Similar presentations:

Buckling-restrained brace

1.

Chapter 1: Composition and history of Buckling‐restrained BracesBUCKLING-RESTRAINED BRACE

HISTORY, DESIGN and APPLICATIONS

Toru Takeuchi, Akira Wada

Ryota Matsui, Ben Sitler, Pao-Chun Lin,

Fatih Sutcu, Hiroyasu Sakata, Zhe Qu

1

1

Buckling‐restrained Braces and Applications

2.

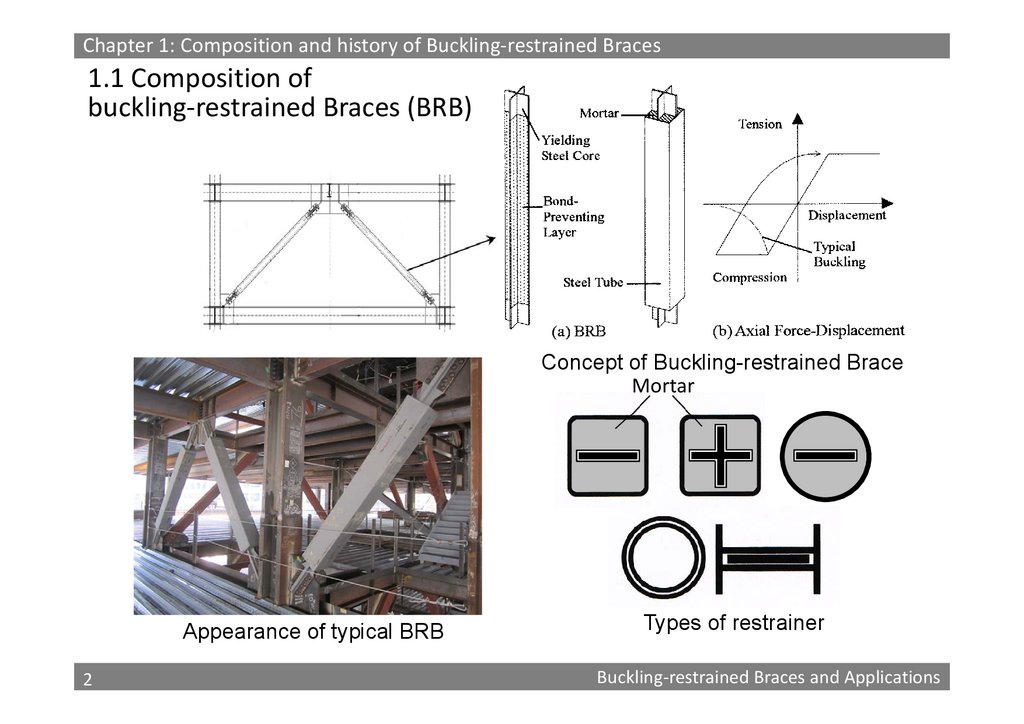

Chapter 1: Composition and history of Buckling‐restrained Braces1.1 Composition of

buckling‐restrained Braces (BRB)

Concept of Buckling-restrained Brace

Mortar

Appearance of typical BRB

2

2

Types of restrainer

Buckling‐restrained Braces and Applications

3.

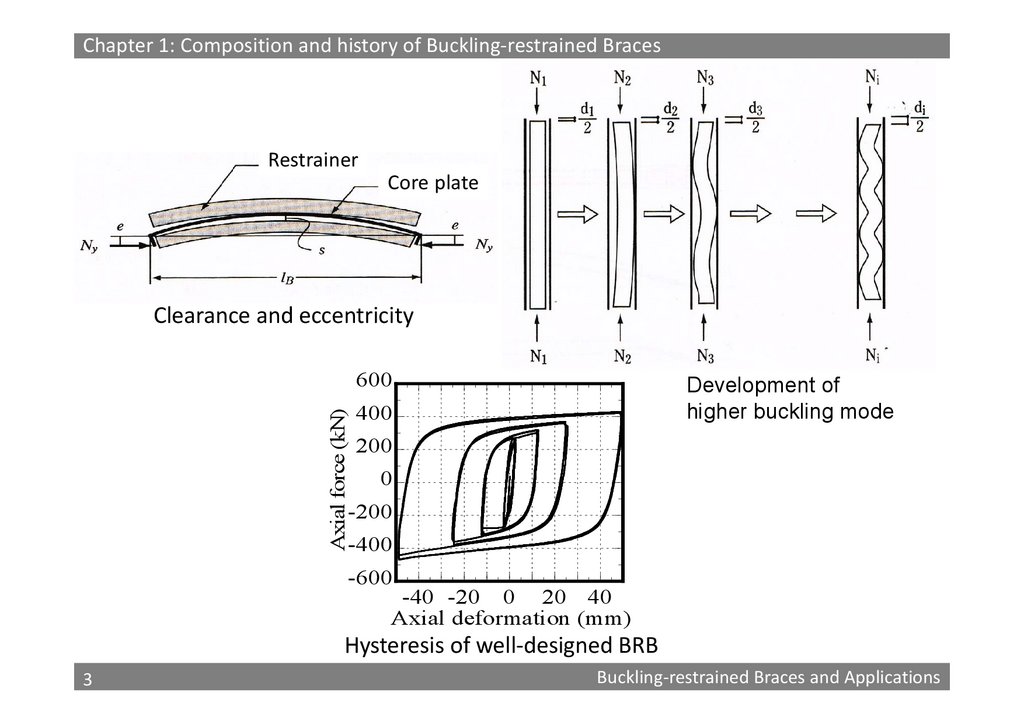

Chapter 1: Composition and history of Buckling‐restrained BracesRestrainer

Core plate

Clearance and eccentricity

Axial force (kN)

600

Development of

higher buckling mode

400

200

0

-200

-400

-600

-40 -20 0 20 40

Axial deformation (mm)

Hysteresis of well‐designed BRB

3

3

Buckling‐restrained Braces and Applications

4.

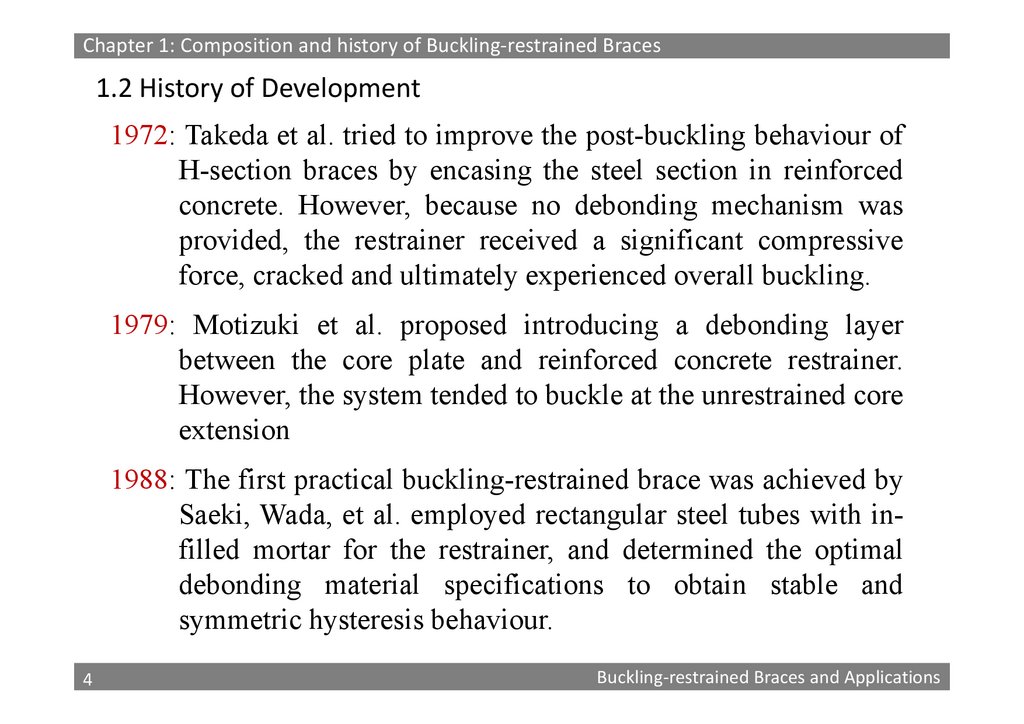

Chapter 1: Composition and history of Buckling‐restrained Braces1.2 History of Development

1972: Takeda et al. tried to improve the post-buckling behaviour of

H-section braces by encasing the steel section in reinforced

concrete. However, because no debonding mechanism was

provided, the restrainer received a significant compressive

force, cracked and ultimately experienced overall buckling.

1979: Motizuki et al. proposed introducing a debonding layer

between the core plate and reinforced concrete restrainer.

However, the system tended to buckle at the unrestrained core

extension

1988: The first practical buckling-restrained brace was achieved by

Saeki, Wada, et al. employed rectangular steel tubes with infilled mortar for the restrainer, and determined the optimal

debonding material specifications to obtain stable and

symmetric hysteresis behaviour.

4

4

Buckling‐restrained Braces and Applications

5.

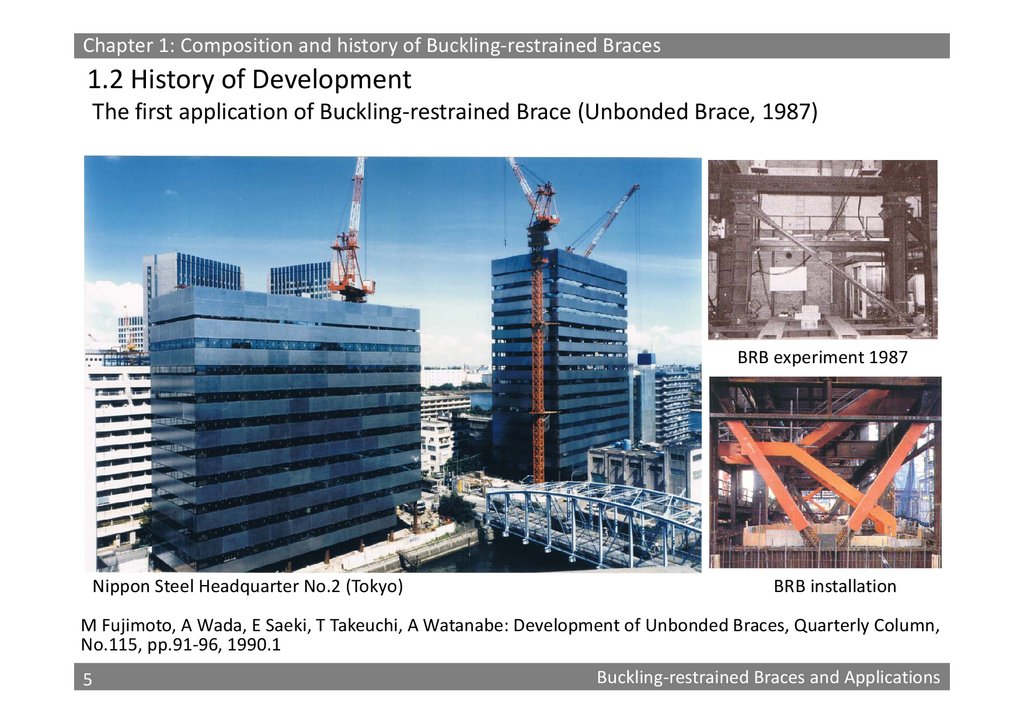

Chapter 1: Composition and history of Buckling‐restrained Braces1.2 History of Development

The first application of Buckling‐restrained Brace (Unbonded Brace, 1987)

BRB experiment 1987

Nippon Steel Headquarter No.2 (Tokyo)

BRB installation

M Fujimoto, A Wada, E Saeki, T Takeuchi, A Watanabe: Development of Unbonded Braces, Quarterly Column,

No.115, pp.91‐96, 1990.1

5

5

Buckling‐restrained Braces and Applications

6.

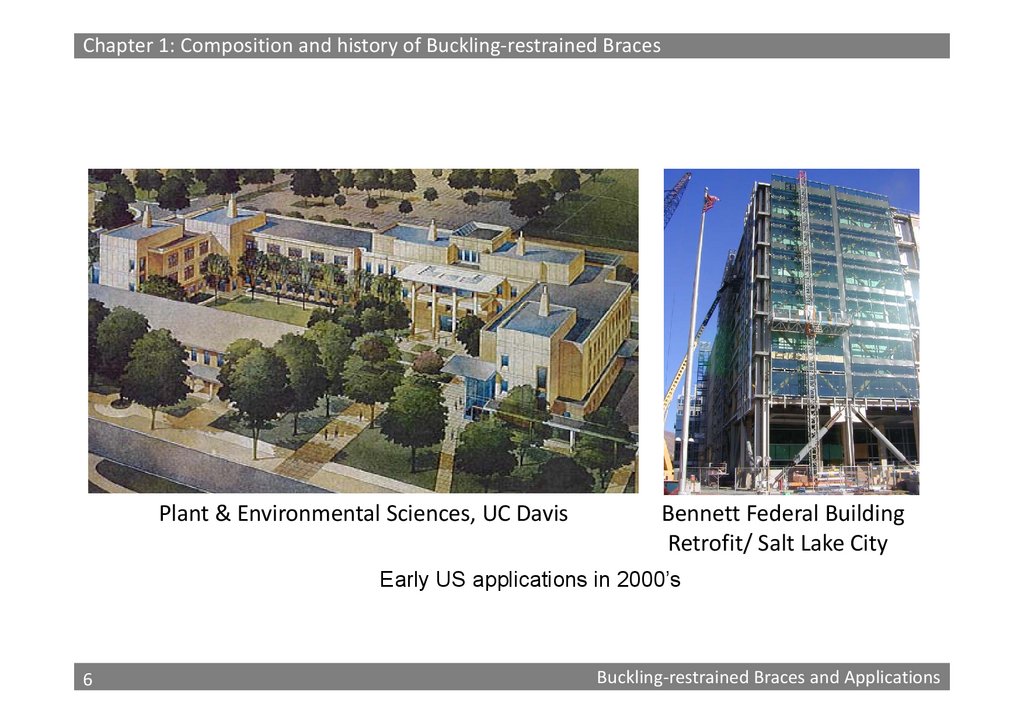

Chapter 1: Composition and history of Buckling‐restrained BracesPlant & Environmental Sciences, UC Davis

Bennett Federal Building

Retrofit/ Salt Lake City

Early US applications in 2000’s

6

6

Buckling‐restrained Braces and Applications

7.

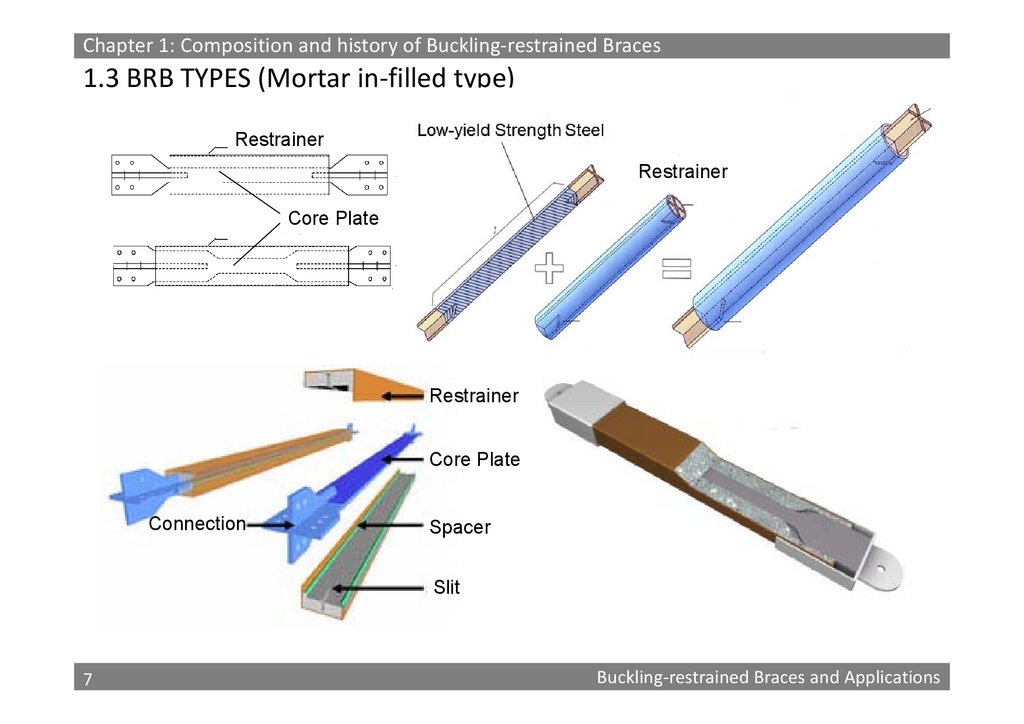

Chapter 1: Composition and history of Buckling‐restrained Braces1.3 BRB TYPES (Mortar in‐filled type)

Restrainer

Restrainer

Core Plate

Restrainer

Core Plate

Connection

Spacer

Slit

7

7

Buckling‐restrained Braces and Applications

8.

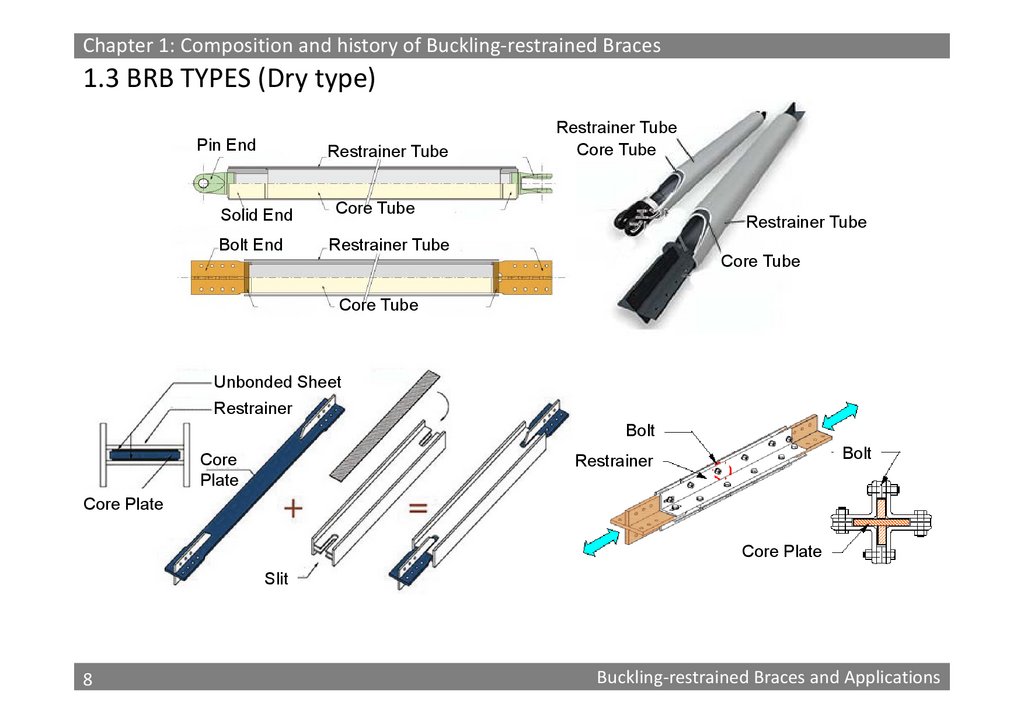

Chapter 1: Composition and history of Buckling‐restrained Braces1.3 BRB TYPES (Dry type)

Pin End

Restrainer Tube

Solid End

Bolt End

Restrainer Tube

Core Tube

Core Tube

Restrainer Tube

Restrainer Tube

Core Tube

Core Tube

Unbonded Sheet

Restrainer

Bolt

Core

Plate

Bolt

Restrainer

Core Plate

Core Plate

Slit

8

8

Buckling‐restrained Braces and Applications

9.

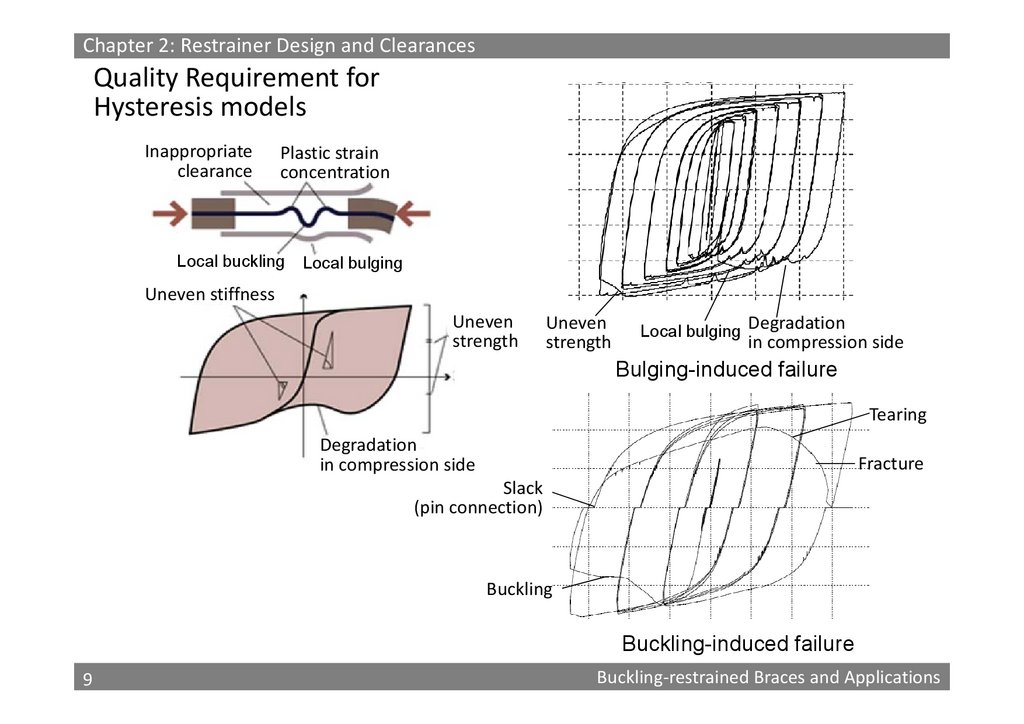

Chapter 2: Restrainer Design and ClearancesQuality Requirement for

Hysteresis models

Inappropriate

clearance

Plastic strain

concentration

Local buckling

Local bulging

Uneven stiffness

Uneven

strength

Uneven

strength

Local bulging Degradation

in compression side

Bulging-induced failure

Tearing

Degradation

in compression side

Fracture

Slack

(pin connection)

Buckling

Buckling-induced failure

9

9

Buckling‐restrained Braces and Applications

10.

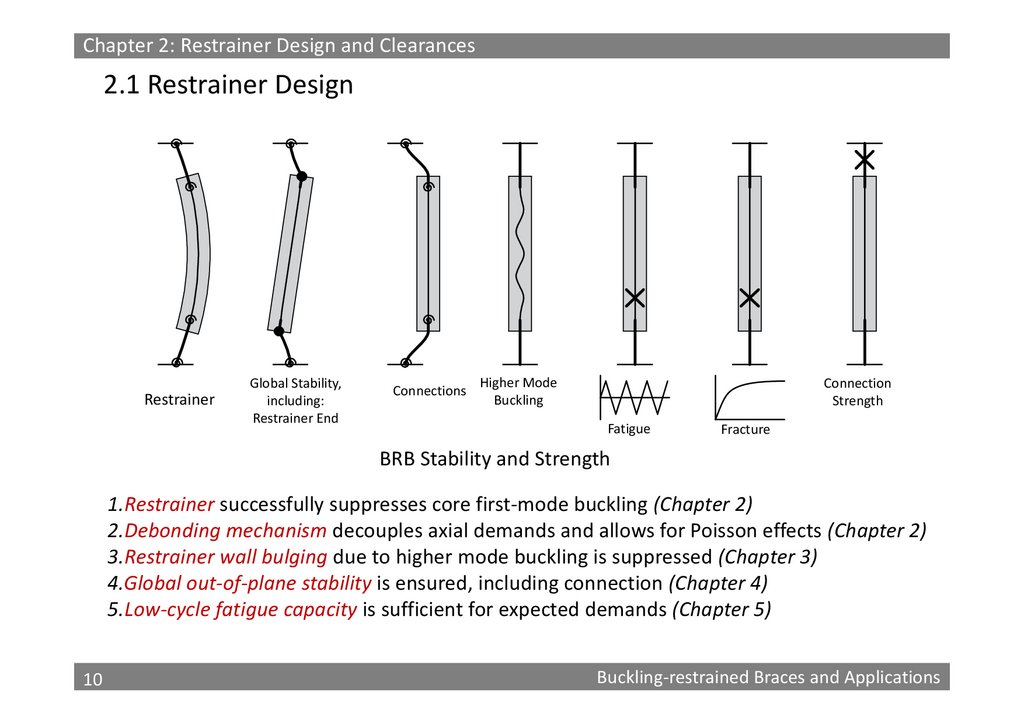

Chapter 2: Restrainer Design and Clearances2.1 Restrainer Design

Restrainer

Global Stability,

including:

Restrainer End

Connections

Higher Mode

Buckling

Connection

Strength

Fatigue

Fracture

BRB Stability and Strength

1.Restrainer successfully suppresses core first‐mode buckling (Chapter 2)

2.Debonding mechanism decouples axial demands and allows for Poisson effects (Chapter 2)

3.Restrainer wall bulging due to higher mode buckling is suppressed (Chapter 3)

4.Global out‐of‐plane stability is ensured, including connection (Chapter 4)

5.Low‐cycle fatigue capacity is sufficient for expected demands (Chapter 5)

10

10

Buckling‐restrained Braces and Applications

11.

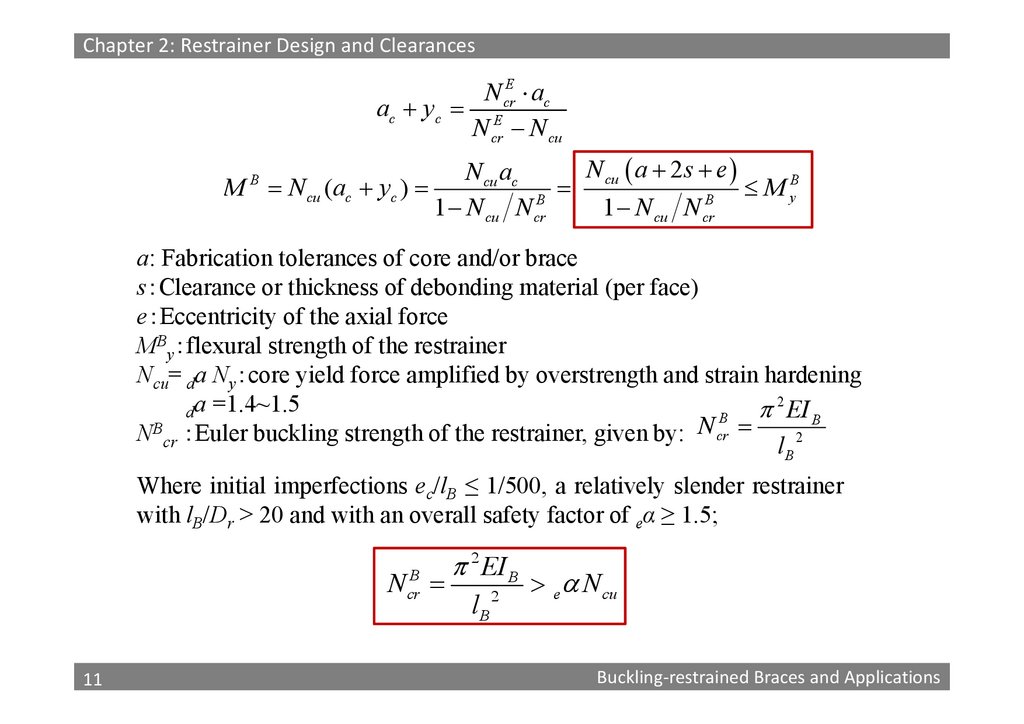

Chapter 2: Restrainer Design and ClearancesN crE ac

ac yc E

N cr N cu

N cu a 2s e

N cu ac

B

M N cu (ac yc )

M

y

1 N cu N crB

1 N cu N crB

B

a: Fabrication tolerances of core and/or brace

s Clearance or thickness of debonding material (per face)

e Eccentricity of the axial force

MBy flexural strength of the restrainer

Ncu= da Ny core yield force amplified by overstrength and strain hardening

da =1.4~1.5

2 EI B

B

NBcr Euler buckling strength of the restrainer, given by: N cr

lB 2

Where initial imperfections ec/lB ≤ 1/500, a relatively slender restrainer

with lB/Dr > 20 and with an overall safety factor of eα ≥ 1.5;

N crB

11

11

2 EI B

lB

2

e N cu

Buckling‐restrained Braces and Applications

12.

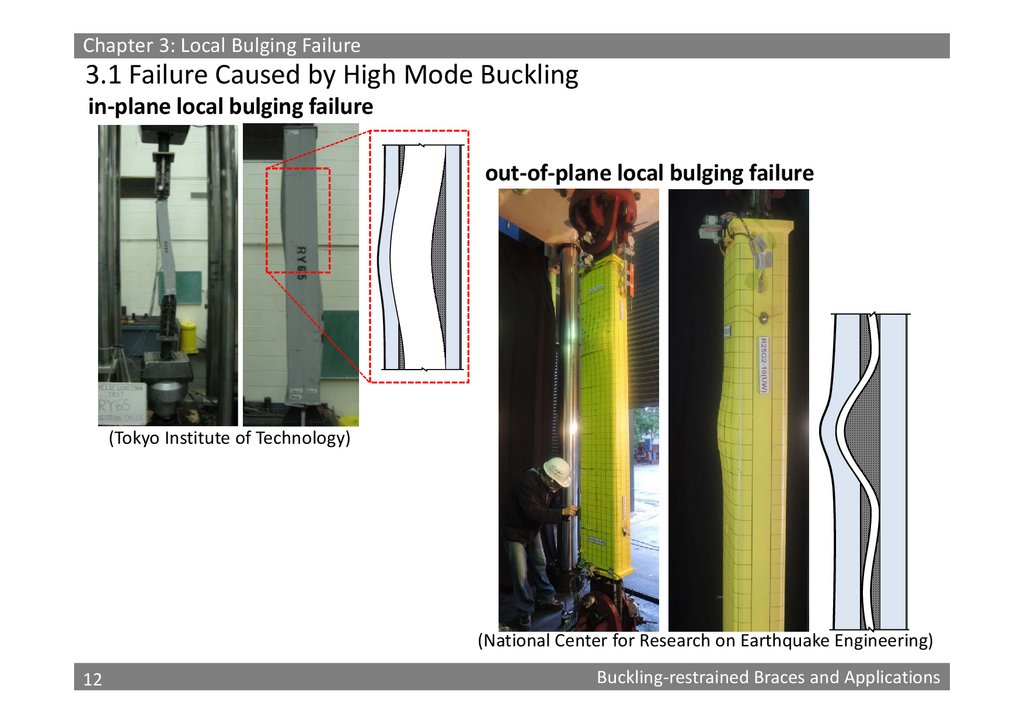

Chapter 3: Local Bulging Failure3.1 Failure Caused by High Mode Buckling

in‐plane local bulging failure

out‐of‐plane local bulging failure

(Tokyo Institute of Technology)

(National Center for Research on Earthquake Engineering)

12

12

Buckling‐restrained Braces and Applications

13.

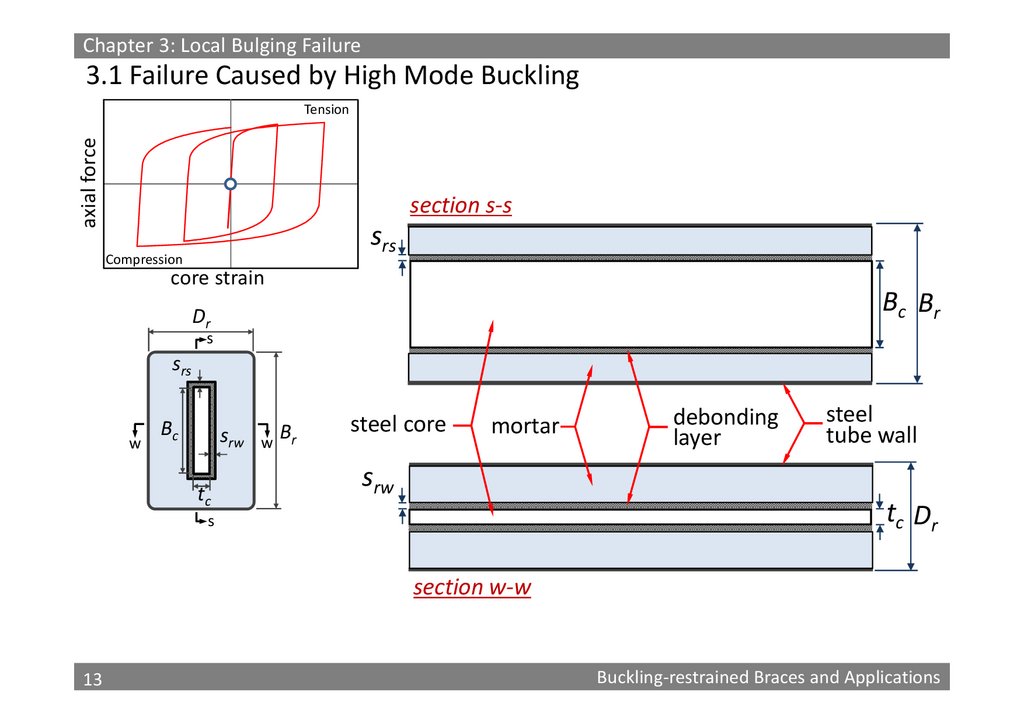

Chapter 3: Local Bulging Failure3.1 Failure Caused by High Mode Buckling

axial force

Tension

section s‐s

srs

Compression

core strain

Bc Br

Bc

Dr

s

srs

w

Bc

srw

tc

w

Br

steel core

mortar

debonding

layer

steel

tube wall

srw

tc Dr

s

section w‐w

13

13

Buckling‐restrained Braces and Applications

14.

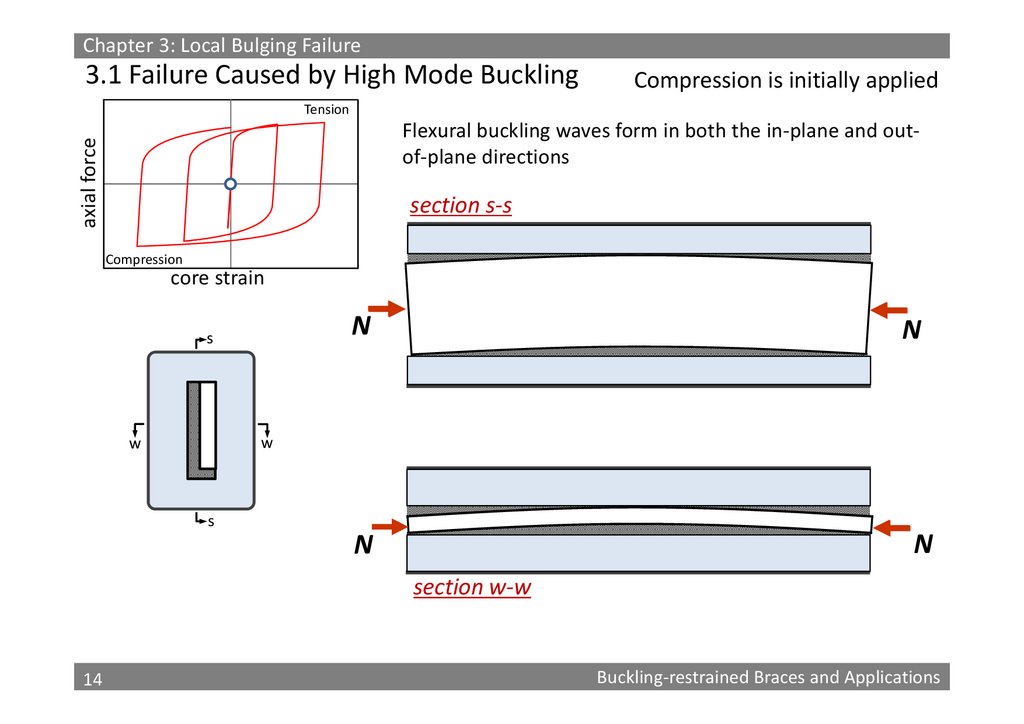

Chapter 3: Local Bulging Failure3.1 Failure Caused by High Mode Buckling

Compression is initially applied

Tension

axial force

Flexural buckling waves form in both the in‐plane and out‐

of‐plane directions

section s‐s

Compression

core strain

N

s

N

w

w

s

N

N

section w‐w

14

14

Buckling‐restrained Braces and Applications

15.

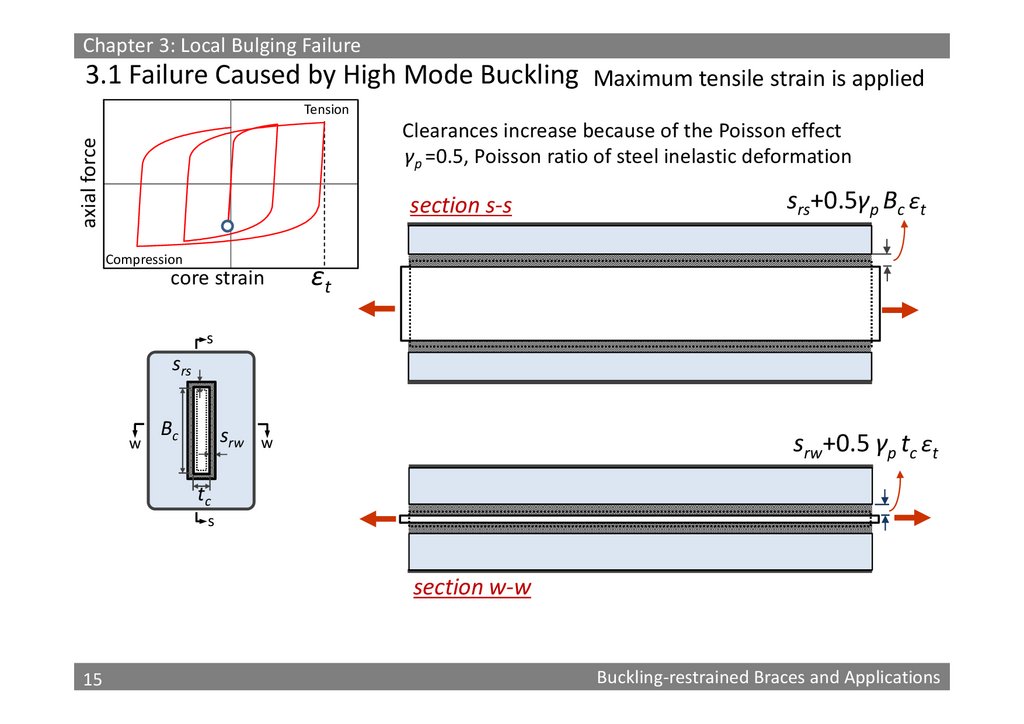

Chapter 3: Local Bulging Failure3.1 Failure Caused by High Mode Buckling Maximum tensile strain is applied

Tension

axial force

Clearances increase because of the Poisson effect

γp =0.5, Poisson ratio of steel inelastic deformation

section s‐s

Compression

core strain

srs+0.5γp Bc ɛt

ɛt

s

srs

w

Bc

srw

srw+0.5 γp tc ɛt

w

tc

s

section w‐w

15

15

Buckling‐restrained Braces and Applications

16.

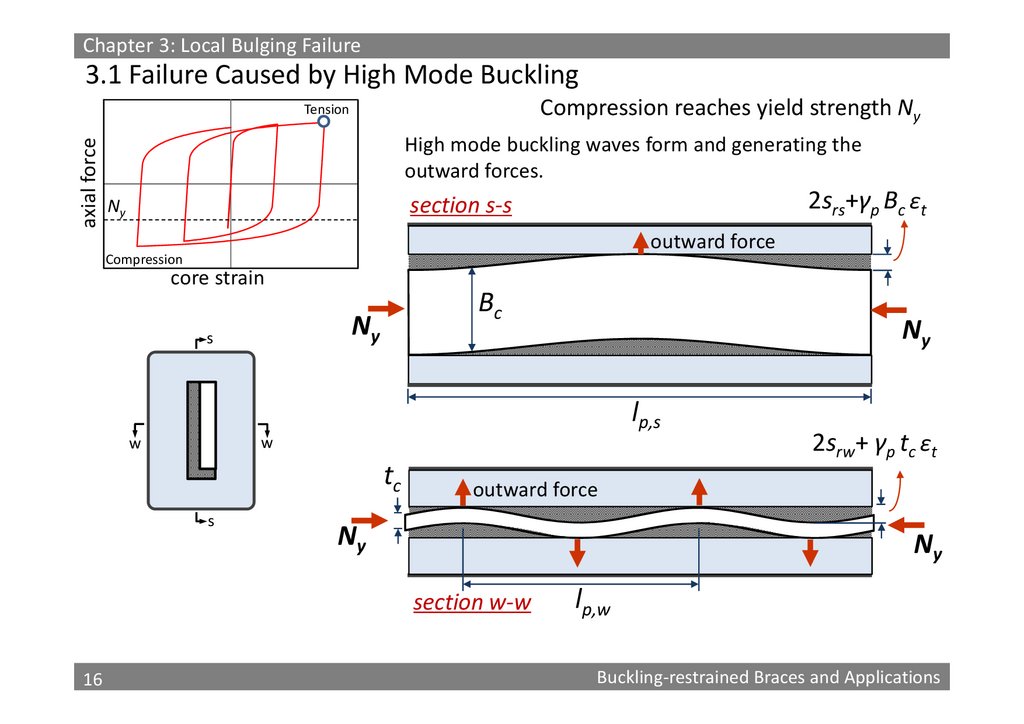

Chapter 3: Local Bulging Failure3.1 Failure Caused by High Mode Buckling

Compression reaches yield strength Ny

axial force

Tension

High mode buckling waves form and generating the

outward forces.

2srs+γp Bc ɛt

section s‐s

Ny

outward force

Compression

core strain

Bc

Ny

s

Ny

lp,s

w

w

tc

s

outward force

Ny

Ny

section w‐w

16

16

2srw+ γp tc ɛt

lp,w

Buckling‐restrained Braces and Applications

17.

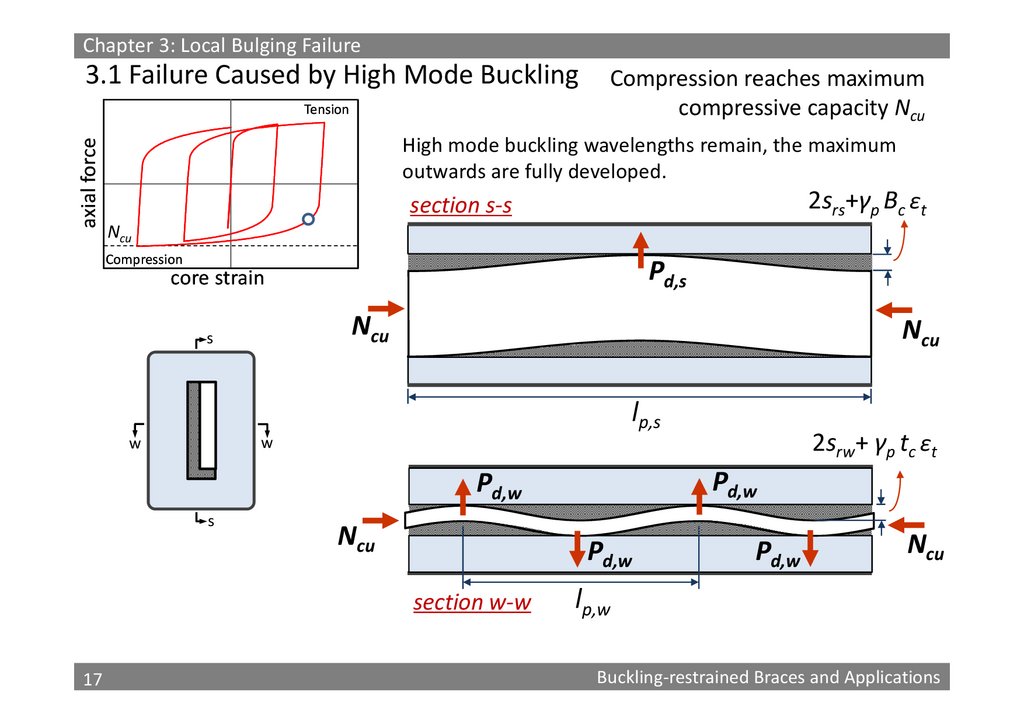

Chapter 3: Local Bulging Failure3.1 Failure Caused by High Mode Buckling

axial force

Tension

Compression reaches maximum

compressive capacity Ncu

High mode buckling wavelengths remain, the maximum

outwards are fully developed.

2srs+γp Bc ɛt

section s‐s

Ncu

Compression

Pd,s

core strain

Ncu

s

Ncu

lp,s

Pd,w

Pd,w

s

Ncu

Pd,w

section w‐w

17

17

2srw+ γp tc ɛt

w

w

Pd,w

Ncu

lp,w

Buckling‐restrained Braces and Applications

18.

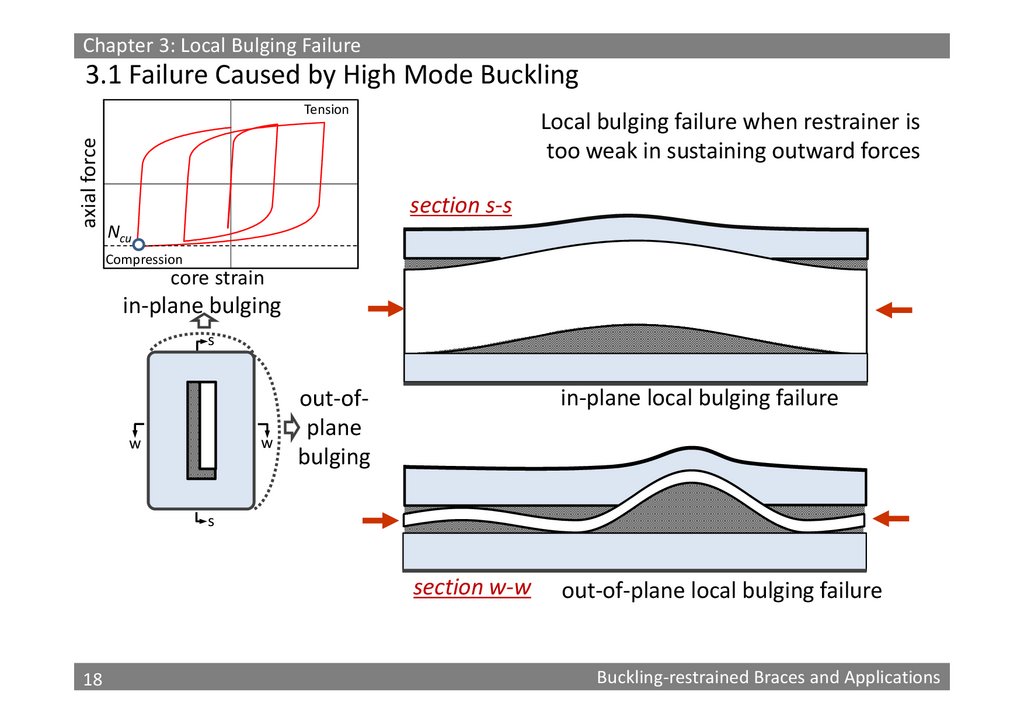

Chapter 3: Local Bulging Failure3.1 Failure Caused by High Mode Buckling

axial force

Tension

Local bulging failure when restrainer is

too weak in sustaining outward forces

section s‐s

Ncu

Compression

core strain

in‐plane bulging

s

w

w

in‐plane local bulging failure

out‐of‐

plane

bulging

s

section w‐w

18

18

out‐of‐plane local bulging failure

Buckling‐restrained Braces and Applications

19.

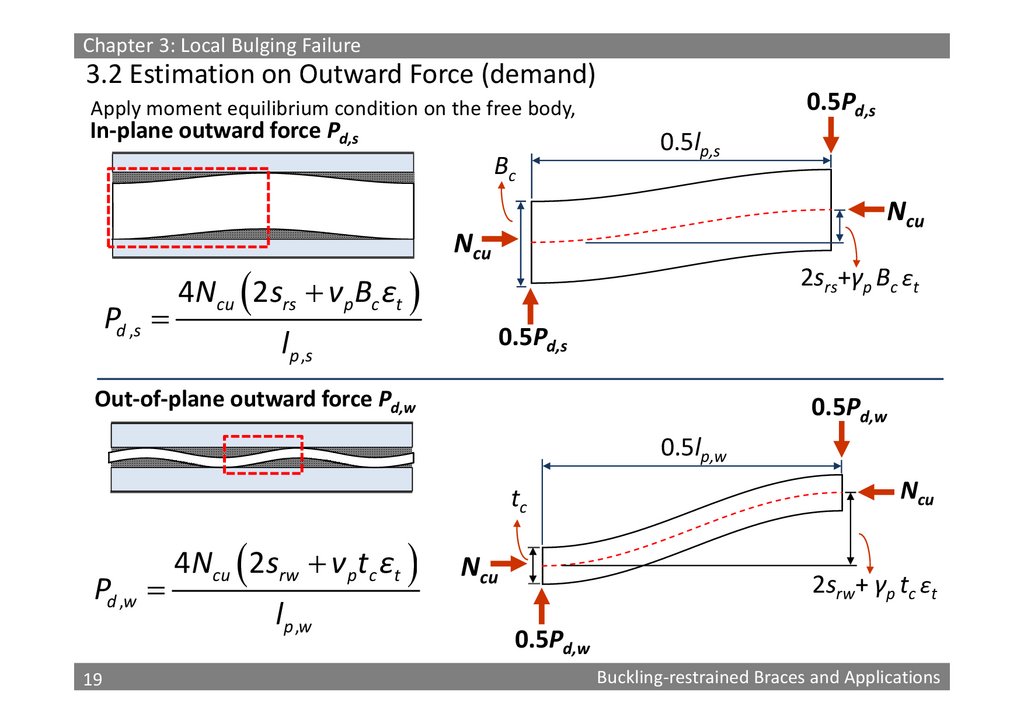

Chapter 3: Local Bulging Failure3.2 Estimation on Outward Force (demand)

0.5Pd,s

Apply moment equilibrium condition on the free body,

In‐plane outward force Pd,s

Bc

Pd ,s

4Ncu 2 srs ν pBc εt

0.5lp,s

Ncu

Ncu

2srs+γp Bc ɛt

0.5Pd,s

l p ,s

Out‐of‐plane outward force Pd,w

0.5Pd,w

0.5lp,w

tc

Pd ,w

19

19

4Ncu 2 srw ν pt c εt

lp ,w

Ncu

Ncu

2srw+ γp tc ɛt

0.5Pd,w

Buckling‐restrained Braces and Applications

20.

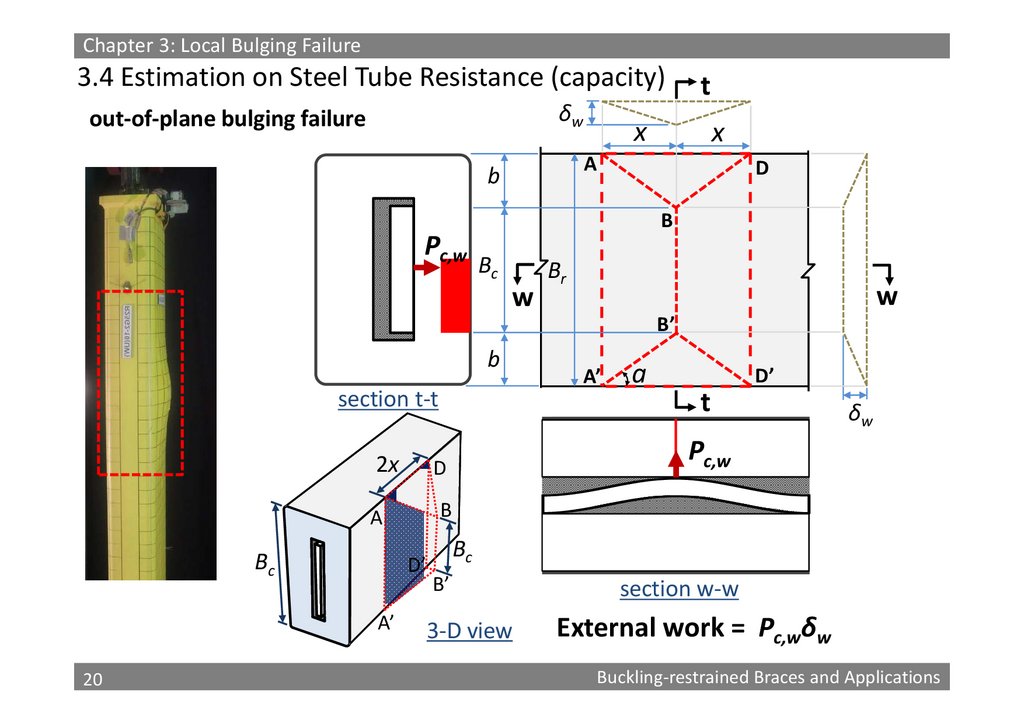

Chapter 3: Local Bulging Failure3.4 Estimation on Steel Tube Resistance (capacity)

δw

out‐of‐plane bulging failure

t

x

x

A

b

D

B

Pc,w

Bc

w

Br

w

B’

b

section t‐t

2x

20

20

D’

t

δw

B

D’

A’

a

Pc,w

D

A

Bc

A’

Bc

B’

3‐D view

section w‐w

External work = Pc,wδw

Buckling‐restrained Braces and Applications

21.

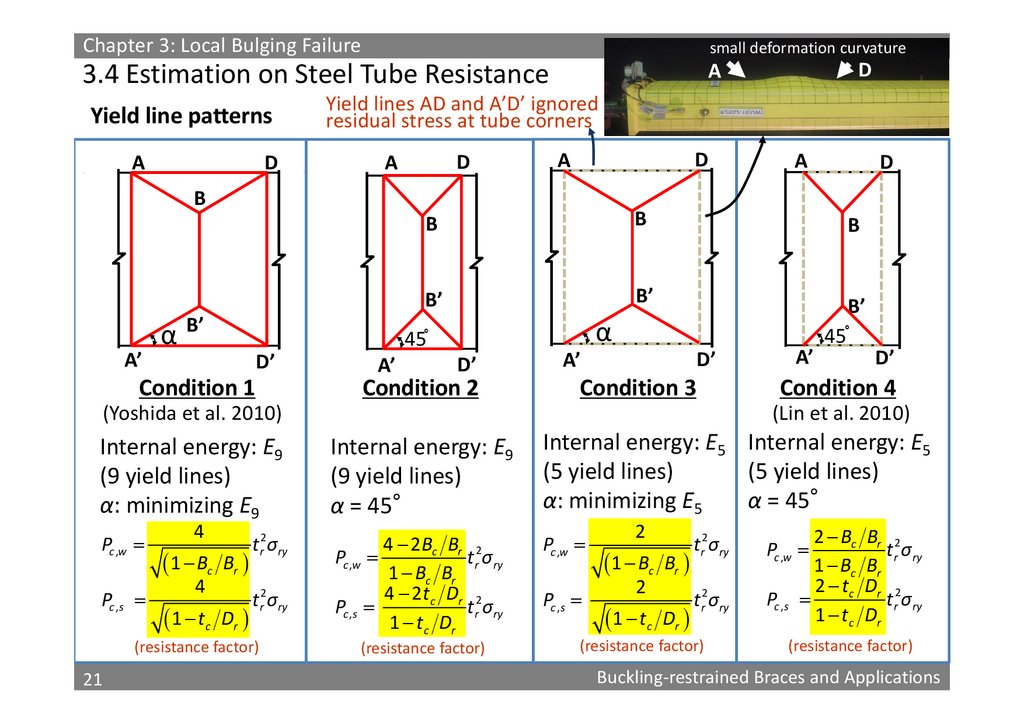

Chapter 3: Local Bulging Failuresmall deformation curvature

3.4 Estimation on Steel Tube Resistance

A

Yield line patterns

D

A

Yield lines AD and A’D’ ignored

residual stress at tube corners

D

A

D

A

B

A’

α

B’

Condition 1

A’

A

D

B

B

B

B’

B’

B’

45。

D’

D

α

D’

Condition 2

A’

D’

A’

Condition 3

(Yoshida et al. 2010)

45。

D’

Condition 4

(Lin et al. 2010)

Internal energy: E9

(9 yield lines)

α: minimizing E9

Internal energy: E9

(9 yield lines)

α = 45°

Internal energy: E5 Internal energy: E5

(5 yield lines)

(5 yield lines)

α: minimizing E5

α = 45°

Pc ,w

4 2 Bc Br 2

Pc ,w

t r σry

1 Bc Br

4 2t c Dr 2

Pc ,s

t r σry

1 t c Dr

Pc ,w

Pc ,s

4

1 Bc

Br

4

1 t c

Dr

t r2σry

t r2σry

(resistance factor)

21

21

(resistance factor)

Pc ,s

2

1 Bc

Br

2

1 t c

Dr

2 Bc

1 Bc

2 tc

1 tc

t r2σry

Pc ,w

t r2σry

Pc ,s

(resistance factor)

Br 2

t r σry

Br

Dr 2

t r σry

Dr

(resistance factor)

Buckling‐restrained Braces and Applications

22.

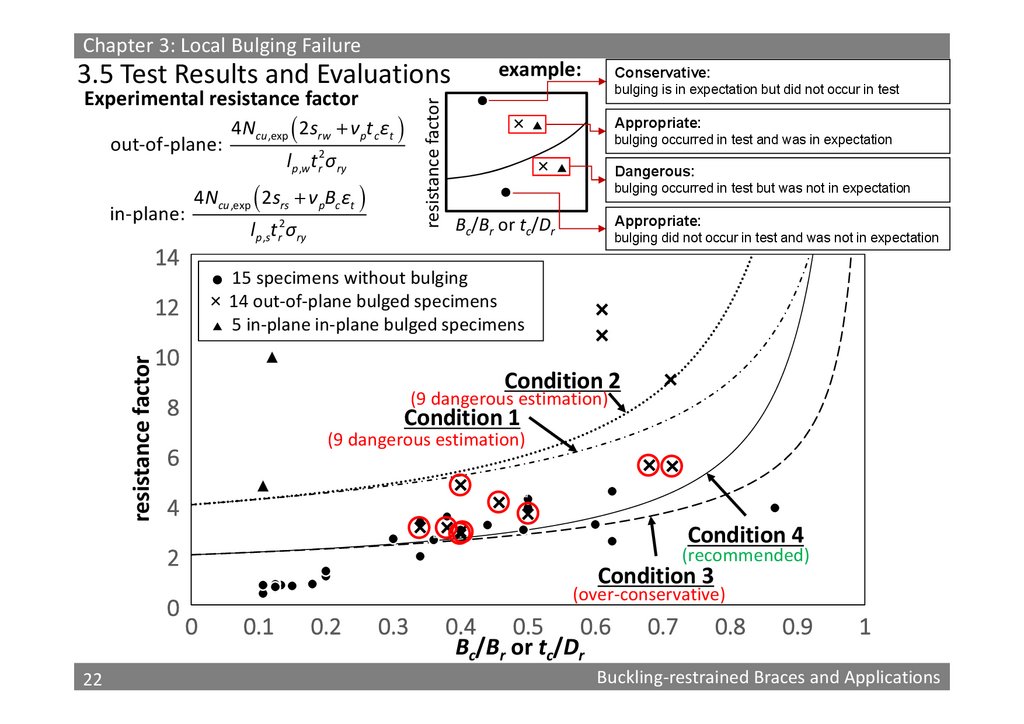

Chapter 3: Local Bulging Failureexample:

Experimental resistance factor

out‐of‐plane:

in‐plane:

4Ncu ,exp 2 srw ν pt c εt

2

p ,w r ry

l tσ

4Ncu ,exp 2 srs ν pBc εt

14

lp ,st r2σry

resistance factor

3.5 Test Results and Evaluations

Conservative:

bulging is in expectation but did not occur in test

Appropriate:

×▲

bulging occurred in test and was in expectation

×▲

Dangerous:

bulging occurred in test but was not in expectation

Appropriate:

Bc/Br or tc/Dr

bulging did not occur in test and was not in expectation

15 specimens without bulging

× 14 out‐of‐plane bulged specimens

▲ 5 in‐plane in‐plane bulged specimens

12

resistance factor

10

Condition 2

(9 dangerous estimation)

8

Condition 1

(9 dangerous estimation)

6

4

Condition 4

(recommended)

2

0

22

22

Condition 3

(over‐conservative)

0

0.1

0.2

0.3

0.4 0.5 0.6

Bc/Br or tc/Dr

0.7

0.8

0.9

1

Buckling‐restrained Braces and Applications

23.

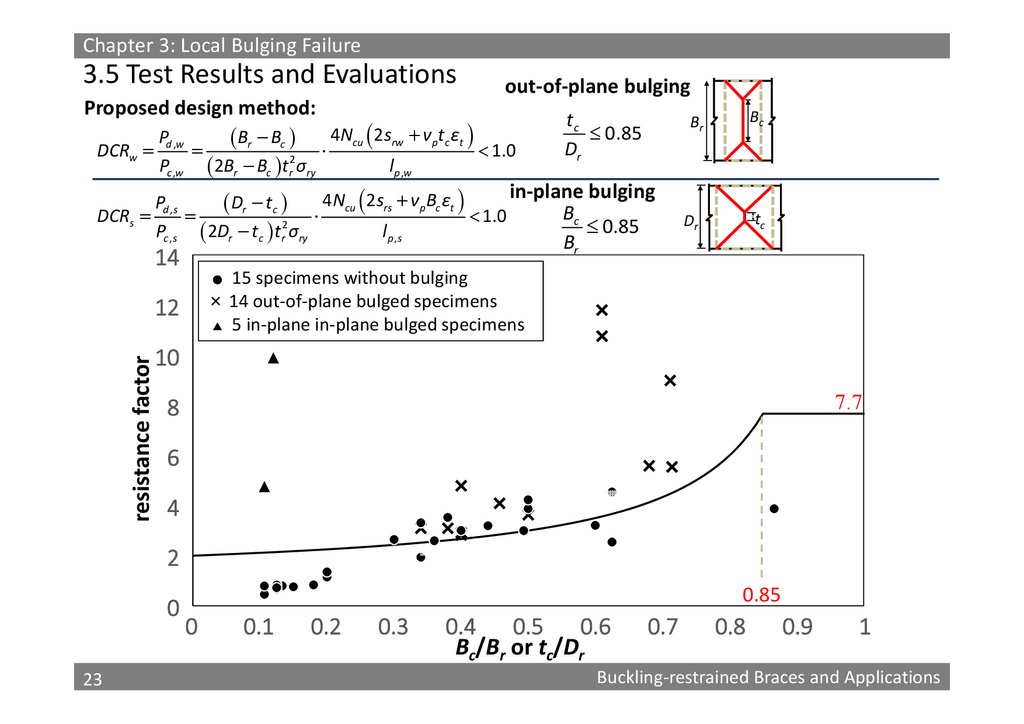

Chapter 3: Local Bulging Failure3.5 Test Results and Evaluations

Proposed design method:

Pd ,w

Br Bc

Pc ,w 2Br Bc tr2σry

DCRw

4Ncu 2srw ν ptc εt

lp ,w

out‐of‐plane bulging

1.0

tc

0.85

Dr

Bc

Br

in‐plane bulging

4Ncu 2srs ν pBc εt

Pd ,s

Dr tc

Bc

1.0

DCRs

0.85

Pc ,s 2Dr tc tr2σry

lp ,s

tc

Dr

Br

14

15 specimens without bulging

× 14 out‐of‐plane bulged specimens

▲ 5 in‐plane in‐plane bulged specimens

12

resistance factor

10

7.7

8

6

4

2

0

23

23

0.85

0

0.1

0.2

0.3

0.4 0.5 0.6

Bc/Br or tc/Dr

0.7

0.8

0.9

1

Buckling‐restrained Braces and Applications

24.

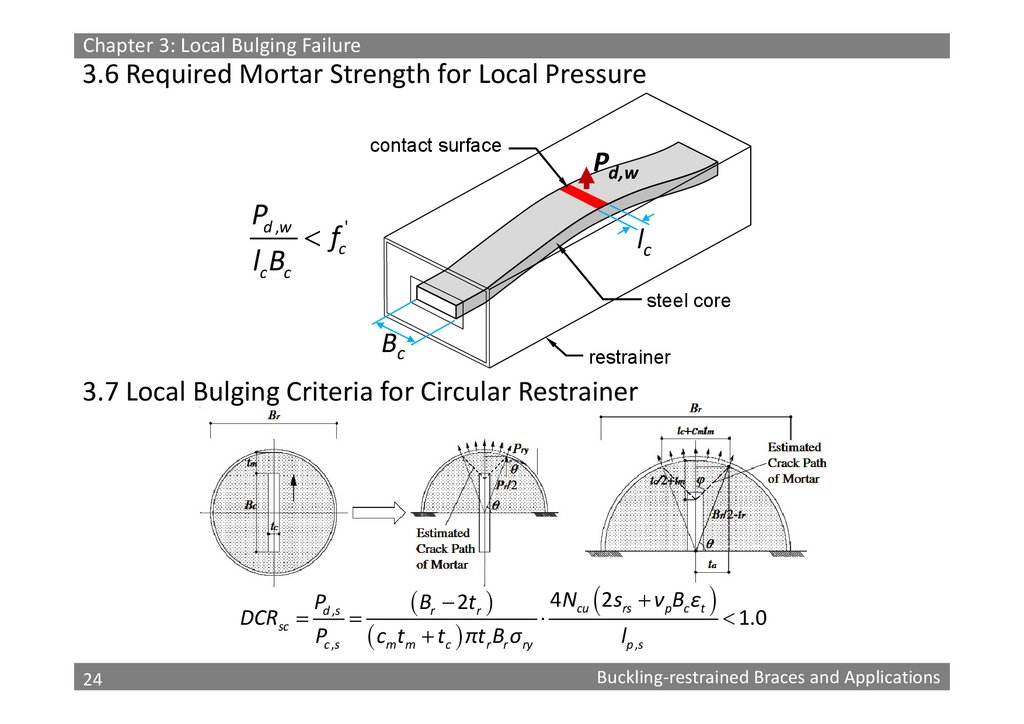

Chapter 3: Local Bulging Failure3.6 Required Mortar Strength for Local Pressure

contact surface

Pd ,w

fc'

lc Bc

Pd,w

lc

steel core

Bc

restrainer

3.7 Local Bulging Criteria for Circular Restrainer

4Ncu 2srs ν pBc εt

Pd ,s

Br 2tr

DCRsc

1.0

Pc ,s cmtm tc πtr Br σry

lp , s

24

24

Buckling‐restrained Braces and Applications

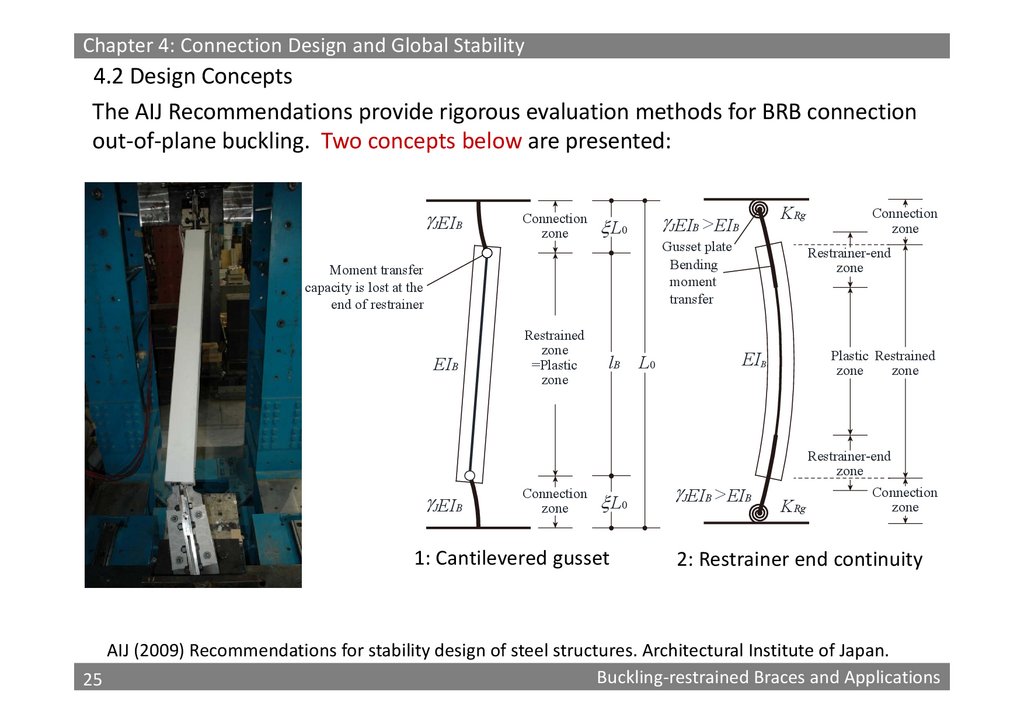

25.

Chapter 4: Connection Design and Global Stability4.2 Design Concepts

The AIJ Recommendations provide rigorous evaluation methods for BRB connection

out‐of‐plane buckling. Two concepts below are presented:

JEIB

Connection

zone

L0

Gusset plate

Bending

moment

transfer

Moment transfer

capacity is lost at the

end of restrainer

EIB

JEIB

Restrained

zone

=Plastic

zone

Connection

zone

KRg

JEIB > EIB

lB

L0

1: Cantilevered gusset

L0

Connection

zone

Restrainer-end

zone

Plastic Restrained

zone

zone

EIB

JEIB > EIB

Restrainer-end

zone

KRg

Connection

zone

2: Restrainer end continuity

AIJ (2009) Recommendations for stability design of steel structures. Architectural Institute of Japan.

25

Buckling‐restrained Braces and Applications

25

26.

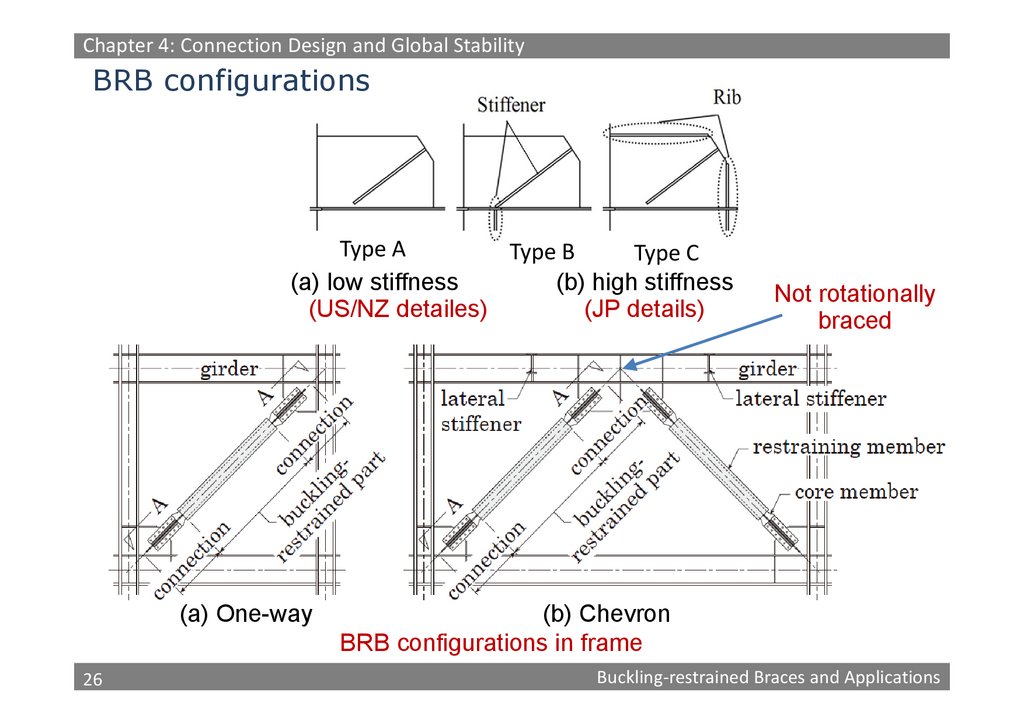

Chapter 4: Connection Design and Global StabilityBRB configurations

Type A

Type B

Type C

(a) low stiffness

(b) high stiffness

(US/NZ detailes)

(JP details)

(a) One-way

26

26

Not rotationally

braced

(b) Chevron

BRB configurations in frame

Buckling‐restrained Braces and Applications

27.

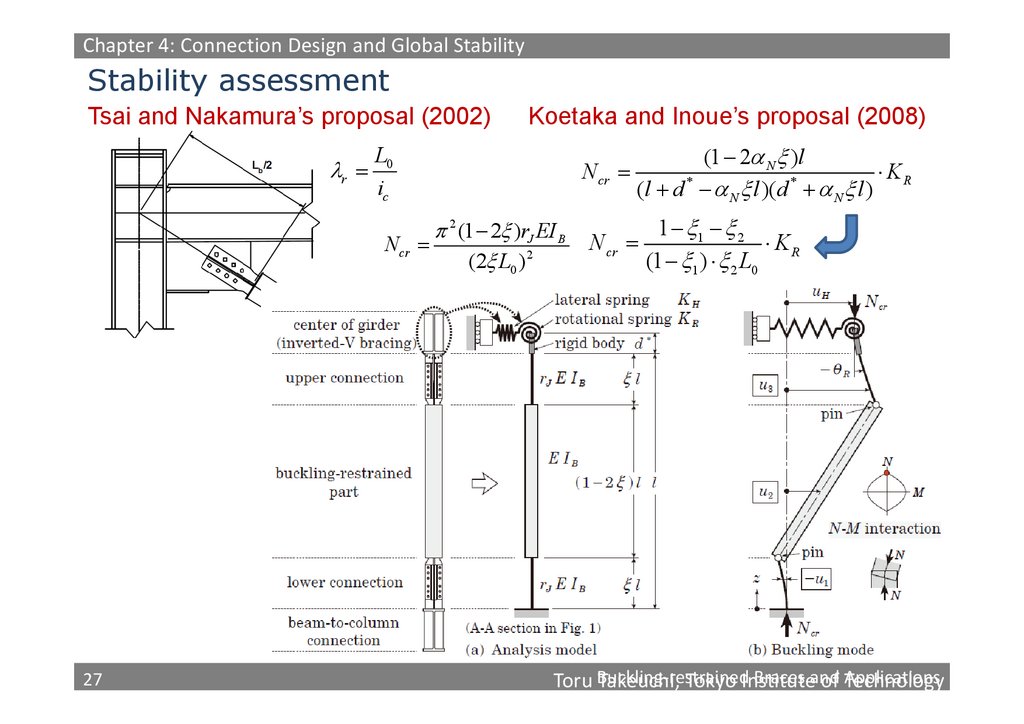

Chapter 4: Connection Design and Global StabilityStability assessment

Tsai and Nakamura’s proposal (2002)

r

Koetaka and Inoue’s proposal (2008)

L0

ic

N cr

2 (1 2 )rJ EI B

N cr

(2 L0 )2

27

27

(1 2 N )l

KR

*

*

(l d N l )( d N l )

N cr

1 1 2

KR

(1 1 ) 2 L0

Braces and

Toru Buckling‐restrained

Takeuchi, Tokyo Institute

of Applications

Technology

28.

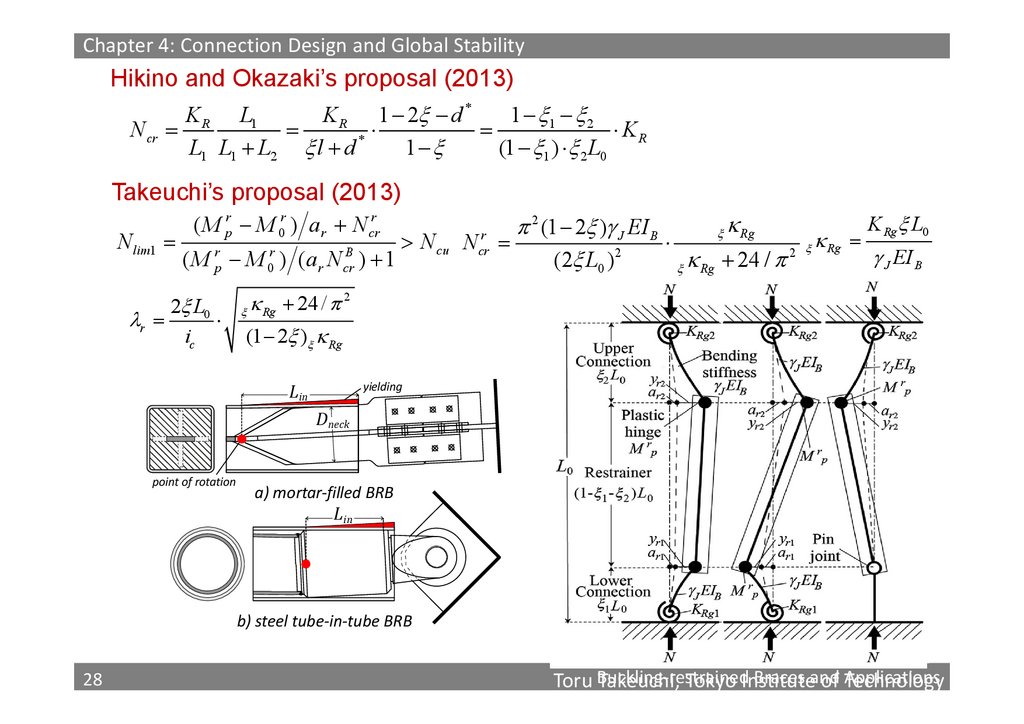

Chapter 4: Connection Design and Global StabilityHikino and Okazaki’s proposal (2013)

K R L1

K R 1 2 d *

1 1 2

N cr

KR

1

(1 1 ) 2 L0

L1 L1 L2 l d *

Takeuchi’s proposal (2013)

N lim1

( M pr M 0r ) ar N crr

( M pr M 0r ) ( ar N crB ) 1

2 L0

r

ic

N cu

K Rg L0

2 (1 2 ) J EI B

Rg

N

2 Rg

J EI B

(2 L0 )2

24

/

Rg

r

cr

Rg 24 / 2

(1 2 ) Rg

Lin

yielding

Dneck

point of rotation

a) mortar‐filled BRB

Lin

b) steel tube‐in‐tube BRB

28

28

Braces and

Toru Buckling‐restrained

Takeuchi, Tokyo Institute

of Applications

Technology

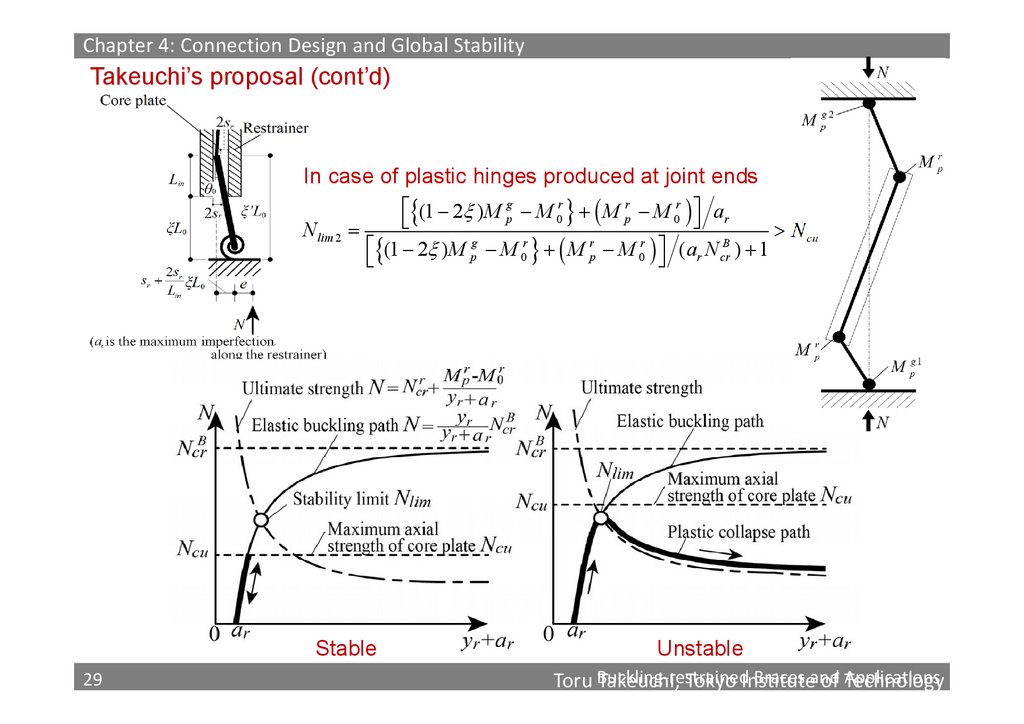

29.

Chapter 4: Connection Design and Global StabilityTakeuchi’s proposal (cont’d)

In case of plastic hinges produced at joint ends

N lim 2

(1 2 ) M pg M 0r M pr M 0r ar

N cu

g

r

r

r

B

(1 2 ) M p M 0 M p M 0 ( ar N cr ) 1

Stable

29

29

Unstable

Braces and

Toru Buckling‐restrained

Takeuchi, Tokyo Institute

of Applications

Technology

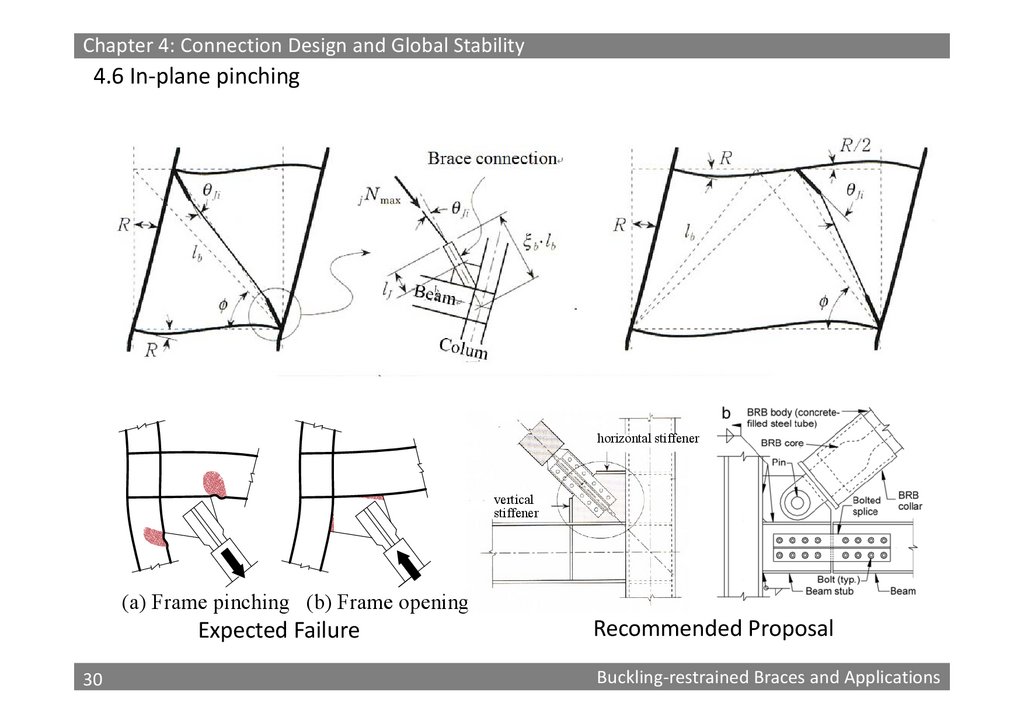

30.

Chapter 4: Connection Design and Global Stability4.6 In‐plane pinching

horizontal stiffener

vertical

stiffener

(a) Frame pinching (b) Frame opening

Expected Failure

30

30

Recommended Proposal

Buckling‐restrained Braces and Applications

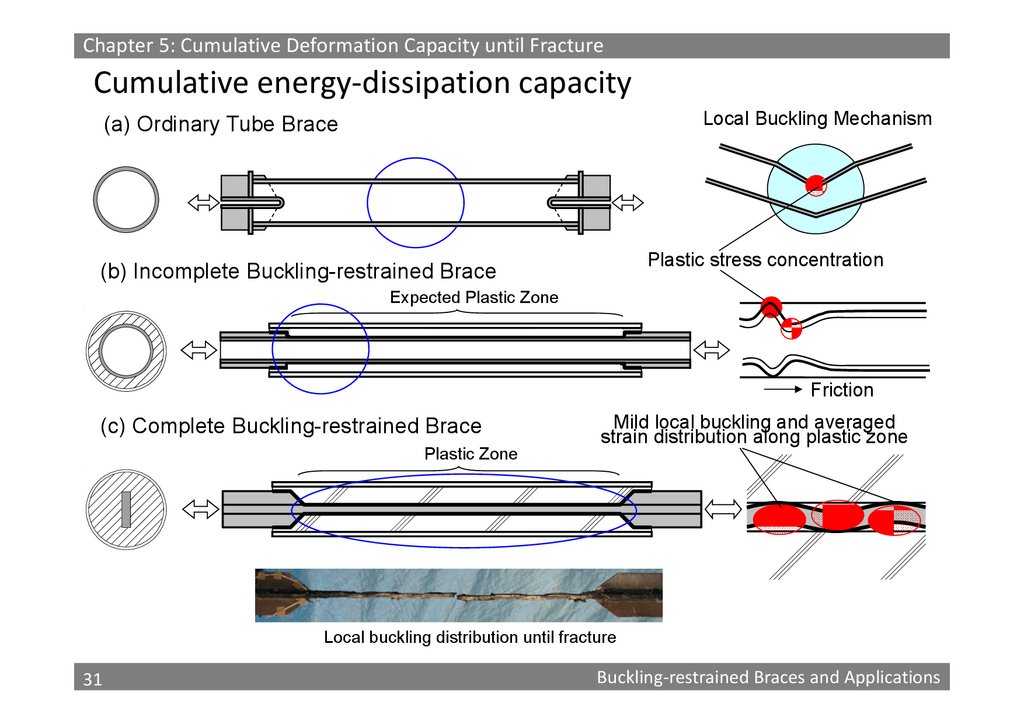

31.

Chapter 5: Cumulative Deformation Capacity until FractureCumulative energy‐dissipation capacity

Local Buckling Mechanism

(a) Ordinary Tube Brace

Plastic stress concentration

(b) Incomplete Buckling-restrained Brace

Expected Plastic Zone

Friction

(c) Complete Buckling-restrained Brace

Plastic Zone

Mild local buckling and averaged

strain distribution along plastic zone

Local buckling distribution until fracture

31

31

Buckling‐restrained Braces and Applications

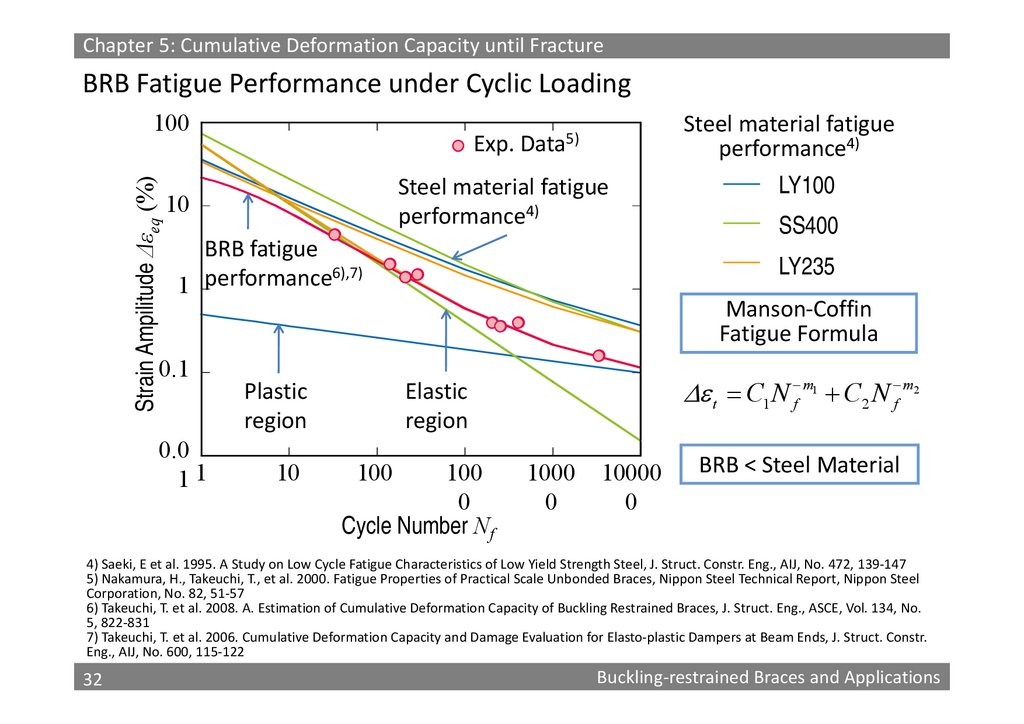

32.

Chapter 5: Cumulative Deformation Capacity until FractureBRB Fatigue Performance under Cyclic Loading

Strain Ampilitude Δεeq (%)

100

Exp.

Steel material fatigue

performance4)

Data5)

Steel material fatigue

performance4)

10

BRB fatigue

6),7)

1 performance

0.1

0.0

11

Plastic

region

10

SS400

LY235

Manson‐Coffin

Fatigue Formula

t C1 N f m C2 N f m

Elastic

region

100

LY100

100

0

Cycle Number Nf

1

1000

0

10000

0

2

BRB < Steel Material

4) Saeki, E et al. 1995. A Study on Low Cycle Fatigue Characteristics of Low Yield Strength Steel, J. Struct. Constr. Eng., AIJ, No. 472, 139‐147

5) Nakamura, H., Takeuchi, T., et al. 2000. Fatigue Properties of Practical Scale Unbonded Braces, Nippon Steel Technical Report, Nippon Steel

Corporation, No. 82, 51‐57

6) Takeuchi, T. et al. 2008. A. Estimation of Cumulative Deformation Capacity of Buckling Restrained Braces, J. Struct. Eng., ASCE, Vol. 134, No.

5, 822‐831

7) Takeuchi, T. et al. 2006. Cumulative Deformation Capacity and Damage Evaluation for Elasto‐plastic Dampers at Beam Ends, J. Struct. Constr.

Eng., AIJ, No. 600, 115‐122

32

32

Buckling‐restrained Braces and Applications

33.

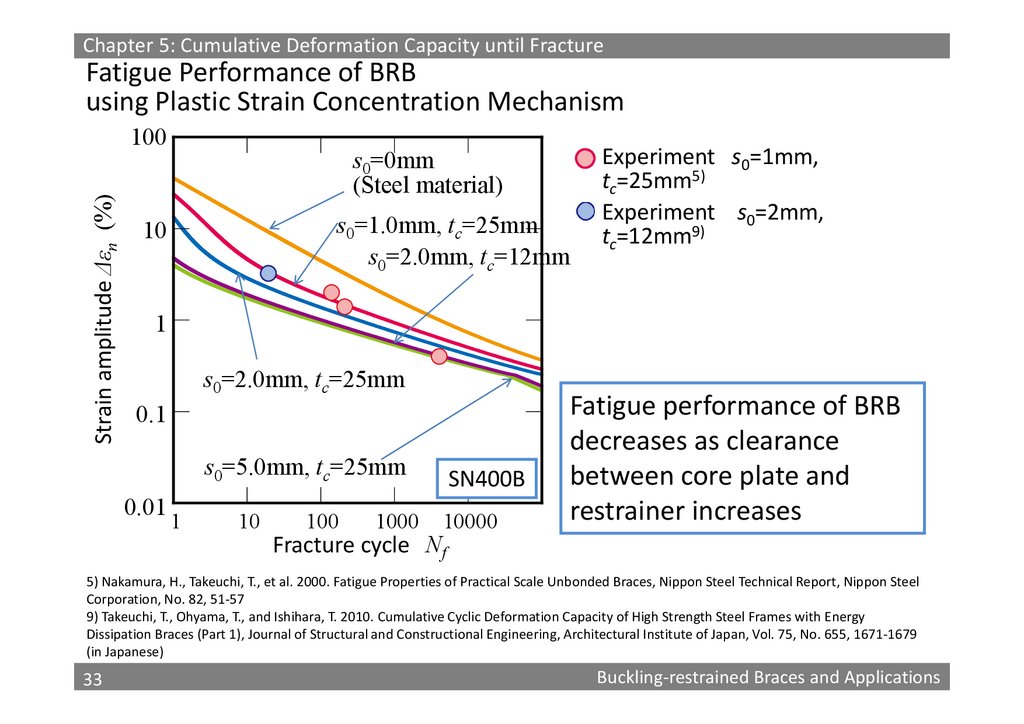

Chapter 5: Cumulative Deformation Capacity until FractureFatigue Performance of BRB

using Plastic Strain Concentration Mechanism

Strain amplitude Δεn (%)

100

s0=0mm

(Steel material)

s0=1.0mm, tc=25mm

s0=2.0mm, tc=12mm

10

Experiment s0=1mm,

tc=25mm5)

Experiment s0=2mm,

tc=12mm9)

1

s0=2.0mm, tc=25mm

0.1

s0=5.0mm, tc=25mm

0.01

1

10

100

1000

SN400B

10000

Fatigue performance of BRB

decreases as clearance

between core plate and

restrainer increases

Fracture cycle Nf

5) Nakamura, H., Takeuchi, T., et al. 2000. Fatigue Properties of Practical Scale Unbonded Braces, Nippon Steel Technical Report, Nippon Steel

Corporation, No. 82, 51‐57

9) Takeuchi, T., Ohyama, T., and Ishihara, T. 2010. Cumulative Cyclic Deformation Capacity of High Strength Steel Frames with Energy

Dissipation Braces (Part 1), Journal of Structural and Constructional Engineering, Architectural Institute of Japan, Vol. 75, No. 655, 1671‐1679

(in Japanese)

33

33

Buckling‐restrained Braces and Applications

34.

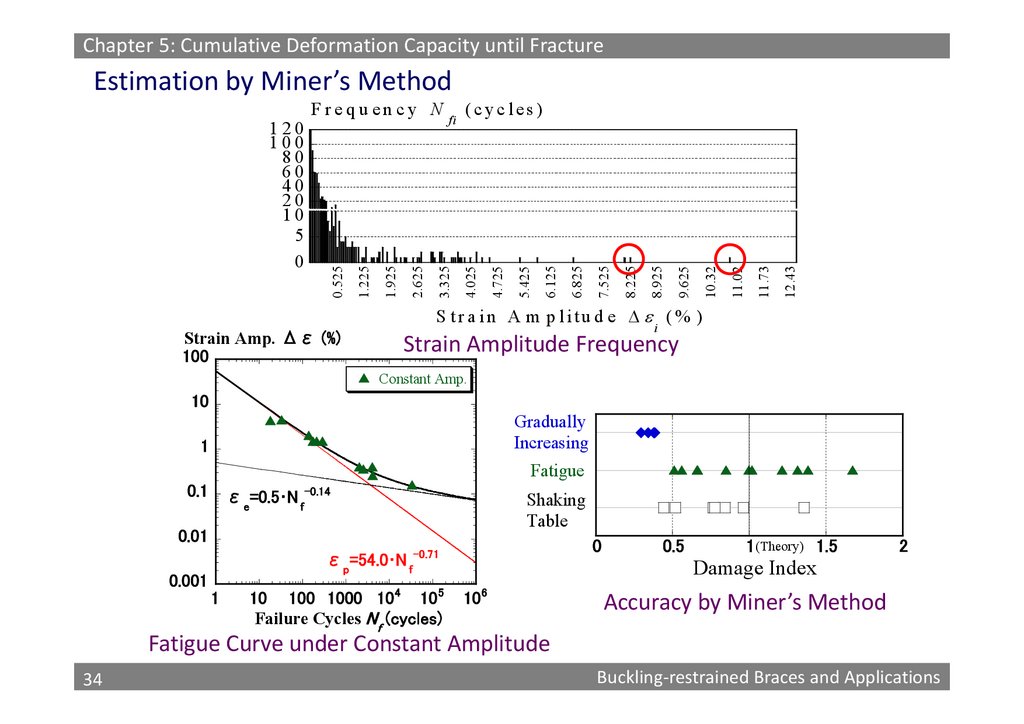

Chapter 5: Cumulative Deformation Capacity until FractureEstimation by Miner’s Method

12.43

11.73

11.02

10.32

9.625

8.925

8.225

7.525

6.825

6.125

5.425

4.725

(cyc les)

4.025

fi

3.325

2.625

1.925

1.225

0.525

120

100

80

60

40

20

10

5

0

F re q u en cy N

S tr a in A m p litu d e (% )

Strain Amp. Δε (%)

100

i

Strain Amplitude Frequency

Constant Amp.

10

Gradually

Increasing

1

Fatigue

0.1

εe=0.5 N f-0.14

Shaking

Table

0.01

0

εp=54.0 N f-0.71

0.001

1

10 100 1000 10 4 10 5

Failure Cycles N f (cycles)

0.5

1(Theory) 1.5

2

Damage Index

10 6

Accuracy by Miner’s Method

Fatigue Curve under Constant Amplitude

34

34

Buckling‐restrained Braces and Applications

35.

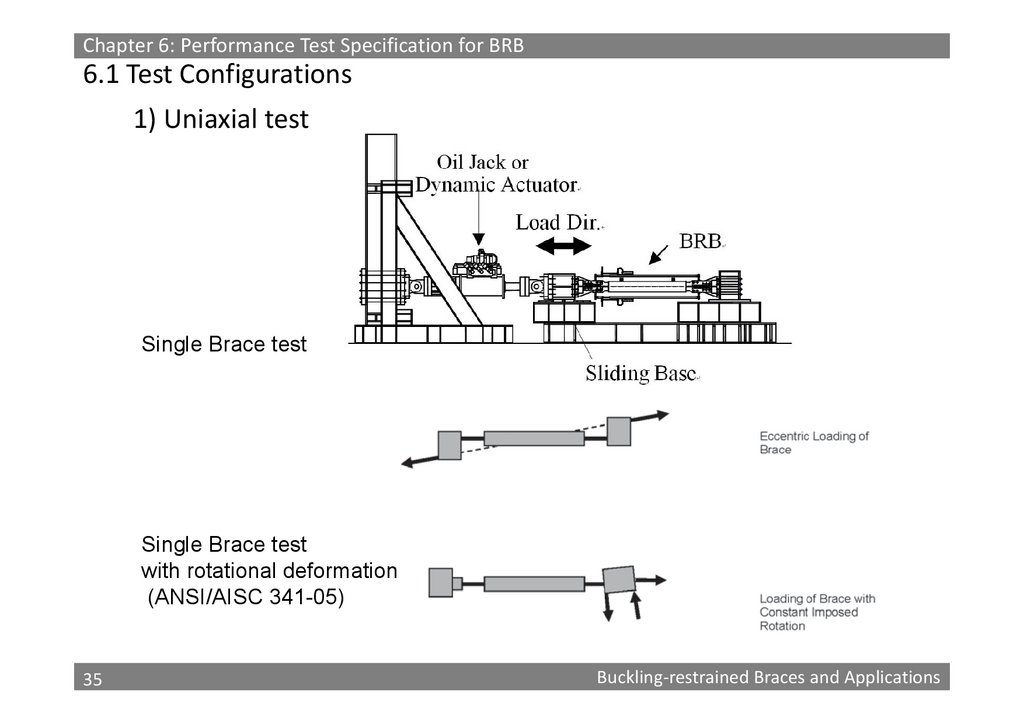

Chapter 6: Performance Test Specification for BRB6.1 Test Configurations

1) Uniaxial test

Single Brace test

Single Brace test

with rotational deformation

(ANSI/AISC 341-05)

35

35

Buckling‐restrained Braces and Applications

36.

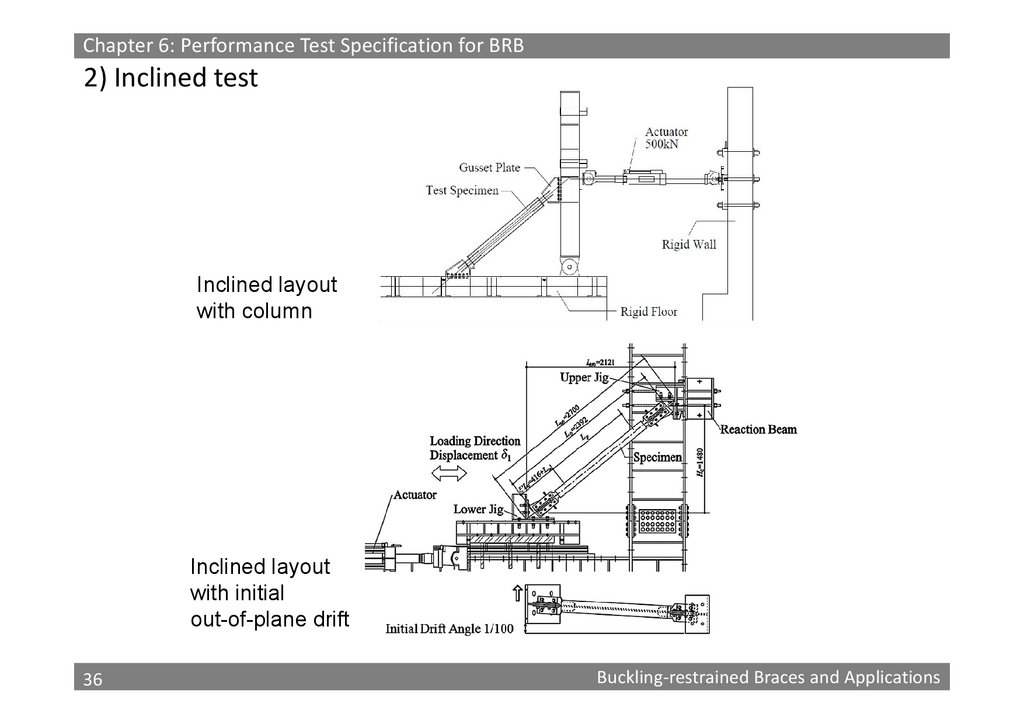

Chapter 6: Performance Test Specification for BRB2) Inclined test

Inclined layout

with column

Inclined layout

with initial

out-of-plane drift

36

36

Buckling‐restrained Braces and Applications

37.

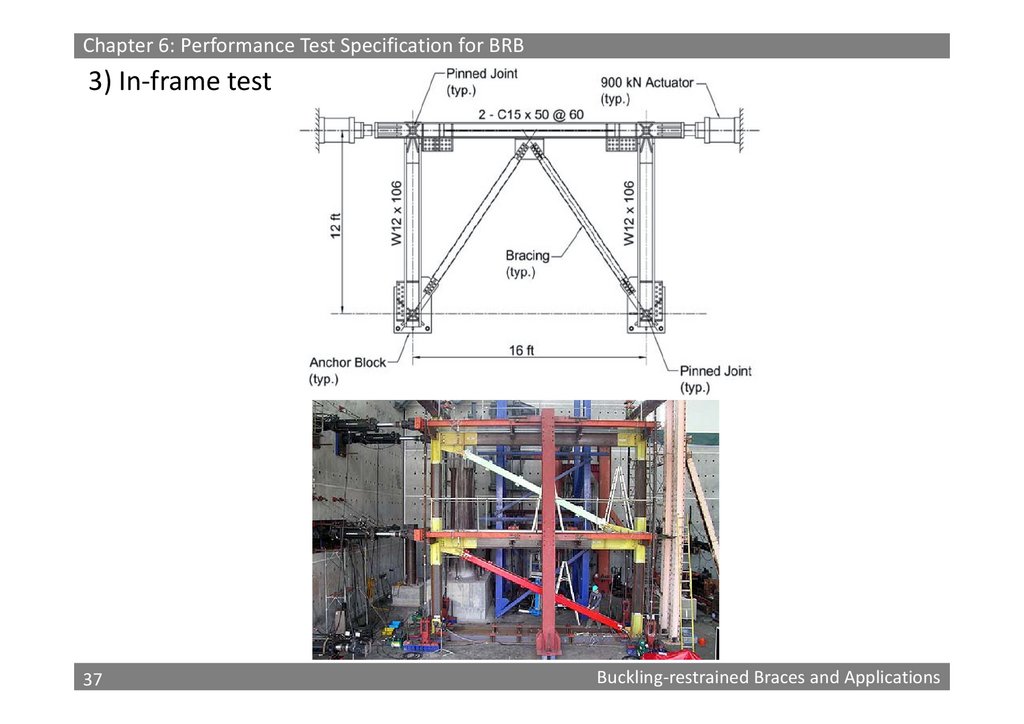

Chapter 6: Performance Test Specification for BRB3) In‐frame test

37

37

Buckling‐restrained Braces and Applications

38.

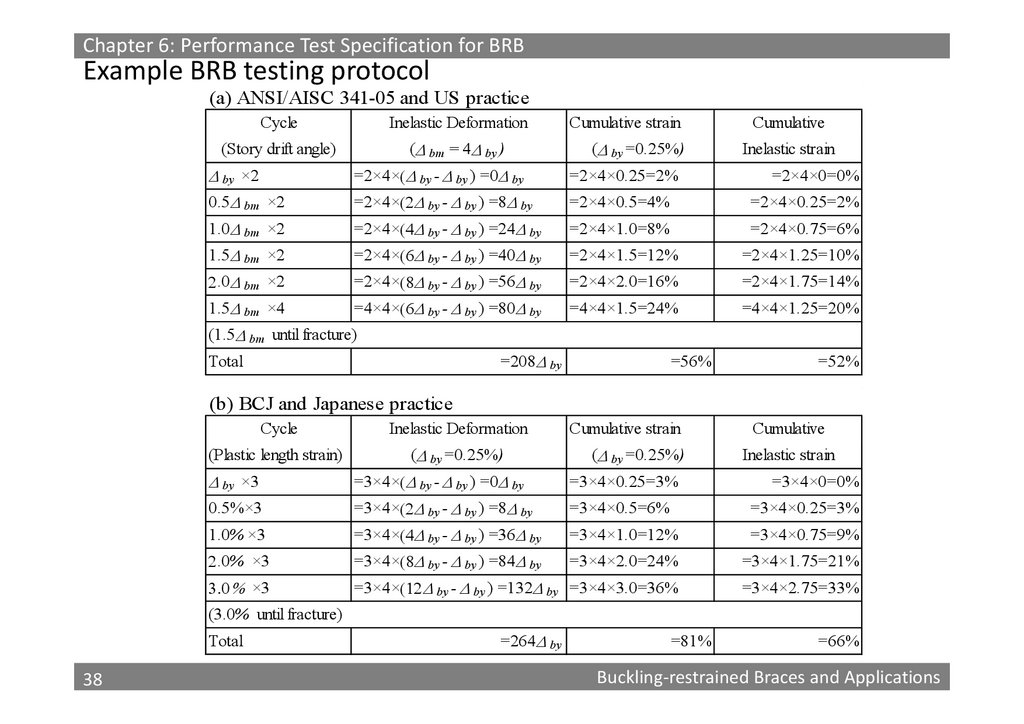

Chapter 6: Performance Test Specification for BRBExample BRB testing protocol

(a) ANSI/AISC 341-05 and US practice

Cycle

Inelastic Deformation

(Story drift angle)

( bm = 4 by )

Cumulative strain

( by =0.25%)

Cumulative

Inelastic strain

by ×2

=2×4× by - by ) =0 by

=2×4×0.25=2%

0.5 bm ×2

=2×4× by - by ) =8 by

=2×4×0.5=4%

=2×4×0.25=2%

1.0 bm ×2

=2×4× by - by ) =24 by

=2×4×1.0=8%

=2×4×0.75=6%

1.5 bm ×2

=2×4× by - by ) =40 by

=2×4×1.5=12%

=2×4×1.25=10%

.0 bm ×2

=2×4× by - by ) =56 by

=2×4×2.0=16%

=2×4×1.75=14%

1.5 bm ×4

=4×4× by - by ) =80 by

=4×4×1.5=24%

=4×4×1.25=20%

=2×4×0=0%

(1.5 bm until fracture)

=208 by

Total

=56%

=52%

(b) BCJ and Japanese practice

Cycle

Inelastic Deformation

(Plastic length strain)

( by =0.25%)

Cumulative strain

( by =0.25%)

Cumulative

Inelastic strain

by ×3

=3×4× by - by ) =0 by

=3×4×0.25=3%

0.5%×3

=3×4× by - by ) =8 by

=3×4×0.5=6%

=3×4×0.25=3%

1.0% ×3

=3×4× by - by ) =36 by

=3×4×1.0=12%

=3×4×0.75=9%

.0% ×3

=3×4× by - by ) =84 by

=3×4×2.0=24%

=3×4×1.75=21%

×3

=3×4× by - by ) =132 by =3×4×3.0=36%

=3×4×2.75=33%

=3×4×0=0%

(3.0% until fracture)

Total

38

38

=264 by

=81%

=66%

Buckling‐restrained Braces and Applications

39.

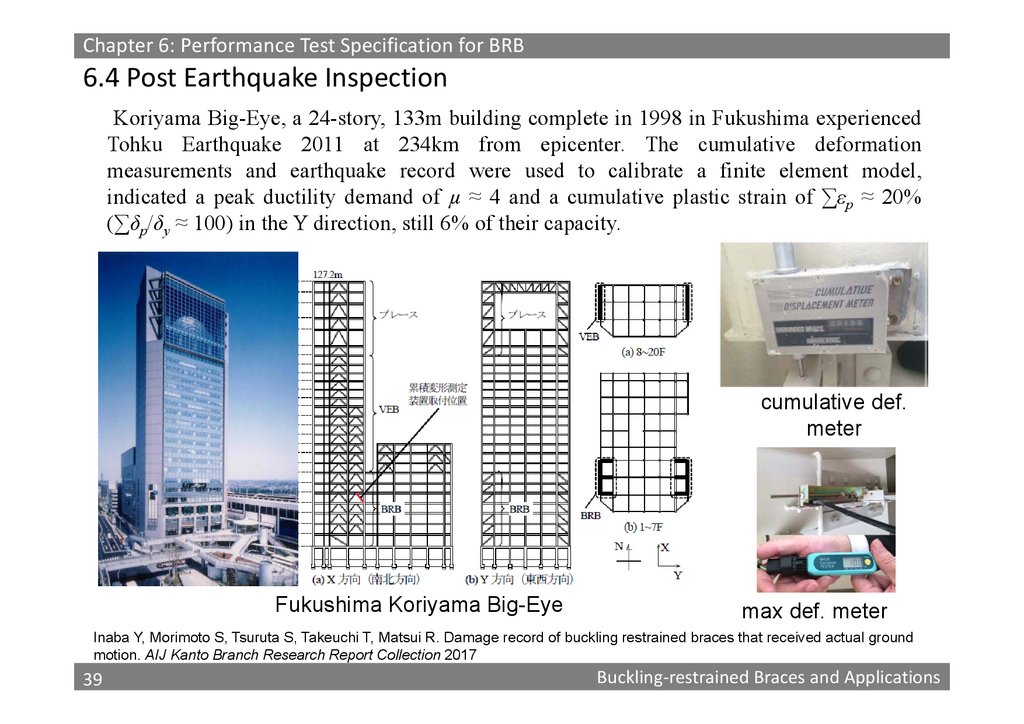

Chapter 6: Performance Test Specification for BRB6.4 Post Earthquake Inspection

Koriyama Big-Eye, a 24-story, 133m building complete in 1998 in Fukushima experienced

Tohku Earthquake 2011 at 234km from epicenter. The cumulative deformation

measurements and earthquake record were used to calibrate a finite element model,

indicated a peak ductility demand of µ ≈ 4 and a cumulative plastic strain of ∑εp ≈ 20%

(∑δp/δy ≈ 100) in the Y direction, still 6% of their capacity.

cumulative def.

meter

Fukushima Koriyama Big-Eye

max def. meter

Inaba Y, Morimoto S, Tsuruta S, Takeuchi T, Matsui R. Damage record of buckling restrained braces that received actual ground

motion. AIJ Kanto Branch Research Report Collection 2017

39

39

Buckling‐restrained Braces and Applications

40.

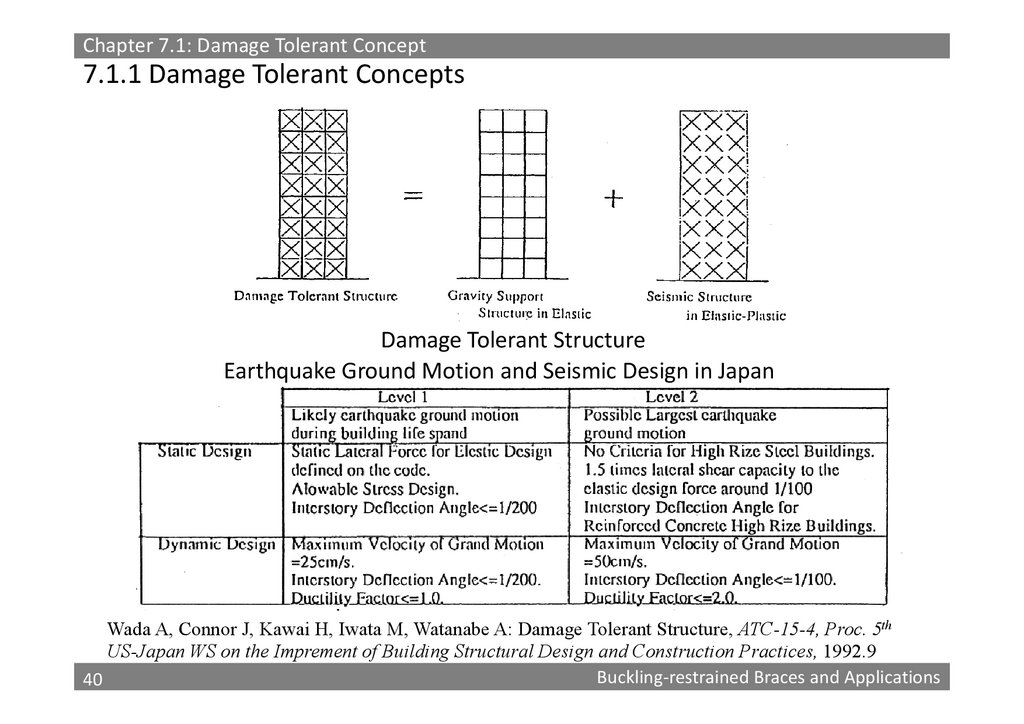

Chapter 7.1: Damage Tolerant Concept7.1.1 Damage Tolerant Concepts

Damage Tolerant Structure

Earthquake Ground Motion and Seismic Design in Japan

Wada A, Connor J, Kawai H, Iwata M, Watanabe A: Damage Tolerant Structure, ATC-15-4, Proc. 5th

US-Japan WS on the Imprement of Building Structural Design and Construction Practices, 1992.9

40

Buckling‐restrained Braces and Applications

40

41.

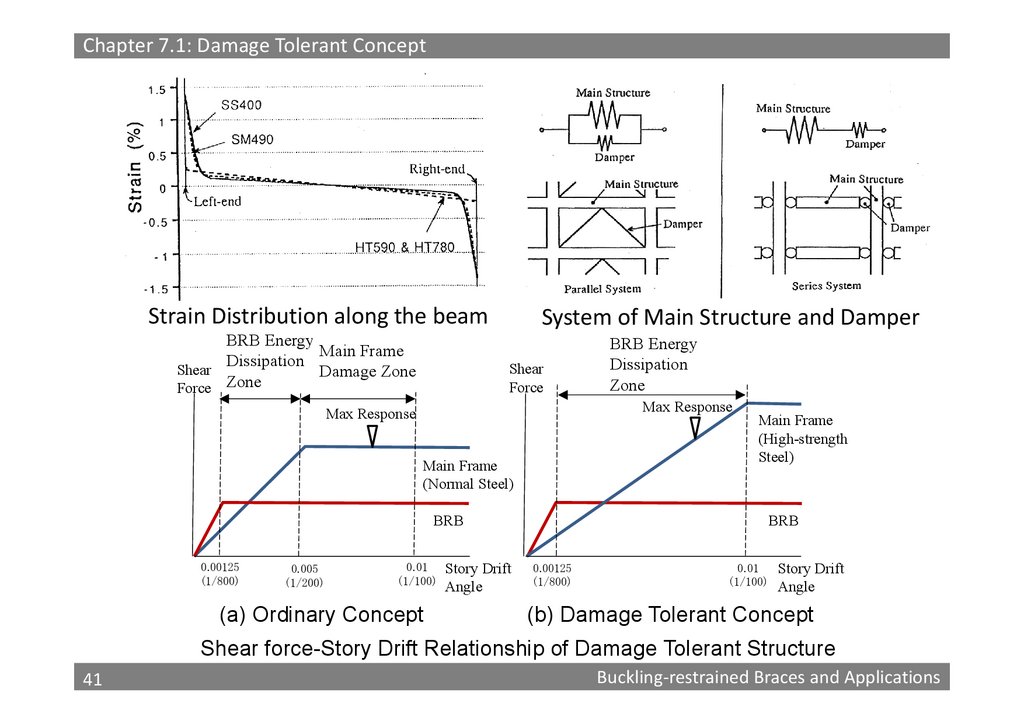

Chapter 7.1: Damage Tolerant ConceptStrain Distribution along the beam

BRB Energy

Main Frame

Dissipation

Shear

Damage Zone

Force Zone

System of Main Structure and Damper

Shear

Force

BRB Energy

Dissipation

Zone

Max Response

Max Response

Main Frame

(Normal Steel)

Main Frame

(High-strength

Steel)

BRB

0.00125

(1/800)

0.005

(1/200)

0.01

(1/100)

(a) Ordinary Concept

Story Drift

Angle

BRB

0.00125

(1/800)

0.01

(1/100)

Story Drift

Angle

(b) Damage Tolerant Concept

Shear force-Story Drift Relationship of Damage Tolerant Structure

41

41

Buckling‐restrained Braces and Applications

42.

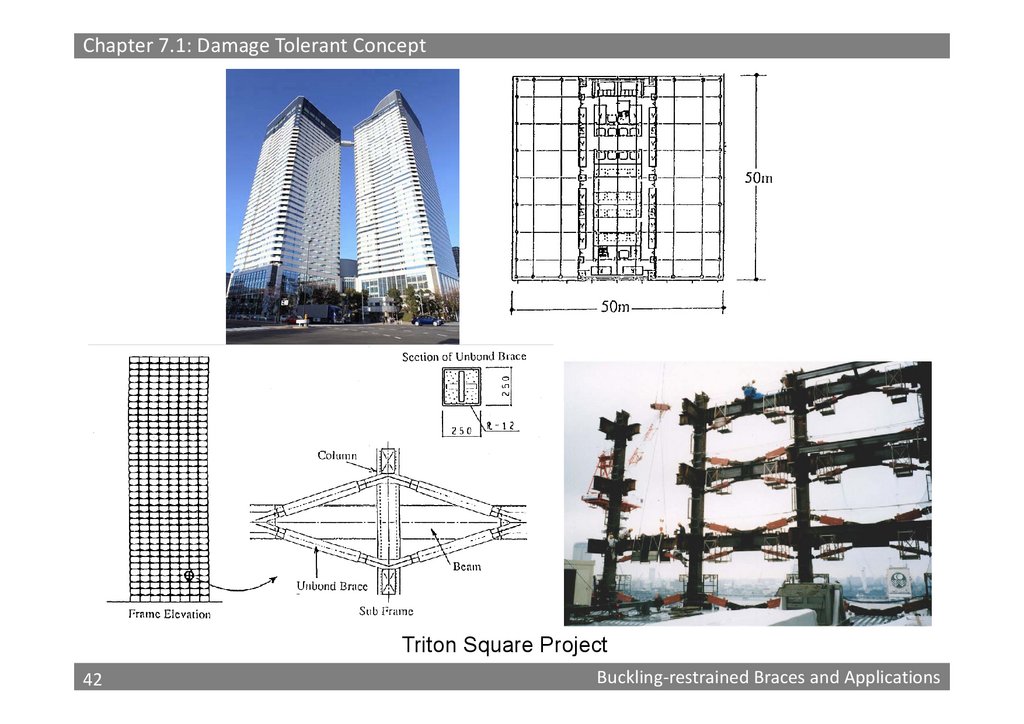

Chapter 7.1: Damage Tolerant ConceptTriton Square Project

42

42

Buckling‐restrained Braces and Applications

43.

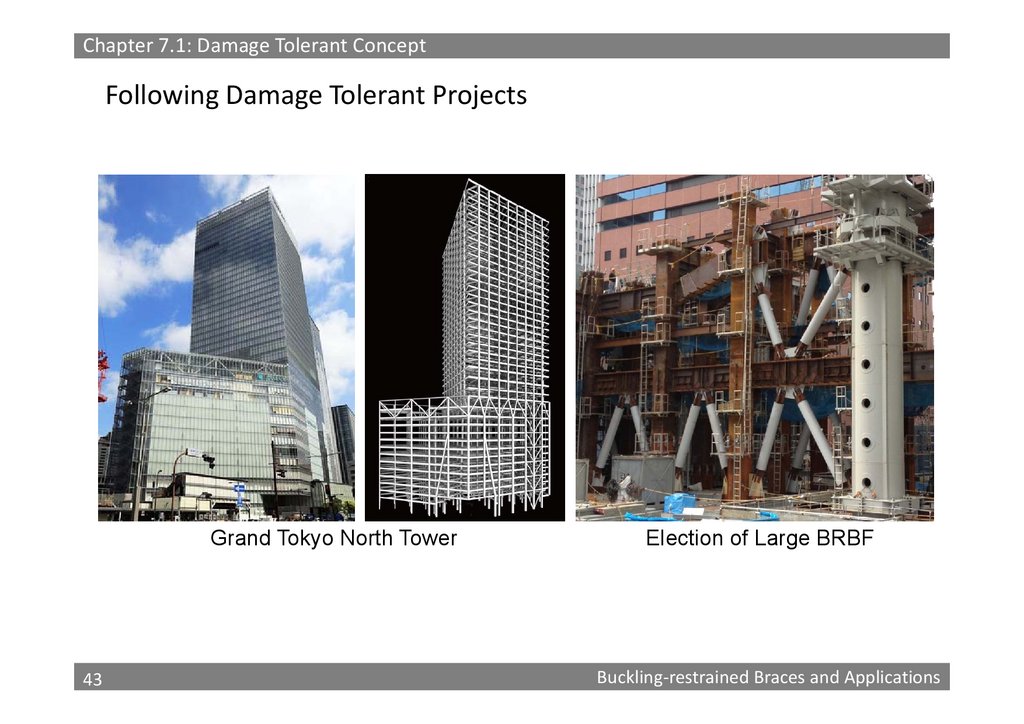

Chapter 7.1: Damage Tolerant ConceptFollowing Damage Tolerant Projects

Grand Tokyo North Tower

43

43

Election of Large BRBF

Buckling‐restrained Braces and Applications

44.

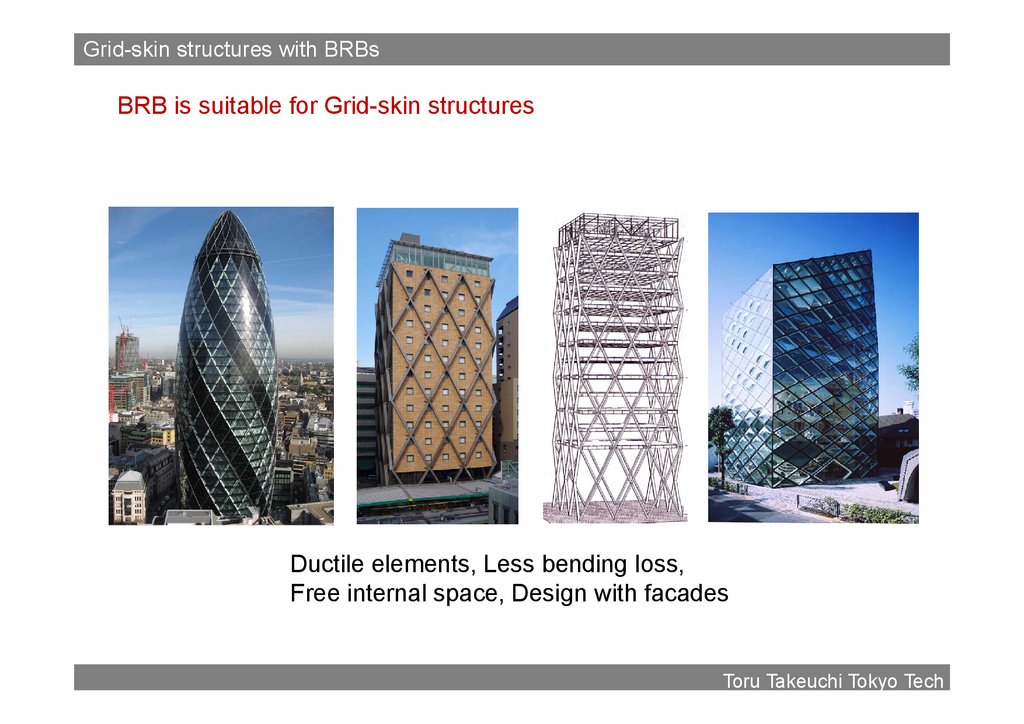

Grid-skin structures with BRBsBRB is suitable for Grid-skin structures

Ductile elements, Less bending loss,

Free internal space, Design with facades

44

Toru Takeuchi Tokyo Tech

45.

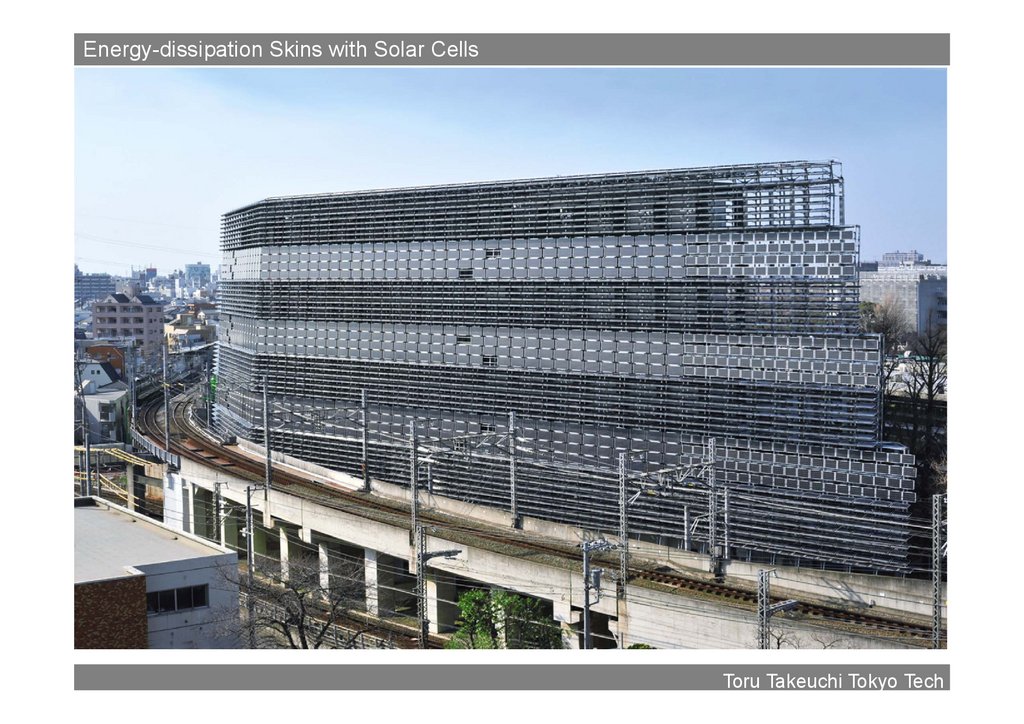

Energy-dissipation Skins with Solar Cells2. Disaster Prevention and Environmental Sustainability

Cg南側

45

Toru Takeuchi Tokyo Tech

46.

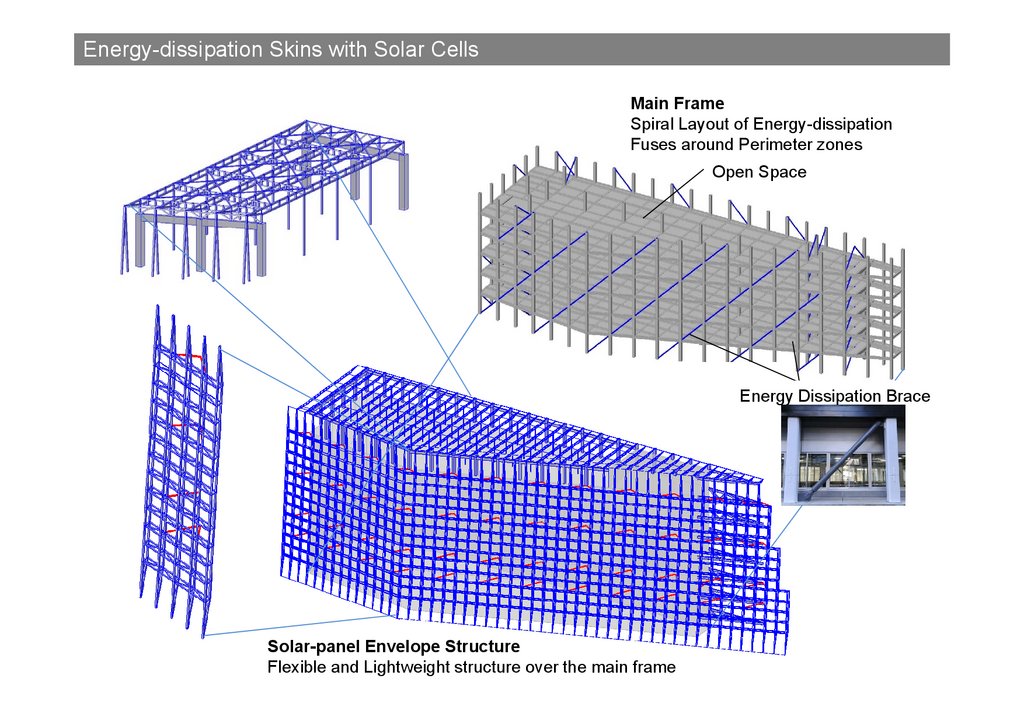

Energy-dissipation Skins with Solar Cells2. Disaster Prevention and Environmental Sustainability

Main Frame

Spiral Layout of Energy-dissipation

Fuses around Perimeter zones

Open Space

Energy Dissipation Brace

46

Solar-panel Envelope Structure

Flexible and Lightweight structure over the main frame

47.

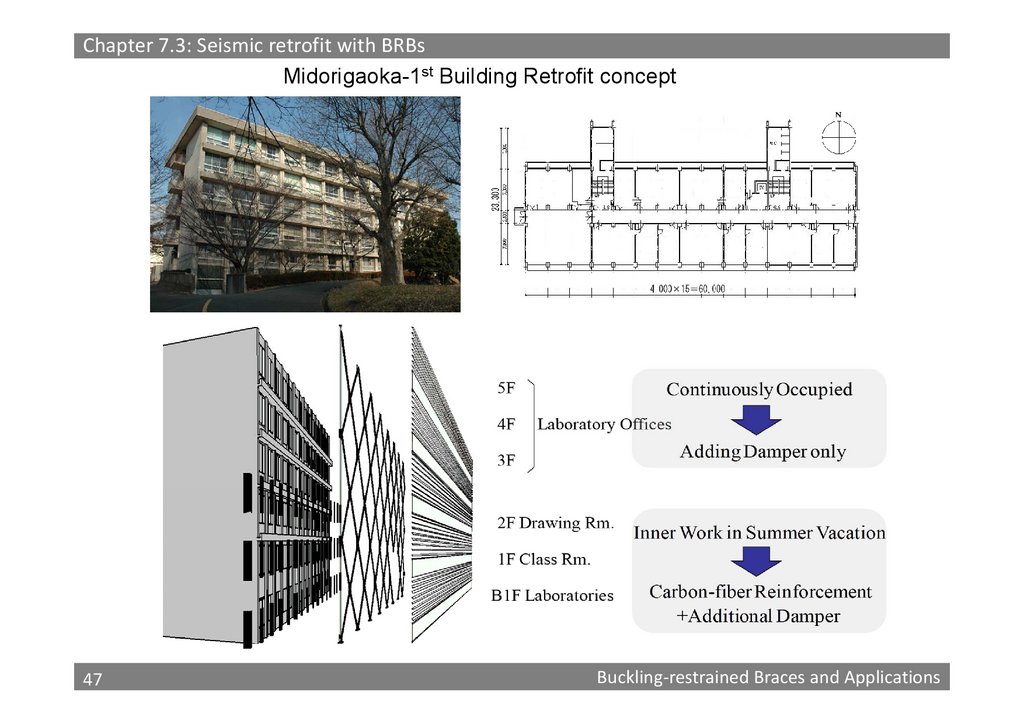

Chapter 7.3: Seismic retrofit with BRBsMidorigaoka-1st Building Retrofit concept

47

47

Buckling‐restrained Braces and Applications

48.

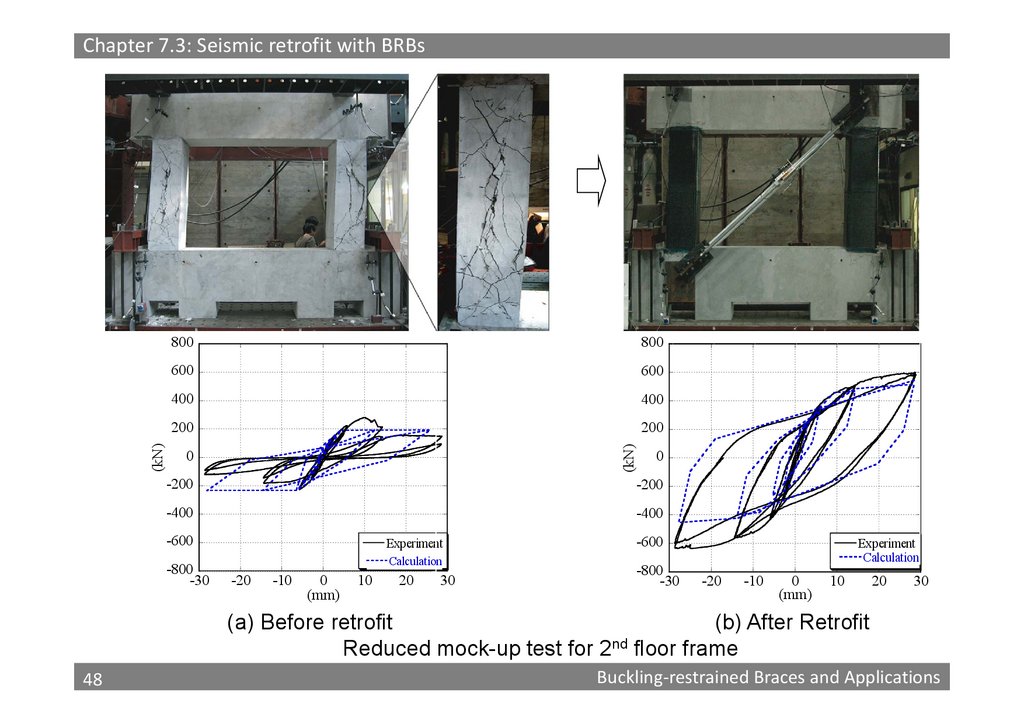

800800

600

600

400

400

200

200

(kN)

(kN)

Chapter 7.3: Seismic retrofit with BRBs

0

0

-200

-200

-400

-400

-600

-800

-30

Experiment

Calculation

-20

-10

0

(mm)

10

20

30

-600

-800

-30

Experiment

Calculation

-20

-10

0

(mm)

10

20

30

(a) Before retrofit

(b) After Retrofit

Reduced mock-up test for 2nd floor frame

48

48

Buckling‐restrained Braces and Applications

49.

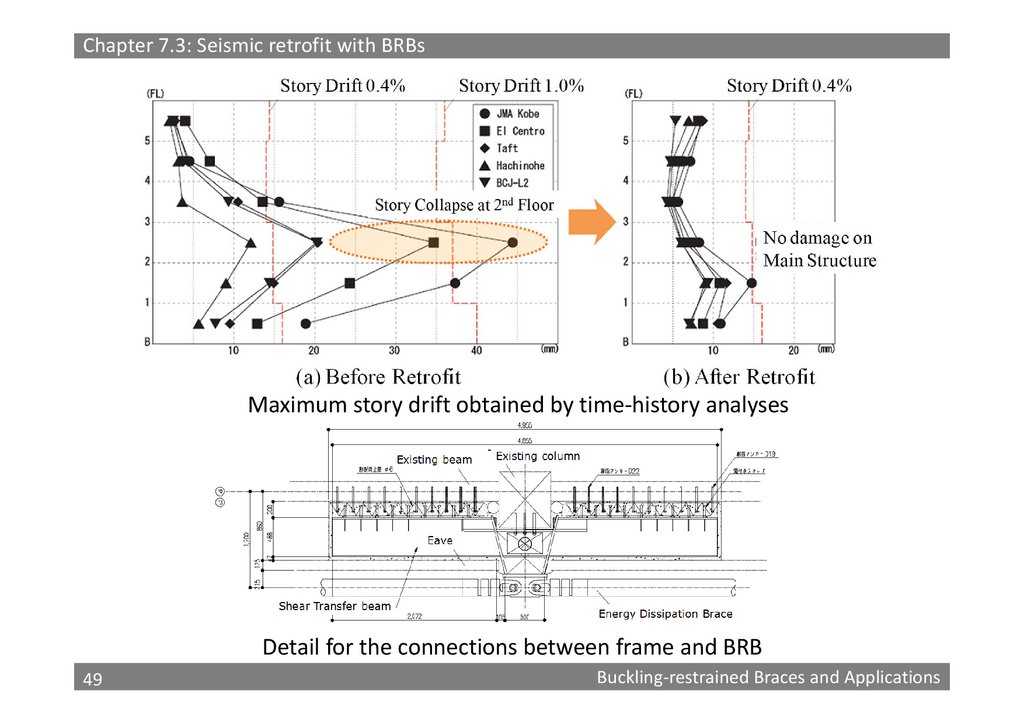

Chapter 7.3: Seismic retrofit with BRBsMaximum story drift obtained by time‐history analyses

Detail for the connections between frame and BRB

49

49

Buckling‐restrained Braces and Applications

50.

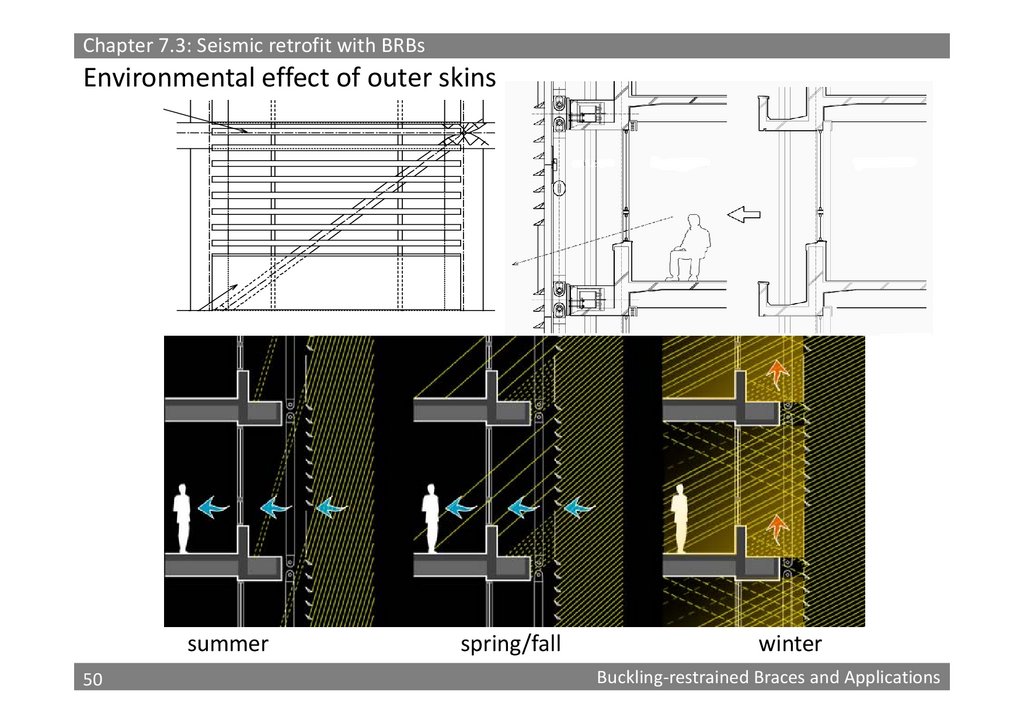

Chapter 7.3: Seismic retrofit with BRBsEnvironmental effect of outer skins

summer

50

50

spring/fall

winter

Buckling‐restrained Braces and Applications

51.

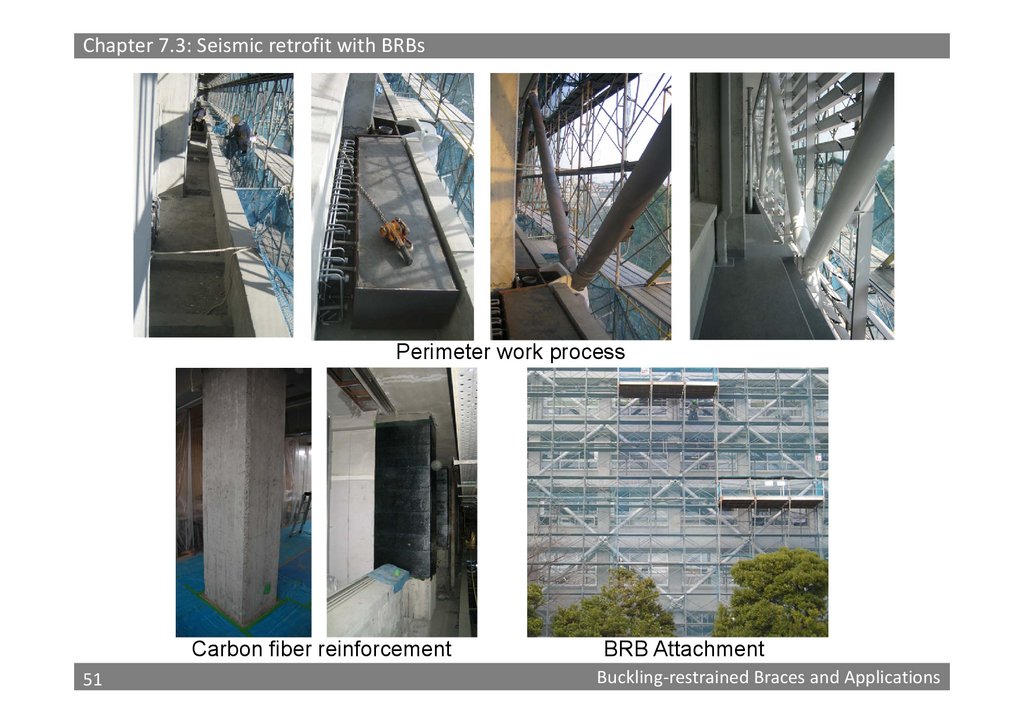

Chapter 7.3: Seismic retrofit with BRBsPerimeter work process

Carbon fiber reinforcement

51

51

BRB Attachment

Buckling‐restrained Braces and Applications

52.

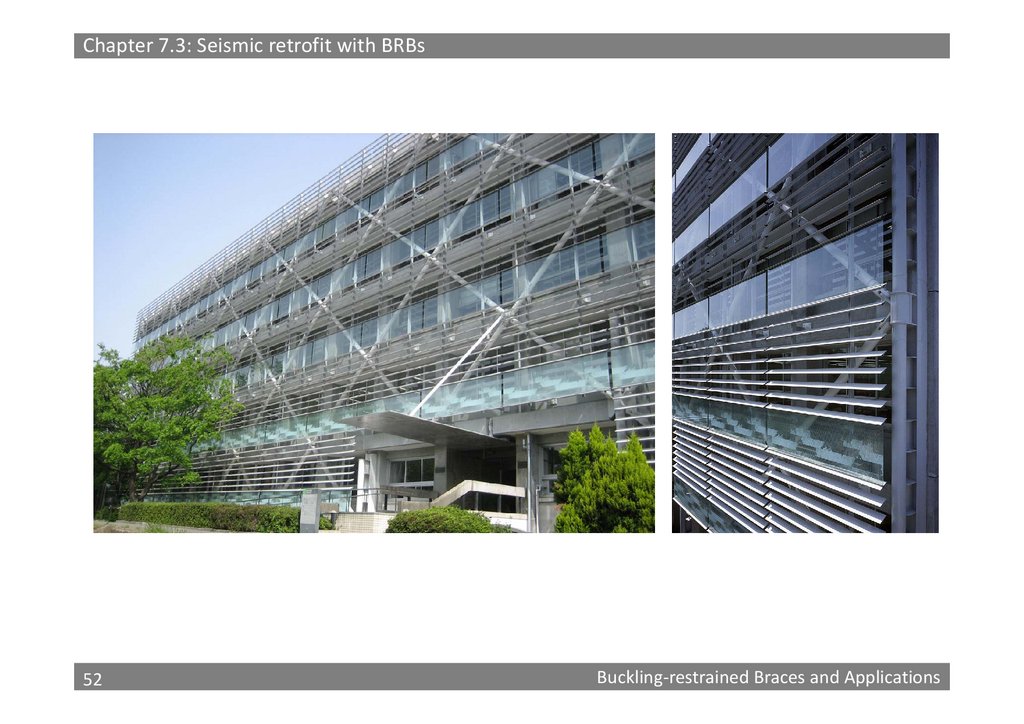

Chapter 7.3: Seismic retrofit with BRBs52

52

Buckling‐restrained Braces and Applications

53.

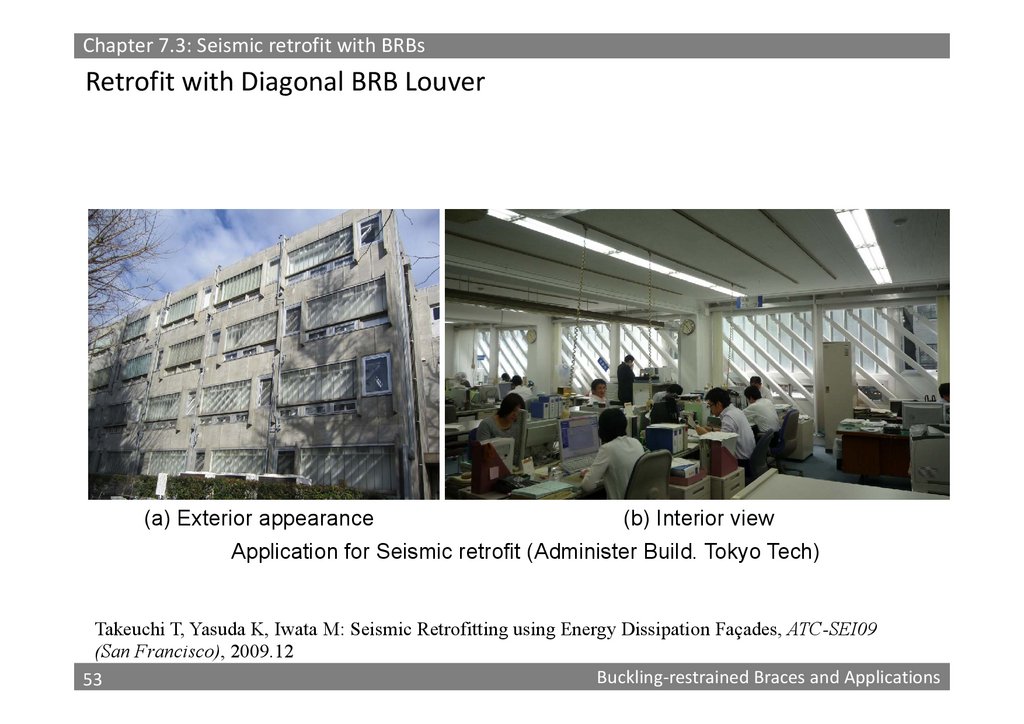

Chapter 7.3: Seismic retrofit with BRBsRetrofit with Diagonal BRB Louver

(a) Exterior appearance

(b) Interior view

Application for Seismic retrofit (Administer Build. Tokyo Tech)

Takeuchi T, Yasuda K, Iwata M: Seismic Retrofitting using Energy Dissipation Façades, ATC-SEI09

(San Francisco), 2009.12

53

Buckling‐restrained Braces and Applications

53

54.

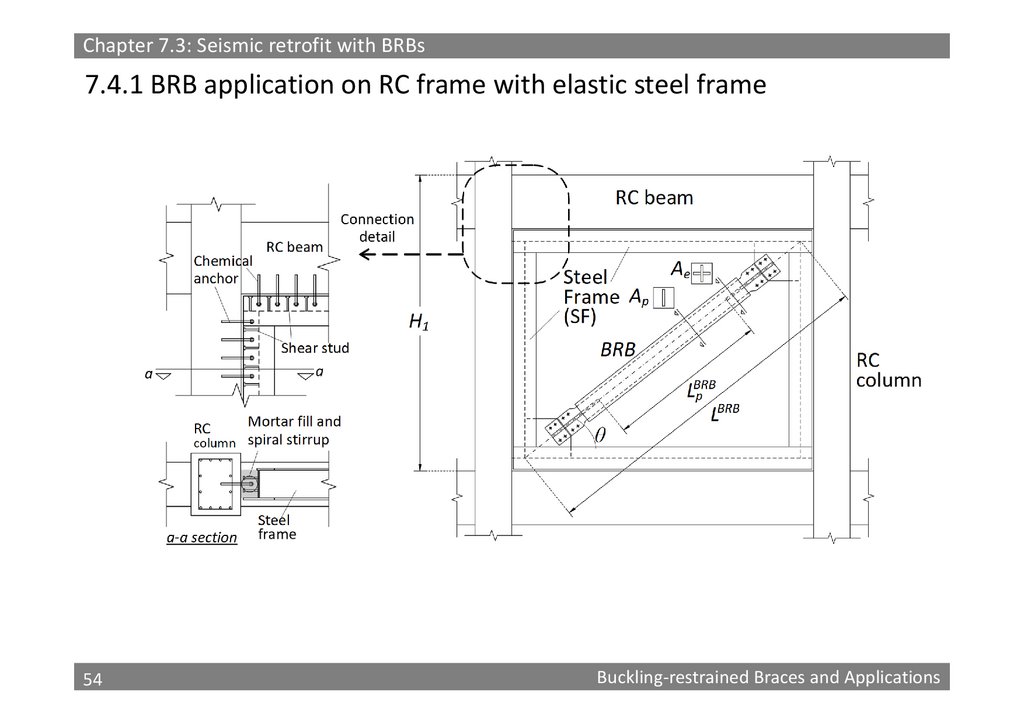

Chapter 7.3: Seismic retrofit with BRBs7.4.1 BRB application on RC frame with elastic steel frame

54

54

Buckling‐restrained Braces and Applications

55.

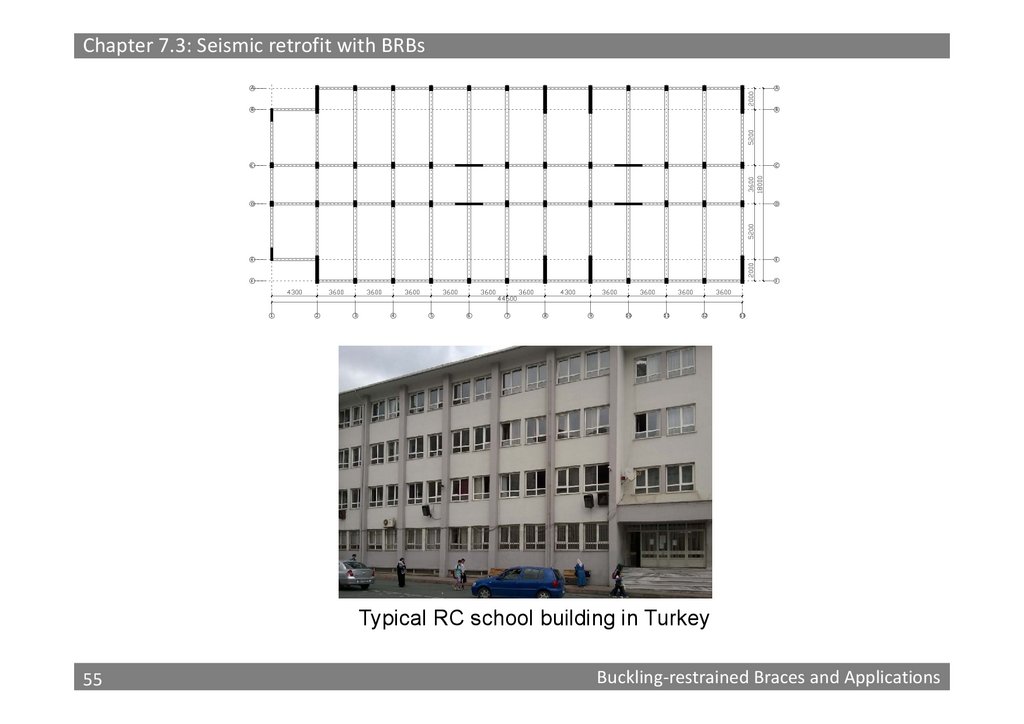

Chapter 7.3: Seismic retrofit with BRBsA

A

B

B

C

C

D

D

E

E

F

F

1

2

3

4

5

6

7

8

9

10

11

12

13

Typical RC school building in Turkey

55

55

Buckling‐restrained Braces and Applications

56.

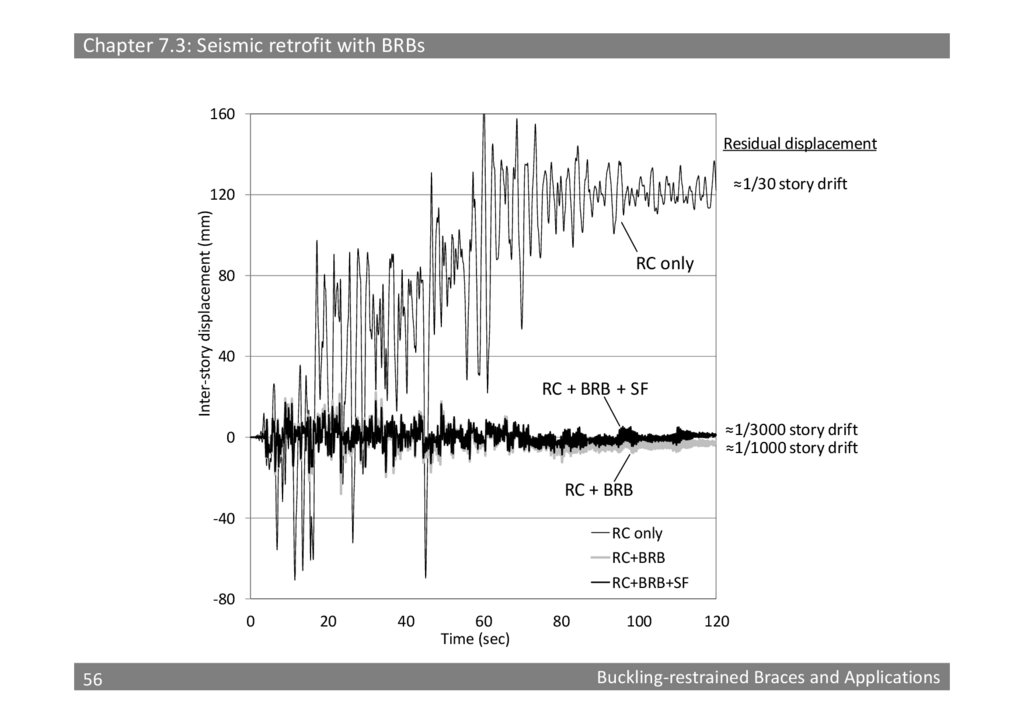

Chapter 7.3: Seismic retrofit with BRBs160

Residual displacement

≈1/30 story drift

Inter‐story displacement (mm)

120

RC only

80

40

RC + BRB + SF

≈1/3000 story drift

≈1/1000 story drift

0

RC + BRB

‐40

RC only

RC+BRB

RC+BRB+SF

‐80

0

56

56

20

40

60

Time (sec)

80

100

120

Buckling‐restrained Braces and Applications

57.

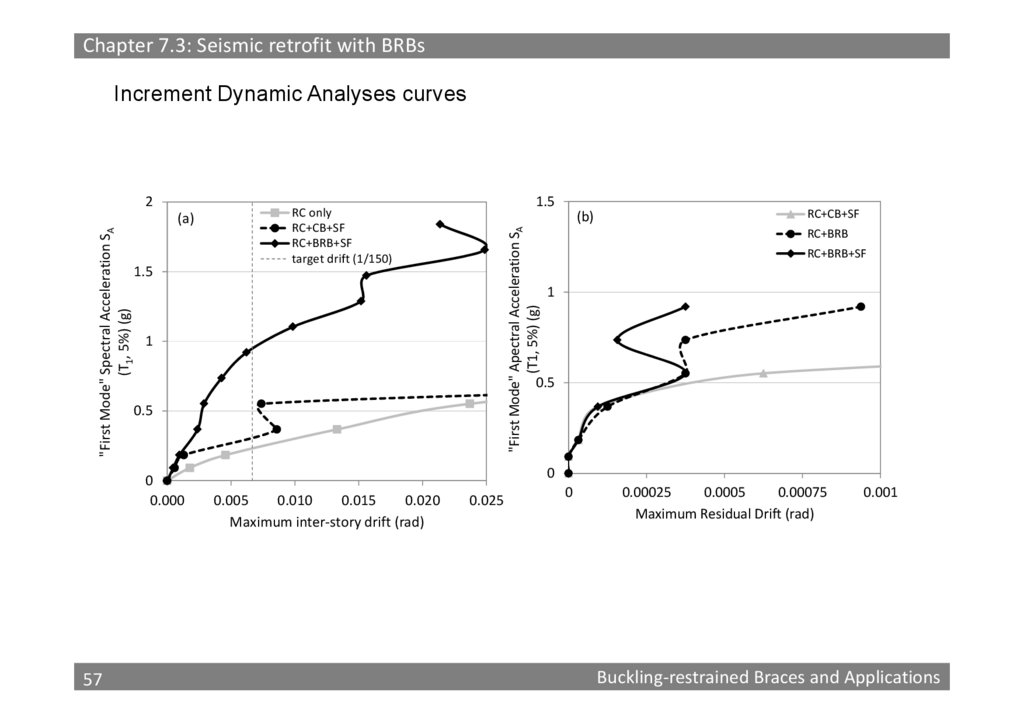

Chapter 7.3: Seismic retrofit with BRBsIncrement Dynamic Analyses curves

"First Mode" Spectral Acceleration SA

(T1, 5%) (g)

(a)

1.5

1.5

RC only

RC+CB+SF

RC+BRB+SF

target drift (1/150)

(b)

"First Mode" Apectral Acceleration SA

(T1, 5%) (g)

2

1

RC+BRB

RC+BRB+SF

1

0.5

0.5

0

0.000

57

57

RC+CB+SF

0

0.005

0.010

0.015

0.020

Maximum inter‐story drift (rad)

0.025

0

0.00025

0.0005

0.00075

Maximum Residual Drift (rad)

0.001

Buckling‐restrained Braces and Applications

58.

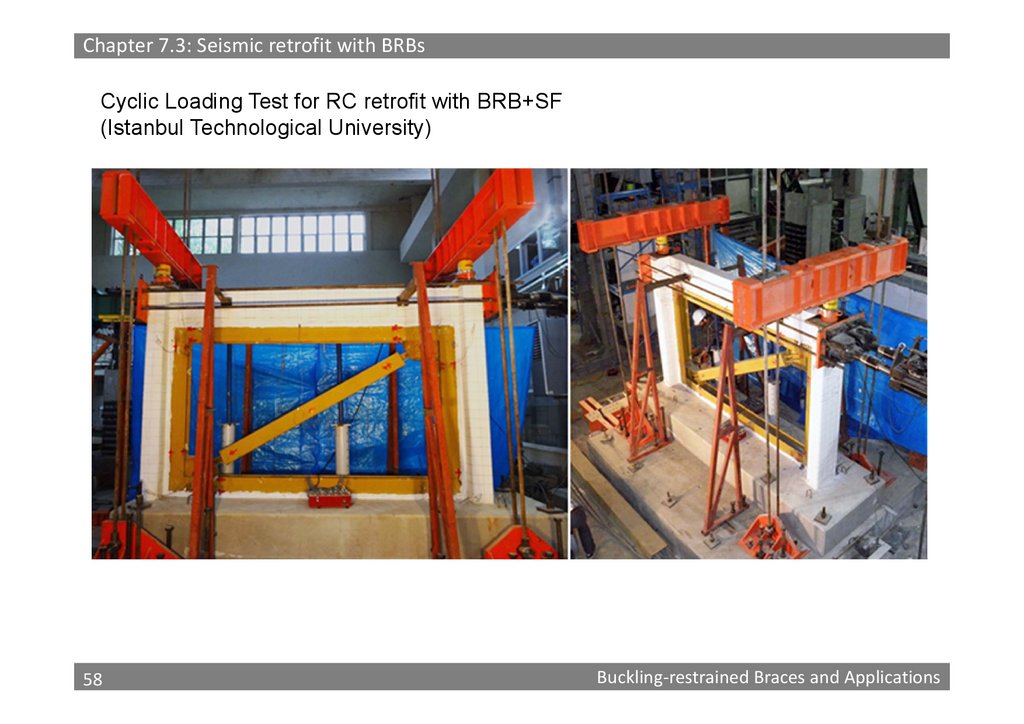

Chapter 7.3: Seismic retrofit with BRBsCyclic Loading Test for RC retrofit with BRB+SF

(Istanbul Technological University)

58

58

Buckling‐restrained Braces and Applications

59.

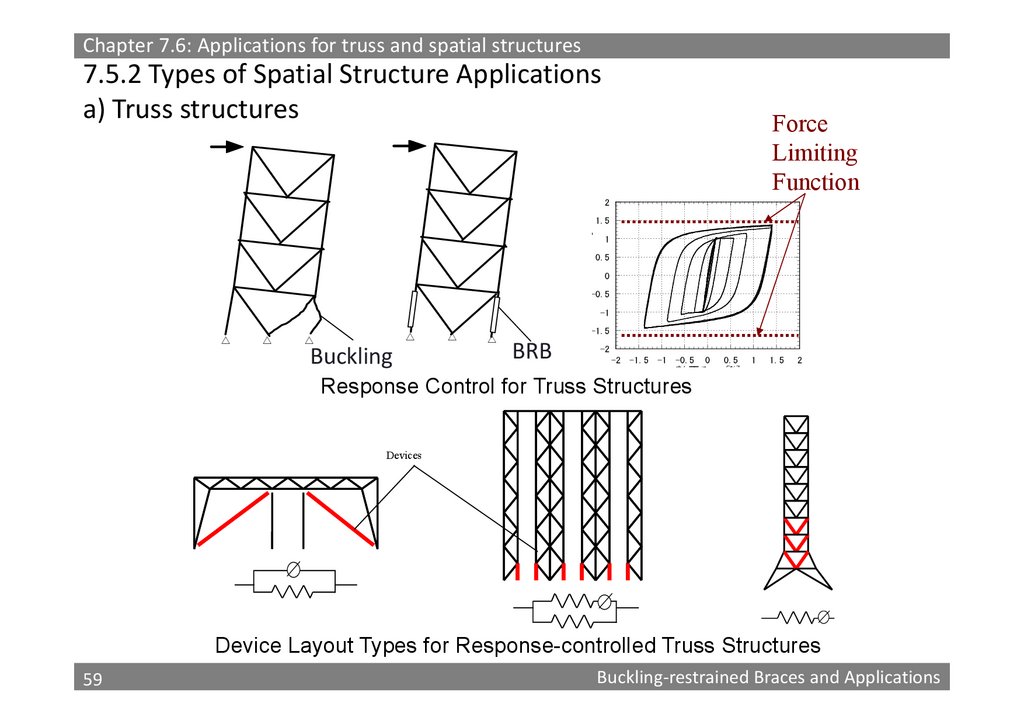

Chapter 7.6: Applications for truss and spatial structures7.5.2 Types of Spatial Structure Applications

a) Truss structures

Force

Limiting

Function

2

y

1.5

1

0.5

0

-0.5

-1

△

△

△

△

Buckling

△

△

-1.5

BRB

-2

-2

-1.5

-1

0

0.5

軸歪み

-0.5

[%]

Response Control for Truss Structures

1

1.5

2

Devices

Device Layout Types for Response-controlled Truss Structures

59

59

Buckling‐restrained Braces and Applications

60.

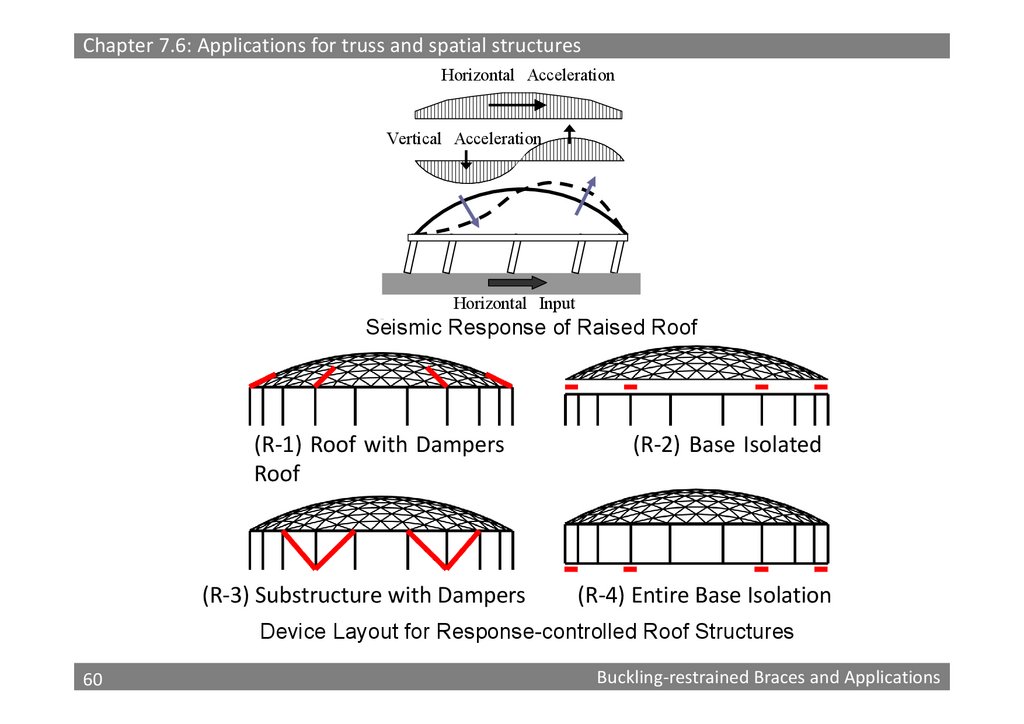

Chapter 7.6: Applications for truss and spatial structuresHorizontal Acceleration

Vertical Acceleration

Horizontal Input

Seismic Response of Raised Roof

(R‐1) Roof with Dampers

Roof

(R‐3) Substructure with Dampers

(R‐2) Base Isolated

(R‐4) Entire Base Isolation

Device Layout for Response-controlled Roof Structures

60

60

Buckling‐restrained Braces and Applications

61.

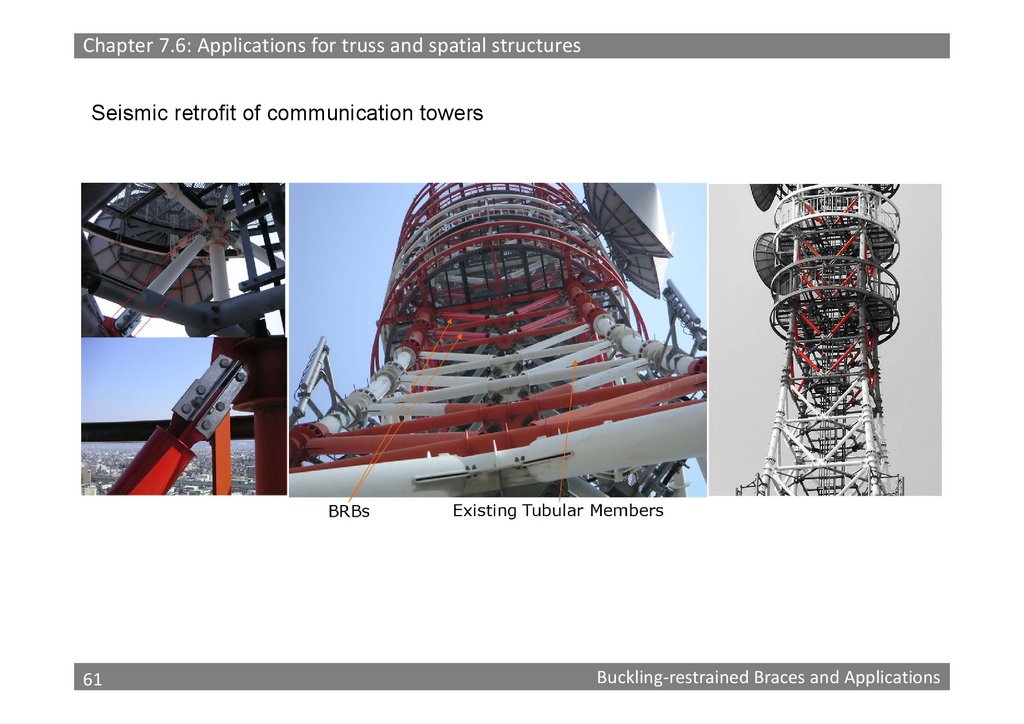

Chapter 7.6: Applications for truss and spatial structuresSeismic retrofit of communication towers

61

61

Buckling‐restrained Braces and Applications

62.

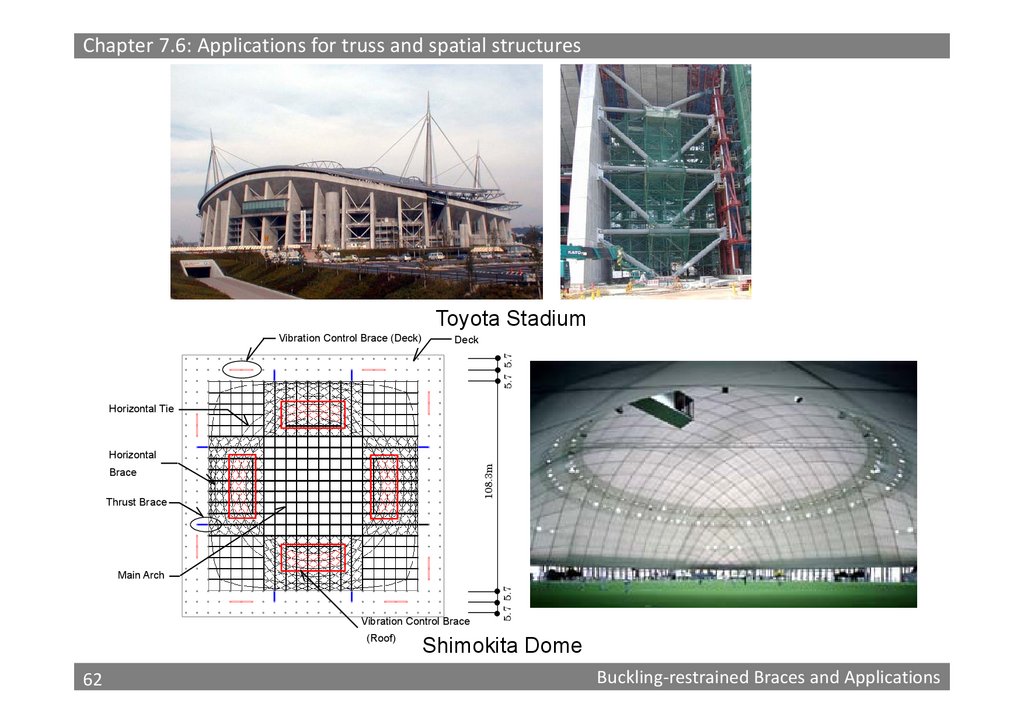

Chapter 7.6: Applications for truss and spatial structuresToyota Stadium

Deck

5.7 5.7

Vibration Control Brace (Deck)

Horizontal Tie

108.3m

Horizontal

Brace

Thrust Brace

Vibration Control Brace

(Roof)

62

62

5.7 5.7

Main Arch

Shimokita Dome

Buckling‐restrained Braces and Applications

63.

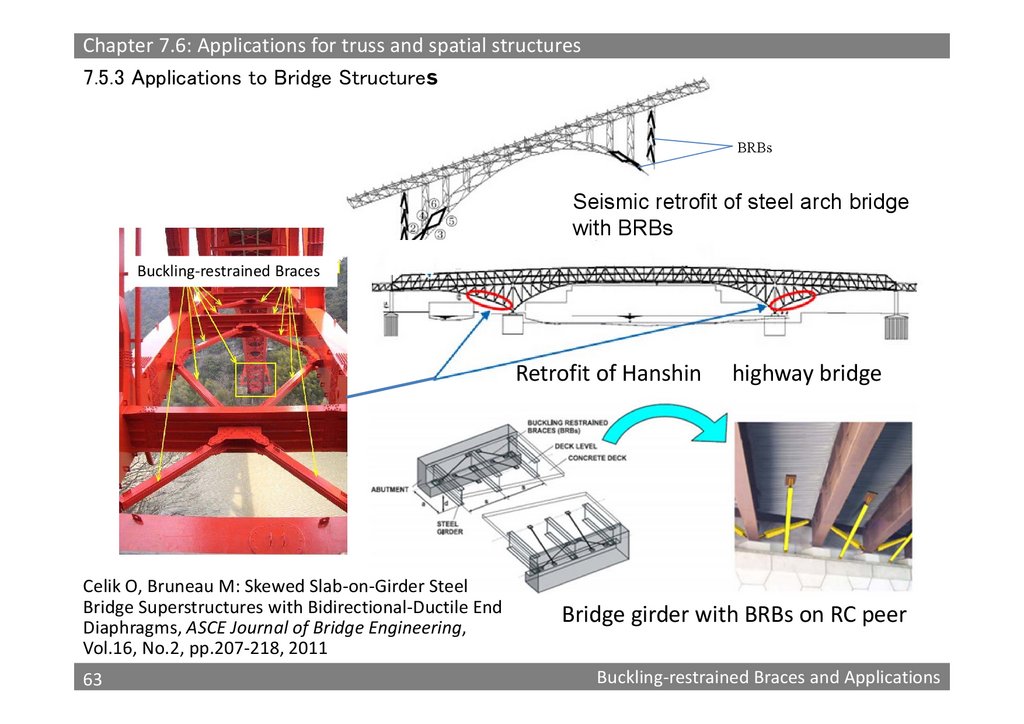

Chapter 7.6: Applications for truss and spatial structures7.5.3 Applications to Bridge Structures

BRBs

Seismic retrofit of steel arch bridge

with BRBs

Buckling‐restrained Braces

Retrofit of Hanshin

Celik O, Bruneau M: Skewed Slab‐on‐Girder Steel

Bridge Superstructures with Bidirectional‐Ductile End

Diaphragms, ASCE Journal of Bridge Engineering,

Vol.16, No.2, pp.207‐218, 2011

63

63

highway bridge

Bridge girder with BRBs on RC peer

Buckling‐restrained Braces and Applications

64.

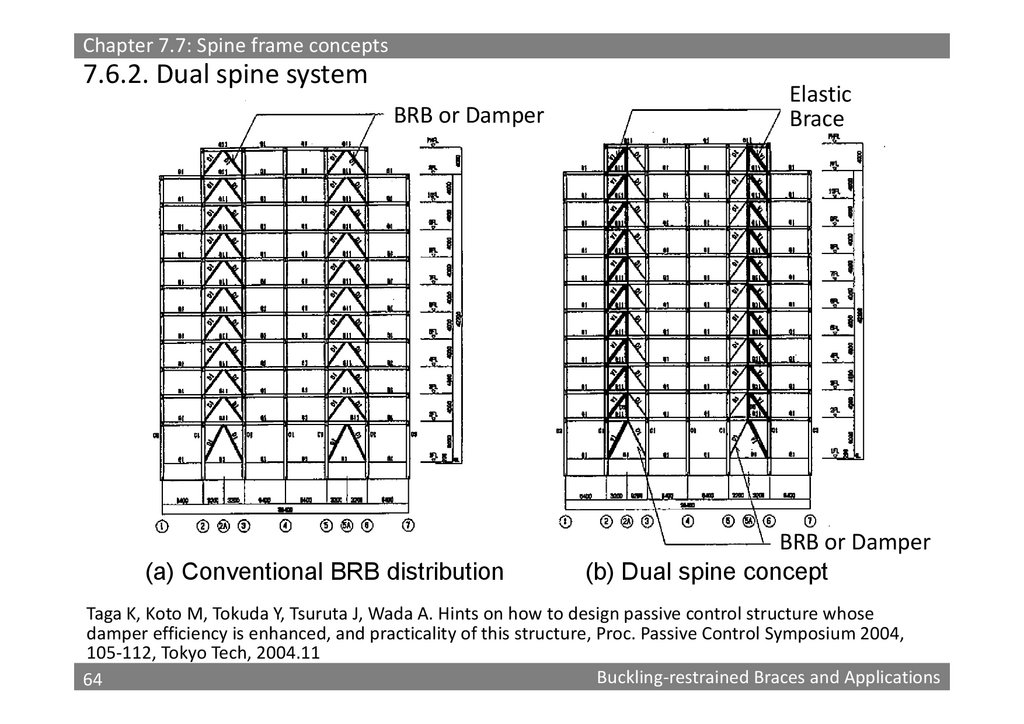

Chapter 7.7: Spine frame concepts7.6.2. Dual spine system

BRB or Damper

(a) Conventional BRB distribution

Elastic

Brace

BRB or Damper

(b) Dual spine concept

Taga K, Koto M, Tokuda Y, Tsuruta J, Wada A. Hints on how to design passive control structure whose

damper efficiency is enhanced, and practicality of this structure, Proc. Passive Control Symposium 2004,

105‐112, Tokyo Tech, 2004.11

64

Buckling‐restrained Braces and Applications

64

65.

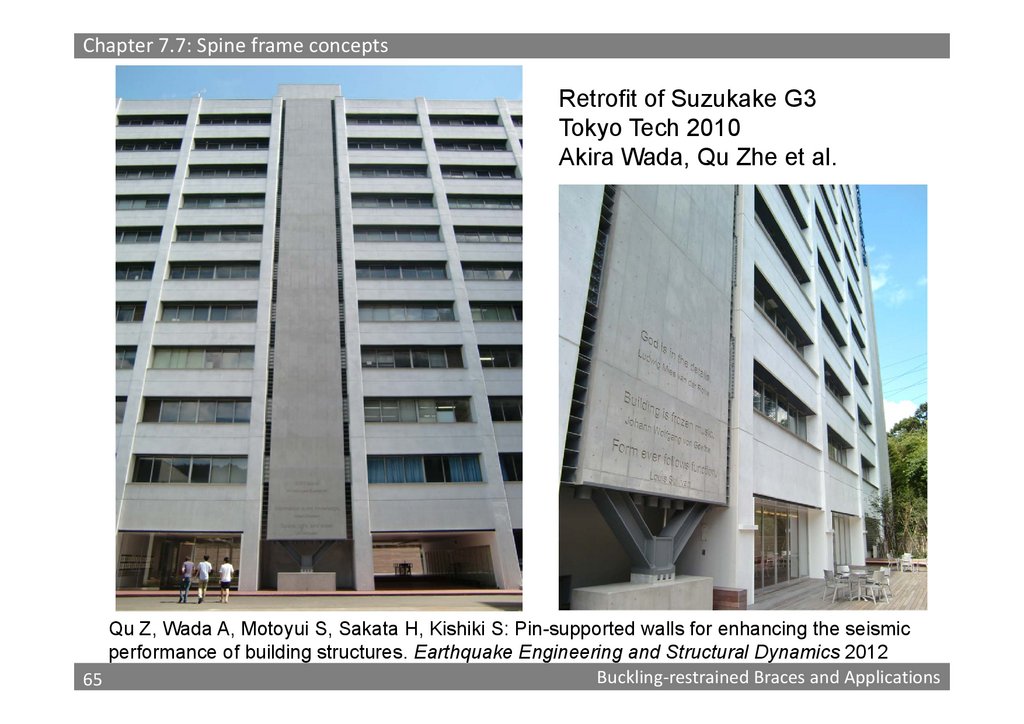

Chapter 7.7: Spine frame conceptsRetrofit of Suzukake G3

Tokyo Tech 2010

Akira Wada, Qu Zhe et al.

Qu Z, Wada A, Motoyui S, Sakata H, Kishiki S: Pin-supported walls for enhancing the seismic

performance of building structures. Earthquake Engineering and Structural Dynamics 2012

65

Buckling‐restrained Braces and Applications

65

66.

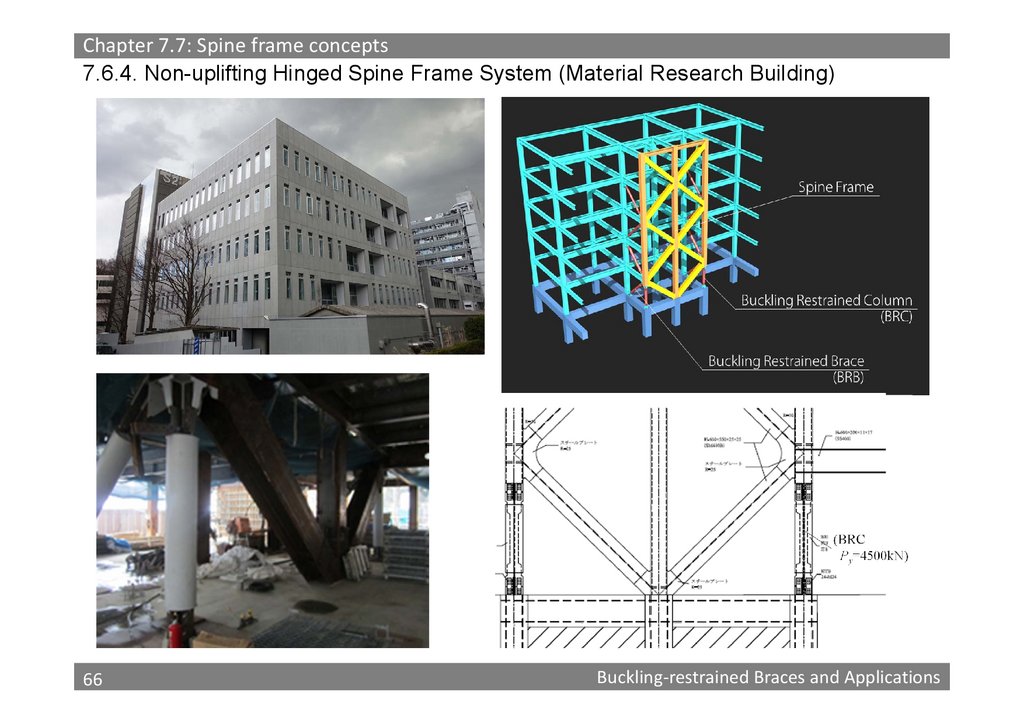

Chapter 7.7: Spine frame concepts7.6.4. Non-uplifting Hinged Spine Frame System (Material Research Building)

66

66

Buckling‐restrained Braces and Applications

67.

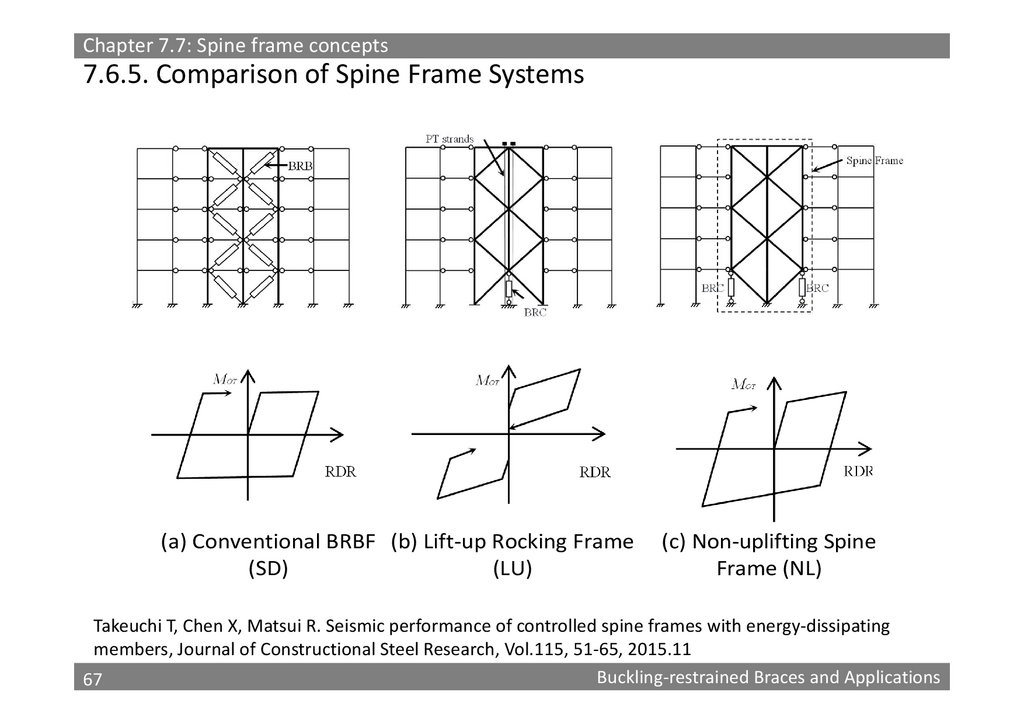

Chapter 7.7: Spine frame concepts7.6.5. Comparison of Spine Frame Systems

(a) Conventional BRBF (b) Lift‐up Rocking Frame

(SD)

(LU)

(c) Non‐uplifting Spine

Frame (NL)

Takeuchi T, Chen X, Matsui R. Seismic performance of controlled spine frames with energy‐dissipating

members, Journal of Constructional Steel Research, Vol.115, 51‐65, 2015.11

67

Buckling‐restrained Braces and Applications

67

68.

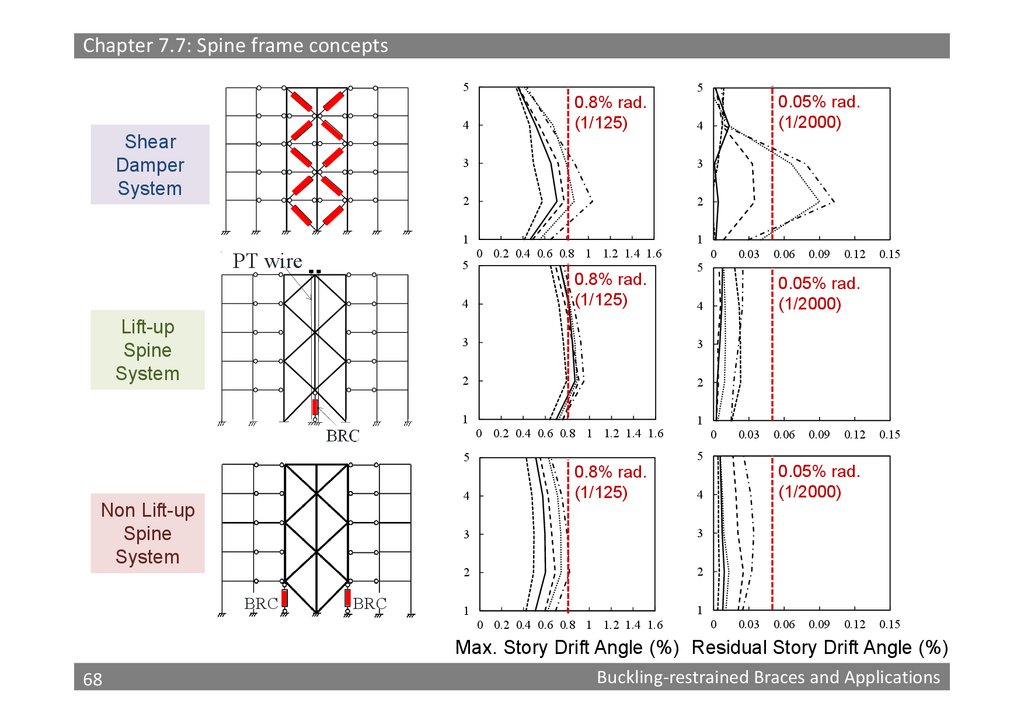

Chapter 7.7: Spine frame concepts5

4

Shear

Damper

System

0.8% rad.

(1/125)

3

2

2

5

4

Lift-up

Spine

System

1

0 0.2 0.4 0.6 0.8 1 1.2 1.4 1.6

0.8% rad.

(1/125)

2

2

0 0.2 0.4 0.6 0.8 1 1.2 1.4 1.6

5

4

BRC

BRC

0.8% rad.

(1/125)

0.03

0.06

0.09

0.12

0.15

0.05% rad.

(1/2000)

4

3

1

Non Lift-up

Spine

System

0

5

3

BRC

0.05% rad.

(1/2000)

4

3

1

PT wire

5

1

0

0.03

5

3

2

2

0.09

0.12

0.15

0.05% rad.

(1/2000)

4

3

0.06

1

1

0 0.2 0.4 0.6 0.8 1 1.2 1.4 1.6

0

0.03

0.06

0.09

0.12

0.15

Max. Story Drift Angle (%) Residual Story Drift Angle (%)

68

68

Buckling‐restrained Braces and Applications

69.

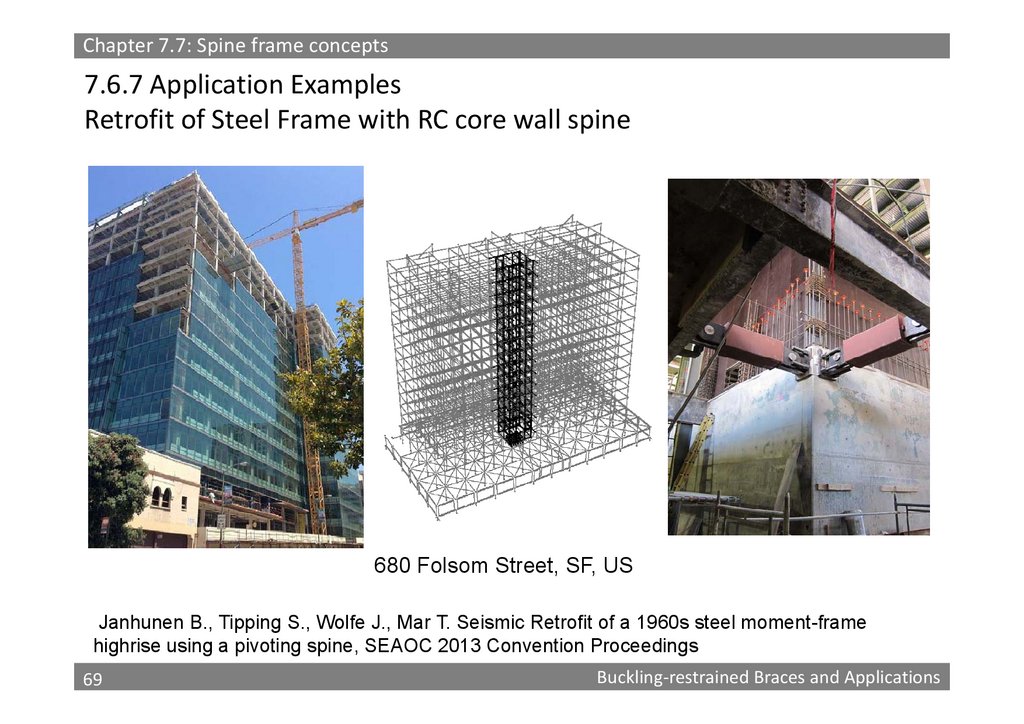

Chapter 7.7: Spine frame concepts7.6.7 Application Examples

Retrofit of Steel Frame with RC core wall spine

680 Folsom Street, SF, US

Janhunen B., Tipping S., Wolfe J., Mar T. Seismic Retrofit of a 1960s steel moment-frame

highrise using a pivoting spine, SEAOC 2013 Convention Proceedings

69

69

Buckling‐restrained Braces and Applications

70.

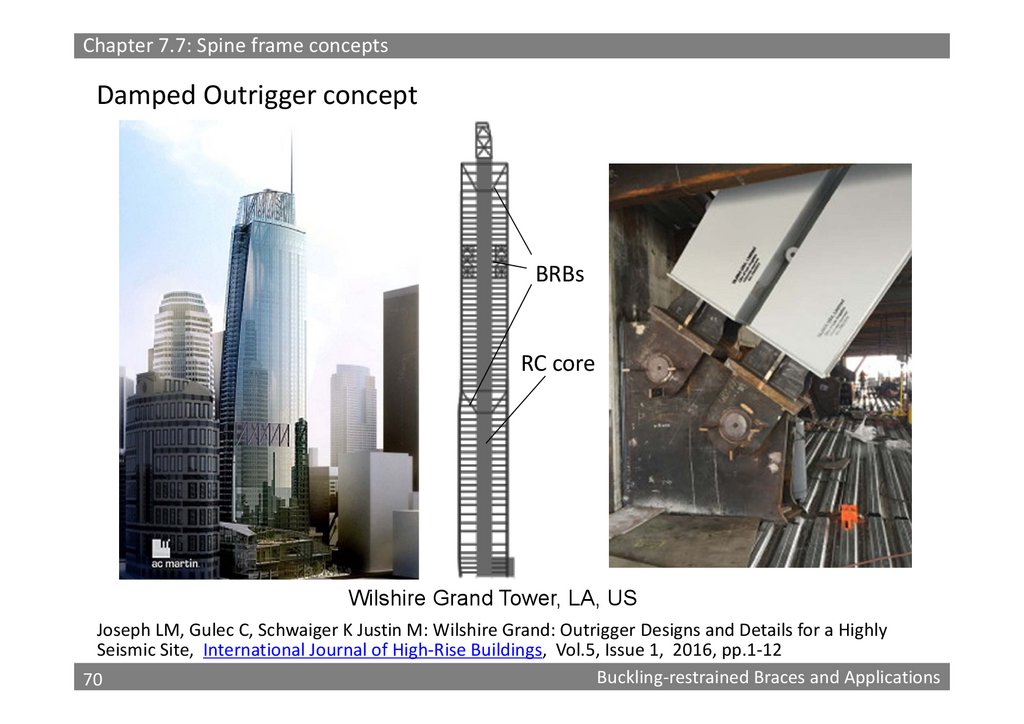

Chapter 7.7: Spine frame conceptsDamped Outrigger concept

BRBs

RC core

Wilshire Grand Tower, LA, US

Joseph LM, Gulec C, Schwaiger K Justin M: Wilshire Grand: Outrigger Designs and Details for a Highly

Seismic Site, International Journal of High‐Rise Buildings, Vol.5, Issue 1, 2016, pp.1‐12

70

Buckling‐restrained Braces and Applications

70

71.

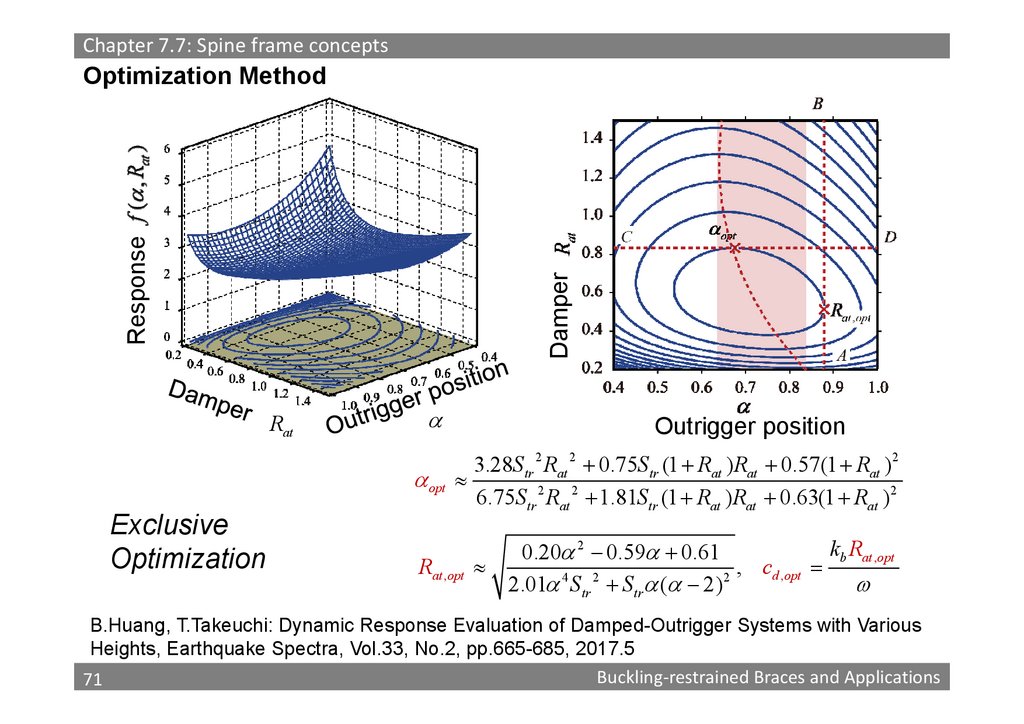

Chapter 7.7: Spine frame conceptsDamper

Response

Optimization Method

Rat

opt

Exclusive

Optimization

Outrigger position

3.28Str 2 Rat 2 0.75Str (1 Rat ) Rat 0.57(1 Rat ) 2

6.75Str 2 Rat 2 1.81Str (1 Rat ) Rat 0.63(1 Rat ) 2

Rat , opt

kb Rat , opt

0.20 2 0.59 0.61

,

c

d , opt

2.01 4 Str 2 Str ( 2) 2

B.Huang, T.Takeuchi: Dynamic Response Evaluation of Damped-Outrigger Systems with Various

Heights, Earthquake Spectra, Vol.33, No.2, pp.665-685, 2017.5

71

Buckling‐restrained Braces and Applications

71

72.

Chapter 7.6: Applications for truss and spatial structuresThe latest knowledge is overviewed in

Buckling-Restrained Braces and

Applications

T. Takeuchi and A. Wada, Japan Society of

Seismic Isolation, 2017

mail to contactjssi@jssi.or.jp

30-years from the first application, BRBs are still actively researched and

expanding applications. I am looking forward to further development in

the future.

72

72

Buckling‐restrained Braces and Applications

73.

Thank you very much for your kind attention73

Construction

Construction