Similar presentations:

Single screw compressor presentation. Working principle & inspection guidelines

1.

Single screw compressor presentationWorking principle & inspection guidelines

2. Daikin Single G-type Screw Compressor

Internal Use OnlyDaikin Single G-type Screw

Compressor

G - Type Single Screw

R134a

Up to 90 KW120 Hp

R407C

Up to 135KW/180 Hp

22-Apr-20

2

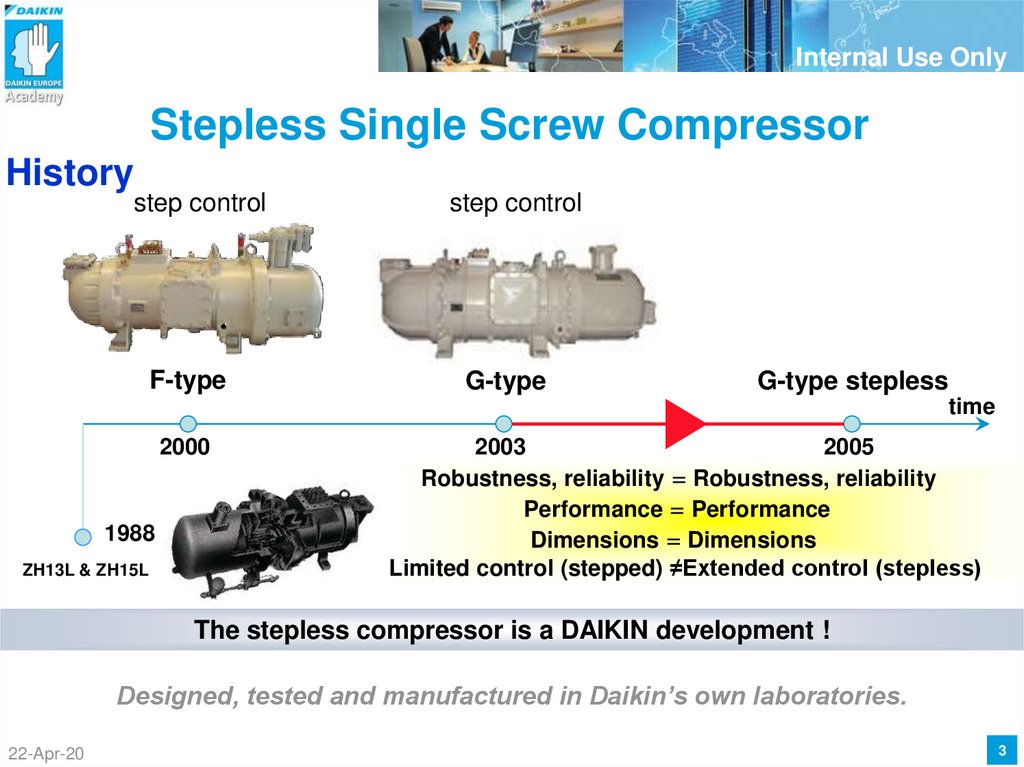

3. Stepless Single Screw Compressor

Internal Use OnlyStepless Single Screw Compressor

History

step control

F-type

step control

G-type

G-type stepless

time

2000

1988

ZH13L & ZH15L

2003

2005

Robustness, reliability = Robustness, reliability

Performance = Performance

Dimensions = Dimensions

Limited control (stepped) ≠Extended control (stepless)

The stepless compressor is a DAIKIN development !

Designed, tested and manufactured in Daikin’s own laboratories.

22-Apr-20

3

4. G type compressor

Internal Use OnlyG type compressor

• Nomenclature

3-5-7-9 sizes

G, G4 = step

GU,G5, G6 =Stepless

22-Apr-20

4

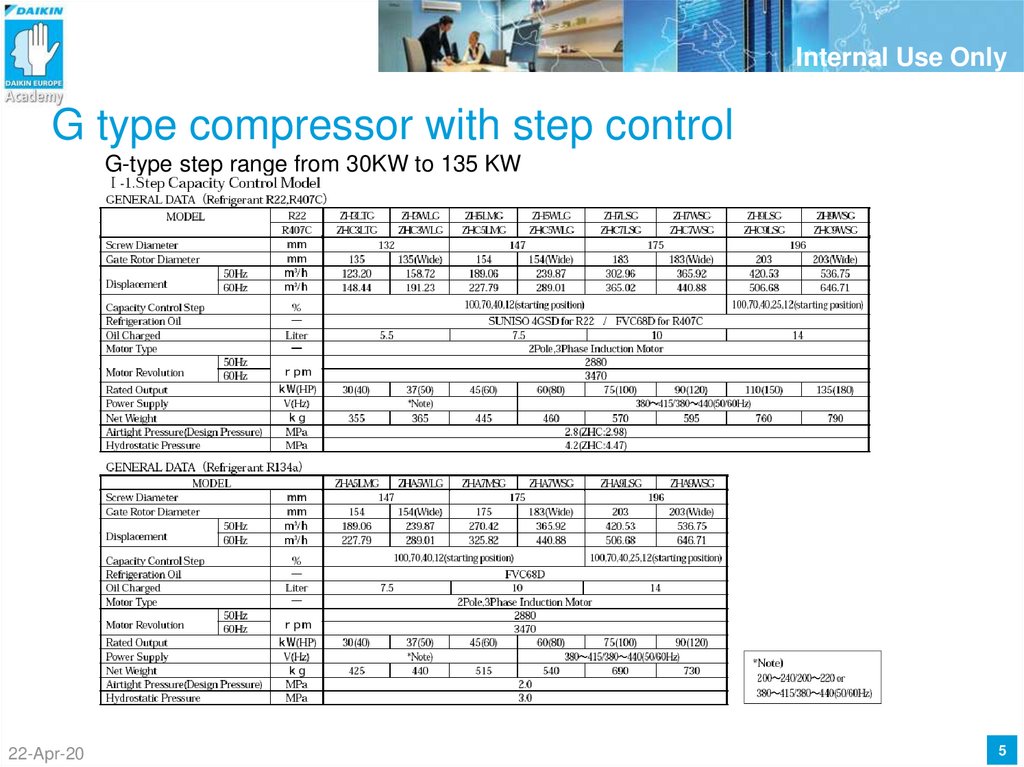

5. G type compressor with step control

Internal Use OnlyG type compressor with step control

G-type step range from 30KW to 135 KW

22-Apr-20

5

6. G type compressor with stepless control

Internal Use OnlyG type compressor with stepless control

G-type stepless range from 30KW to 135 KW

22-Apr-20

6

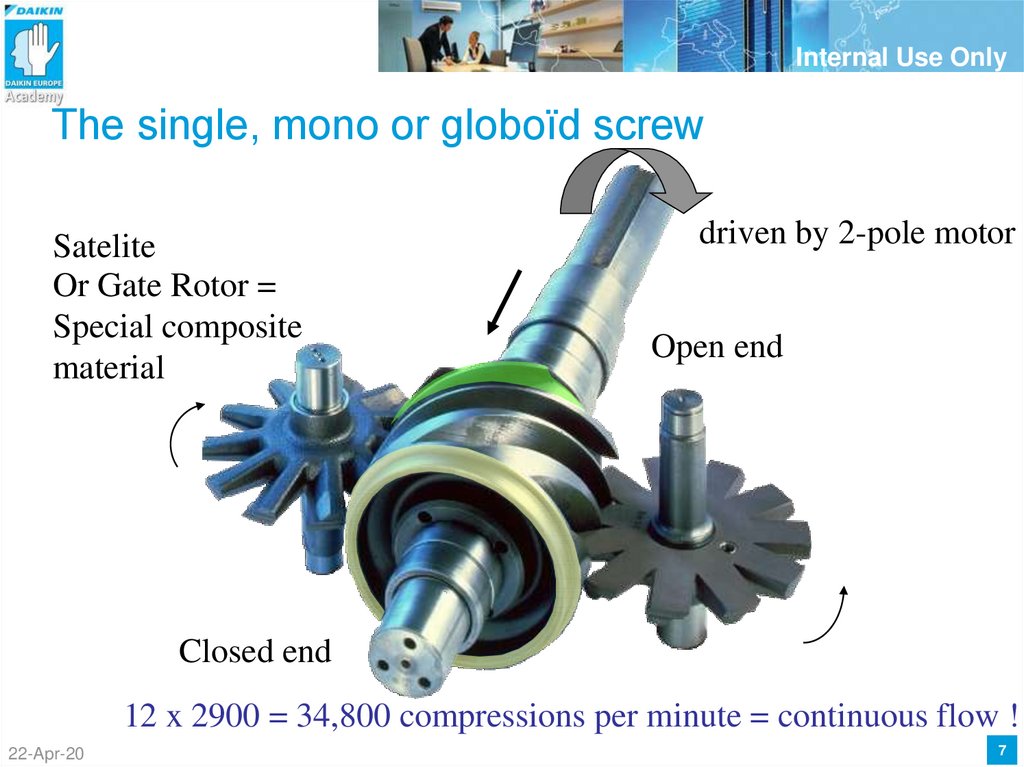

7. The single, mono or globoïd screw

Internal Use OnlyThe single, mono or globoïd screw

Satelite

Or Gate Rotor =

Special composite

material

driven by 2-pole motor

Open end

Closed end

12 x 2900 = 34,800 compressions per minute = continuous flow !

22-Apr-20

7

8. Gate rotor and gate rotorshaft

Internal Use OnlyGate rotor and gate rotorshaft

22-Apr-20

8

9. The G-type screw compressor

Internal Use OnlyThe G-type screw compressor

Oil separator

& capacitycontrol

22-Apr-20

Compression

section

Motor &

suction section

9

10. The Heart of the single screw compressor

Internal Use OnlyThe Heart of the single screw compressor

Oil separator

& capacitycontrol

22-Apr-20

Compression

section

Motor &

suction section

10

11. The flow inside compressor

Internal Use OnlyThe flow inside compressor

22-Apr-20

11

12.

Internal Use OnlyCompression

Principle

22-Apr-20

12

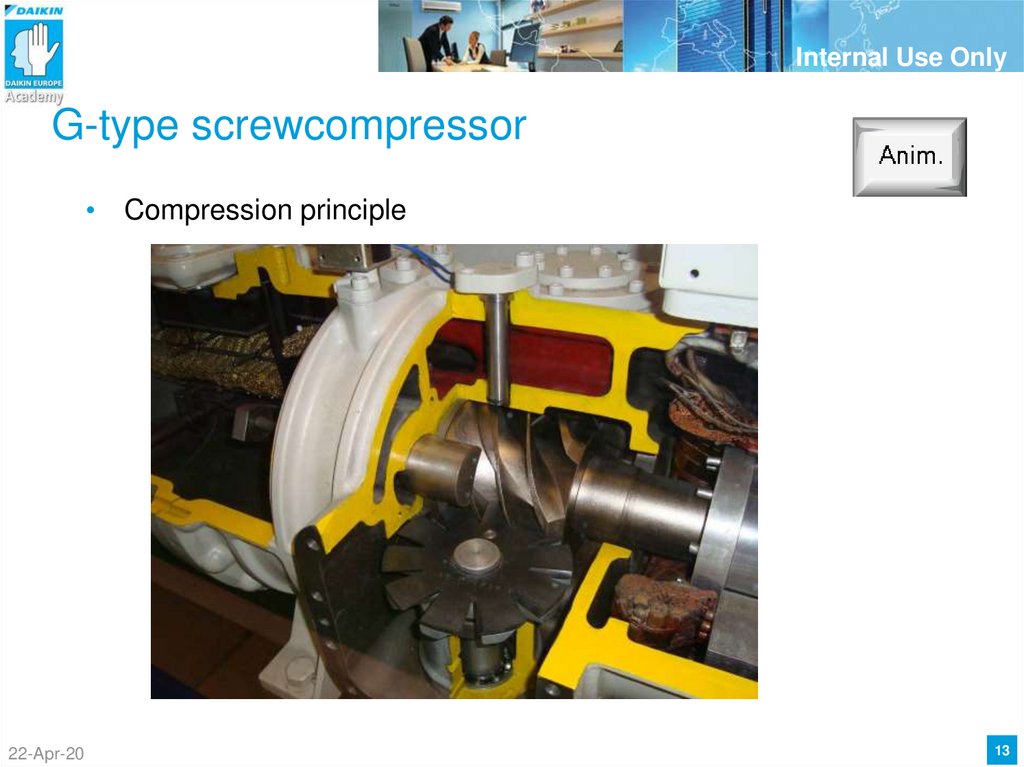

13. G-type screwcompressor

Internal Use OnlyG-type screwcompressor

• Compression principle

22-Apr-20

13

14. Capacity adjustment design

Internal Use OnlyCapacity adjustment design

Loading & Unloading

Mechanism

G types until 2005

G types from 2005

step control

stepless control

3 to 4 fixed capacity steps

Continuous control

between 30 and 100%

F types

22-Apr-20

14

15. Capacity adjustment design step

Internal Use OnlyCapacity adjustment design step

Step control

Principle

Is based on internal

pressure differences

Selection of capacity

step with solenoid

valves

22-Apr-20

15

16. step control/essential parts

Internal Use Onlystep control/essential parts

• Capacity solenoid valves

12

70%

40%

12%

12

22-Apr-20

16

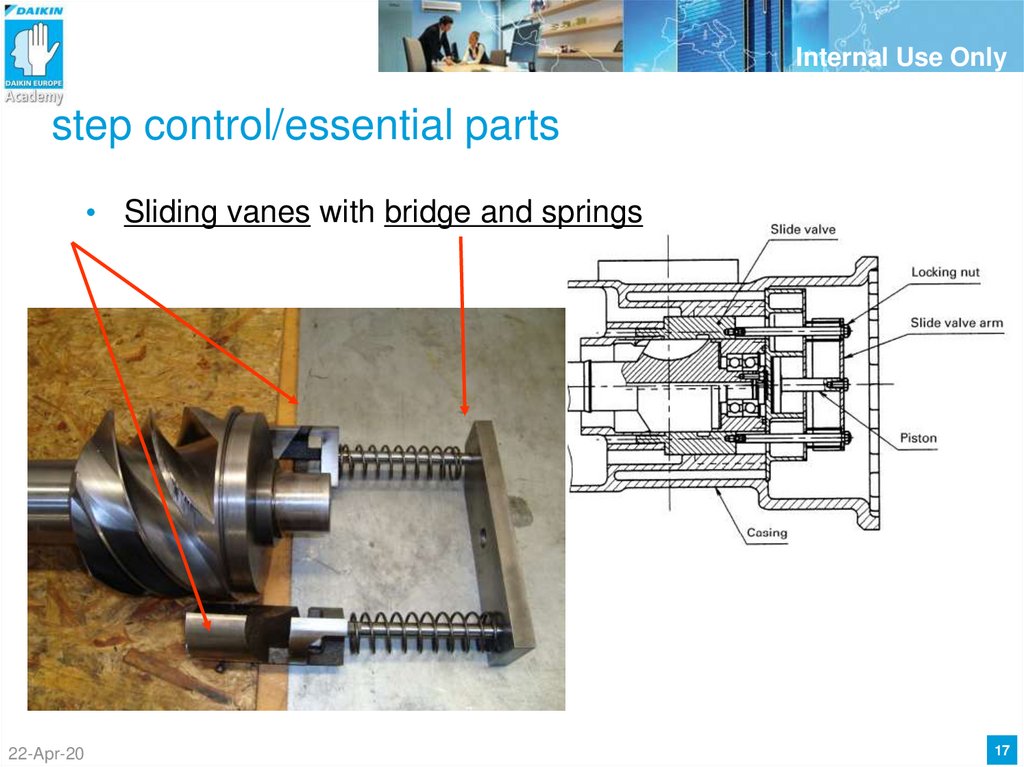

17. step control/essential parts

Internal Use Onlystep control/essential parts

• Sliding vanes with bridge and springs

22-Apr-20

17

18. step control/essential parts

Internal Use Onlystep control/essential parts

• Slide vane bridge with capacity cylinder/piston

12%

40%

70%

Springs

70

%

22-Apr-20

40

%

12

%

18

19. Capacity adjustment design

Internal Use OnlyCapacity adjustment design

22-Apr-20

19

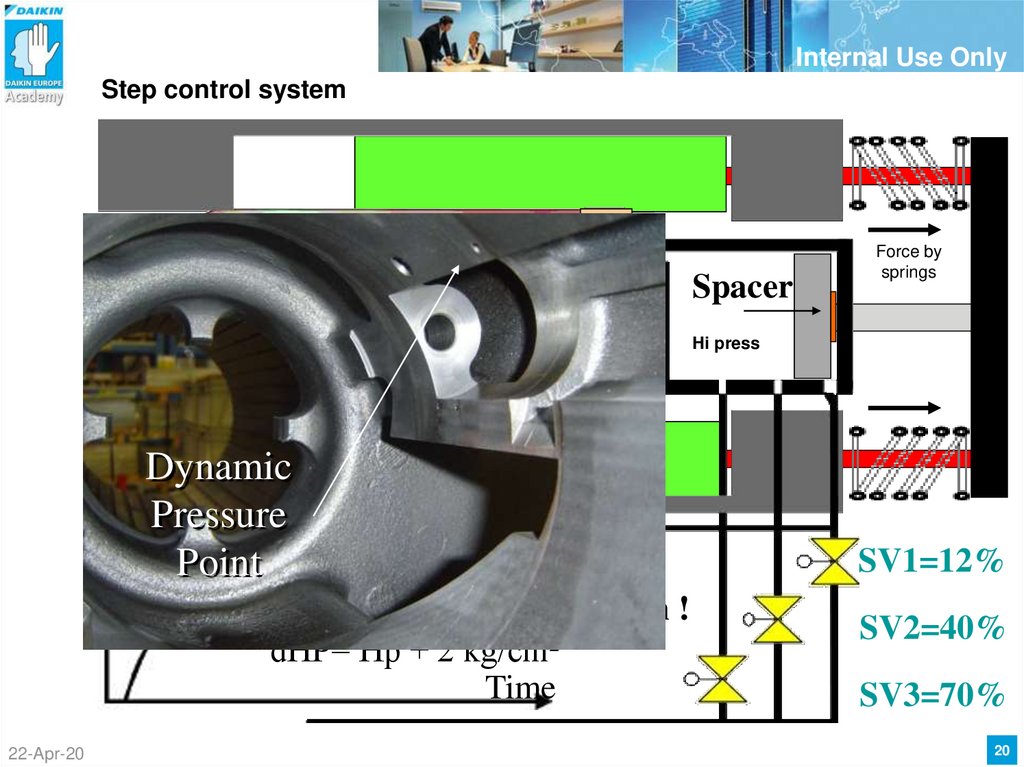

20.

Internal Use OnlyStep control system

Dynamic

pressure

point

Spacer

Force by

springs

Hi press

Screw rotor

Dynamic

Pressure

Pressure

dHp

Point

Hp

Energized = open !

dHP= Hp + 2 kg/cm²

Time

Low pressure side

22-Apr-20

SV1=12%

SV2=40%

SV3=70%

20

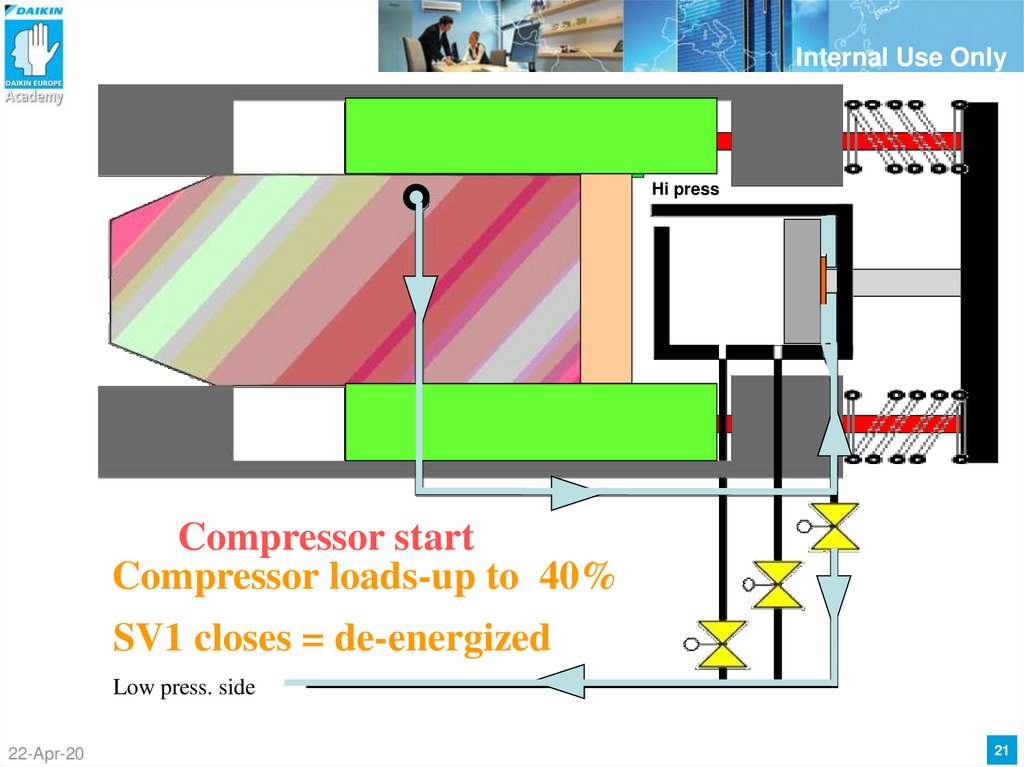

21.

Internal Use OnlyHi press

Compressor start

Compressor loads-up to 40%

SV1 closes = de-energized

Low press. side

22-Apr-20

12%

capacity

21

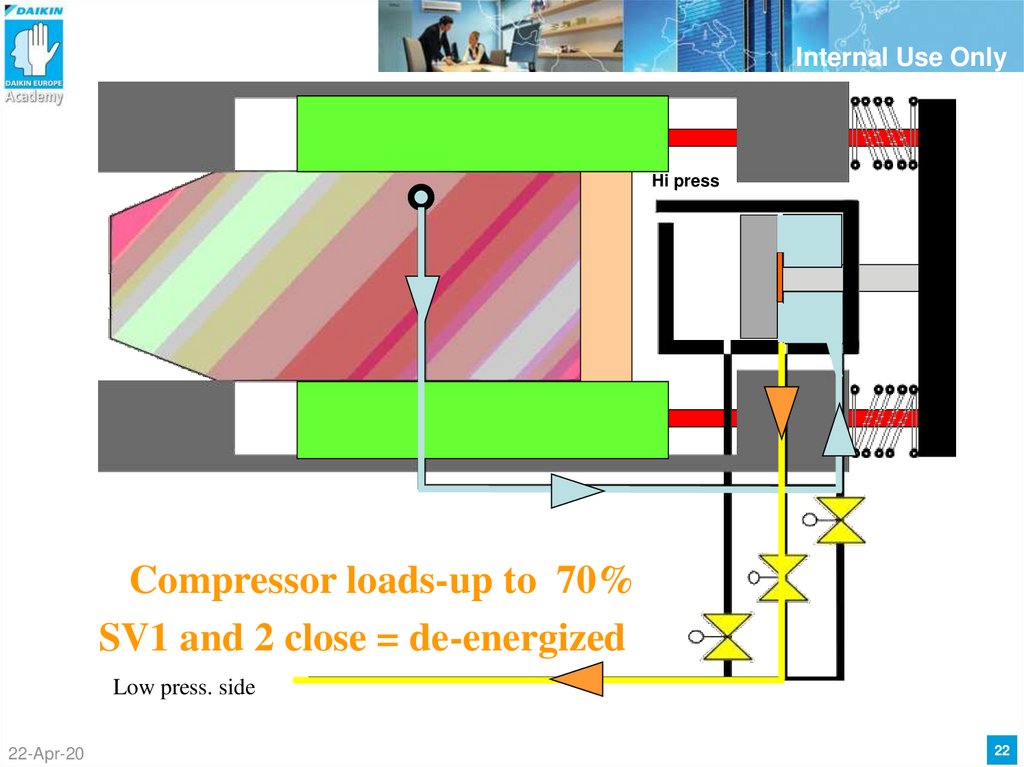

22.

Internal Use OnlyHi press

Compressor loads-up to 70%

SV1 and 2 close = de-energized

Low press. side

22-Apr-20

40%

capacity

22

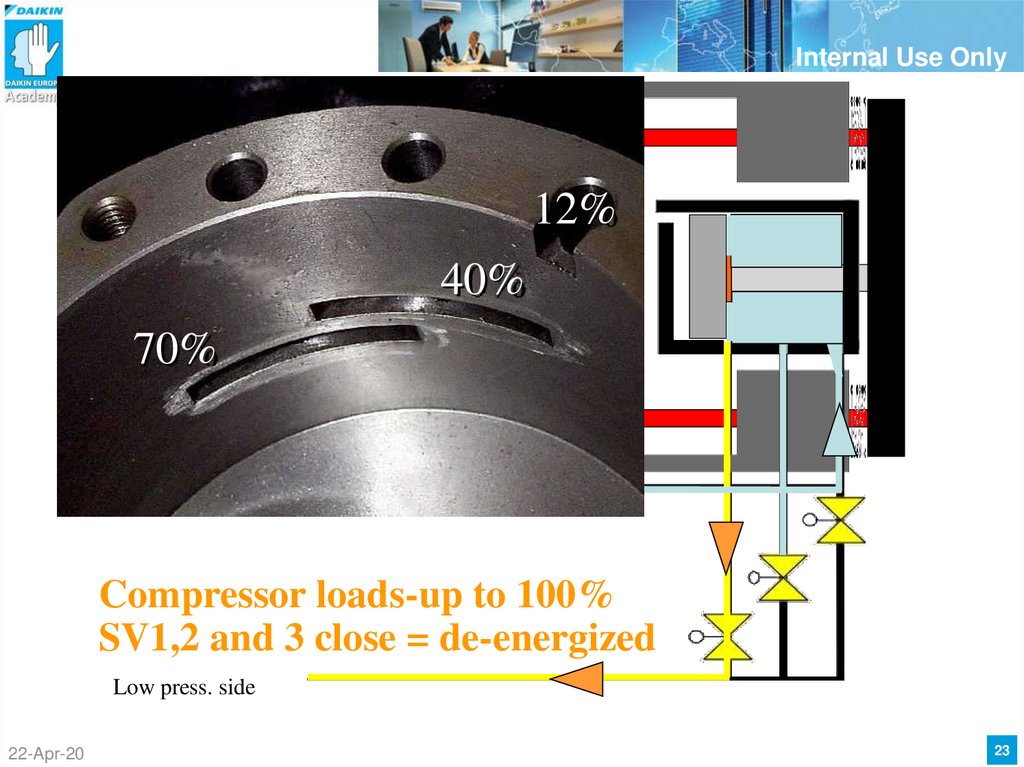

23.

Internal Use Only12%

40%

70%

Compressor loads-up to 100%

SV1,2 and 3 close = de-energized

Low press. side

22-Apr-20

70%

capacity

23

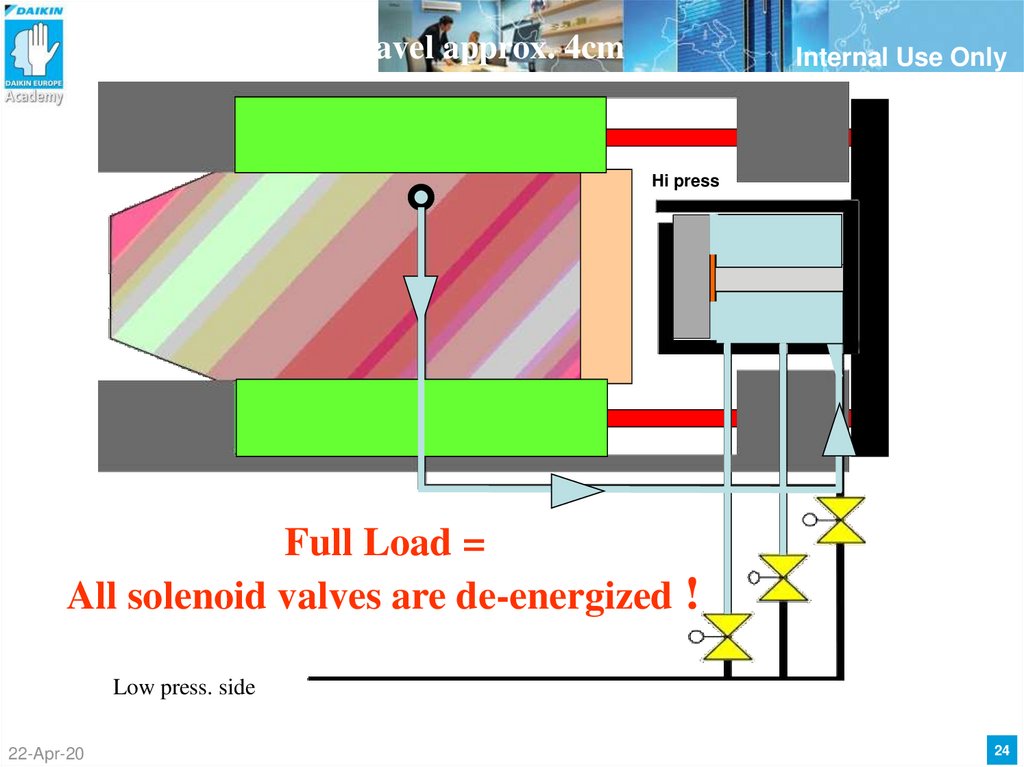

24.

Full travel approx. 4cmInternal Use Only

Hi press

Full Load =

All solenoid valves are de-energized !

Low press. side

22-Apr-20

24

25. Capacity adjustment design stepLESS

Internal Use OnlyCapacity adjustment design stepLESS

Stepless control

Principle

Is based on internal

pressure differences

Regulation of stepless

capacity step with motor

22-Apr-20

25

26. Stepless Single Screw Compressor

Internal Use OnlyStepless Single Screw Compressor

STEPLESS capacity regulation

The compressor has built-in capacity control by 30 – 100%

by stepless slide valve mechanism, and adjustable volumetric ratio

Chiller Load

Chiller Load

100%

100%

30%

Starting position

12%

Demand

Single Circuit

22-Apr-20

15%

12%

Starting position

Demand

Double Circuit

Designed, tested and manufactured in Daikin’s own laboratories.

26

27. G type compressor with stepless control

Internal Use OnlyG type compressor with stepless control

12 % solenoid

Step / motor module

22-Apr-20

27

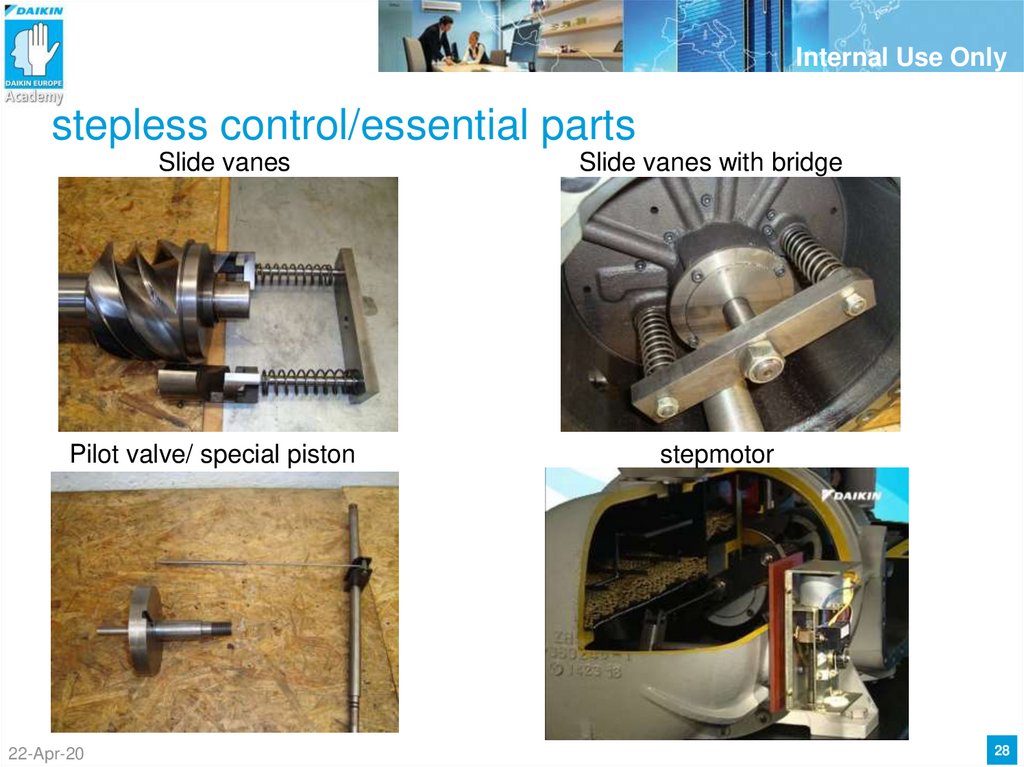

28. stepless control/essential parts

Internal Use Onlystepless control/essential parts

Slide vanes

Pilot valve/ special piston

22-Apr-20

Slide vanes with bridge

stepmotor

28

29. Stepless Single Screw Compressor

Internal Use OnlyStepless Single Screw Compressor

STEPLESS capacity regulation

How does it work ?

Pilot Valve + cylinder

Loading and unloading via Pilot Valve:

-Pilot valve is driven by rod mechanism

-The rod mechanism is driven by

shaded-pole motor

Loading

Unloading

High pressure side

22-Apr-20

Rod mechanism

29

30. Stepless control

Internal Use OnlyStepless control

STEPLESS capacity regulation

How does it work ?

Pilot Valve

Balancing hole

Bleedhole for pilot valve

High pressure side

Loading

Unloading

22-Apr-20

Rod mechanism

30

31. Stepless regulation/pressure difference

Internal Use OnlyStepless regulation/pressure difference

Sliding Vane

Spring

Load/unload

mechanism

HP (High Pressure)

HP = High pressure =

Pressure of refrigerant at

discharge port

HP

HP dHP

dHp = dynamic high

pressure =

Piston

HP

dHP

Pressure of refrigerant at

just before discharge port =

dHp slightly > HP

Main screw

Dynamic HP

22-Apr-20

HP (High Pressure)

31

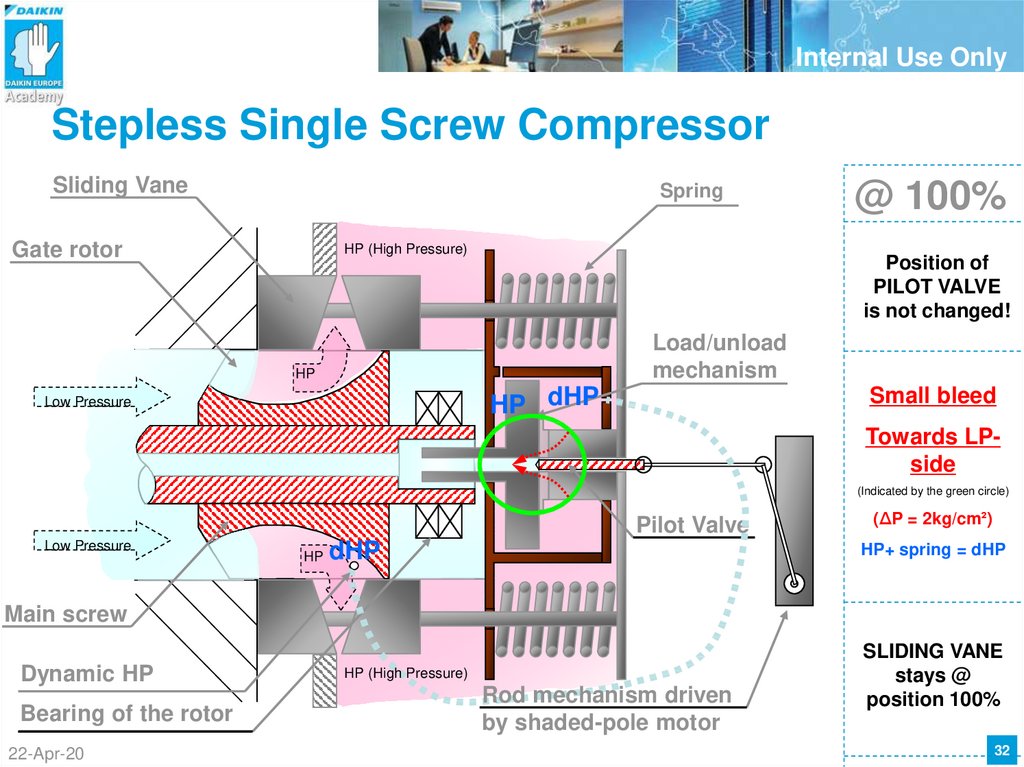

32. Stepless Single Screw Compressor

Internal Use OnlyStepless Single Screw Compressor

Sliding Vane

Spring

Gate rotor

HP (High Pressure)

@ 100%

Position of

PILOT VALVE

is not changed!

Load/unload

mechanism

HP

HP dHP

Low Pressure

Small bleed

Towards LPside

(Indicated by the green circle)

Pilot Valve

Low Pressure

HP

dHP

(ΔP = 2kg/cm²)

HP+ spring = dHP

Main screw

Dynamic HP

Bearing of the rotor

22-Apr-20

HP (High Pressure)

Rod mechanism driven

by shaded-pole motor

SLIDING VANE

stays @

position 100%

32

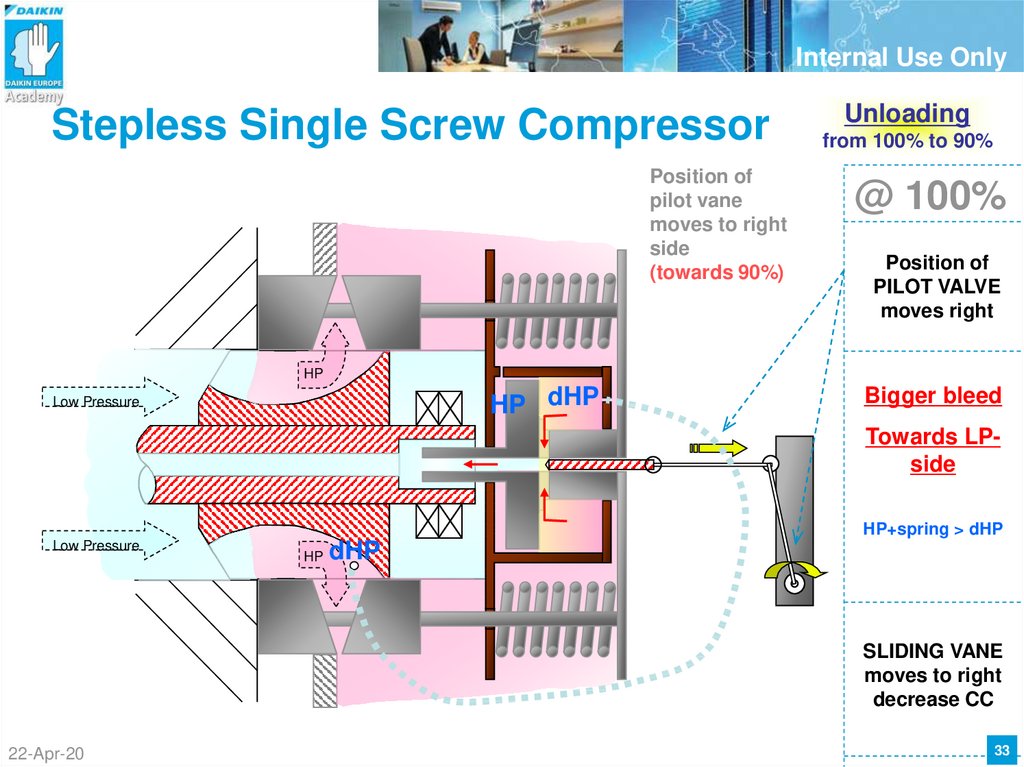

33. Stepless Single Screw Compressor

Internal Use OnlyStepless Single Screw Compressor

Position of

pilot vane

moves to right

side

(towards 90%)

Unloading

from 100% to 90%

@ 100%

Position of

PILOT VALVE

moves right

HP

HP dHP

Low Pressure

Bigger bleed

Towards LPside

HP+spring > dHP

Low Pressure

HP

dHP

SLIDING VANE

moves to right

decrease CC

22-Apr-20

33

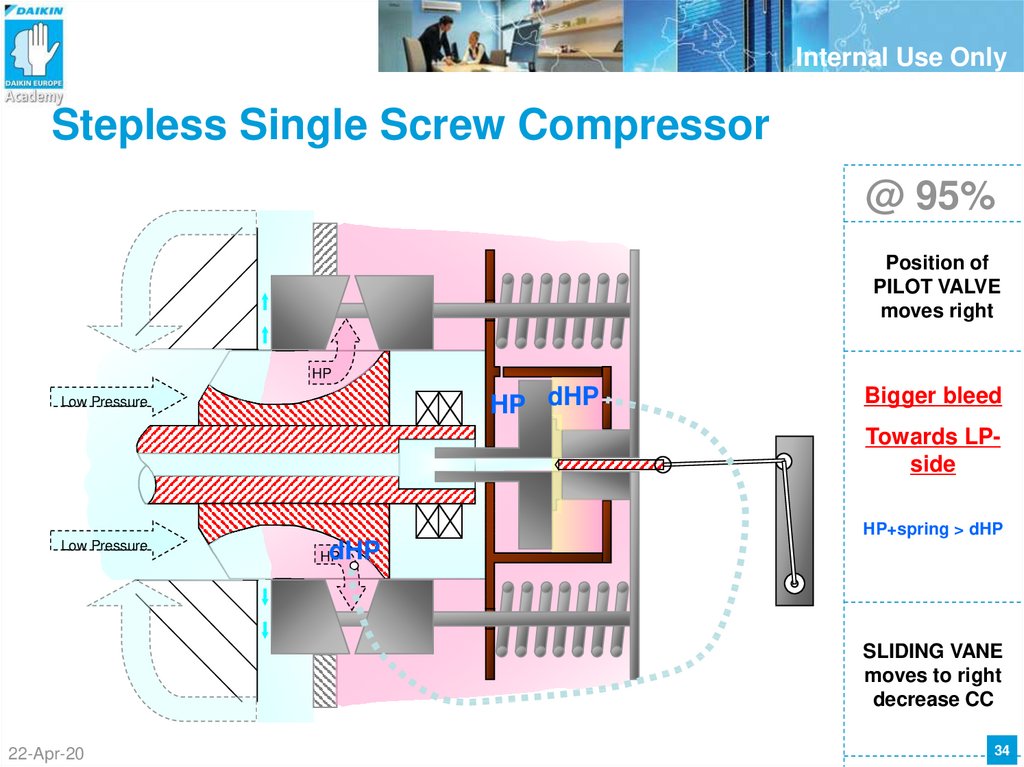

34. Stepless Single Screw Compressor

Internal Use OnlyStepless Single Screw Compressor

@ 95%

Position of

PILOT VALVE

moves right

HP

HP dHP

Low Pressure

Bigger bleed

Towards LPside

HP+spring > dHP

Low Pressure

dHP

HP

SLIDING VANE

moves to right

decrease CC

22-Apr-20

34

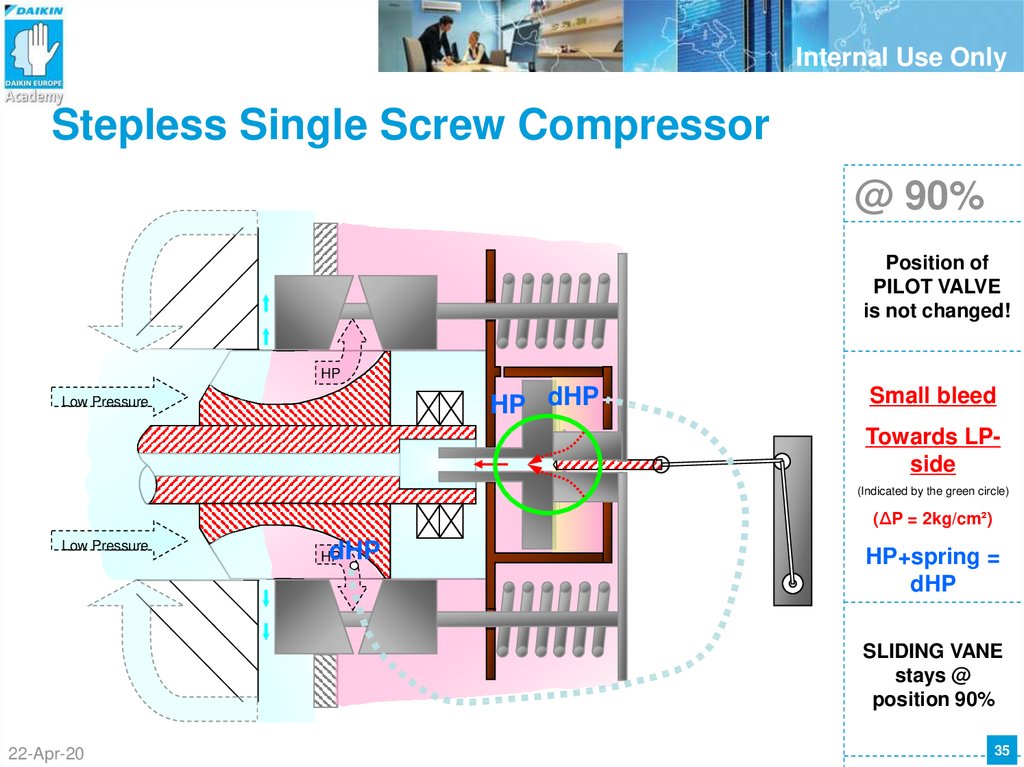

35. Stepless Single Screw Compressor

Internal Use OnlyStepless Single Screw Compressor

@ 90%

Position of

PILOT VALVE

is not changed!

HP

HP dHP

Low Pressure

Small bleed

Towards LPside

(Indicated by the green circle)

(ΔP = 2kg/cm²)

Low Pressure

dHP

HP

HP+spring =

dHP

SLIDING VANE

stays @

position 90%

22-Apr-20

35

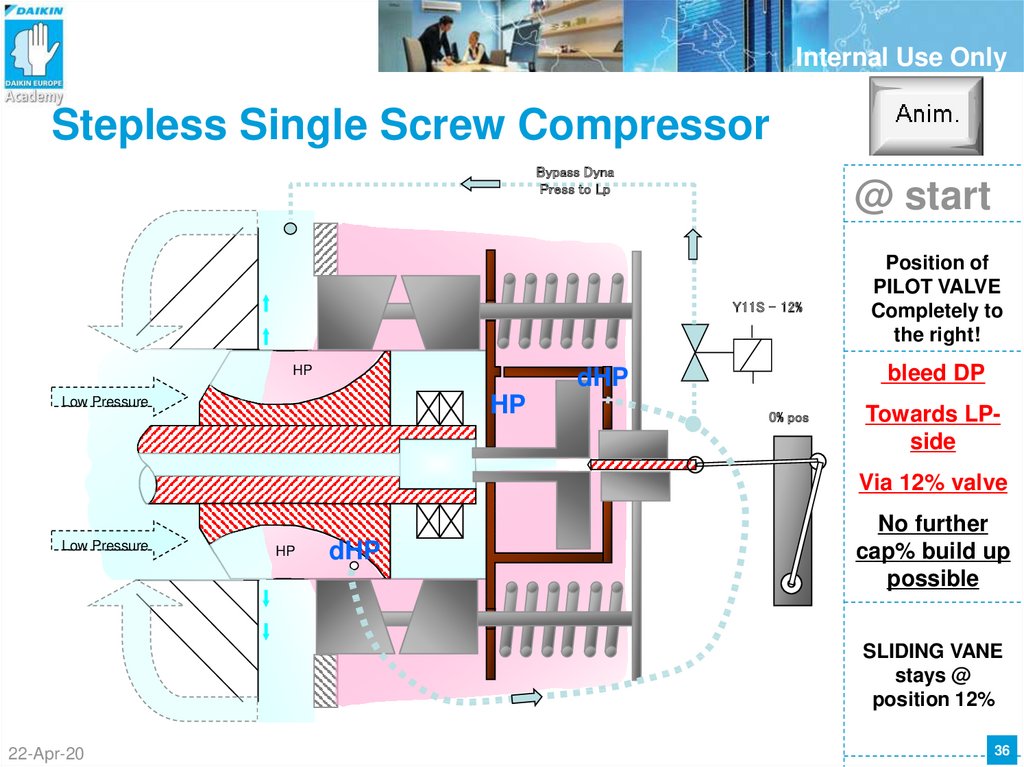

36. Stepless Single Screw Compressor

Internal Use OnlyStepless Single Screw Compressor

Bypass Dyna

Press to Lp

@ start

Y11S – 12%

HP

bleed DP

dHP

HP

Low Pressure

Position of

PILOT VALVE

Completely to

the right!

0% pos

Towards LPside

Via 12% valve

Low Pressure

HP

dHP

No further

cap% build up

possible

SLIDING VANE

stays @

position 12%

22-Apr-20

36

37. Stepless Single Screw Compressor

Internal Use OnlyStepless Single Screw Compressor

• Start up sequence

capacity

100%

30%

Upload

possible

12 %

0%

20 s

40 s

120 s

180 S

Time

Compress

Start

22-Apr-20

37

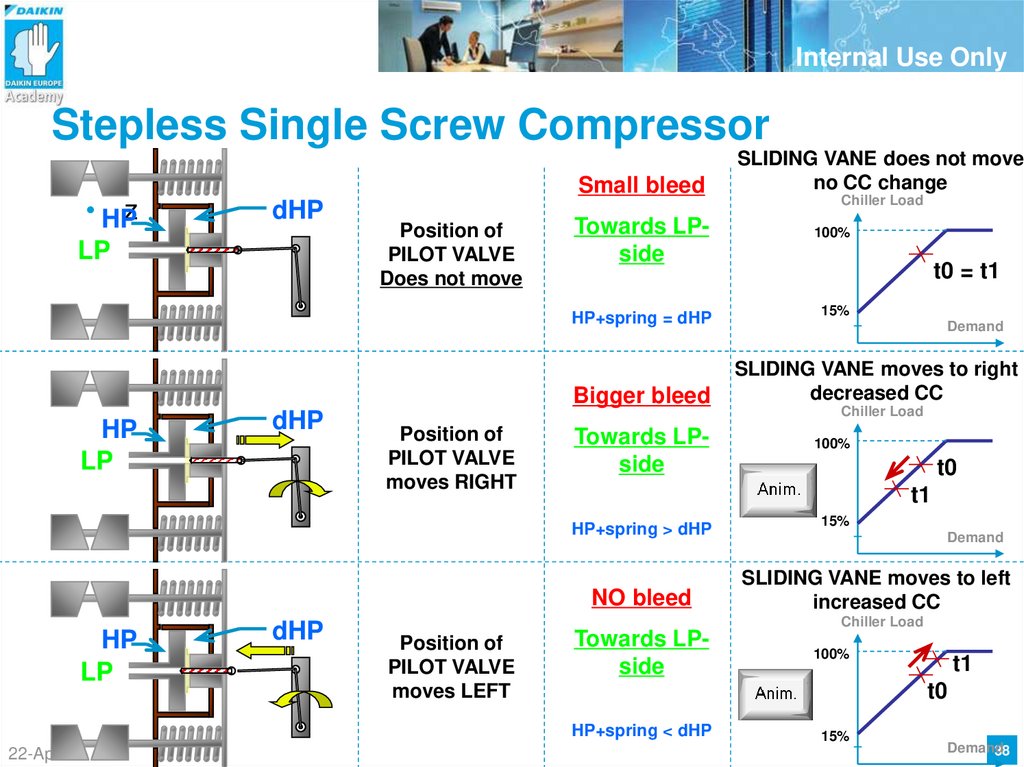

38. Stepless Single Screw Compressor

Internal Use OnlyStepless Single Screw Compressor

• HPz

Small bleed

dHP

LP

Position of

PILOT VALVE

Does not move

Towards LPside

HP+spring = dHP

Bigger bleed

HP

LP

dHP

Position of

PILOT VALVE

moves RIGHT

Towards LPside

NO bleed

dHP

100%

t0 = t1

15%

Demand

SLIDING VANE moves to right

decreased CC

Chiller Load

100%

t0

15%

Demand

SLIDING VANE moves to left

increased CC

Chiller Load

Position of

PILOT VALVE

moves LEFT

Towards LPside

100%

t1

t0

HP+spring < dHP

22-Apr-20

Chiller Load

t1

HP+spring > dHP

HP

LP

SLIDING VANE does not move

no CC change

15%

Demand

38

39. Stepless Single Screw Compressor

Internal Use OnlyStepless Single Screw Compressor

• Step motor feedback principle

Vcc

Vcc = 21V Single circuit

GND

input

V pot

(double circuit)

Vcc = 12V double circuit

Vpot= Vcc * Rpot

Rpot + R 470

5

white

Red (6) or black (4)

V+

Feedback from potentiometer

R 470

R Pot

Potentiometer Output

@ 100% R=+/- 125 Ohm

@ 30% R=+/- 35 Ohm

22-Apr-20

39

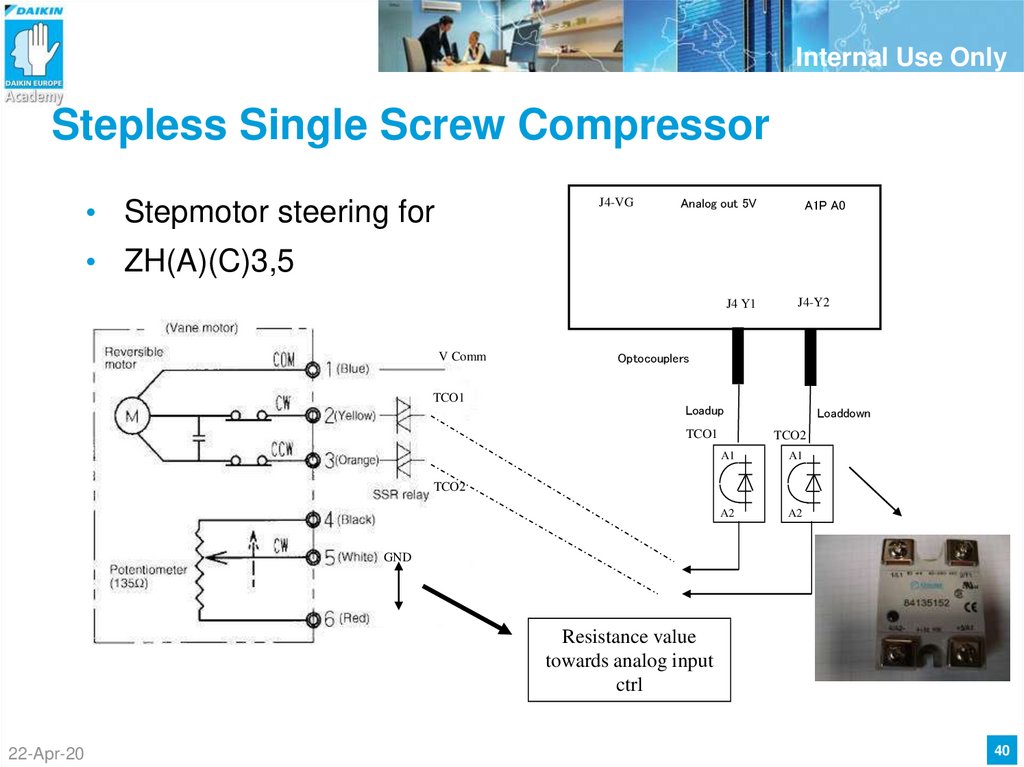

40. Stepless Single Screw Compressor

Internal Use OnlyStepless Single Screw Compressor

• Stepmotor steering for

J4-VG

Analog out 5V

A1P A0

• ZH(A)(C)3,5

J4 Y1

V Comm

TCO1

J4-Y2

Optocouplers

Loadup

TCO1

Loaddown

TCO2

A1

A1

A2

A2

TCO2

GND

Resistance value

towards analog input

ctrl

22-Apr-20

40

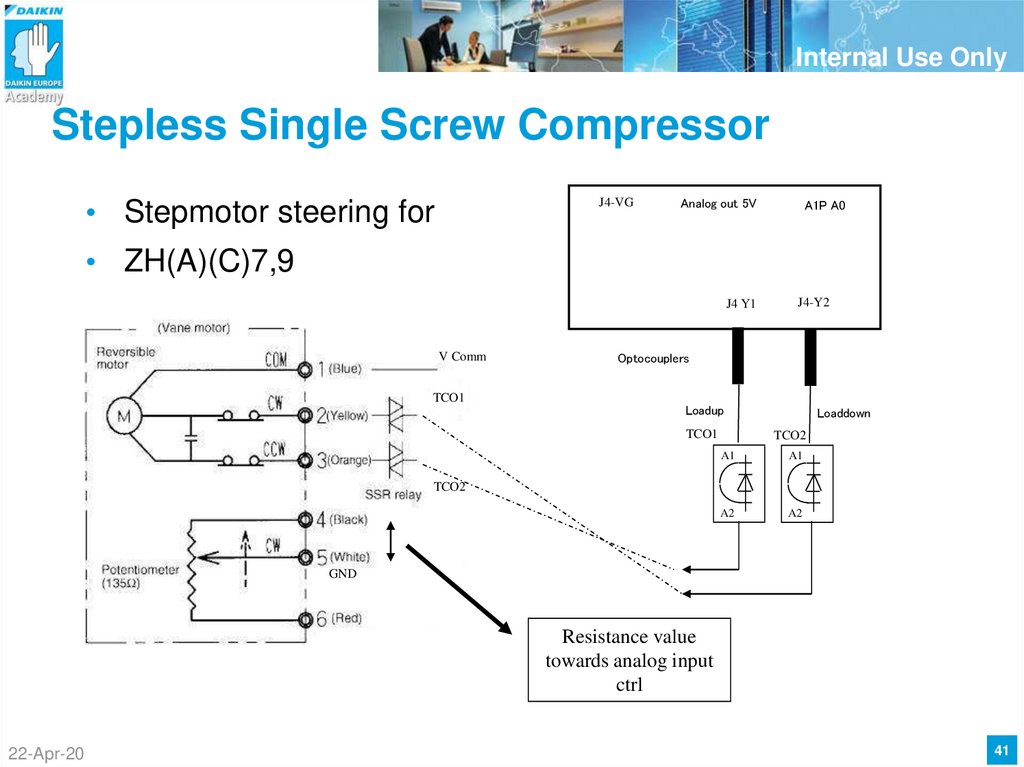

41. Stepless Single Screw Compressor

Internal Use OnlyStepless Single Screw Compressor

• Stepmotor steering for

J4-VG

Analog out 5V

A1P A0

• ZH(A)(C)7,9

J4 Y1

V Comm

TCO1

J4-Y2

Optocouplers

Loadup

TCO1

Loaddown

TCO2

A1

A1

A2

A2

TCO2

GND

Resistance value

towards analog input

ctrl

22-Apr-20

41

42. Stepless Single Screw Compressor

Internal Use OnlyStepless Single Screw Compressor

• Stepmotorconnections

ZH.. 3& 5 types

VM30APTE

ZH.. 7&9 types

VM30APZTE

Motor connection

On terminals 2-3

To be switched

GND

GND

230V from SSR’s

230V from SSR’s

Towards anaog

input controller

22-Apr-20

Towards analog

input controller

42

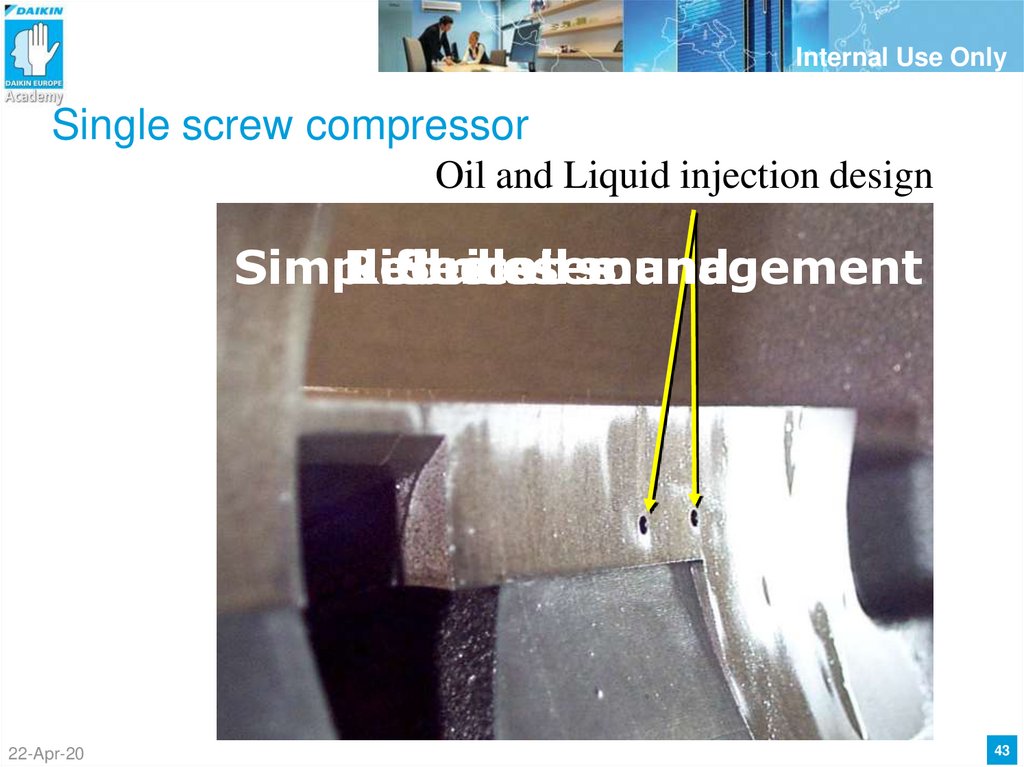

43. Single screw compressor

Internal Use OnlySingle screw compressor

Oil and Liquid injection design

Simplified

Reduces

Lubricates

Cools

Seals

oil sound

management

22-Apr-20

43

44. Single screw compressor

Internal Use OnlySingle screw compressor

• Liquid injection point (fixed oriffice)

Cool Main screw

• Never shut off,

during operation

compressor

• For pumpdown use

integrated pump

down function of

controller

22-Apr-20

44

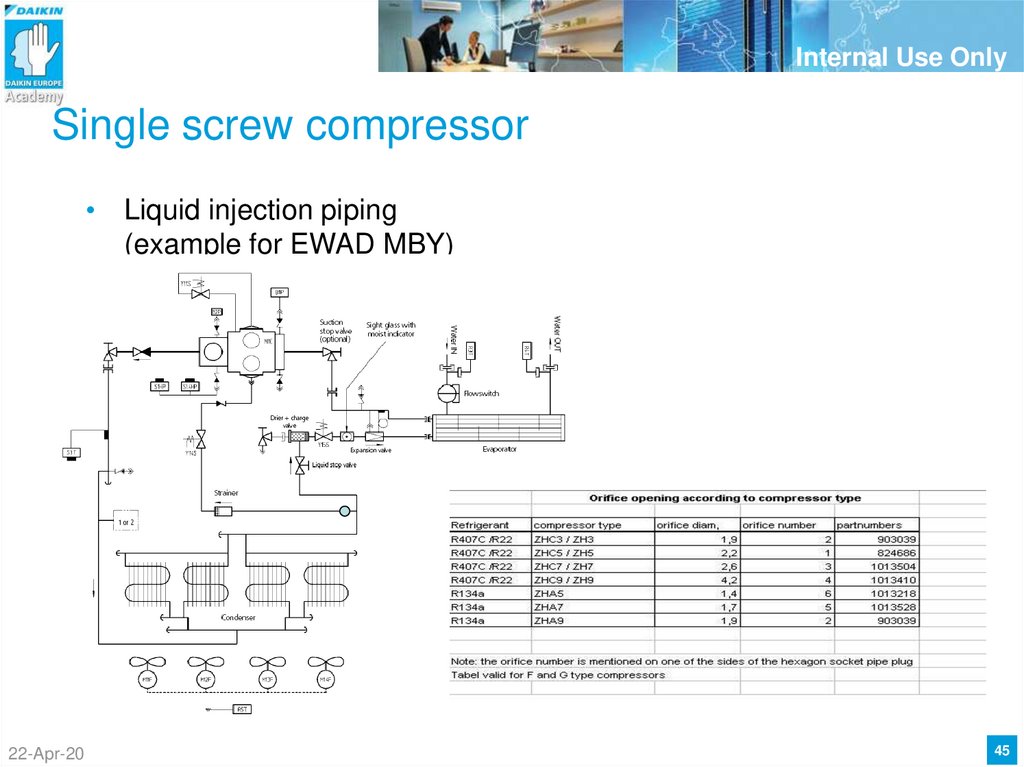

45. Single screw compressor

Internal Use OnlySingle screw compressor

• Liquid injection piping

(example for EWAD MBY)

22-Apr-20

45

46. Single screw compressor

Internal Use OnlySingle screw compressor

Periodic Inspection

22-Apr-20

46

47. Single screw compressor - Inspection

Internal Use OnlySingle screw compressor - Inspection

Periodic Inspection - Check points

Insulation Resistance of the Motor.

Inspection/Changement of the Refrigerant Oil.

Inspection the Gate Rotor.

Cleaning the Suction filter.

22-Apr-20

47

48. Single screw compressor - Inspection

Internal Use OnlySingle screw compressor - Inspection

Check points

Insulation Resistance of the Motor.

After 1year of operation.

Use a 500-V megger.

Loose all the wires.

Measure between the phases

Measure between the CTP and phases

Measure between earth, CTP and phases

Value >= 3MΩ

22-Apr-20

48

49. Single screw compressor - Inspection

Internal Use OnlySingle screw compressor - Inspection

Check points

Inspection/Changement of the Refrigerant Oil.

Take a oil sample on one of the two oil drain ports.

Check oil (color, acid test, moisture, …)

Reduce the pressure (pump down).

Recover the internal rest pressure.

Take a oil sample on one of the two oil drain ports.

Check oil (color, acid test, moisture, …)

After 7500 hr or 4 years operation. Adviced to change oil

22-Apr-20

49

50. Single screw compressor - Inspection

Internal Use OnlySingle screw compressor - Inspection

• Oil drain ports

22-Apr-20

50

51. Single screw compressor - Inspection

Internal Use OnlySingle screw compressor - Inspection

• Oil charging port & service port (vacuum pump)

Service port

22-Apr-20

51

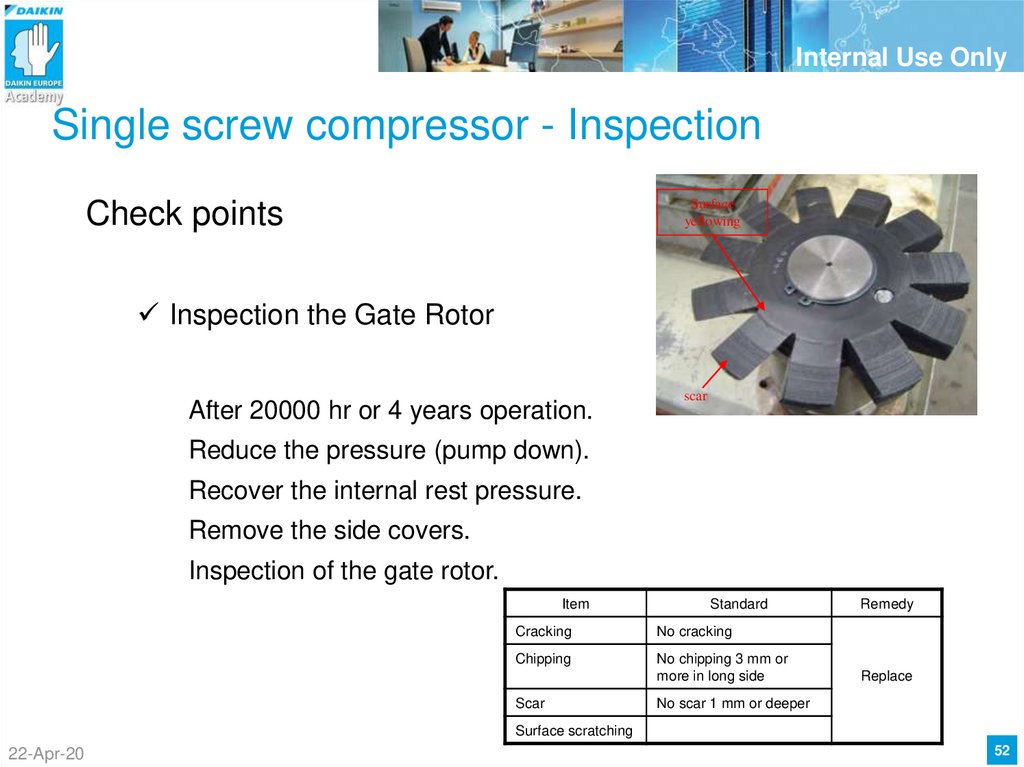

52. Single screw compressor - Inspection

Internal Use OnlySingle screw compressor - Inspection

Surface

yellowing

Check points

Inspection the Gate Rotor

After 20000 hr or 4 years operation.

scar

Reduce the pressure (pump down).

Recover the internal rest pressure.

Remove the side covers.

Inspection of the gate rotor.

Item

Standard

Cracking

No cracking

Chipping

No chipping 3 mm or

more in long side

Scar

Remedy

Replace

No scar 1 mm or deeper

Surface scratching

22-Apr-20

52

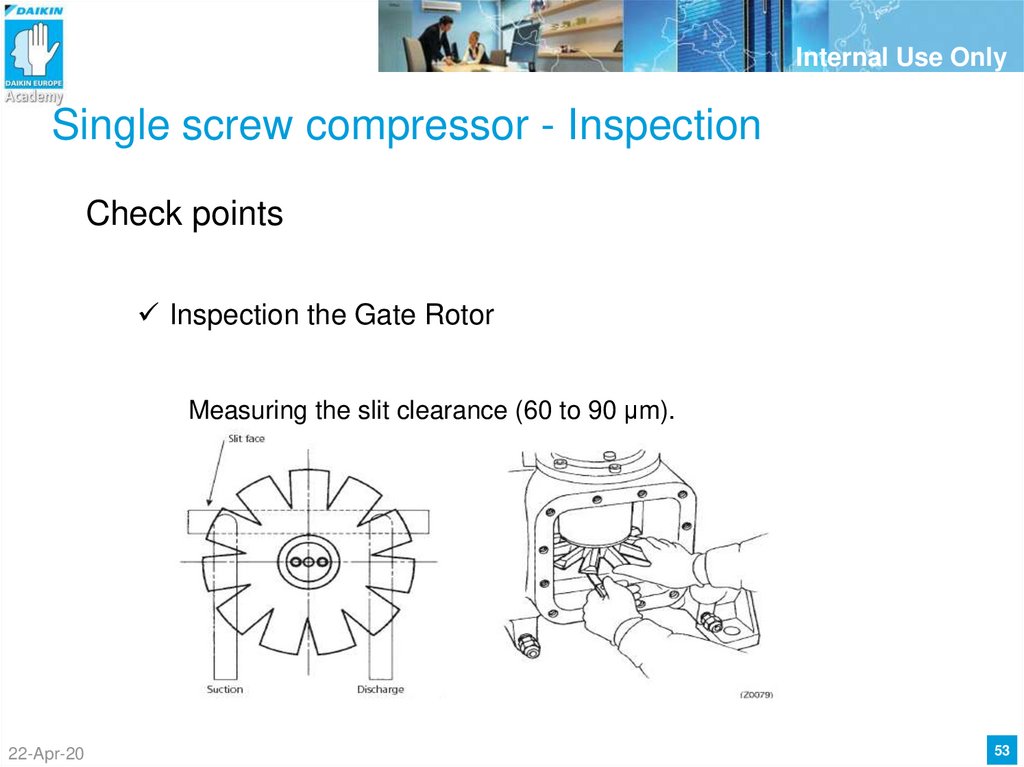

53. Single screw compressor - Inspection

Internal Use OnlySingle screw compressor - Inspection

Check points

Inspection the Gate Rotor

Measuring the slit clearance (60 to 90 μm).

22-Apr-20

53

54. Single screw compressor - Inspection

Internal Use OnlySingle screw compressor - Inspection

Check points

Cleaning the Suction Filter

After 20000 hr or 4 years operation.

Reduce the pressure (pump down).

Recover the internal rest pressure.

Disconnect the suction pipe.

Clean the suction filter with compressed air.

22-Apr-20

54

55. Single screw compressor

Internal Use OnlySingle screw compressor

Overhaul

22-Apr-20

55

56. Low Maintenance Costs

Internal Use OnlyLow Maintenance Costs

Only three rotating parts ...

22-Apr-20

56

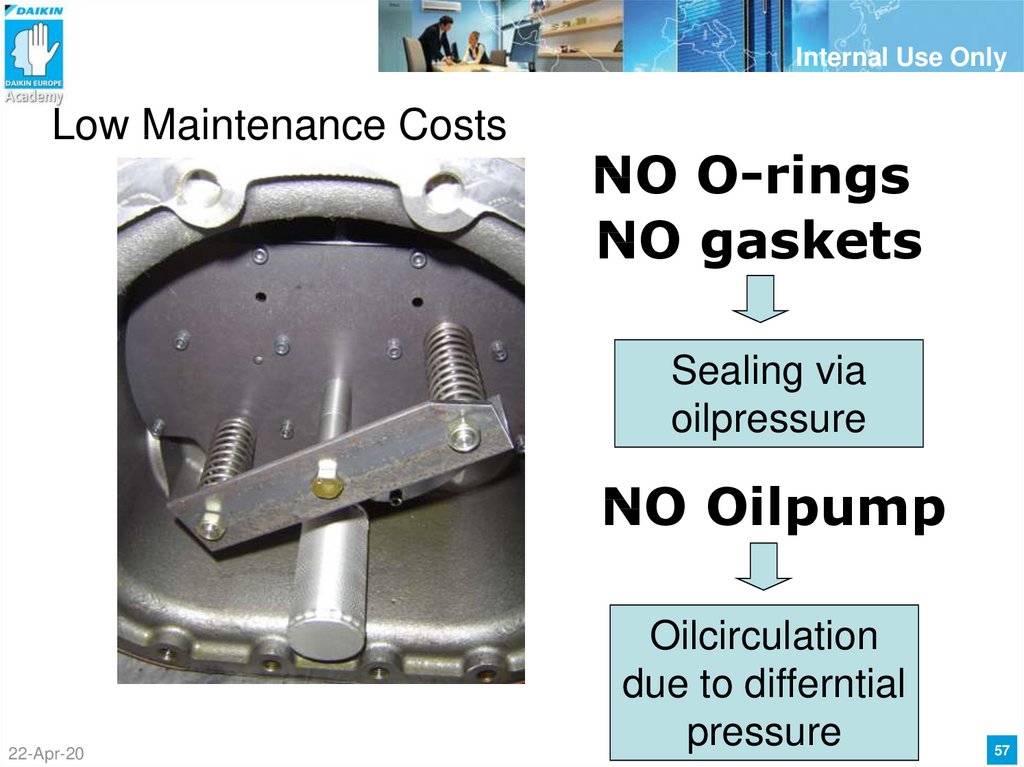

57. Low Maintenance Costs

Internal Use OnlyLow Maintenance Costs … and two sliding parts

NO O-rings

NO gaskets

Sealing via

oilpressure

NO Oilpump

22-Apr-20

Oilcirculation

due to differntial

pressure

57

58. Single Screw Compressor - Overhaul

Internal Use OnlySingle Screw Compressor - Overhaul

Overhaul

(see service manual Si50-402A)

• Overhaul interval:40.000 hrs or 7 years, wichever comes first

• Change of oil

• Change of gate rotors if needed + O-rings

• Change of all gaskets and O-rings

• Change of all bearings (mainscrew and gaterotor bearings

Complete dismanteling of compressor needed

22-Apr-20

58

59. Single Screw Compressor - Overhaul

Internal Use OnlySingle Screw Compressor - Overhaul

Overhaul Instructions Chart (See Service Manual SiE50-402A)

1. Disassembly and Inspection

22-Apr-20

Drain The Oil

Remove Side Covers

Inspection of The Gate Rotors and Surrounding Parts

Dissamble The Gate Rotor and Surrounding Parts

Remove and Install The Gate Rotor

Remove The Suction End Cover

Remove The Motor Rotor

Disassemble The Loading/Unloading Mechanism

Remove and Disassemble The Screw Assembly Pulley

59

60. Single Screw Compressor - Overhaul

Internal Use OnlySingle Screw Compressor - Overhaul

Overhaul Instructions Chart(See Service Manual SiE50-402A)

2. Replacing The Bearing

Remove The Bearings

Suction end cover bearing (Outer ring)

Screw shaft bearing (Inner ring)

Main bearing (matched pair)

Gate rotor bearings ( 4 )

Install The Bearings

22-Apr-20

60

61. Single Screw Compressor - Overhaul

Internal Use OnlySingle Screw Compressor - Overhaul

Overhaul Instructions Chart (See Service Manual SiE50-402A)

3. Final Assembly

Assemble The Screw Shaft and Main Bearing Holder

Insert The Screw Shaft

Install The Motor Rotor

Install The Suction End Cover

Verify The Position of The Screw Rotor

Install The Gate Rotor and Adjust The Slit Clearance

Install The Main Bearing Holder Fixing Plate, Assemble The Loading/Unloading

Mechanism and Instal The Oil Filter

Install The Discharge End Cover

22-Apr-20

61

62. Single Screw Compressor - Overhaul

Internal Use OnlySingle Screw Compressor - Overhaul

Overhaul Instructions Chart

(See Service Manual SiE50-402a)

4. Airtightness Test

Using dry air mixed with refrigerant, or Nitrogen, pressurize to A

22-Apr-20

62

63. Single Screw Compressor - Overhaul

Internal Use OnlySingle Screw Compressor - Overhaul

Overhaul Instructions Chart

(See Service Manual SiE50-402a)

5. Charging Oil

Charge the same quantity of oil removed during disassembly

Devide the quantity over the suction and discharge side

22-Apr-20

63

64. Single Screw Compressor - Overhaul

Internal Use OnlySingle Screw Compressor - Overhaul

Overhaul Instructions Chart (See Service Manual SiE50-402a)

6. Caution in Test Operation

Check the tightness of all bolts

Check wiring connection

Check pressures

Check noise and vibrations

22-Apr-20

64

65. Single Screw Compressor – Overhaul pics

Internal Use OnlySingle Screw Compressor – Overhaul pics

22-Apr-20

65

66. Stepless Single Screw Compressor

Internal Use OnlyStepless Single Screw Compressor

• 12 % solenoid valve

22-Apr-20

66

industry

industry