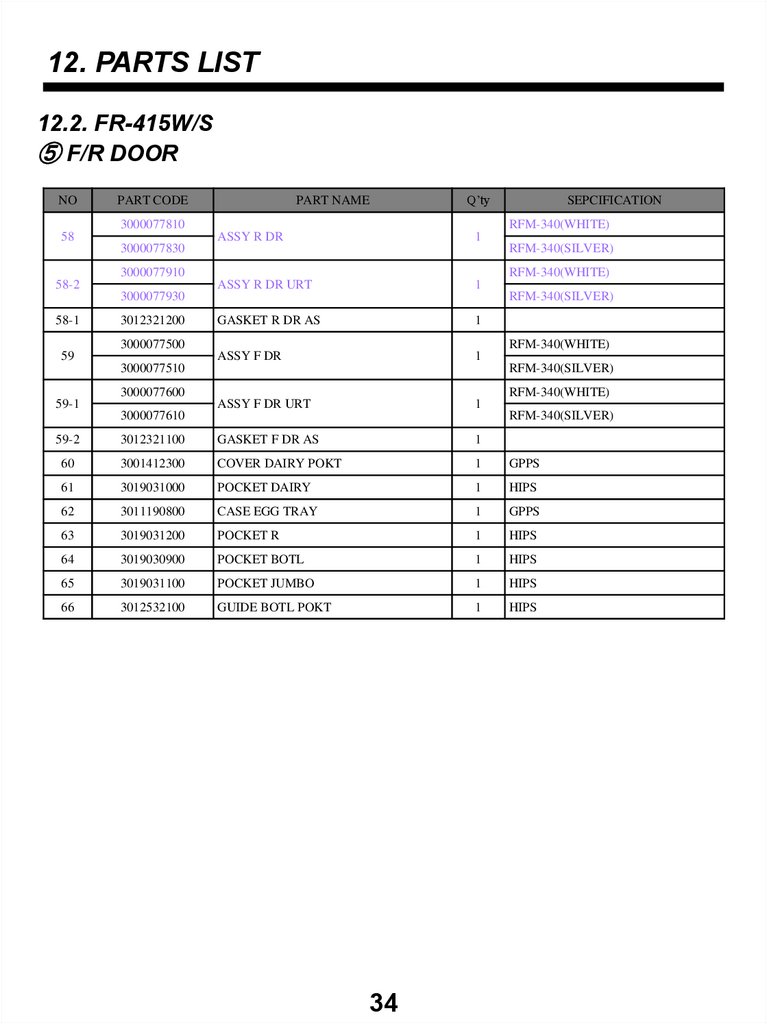

12. PARTS LIST12.2. FR-415W/S

⑤ F/R DOOR

NO

PART CODE

PART NAME

Q’ty

3000077810

58

RFM-340(WHITE)

ASSY R DR

1

3000077830

RFM-340(SILVER)

3000077910

58-2

RFM-340(WHITE)

ASSY R DR URT

1

3000077930

58-1

3012321200

RFM-340(SILVER)

GASKET R DR AS

1

ASSY F DR

1

3000077500

59

RFM-340(WHITE)

3000077510

RFM-340(SILVER)

3000077600

59-1

SEPCIFICATION

RFM-340(WHITE)

ASSY F DR URT

1

3000077610

RFM-340(SILVER)

59-2

3012321100

GASKET F DR AS

1

60

3001412300

COVER DAIRY POKT

1

GPPS

61

3019031000

POCKET DAIRY

1

HIPS

62

3011190800

CASE EGG TRAY

1

GPPS

63

3019031200

POCKET R

1

HIPS

64

3019030900

POCKET BOTL

1

HIPS

65

3019031100

POCKET JUMBO

1

HIPS

66

3012532100

GUIDE BOTL POKT

1

HIPS

34

36.

13. PCB CONTROL FUNCTIONFR-417W, FR-417S

NO

1.

FUCTION

DISPLAY

CONTENTS

1) LOW STEP LED ON : WHEN TEMP S/W IS PRESSED 1 TIME.

2) LOW-MID STEP LED ON : WHEN TEMP S/W IS PRESSED 2 TIMES.

3) MID STEP LED ON : WHEN TEMP S/W IS PRESSED 3 TIMES.

4) MID-HIGH STEP LED ON : WHEN TEMP S/W IS PRESSED 4 TIMES.

5) HIGH STEP LED ON : WHEN TEMP S/W IS PRESSED 5 TIMES.

6) ERROR LED DISPLAY (ON MAIN PCB)

- R1 ERROR : MID LED is on & off continually.

- RT ERROR : LOW-MID LED is on & off continually.

- D1 ERROR : LOW LED is on & off continually.

- DOOR ERROR : LOW-MID & MID LED is on & off continually.

- C1 ERROR : LOW & MID LED is on & off continually.

- F3 ERROR : LOW & LOW-MID LED is on & off continually.

- FORCED DEFROST OF CONDITION : LOW, MID, HIGH Led Lamps

are on.

- SHORT CIRCUIT OF CONDITION for A/S : LOW-MID, MID-HIGH, SCOOL Led Lamps are on.

- SHORT CIRCUIT OF CONDITION for Energy Efficiency : MID-HIGH,

HIGH, S-COOL Led Lamps are on & off.

35

37.

NOFUCTION

CONTENTS

1) TEMP. CONTROL SWITCH

1.1- TEMP. CONTROL

When TEMP CONTROL button is pressed, the led lamps MID,

MID-HIGH,HIGH,LOW,LOW-MID will be on in sequence.

TEMPERATURE will be set if the button doesn’t get pressed again

within 5 sec.

1.2- FORCED DEFROST : will be start when this button pushed for

over 5 seconds continuously.

1.3- SHORT CIRCUIT OPERATION : will be started and stopped when

this button pushed over 30 times.

2) TEMPERATURE CONTROL

2.1- COMP will be controlled by the on/off condition of each mode.

2.2- STEP DIFF of ROOM R : LOW/LOW-MID – 1.5 deg,

LOW-MID/MID – 1.5 deg,

MID/MID-HIGH – 2.0 deg,

MID-HIGH/HIGH – 2.0 deg

2.3- OFF point of ROOM R in MID position : 2.0°C

2.4- ON/OFF DIFF of ROOM R : 1.7°C

2.

TEMPERATURE

ADJUSTMENT

&

CONTROL

3) FORCED DEFROST

3.1- Defrost mode will be Started independent of the cycle.

3.2- The flow is same as the general defrost mode flow.

4) SHORT CIRCUIT OPERATION

4.1- COMP & FAN will be on independent of the operation condition.

4.2- The time limit of SHORT CIRCUIT OPERATION : 18 hrs

36

38.

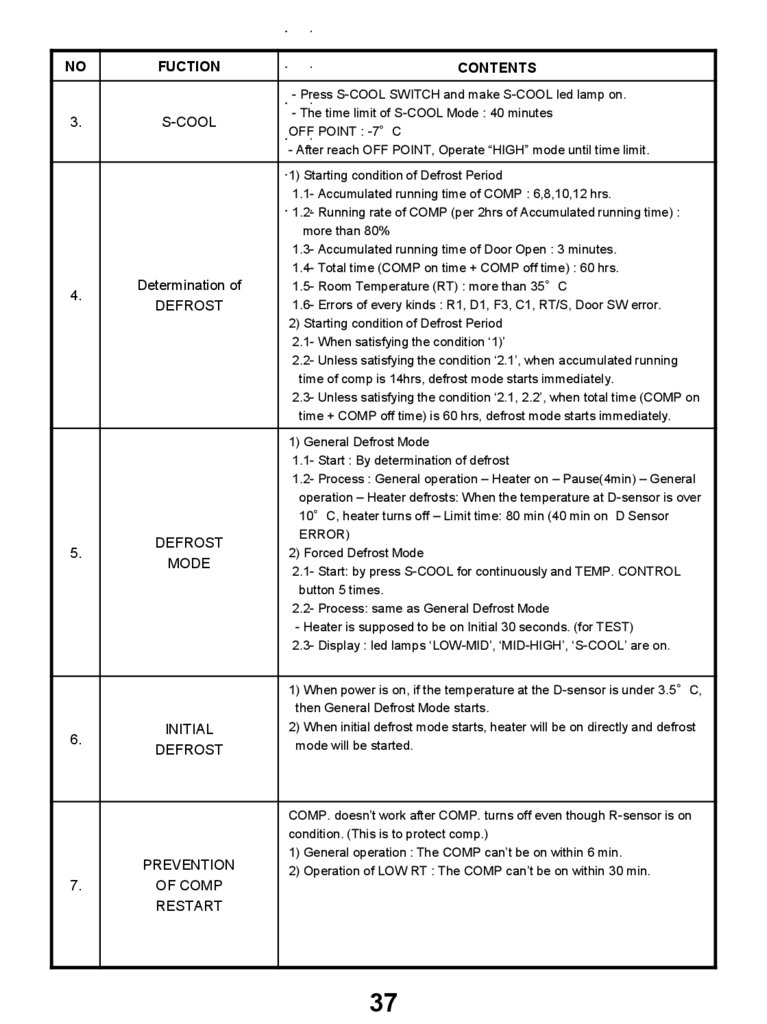

NO3.

4.

5.

6.

7.

FUCTION

S-COOL

Determination of

DEFROST

DEFROST

MODE

INITIAL

DEFROST

PREVENTION

OF COMP

RESTART

CONTENTS

- Press S-COOL SWITCH and make S-COOL led lamp on.

- The time limit of S-COOL Mode : 40 minutes

OFF POINT : -7°C

- After reach OFF POINT, Operate “HIGH” mode until time limit.

1) Starting condition of Defrost Period

1.1- Accumulated running time of COMP : 6,8,10,12 hrs.

1.2- Running rate of COMP (per 2hrs of Accumulated running time) :

more than 80%

1.3- Accumulated running time of Door Open : 3 minutes.

1.4- Total time (COMP on time + COMP off time) : 60 hrs.

1.5- Room Temperature (RT) : more than 35°C

1.6- Errors of every kinds : R1, D1, F3, C1, RT/S, Door SW error.

2) Starting condition of Defrost Period

2.1- When satisfying the condition ‘1)’

2.2- Unless satisfying the condition ‘2.1’, when accumulated running

time of comp is 14hrs, defrost mode starts immediately.

2.3- Unless satisfying the condition ‘2.1, 2.2’, when total time (COMP on

time + COMP off time) is 60 hrs, defrost mode starts immediately.

1) General Defrost Mode

1.1- Start : By determination of defrost

1.2- Process : General operation – Heater on – Pause(4min) – General

operation – Heater defrosts: When the temperature at D-sensor is over

10°C, heater turns off – Limit time: 80 min (40 min on D Sensor

ERROR)

2) Forced Defrost Mode

2.1- Start: by press S-COOL for continuously and TEMP. CONTROL

button 5 times.

2.2- Process: same as General Defrost Mode

- Heater is supposed to be on Initial 30 seconds. (for TEST)

2.3- Display : led lamps ‘LOW-MID’, ‘MID-HIGH’, ‘S-COOL’ are on.

1) When power is on, if the temperature at the D-sensor is under 3.5°C,

then General Defrost Mode starts.

2) When initial defrost mode starts, heater will be on directly and defrost

mode will be started.

COMP. doesn’t work after COMP. turns off even though R-sensor is on

condition. (This is to protect comp.)

1) General operation : The COMP can’t be on within 6 min.

2) Operation of LOW RT : The COMP can’t be on within 30 min.

37

39.

NOFUCTION

CONTENTS

- ERROR DISPLAY

- When error happens, it is displayed on led lamp.

1) R1 ERROR (It happens when R-Sensor is OPEN or SHORT)

1.1- DISPLAY : MID LED is on & off continually.

1.2- CONTROL : Controlled by the condition of RT

(Unit : min)

RT/S TEMP

COMP. Operating TIME

(ON/OFF)

8.

9.

10.

ERROR

DISPLAY

&

CONTROL

SHORT CIRCUIT

TEST

FUNCTION

OF

TIME REDUCTION

~13°C ~19°C ~29°C 29°C~

6/34

10/30

16/24

20/20

1.3- CANCEL : when R-Sensor is working normally.

2) RT ERROR (It happens when RT-Sensor is OPEN or SHORT)

2.1- DISPLAY : LOW-MID LED is on & off continually.

2.2- CONTROL : The system is normally operating but the controlling by

RT-Sensor doesn’t work.

2.3- CANCEL : when RT-Sensor is working normally.

3) D1 ERROR (It happens when D-Sensor is OPEN or SHORT)

3.1- DISPLAY : LOW LED is on & off continually.

3.2- CONTROL : Return to next limit defrost time (80 min)

3.3- CANCEL : when D-Sensor is working normally.

4) DR ERROR

4.1- DISPLAY : LOW-MID,MID LED Lamps are on & off continually.

4.2- CONTROL : Deletion of function related door switch sensing

4.3- If door switch (open & close) is sensed, the error is terminated

automatically

5) C1 ERROR (When D-Sensor is more than -5°C, Comp operates over

3 hrs)

5.1- DISPLAY : LOW & MID LED Lamps are on & off continually.

5.2- CONTROL : The system is normally operating

5.3- CANCEL : When Comp is off, D-Sensor is less than -5°C.

6) F3 ERROR (Return to next limit defrost time (80 min))

6.1- DISPLAY : LOW & LOW-MID LED Lamps are on & off continually.

6.2- CONTROL : At Defrost Mode, Deletion of Pre-cool Mode.

6.3- CANCEL : Completion of defrost returned by D-Sensor.

1) START : by pressing TEMP CONTROL Button 30 times continuously.

2) CANCEL : the system generally operates after the limit time 18 hrs.

passes.

3) DISPLAY : LED lamps are LOW-MID, MID-HIGH, S-COOL on.

4) CONTROL : COMP & FAN will be on independent of the operating

condition. (There is no defrost mode on this test.)

1) HOW TO REDUCE

1 min : Click FAST KEY one time

30 min : If you press FAST KEY continuously, you can reduce 30

minutes on each 2.5 seconds with buzzer.

2) Practice Use : Can be applied to reduce needless time on test.

EX) function of stop for 6 min

38

40.

NO11.

FUCTION

CONTENTS

FUCTION

OF

LOW ROOM

1) Condition of LOW RT TEMP

1.1- LOW RT Period : RT SENSOR ≤ 19°C

1.2- DIFF of LOW ROOM RT : 1 deg (Hysterisys Diff)

2) Control

2.1- When Comp. is on, R-Sensor HTR is off.

When it passes 6 min after COMP is off. R-Sensor HTR is on until

COMP is on.

2.2- COMP can’t be on within 30 min after COMP is off.

2.3- Prevention time of COMP restart can change ; If satisfy ‘a’, ’b’

condition simultaneously, prevention time of COMP restart changes 6

min.

a. Accumulated running time of COMP passes 20 seconds after COMP

is off.

b. R-Sensor is more than ‘ON’ Point TEMP.

2.4- When it is not the mode of LOW ROOM TEMP or RT-Sensor is on

ERROR (open or short), R-Sensor HTR is off.

1) LOW COOLING OPTION

1.1- R-SENSOR OFF POINT ADJUSTMENT (1.5 DEG. DOWN)

1.2- Adjust as below on LOW COOLING MODE for A/S

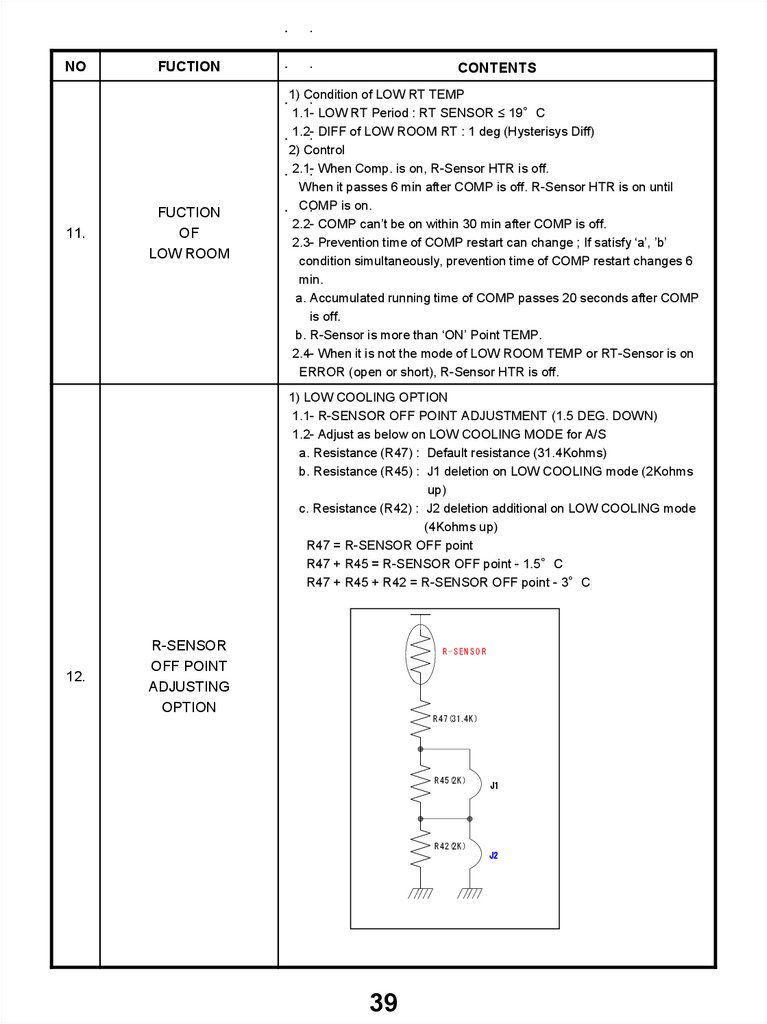

a. Resistance (R47) : Default resistance (31.4Kohms)

b. Resistance (R45) : J1 deletion on LOW COOLING mode (2Kohms

up)

c. Resistance (R42) : J2 deletion additional on LOW COOLING mode

(4Kohms up)

R47 = R-SENSOR OFF point

R47 + R45 = R-SENSOR OFF point - 1.5°C

R47 + R45 + R42 = R-SENSOR OFF point - 3°C

12.

R-SENSOR

OFF POINT

ADJUSTING

OPTION

R -SEN SO R

R 47(31.4K )

R 45(2K )

J1

R 42(2K )

J2

39

41.

NOFUCTION

CONTENTS

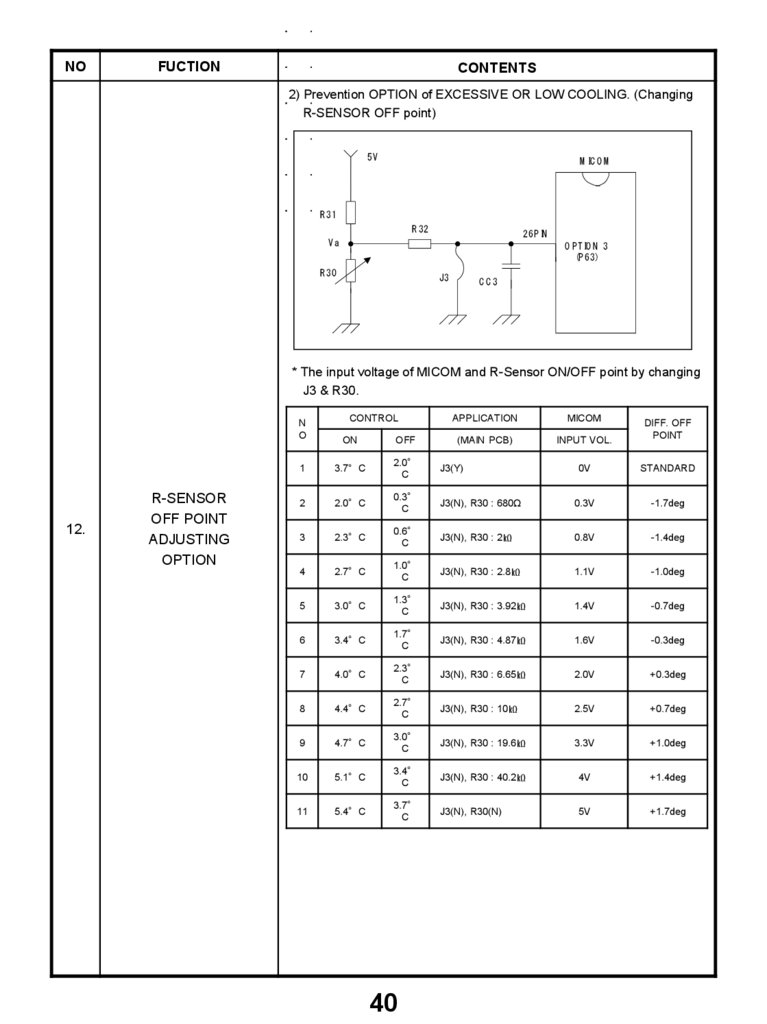

2) Prevention OPTION of EXCESSIVE OR LOW COOLING. (Changing

R-SENSOR OFF point)

5V

M IC O M

R 31

R 32

26P IN

Va

O P TIO N 3

(P 63)

R 30

J3

CC3

* The input voltage of MICOM and R-Sensor ON/OFF point by changing

J3 & R30.

N

O

12.

R-SENSOR

OFF POINT

ADJUSTING

OPTION

CONTROL

APPLICATION

MICOM

(MAIN PCB)

INPUT VOL.

ON

OFF

1

3.7°C

2.0°

C

J3(Y)

2

2.0°C

0.3°

C

3

2.3°C

4

DIFF. OFF

POINT

0V

STANDARD

J3(N), R30 : 680Ω

0.3V

-1.7deg

0.6°

C

J3(N), R30 : 2㏀

0.8V

-1.4deg

2.7°C

1.0°

C

J3(N), R30 : 2.8㏀

1.1V

-1.0deg

5

3.0°C

1.3°

C

J3(N), R30 : 3.92㏀

1.4V

-0.7deg

6

3.4°C

1.7°

C

J3(N), R30 : 4.87㏀

1.6V

-0.3deg

7

4.0°C

2.3°

C

J3(N), R30 : 6.65㏀

2.0V

+0.3deg

8

4.4°C

2.7°

C

J3(N), R30 : 10㏀

2.5V

+0.7deg

9

4.7°C

3.0°

C

J3(N), R30 : 19.6㏀

3.3V

+1.0deg

10

5.1°C

3.4°

C

J3(N), R30 : 40.2㏀

4V

+1.4deg

11

5.4°C

3.7°

C

J3(N), R30(N)

5V

+1.7deg

40

42.

NOFUCTION

CONTENTS

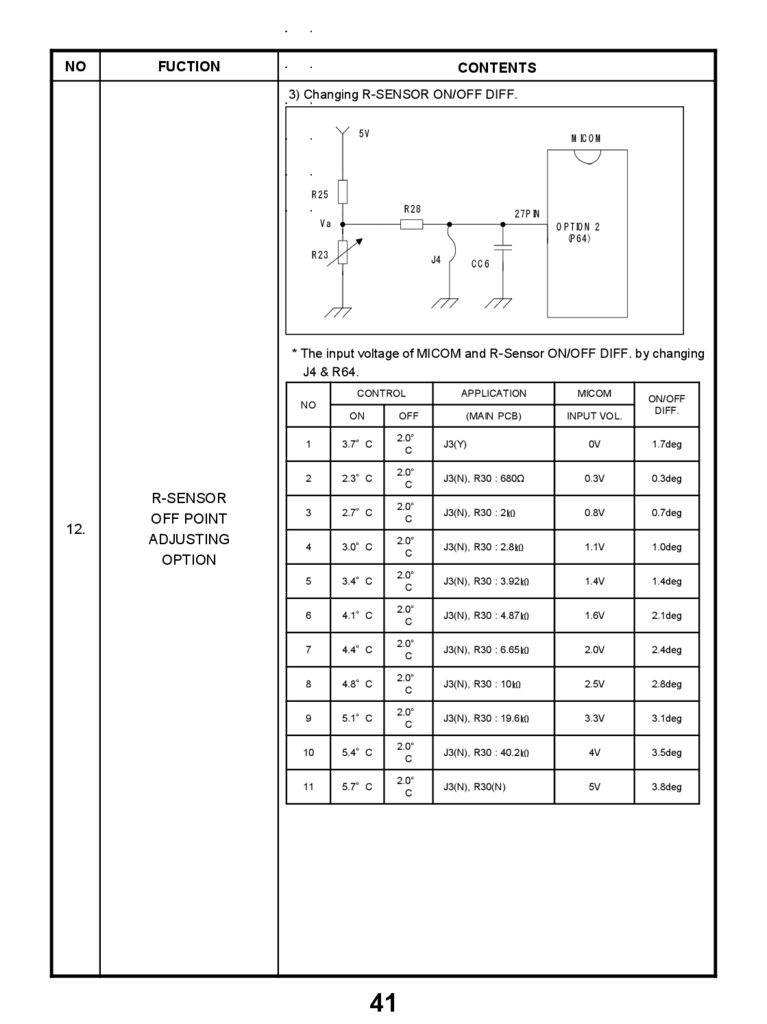

3) Changing R-SENSOR ON/OFF DIFF.

5V

M IC O M

R 25

R 28

27P IN

Va

O P TIO N 2

(P 64)

R 23

J4

CC6

* The input voltage of MICOM and R-Sensor ON/OFF DIFF. by changing

J4 & R64.

CONTROL

APPLICATION

MICOM

(MAIN PCB)

INPUT VOL.

NO

12.

R-SENSOR

OFF POINT

ADJUSTING

OPTION

ON

OFF

1

3.7°C

2.0°

C

J3(Y)

2

2.3°C

2.0°

C

3

2.7°C

4

ON/OFF

DIFF.

0V

1.7deg

J3(N), R30 : 680Ω

0.3V

0.3deg

2.0°

C

J3(N), R30 : 2㏀

0.8V

0.7deg

3.0°C

2.0°

C

J3(N), R30 : 2.8㏀

1.1V

1.0deg

5

3.4°C

2.0°

C

J3(N), R30 : 3.92㏀

1.4V

1.4deg

6

4.1°C

2.0°

C

J3(N), R30 : 4.87㏀

1.6V

2.1deg

7

4.4°C

2.0°

C

J3(N), R30 : 6.65㏀

2.0V

2.4deg

8

4.8°C

2.0°

C

J3(N), R30 : 10㏀

2.5V

2.8deg

9

5.1°C

2.0°

C

J3(N), R30 : 19.6㏀

3.3V

3.1deg

10

5.4°C

2.0°

C

J3(N), R30 : 40.2㏀

4V

3.5deg

11

5.7°C

2.0°

C

J3(N), R30(N)

5V

3.8deg

41

electronics

electronics