Similar presentations:

ACS large drive family

1. ACS large drive family

ACS6000cAC/AC

•direct AC to AC converter(cyclo), no DClink

•SCR Thyristor

•synchronous motor(AC motor with DC

excitation)

•high power and low speed, example

roughing mills and ship main propulsion

AC/AC

SM

AC/AC

ACS6000sd

© Copyright 2003 ABB - 1 -

•AC/DC/AC drive with DC-link

•IGCT semiconductor which is gate

commutated

•synchronous motor(AC motor with DC

excitation)

•best possible performance with DTC

•cold rolling mills and mine hoists

ACS6000ad / ACS1000

•AC/DC/AC drive with DC-link

•IGCT semiconductor

•induction motor(no excitation)

•6000ad for marine application

•1000 for pumps and fans

AC/DC

DC/AC

SM

AC/DC

DC/AC

IM

2. ACS6000c cycloconverter drive

Main components of cycloconverter drive:• Main circuit breaker

• Transformers to connect the drive to high

voltage network 6..36kV.

• Cycloconverter

• High speed circuit breakers

© Copyright 2003 ABB - 2 -

• 3 or 2*3 phase Synchronous motor(ACmotor) with DC-excitation

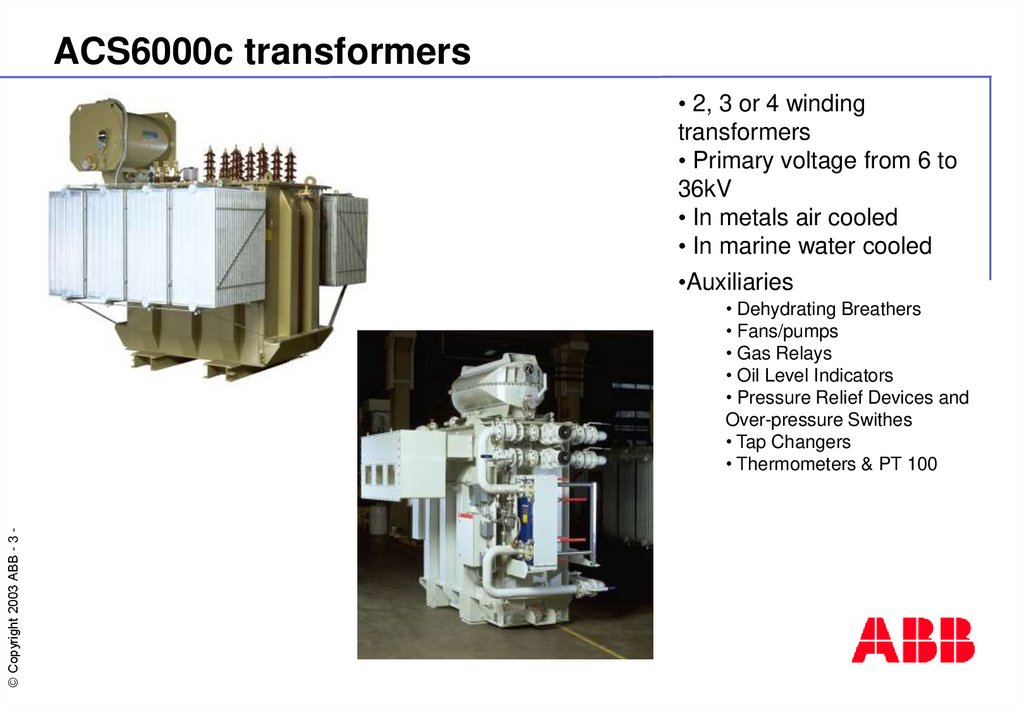

3. ACS6000c transformers

• 2, 3 or 4 windingtransformers

• Primary voltage from 6 to

36kV

• In metals air cooled

• In marine water cooled

•Auxiliaries

© Copyright 2003 ABB - 3 -

• Dehydrating Breathers

• Fans/pumps

• Gas Relays

• Oil Level Indicators

• Pressure Relief Devices and

Over-pressure Swithes

• Tap Changers

• Thermometers & PT 100

4. ACS6000c system description

© Copyright 2003 ABB - 4 -Basic 3-phase cycloconverter

three phase units

one water or air cooling unit

two control units

one excitation unit

5. ACS6000c system description

2 ) 6-pulse, 3-phase motor, separatedphase windings

1 ) 6-pulse, 3-phase motor

6p 6p

6p 6p

6p 6p

SM

6p 6p

6p 6p

6p 6p

3 ) 6-pulse, 2*3-phase motor, separated

stators

4 ) 12-pulse, 3-phase motor

6p 6p

6p 6p

6p 6p

6p 6p

6p 6p

6p 6p

SM

© Copyright 2003 ABB - 5 -

SM

6p 6p

6p 6p

6p 6p

6p 6p

6p 6p

6p 6p

SM

6. ACS6000c cycloconverter drive

Phase© Copyright 2003 ABB - 6 -

current

Excitation current

(DC current)

Positive bridge

Negative bridge

7. ACS6000c Phase unit main parts

3 phase supply(1000..1200VAC)3 overvoltage suppressors

PAI

12 (24 if parallel) fuses

GDR

12 thyristor’s

12 RC circuits

12 pulse transformers

2 Gate DRiver boards

1 Pulse Amplifier Interface board

1 Thyristor STAtus measurement

board

1 voltage tranducer

1 shunt and current tranducer

To CCB

STA

© Copyright 2003 ABB - 7 -

U

Neutral point of

cycloconveter

I

HSCB/motor

8. ACS6000c thyristor

Thyristorthyristor

module

type

© Copyright 2003 ABB - 8 -

W1-49-10

W2-73-10

W2-84-10

W3-96-10

A2-49-10

A2-73-10

A3-73-10

A3-84-10

A3-96-10

max.

overload 60 s [A]

continuous (preload 1/2 * I60s )

current [A]

1600

2850

4150

5200

1420

2300

2700

3750

4500

Micro switch

Fuse

overload

preload

1850

3400

5250

6700

1760

3050

3200

4500

5600

925

1700

2625

3350

880

1525

1600

2250

2800

Thyristor type

5STP1242F0000

5STP1842F0001

5STP2842F0017

5STP3842F0007

5STP1242F0000

5STP1242F0000

5STP1842F0001

5STP2842F0017

5STP3842F0007

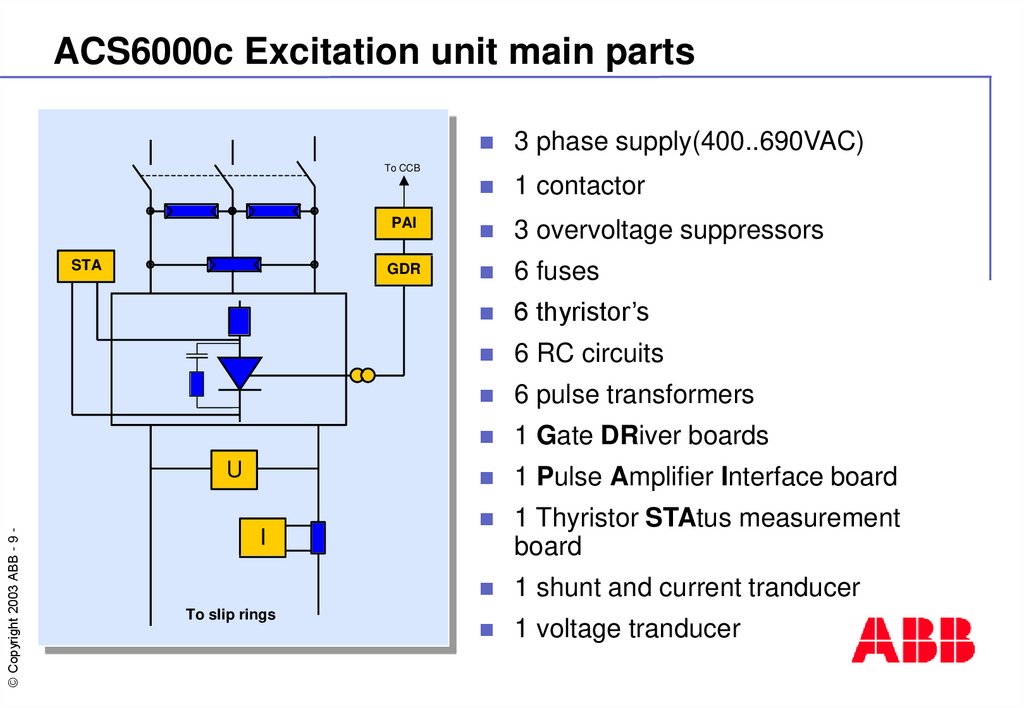

9. ACS6000c Excitation unit main parts

3 phase supply(400..690VAC)1 contactor

PAI

3 overvoltage suppressors

GDR

6 fuses

6 thyristor’s

6 RC circuits

6 pulse transformers

1 Gate DRiver boards

1 Pulse Amplifier Interface board

1 Thyristor STAtus measurement

board

1 shunt and current tranducer

1 voltage tranducer

To CCB

STA

© Copyright 2003 ABB - 9 -

U

I

To slip rings

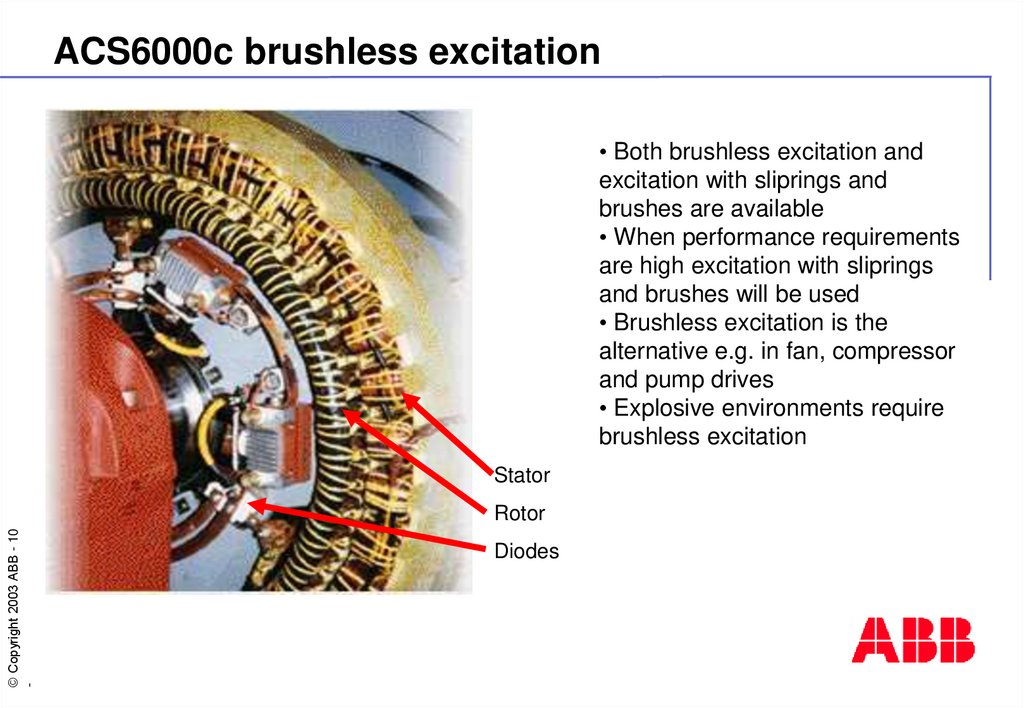

10. ACS6000c brushless excitation

• Both brushless excitation andexcitation with sliprings and

brushes are available

• When performance requirements

are high excitation with sliprings

and brushes will be used

• Brushless excitation is the

alternative e.g. in fan, compressor

and pump drives

• Explosive environments require

brushless excitation

Stator

© Copyright 2003 ABB - 10

-

Rotor

Diodes

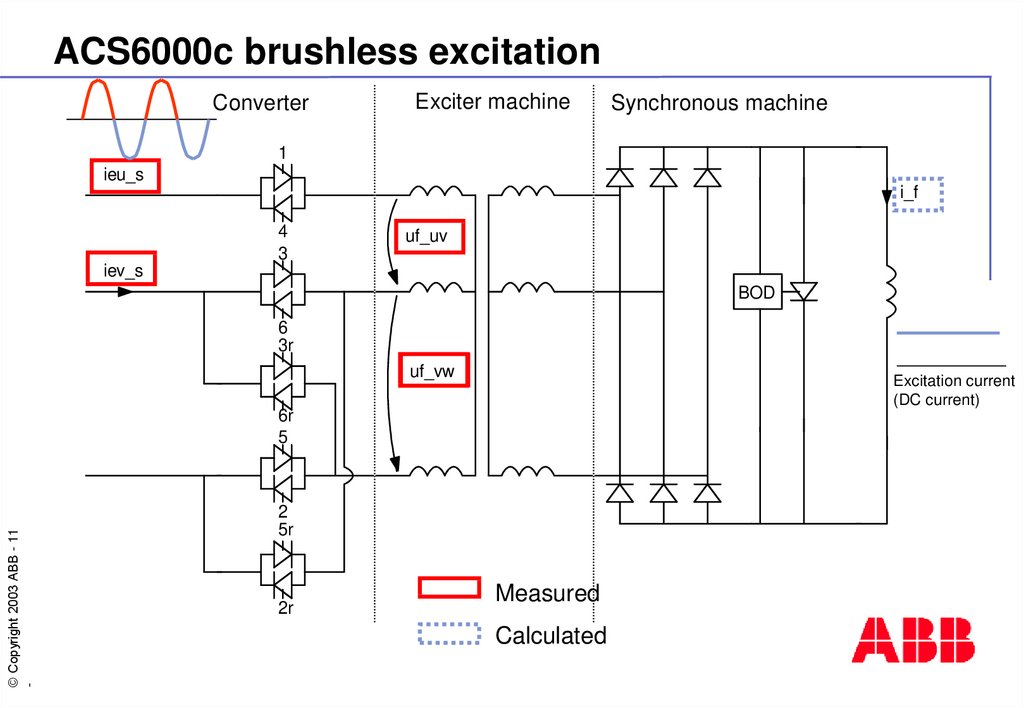

11. ACS6000c brushless excitation

ConverterExciter machine

Synchronous machine

1

ieu_s

i_f

4

3

uf_uv

iev_s

BOD

6

3r

uf_vw

Excitation current

(DC current)

© Copyright 2003 ABB - 11

-

6r

5

2

5r

2r

Measured

Calculated

12. ACS6000c brushless excitation

ThyristorsPulse transformers

Supply fuses

© Copyright 2003 ABB - 12

-

Supply cables

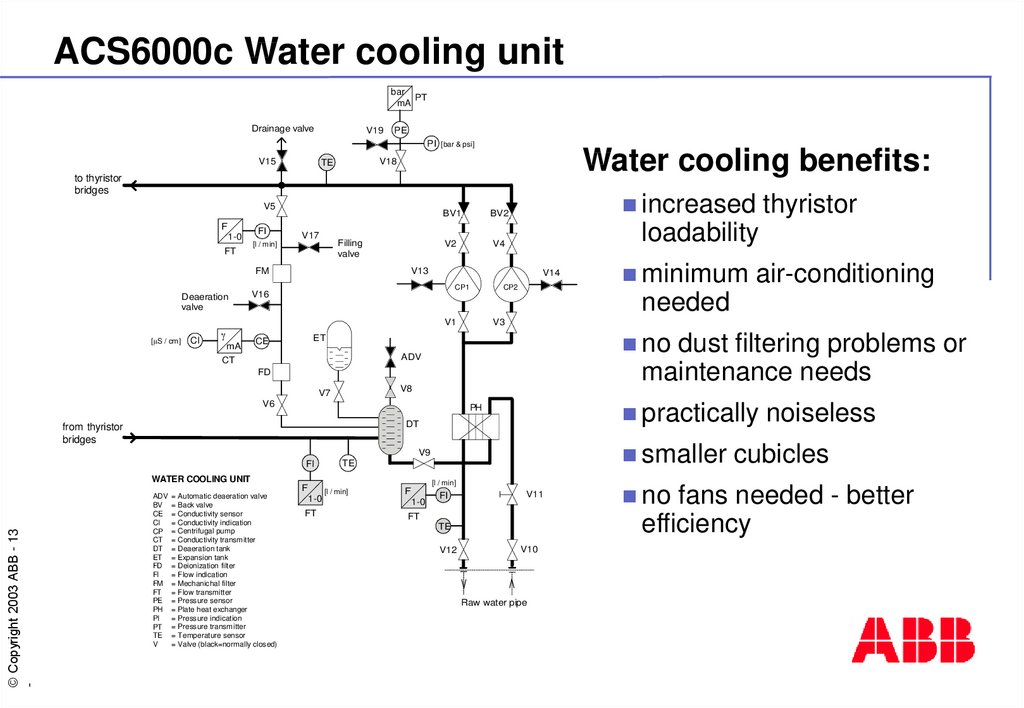

13. ACS6000c Water cooling unit

barPT

mA

Drainage valve

V19

PE

PI [bar & psi]

V15

Water cooling benefits:

V18

TE

to thyristor

bridges

V5

F

1-0

FT

FI

V17

[l / min]

Filling

valve

BV2

V2

V4

V16

CI

mA

CE

CP2

no

dust filtering problems or

maintenance needs

ET

FD

V8

V7

V6

practically

PH

DT

from thyristor

bridges

smaller

V9

FI

TE

WATER COOLING UNIT

© Copyright 2003 ABB - 13

-

air-conditioning

V3

ADV

= Automatic deaeration valve

= Back valve

= Conductivity sensor

= Conductivity indication

= Centrifugal pump

= Conductivity transmitter

= Deaeration tank

= Expansion tank

= Deionization filter

= Flow indication

= Mechanichal filter

= Flow transmitter

= Pressure sensor

= Plate heat exchanger

= Pressure indication

= Pressure transmitter

= Temperature sensor

= Valve (black=normally closed)

minimum

needed

CT

ADV

BV

CE

CI

CP

CT

DT

ET

FD

FI

FM

FT

PE

PH

PI

PT

TE

V

thyristor

loadability

V14

CP1

V1

[ S / cm]

increased

V13

FM

Deaeration

valve

BV1

F

[l / min]

1-0

FT

[l / min]

F

1-0

FI

V11

FT

TE

V12

V10

Raw water pipe

no

noiseless

cubicles

fans needed - better

efficiency

14. ACS6000c Water cooling unit

Expansion vesselTwo pumps

Ion-compound

ion-compound water flow

meter

Pressure sensors

© Copyright 2003 ABB - 14

-

External water cooling

connection

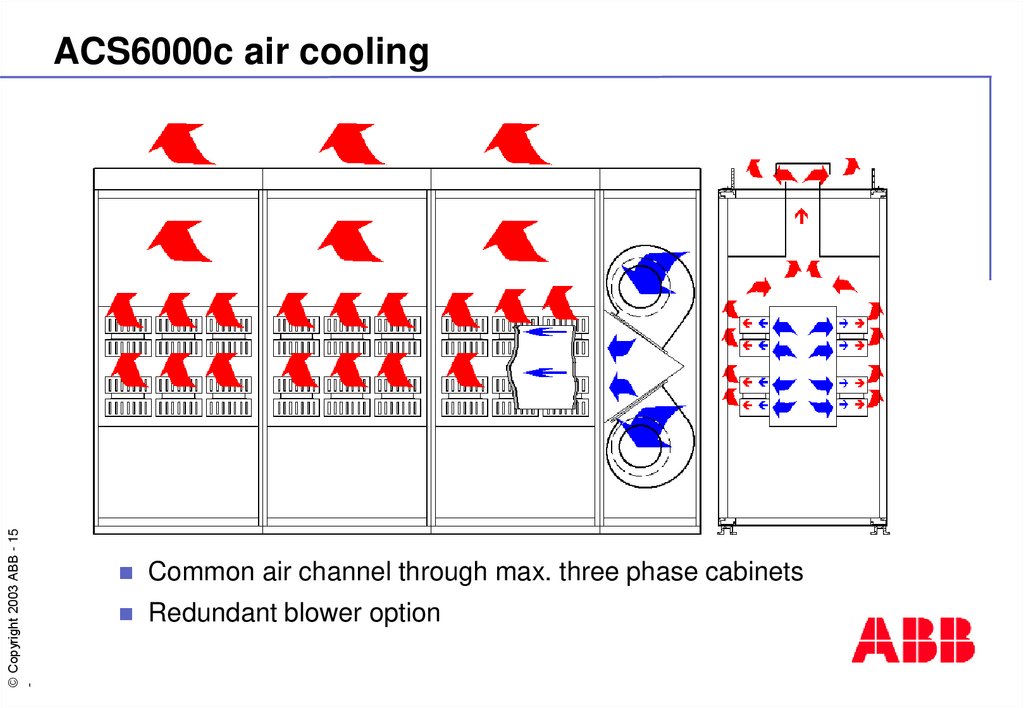

15. ACS6000c air cooling

© Copyright 2003 ABB - 15-

ACS6000c air cooling

Common air channel through max. three phase cabinets

Redundant blower option

16. ACS6000c high speed circuit breakers(HSCB)

© Copyright 2003 ABB - 16-

ACS6000c high speed circuit breakers(HSCB)

Made by Secheron,

Geneva, Switzerland

Nominal voltages up to

4000V

Maximum rated currents

up to 6000A

More selective protection

in case of short circuit in

motor or commutation

failure during

regenerating(loss of supply

voltage)

Voltage level of the fuses

lower. 1.25kV instead of

2.0kV without HSCB

17. ACS6000c HSCB operation

ARC CHUTE© Copyright 2003 ABB - 17

-

MOVING CONTACT

COIL

Fork

TRIPPING DEVICE

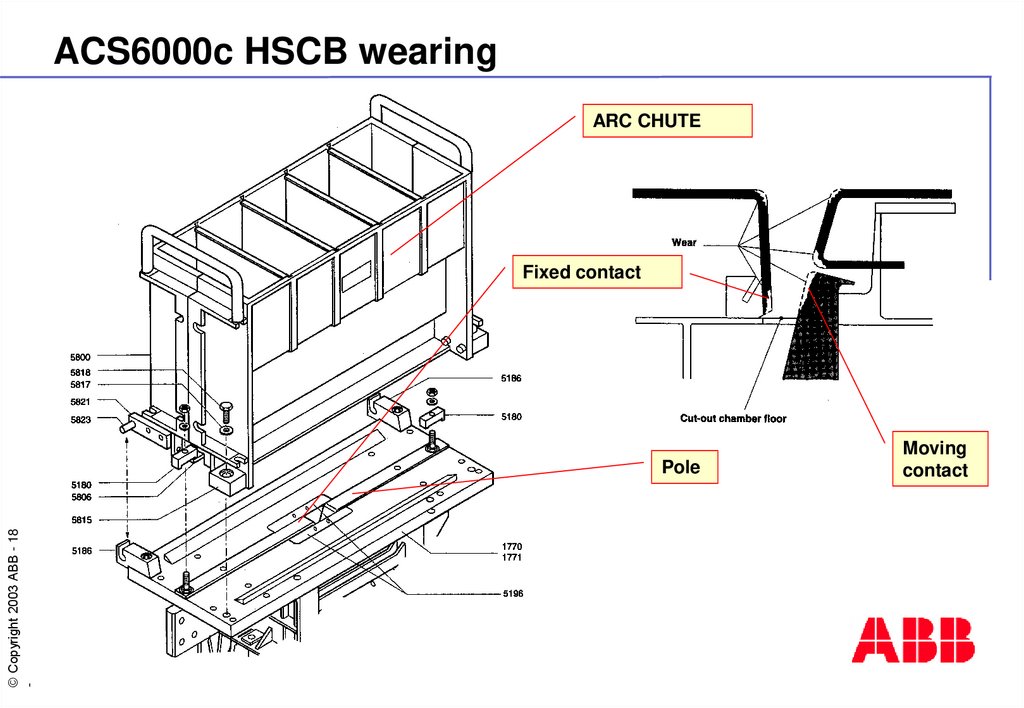

18. ACS6000c HSCB wearing

ARC CHUTEFixed contact

© Copyright 2003 ABB - 18

-

Pole

Moving

contact

19. ACS6000c HSCB setting

© Copyright 2003 ABB - 19-

ACS6000c HSCB setting

Trip limit=

1.41 × maximum motor current ×1.3

1.41 × 2100A × 1.3=3850A

Phase current

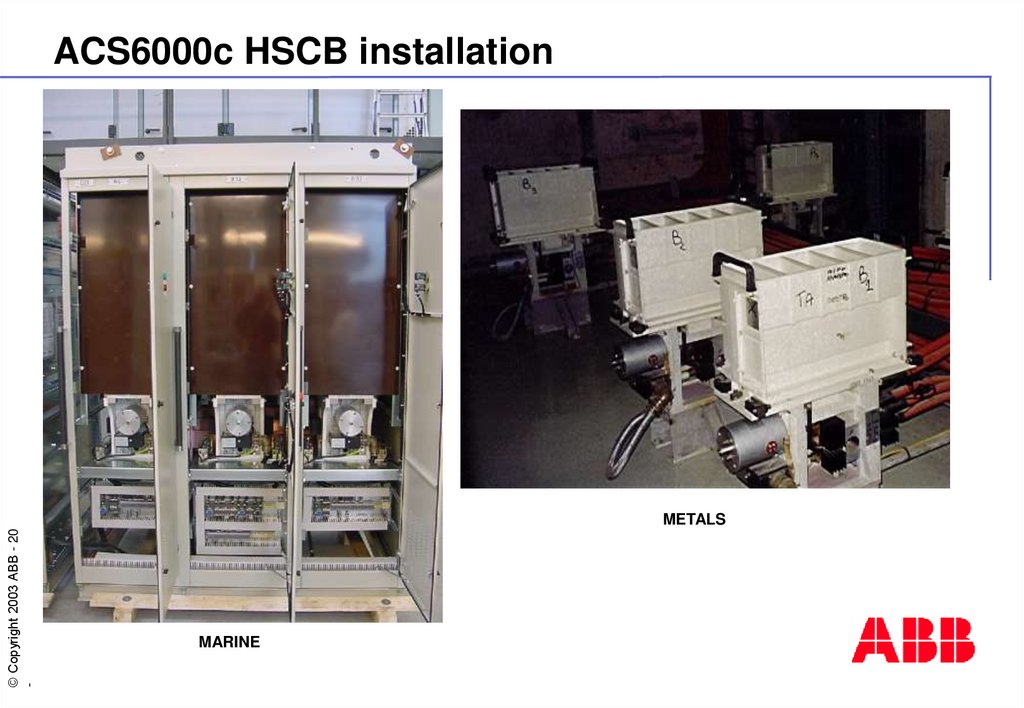

20. ACS6000c HSCB installation

© Copyright 2003 ABB - 20-

METALS

MARINE

21. ACS6000c, Synchronous motor compared to DC

© Copyright 2003 ABB - 21-

Smaller mechanical size

No commutation problems

Lower losses

Full overload up to max speed

Less maintenance

Moment of inertia can be kept low: long

rotor, small diameter

AC-Synchronous motor is thermally less

critical

Stator monitored with Pt-100

elements

Rotor construction is not thermally

critical

Gearless solutions: noise - losses

22. ACS6000c, SM rotor design

Salient pole motor with highoverloadability and easy cooling of

rotor

means smaller inertia and lower weight

means lower losses in the rotor

means higher margins to the pole angle

limit (90 degrees)

direct cooling of the excitation windings

© Copyright 2003 ABB - 22

-

Salient pole rotor with removable

poles

means only a pole as a spare part, not

the whole rotor

means that the rotor can be repaired at

site

23. ACS6000c control

AMC3 with DDCS -Optic LinksFieldbus Adapter

to other systems

or link to the

Advant Controller

RS485

Application and Motor

Controller, AMC3

Control panel

PC Link

CONVERTER

CONTROL

BOARDS

(CCB)

S800 I/O Station

© Copyright 2003 ABB - 23

-

Temperature measurement

Gray encoder interface

Pulse encoder interface

Position feedback

Speed feedback

PT100

PAI

Converter PAI

PAI

Unit 1

Converter

Excitation

Unit

N

Unit

24. ACS6000c control

PROCESS AND USER I/OCOMMON ELECTRONICS

S800 I/O STATION

TO ADVANT

CONTROLLER

TB820

FIELDBUS

ADAPTER

TACHOM.

BOARD

NTAC-02

PROCESS I/O

GRAY ENC. BASIC I/O

BOARD

UNITS

(GRB)

(BIO1...3)

CDP

312

DRIVE CONTROL

D

D

C

S

D

D

C

S

R

S4

85

D

D

C

S

CONVERTER UNIT 1

LOCAL

I/O

D

D

C

S

CONVERTER

CONTROL

BOARD (CCB)

MUB MUB

CONVERTER UNIT 3

STA

STA

STA

APPLICATION AND MOTOR

CONTROL BOARD (AMC3)

MUB MUB

CONVERTER UNIT 2

CONVERTER

CONTROL

BOARD (CCB)

POWER

SUPPLY

PULSE AMPL. GDR

INTERFACE

GDR

(PAI)

LOCAL

I/O

POWER

SUPPLY

PULSE AMPL. GDR

INTERFACE

GDR

(PAI)

LOCAL

I/O

POWER

SUPPLY

PULSE AMPL. GDR

INTERFACE

GDR

(PAI)

EXCITATION UNIT

STA

LOCAL

I/O

POWER

SUPPLY

PULSE AMPL. GDR

INTERFACE

(PAI)

DDCS

DDCS

DDCS

DDCS

© Copyright 2003 ABB - 24

-

MEAS.UNIT

INTERF.(MUI)

MTR

MEAS.UNIT

INTERF.(MUI)

1...8

1...8

1...8

1...8

MTR

MTR

MTR

25. ACS6000c speed and current control loops

AMC3Speed controller and

current reference

calculation

CCB

Phase unit

Current

controller

Synchronization

and firing logic

Speed

reference

Current

measurement

Motor

SM

© Copyright 2003 ABB - 25

-

Rotor position

measurement

SE

Speed

measurement

PG

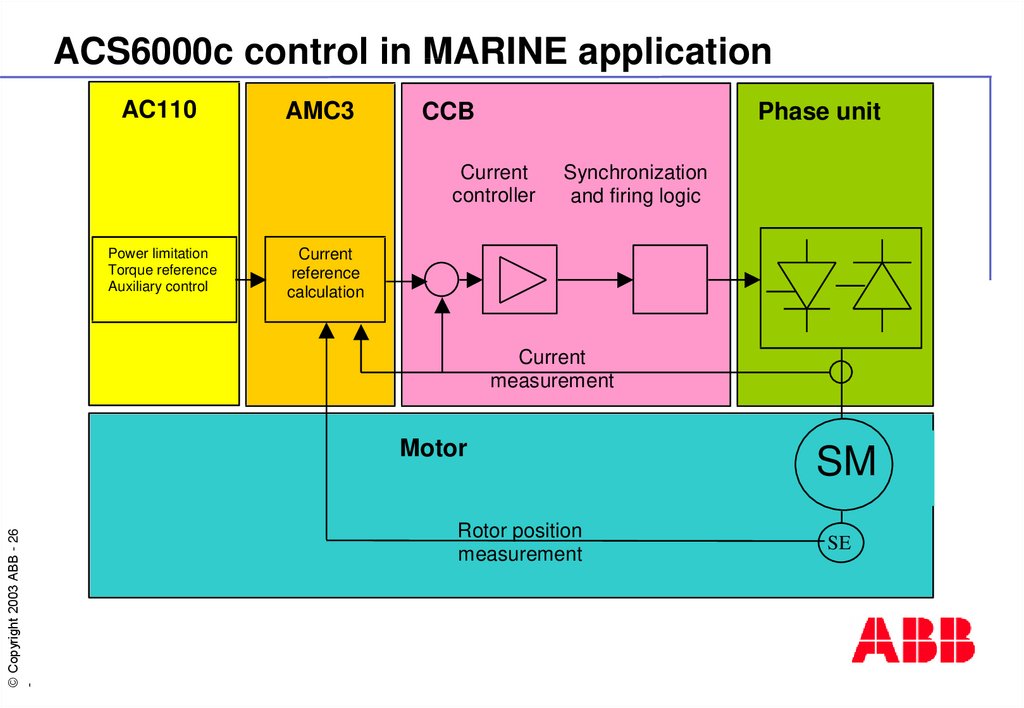

26. ACS6000c control in MARINE application

AC110AMC3

CCB

Phase unit

Current

controller

Power limitation

Torque reference

Auxiliary control

Synchronization

and firing logic

Current

reference

calculation

Current

measurement

© Copyright 2003 ABB - 26

-

Motor

Rotor position

measurement

SM

SE

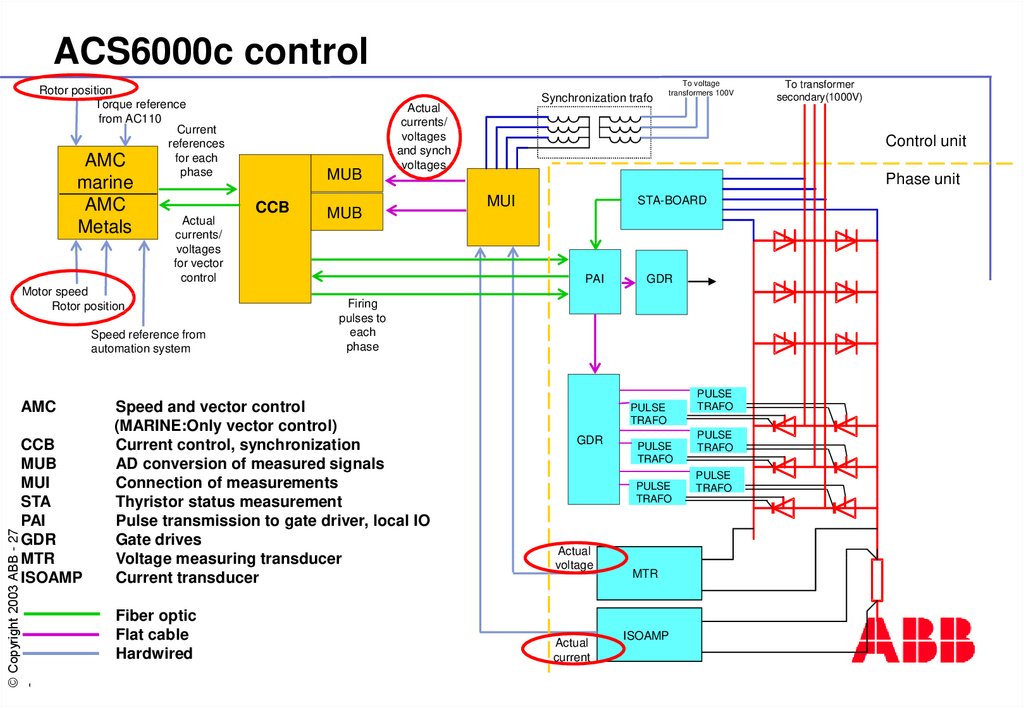

27. ACS6000c control

Rotor positionTorque reference

from AC110

Current

references

for each

AMC

phase

marine

AMC

Metals

CCB

Actual

currents/

voltages

for vector

control

Motor speed

Rotor position

Speed reference from

automation system

AMC

© Copyright 2003 ABB - 27

-

CCB

MUB

MUI

STA

PAI

GDR

MTR

ISOAMP

MUB

Actual

currents/

voltages

and synch

voltages

MUB

To voltage

transformers 100V

To transformer

secondary(1000V)

Control unit

Phase unit

MUI

STA-BOARD

PAI

GDR

Firing

pulses to

each

phase

Speed and vector control

(MARINE:Only vector control)

Current control, synchronization

AD conversion of measured signals

Connection of measurements

Thyristor status measurement

Pulse transmission to gate driver, local IO

Gate drives

Voltage measuring transducer

Current transducer

Fiber optic

Flat cable

Hardwired

Synchronization trafo

PULSE

TRAFO

GDR

PULSE

TRAFO

PULSE

TRAFO

Actual

voltage

Actual

current

MTR

ISOAMP

PULSE

TRAFO

PULSE

TRAFO

PULSE

TRAFO

industry

industry