Similar presentations:

Service training on demand

1.

一站式满足您的物料搬运需求Service training on demand

2018.03.01

诺力智能装备股份有限公司

NOBLELIFT INTELLIGENT EQUIPMENT CO.,LTD.

诺力智能装备股份有限公司

2.

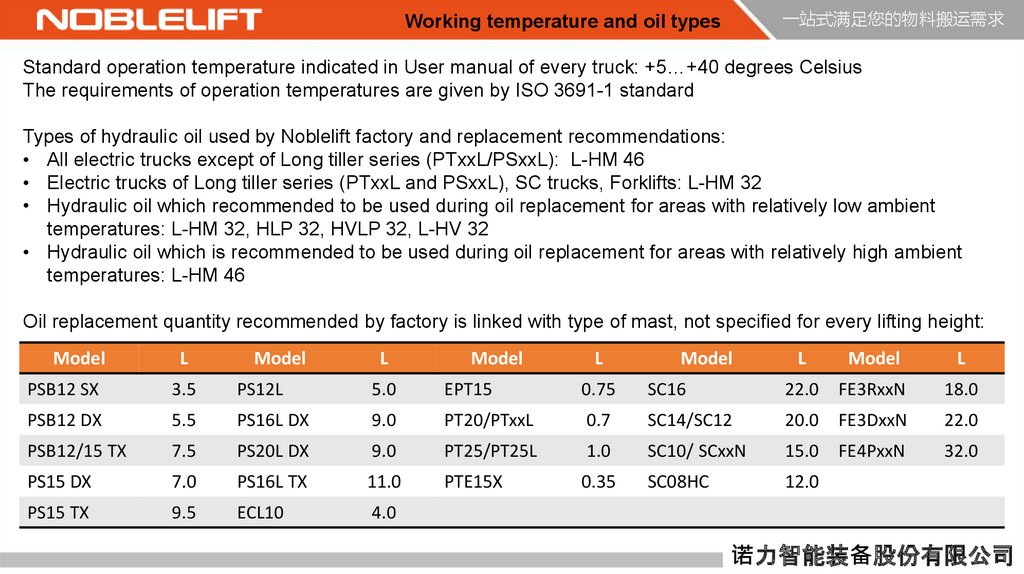

一站式满足您的物料搬运需求Working temperature and oil types

Standard operation temperature indicated in User manual of every truck: +5…+40 degrees Celsius

The requirements of operation temperatures are given by ISO 3691-1 standard

Types of hydraulic oil used by Noblelift factory and replacement recommendations:

• All electric trucks except of Long tiller series (PTxxL/PSxxL): L-HM 46

• Electric trucks of Long tiller series (PTxxL and PSxxL), SC trucks, Forklifts: L-HM 32

• Hydraulic oil which recommended to be used during oil replacement for areas with relatively low ambient

temperatures: L-HM 32, HLP 32, HVLP 32, L-HV 32

• Hydraulic oil which is recommended to be used during oil replacement for areas with relatively high ambient

temperatures: L-HM 46

Oil replacement quantity recommended by factory is linked with type of mast, not specified for every lifting height:

Model

L

Model

L

Model

L

Model

L

Model

L

PSB12 SX

3.5

PS12L

5.0

EPT15

0.75

SC16

22.0

FE3RxxN

18.0

PSB12 DX

5.5

PS16L DX

9.0

PT20/PTxxL

0.7

SC14/SC12

20.0

FE3DxxN

22.0

PSB12/15 TX

7.5

PS20L DX

9.0

PT25/PT25L

1.0

SC10/ SCxxN

15.0

FE4PxxN

32.0

PS15 DX

7.0

PS16L TX

11.0

PTE15X

0.35

SC08HC

12.0

PS15 TX

9.5

ECL10

4.0

诺力智能装备股份有限公司

3.

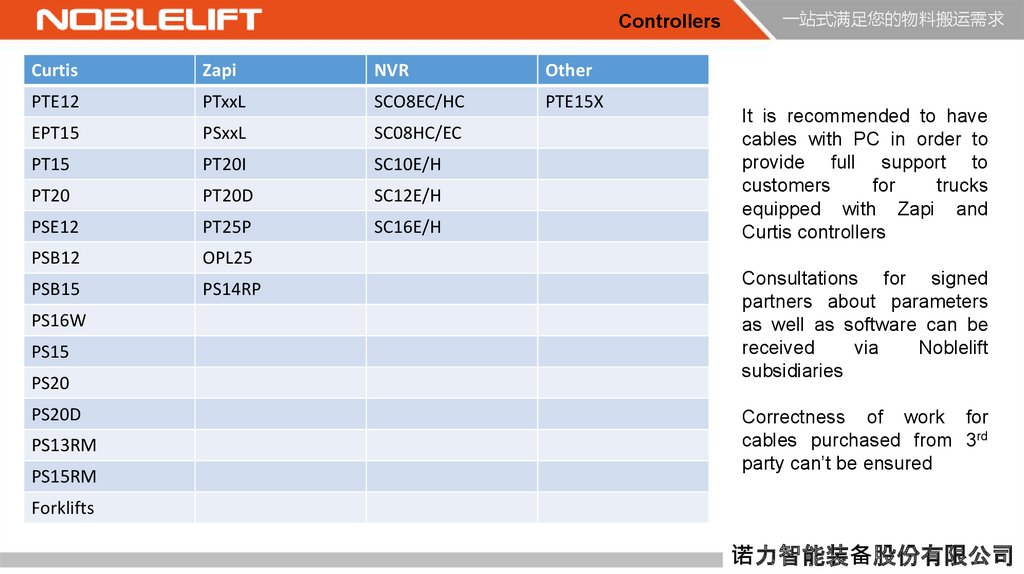

ControllersCurtis

Zapi

NVR

Other

PTE12

PTxxL

SCO8EC/HC

PTE15X

EPT15

PSxxL

SC08HC/EC

PT15

PT20I

SC10E/H

PT20

PT20D

SC12E/H

PSE12

PT25P

SC16E/H

PSB12

OPL25

PSB15

PS14RP

PS16W

PS15

PS20

PS20D

PS13RM

PS15RM

一站式满足您的物料搬运需求

It is recommended to have

cables with PC in order to

provide full support to

customers

for

trucks

equipped with Zapi and

Curtis controllers

Consultations for signed

partners about parameters

as well as software can be

received

via

Noblelift

subsidiaries

Correctness of work for

cables purchased from 3rd

party can’t be ensured

Forklifts

诺力智能装备股份有限公司

4.

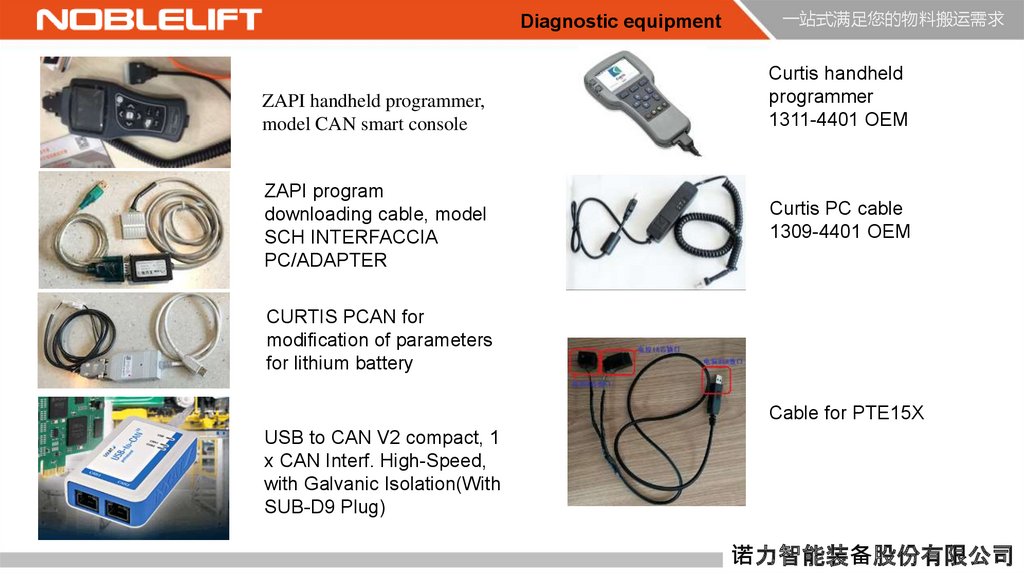

Diagnostic equipmentZAPI handheld programmer,

model CAN smart console

ZAPI program

downloading cable, model

SCH INTERFACCIA

PC/ADAPTER

一站式满足您的物料搬运需求

Curtis handheld

programmer

1311-4401 OEM

Curtis PC cable

1309-4401 OEM

CURTIS PCAN for

modification of parameters

for lithium battery

Cable for PTE15X

USB to CAN V2 compact, 1

x CAN Interf. High-Speed,

with Galvanic Isolation(With

SUB-D9 Plug)

诺力智能装备股份有限公司

5.

Chains一站式满足您的物料搬运需求

When a forklift truck leaf chain is in mint condition, the rivet pins and articulating link apertures are almost

perfectly cylindrical in shape and have a very smooth surface finish.

This ideal state has excellent bearing properties which are necessary for smooth, quiet and efficient operation.

It is inevitable, however, that a forklift truck chain will wear leading to the deterioration of these properties.

When the rivet pins wear (a process known as Galling). Furthermore, the apertures in the link plates elongate.

Most leaf chain rivet pins are produced with a case hardened outer surface. It is generally accepted that a 3%

worn leaf chain will lose approximately 18% of its tensile strength.

Over time the castellations will become so deep that the case hardening of the leaf chain rivet pin will be

completely destroyed. Once the surface has worn away it will become considerably weaker and potentially

very dangerous. It is, therefore, necessary to limit the level of acceptable leaf chain wear.

The FB professional chain wear gauge (CWG) is a precision tool that has been purposely designed for the

accurate measurement of chain wear in leaf chain/forklift chain. It states in the accompanying instructions that

at a percentage elongation of 2% the chain will need to be carefully monitored if it is to be still used. At 3%

elongation, the chain is considered a safety risk and should be replaced immediately.

诺力智能装备股份有限公司

6.

一站式满足您的物料搬运需求Chains

Type

LH0866

Types

Chains

CL12S

LH1234

8x31 CL12F.2-5

PS E/B12

CL12D

LH1046

12.7 mm / ½”

15.875 mm / 5/8”

LH1066

CL12F

LH1234

CL15D

LH1244

8x40 GB/T882-2008

CL15F

LH1244

8x35 GB/T882-2008

CL15H

LH1066

6x35 GB/T882-2008

CL15Z

LH1066

6x35 GB/T882-2008

PS16W

CG16H

LH1066

6x35 GB/T882-2008

ECL10

ECL10

6x40 GB/T880-2008

PS12LD

12A-1

LH1046

PS12LF

LH1066

6x45 GB/T882-2008

PS16LD/M

LH1066

6x45 GB/T882-2008

PS16LF/M

LH1066

6x45 GB/T882-2008

PS16LH/M

LH1066

6x45 GB/T882-2008

PS16LZ/M

LH1066

6x45 GB/T882-2008

PS20LD/M

LH1266

8x50 GB/T882-2008

PS B15

PS 12L

PS 16L/SL

LH1234

LH1244

LH1266

PS 20L/SL

19.05 mm / ¾”

12A-1

PS 15/SL

PS 20

At 3% elongation, the chain is considered a safety

risk and should be replaced immediately.

Pins

6x40 GB/T880-2008

8x31 CL12F.2-5

Pitch (mm/inches) NEW

LH1044

LH1046

Models

CG

CLB12

CS12

CS15

6x35 GB/T882-2008

PS20LF/M

LH1266

8x50 GB/T882-2008

PS20LH/M

PS20LZ/M

LH1266

8x50 GB/T882-2008

LH1266

8x50 GB/T882-2008

PS20LZ/M

LH1066

6x45 GB/T882-2008

CS15D/M

LH1244

8x40 GB/T882-2008

CS15F/M

LH1244

8x35 GB/T882-2008

CS15Z/M

LH1066

6x45 GB/T882-2008

CS20D

LH1066

6x45 GB/T882-2008

CSD20D

LH1244

8x35 GB/T882-2008

CSD20F

LH1244

8x35 GB/T882-2008

CG

LH0866

5x40 GB/T882-2008

CLB12/F

LH1234

CLB12I

LH1234

8x40 CS1232.4-2

8x40 CS1232.4-2

CS12/F

LH1234

CS15/M/G

LH1244

8x40 CS1232.4-2

8x40 GB/T882-2008

CS15F/M

LH1244

CS15III/M

CS15T/TG

LH0866

8x40 CS1232.4-2

5x40 GB/T882-2008

LH0866

5x40 GB/T882-2008

CS15T/TG

LH1044

6x35 GB/T882-2008

诺力智能装备股份有限公司

7.

Chains一站式满足您的物料搬运需求

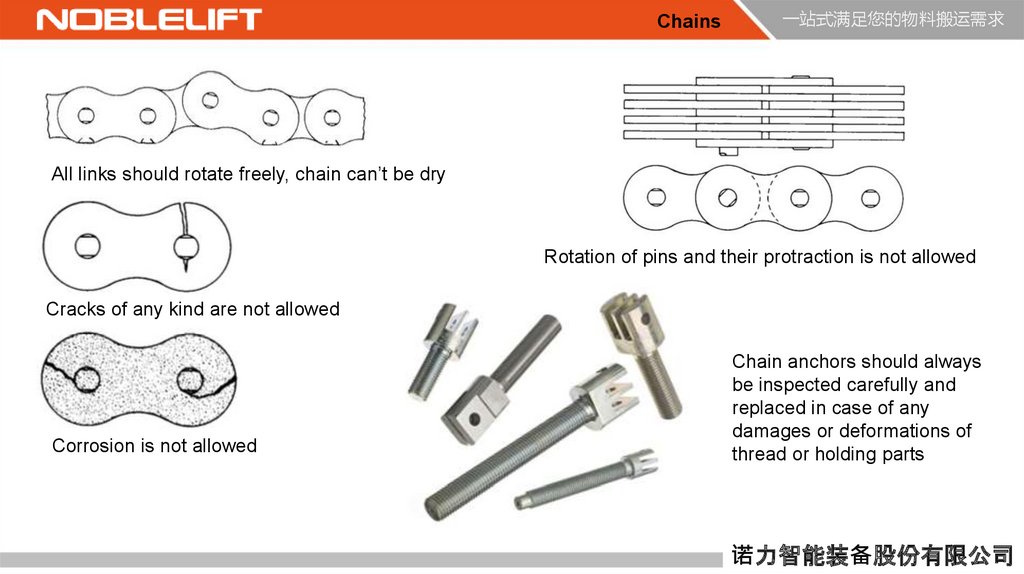

All links should rotate freely, chain can’t be dry

Rotation of pins and their protraction is not allowed

Cracks of any kind are not allowed

Corrosion is not allowed

Chain anchors should always

be inspected carefully and

replaced in case of any

damages or deformations of

thread or holding parts

诺力智能装备股份有限公司

8.

Electromagnetic brakes一站式满足您的物料搬运需求

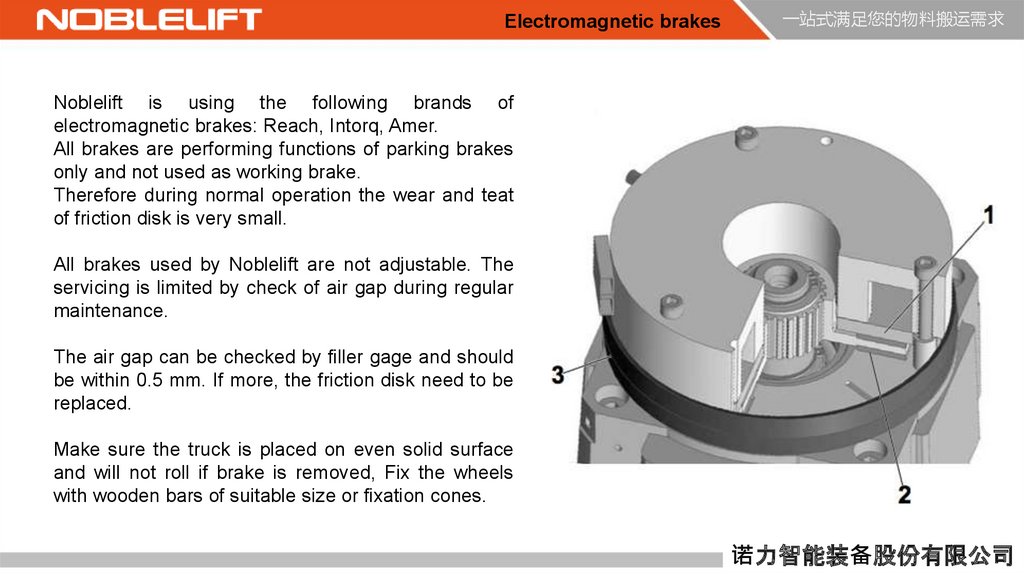

Noblelift is using the following brands of

electromagnetic brakes: Reach, Intorq, Amer.

All brakes are performing functions of parking brakes

only and not used as working brake.

Therefore during normal operation the wear and teat

of friction disk is very small.

All brakes used by Noblelift are not adjustable. The

servicing is limited by check of air gap during regular

maintenance.

The air gap can be checked by filler gage and should

be within 0.5 mm. If more, the friction disk need to be

replaced.

Make sure the truck is placed on even solid surface

and will not roll if brake is removed, Fix the wheels

with wooden bars of suitable size or fixation cones.

诺力智能装备股份有限公司

9.

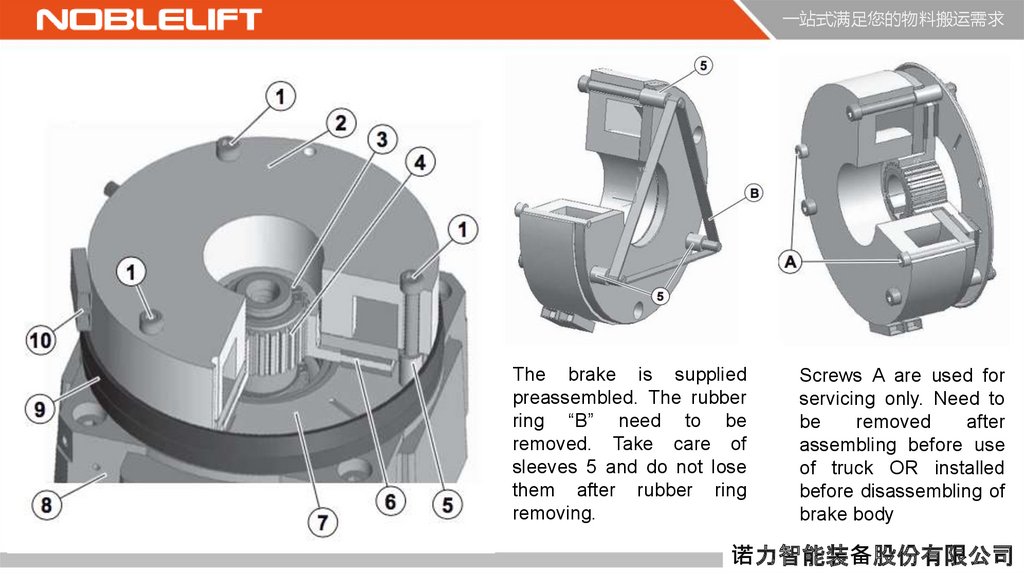

一站式满足您的物料搬运需求The brake is supplied

preassembled. The rubber

ring “B” need to be

removed. Take care of

sleeves 5 and do not lose

them after rubber ring

removing.

Screws A are used for

servicing only. Need to

be

removed

after

assembling before use

of truck OR installed

before disassembling of

brake body

诺力智能装备股份有限公司

10.

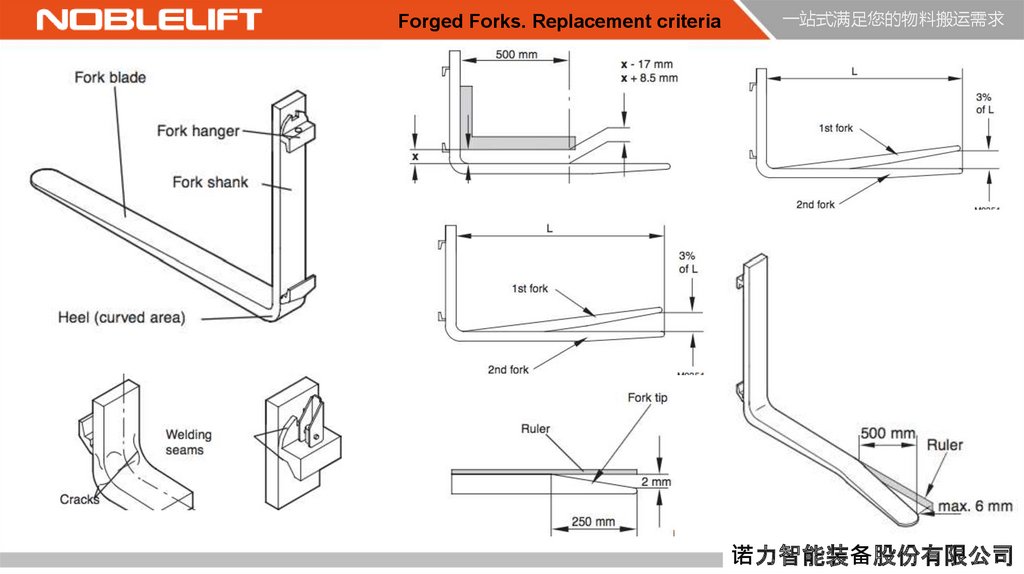

Forged Forks. Replacement criteria一站式满足您的物料搬运需求

诺力智能装备股份有限公司

11.

Welded Forks一站式满足您的物料搬运需求

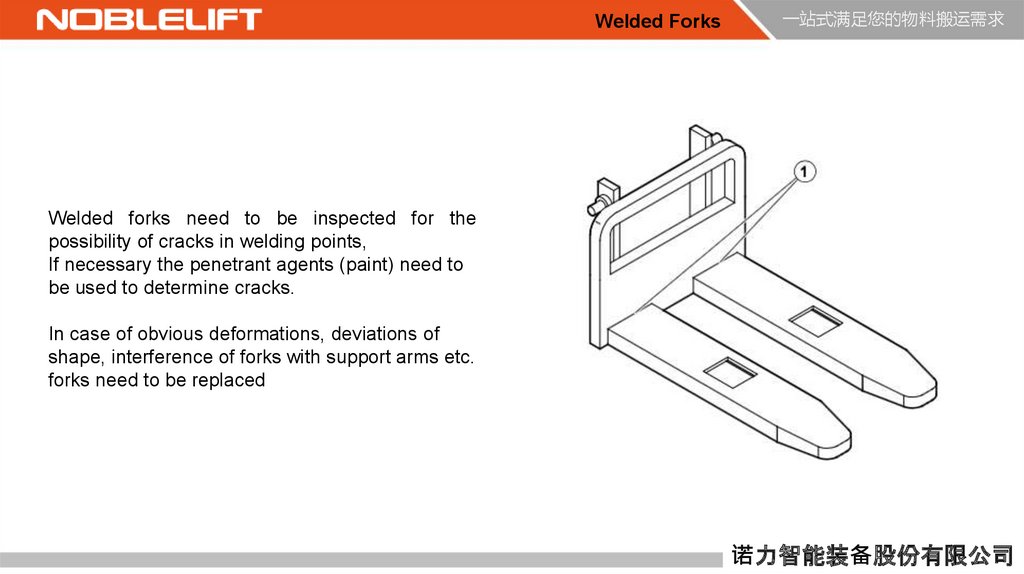

Welded forks need to be inspected for the

possibility of cracks in welding points,

If necessary the penetrant agents (paint) need to

be used to determine cracks.

In case of obvious deformations, deviations of

shape, interference of forks with support arms etc.

forks need to be replaced

诺力智能装备股份有限公司

12.

Cylinders and seals一站式满足您的物料搬运需求

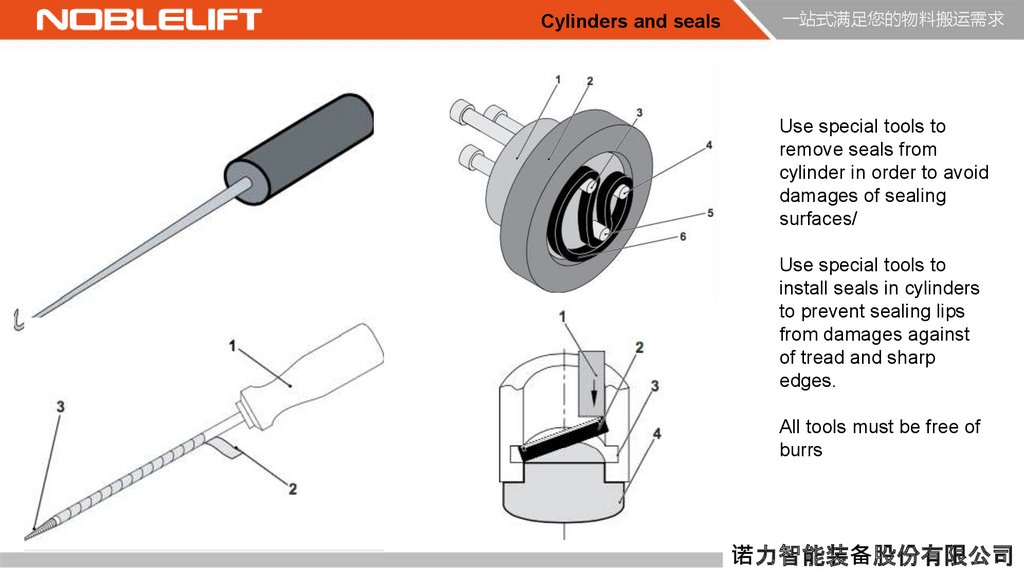

Use special tools to

remove seals from

cylinder in order to avoid

damages of sealing

surfaces/

Use special tools to

install seals in cylinders

to prevent sealing lips

from damages against

of tread and sharp

edges.

All tools must be free of

burrs

诺力智能装备股份有限公司

13.

Mast and rollers adjustment一站式满足您的物料搬运需求

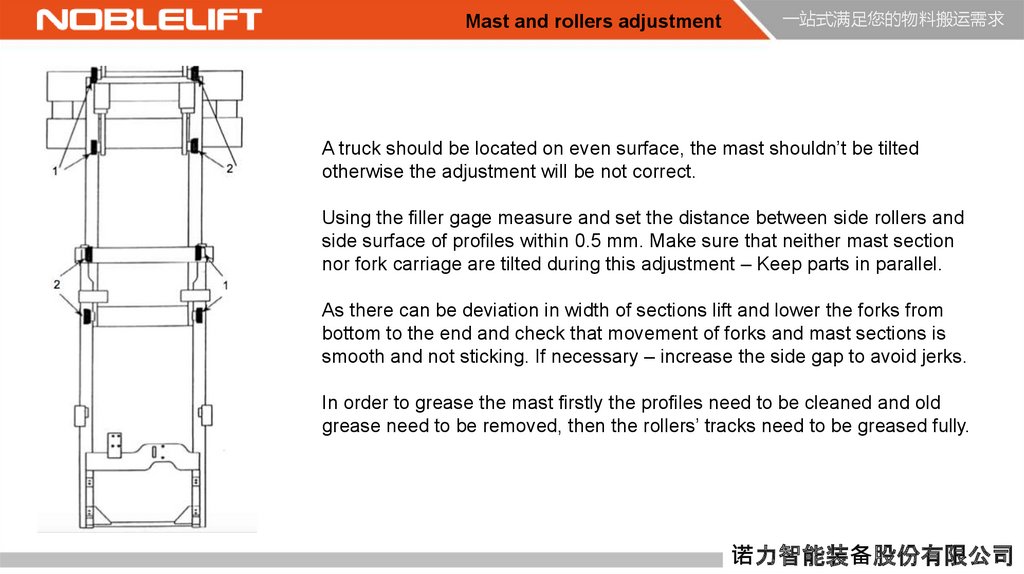

A truck should be located on even surface, the mast shouldn’t be tilted

otherwise the adjustment will be not correct.

Using the filler gage measure and set the distance between side rollers and

side surface of profiles within 0.5 mm. Make sure that neither mast section

nor fork carriage are tilted during this adjustment – Keep parts in parallel.

As there can be deviation in width of sections lift and lower the forks from

bottom to the end and check that movement of forks and mast sections is

smooth and not sticking. If necessary – increase the side gap to avoid jerks.

In order to grease the mast firstly the profiles need to be cleaned and old

grease need to be removed, then the rollers’ tracks need to be greased fully.

诺力智能装备股份有限公司

14.

Lubricants一站式满足您的物料搬运需求

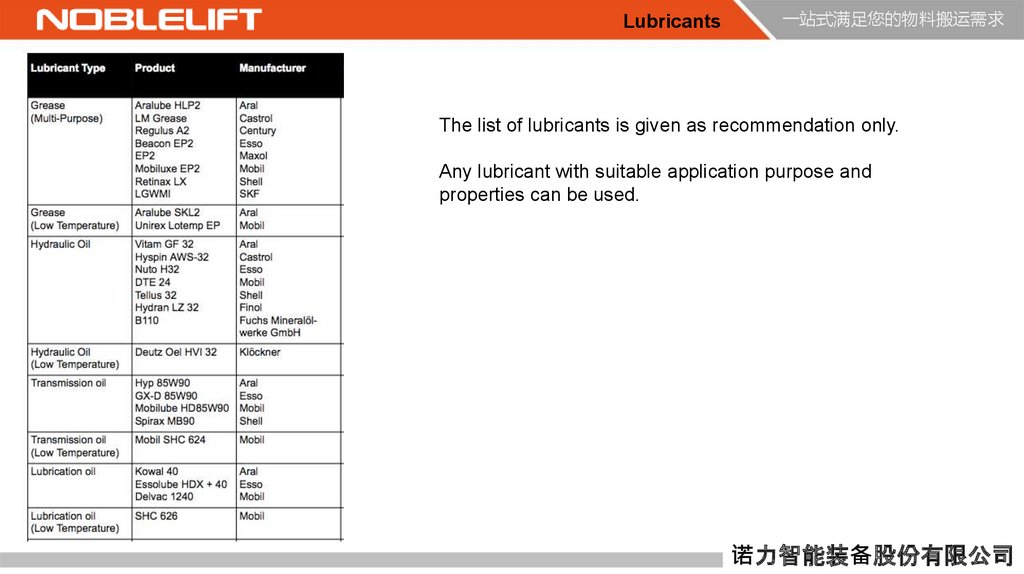

The list of lubricants is given as recommendation only.

Any lubricant with suitable application purpose and

properties can be used.

诺力智能装备股份有限公司

15.

Contactors一站式满足您的物料搬运需求

Contacts of contactors are subjects of natural wear and tear.

If the silver coating is worn out or damaged, the contactor

need to be replaced.

The cleaning of contacts from results of burning (blackened

and other defects) will not solve the problem and generally will

cause the wear even faster.

Springs of contactor must be free of any defects and

corrosion.

In order to check the coil measure its resistance. If the

resistance is endless or no resistance recorded – the coil is

damaged and contactor needs to be replaced.

诺力智能装备股份有限公司

16.

一站式满足您的物料搬运需求THANK YOU

NOBLELIFT INTELLIGENT EQUIPMENT CO.,LTD.

Add: #528 Changzhou Road, Taihu Sub-district, Changxing, Zhejiang, China

Tel: +86-572-6210817

Fax: +86-572-6120777

Web : www.noblelift.com

Email: info@noblelift.com

诺力智能装备股份有限公司

mechanics

mechanics advertising

advertising