Similar presentations:

Cement production process

1.

CEMENT PRODUCTIONPROCESS

2.

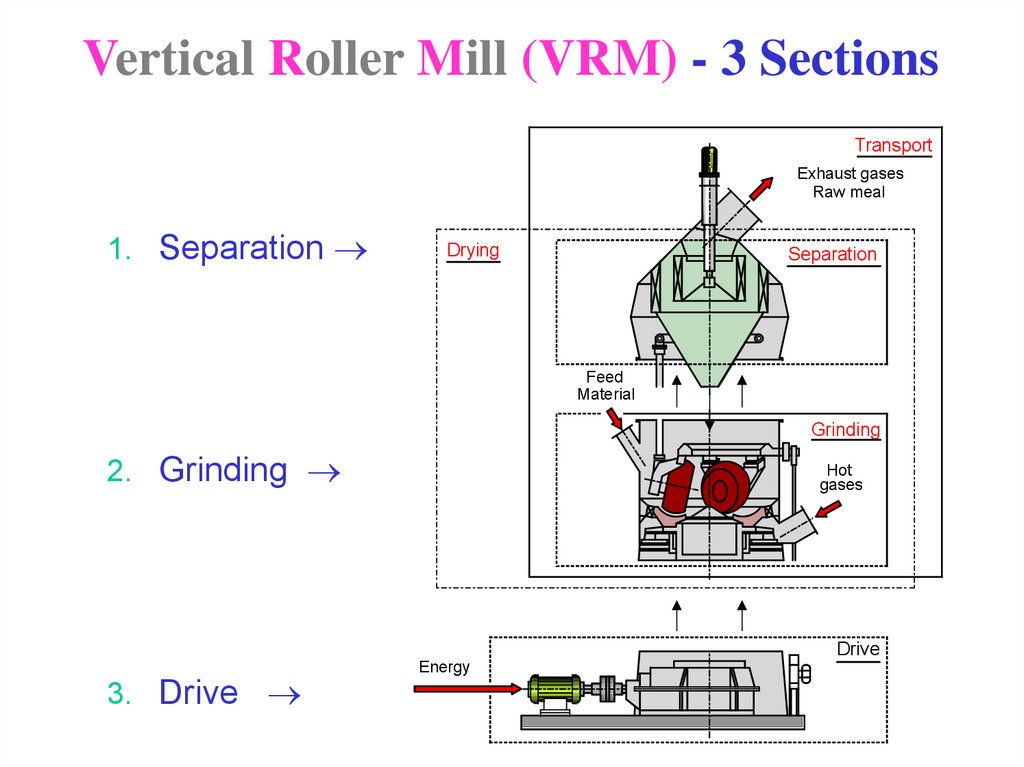

ROLLER MILL3. Vertical Roller Mill (VRM) - 3 Sections

TransportExhaust gases

Raw meal

1. Separation

Drying

Separation

Feed

Material

Grinding

2. Grinding

Hot

gases

Drive

3. Drive

Energy

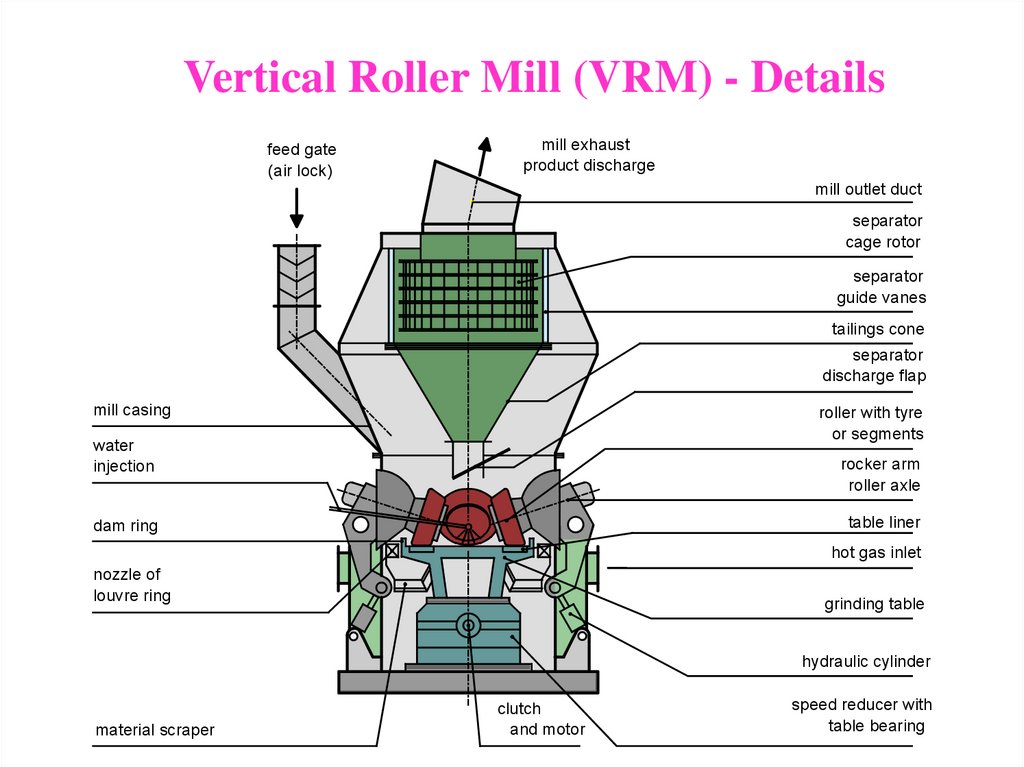

4. Vertical Roller Mill (VRM) - Details

feed gate(air lock)

mill exhaust

product discharge

mill outlet duct

separator

cage rotor

separator

guide vanes

tailings cone

separator

discharge flap

mill casing

roller with tyre

or segments

water

injection

rocker arm

roller axle

table liner

dam ring

hot gas inlet

nozzle of

louvre ring

grinding table

hydraulic cylinder

material scraper

clutch

and motor

speed reducer with

table bearing

5.

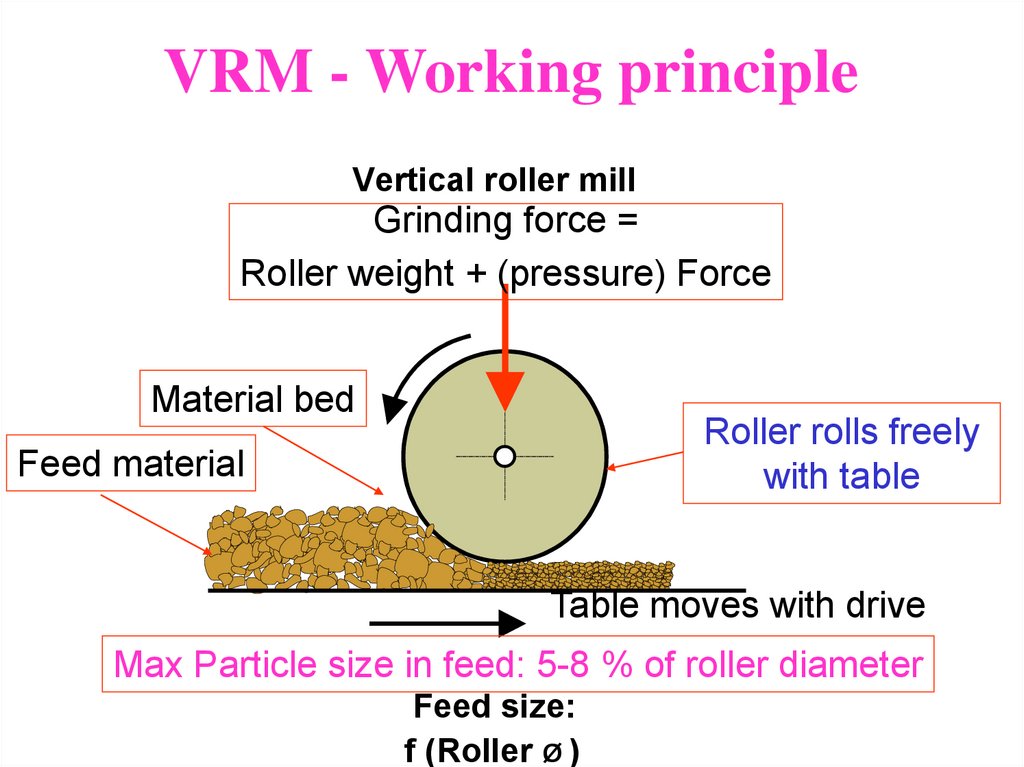

VRM - Working principleVertical roller mill

Grinding force =

Roller weight + (pressure) Force

Material bed

Roller rolls freely

with table

Feed material

Table moves with drive

Max Particle size in feed: 5-8 % of roller diameter

Feed size:

f (Roller Ø )

6.

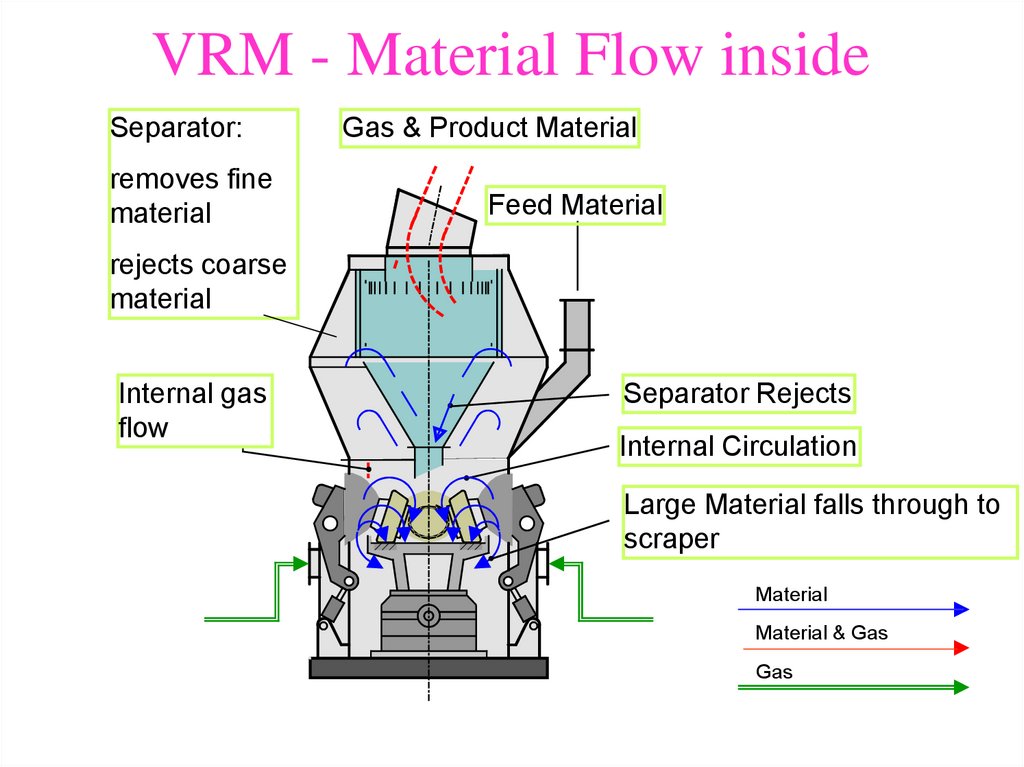

VRM - Material Flow insideSeparator:

removes fine

material

Gas & Product Material

Feed Material

rejects coarse

material

Internal gas

flow

Separator Rejects

Internal Circulation

Large Material falls through to

scraper

Material

Material & Gas

Gas

7.

VRM - Some Common Mill ConfigurationsG.Pfeiffer

Loesche

FLS Atox

Polysius

8.

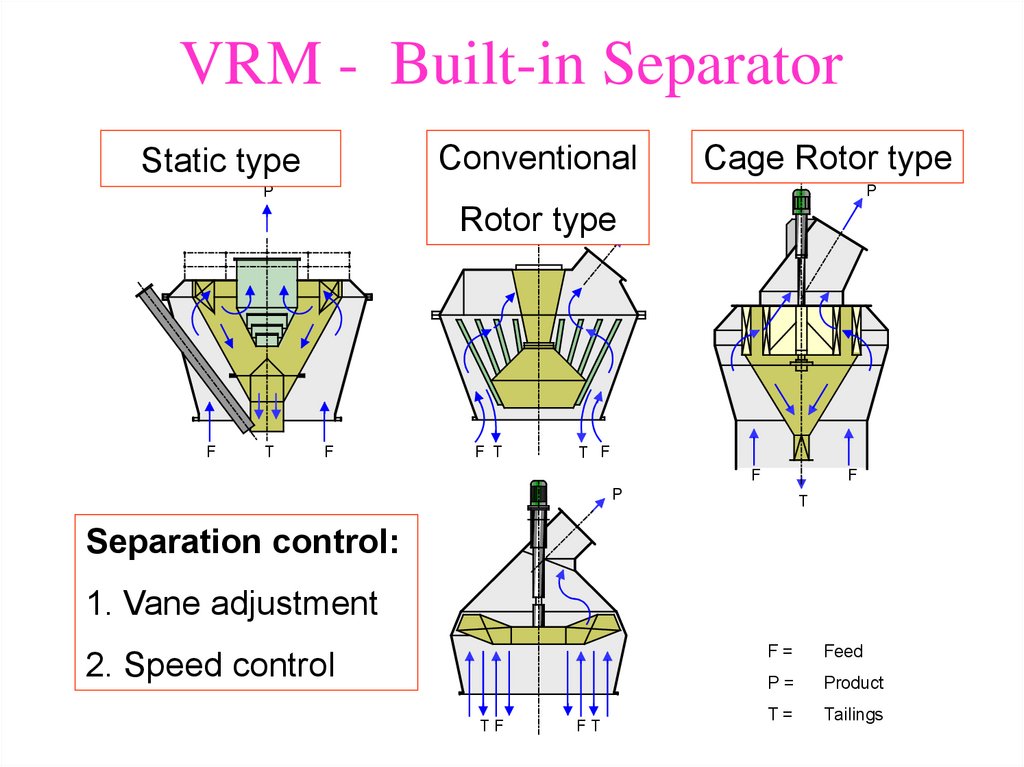

VRM - Built-in Separatorstatic separator

Static

type

conventional rotor type

Conventional

cage rotor type

Cage

Rotor type

with guide vanes

P

P

Rotor type

F

T

F

F T

P

T F

F

F

P

T

Separation control:

1. Vane adjustment

2. Speed control

TF

FT

F=

Feed

P=

Product

T=

Tailings

9.

Separators ofrd

3

Generation

(Vertical roller mill)

Reject cone

Cage rotor

Guide vane system

10.

VRM - Separator FotosAngle affects

product sizing

Rotor speed affects

product fineness

Rotor seal affects

separator efficiency

11.

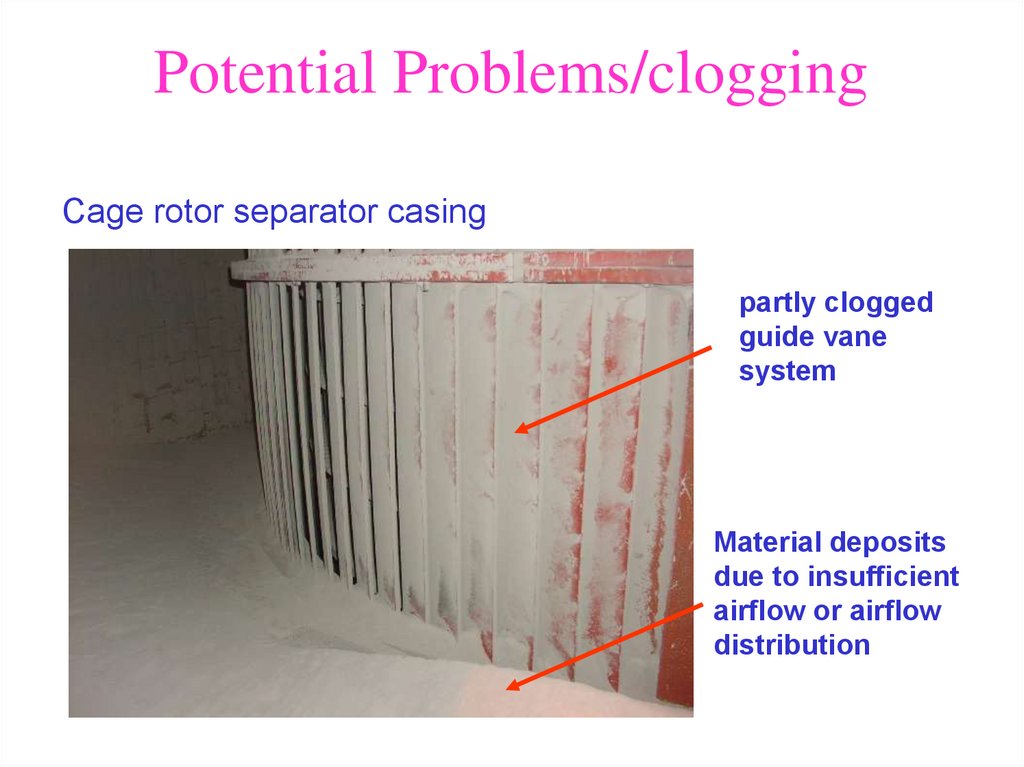

Potential Problems/cloggingCage rotor separator casing

partly clogged

guide vane

system

Material deposits

due to insufficient

airflow or airflow

distribution

12.

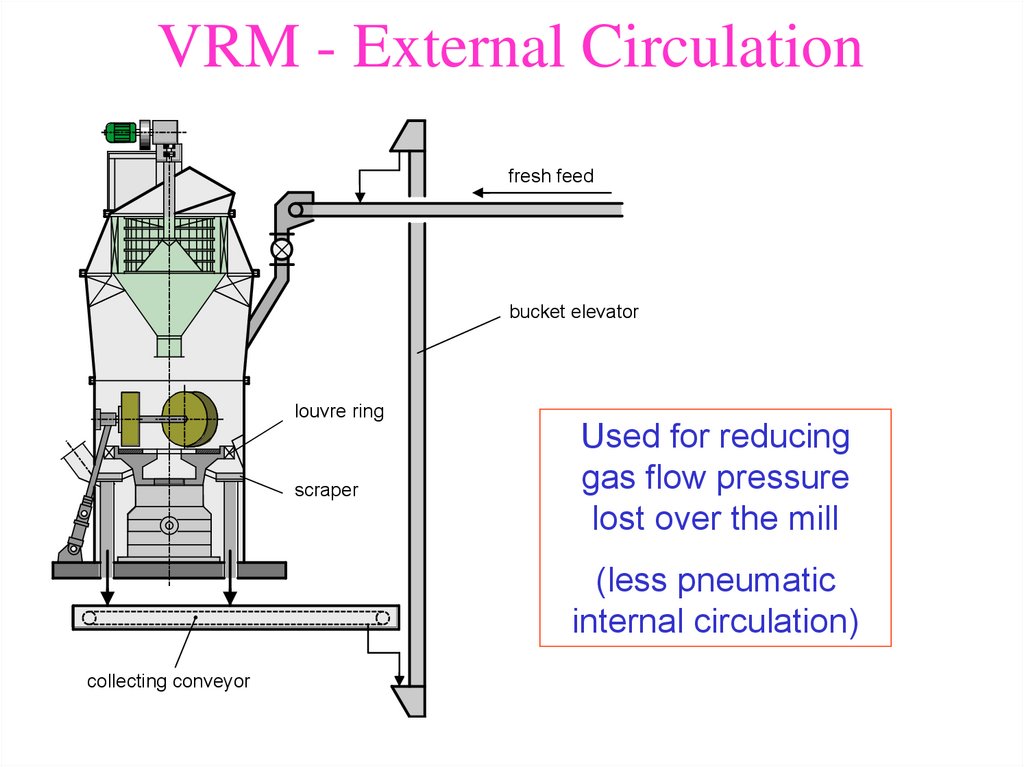

VRM - External Circulationfresh feed

bucket elevator

louvre ring

scraper

Used for reducing

gas flow pressure

lost over the mill

(less pneumatic

internal circulation)

collecting conveyor

13.

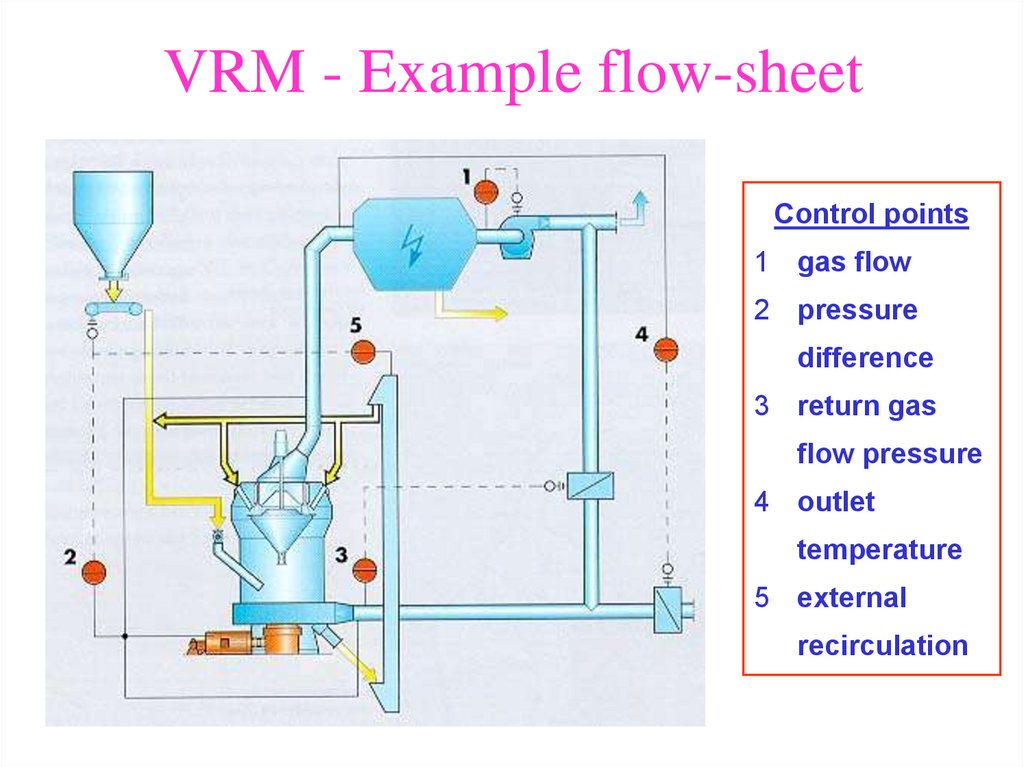

VRM - Example flow-sheetControl points

1 gas flow

2 pressure

difference

3 return gas

flow pressure

4 outlet

temperature

5 external

recirculation

14.

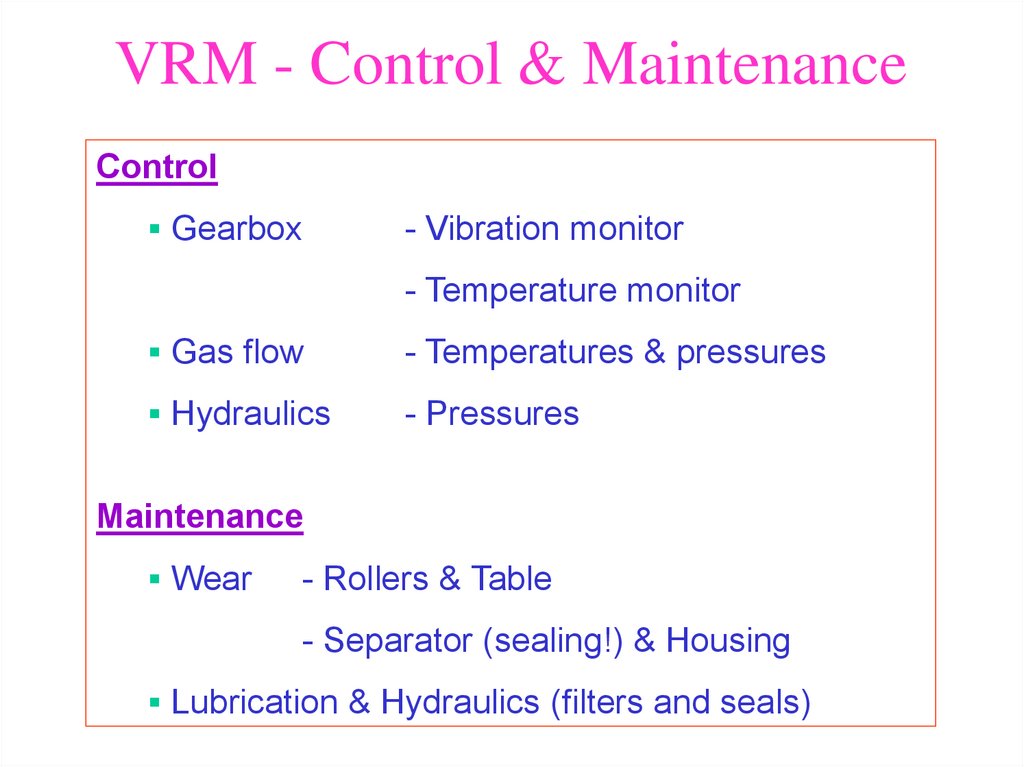

VRM - Control & MaintenanceControl

Gearbox

- Vibration monitor

- Temperature monitor

Gas flow

- Temperatures & pressures

Hydraulics

- Pressures

Maintenance

Wear

- Rollers & Table

- Separator (sealing!) & Housing

Lubrication & Hydraulics (filters and seals)

15.

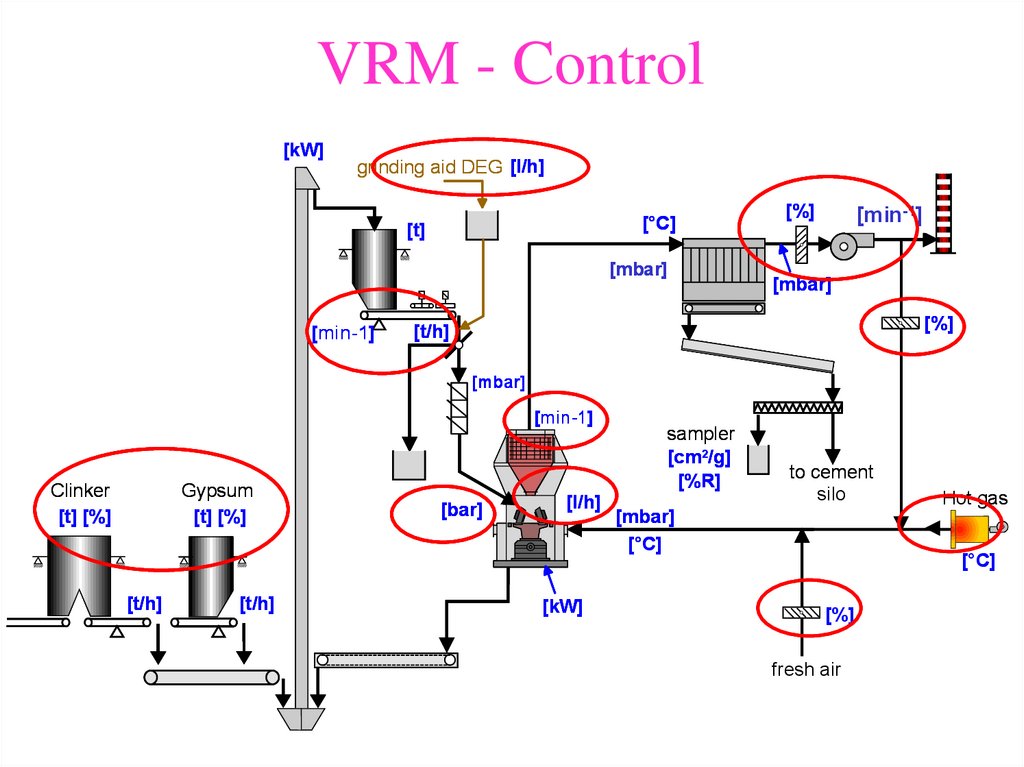

VRM - Control[kW]

grinding aid DEG [l/h]

[°C]

[t]

[mbar]

[min-1]

[%]

-1]

[min

[l/min]

[mbar]

[%]

[t/h]

[mbar]

[min-1]

Clinker

[t] [%]

Gypsum

[t] [%]

[t/h]

[t/h]

[bar]

[l/h]

[kW]

sampler

[cm2/g]

[%R]

to cement

silo

[mbar]

[°C]

Hot gas

[°C]

[%]

fresh air

16.

Vertical roller mill internals suffering from wearOutlet duct

Inlet chute

Separator

Separator cone

Mill housing

Armour &

nozzle rings

Rollers and

table liners

Scrapers

17.

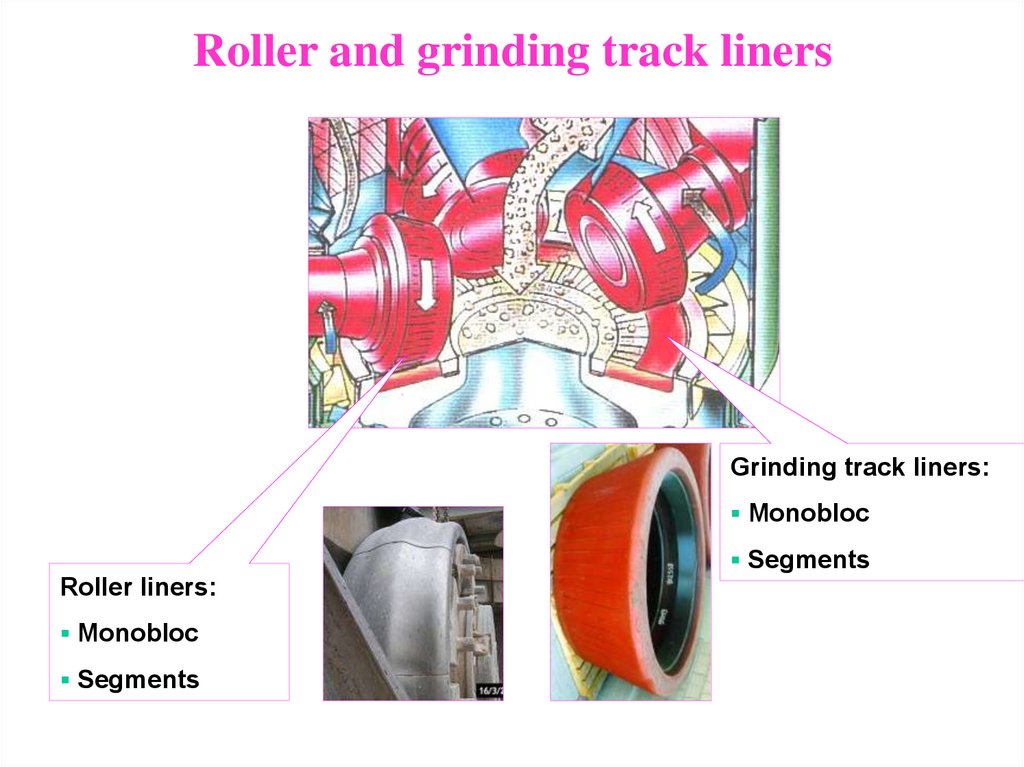

Roller and grinding track linersGrinding track liners:

Monobloc

Segments

Roller liners:

Monobloc

Segments

18.

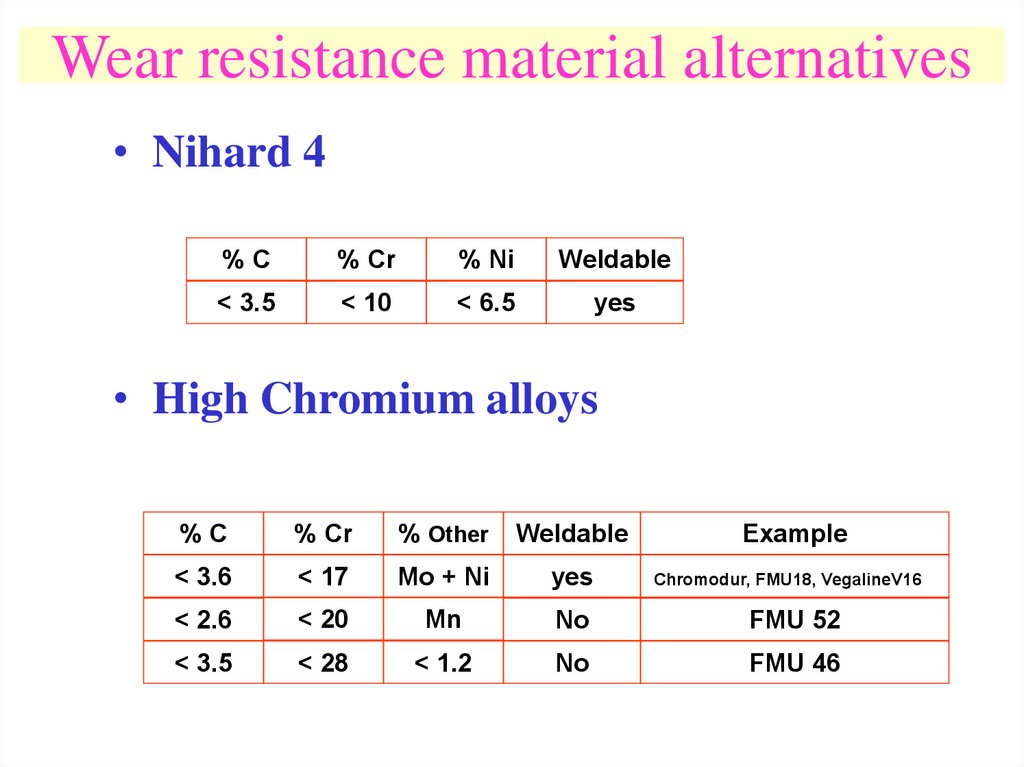

Wear resistance material alternatives• Nihard 4

%C

% Cr

% Ni

Weldable

< 3.5

< 10

< 6.5

yes

• High Chromium alloys

%C

% Cr

% Other

Weldable

Example

< 3.6

< 17

Mo + Ni

yes

Chromodur, FMU18, VegalineV16s

< 2.6

< 20

Mn

No

FMU 52

< 3.5

< 28

< 1.2

No

FMU 46

19.

Wear resistance material alternatives• Metallic inserts roller liner

Soft material base

Hard metallic insert

20.

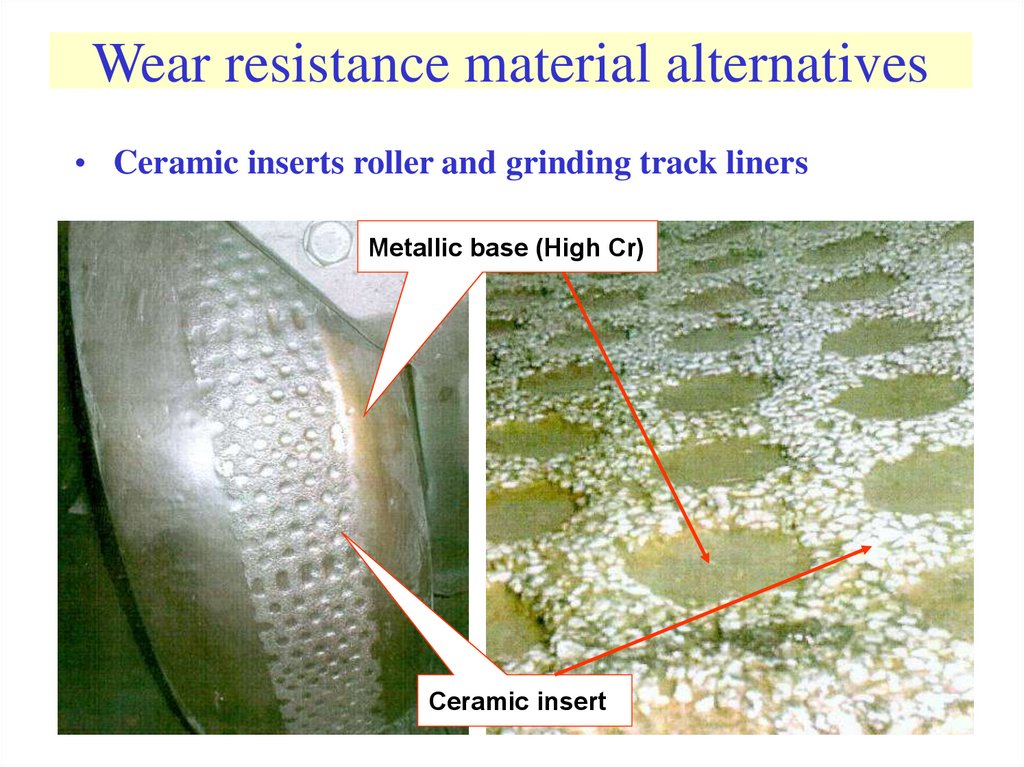

Wear resistance material alternatives• Ceramic inserts roller and grinding track liners

Metallic base (High Cr)

Ceramic insert

21.

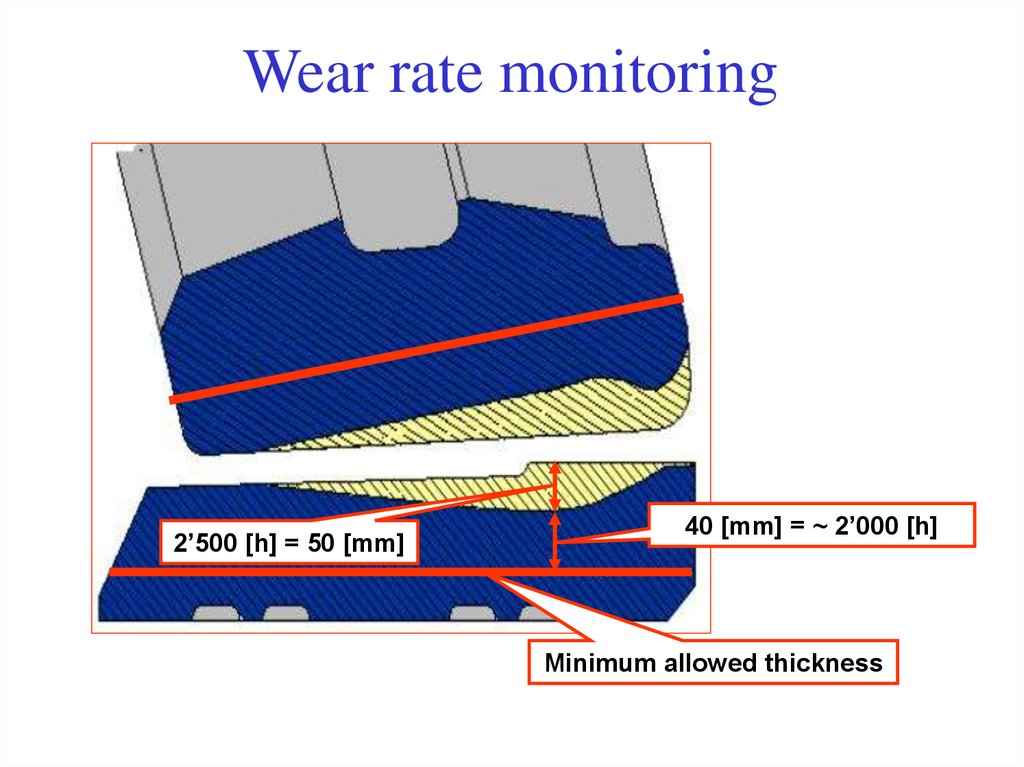

Wear rate monitoring2’500 [h] = 50 [mm]

40 [mm] = ~ 2’000 [h]

Minimum allowed thickness

22.

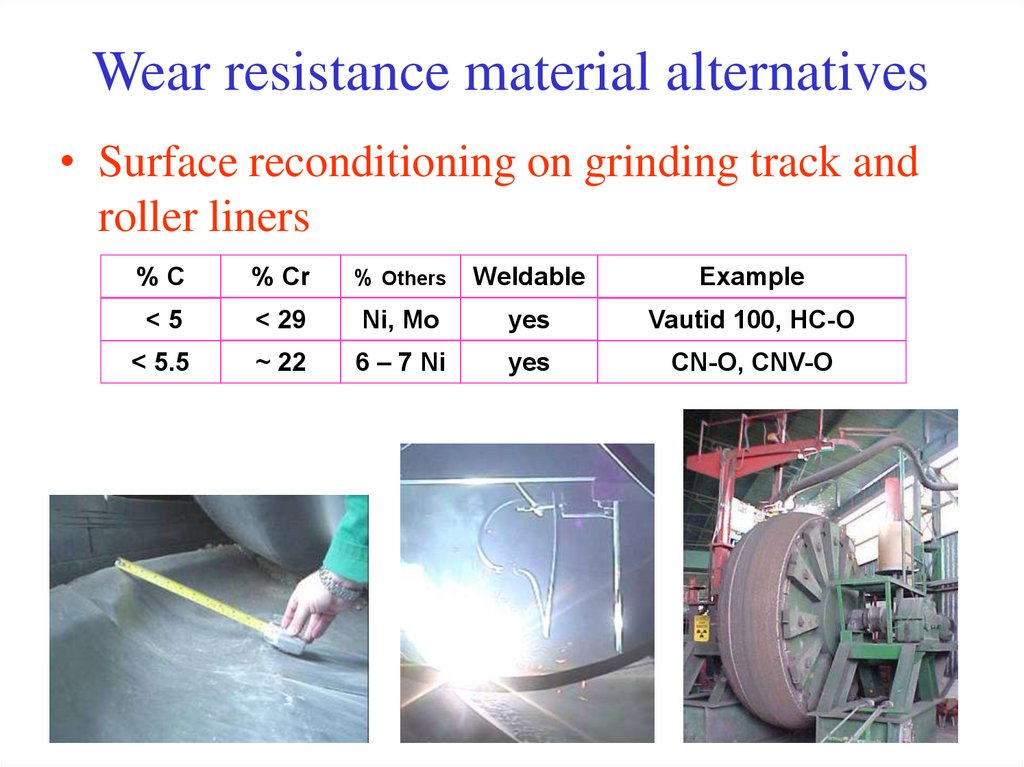

Wear resistance material alternatives• Surface reconditioning on grinding track and

roller liners

%C

% Cr

% Others

Weldable

Example

<5

< 29

Ni, Mo

yes

Vautid 100, HC-O

< 5.5

~ 22

6 – 7 Ni

yes

CN-O, CNV-O

23.

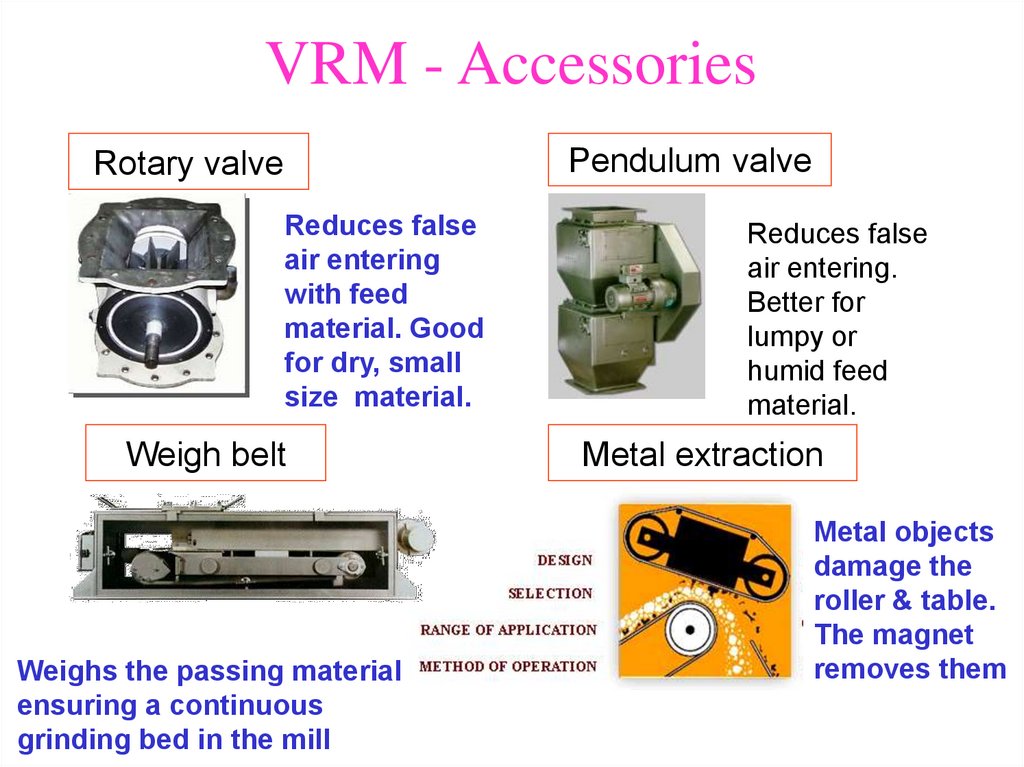

VRM - AccessoriesPendulum valve

Rotary valve

Reduces false

air entering

with feed

material. Good

for dry, small

size material.

Weigh belt

Weighs the passing material

ensuring a continuous

grinding bed in the mill

Reduces false

air entering.

Better for

lumpy or

humid feed

material.

Metal extraction

Metal objects

damage the

roller & table.

The magnet

removes them

industry

industry