Similar presentations:

Hermes10 A과제-PJT

1.

SAMSUNG Side by Side RefrigeratorHERMES10 A과제-PJT

TRAINING MANUAL

BASIC : RSH5ZEPN

MODEL NAME (MODEL CODE) : RSH5****

RSH5***

Mar. 2010

Refrigerator Division

2.

CONTENTS1. Product Introduction

2. Instruction of Function

3. Alignment & Adjustment

4. Disassembly & Reassembly

5. SELF DIAGNOSIS & TROUBLE SHOOTING

6. Block diagram

7. PCB diagram

8. Wiring diagram

9. Reference Information

3.

1.Product Introduction1-1. Charcteristics

Comparison with basic

Changed Part

Door

H o m eBar

Door

D isp lay

Insert

D escrip tio n

N ew desig n

Soft to u ch typ e H o m e Bar

N ew desig n D isp lay

Co nvertib le N ew desig n Co nvertib le

Basic

Current

4.

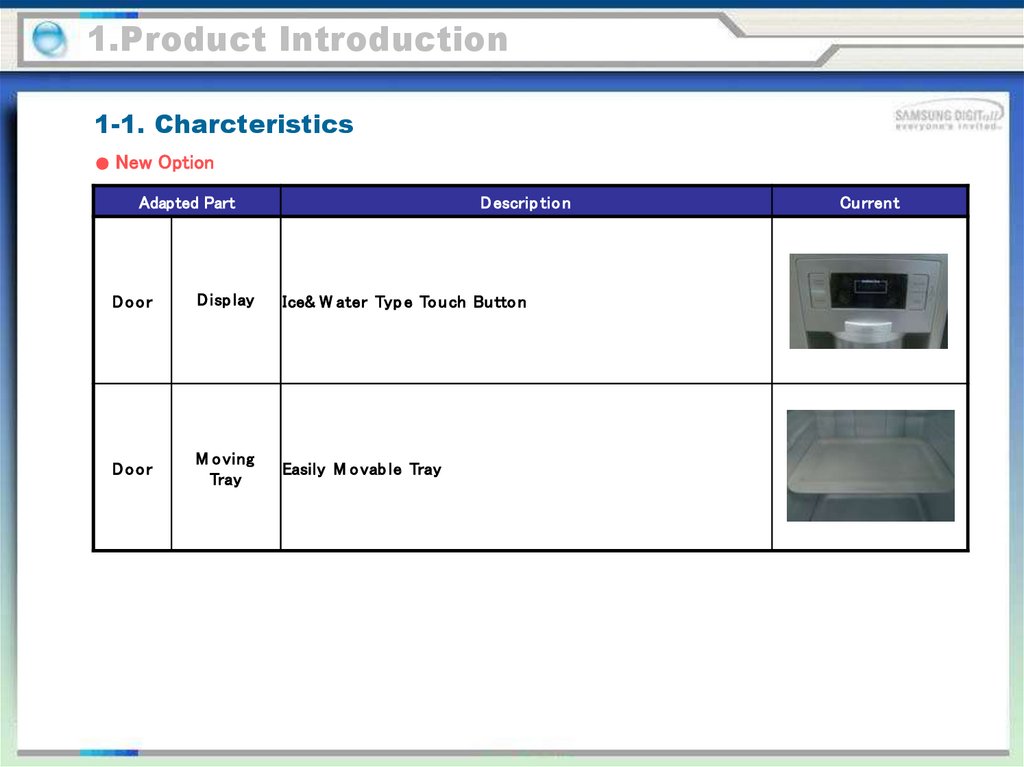

1.Product Introduction1-1. Charcteristics

New Option

Adapted Part

D escrip tio n

Door

D isp lay

Ice& W ater Typ e To u ch Bu tto n

Door

M o ving

Tray

Easily M o vab le Tray

Current

5.

1.Product Introduction1-1. Product Feature

TWIN Cooling TDM

By monitoring the states of the freezer and the fridge compartments

on a real time basis, it runs both of the evaporators in optimal

conditions and makes it possible to maintain world best 71%of

humidity in the fridge compartment and extend storage life with

much freshness.

CoolSelect Zone™Drawer

With this state of the art feature,you can select Quick Cool, Thaw or

Select buttons to quickly chill, thaw and cool items just in the

CoolSelect drawer. Select Soft Freeze, Cool or 0 Zone to control

the temperature of drawer.

EASY OPENNING

Doors can be opened easily and smoothly with this “Easy

Handle ”for the customer satisfaction.

DELICATESSEN BOX

New concept box design on Fridge door for efficiency of

storage space & convenient separation of all kinds of food.

EASILY MOVABLE TRAY

New concept tray to increase the movability with food

simultaneously. Useful for storage of dessert and cake etc.

6.

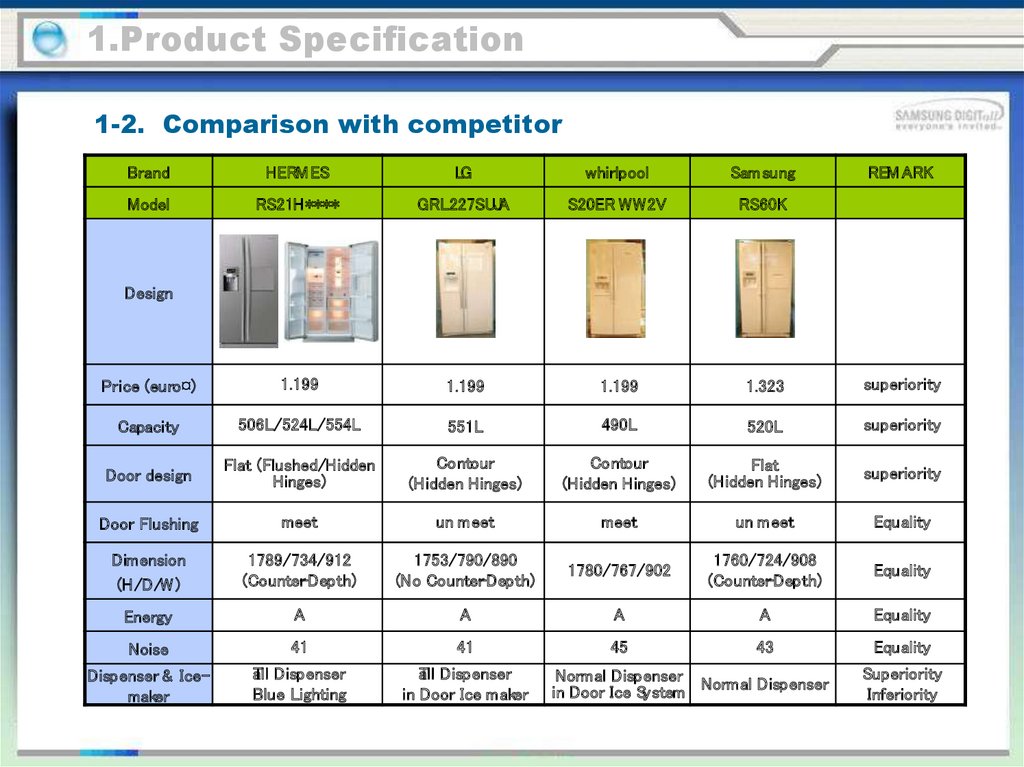

1.Product Specification1-2. Comparison with competitor

Brand

HERM ES

LG

whirlpool

Sam sung

REM ARK

Model

RS21H****

GRL227SUJA

S20ER WW2V

RS60K

Price (euro¤)

1.199

1.199

1.199

1.323

superiority

Capacity

506L/524L/554L

551L

490L

520L

superiority

Door design

Flat (Flushed/Hidden

Hinges)

Contour

(Hidden Hinges)

Contour

(Hidden Hinges)

Flat

(Hidden Hinges)

superiority

Door Flushing

meet

un meet

meet

un meet

Equality

Dimension

(H/D/W )

1789/734/912

(Counter-Depth)

1753/790/890

(No Counter-Depth)

1780/767/902

1760/724/908

(Counter-Depth)

Equality

Energy

A

A

A

A

Equality

Noise

41

41

45

43

Equality

Dispenser & Icemaker

aTll Dispenser

Blue Lighting

aTll Dispenser

in Door Ice maker

Design

Normal Dispenser

in Door Ice System Normal Dispenser

Superiority

Inferiority

7.

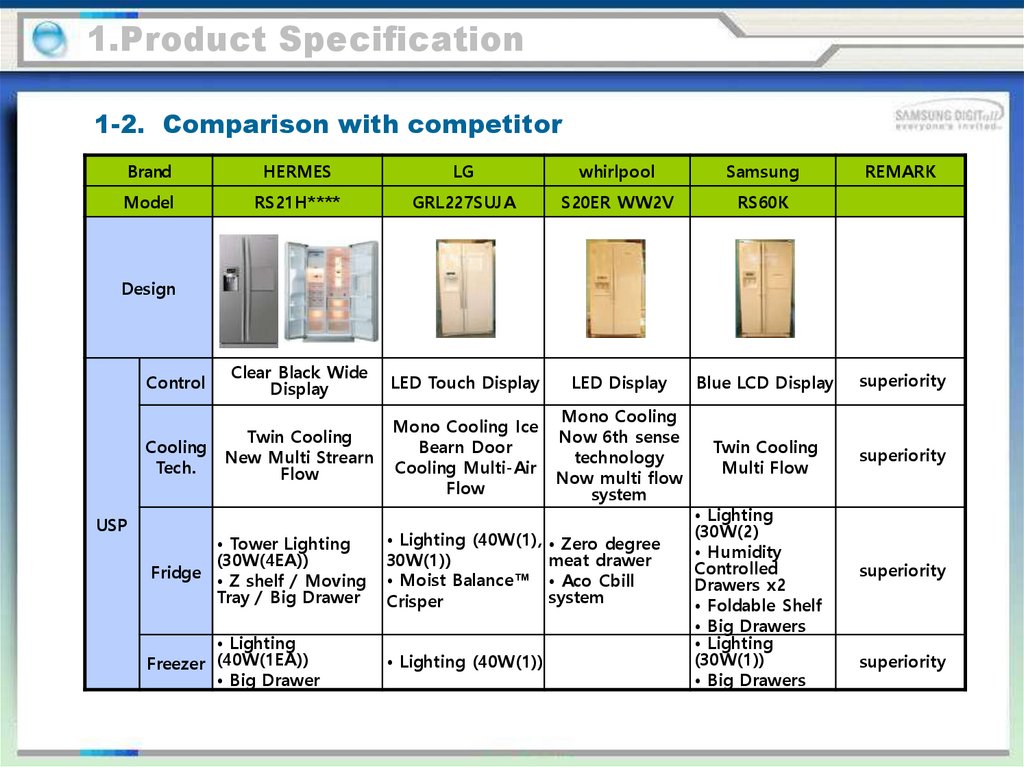

1.Product Specification1-2. Comparison with competitor

Brand

HERMES

LG

whirlpool

Samsung

REMARK

Model

RS21H****

GRL227SUJA

S20ER WW2V

RS60K

Control

Clear Black Wide

Display

LED Touch Display

LED Display

Blue LCD Display

superiority

Cooling

Tech.

Twin Cooling

New Multi Strearn

Flow

Mono Cooling Ice

Bearn Door

Cooling Multi-Air

Flow

Mono Cooling

Now 6th sense

technology

Now multi flow

system

Twin Cooling

Multi Flow

superiority

Design

USP

• Tower Lighting

(30W(4EA))

Fridge • Z shelf / Moving

Tray / Big Drawer

• Lighting (40W(1),

30W(1))

• Moist Balance™

Crisper

• Lighting

Freezer (40W(1EA))

• Big Drawer

• Lighting (40W(1))

• Zero degree

meat drawer

• Aco Cbill

system

• Lighting

(30W(2)

• Humidity

Controlled

Drawers x2

• Foldable Shelf

• Big Drawers

• Lighting

(30W(1))

• Big Drawers

superiority

superiority

8.

1.Product Introduction1-3. Parts Name (RSJ1 Series)

Delicatessen

Shelf

Wine Shelf

Ice Chute

Moving Shelf (optional)

Z shelf

Shelf

Egg tray

Door Bin

Coolselect Zone

Drawer (optional)

Fruit & V

egetable drawer

Drawer

Door Bin

9.

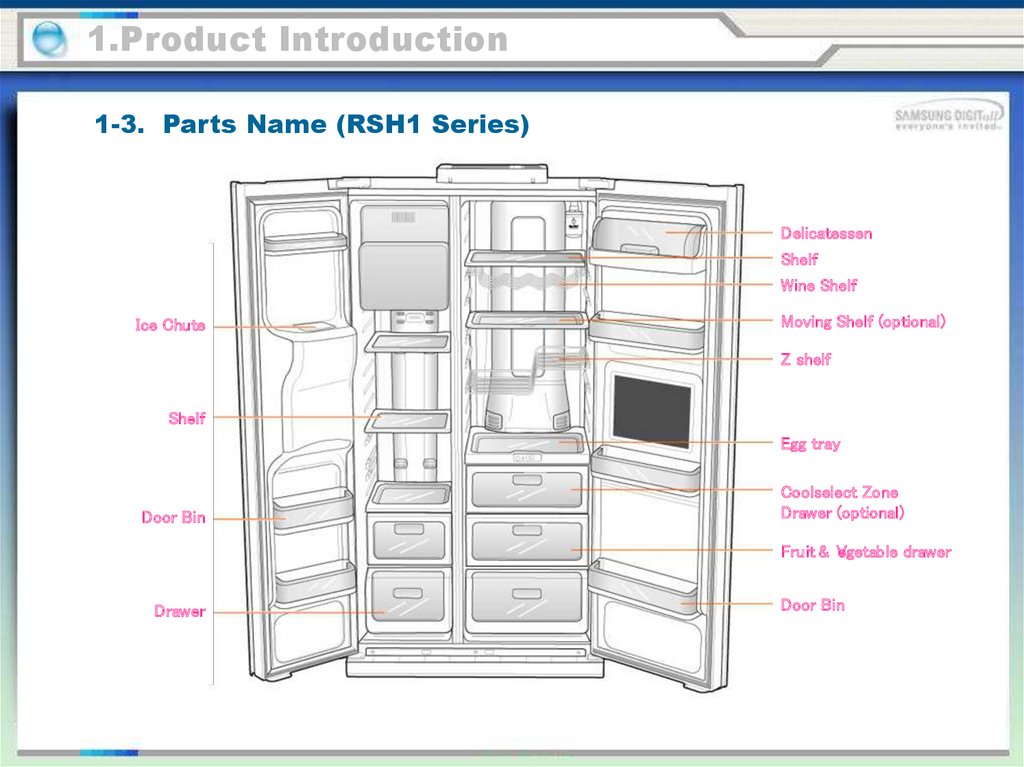

1.Product Introduction1-3. Parts Name (RSH1 Series)

Delicatessen

Shelf

Wine Shelf

Ice Chute

Moving Shelf (optional)

Z shelf

Shelf

Egg tray

Door Bin

Coolselect Zone

Drawer (optional)

Fruit & V

egetable drawer

Drawer

Door Bin

10.

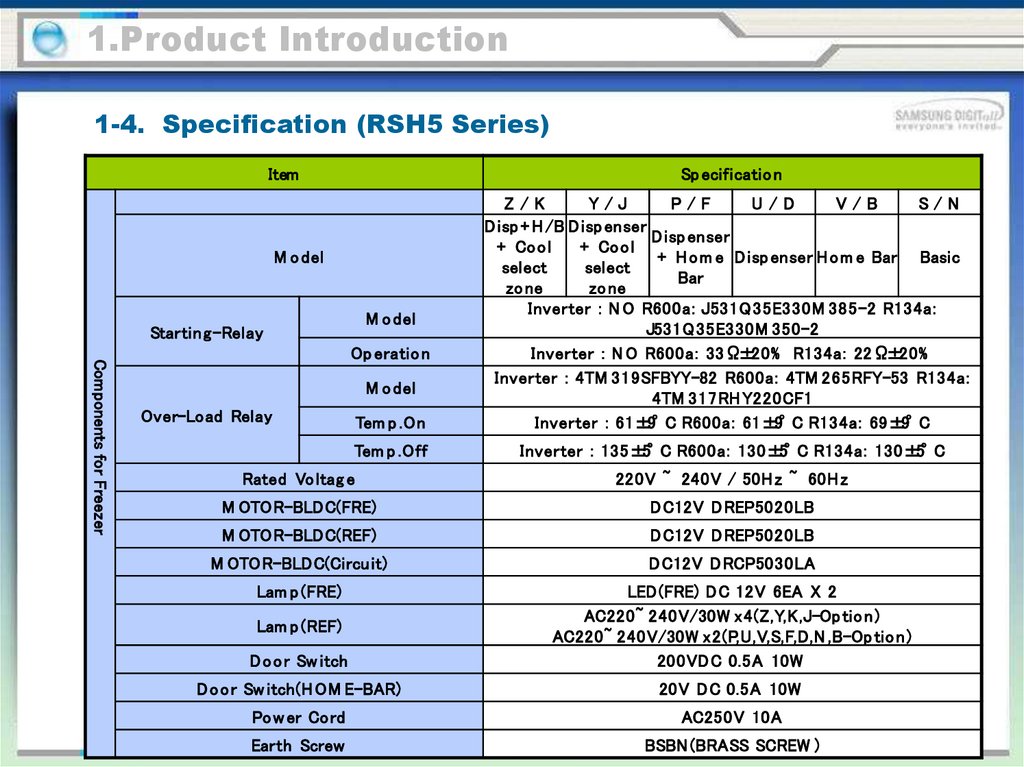

1.Product Introduction1-4. Specification (RSH5 Series)

Item

Specification

Z/K

Y/J

P/F

U/D

V/B

Disp+H/B+ Dispenser+

Dispenser+

Cool select Cool select

Dispenser Home Bar

Home Bar

zone

zone

Model

Defrost- Heater(FRE)

Defrost-Heater(REF)

Components for Freezer

Conducting at F

Defrosting

Conducting at R

Defrosting

DISPEN SER HEA

TER

Interlock with F-FAN

HOME-BAR HEA

TER

Interlock with COM P

WA

TER PIPE HEA

TER

-

WA

TER PIPE HEA

TER

-

Bimetal for preventing overheating of Freezer

Defrost-Heater

Bimetal for preventing overheating of Refrigerator

Defrost-Heater

Condenser for

Running

COM PRESSOR (Package

Star ting

type)

S/N

Basic

Sheath Heater 230V 230W

Sheath Heater 230V 140W

AC230V

5W

AC230V

7W

AC230V

10W

AC230V

5W

AC230V

5W

AC230V

10W

AC230V

5W

AC230V

5W

AC230V

7W

AC230V

10W

AC230V

5W

AC230V

5W

-

-

-

AC230V

7W

-

-

-

-

-

AC230V

10W

AC230V

5W

Bimetal thermostat(BT-121-M )

On: 40°C Off : 60°C

Thermo-Fuse (Cutoff : 110°C)

Inver ter : NO R600a: 450VAC/5.0㎌ R134a: 450VAC/5.0㎌

-

11.

1.Product Introduction1-4. Specification (RSH5 Series)

Item

Sp ecificatio n

M o del

M o del

Startin g-Relay

Components for Freezer

Op eratio n

M o del

Over-Load Relay

Tem p .On

Tem p .Off

Z/K

Y/J

P/F

U/D

V/B

S/N

D isp + H /B D isp enser

D isp enser

+ Co o l

+ Co o l

+ H o m e D isp enser H o m e Bar Basic

select

select

Bar

zo ne

zo ne

Inverter : N O R600a: J531Q35E330M 385-2 R134a:

J531Q35E330M 350-2

Inverter : N O R600a: 33Ω±20% R134a: 22Ω±20%

Inverter : 4TM 319SFBYY-82 R600a: 4TM 265RFY-53 R134a:

4TM 317RH Y220CF1

Inverter : 61±9°C R600a: 61±9°C R134a: 69±9°C

Inverter : 135±5°C R600a: 130±5°C R134a: 130±5°C

Rated Vo ltag e

220V ~ 240V / 50H z ~ 60H z

M OTOR-BLDC(FRE)

D C12V D REP5020LB

M OTOR-BLDC(REF)

D C12V D REP5020LB

M OTOR-BLDC(Circu it)

D C12V D RCP5030LA

Lam p (FRE)

D o o r Sw itch

LED (FRE) D C 12V 6EA X 2

AC220~ 240V/30W x4(Z,Y,K,J-Op tio n)

AC220~ 240V/30W x2(P,U,V,S,F,D,N ,B-Op tio n)

200VD C 0.5A 10W

D o o r Sw itch(H OM E-BAR)

20V D C 0.5A 10W

Po w er Co rd

AC250V 10A

Earth Screw

BSBN (BRASS SCREW )

Lam p (REF)

12.

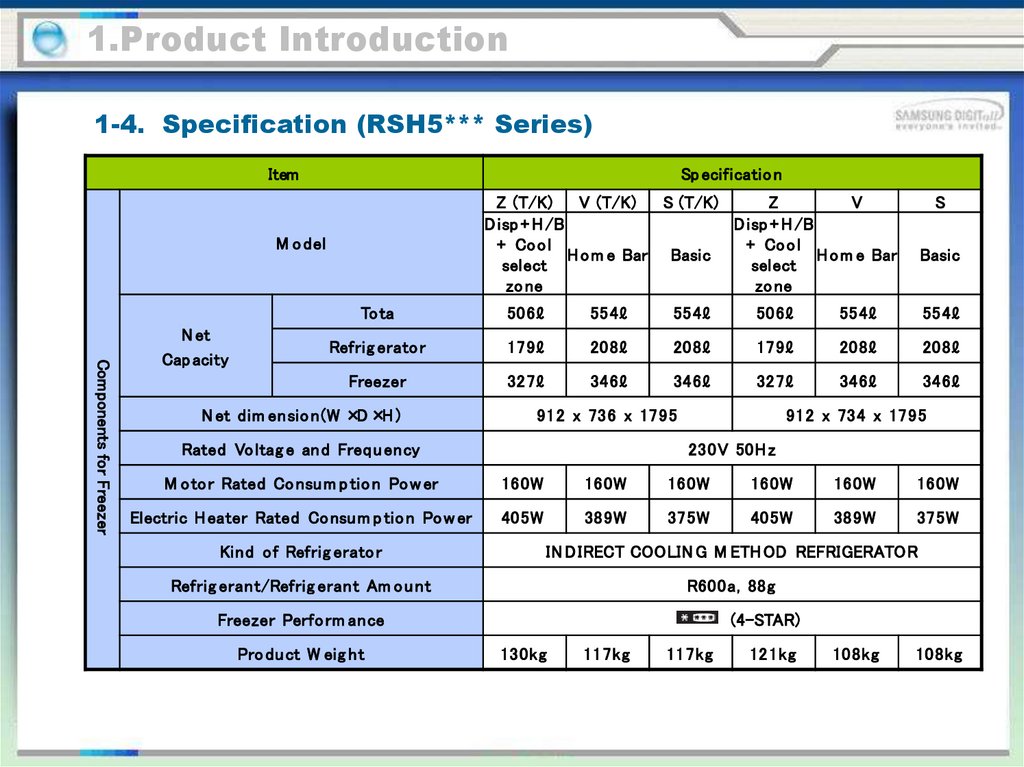

1.Product Introduction1-4. Specification (RSH5*** Series)

Item

Sp ecificatio n

Z (T/K)

V (T/K)

S (T/K)

Z

V

D isp + H /B

D isp + H /B

+ Co o l

+ Co o l

H o m e Bar Basic

H o m e Bar

select

select

zo ne

zo ne

M o del

Components for Freezer

N et

Cap acity

S

Basic

To ta

506ℓ

554ℓ

554ℓ

506ℓ

554ℓ

554ℓ

Refrig erato r

179ℓ

208ℓ

208ℓ

179ℓ

208ℓ

208ℓ

Freezer

327ℓ

346ℓ

346ℓ

327ℓ

346ℓ

346ℓ

N et dim ensio n(W ×D ×H )

912 x 736 x 1795

Rated Vo ltag e an d Freq u ency

912 x 734 x 1795

230V 50H z

M o to r Rated Co nsu m p tio n Po w er

160W

160W

160W

160W

160W

160W

Electric H eater Rated Co nsu m p tio n Po w er

405W

389W

375W

405W

389W

375W

Kind of Refrig erato r

IN D IRECT COOLIN G M ETH OD REFRIGERATOR

Refrig erant/Refrig erant Am o u nt

R600a, 88g

Freezer Perfo rm ance

Pro du ct W eig ht

(4-STAR)

130kg

117kg

117kg

121kg

108kg

108kg

13.

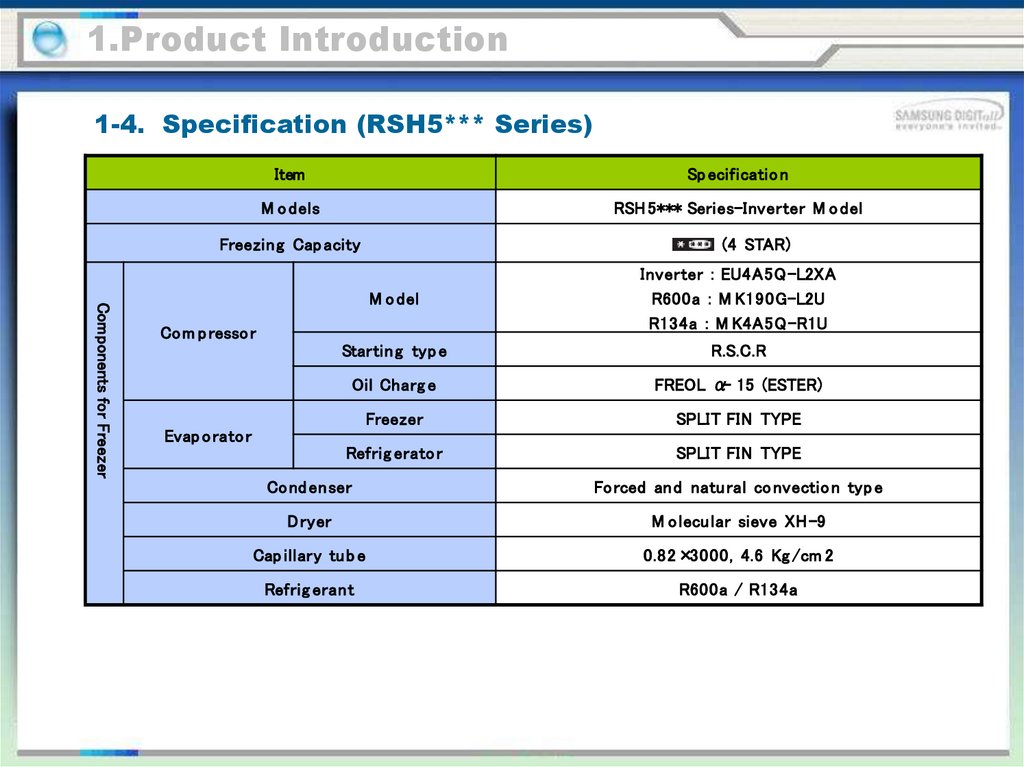

1.Product Introduction1-4. Specification (RSH5*** Series)

Item

Sp ecificatio n

M o dels

RSH 5*** Series-Inverter M o del

Freezing Cap acity

(4 STAR)

Components for Freezer

M o del

Inverter : EU4A5Q-L2XA

R600a : M K190G-L2U

R134a : M K4A5Q-R1U

Startin g typ e

R.S.C.R

Oil Charg e

FREOL α- 15 (ESTER)

Freezer

SPLIT FIN TYPE

Refrig erato r

SPLIT FIN TYPE

Co m p resso r

Evap o rato r

Co nd enser

Fo rced and natu ral co nvectio n typ e

D ryer

M o lecu lar sieve XH -9

Cap illary tu b e

0.82×3000, 4.6 Kg /cm 2

Refrig erant

R600a / R134a

14.

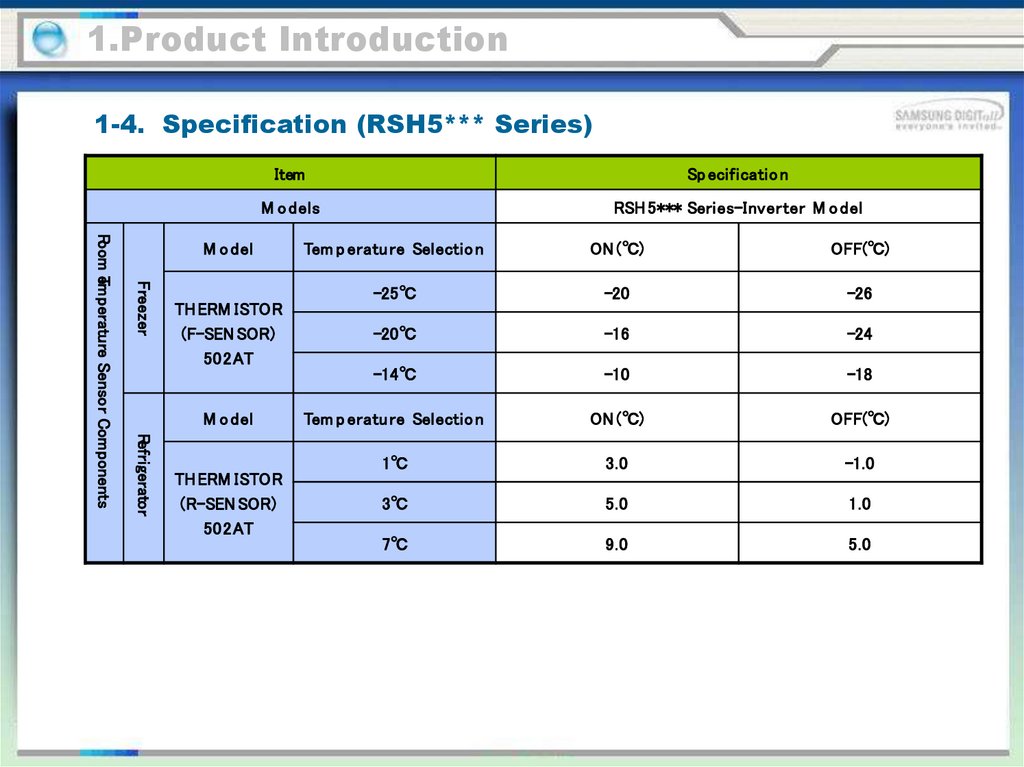

1.Product Introduction1-4. Specification (RSH5*** Series)

Item

Sp ecificatio n

M o dels

RSH 5*** Series-Inverter M o del

Freezer

TH ERM ISTOR

(F-SEN SOR)

502AT

M o del

Refrigerator

Room eTmperature Sensor Components

M o del

TH ERM ISTOR

(R-SEN SOR)

502AT

Tem p eratu re Selectio n

ON (℃)

OFF(℃)

-25℃

-20

-26

-20℃

-16

-24

-14℃

-10

-18

Tem p eratu re Selectio n

ON (℃)

OFF(℃)

1℃

3.0

-1.0

3℃

5.0

1.0

7℃

9.0

5.0

15.

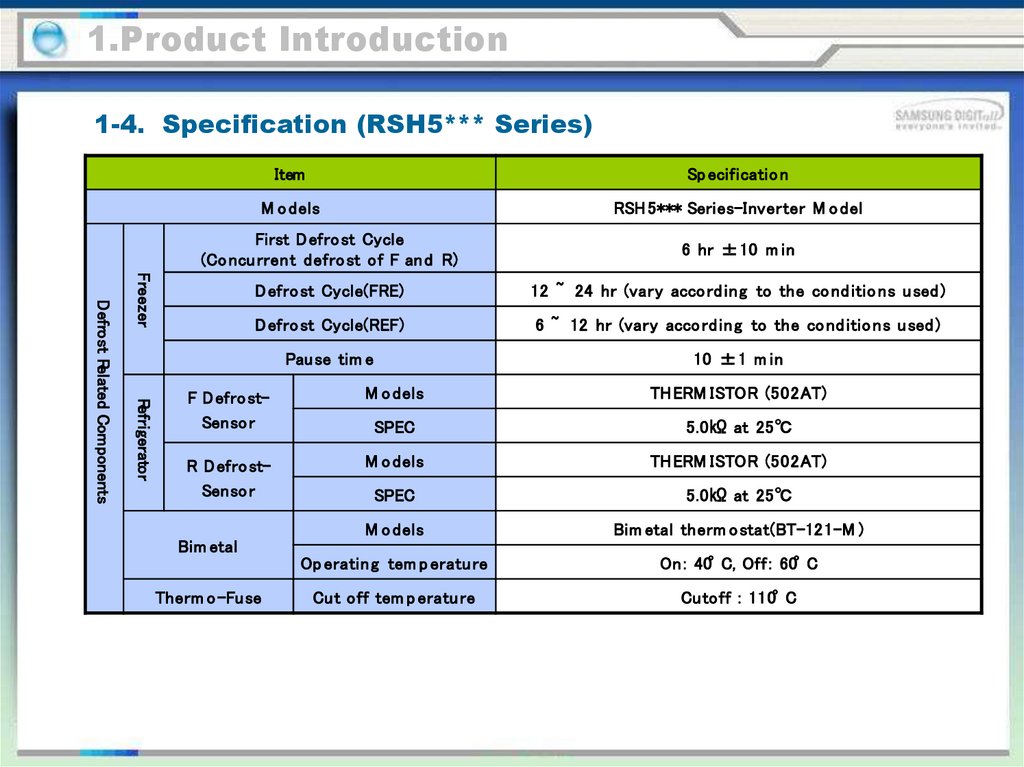

1.Product Introduction1-4. Specification (RSH5*** Series)

Item

Sp ecificatio n

M o dels

RSH 5*** Series-Inverter M o del

6 hr ±10 m in

D efro st Cycle(FRE)

12 ~ 24 hr (vary acco rd ing to the co nd itio ns u sed )

D efro st Cycle(REF)

6 ~ 12 hr (vary acco rd in g to the co nd itio ns u sed )

Pau se tim e

10 ±1 m in

Freezer

Refrigerator

Defrost Related Components

First D efro st Cycle

(Co ncu rrent defro st of F an d R)

F D efro stSenso r

M o dels

TH ERM ISTOR (502AT)

SPEC

5.0㏀ at 25℃

R D efro stSenso r

M o dels

TH ERM ISTOR (502AT)

SPEC

5.0㏀ at 25℃

M o dels

Bim etal therm o stat(BT-121-M )

Op eratin g tem p eratu re

On : 40°C, Off : 60°C

Cut off tem p eratu re

Cutoff : 110°C

Bim etal

Therm o -Fuse

16.

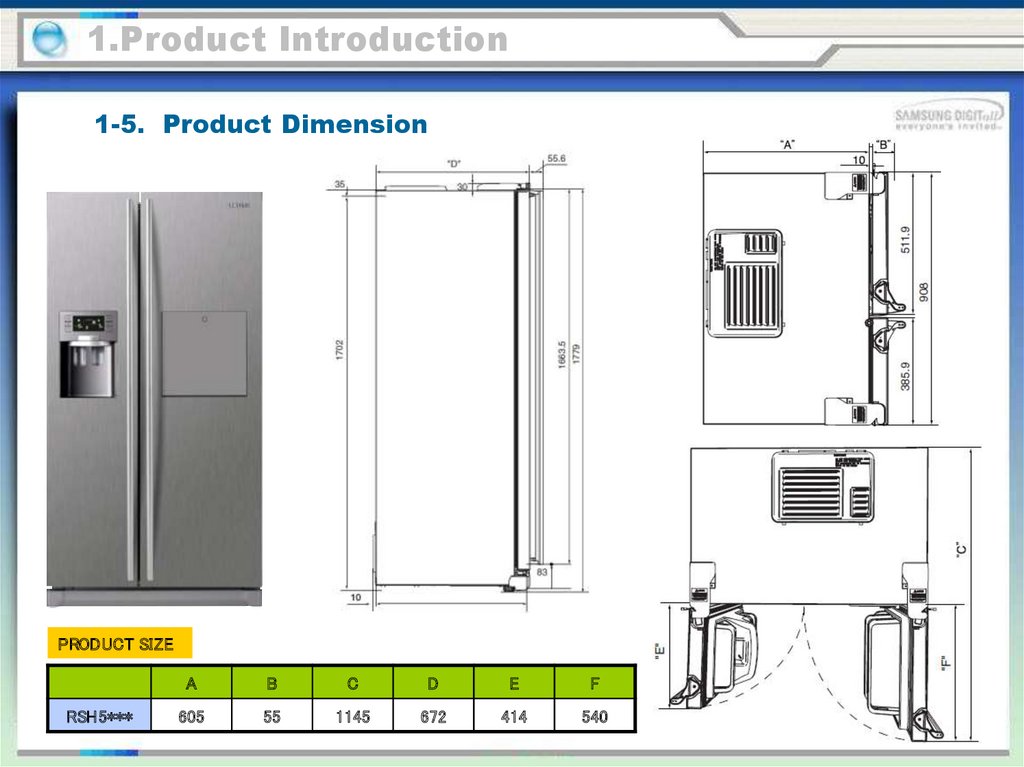

1.Product Introduction1-5. Product Dimension

PRODUCT SIZE

RSH5***

A

B

C

D

E

F

605

55

1145

672

414

540

17.

1.Product Introduction1-6. Refrigeration TDM Cycle

Compressor

SPIRAL-CONDENSER

FRIDGE HOT PIPE

Fridge Capillar y uTbe

Fridge Evaporator

Dr yer

3WA

Y VALVE

CONNECTED CAPILL ARY

Freezer Capillar y uTbe

ACCUM UL A

TOR

Compressor

Freezer Evaporator

SUCTION PIPE

18.

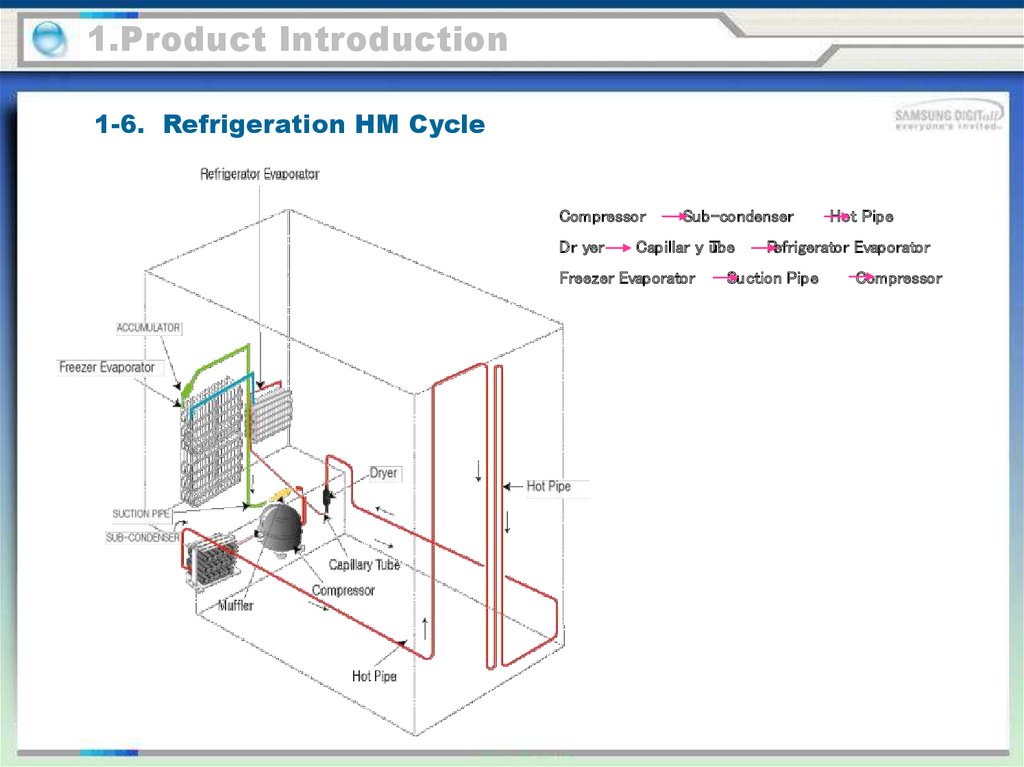

1.Product Introduction1-6. Refrigeration HM Cycle

Compressor

Dr yer

Sub-condenser

Capillar y uTbe

Freezer Evaporator

Hot Pipe

Refrigerator Evaporator

Suction Pipe

Compressor

19.

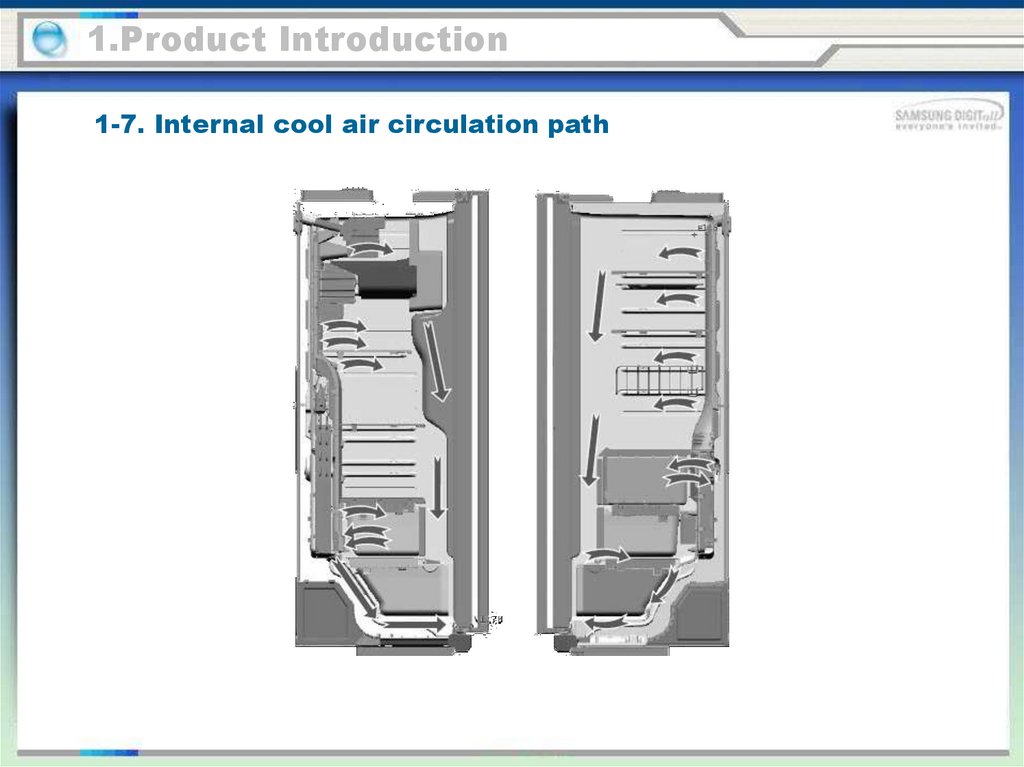

1.Product Introduction1-7. Internal cool air circulation path

20.

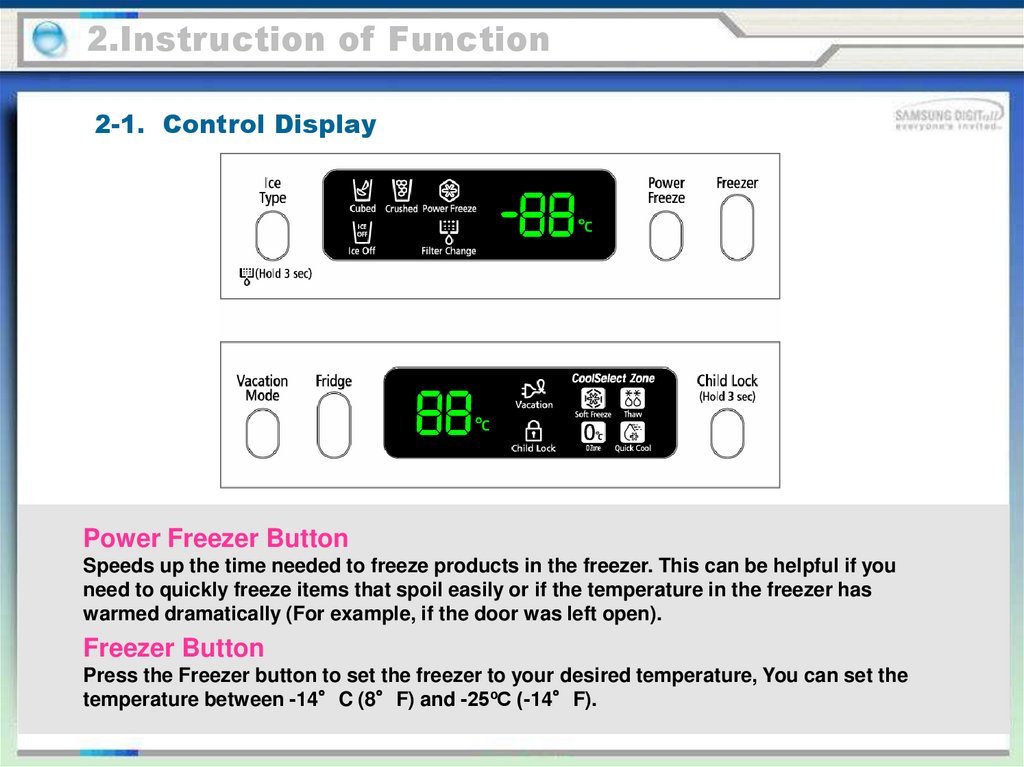

2.Instruction of Function2-1. Control Display

Power Freezer Button

Speeds up the time needed to freeze products in the freezer. This can be helpful if you

need to quickly freeze items that spoil easily or if the temperature in the freezer has

warmed dramatically (For example, if the door was left open).

Freezer Button

Press the Freezer button to set the freezer to your desired temperature, You can set the

temperature between -14°C (8°F) and -25ºC (-14°F).

21.

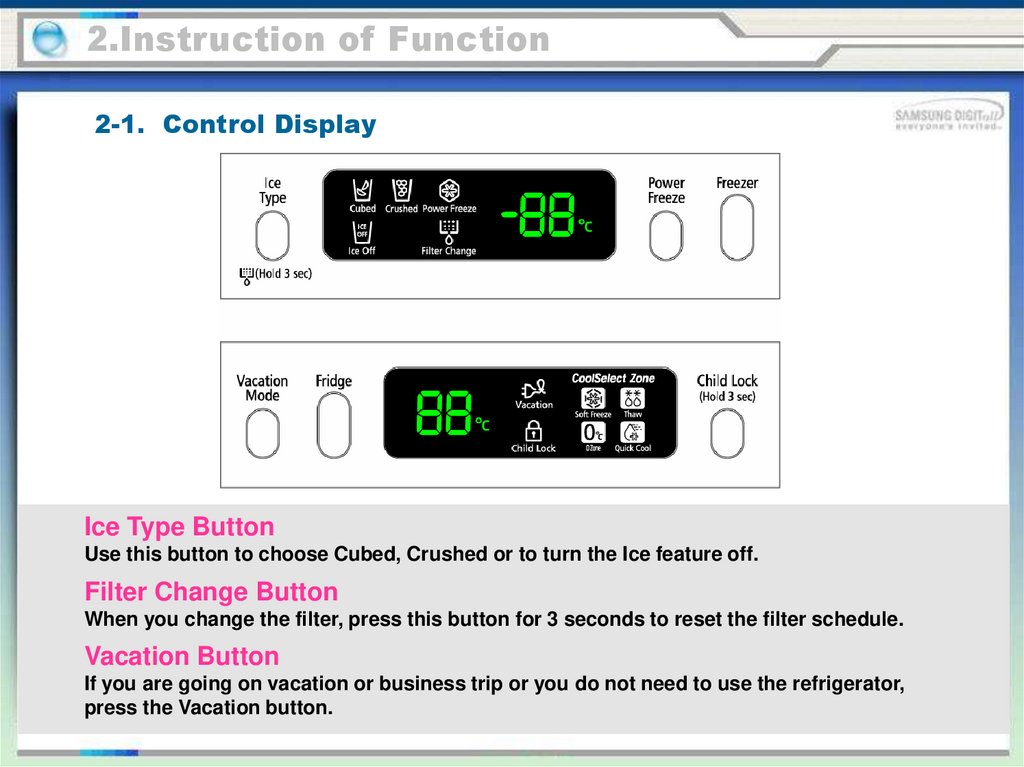

2.Instruction of Function2-1. Control Display

Ice Type Button

Use this button to choose Cubed, Crushed or to turn the Ice feature off.

Filter Change Button

When you change the filter, press this button for 3 seconds to reset the filter schedule.

Vacation Button

If you are going on vacation or business trip or you do not need to use the refrigerator,

press the Vacation button.

22.

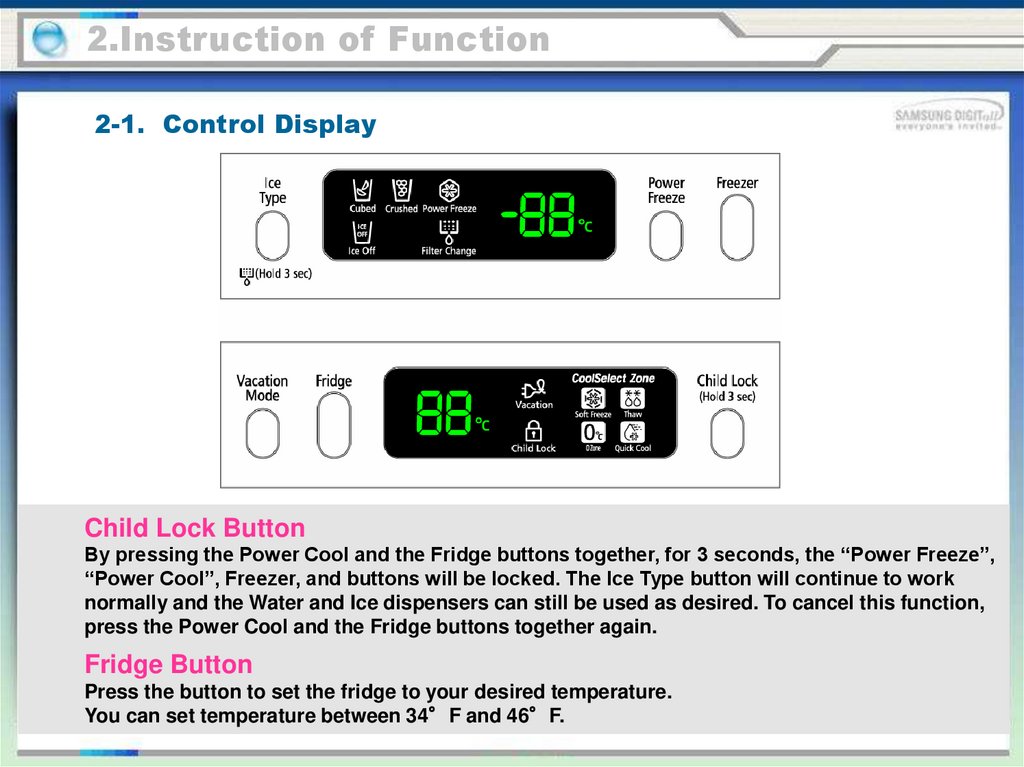

2.Instruction of Function2-1. Control Display

Child Lock Button

By pressing the Power Cool and the Fridge buttons together, for 3 seconds, the “Power Freeze”,

“Power Cool”, Freezer, and buttons will be locked. The Ice Type button will continue to work

normally and the Water and Ice dispensers can still be used as desired. To cancel this function,

press the Power Cool and the Fridge buttons together again.

Fridge Button

Press the button to set the fridge to your desired temperature.

You can set temperature between 34°F and 46°F.

23.

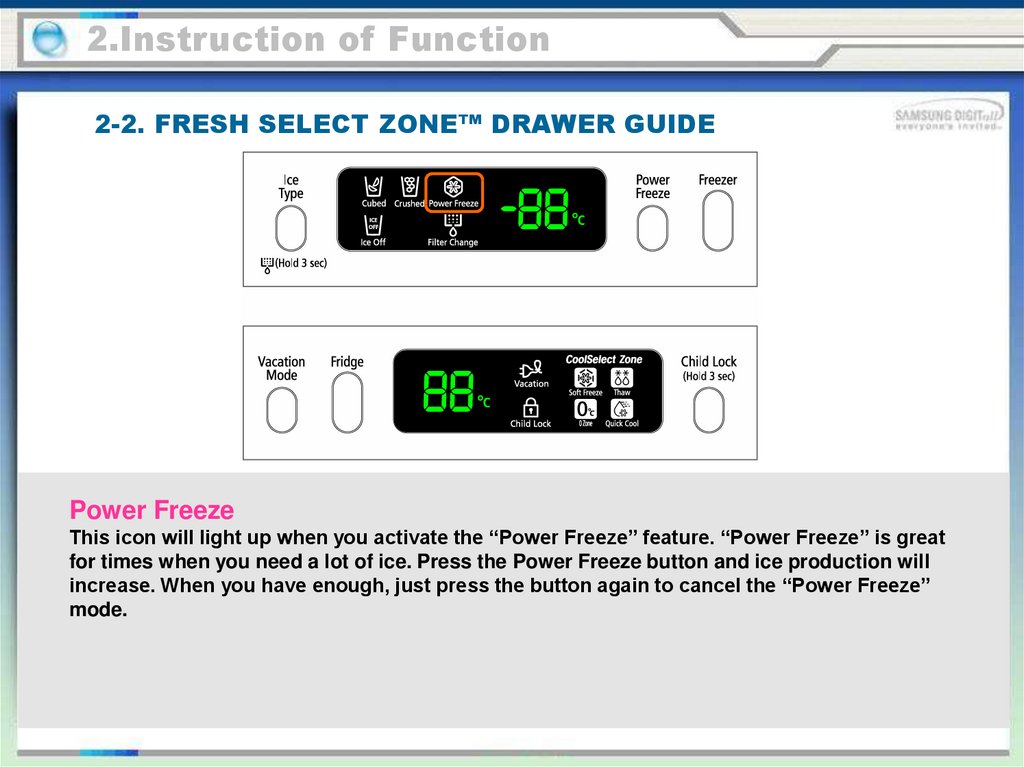

2.Instruction of Function2-2. FRESH SELECT ZONE™ DRAWER GUIDE

Power Freeze

This icon will light up when you activate the “Power Freeze” feature. “Power Freeze” is great

for times when you need a lot of ice. Press the Power Freeze button and ice production will

increase. When you have enough, just press the button again to cancel the “Power Freeze”

mode.

24.

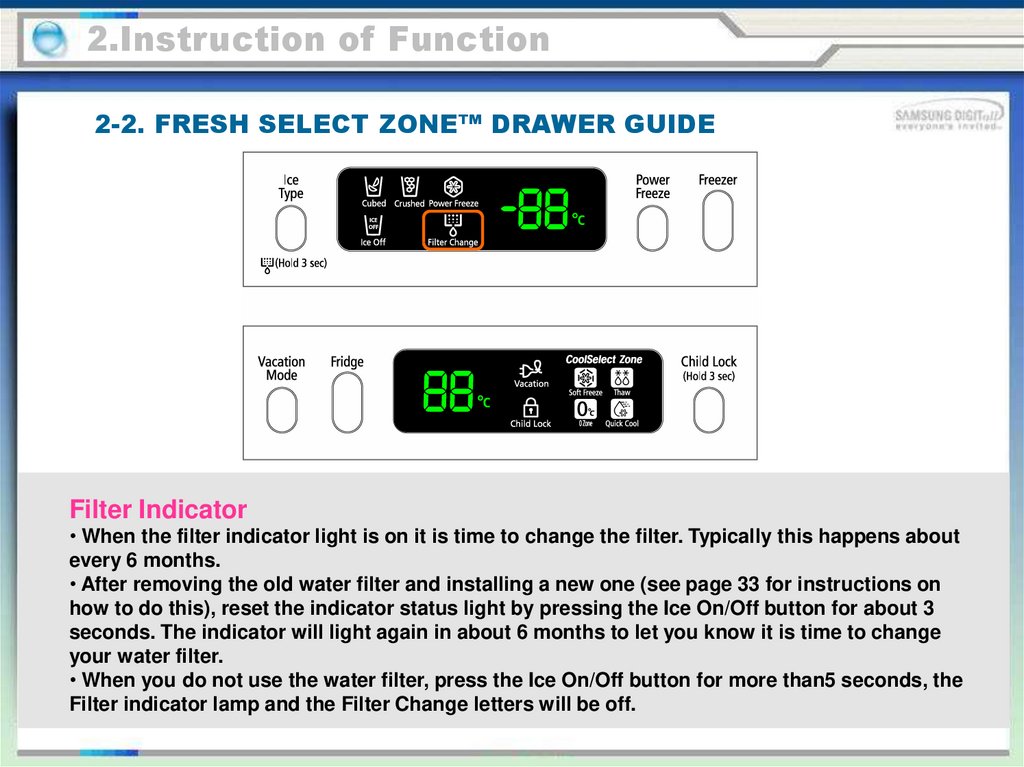

2.Instruction of Function2-2. FRESH SELECT ZONE™ DRAWER GUIDE

Filter Indicator

• When the filter indicator light is on it is time to change the filter. Typically this happens about

every 6 months.

• After removing the old water filter and installing a new one (see page 33 for instructions on

how to do this), reset the indicator status light by pressing the Ice On/Off button for about 3

seconds. The indicator will light again in about 6 months to let you know it is time to change

your water filter.

• When you do not use the water filter, press the Ice On/Off button for more than5 seconds, the

Filter indicator lamp and the Filter Change letters will be off.

25.

2.Instruction of Function2-2. FRESH SELECT ZONE™ DRAWER GUIDE

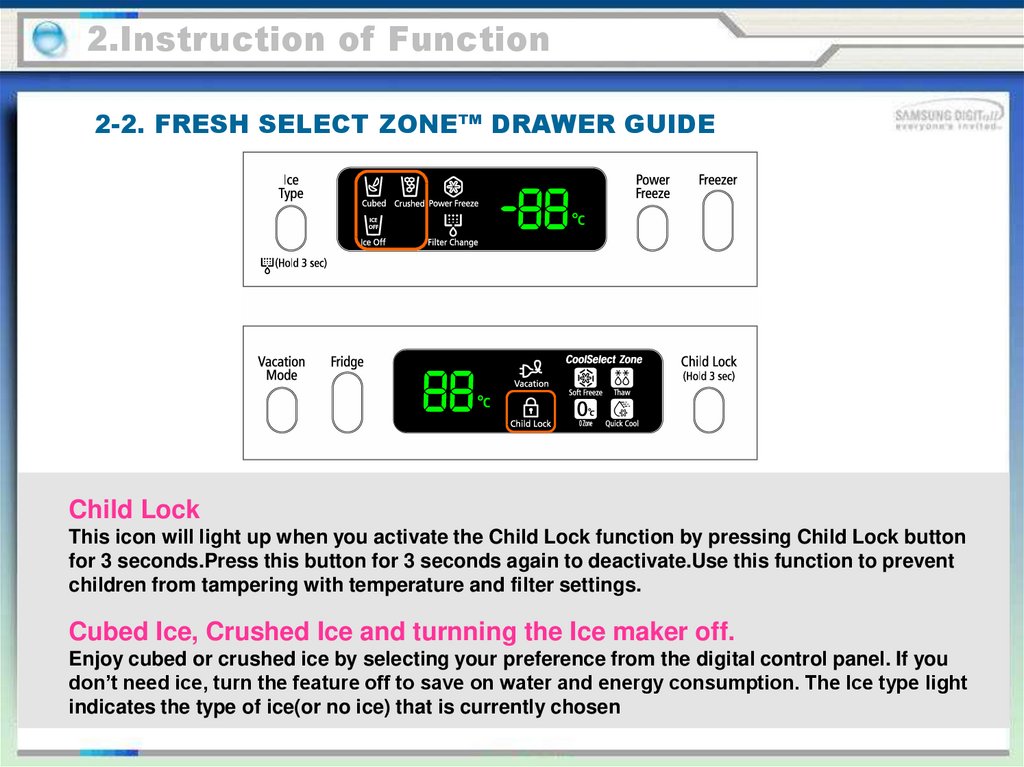

Child Lock

This icon will light up when you activate the Child Lock function by pressing Child Lock button

for 3 seconds.Press this button for 3 seconds again to deactivate.Use this function to prevent

children from tampering with temperature and filter settings.

Cubed Ice, Crushed Ice and turnning the Ice maker off.

Enjoy cubed or crushed ice by selecting your preference from the digital control panel. If you

don’t need ice, turn the feature off to save on water and energy consumption. The Ice type light

indicates the type of ice(or no ice) that is currently chosen

26.

2.Instruction of Function2-3. Ice Maker Function

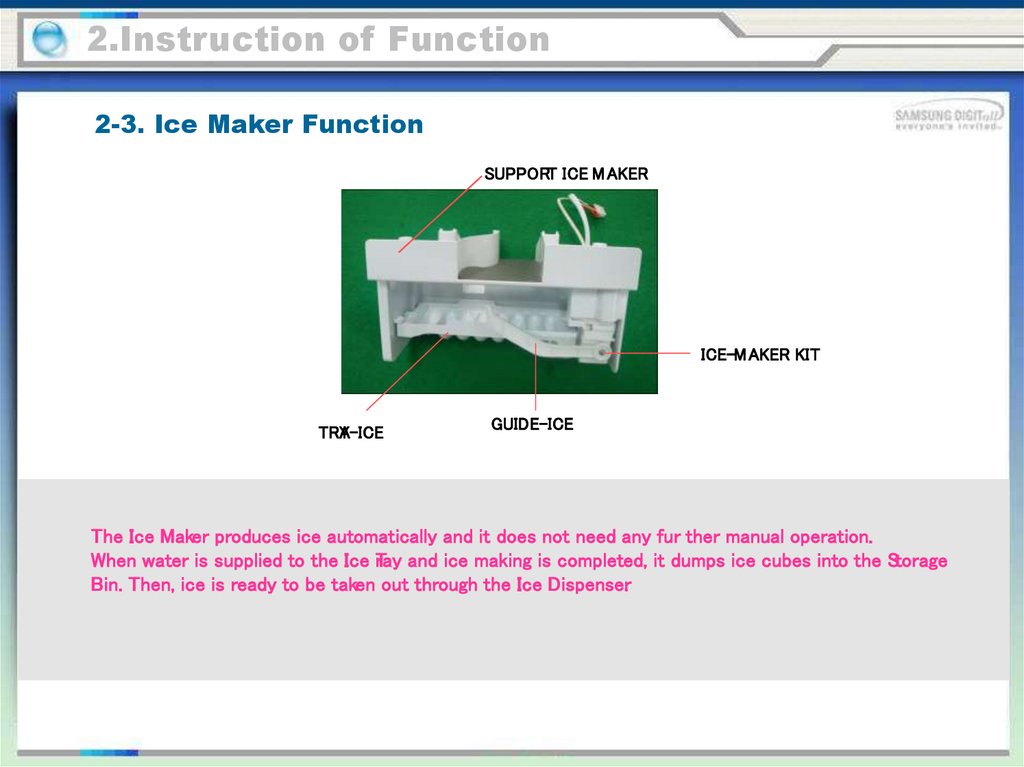

SUPPORT ICE M AKER

ICE-M AKER KIT

TRA

Y-ICE

GUIDE-ICE

The Ice Maker produces ice automatically and it does not need any fur ther manual operation.

When water is supplied to the Ice T

ray and ice making is completed, it dumps ice cubes into the Storage

Bin. Then, ice is ready to be taken out through the Ice Dispenser.

27.

2.Instruction of Function2-3. Ice Maker Function

1) Initial Operation

1-1) At the initial power on, it maintains the Ice Tray in horizontal position for 2 hours.

1-2) After the 2-hour delay, the Eject Sensor attached on the bottom of the Ice Tray will check

its temperature. When it maintains -17.0 °C or lower for more than 5 minutes, the Ice Tray rotates to

dump the ice cubes into the Ice Storage Bin.

2) Water Supply Function

2-1) After completing the Ice Ejection (Initial,Normal,Test),it will check whether the Ice Tray is horizontal.

Then, when the Ice Tray is parallel,the Water Solenoid Valve located in the Machine Room will

operate to supply water to the Ice Tray.

3) Ice Making Function

After supplying water to the Ice Tray,it freezes the water and checks whether the water is turned into

solid ice.This whole process is called Ice Making.This will be decided with the pick-up temperature

(adjustable)of the Ice-Maker Sensor.

3-1) In 58 minutes (65 minutes upon overload)after water supply to the Ice Tray, it checks the

temperature of the Ice-Maker Sensor.

3-2) When the pick-up temperature of the Ice-Maker Sensor stays at lower than -17.0 °C for 5minutes,

it'll be considered as Ice Making is completed.

NOTE

During the Ice Making,the set temperature on the Display Panel won't change.

But, until the Ice Storage Bin becomes full of ice, it operates with -25 °C setting.

When the Ice Bin gets full, the Freezer compartment operates based on the

user set temperature (the temperature on the Display Panel).

28.

2.Instruction of Function2-3. Ice Maker Function

4) Ice Ejection

The Ice Ejection is an operation that separates the completely frozen ice from the Ice Tray after

the completion of Ice Making.

4-1) To separate the ice, the Motor Driver IC in MAIN PCB make the Auger Motor rotate clockwise.

At this time, the rotating Ice Tray comes in contact with a fixture at one of its corners to twist itself.

Therefore, Ice on the Ice Tray is to be separated and dropped into the Ice Storage Bin.

4-2) When the Ice Ejection is completed,it will supply water to the Ice Tray (refer to 2)Water Supply

Function).

5) Test Function

It is to run the Ice-Maker intentionally for the purpose of an operational test or repairing.

When you press the Test S/W (refer to the figure)attached on the Ice-Maker for over 1.5 sec,

it starts operating.

5-1) When the Ice-Maker is in the middle of Ice Ejection, Horizontal Positioning or Water Supply, it does

not carry out the Test function. So, when it comes to a complete horizontal position, the Test

function reacts. Also, when the Ice Bin is full with ice, the Test function does not work.

And, once the Ice Filler Lever frees its switch (indicating that the Ice Bin is not filled up),

the Test function works.

5-2) When pressing the Test button for more than 1.5 sec with the Ice Tray in its horizontal position,

it will perform the Ice Ejection whether or not water is completely frozen. So, when the water is not

completely frozen, it will splash out (so, it needs care).

After completing the Test function, it will fill up the Ice Tray again. With this Test function, you can

check Ice Ejection, Horizontal Positioning and Water Supply.When the Test function is properly

carried out,it will send out "Ding Dong" sound and supply water to the Ice Tray.

If there is no "Ding Dong"sound,the Ice Maker could be defective and it needs repairing.

29.

2.Instruction of Function2-3. Ice Maker Function

5-3) When it completes water supplying, it will circle through in the following order.

Ice Making ➞ Ice Ejection ➞ Horizontal Positioning ➞ Water Supply

6) Ice Off (No Ice Production)

When ice is not needed, ice production can be stopped by pressing the Ice Off button on the

Display Panel.

1-1) Each time the Ice Off button is pressed, the Ice Off indicator lamp will be turned on and off.

1-2) The default setting is the Ice Producing. So, upon the initial Power-On the Ice Off lamp is off.

1-3) When the Ice Off (its lamp is on) is selected, the Ice Maker does not work.

1-4) When the Ice Off button is pressed, its lamp is turned off immediately. But, when it is in the

middle of Water Supply, Ice Ejection or Horizontal Positioning, the Ice Making function stops

after the water supply to the Ice Tray.

1-5) When turning off the Ice Off lamp and starting the Ice Making again, it will count time from

the point that the Ice Off is cancelled. Then, when it becomes 90 minutes, the Ice Maker

Sensor will read its temperature to decide whether to go to the next stage (Ice Ejection).

7) Functions when the Freezer Door is open

When the Freezer Door is open, the Freezer Fan stops operating for noise reduction.

1-1) When the Freezer Door is open during Ice Ejection or Horizontal Positioning, all functions

will stop. And, when the door is closed, it will go to the normal operation mode.

1-2) When it is in the middle of Water Supply, it continues supplying water regardless of

Freezer Door status (Open or Closed).

1-3) So, when the Ice Tray is tilted with the Freezer Door open, it indicates that the Freezer Door

is opened during Ice Ejection or Horizontal Positioning. So, to make the Ice Tray horizontal

and water supplied, close the Freezer Door and check if the Ice Tray is horizontal in 30

seconds. If it is not horizontal, it is defective. Also, when the Ice Tray is tilted, the Test

function does not work. To run the Test function, wait until it completes water supplying.

30.

2. Product function2-4. Defrost Function

1) Freezer and Fridge defrost will be determined by the total Comp-On time.

2) With the initial power on,the unit carries out Freezer and Fridge defrost when the total CompOn time becomes 6 hours.

3) The defrost cycle varies from 6 to 19 hours depending on its working conditions.

4) The defrost cycle is to be decided depending on the ambient temperature,the number of the

Freezer and Fridge door openings,and the duration of the Freezer and the Fridge door

openings.

5) The followings are the Defrost reset temperatures based on the Fridge defrost sensor ost and

the Freezer defrost sensor sensor temperatures.

Defrost Reset Temperature

NOTE

Fridge

Freezer

12°C

12°C

Remarks

The Defrost reset temperature can be changed without notice for functional imp

rovements.

31.

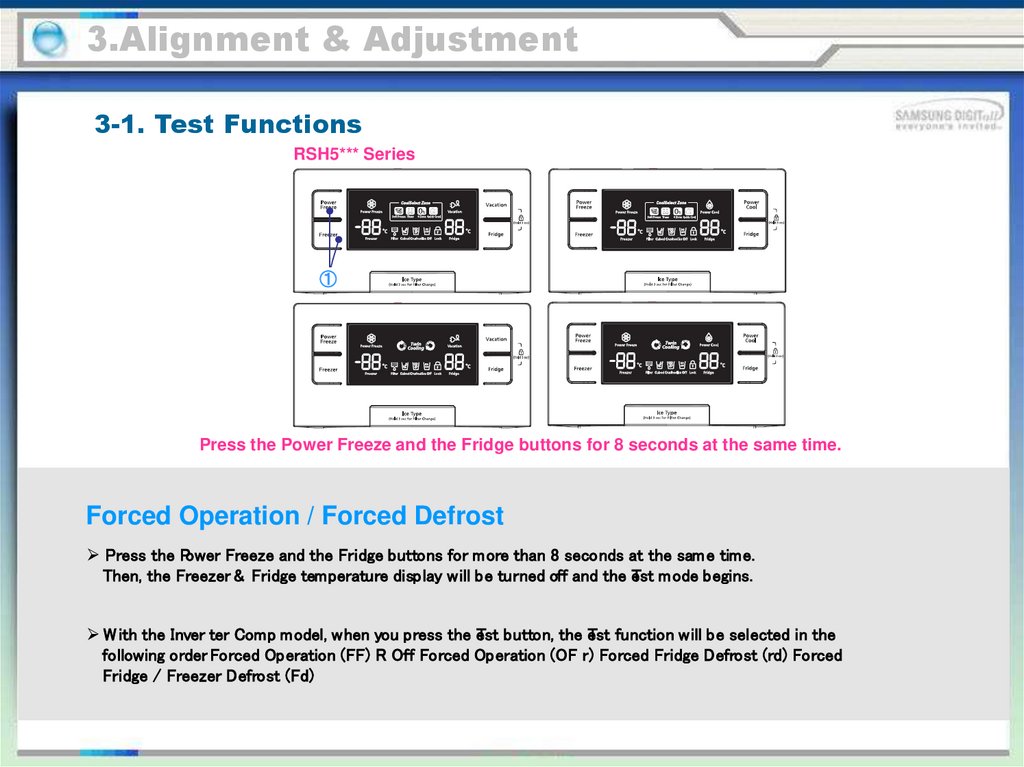

3.Alignment & Adjustment3-1. Test Functions

RSH5*** Series

①

Press the Power Freeze and the Fridge buttons for 8 seconds at the same time.

Forced Operation / Forced Defrost

Press the Power Freeze and the Fridge buttons for more than 8 seconds at the sam e time.

Then, the Freezer & Fridge temperature display will be turned off and the eTst mode begins.

W ith the Inver ter Comp model, when you press the eTst button, the eTst function will be selected in the

following order. Forced Operation (FF) R Off Forced Operation (OF r) Forced Fridge Defrost (rd) Forced

Fridge / Freezer Defrost (Fd)

32.

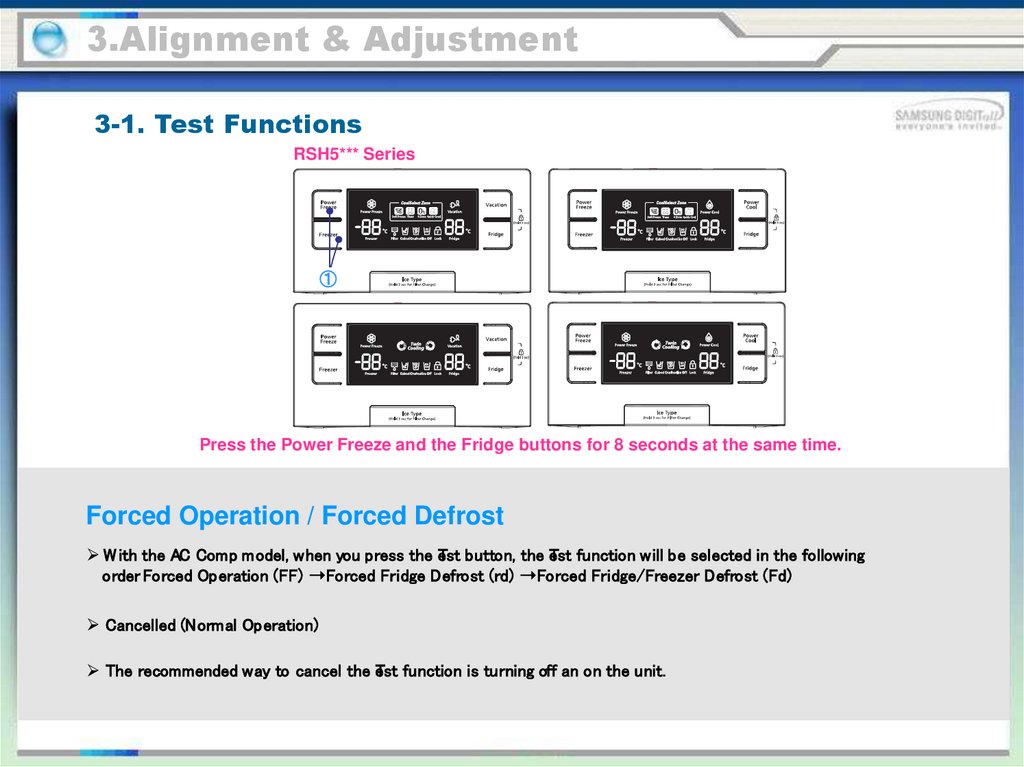

3.Alignment & Adjustment3-1. Test Functions

RSH5*** Series

①

Press the Power Freeze and the Fridge buttons for 8 seconds at the same time.

Forced Operation / Forced Defrost

W ith the AC Comp model, when you press the eTst button, the eTst function will be selected in the following

order. Forced Operation (FF) ➝Forced Fridge Defrost (rd) ➝Forced Fridge/Freezer Defrost (Fd)

Cancelled (Normal Operation)

The recommended way to cancel the eTst function is turning off an on the unit.

33.

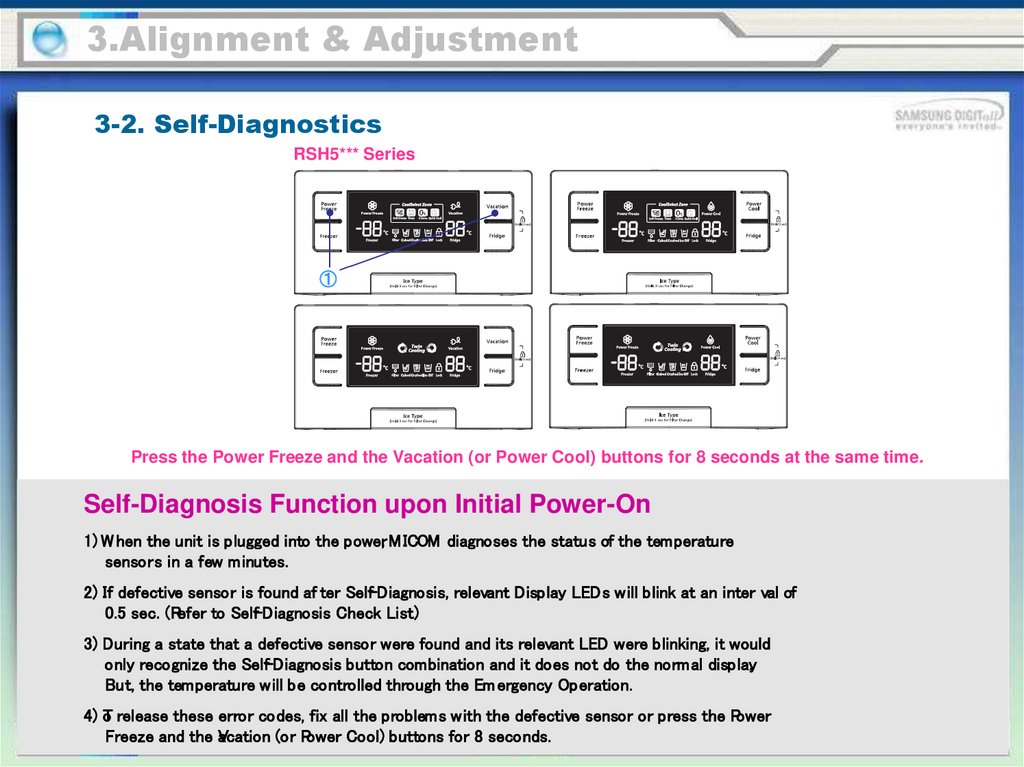

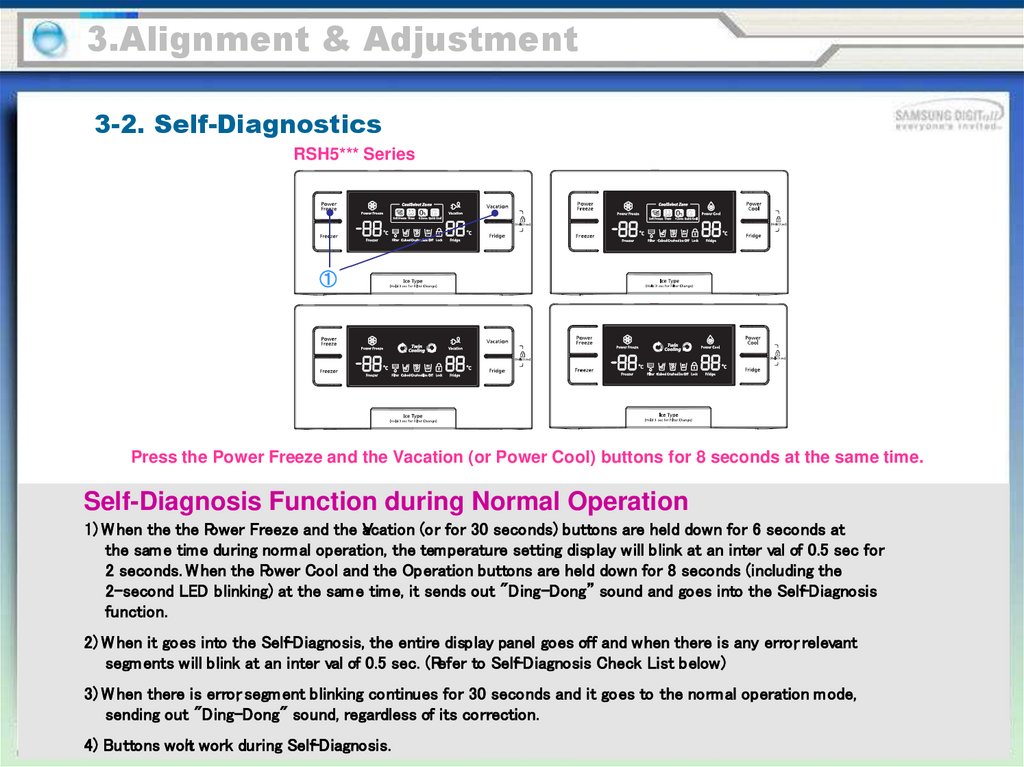

3.Alignment & Adjustment3-2. Self-Diagnostics

RSH5*** Series

①

Press the Power Freeze and the Vacation (or Power Cool) buttons for 8 seconds at the same time.

Self-Diagnosis Function upon Initial Power-On

1) W hen the unit is plugged into the power, M ICOM diagnoses the status of the temperature

sensors in a few minutes.

2) If defective sensor is found af ter Self-Diagnosis, relevant Display LEDs will blink at an inter val of

0.5 sec. (Refer to Self-Diagnosis Check List)

3) During a state that a defective sensor were found and its relevant LED were blinking, it would

only recognize the Self-Diagnosis button combination and it does not do the normal display.

But, the temperature will be controlled through the Em ergency Operation.

4) oT release these error codes, fix all the problems with the defective sensor or press the Power

Freeze and the V

acation (or Power Cool) buttons for 8 seconds.

34.

3.Alignment & Adjustment3-2. Self-Diagnostics

RSH5*** Series

①

Press the Power Freeze and the Vacation (or Power Cool) buttons for 8 seconds at the same time.

Self-Diagnosis Function during Normal Operation

1) W hen the the Power Freeze and the aVcation (or for 30 seconds) buttons are held down for 6 seconds at

the sam e time during normal operation, the temperature setting display will blink at an inter val of 0.5 sec for

2 seconds. W hen the Power Cool and the Operation buttons are held down for 8 seconds (including the

2-second LED blinking) at the sam e time, it sends out "Ding-Dong” sound and goes into the Self-Diagnosis

function.

2) W hen it goes into the Self-Diagnosis, the entire display panel goes off and when there is any error, relevant

segm ents will blink at an inter val of 0.5 sec. (Refer to Self-Diagnosis Check List below)

3) W hen there is error, segm ent blinking continues for 30 seconds and it goes to the normal operation mode,

sending out "Ding-Dong" sound, regardless of its correction.

4) Buttons won't work during Self-Diagnosis.

35.

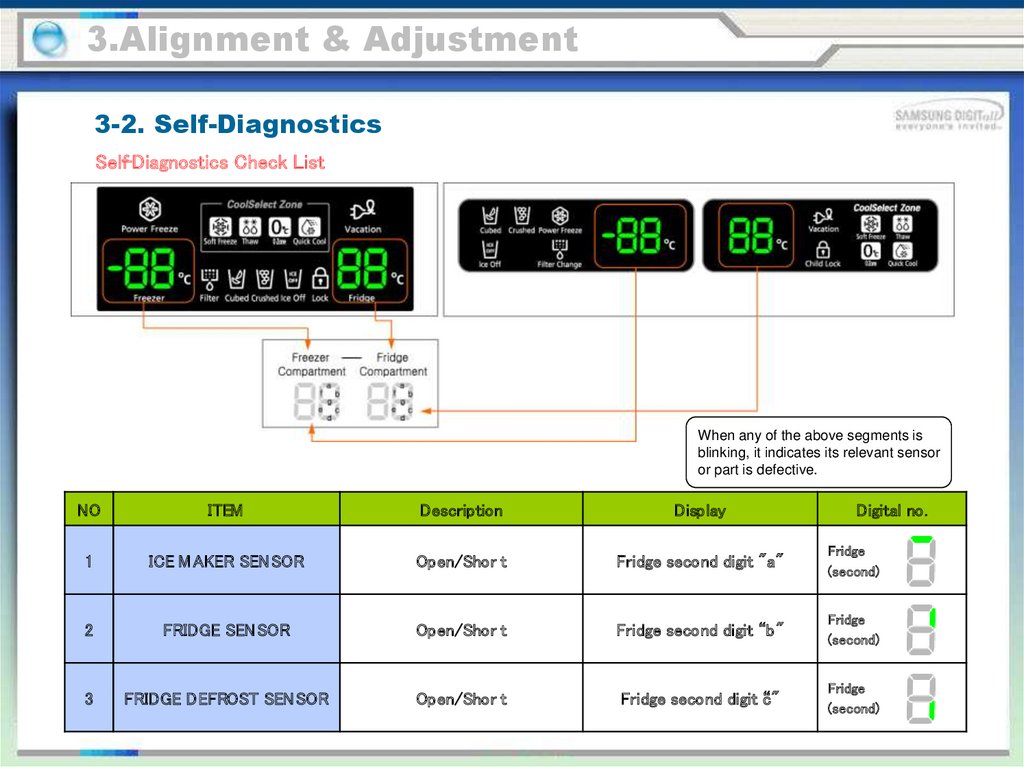

3.Alignment & Adjustment3-2. Self-Diagnostics

Self-Diagnostics Check List

When any of the above segments is

blinking, it indicates its relevant sensor

or part is defective.

NO

ITEM

Description

Display

Digital no.

1

ICE M AKER SEN SOR

Open/Shor t

Fridge second digit "a"

Fridge

(second)

2

FRIDGE SEN SOR

Open/Shor t

Fridge second digit “b"

Fridge

(second)

3

FRIDGE DEFROST SEN SOR

Open/Shor t

Fridge second digit “c"

Fridge

(second)

36.

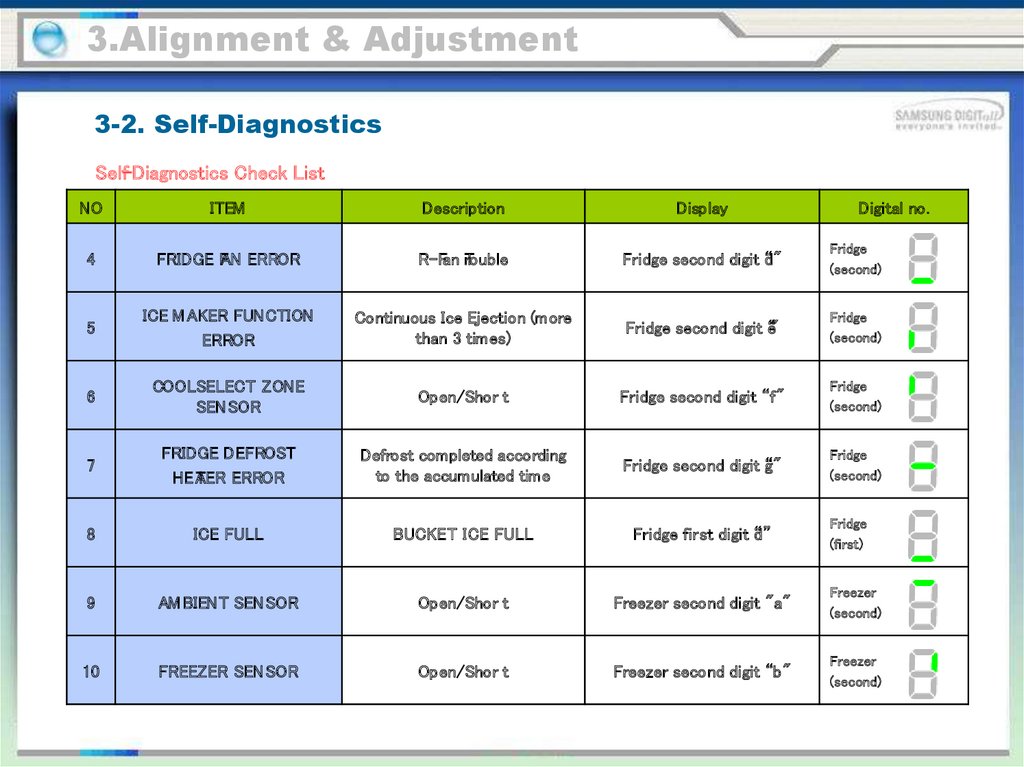

3.Alignment & Adjustment3-2. Self-Diagnostics

Self-Diagnostics Check List

NO

ITEM

Description

Display

Digital no.

4

FRIDGE FAN ERROR

R-Fan rTouble

Fridge second digit “d"

Fridge

(second)

5

ICE M AKER FUNCTION

ERROR

Continuous Ice Ejection (more

than 3 times)

Fridge second digit “e"

Fridge

(second)

6

COOLSELECT ZONE

SEN SOR

Open/Shor t

Fridge second digit “f"

Fridge

(second)

7

FRIDGE DEFROST

HEA

TER ERROR

Defrost completed according

to the accumulated time

Fridge second digit “g"

Fridge

(second)

8

ICE FULL

BUCKET ICE FULL

Fridge first digit “d”

9

AM BIENT SEN SOR

Open/Shor t

Freezer second digit "a"

Freezer

(second)

10

FREEZER SEN SOR

Open/Shor t

Freezer second digit “b"

Freezer

(second)

Fridge

(first)

37.

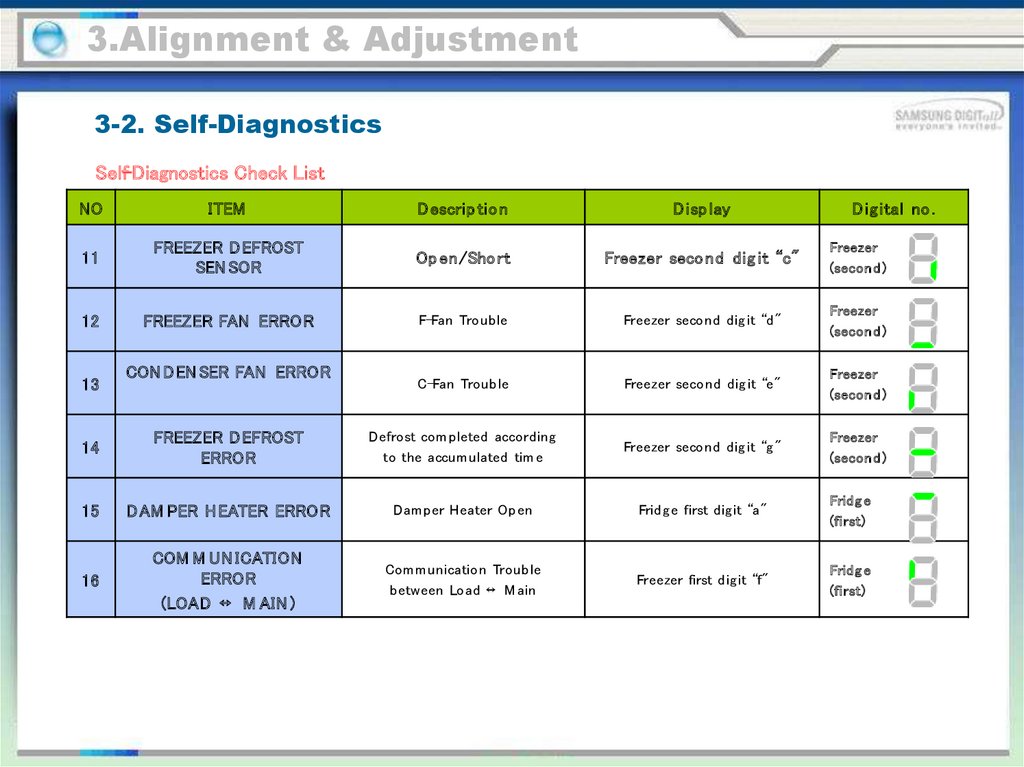

3.Alignment & Adjustment3-2. Self-Diagnostics

Self-Diagnostics Check List

NO

ITEM

D escrip tio n

D isp lay

11

FREEZER D EFROST

SEN SOR

Op en/Sho rt

Freezer seco nd dig it “c"

Freezer

(secon d )

12

FREEZER FAN ERROR

F-Fan Troub le

Freezer second d ig it “d "

Freezer

(secon d )

C-Fan Troub le

Freezer second d ig it “e"

Freezer

(secon d )

Freezer

(secon d )

13

CON DEN SER FAN ERROR

D ig ital no .

14

FREEZER D EFROST

ERROR

Defrost com p leted accord ing

to the accum ulated tim e

Freezer second d ig it “g "

15

DAM PER H EATER ERROR

Dam p er Heater Op en

Frid g e first d ig it “a"

Frid g e

(first)

16

COM M UN ICATION

ERROR

(LOAD ↔ M AIN )

Com m unication Troub le

b etween Load ↔ M ain

Freezer first d ig it “f"

Frid g e

(first)

38.

3.Alignment & Adjustment3-2. Self-Diagnostics

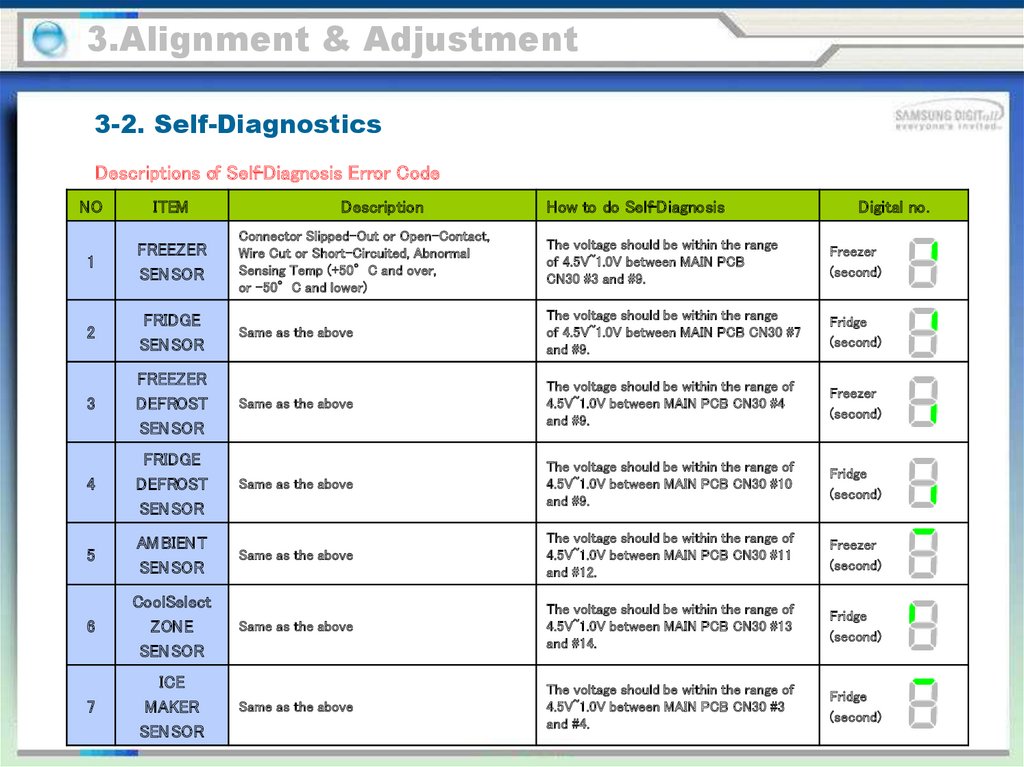

Descriptions of Self-Diagnosis Error Code

NO

ITEM

Description

How to do Self-Diagnosis

Digital no.

1

FREEZER

SEN SOR

Connector Slipped-Out or Open-Contact,

Wire Cut or Short-Circuited, Abnormal

Sensing Temp (+50°C and over,

or -50°C and lower)

The voltage should be within the range

of 4.5V~1.0V between MAIN PCB

CN30 #3 and #9.

Freezer

(second)

2

FRIDGE

SEN SOR

Same as the above

The voltage should be within the range

of 4.5V~1.0V between MAIN PCB CN30 #7

and #9.

Fridge

(second)

3

FREEZER

DEFROST

SEN SOR

Same as the above

The voltage should be within the range of

4.5V~1.0V between MAIN PCB CN30 #4

and #9.

Freezer

(second)

4

FRIDGE

DEFROST

SEN SOR

Same as the above

The voltage should be within the range of

4.5V~1.0V between MAIN PCB CN30 #10

and #9.

Fridge

(second)

5

AM BIENT

SEN SOR

Same as the above

The voltage should be within the range of

4.5V~1.0V between MAIN PCB CN30 #11

and #12.

Freezer

(second)

6

CoolSelect

ZONE

SEN SOR

Same as the above

The voltage should be within the range of

4.5V~1.0V between MAIN PCB CN30 #13

and #14.

Fridge

(second)

7

ICE

MAKER

SEN SOR

Same as the above

The voltage should be within the range of

4.5V~1.0V between MAIN PCB CN30 #3

and #4.

Fridge

(second)

39.

3.Alignment & Adjustment3-2. Self-Diagnostics

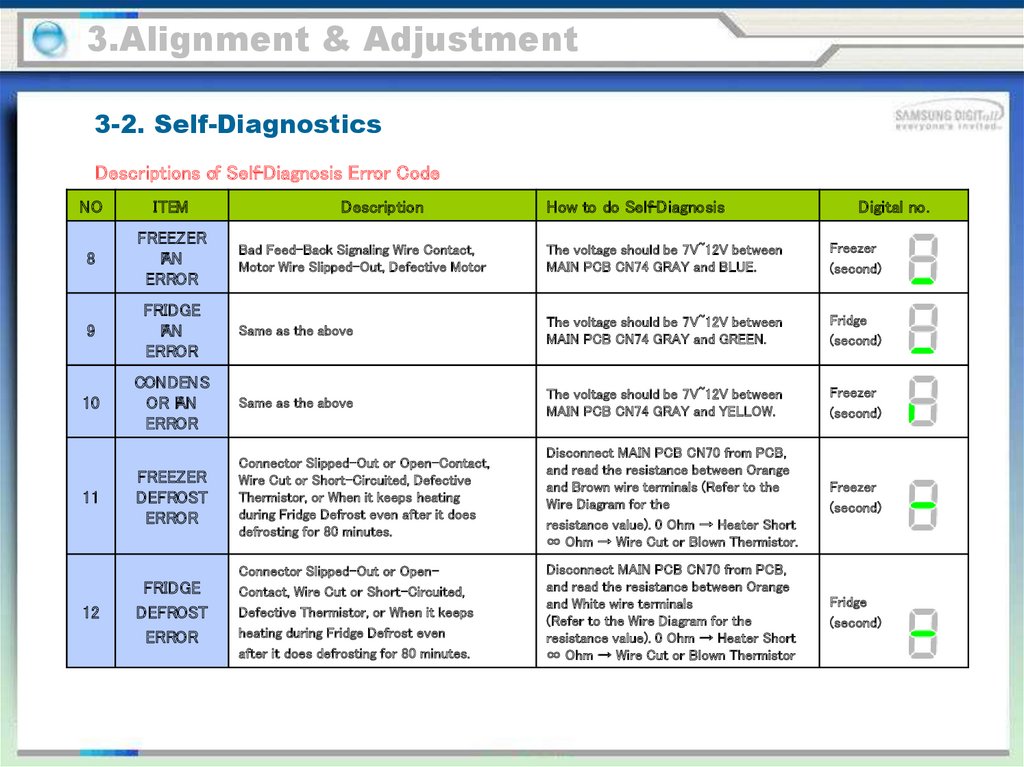

Descriptions of Self-Diagnosis Error Code

NO

ITEM

8

FREEZER

FAN

ERROR

Description

How to do Self-Diagnosis

Digital no.

Bad Feed-Back Signaling Wire Contact,

Motor Wire Slipped-Out, Defective Motor

The voltage should be 7V~12V between

MAIN PCB CN74 GRAY and BLUE.

Freezer

(second)

9

FRIDGE

FAN

ERROR

Same as the above

The voltage should be 7V~12V between

MAIN PCB CN74 GRAY and GREEN.

Fridge

(second)

10

CONDENS

OR FAN

ERROR

Same as the above

The voltage should be 7V~12V between

MAIN PCB CN74 GRAY and YELLOW.

Freezer

(second)

FREEZER

DEFROST

ERROR

Connector Slipped-Out or Open-Contact,

Wire Cut or Short-Circuited, Defective

Thermistor, or When it keeps heating

during Fridge Defrost even after it does

defrosting for 80 minutes.

Disconnect MAIN PCB CN70 from PCB,

and read the resistance between Orange

and Brown wire terminals (Refer to the

Wire Diagram for the

resistance value). 0 Ohm → Heater Short

∞ Ohm → Wire Cut or Blown Thermistor.

Freezer

(second)

FRIDGE

DEFROST

ERROR

Connector Slipped-Out or OpenContact, Wire Cut or Short-Circuited,

Defective Thermistor, or When it keeps

heating during Fridge Defrost even

after it does defrosting for 80 minutes.

Disconnect MAIN PCB CN70 from PCB,

and read the resistance between Orange

and White wire terminals

(Refer to the Wire Diagram for the

resistance value). 0 Ohm → Heater Short

∞ Ohm → Wire Cut or Blown Thermistor

Fridge

(second)

11

12

40.

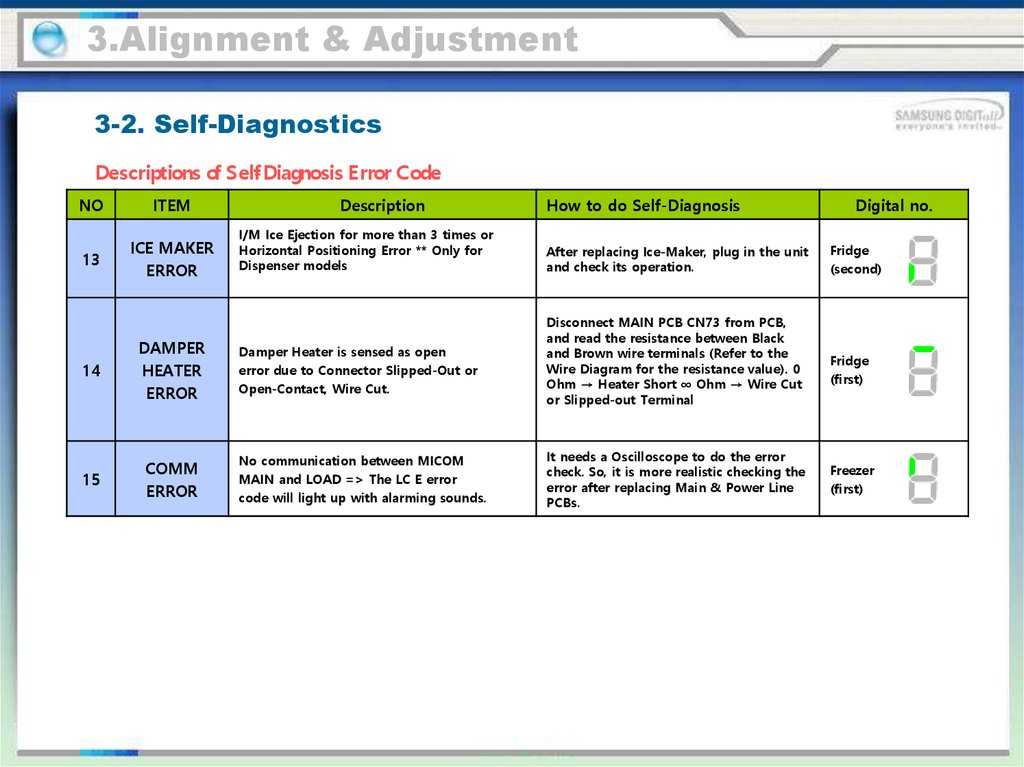

3.Alignment & Adjustment3-2. Self-Diagnostics

Descriptions of Self- Diagnosis Error Code

NO

ITEM

13

ICE MAKER

ERROR

14

DAMPER

HEATER

ERROR

15

COMM

ERROR

Description

I/M Ice Ejection for more than 3 times or

Horizontal Positioning Error ** Only for

Dispenser models

Damper Heater is sensed as open

error due to Connector Slipped-Out or

Open-Contact, Wire Cut.

No communication between MICOM

MAIN and LOAD => The LC E error

code will light up with alarming sounds.

How to do Self-Diagnosis

After replacing Ice-Maker, plug in the unit

and check its operation.

Disconnect MAIN PCB CN73 from PCB,

and read the resistance between Black

and Brown wire terminals (Refer to the

Wire Diagram for the resistance value). 0

Ohm → Heater Short ∞ Ohm → Wire Cut

or Slipped-out Terminal

It needs a Oscilloscope to do the error

check. So, it is more realistic checking the

error after replacing Main & Power Line

PCBs.

Digital no.

Fridge

(second)

Fridge

(first)

Freezer

(first)

41.

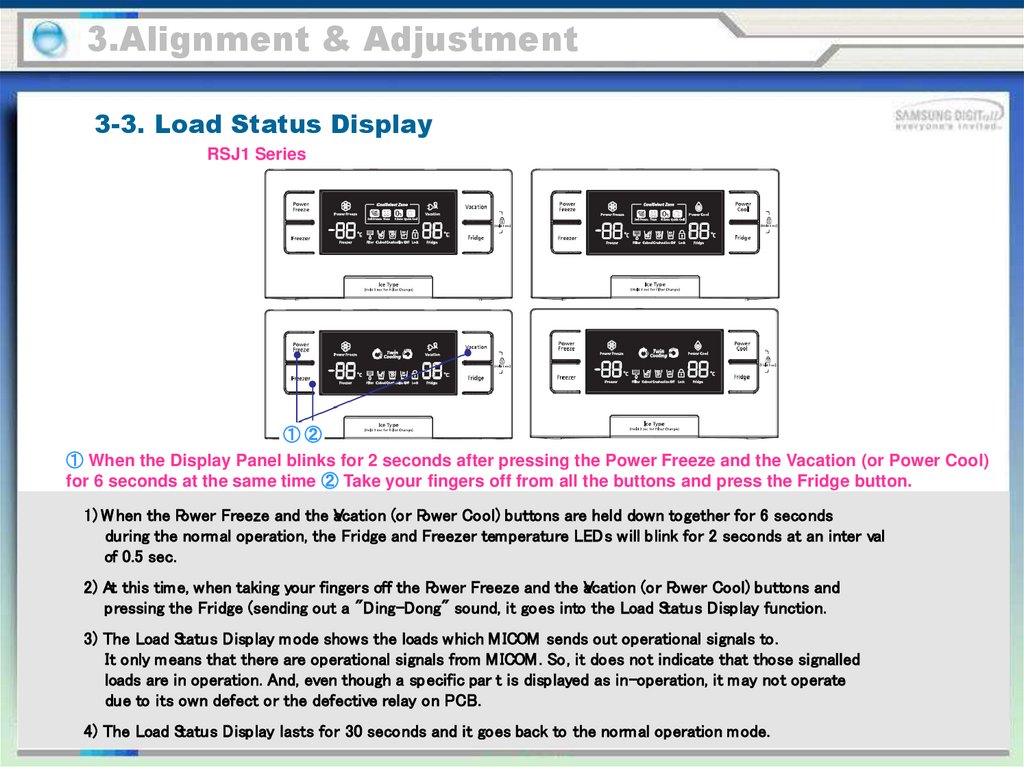

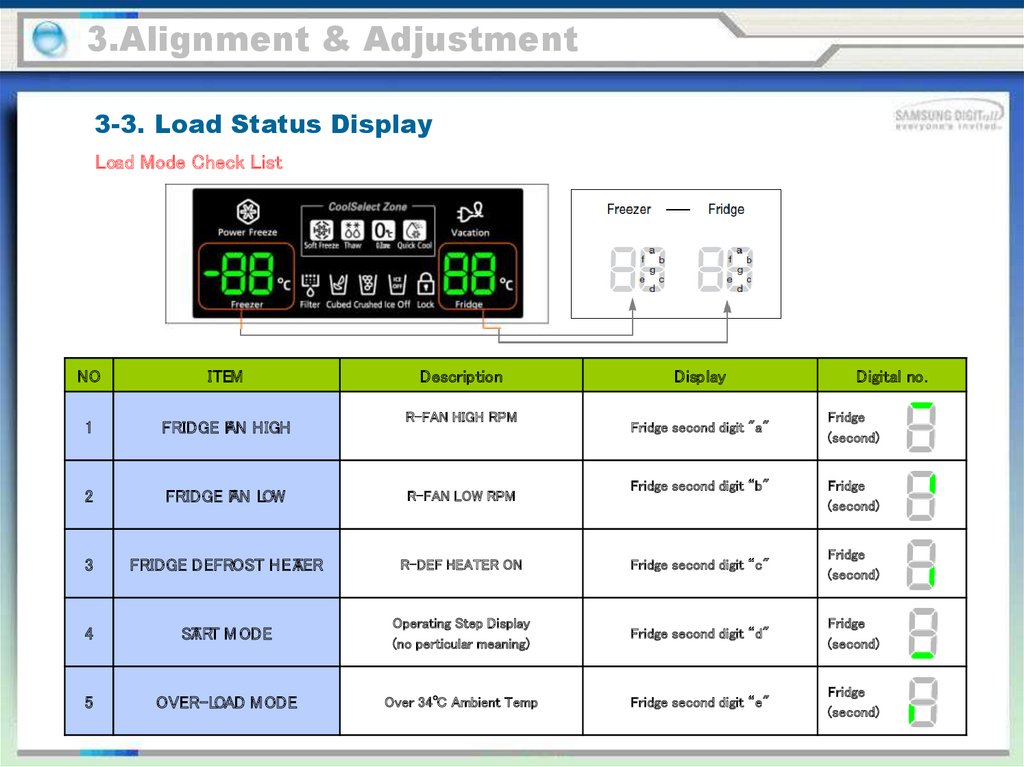

3.Alignment & Adjustment3-3. Load Status Display

RSJ1 Series

①②

① When the Display Panel blinks for 2 seconds after pressing the Power Freeze and the Vacation (or Power Cool)

for 6 seconds at the same time ② Take your fingers off from all the buttons and press the Fridge button.

1) W hen the Power Freeze and the V

acation (or Power Cool) buttons are held down together for 6 seconds

during the normal operation, the Fridge and Freezer temperature LEDs will blink for 2 seconds at an inter val

of 0.5 sec.

2) At this time, when taking your fingers off the Power Freeze and the V

acation (or Power Cool) buttons and

pressing the Fridge (sending out a "Ding-Dong" sound, it goes into the Load Status Display function.

3) The Load Status Display mode shows the loads which M ICOM sends out operational signals to.

It only means that there are operational signals from M ICOM . So, it does not indicate that those signalled

loads are in operation. And, even though a specific par t is displayed as in-operation, it may not operate

due to its own defect or the defective relay on PCB.

4) The Load Status Display lasts for 30 seconds and it goes back to the normal operation mode.

42.

3.Alignment & Adjustment3-3. Load Status Display

Load Mode Check List

NO

ITEM

Description

1

FRIDGE FAN HIGH

2

FRIDGE FAN LOW

R-FAN LOW RPM

3

FRIDGE DEFROST HEA

TER

R-DEF HEATER ON

Fridge second digit “c"

Fridge

(second)

4

ST

ART M ODE

Operating Step Display

(no perticular meaning)

Fridge second digit “d"

Fridge

(second)

5

OVER-LOAD M ODE

Over 34℃ Ambient Temp

Fridge second digit “e"

Fridge

(second)

R-FAN HIGH RPM

Display

Fridge second digit "a"

Fridge second digit “b"

Digital no.

Fridge

(second)

Fridge

(second)

43.

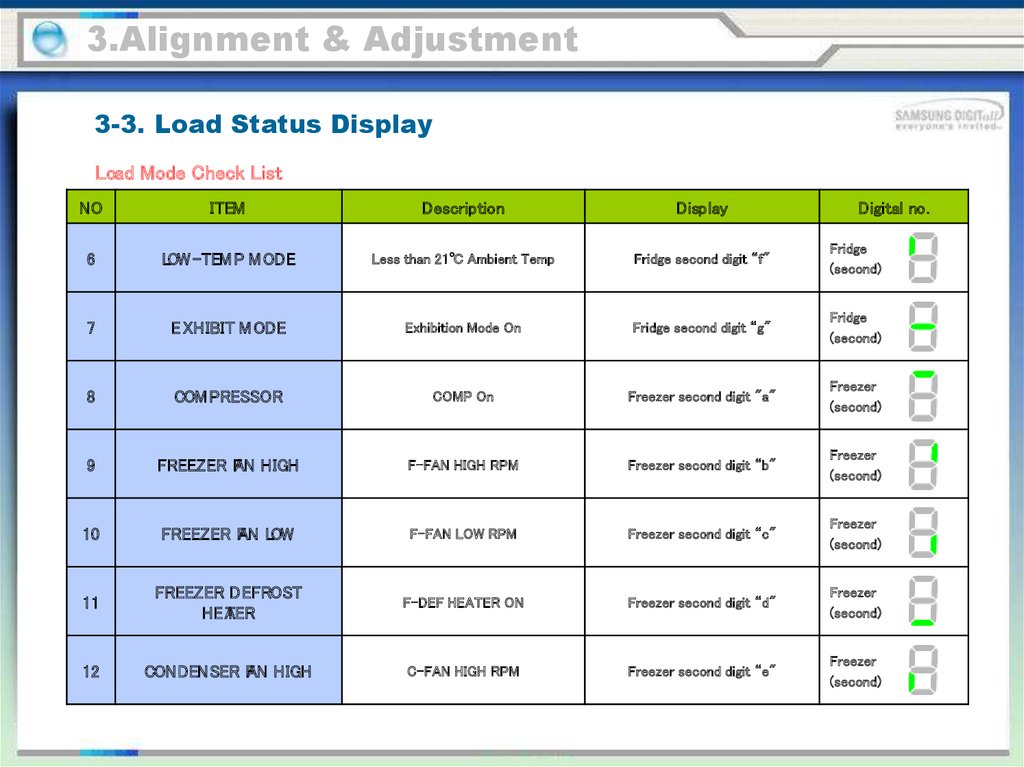

3.Alignment & Adjustment3-3. Load Status Display

Load Mode Check List

NO

ITEM

Description

Display

Digital no.

6

LOW -TEM P M ODE

Less than 21℃ Ambient Temp

Fridge second digit “f"

Fridge

(second)

7

E XHIBIT M ODE

Exhibition Mode On

Fridge second digit “g"

Fridge

(second)

8

COM PRESSOR

COMP On

Freezer second digit "a"

Freezer

(second)

9

FREEZER FAN HIGH

F-FAN HIGH RPM

Freezer second digit “b"

Freezer

(second)

10

FREEZER FAN LOW

F-FAN LOW RPM

Freezer second digit “c"

Freezer

(second)

11

FREEZER DEFROST

HEA

TER

F-DEF HEATER ON

Freezer second digit “d"

Freezer

(second)

12

CONDENSER FAN HIGH

C-FAN HIGH RPM

Freezer second digit “e"

Freezer

(second)

44.

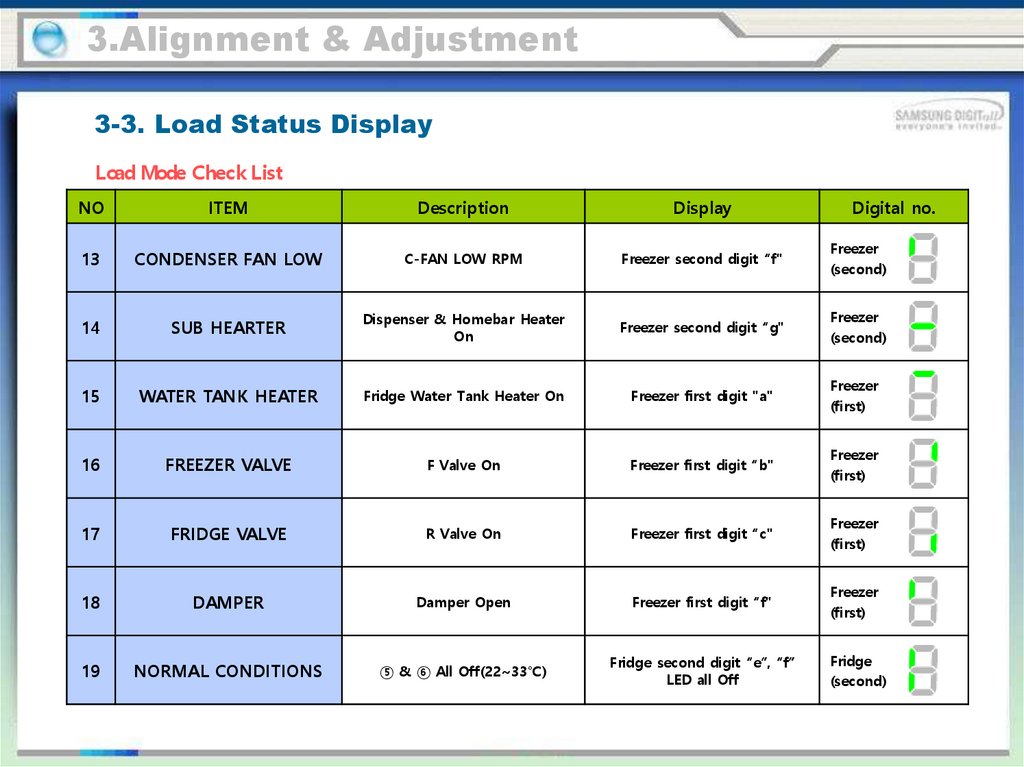

3.Alignment & Adjustment3-3. Load Status Display

Load Mode Check List

NO

ITEM

Description

Display

Digital no.

13

CONDENSER FAN LOW

C-FAN LOW RPM

Freezer second digit “f"

Freezer

(second)

14

SUB HEARTER

Dispenser & Homebar Heater

On

Freezer second digit “g"

Freezer

(second)

15

WATER TANK HEATER

Fridge Water Tank Heater On

Freezer first digit "a"

Freezer

(first)

16

FREEZER VALVE

F Valve On

Freezer first digit “b"

Freezer

(first)

17

FRIDGE VALVE

R Valve On

Freezer first digit “c"

Freezer

(first)

18

DAMPER

Damper Open

Freezer first digit “f"

Freezer

(first)

19

NORMAL CONDITIONS

⑤ & ⑥ All Off(22~33℃)

Fridge second digit “e”, “f”

LED all Off

Fridge

(second)

45.

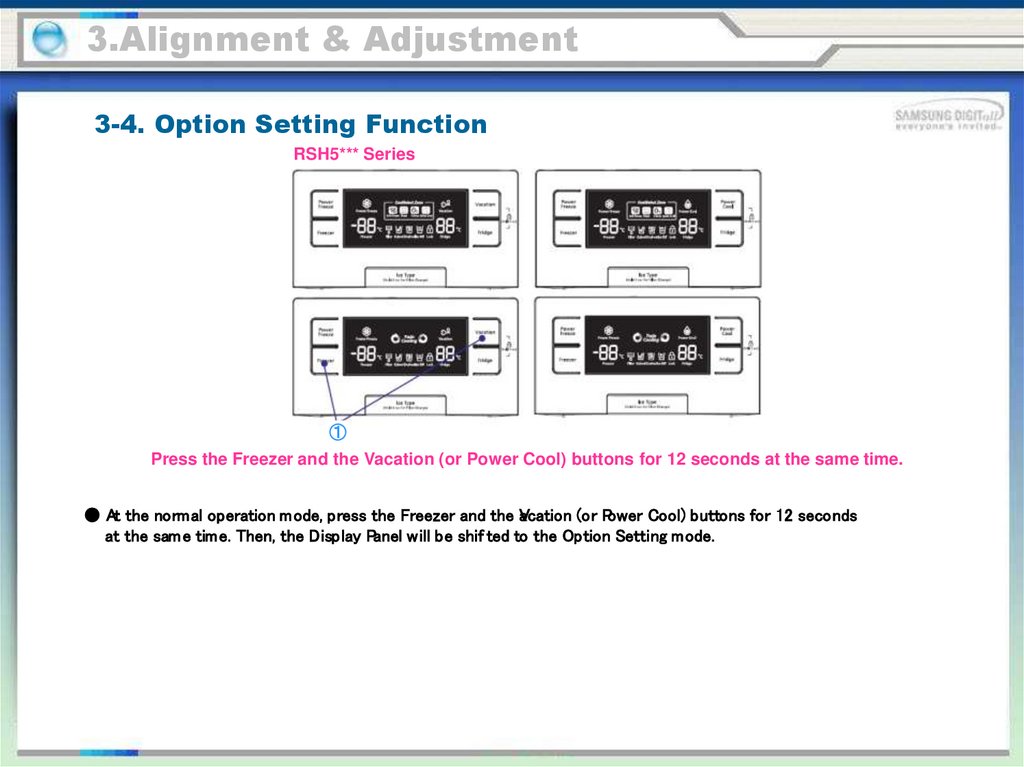

3.Alignment & Adjustment3-4. Option Setting Function

RSH5*** Series

①

Press the Freezer and the Vacation (or Power Cool) buttons for 12 seconds at the same time.

● At the normal operation mode, press the Freezer and the V

acation (or Power Cool) buttons for 12 seconds

at the sam e time. Then, the Display Panel will be shif ted to the Option Setting mode.

46.

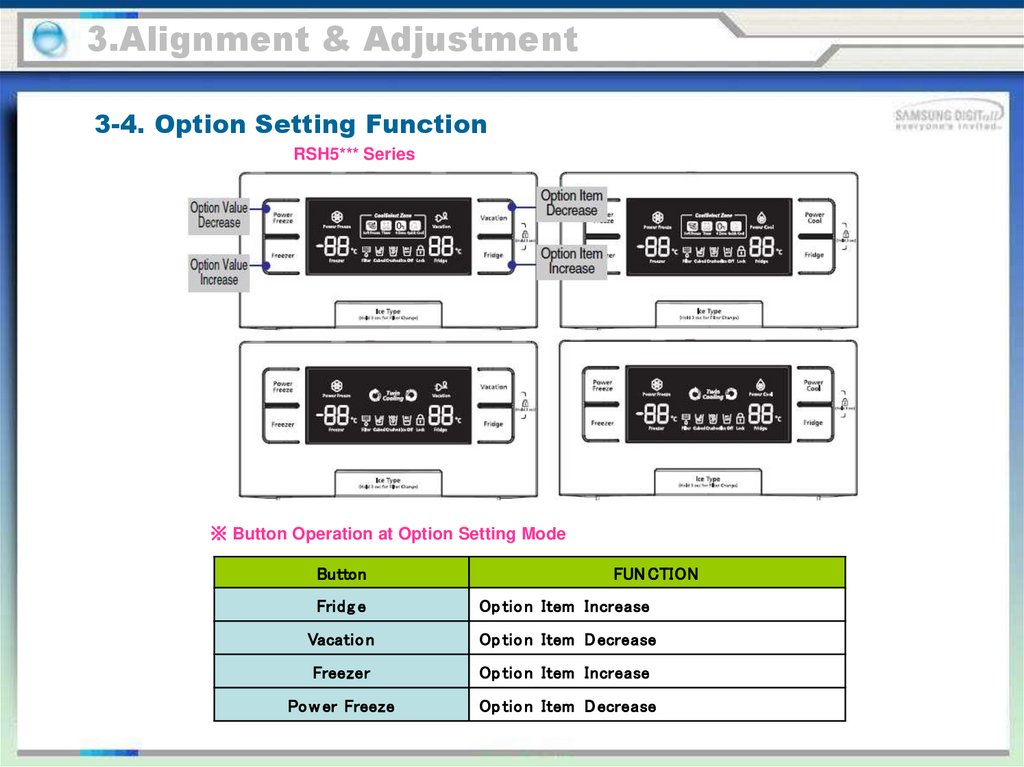

3.Alignment & Adjustment3-4. Option Setting Function

RSH5*** Series

※ Button Operation at Option Setting Mode

Button

FUN CTION

Fridg e

Op tio n Item Increase

Vacatio n

Op tio n Item D ecrease

Freezer

Op tio n Item Increase

Po w er Freeze

Op tio n Item D ecrease

47.

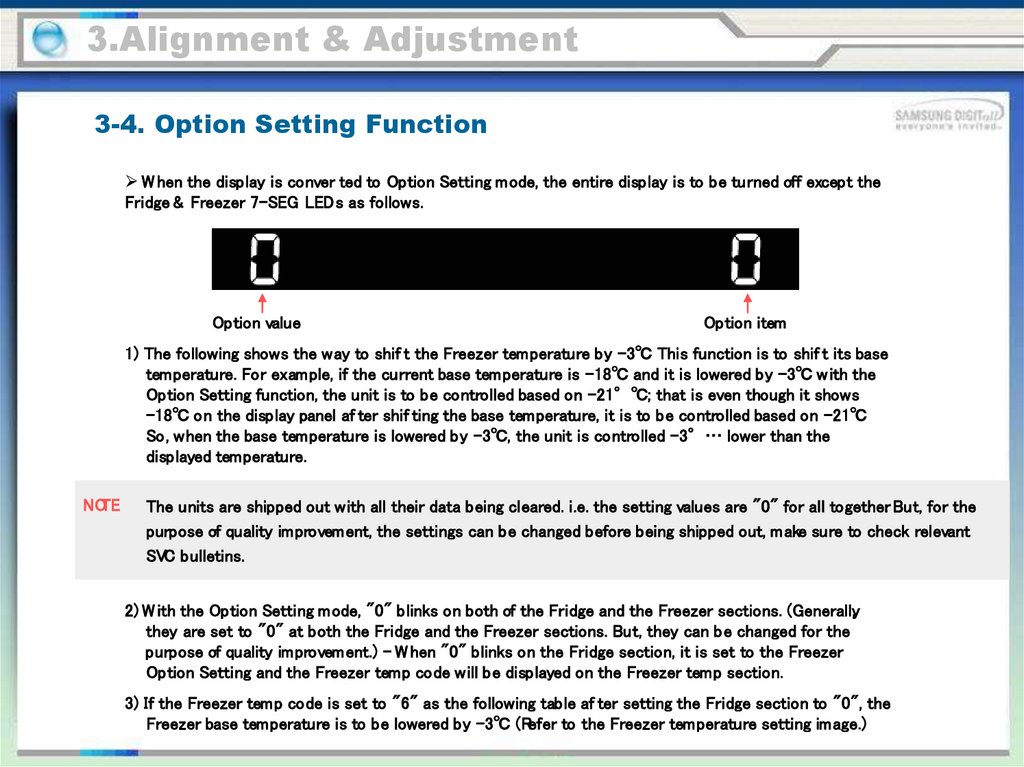

3.Alignment & Adjustment3-4. Option Setting Function

W hen the display is conver ted to Option Setting mode, the entire display is to be turned off except the

Fridge & Freezer 7-SEG LEDs as follows.

Option value

Option item

1) The following shows the way to shif t the Freezer temperature by -3℃ This function is to shif t its base

temperature. For example, if the current base temperature is -18℃ and it is lowered by -3℃ w ith the

Option Setting function, the unit is to be controlled based on -21°℃; that is even though it shows

-18℃ on the display panel af ter shif ting the base temperature, it is to be controlled based on -21℃

So, when the base temperature is lowered by -3℃, the unit is controlled -3°… lower than the

displayed temperature.

NOTE

The units are shipped out with all their data being cleared. i.e. the setting values are "0" for all together. But, for the

purpose of quality improvement, the settings can be changed before being shipped out, make sure to check relevant

SVC bulletins.

2) W ith the Option Setting mode, "0" blinks on both of the Fridge and the Freezer sections. (Generally,

they are set to "0" at both the Fridge and the Freezer sections. But, they can be changed for the

purpose of quality improvement.) - W hen "0" blinks on the Fridge section, it is set to the Freezer

Option Setting and the Freezer temp code will be displayed on the Freezer temp section.

3) If the Freezer temp code is set to "6" as the following table af ter setting the Fridge section to "0", the

Freezer base temperature is to be lowered by -3℃ (Refer to the Freezer temperature setting image.)

48.

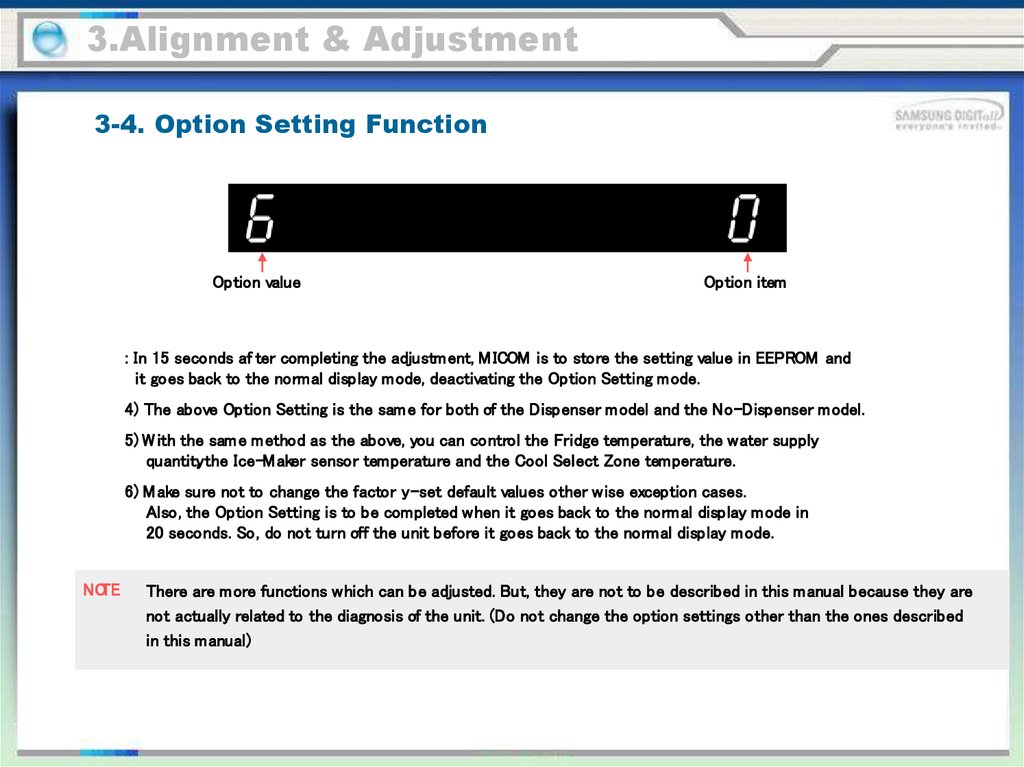

3.Alignment & Adjustment3-4. Option Setting Function

Option value

Option item

: In 15 seconds af ter completing the adjustment, M ICOM is to store the setting value in EEPROM and

it goes back to the normal display mode, deactivating the Option Setting mode.

4) The above Option Setting is the sam e for both of the Dispenser model and the No-Dispenser model.

5) W ith the sam e method as the above, you can control the Fridge temperature, the water supply

quantity, the Ice-M aker sensor temperature and the Cool Select Zone temperature.

6) M ake sure not to change the factor y-set default values other wise exception cases.

Also, the Option Setting is to be completed when it goes back to the normal display mode in

20 seconds. So, do not turn off the unit before it goes back to the normal display mode.

NOTE

There are more functions which can be adjusted. But, they are not to be described in this manual because they are

not actually related to the diagnosis of the unit. (Do not change the option settings other than the ones described

in this manual)

49.

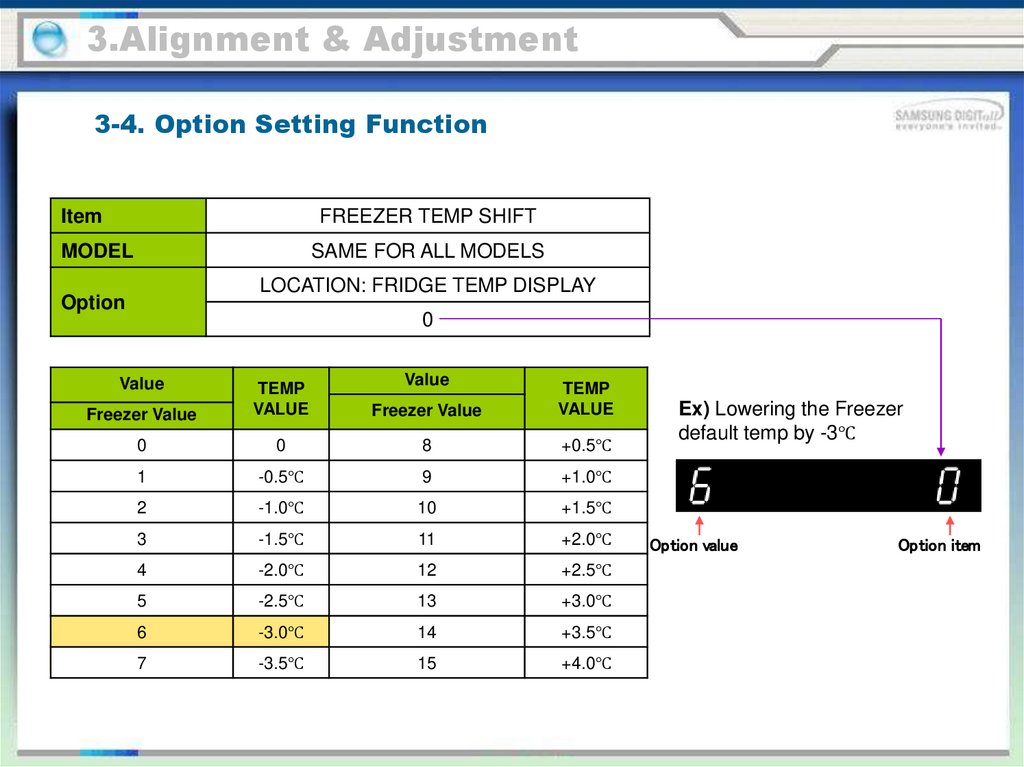

3.Alignment & Adjustment3-4. Option Setting Function

Item

FREEZER TEMP SHIFT

MODEL

SAME FOR ALL MODELS

LOCATION: FRIDGE TEMP DISPLAY

Option

0

Value

Value

Freezer Value

TEMP

VALUE

Freezer Value

TEMP

VALUE

0

0

8

+0.5℃

1

-0.5℃

9

+1.0℃

2

-1.0℃

10

+1.5℃

3

-1.5℃

11

+2.0℃

4

-2.0℃

12

+2.5℃

5

-2.5℃

13

+3.0℃

6

-3.0℃

14

+3.5℃

7

-3.5℃

15

+4.0℃

Ex) Lowering the Freezer

default temp by -3℃

Option value

Option item

50.

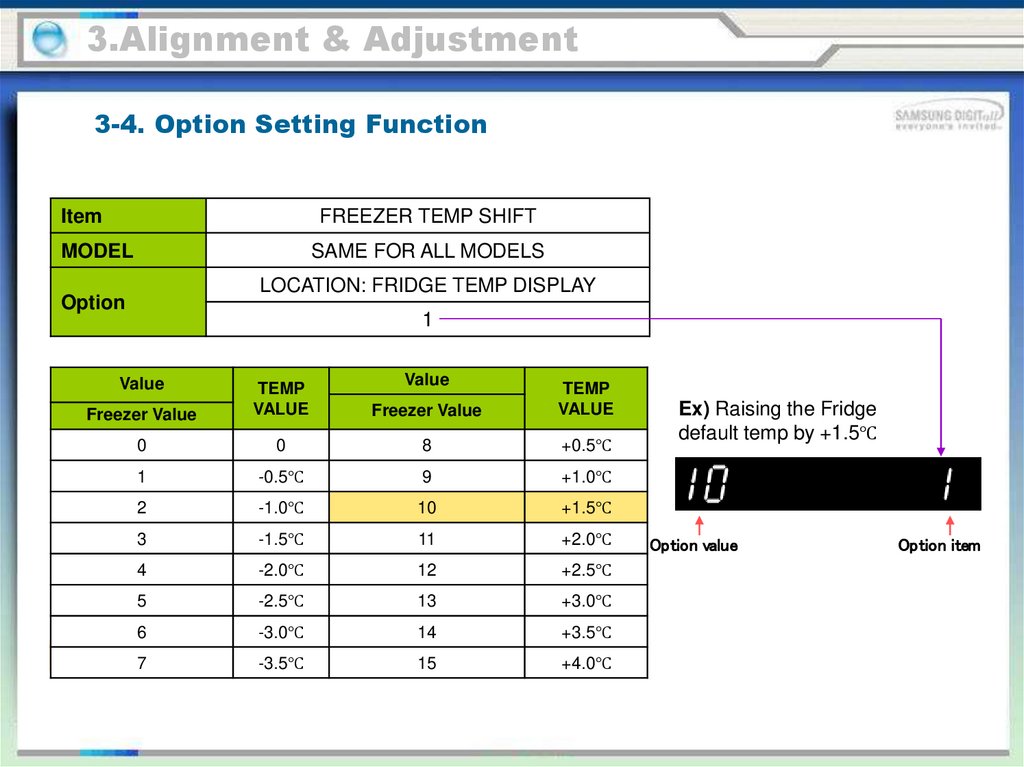

3.Alignment & Adjustment3-4. Option Setting Function

Item

FREEZER TEMP SHIFT

MODEL

SAME FOR ALL MODELS

LOCATION: FRIDGE TEMP DISPLAY

Option

1

Value

Value

Freezer Value

TEMP

VALUE

Freezer Value

TEMP

VALUE

0

0

8

+0.5℃

1

-0.5℃

9

+1.0℃

2

-1.0℃

10

+1.5℃

3

-1.5℃

11

+2.0℃

4

-2.0℃

12

+2.5℃

5

-2.5℃

13

+3.0℃

6

-3.0℃

14

+3.5℃

7

-3.5℃

15

+4.0℃

Ex) Raising the Fridge

default temp by +1.5℃

Option value

Option item

51.

3.Alignment & Adjustment3-4. Option Setting Function

It controls the water supply quantity with the Flow Sensor.

item

Display Position

Ice-Maker Water Supply

Qty Control

2

Water Supply Quantity

Option Value

(Freezer Temp)

85CC

0

95CC

1

Ex) Changing the water supply quantity to 85cc

Option value

Option item

52.

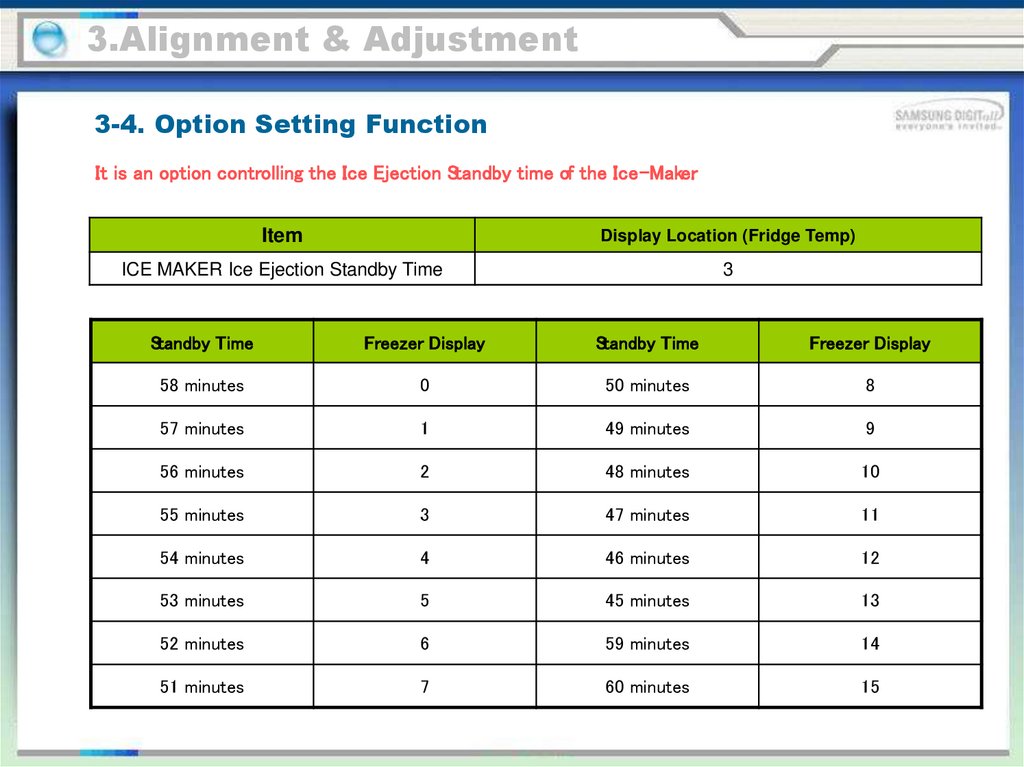

3.Alignment & Adjustment3-4. Option Setting Function

It is an option controlling the Ice Ejection Standby time of the Ice-Maker.

Item

Display Location (Fridge Temp)

ICE MAKER Ice Ejection Standby Time

3

Standby Time

Freezer Display

Standby Time

Freezer Display

58 minutes

0

50 minutes

8

57 minutes

1

49 minutes

9

56 minutes

2

48 minutes

10

55 minutes

3

47 minutes

11

54 minutes

4

46 minutes

12

53 minutes

5

45 minutes

13

52 minutes

6

59 minutes

14

51 minutes

7

60 minutes

15

53.

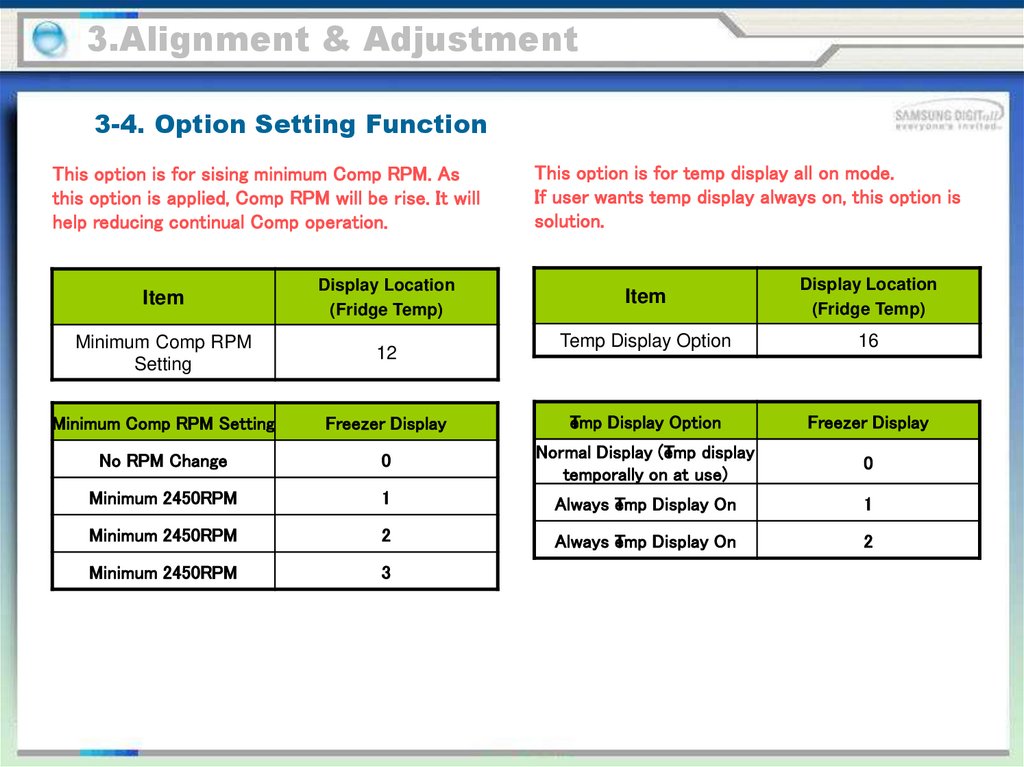

3.Alignment & Adjustment3-4. Option Setting Function

This option is for sising minimum Comp RPM. As

this option is applied, Comp RPM will be rise. It will

help reducing continual Comp operation.

This option is for temp display all on mode.

If user wants temp display always on, this option is

solution.

Item

Display Location

(Fridge Temp)

Temp Display Option

16

Freezer Display

T

emp Display Option

Freezer Display

No RPM Change

0

Normal Display (T

emp display

temporally on at use)

0

Minimum 2450RPM

1

Always T

emp Display On

1

Minimum 2450RPM

2

Always T

emp Display On

2

Minimum 2450RPM

3

Item

Display Location

(Fridge Temp)

Minimum Comp RPM

Setting

12

Minimum Comp RPM Setting

54.

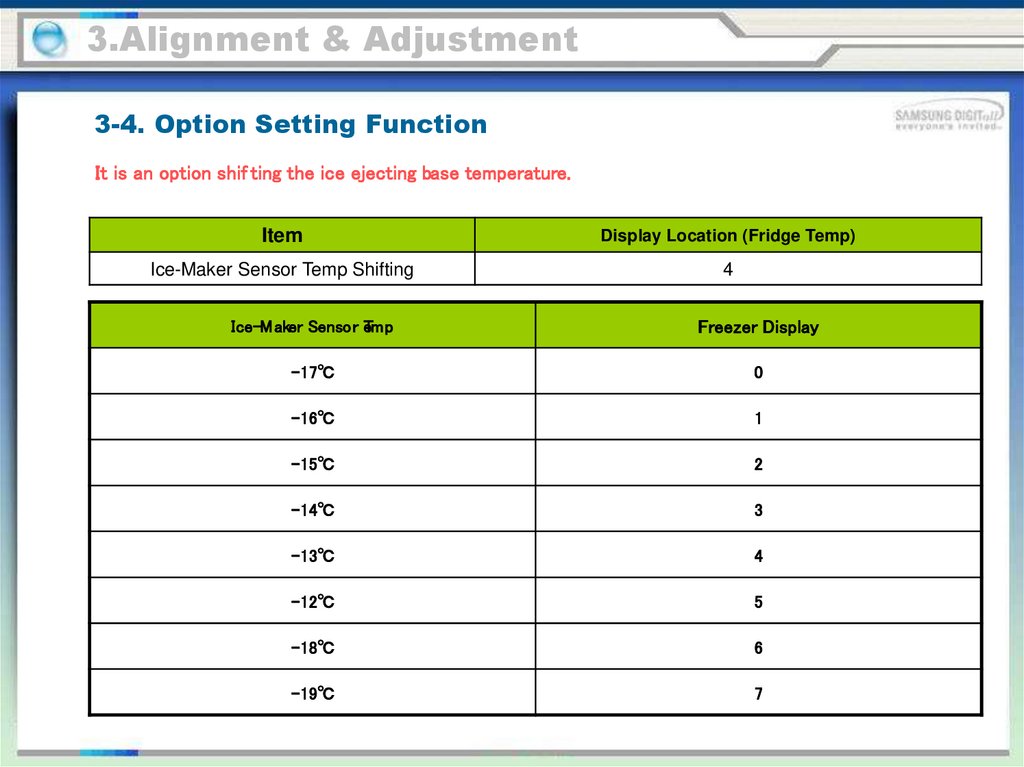

3.Alignment & Adjustment3-4. Option Setting Function

It is an option shif ting the ice ejecting base temperature.

Item

Display Location (Fridge Temp)

Ice-Maker Sensor Temp Shifting

4

Ice-M aker Sensor eTmp

Freezer Display

-17℃

0

-16℃

1

-15℃

2

-14℃

3

-13℃

4

-12℃

5

-18℃

6

-19℃

7

55.

3.Alignment & Adjustment3-4. Option Setting Function

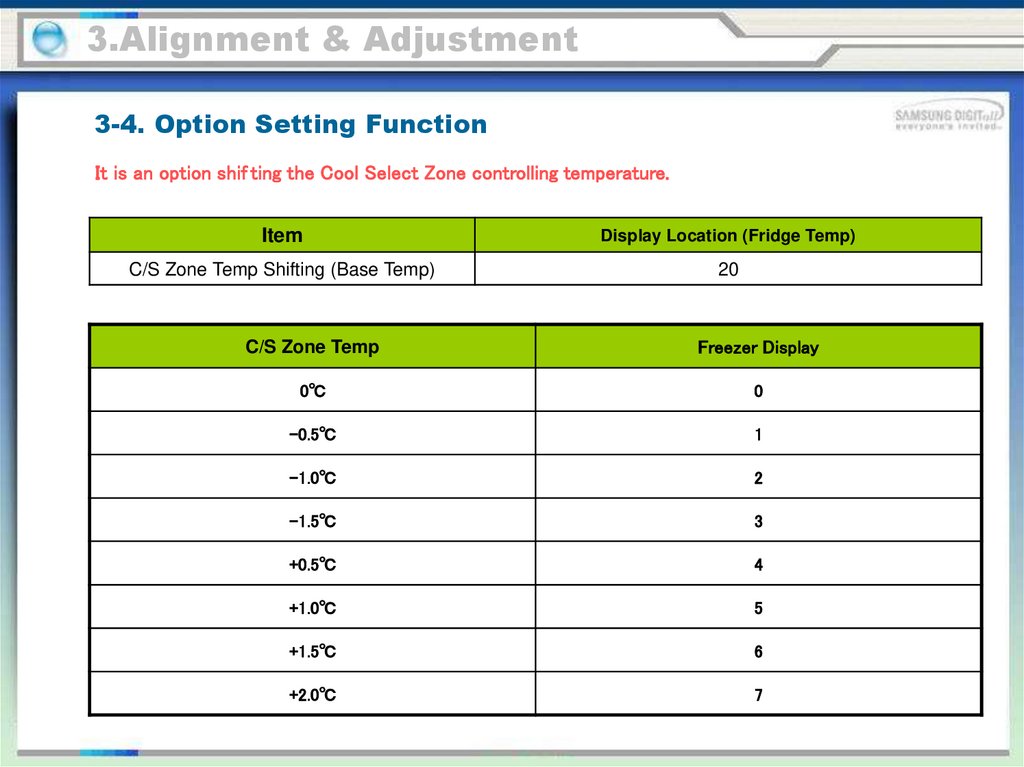

It is an option shif ting the Cool Select Zone controlling temperature.

Item

Display Location (Fridge Temp)

C/S Zone Temp Shifting (Base Temp)

20

C/S Zone Temp

Freezer Display

0℃

0

-0.5℃

1

-1.0℃

2

-1.5℃

3

+0.5℃

4

+1.0℃

5

+1.5℃

6

+2.0℃

7

56.

4.Disassembly & Reassembly4-1. Necessary tools for disassembly and reassembly

Unplug the refrigerator before cleaning and making repairs.

Do not dissemble or repair the refrigerator by yourself.

You run risk of causing a fire, malfunction and/or personal injury.

Remove any foreign matter or dust from the power plug pins.

Otherwise there is a risk of fire.

Do not use a cord that shows cracks or abrasion damage along its length or at either end.

Do not plug several appliances into the same multiple power board. The refrigerator should

always be plugged into its own individual electrical which has a voltage rating that matched

the rating plate.

- This provides the best performance and also prevents overloading house wiring circuits,

which could cause a fire hazard from overheated wires.

• Do not install the refrigerator in a damp place or place where it may come in contact with

water.

- Deteriorated insulation of electrical parts may cause an electric shock or fire.

• The refrigerator must be grounded.

- You must ground the refrigerator to prevent any power leakages or electric shocks caused

by

current leakage from the refrigerator.

• Do not put bottles or glass containers in the freezer.

- When the contents freeze, the glass may break and cause personal injury.

• Do not store volatile or flammable substances in the refrigerator.

- The storage of benzene, thinner, alcohol, ether, LP gas and other such products may cause

57.

4.Disassembly & Reassembly4-1. Necessary tools for disassembly and reassembly

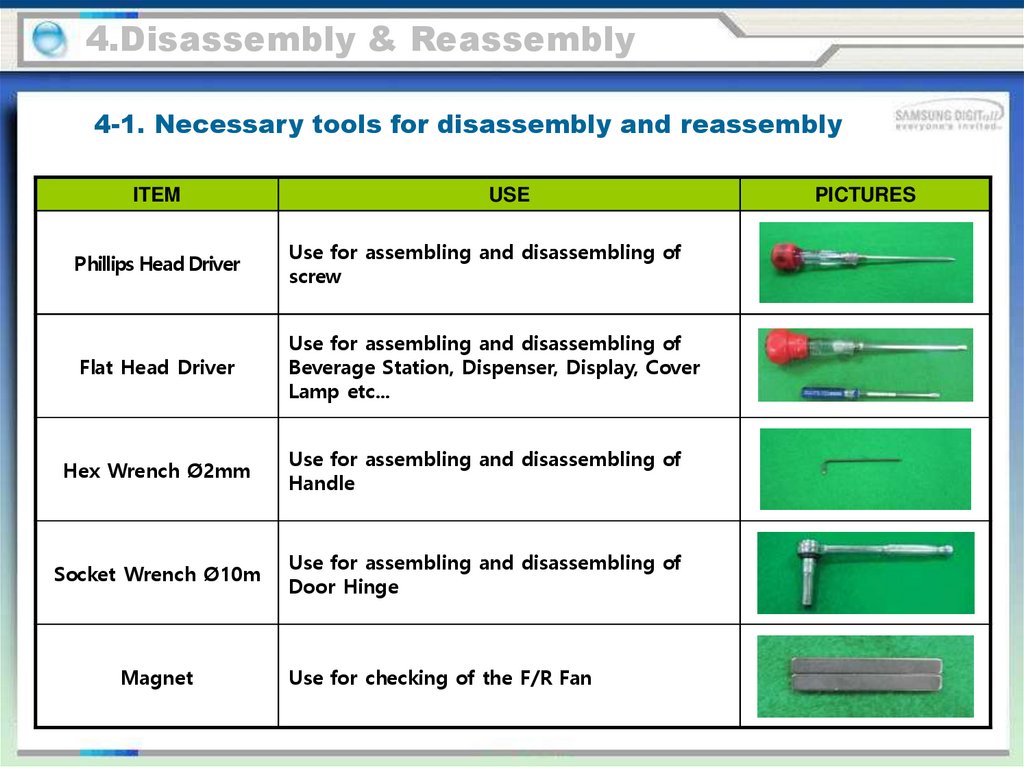

ITEM

USE

Phillips Head Driver

Use for assembling and disassembling of

screw

Flat Head Driver

Use for assembling and disassembling of

Beverage Station, Dispenser, Display, Cover

Lamp etc...

Hex Wrench Ø2mm

Use for assembling and disassembling of

Handle

Socket Wrench Ø10m

Use for assembling and disassembling of

Door Hinge

Magnet

Use for checking of the F/R Fan

PICTURES

58.

4.Disassembly & Reassembly4-2. Freezer Display

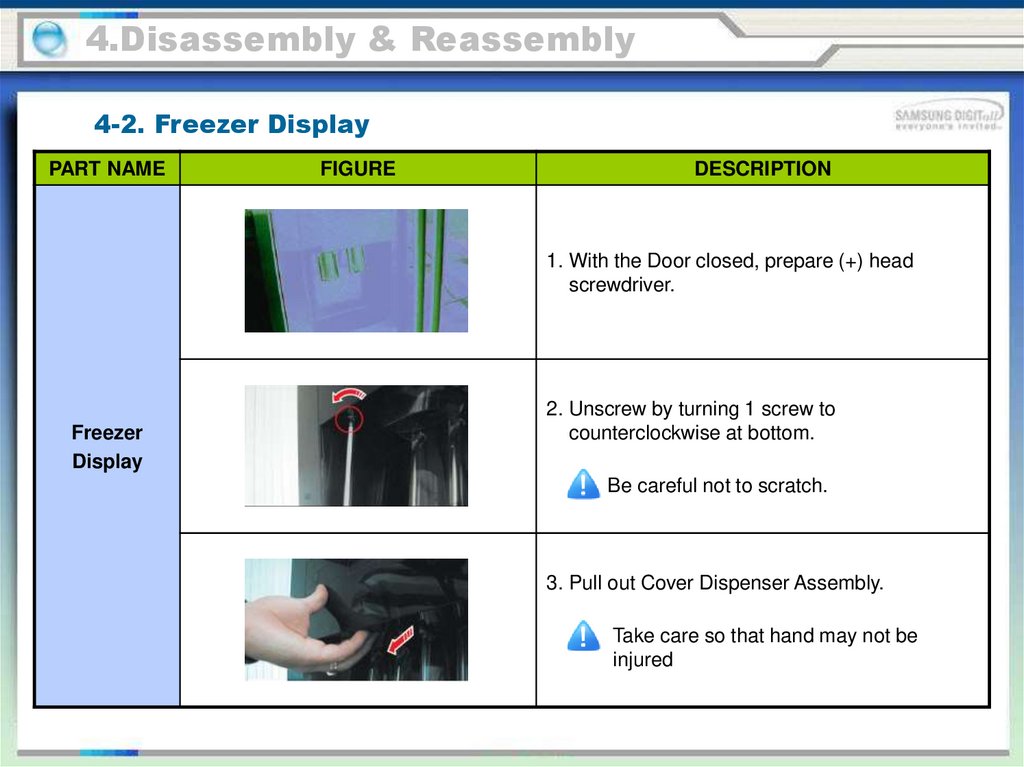

PART NAME

FIGURE

DESCRIPTION

1. With the Door closed, prepare (+) head

screwdriver.

Freezer

Display

2. Unscrew by turning 1 screw to

counterclockwise at bottom.

Be careful not to scratch.

3. Pull out Cover Dispenser Assembly.

Take care so that hand may not be

injured

59.

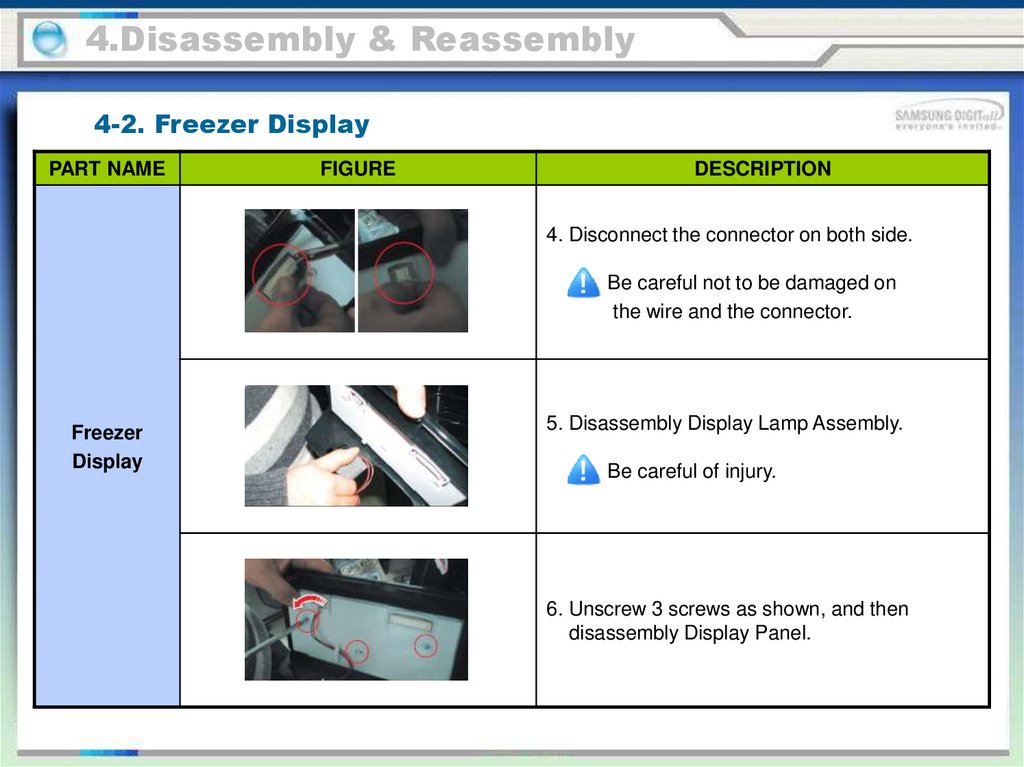

4.Disassembly & Reassembly4-2. Freezer Display

PART NAME

FIGURE

DESCRIPTION

4. Disconnect the connector on both side.

Be careful not to be damaged on

the wire and the connector.

Freezer

Display

5. Disassembly Display Lamp Assembly.

Be careful of injury.

6. Unscrew 3 screws as shown, and then

disassembly Display Panel.

60.

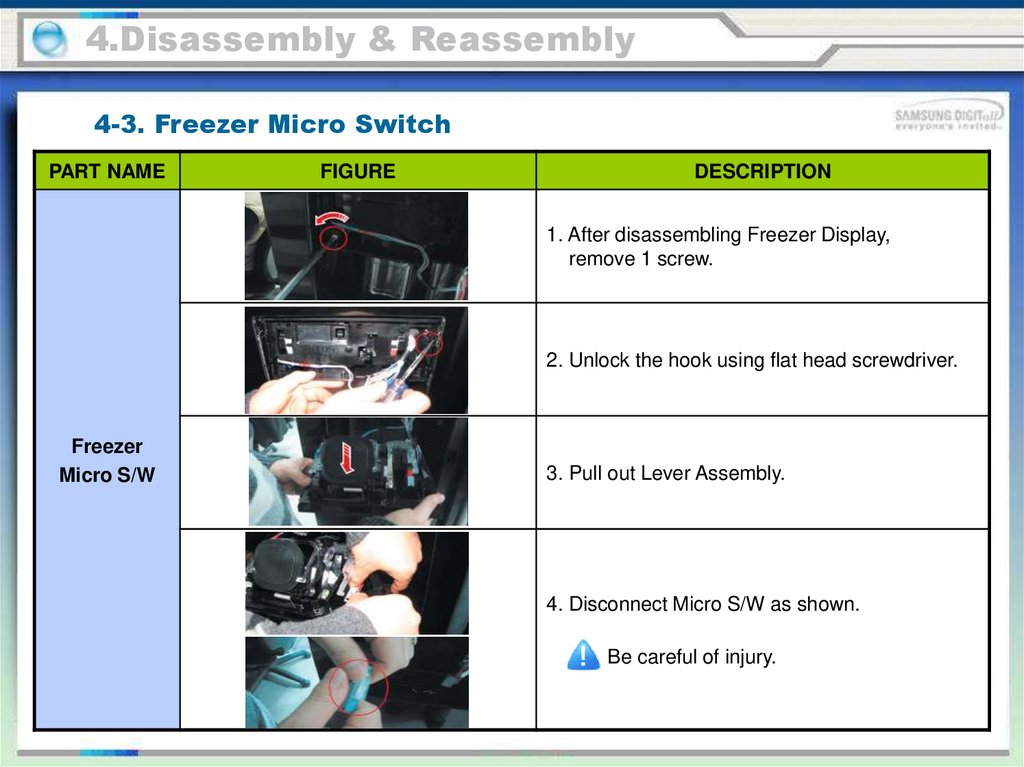

4.Disassembly & Reassembly4-3. Freezer Micro Switch

PART NAME

FIGURE

DESCRIPTION

1. After disassembling Freezer Display,

remove 1 screw.

2. Unlock the hook using flat head screwdriver.

Freezer

Micro S/W

3. Pull out Lever Assembly.

4. Disconnect Micro S/W as shown.

Be careful of injury.

61.

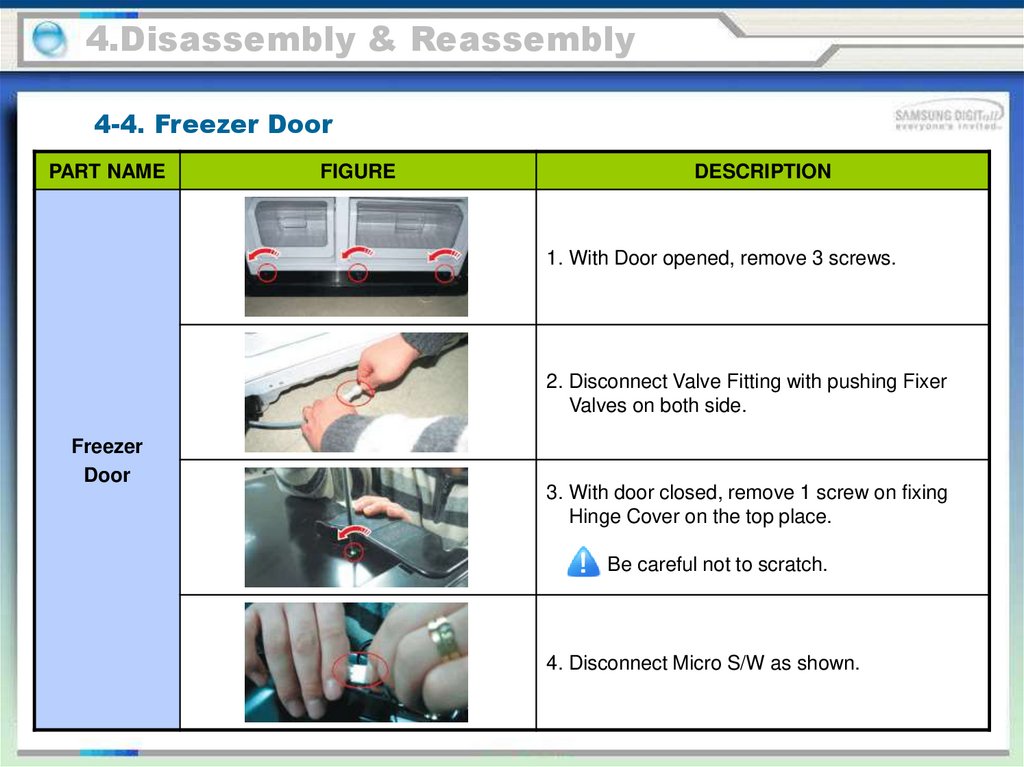

4.Disassembly & Reassembly4-4. Freezer Door

PART NAME

FIGURE

DESCRIPTION

1. With Door opened, remove 3 screws.

2. Disconnect Valve Fitting with pushing Fixer

Valves on both side.

Freezer

Door

3. With door closed, remove 1 screw on fixing

Hinge Cover on the top place.

Be careful not to scratch.

4. Disconnect Micro S/W as shown.

62.

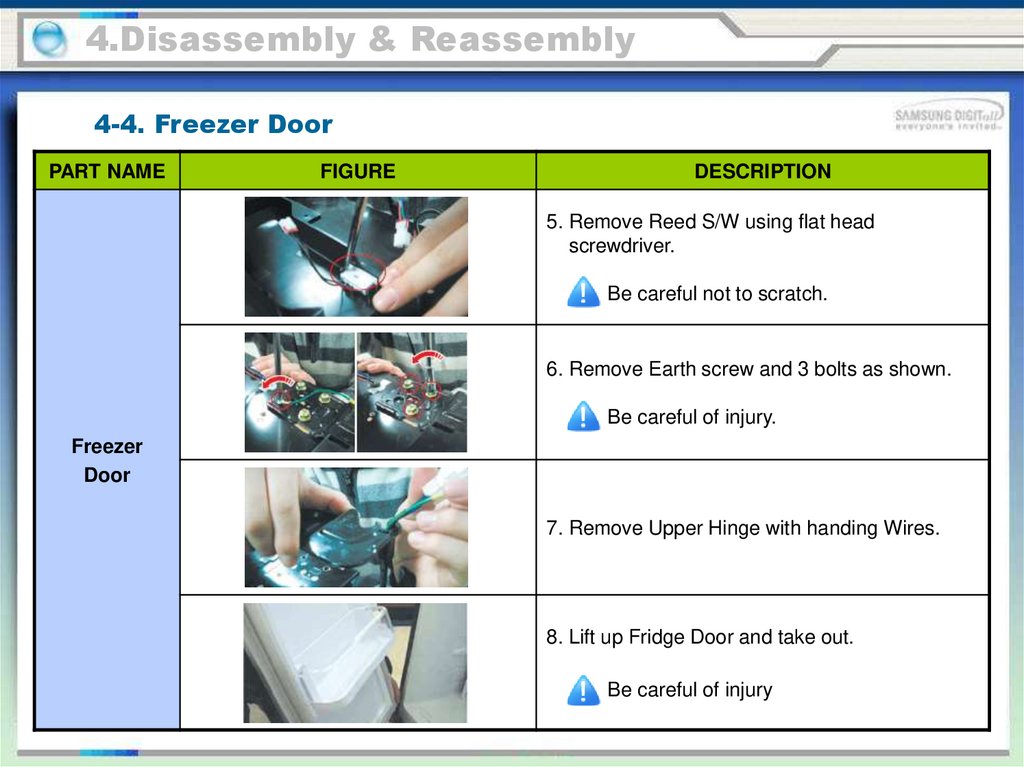

4.Disassembly & Reassembly4-4. Freezer Door

PART NAME

FIGURE

DESCRIPTION

5. Remove Reed S/W using flat head

screwdriver.

Be careful not to scratch.

6. Remove Earth screw and 3 bolts as shown.

Be careful of injury.

Freezer

Door

7. Remove Upper Hinge with handing Wires.

8. Lift up Fridge Door and take out.

Be careful of injury

63.

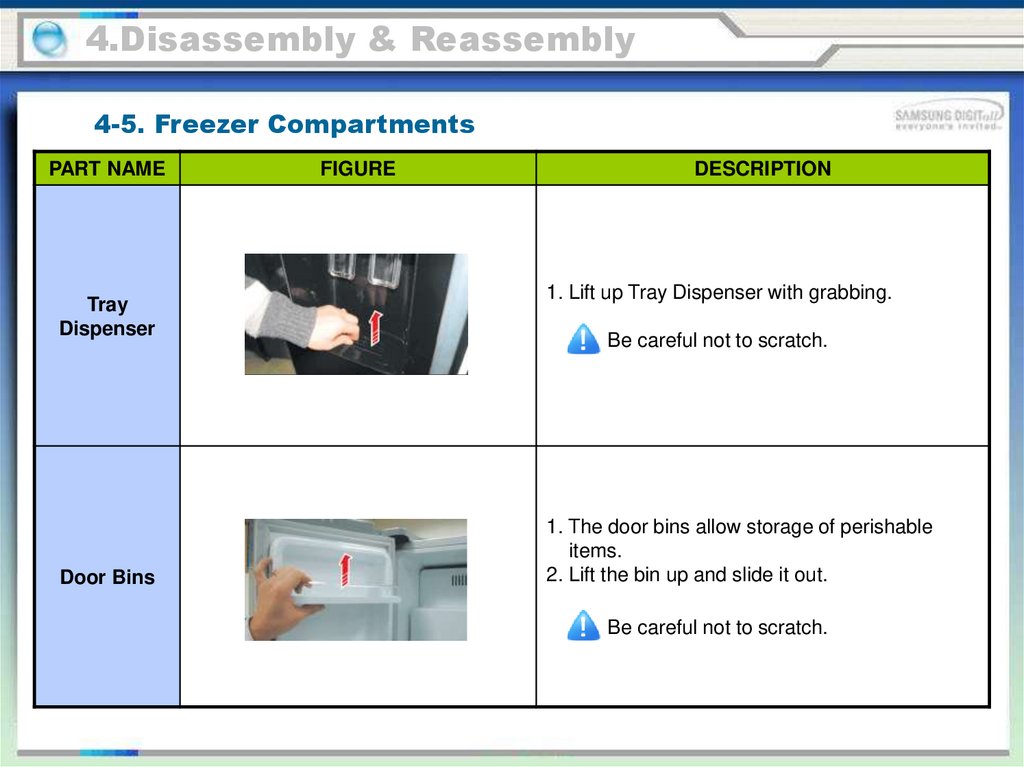

4.Disassembly & Reassembly4-5. Freezer Compartments

PART NAME

Tray

Dispenser

Door Bins

FIGURE

DESCRIPTION

1. Lift up Tray Dispenser with grabbing.

Be careful not to scratch.

1. The door bins allow storage of perishable

items.

2. Lift the bin up and slide it out.

Be careful not to scratch.

64.

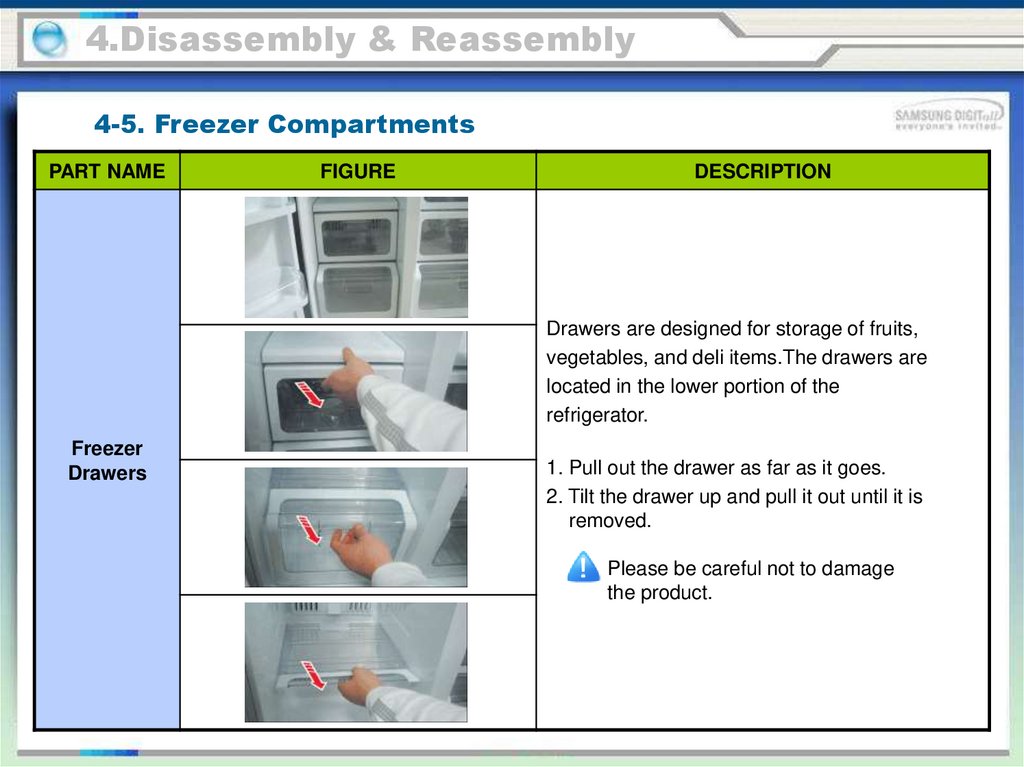

4.Disassembly & Reassembly4-5. Freezer Compartments

PART NAME

FIGURE

DESCRIPTION

Drawers are designed for storage of fruits,

vegetables, and deli items.The drawers are

located in the lower portion of the

refrigerator.

Freezer

Drawers

1. Pull out the drawer as far as it goes.

2. Tilt the drawer up and pull it out until it is

removed.

Please be careful not to damage

the product.

65.

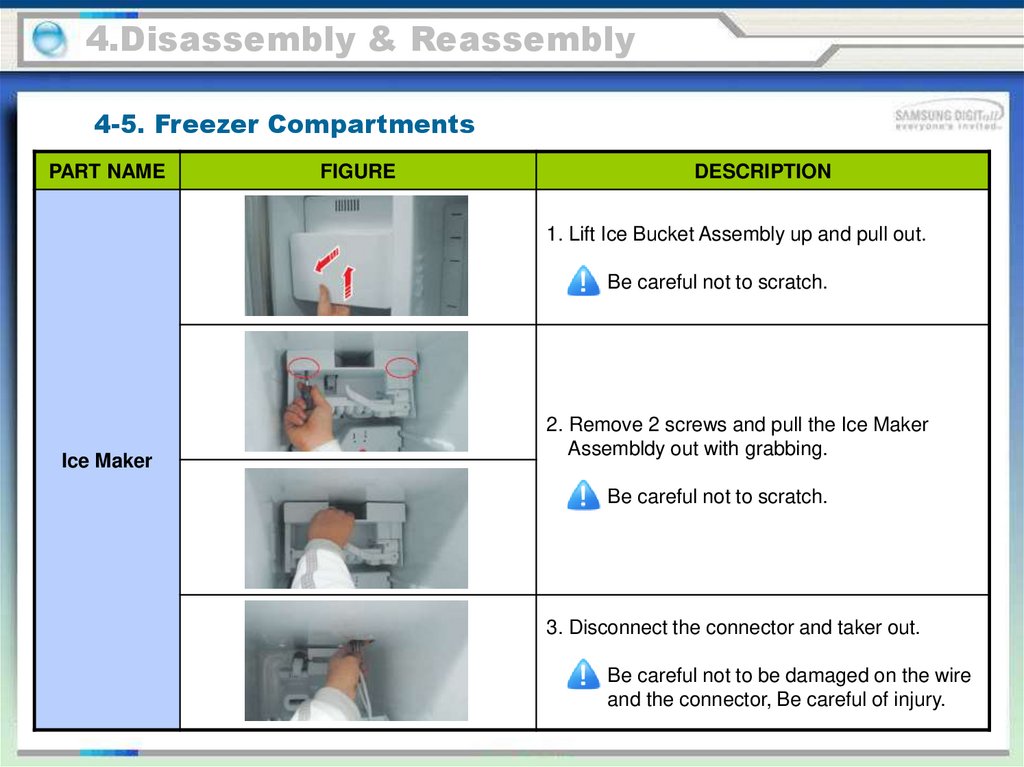

4.Disassembly & Reassembly4-5. Freezer Compartments

PART NAME

FIGURE

DESCRIPTION

1. Lift Ice Bucket Assembly up and pull out.

Be careful not to scratch.

Ice Maker

2. Remove 2 screws and pull the Ice Maker

Assembldy out with grabbing.

Be careful not to scratch.

3. Disconnect the connector and taker out.

Be careful not to be damaged on the wire

and the connector, Be careful of injury.

66.

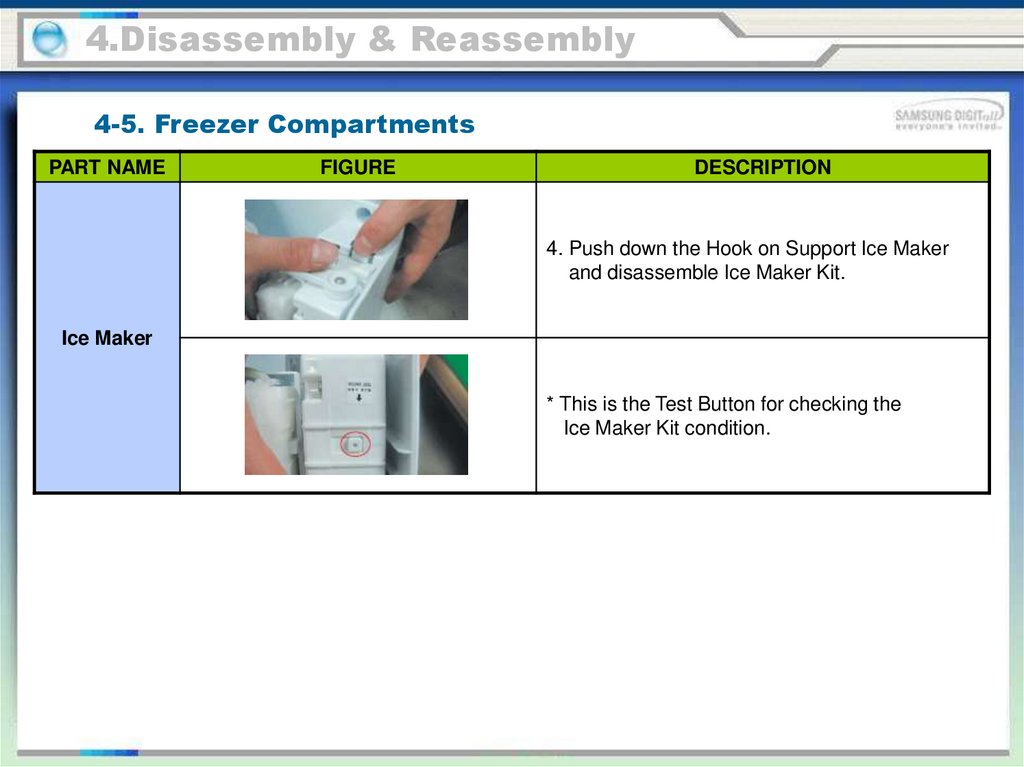

4.Disassembly & Reassembly4-5. Freezer Compartments

PART NAME

FIGURE

DESCRIPTION

4. Push down the Hook on Support Ice Maker

and disassemble Ice Maker Kit.

Ice Maker

* This is the Test Button for checking the

Ice Maker Kit condition.

67.

4.Disassembly & Reassembly4-5. Freezer Compartments

PART NAME

FIGURE

DESCRIPTION

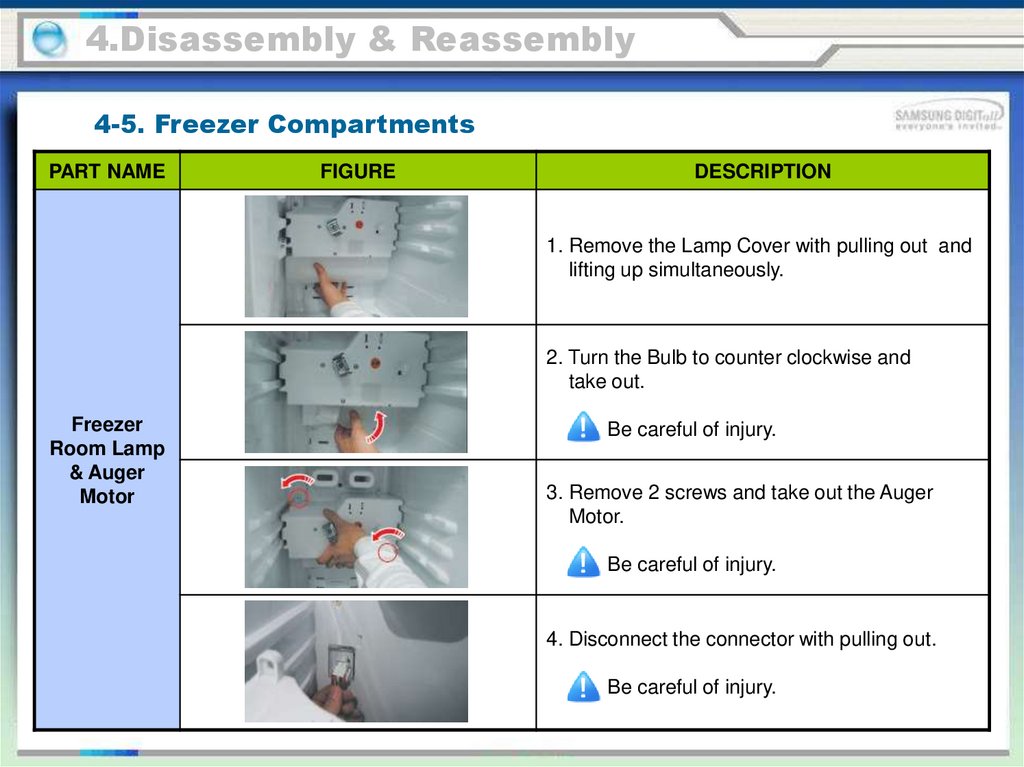

1. Remove the Lamp Cover with pulling out and

lifting up simultaneously.

2. Turn the Bulb to counter clockwise and

take out.

Freezer

Room Lamp

& Auger

Motor

Be careful of injury.

3. Remove 2 screws and take out the Auger

Motor.

Be careful of injury.

4. Disconnect the connector with pulling out.

Be careful of injury.

68.

4.Disassembly & Reassembly4-5. Freezer Compartments

PART NAME

FIGURE

DESCRIPTION

5. Remove the Cover Auger Motor using flat

head screwdriver.

Freezer

Room Lamp

& Auger

Motor

Be careful of injury.

6. After removing the Cover Auger Motor,

unlock the Lamp Socket with pushing down.

69.

4.Disassembly & Reassembly4-5. Freezer Compartments

PART NAME

FIGURE

DESCRIPTION

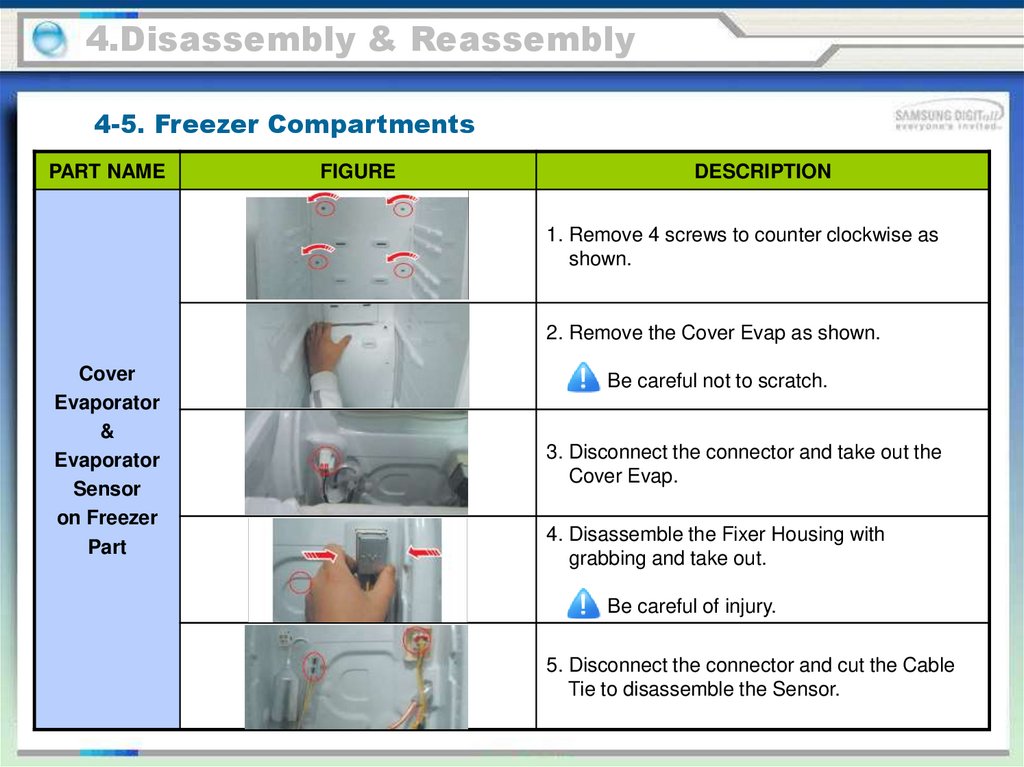

1. Remove 4 screws to counter clockwise as

shown.

2. Remove the Cover Evap as shown.

Cover

Evaporator

&

Evaporator

Sensor

on Freezer

Part

Be careful not to scratch.

3. Disconnect the connector and take out the

Cover Evap.

4. Disassemble the Fixer Housing with

grabbing and take out.

Be careful of injury.

5. Disconnect the connector and cut the Cable

Tie to disassemble the Sensor.

70.

4.Disassembly & Reassembly4-5. Freezer Compartments

PART NAME

FIGURE

DESCRIPTION

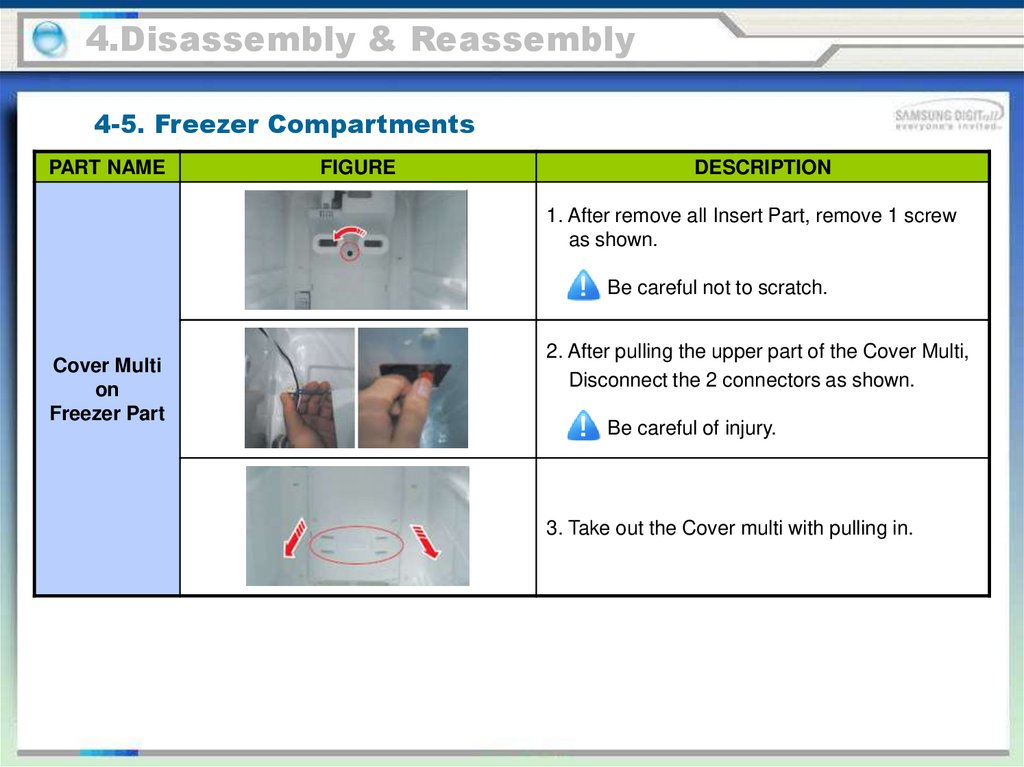

1. After remove all Insert Part, remove 1 screw

as shown.

Be careful not to scratch.

Cover Multi

on

Freezer Part

2. After pulling the upper part of the Cover Multi,

Disconnect the 2 connectors as shown.

Be careful of injury.

3. Take out the Cover multi with pulling in.

71.

4.Disassembly & Reassembly4-5. Freezer Compartments

PART NAME

FIGURE

DESCRIPTION

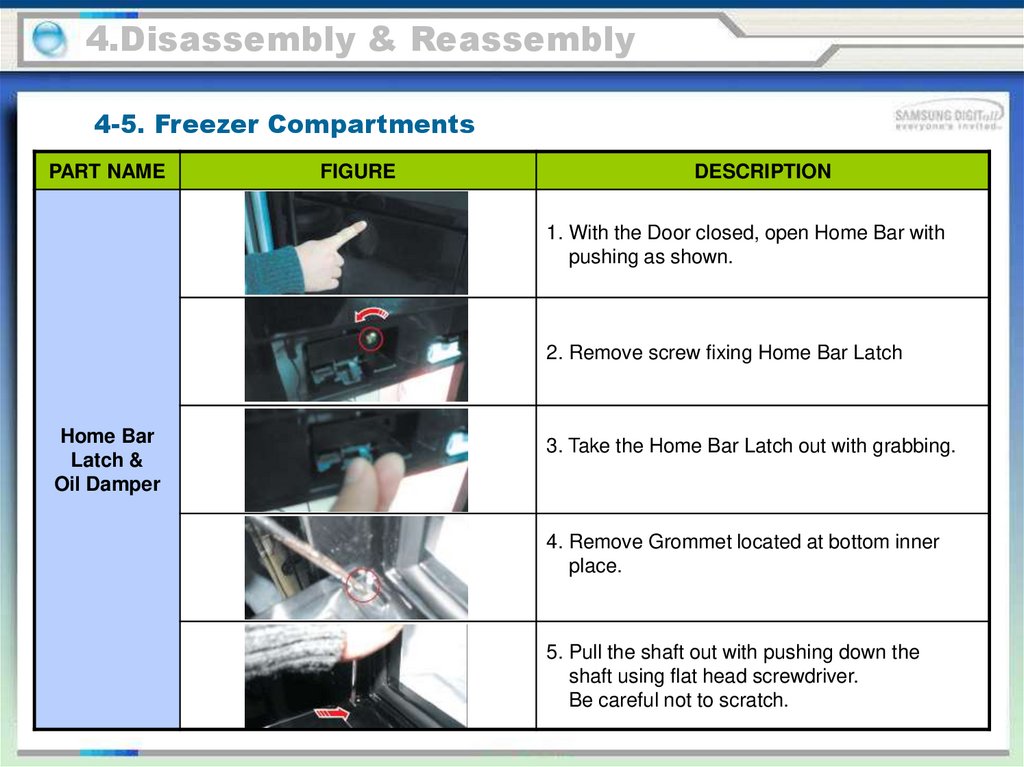

1. With the Door closed, open Home Bar with

pushing as shown.

2. Remove screw fixing Home Bar Latch

Home Bar

Latch &

Oil Damper

3. Take the Home Bar Latch out with grabbing.

4. Remove Grommet located at bottom inner

place.

5. Pull the shaft out with pushing down the

shaft using flat head screwdriver.

Be careful not to scratch.

72.

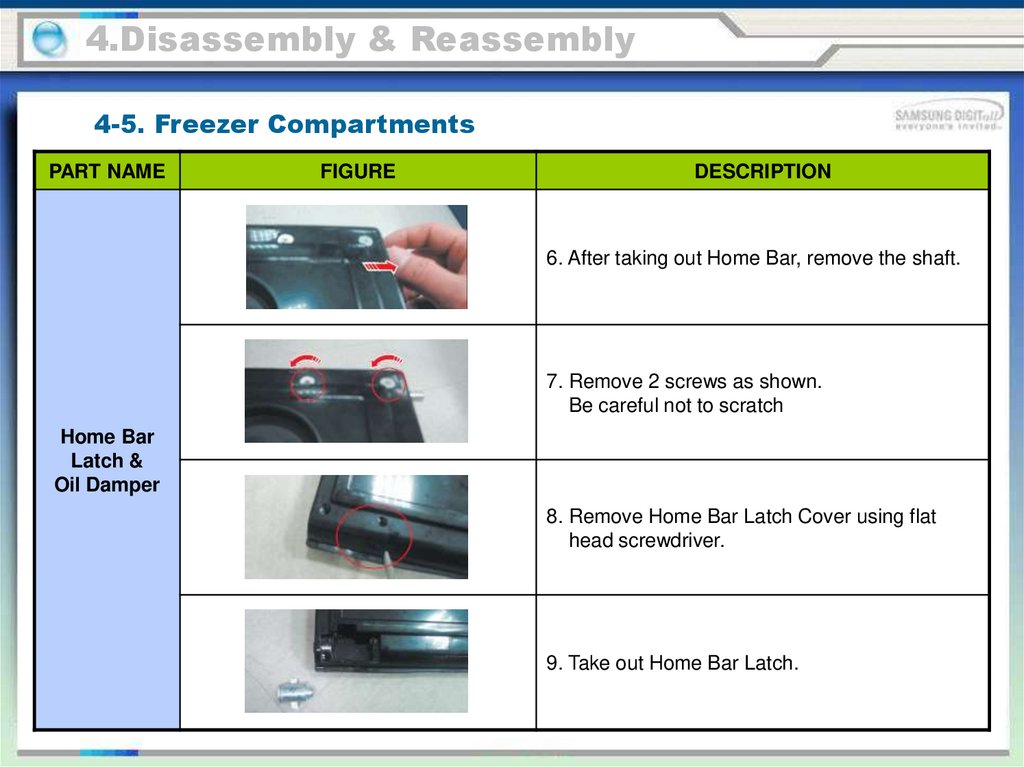

4.Disassembly & Reassembly4-5. Freezer Compartments

PART NAME

FIGURE

DESCRIPTION

6. After taking out Home Bar, remove the shaft.

7. Remove 2 screws as shown.

Be careful not to scratch

Home Bar

Latch &

Oil Damper

8. Remove Home Bar Latch Cover using flat

head screwdriver.

9. Take out Home Bar Latch.

73.

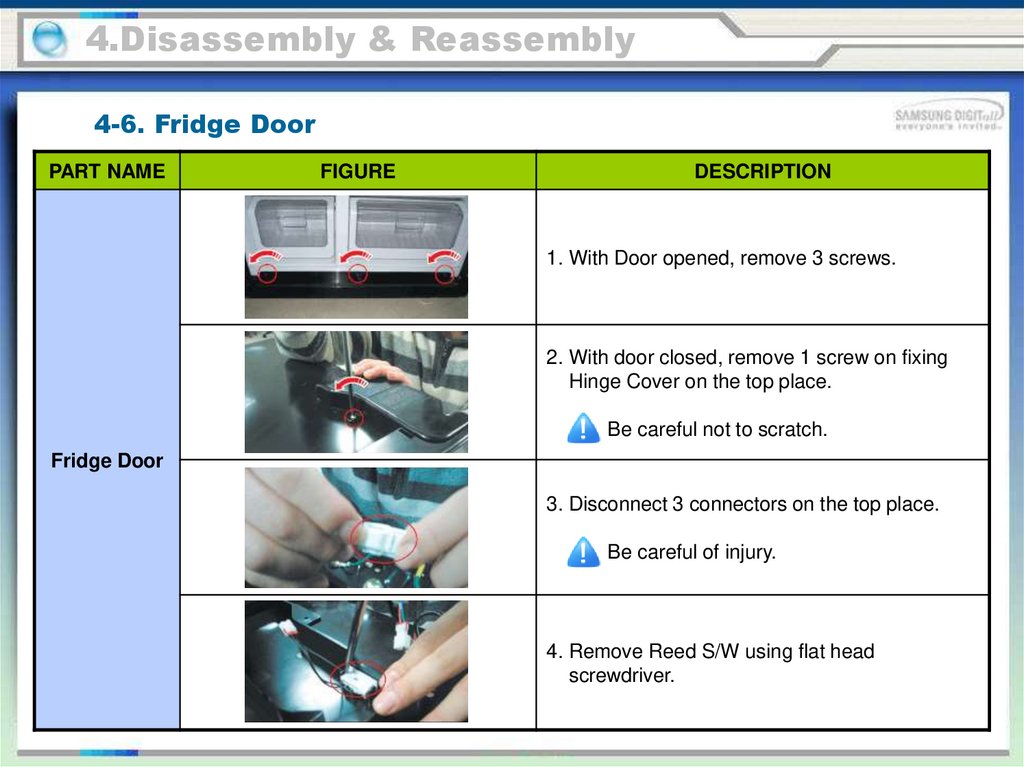

4.Disassembly & Reassembly4-6. Fridge Door

PART NAME

FIGURE

DESCRIPTION

1. With Door opened, remove 3 screws.

2. With door closed, remove 1 screw on fixing

Hinge Cover on the top place.

Be careful not to scratch.

Fridge Door

3. Disconnect 3 connectors on the top place.

Be careful of injury.

4. Remove Reed S/W using flat head

screwdriver.

74.

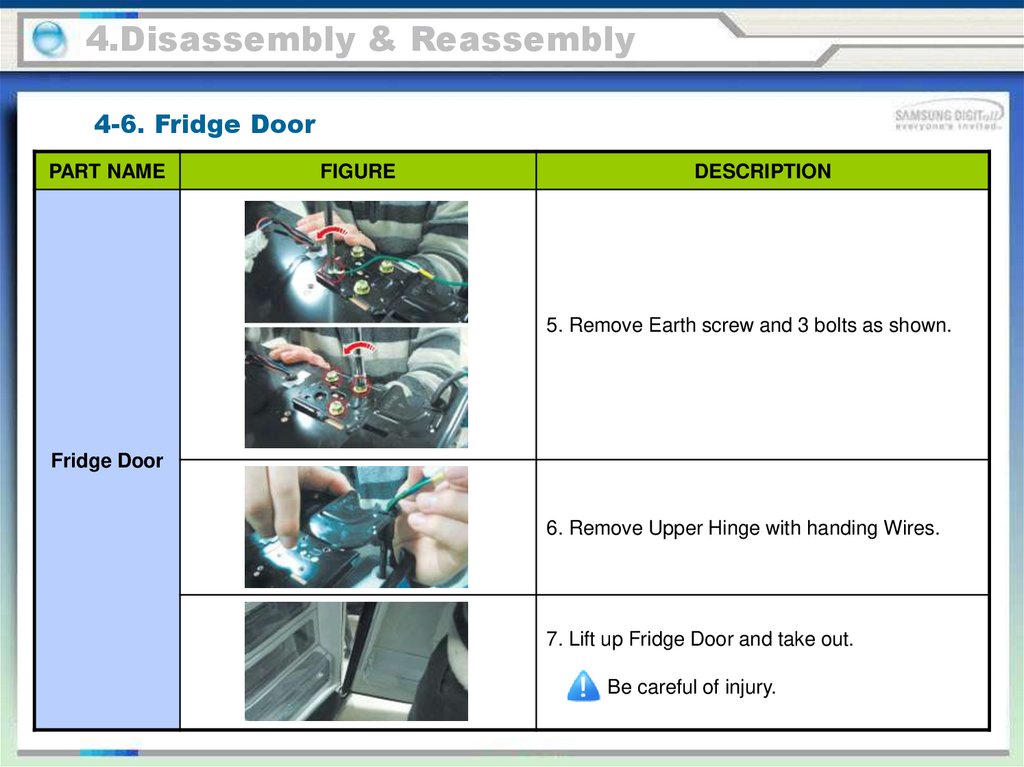

4.Disassembly & Reassembly4-6. Fridge Door

PART NAME

FIGURE

DESCRIPTION

5. Remove Earth screw and 3 bolts as shown.

Fridge Door

6. Remove Upper Hinge with handing Wires.

7. Lift up Fridge Door and take out.

Be careful of injury.

75.

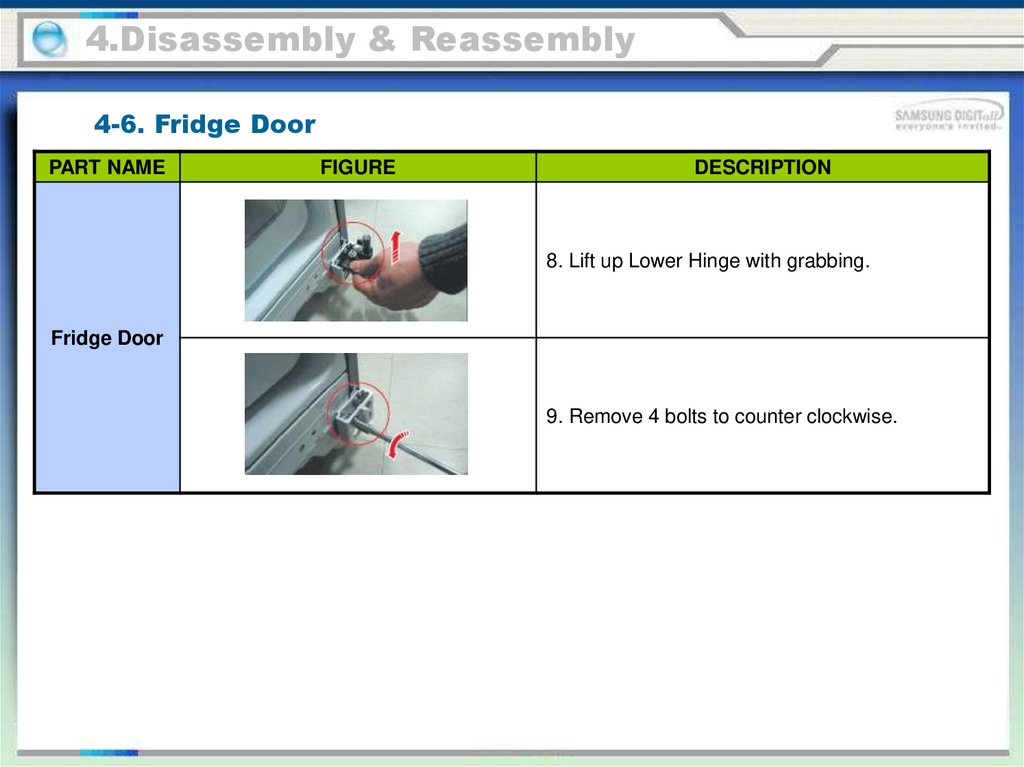

4.Disassembly & Reassembly4-6. Fridge Door

PART NAME

FIGURE

DESCRIPTION

8. Lift up Lower Hinge with grabbing.

Fridge Door

9. Remove 4 bolts to counter clockwise.

76.

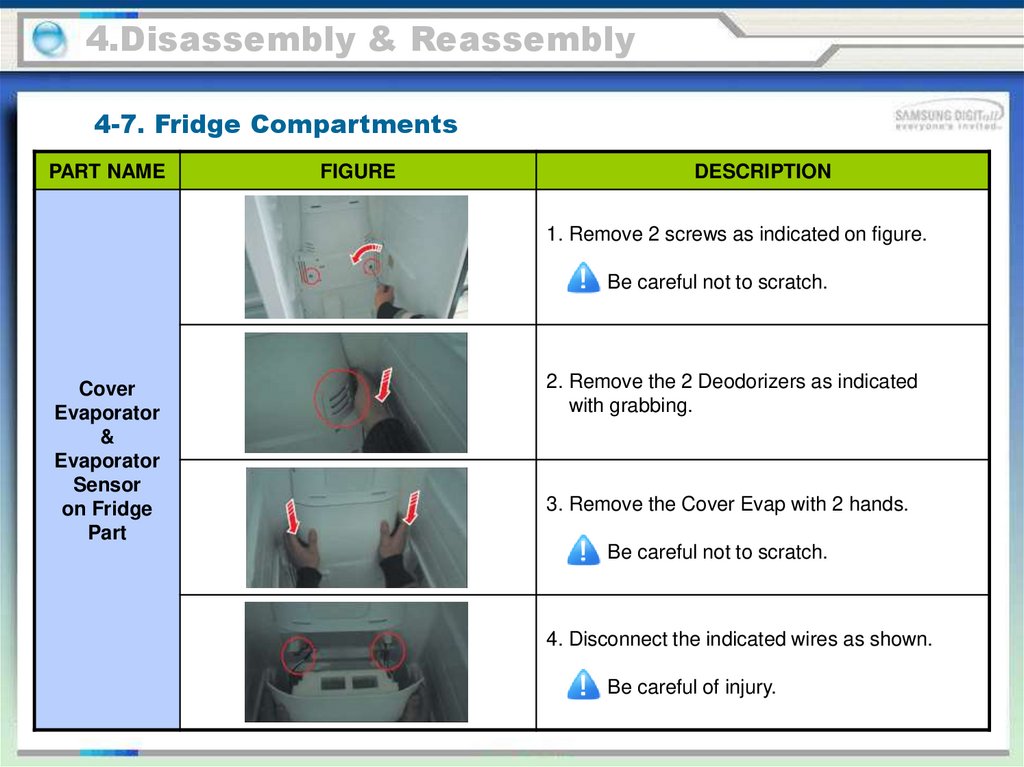

4.Disassembly & Reassembly4-7. Fridge Compartments

PART NAME

FIGURE

DESCRIPTION

1. Remove 2 screws as indicated on figure.

Be careful not to scratch.

Cover

Evaporator

&

Evaporator

Sensor

on Fridge

Part

2. Remove the 2 Deodorizers as indicated

with grabbing.

3. Remove the Cover Evap with 2 hands.

Be careful not to scratch.

4. Disconnect the indicated wires as shown.

Be careful of injury.

77.

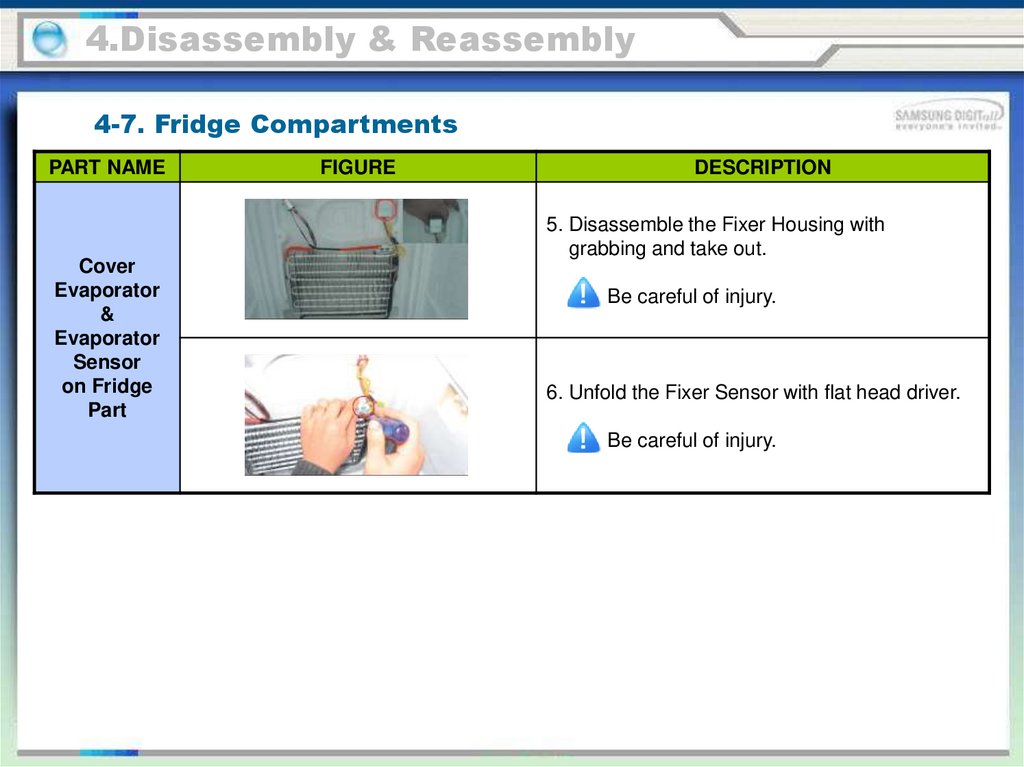

4.Disassembly & Reassembly4-7. Fridge Compartments

PART NAME

Cover

Evaporator

&

Evaporator

Sensor

on Fridge

Part

FIGURE

DESCRIPTION

5. Disassemble the Fixer Housing with

grabbing and take out.

Be careful of injury.

6. Unfold the Fixer Sensor with flat head driver.

Be careful of injury.

78.

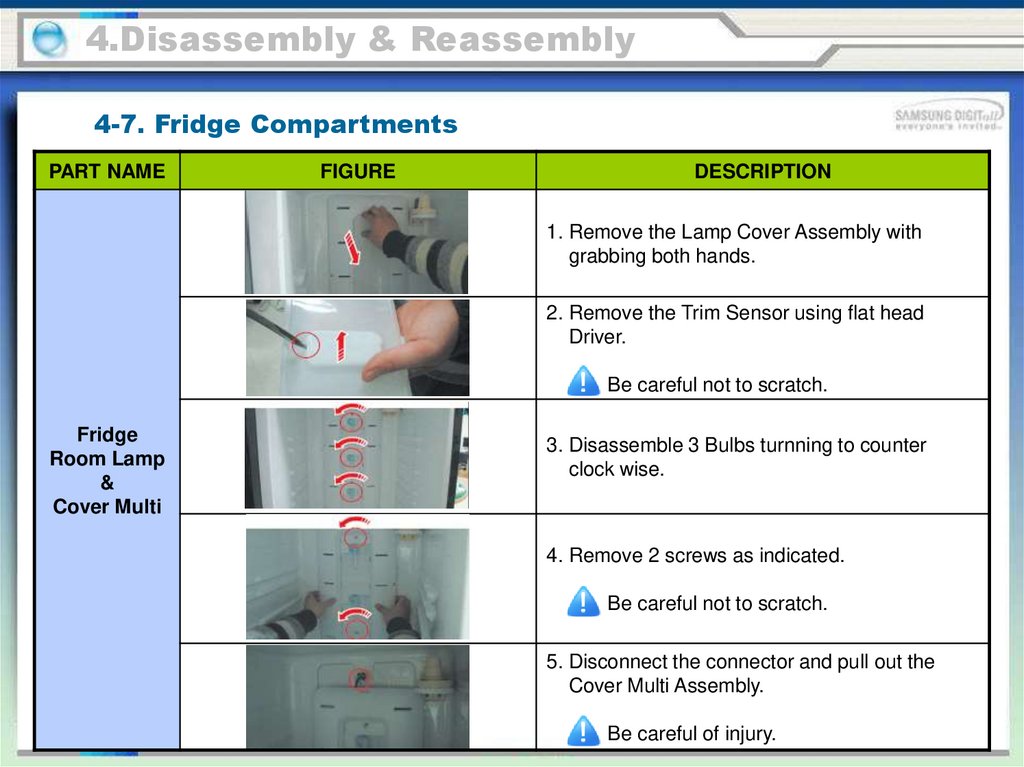

4.Disassembly & Reassembly4-7. Fridge Compartments

PART NAME

FIGURE

DESCRIPTION

1. Remove the Lamp Cover Assembly with

grabbing both hands.

2. Remove the Trim Sensor using flat head

Driver.

Be careful not to scratch.

Fridge

Room Lamp

&

Cover Multi

3. Disassemble 3 Bulbs turnning to counter

clock wise.

4. Remove 2 screws as indicated.

Be careful not to scratch.

5. Disconnect the connector and pull out the

Cover Multi Assembly.

Be careful of injury.

79.

4.Disassembly & Reassembly4-7. Fridge Compartments

PART NAME

Fridge

Shelves

Movable

Tray

Z Shelf

Water Filter

FIGURE

DESCRIPTION

These shelves allow the storage of larger items

and pull out for easy access.

Lift it up and pull the Shelves out to the front.

This Movable Shelf is designed for moving

with foods easily.

Lift it up and pull the Movable Shelf out to

the front.

This Z Shelf is designed for all kinds of wines

and bottles.

Lift it up and pull the Z Shelf out to the front.

Turn the Water Filter to the clock wise and

take out.

Be careful of injury.

80.

4.Disassembly & Reassembly4-7. Fridge Compartments

PART NAME

FIGURE

DESCRIPTION

Drawers are designed for storage of fruits,

vegetables, and deli items.The drawers are

located in the lower portion of the

refrigerator.

Fridge

Drawers

1. Pull out the drawer as far as it goes.

2. Tilt the drawer up and pull it out until it is

removed.

be careful not to damage the product.

81.

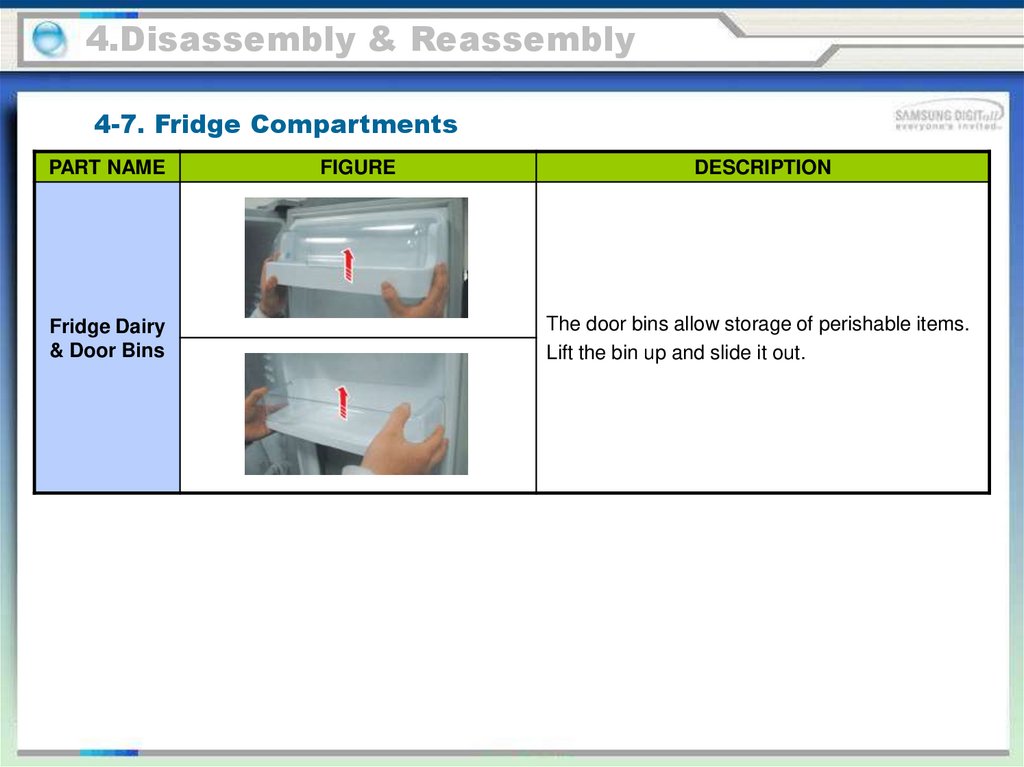

4.Disassembly & Reassembly4-7. Fridge Compartments

PART NAME

Fridge Dairy

& Door Bins

FIGURE

DESCRIPTION

The door bins allow storage of perishable items.

Lift the bin up and slide it out.

82.

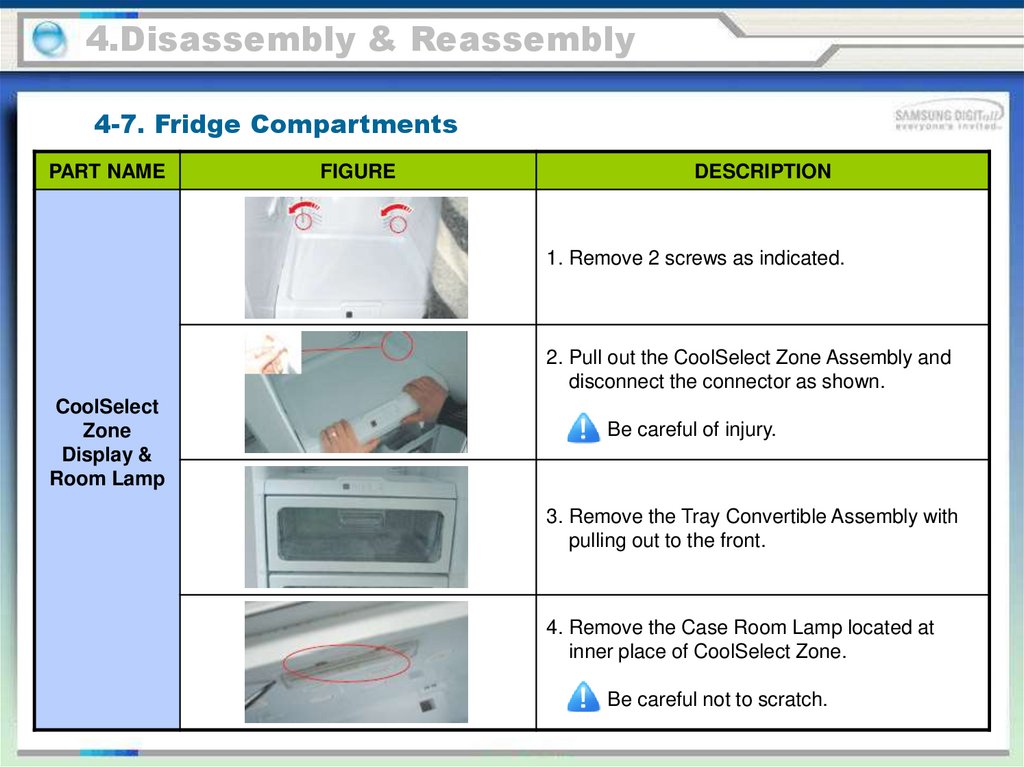

4.Disassembly & Reassembly4-7. Fridge Compartments

PART NAME

FIGURE

DESCRIPTION

1. Remove 2 screws as indicated.

2. Pull out the CoolSelect Zone Assembly and

disconnect the connector as shown.

CoolSelect

Zone

Display &

Room Lamp

Be careful of injury.

3. Remove the Tray Convertible Assembly with

pulling out to the front.

4. Remove the Case Room Lamp located at

inner place of CoolSelect Zone.

Be careful not to scratch.

83.

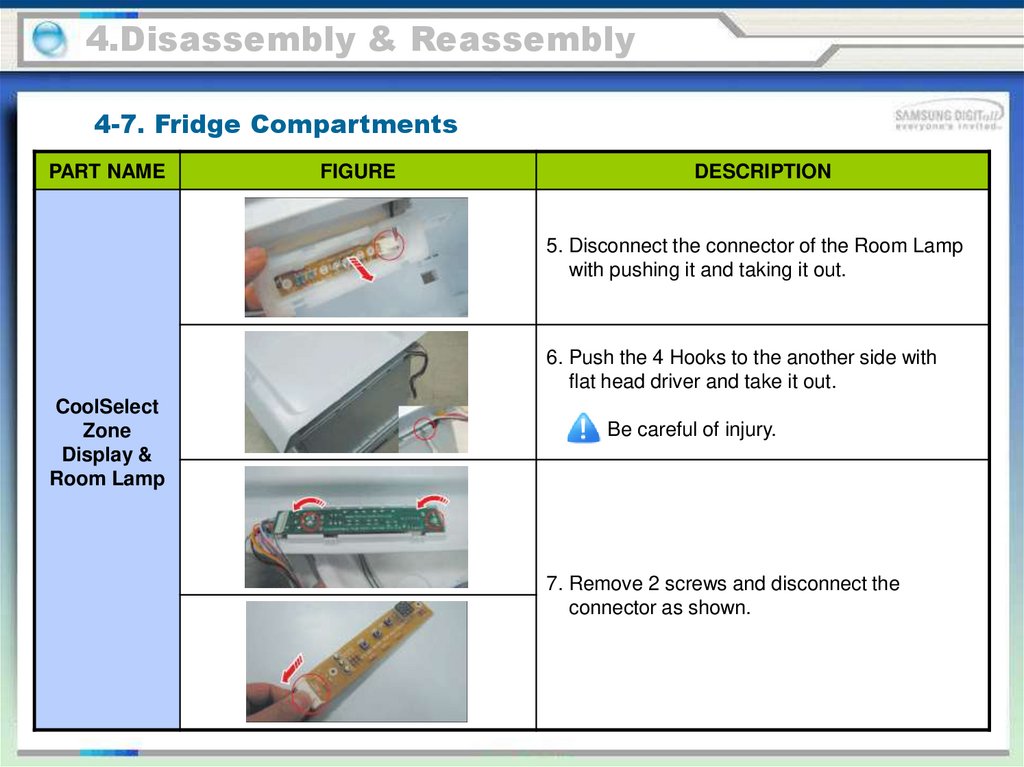

4.Disassembly & Reassembly4-7. Fridge Compartments

PART NAME

FIGURE

DESCRIPTION

5. Disconnect the connector of the Room Lamp

with pushing it and taking it out.

6. Push the 4 Hooks to the another side with

flat head driver and take it out.

CoolSelect

Zone

Display &

Room Lamp

Be careful of injury.

7. Remove 2 screws and disconnect the

connector as shown.

84.

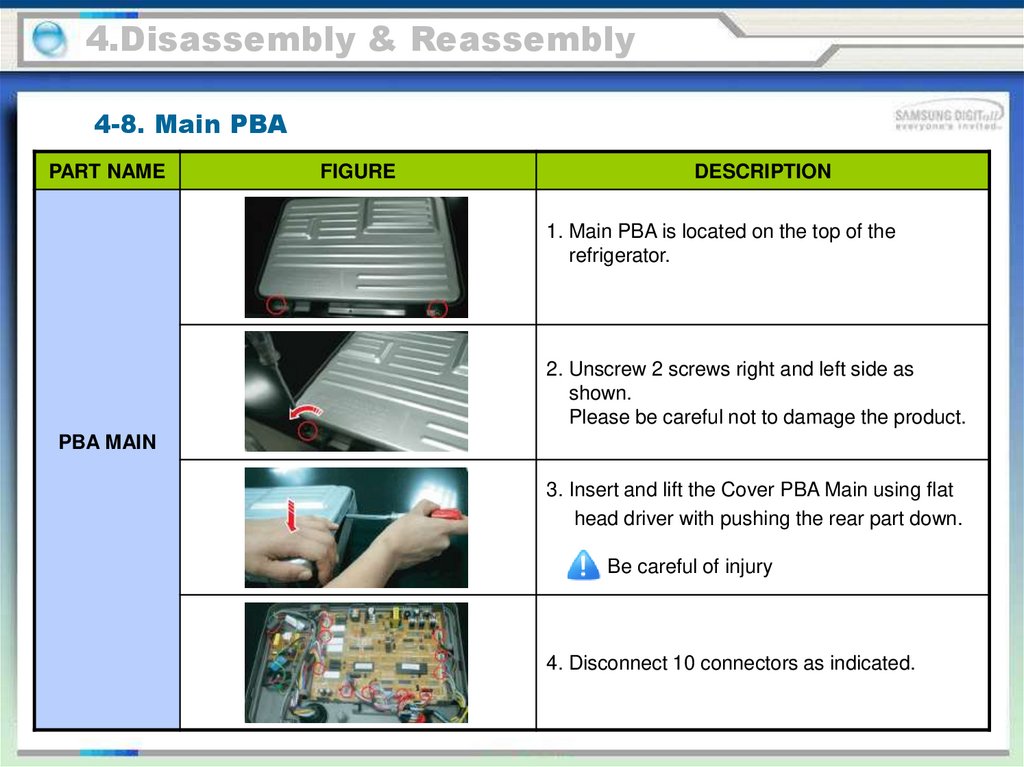

4.Disassembly & Reassembly4-8. Main PBA

PART NAME

FIGURE

DESCRIPTION

1. Main PBA is located on the top of the

refrigerator.

2. Unscrew 2 screws right and left side as

shown.

Please be careful not to damage the product.

PBA MAIN

3. Insert and lift the Cover PBA Main using flat

head driver with pushing the rear part down.

Be careful of injury

4. Disconnect 10 connectors as indicated.

85.

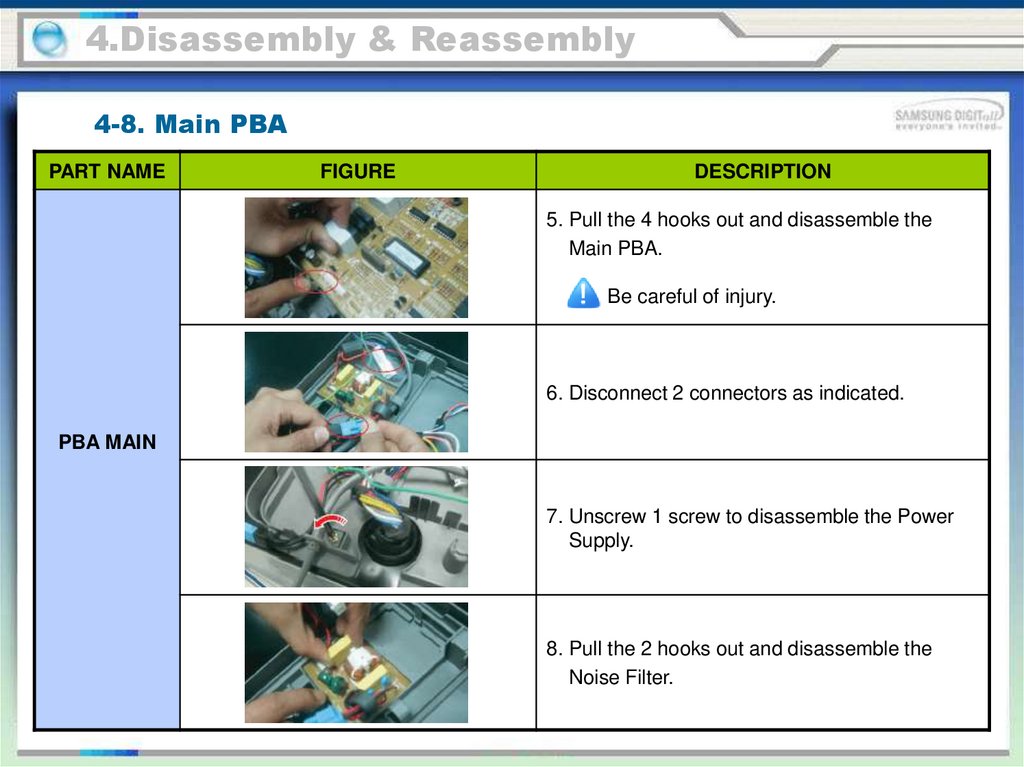

4.Disassembly & Reassembly4-8. Main PBA

PART NAME

FIGURE

DESCRIPTION

5. Pull the 4 hooks out and disassemble the

Main PBA.

Be careful of injury.

6. Disconnect 2 connectors as indicated.

PBA MAIN

7. Unscrew 1 screw to disassemble the Power

Supply.

8. Pull the 2 hooks out and disassemble the

Noise Filter.

86.

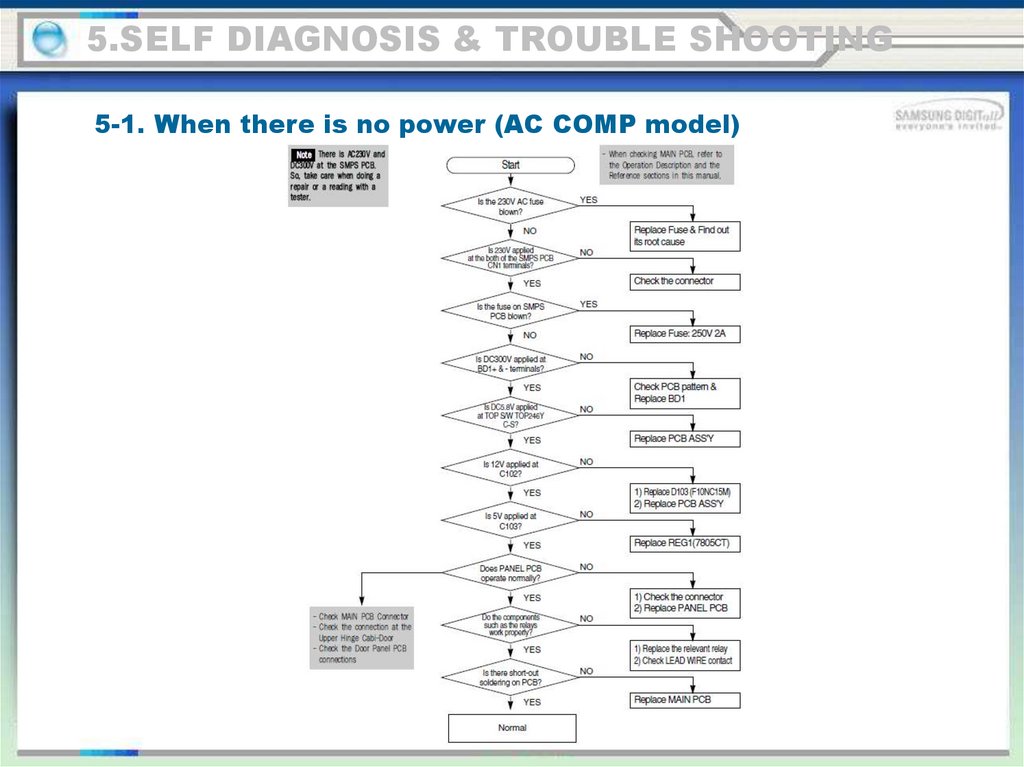

5.SELF DIAGNOSIS & TROUBLE SHOOTING5-1. When there is no power (AC COMP model)

87.

5.SELF DIAGNOSIS & TROUBLE SHOOTING5-1. When there is no power (INVERTER COMP model)

88.

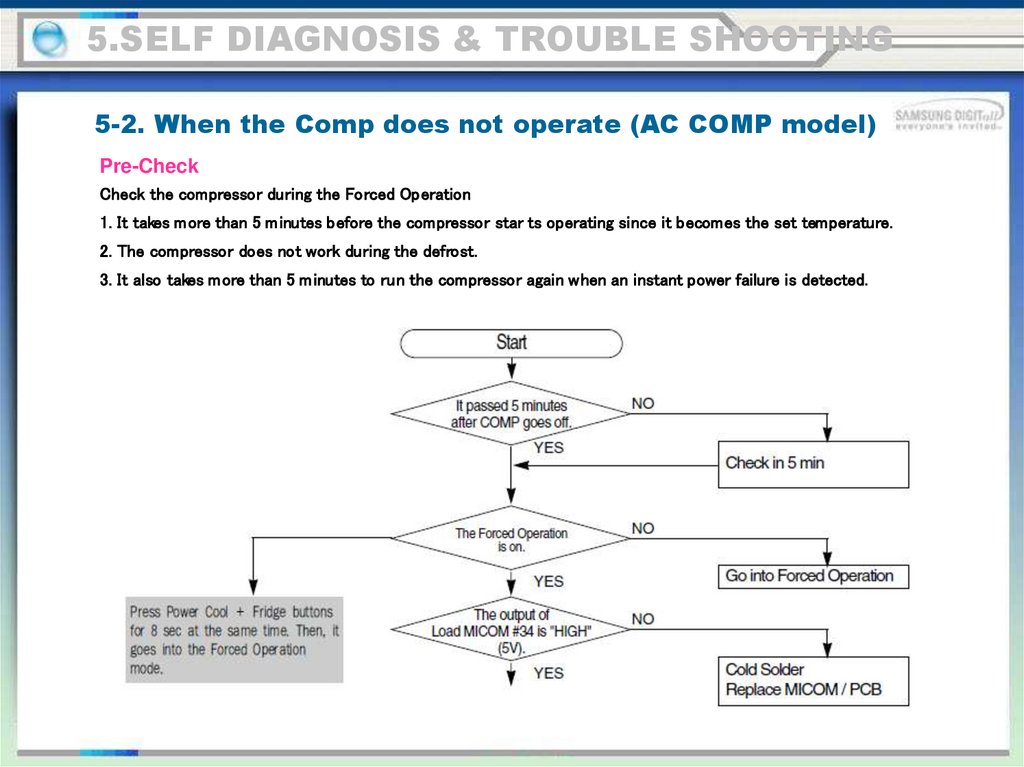

5.SELF DIAGNOSIS & TROUBLE SHOOTING5-2. When the Comp does not operate (AC COMP model)

Pre-Check

Check the compressor during the Forced Operation

1. It takes more than 5 m inutes before the compressor star ts operating since it becomes the set temperature.

2. The compressor does not work during the defrost.

3. It also takes more than 5 m inutes to run the compressor again when an instant power failure is detected.

89.

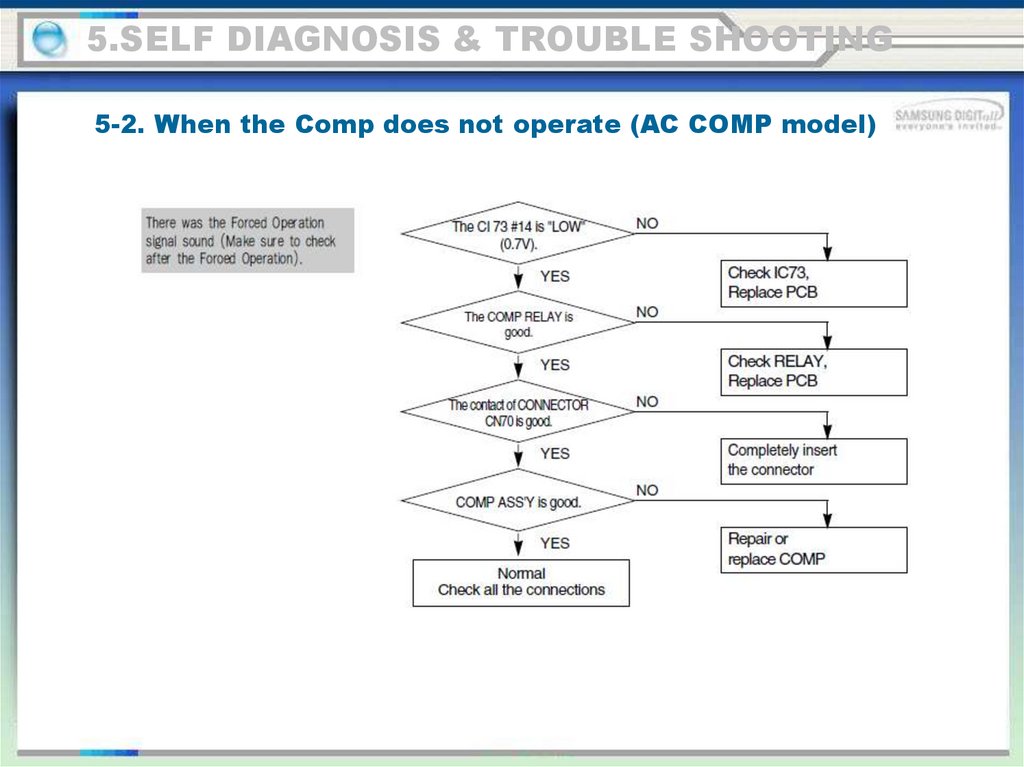

5.SELF DIAGNOSIS & TROUBLE SHOOTING5-2. When the Comp does not operate (AC COMP model)

90.

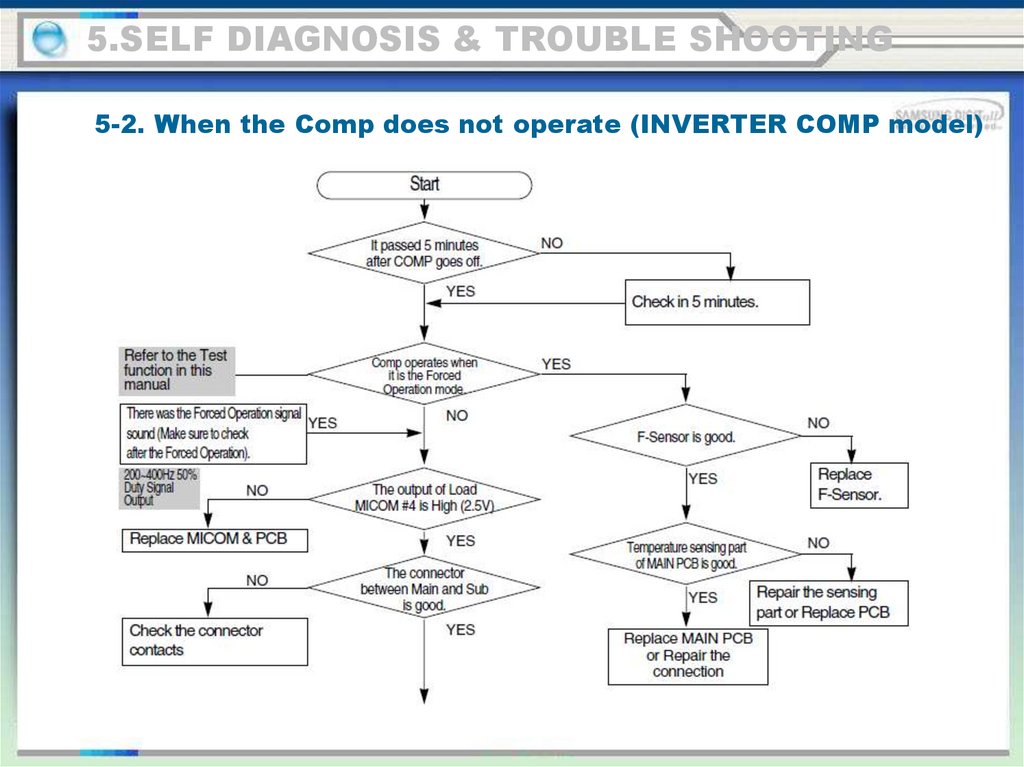

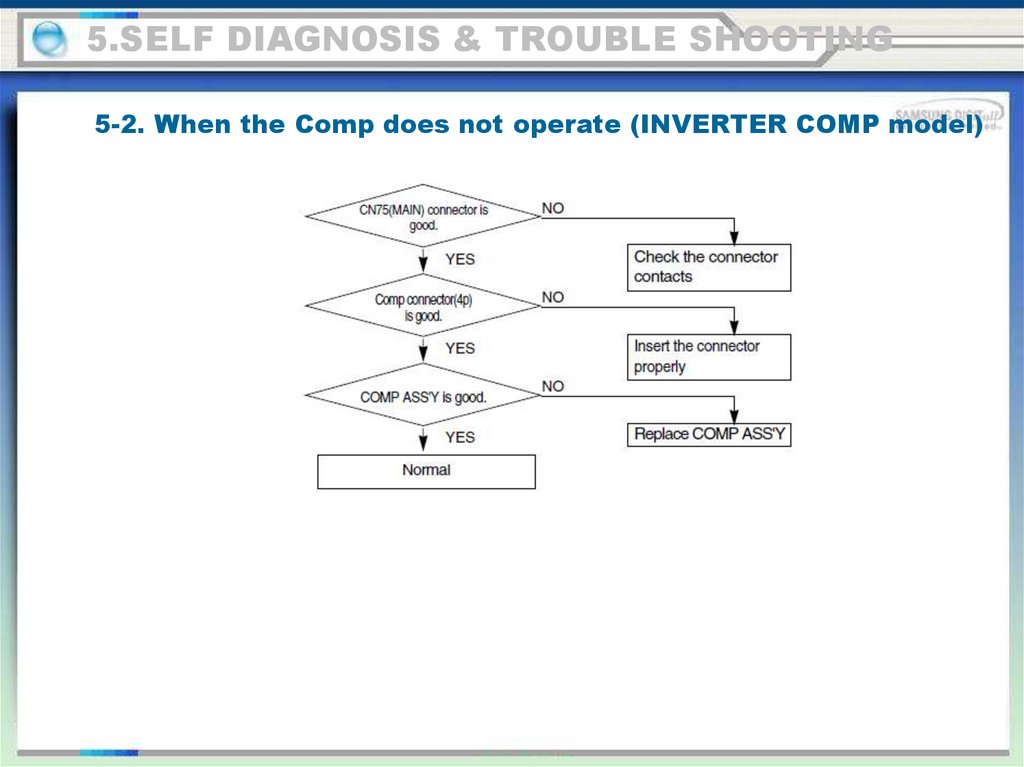

5.SELF DIAGNOSIS & TROUBLE SHOOTING5-2. When the Comp does not operate (INVERTER COMP model)

91.

5.SELF DIAGNOSIS & TROUBLE SHOOTING5-2. When the Comp does not operate (INVERTER COMP model)

92.

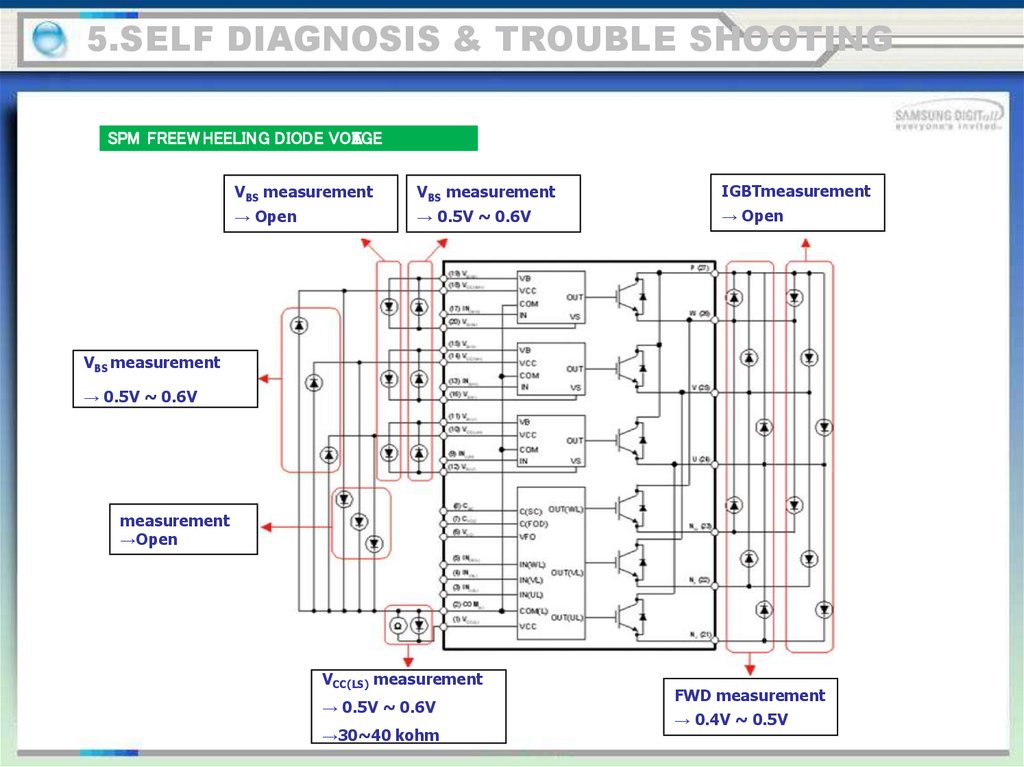

5.SELF DIAGNOSIS & TROUBLE SHOOTINGSPM FREEW HEELING DIODE VOL

A

TGE

VBS measurement

VBS measurement

IGBTmeasurement

→ Open

→ 0.5V ~ 0.6V

→ Open

VBS measurement

→ 0.5V ~ 0.6V

measurement

→Open

VCC(LS) measurement

→ 0.5V ~ 0.6V

→30~40 kohm

FWD measurement

→ 0.4V ~ 0.5V

93.

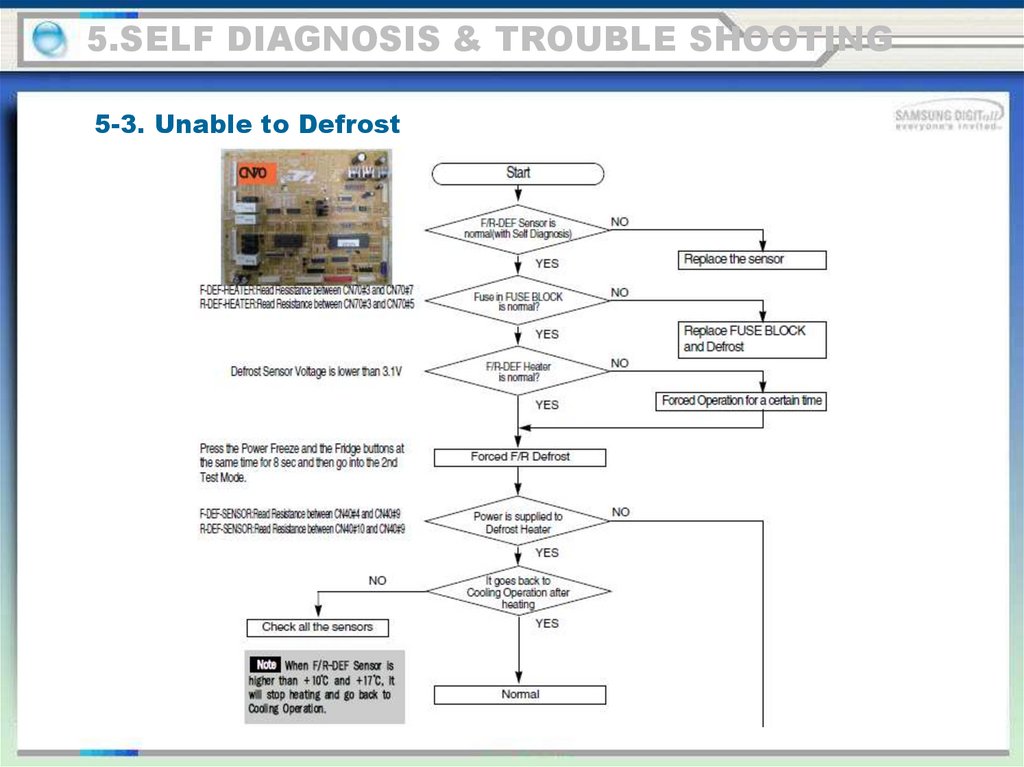

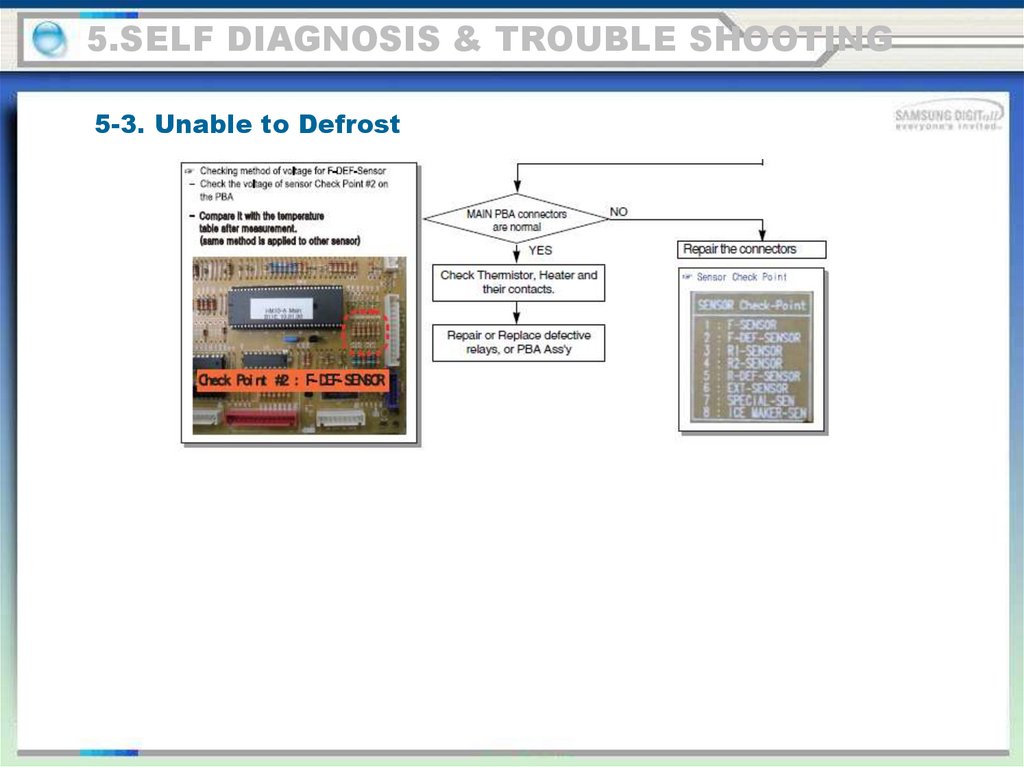

5.SELF DIAGNOSIS & TROUBLE SHOOTING5-3. Unable to Defrost

94.

5.SELF DIAGNOSIS & TROUBLE SHOOTING5-3. Unable to Defrost

95.

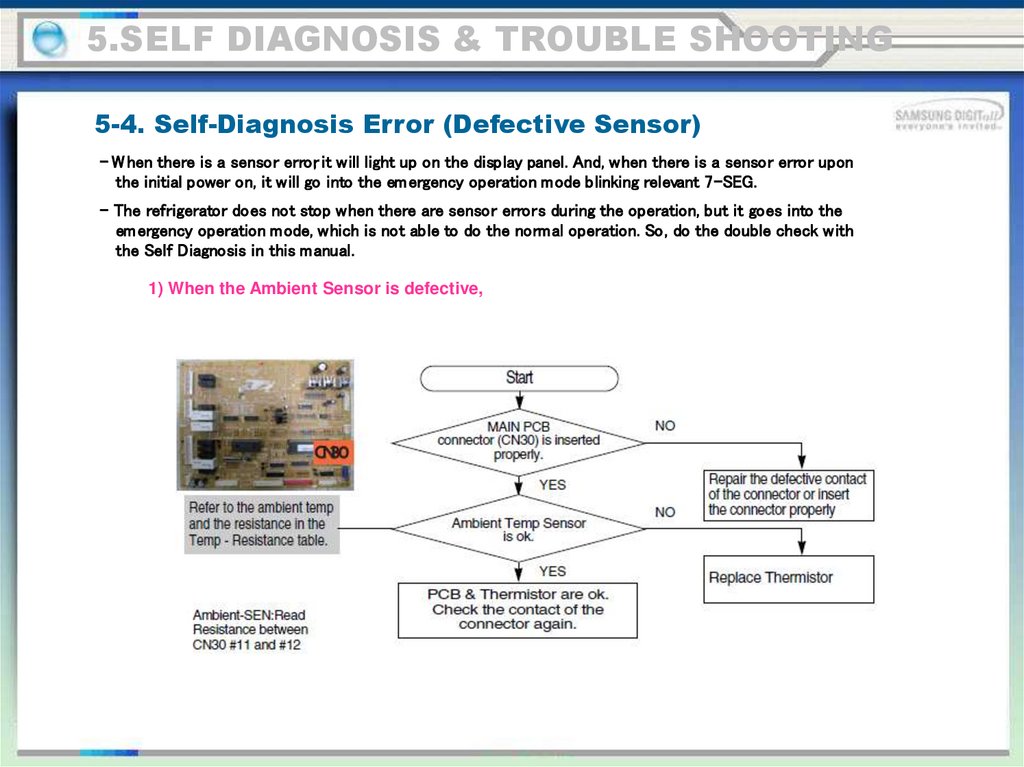

5.SELF DIAGNOSIS & TROUBLE SHOOTING5-4. Self-Diagnosis Error (Defective Sensor)

- W hen there is a sensor error, it will light up on the display panel. And, when there is a sensor error upon

the initial power on, it will go into the em ergency operation mode blinking relevant 7-SEG.

- The refrigerator does not stop when there are sensor errors during the operation, but it goes into the

em ergency operation mode, which is not able to do the normal operation. So, do the double check with

the Self Diagnosis in this manual.

1) When the Ambient Sensor is defective,

96.

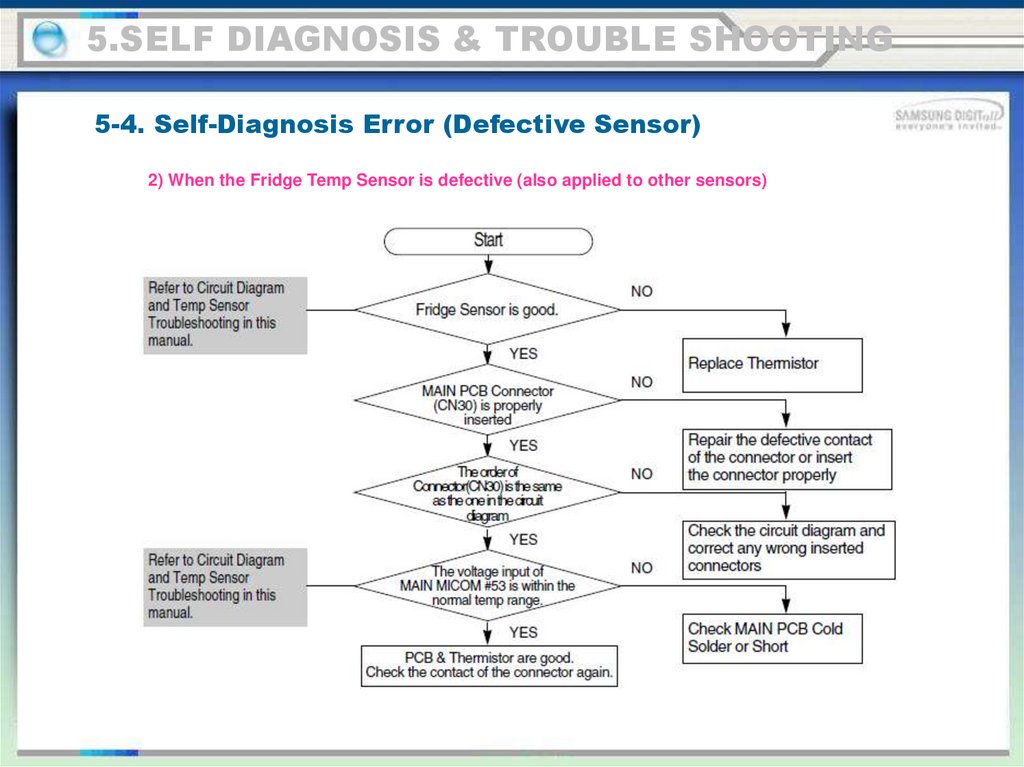

5.SELF DIAGNOSIS & TROUBLE SHOOTING5-4. Self-Diagnosis Error (Defective Sensor)

2) When the Fridge Temp Sensor is defective (also applied to other sensors)

97.

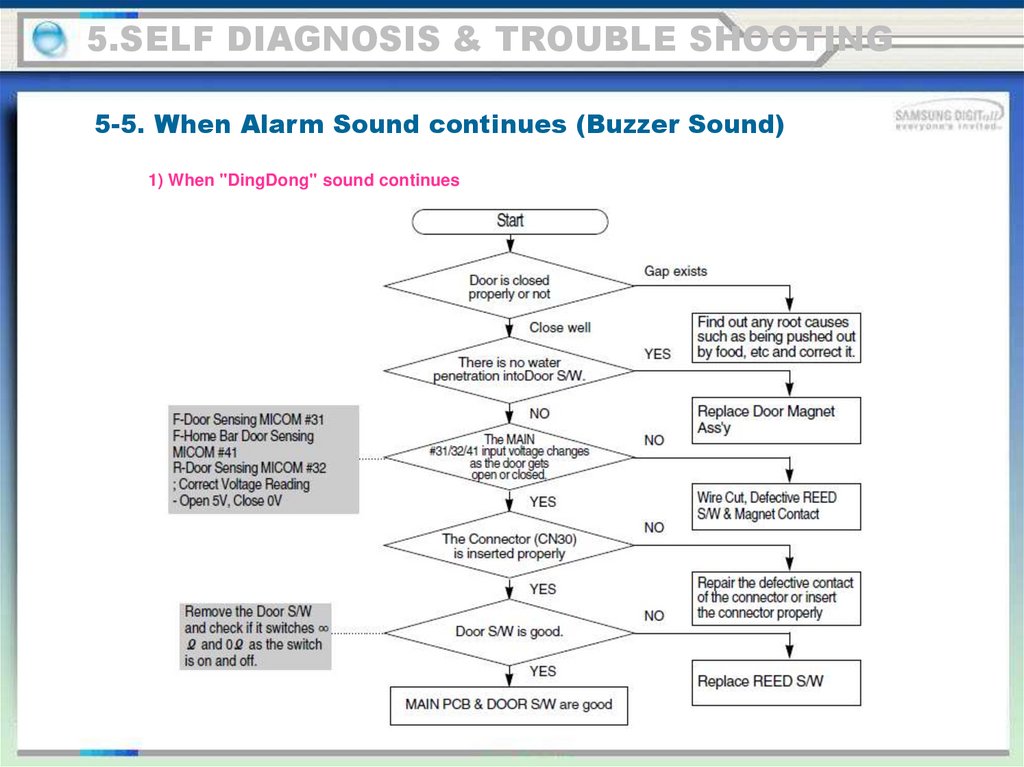

5.SELF DIAGNOSIS & TROUBLE SHOOTING5-5. When Alarm Sound continues (Buzzer Sound)

1) When "DingDong" sound continues

98.

5.SELF DIAGNOSIS & TROUBLE SHOOTING5-5. When Alarm Sound continues (Buzzer Sound)

2) When "Beeping" sounds continue

99.

5.SELF DIAGNOSIS & TROUBLE SHOOTING5-5. When Alarm Sound continues (Buzzer Sound)

3) No Buzzer Sound

This model has a buzzer affixed on the M AIN PCB.

If there is no buzzer sound upon button press, Forced Operation or Door Open, disconnect M AIN PCB and check if

the buzzer is damaged or there is any defective soldering.

(If it is not a soldering problem, it is recommended replacing M AIN PCB due to difficulties in repairing)

※ It may not be able to check when it is a closed built-in environment and there is lots of noise around.

100.

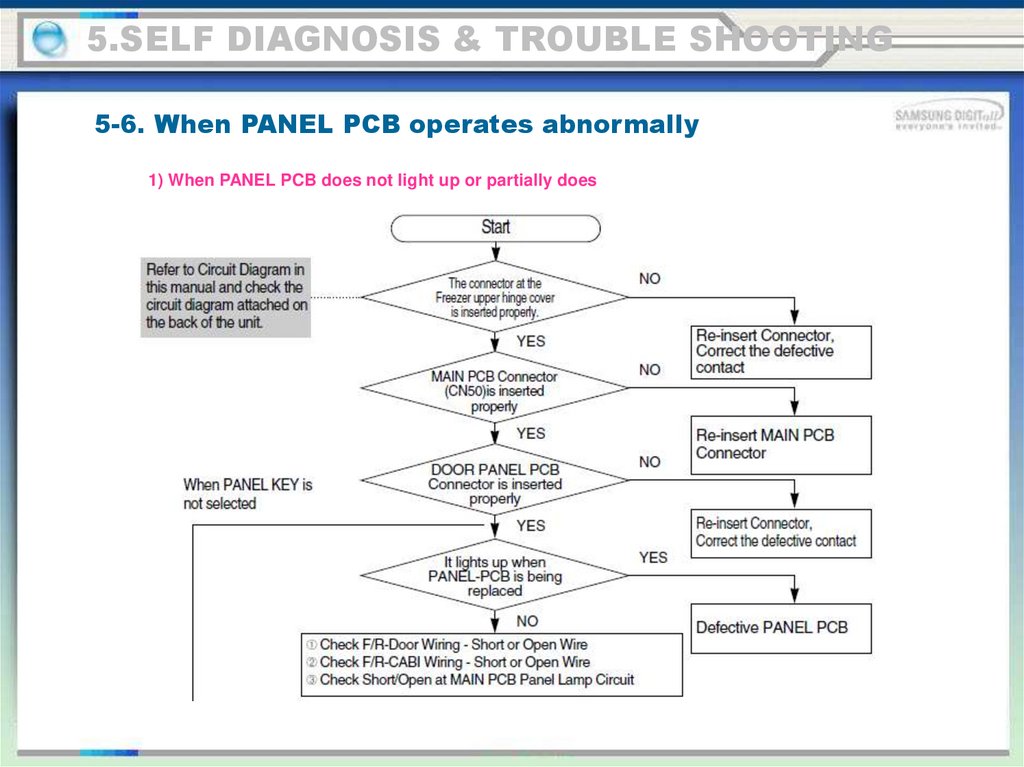

5.SELF DIAGNOSIS & TROUBLE SHOOTING5-6. When PANEL PCB operates abnormally

1) When PANEL PCB does not light up or partially does

101.

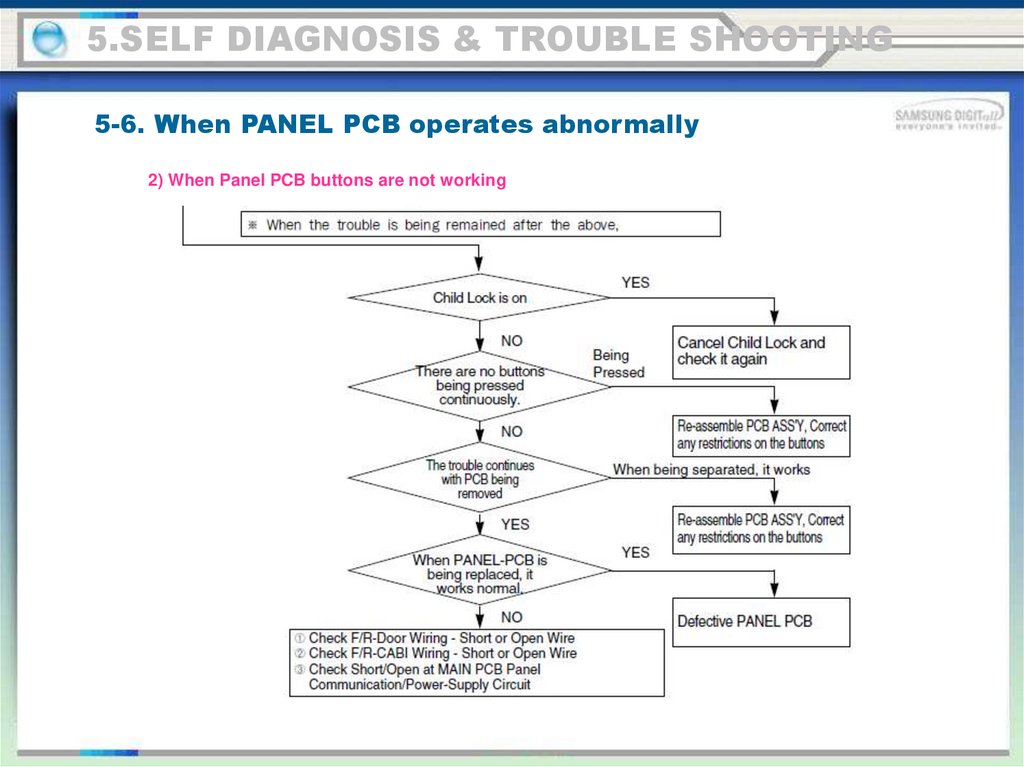

5.SELF DIAGNOSIS & TROUBLE SHOOTING5-6. When PANEL PCB operates abnormally

2) When Panel PCB buttons are not working

102.

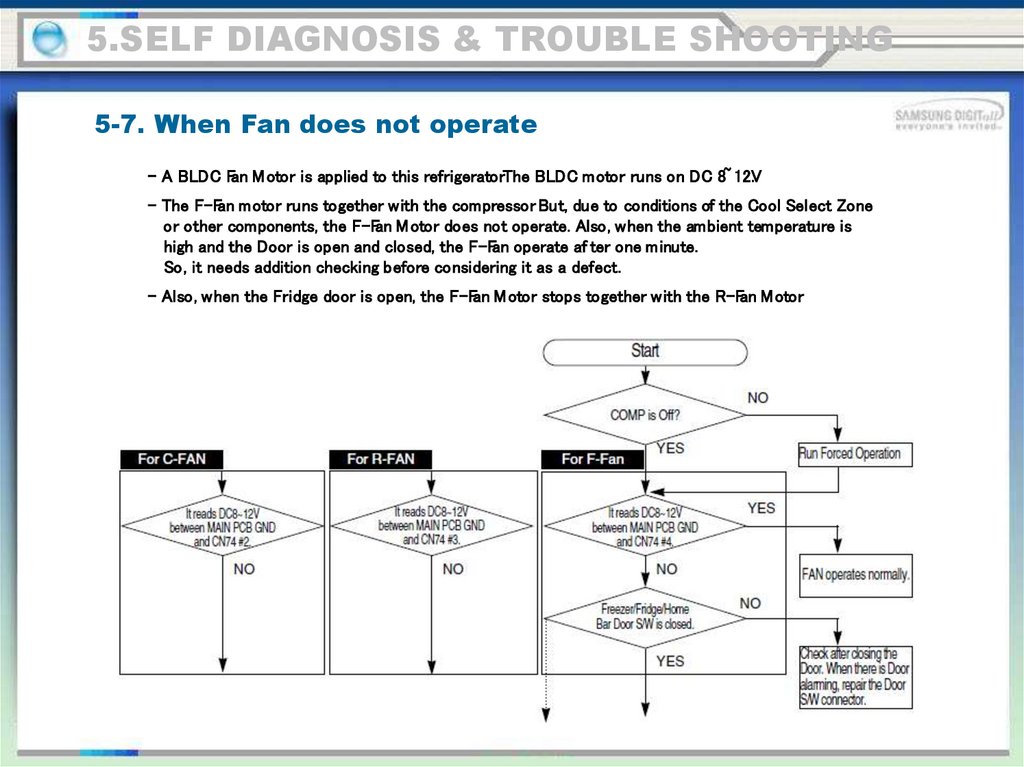

5.SELF DIAGNOSIS & TROUBLE SHOOTING5-7. When Fan does not operate

- A BLDC Fan M otor is applied to this refrigerator.The BLDC motor runs on DC 8~ 12V

.

- The F-Fan motor runs together with the compressor. But, due to conditions of the Cool Select Zone

or other components, the F-Fan M otor does not operate. Also, when the ambient temperature is

high and the Door is open and closed, the F-Fan operate af ter one minute.

So, it needs addition checking before considering it as a defect.

- Also, when the Fridge door is open, the F-Fan M otor stops together with the R-Fan M otor.

103.

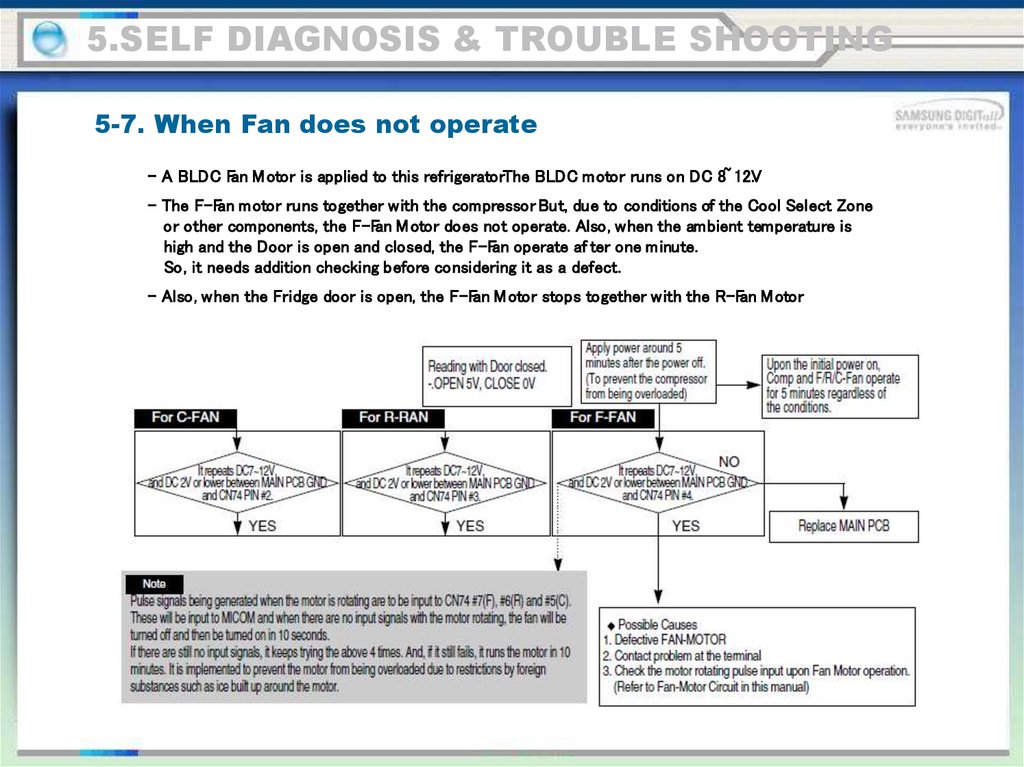

5.SELF DIAGNOSIS & TROUBLE SHOOTING5-7. When Fan does not operate

- A BLDC Fan M otor is applied to this refrigerator.The BLDC motor runs on DC 8~ 12V

.

- The F-Fan motor runs together with the compressor. But, due to conditions of the Cool Select Zone

or other components, the F-Fan M otor does not operate. Also, when the ambient temperature is

high and the Door is open and closed, the F-Fan operate af ter one minute.

So, it needs addition checking before considering it as a defect.

- Also, when the Fridge door is open, the F-Fan M otor stops together with the R-Fan M otor.

104.

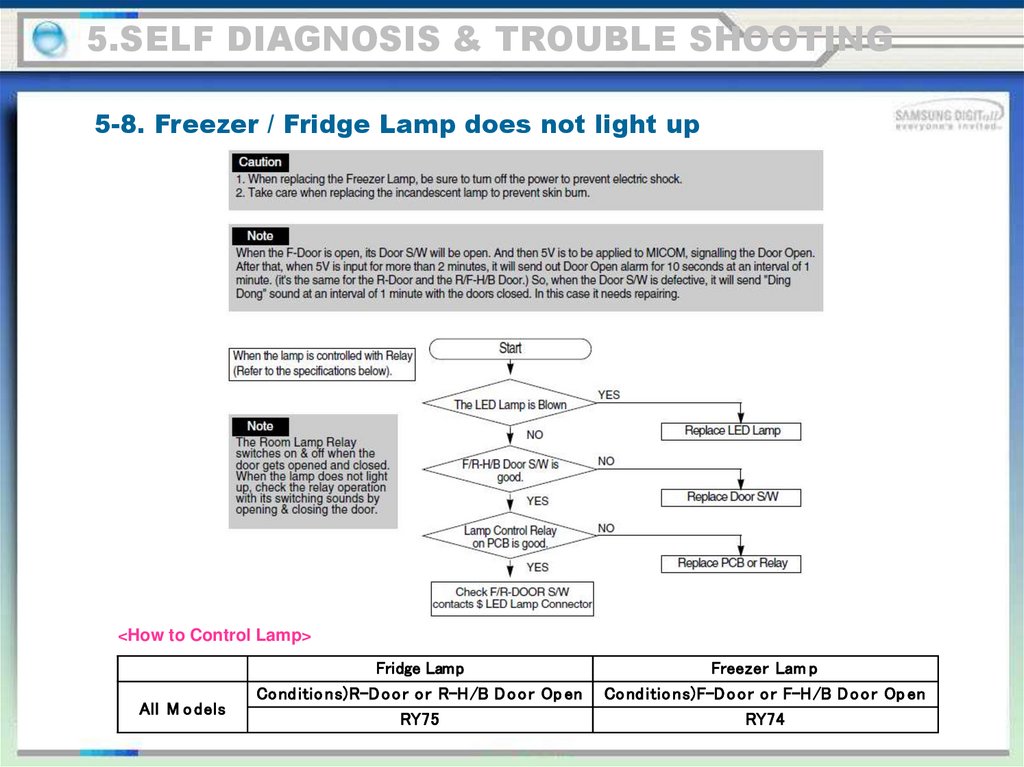

5.SELF DIAGNOSIS & TROUBLE SHOOTING5-8. Freezer / Fridge Lamp does not light up

<How to Control Lamp>

All M o dels

Fridge Lamp

Co nd itio ns)R-D o o r o r R-H/B D o o r Op en

RY75

Freezer Lam p

Co nd itio ns)F-D o o r o r F-H/B D o o r Op en

RY74

105.

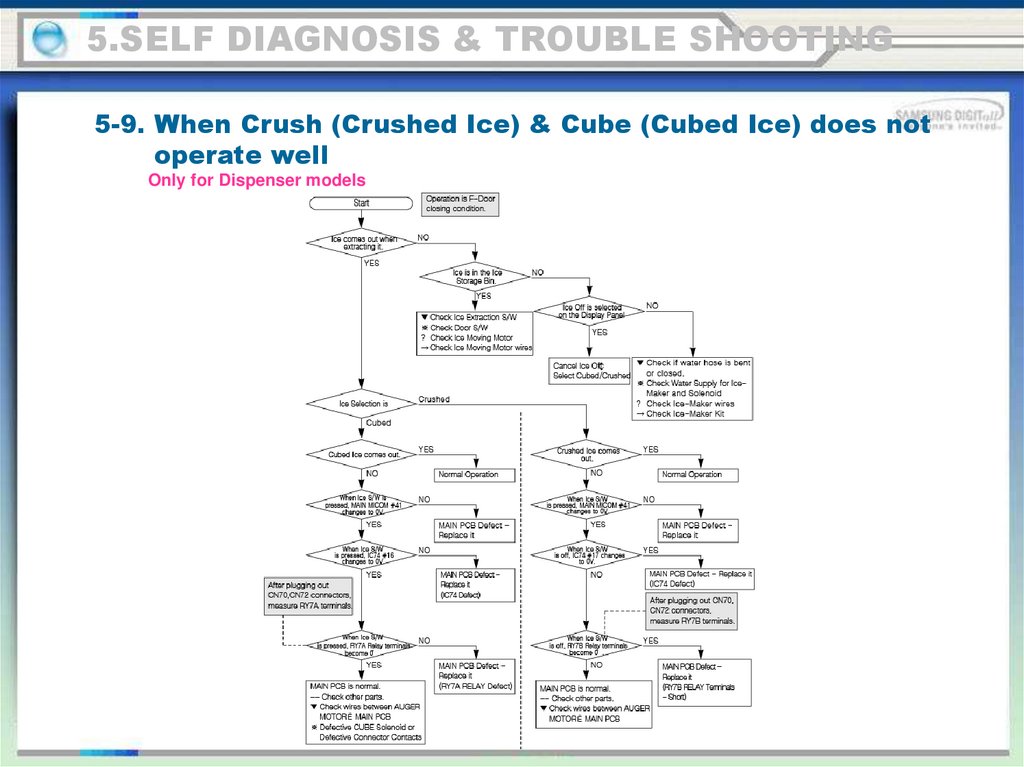

5.SELF DIAGNOSIS & TROUBLE SHOOTING5-9. When Crush (Crushed Ice) & Cube (Cubed Ice) does not

operate well

Only for Dispenser models

106.

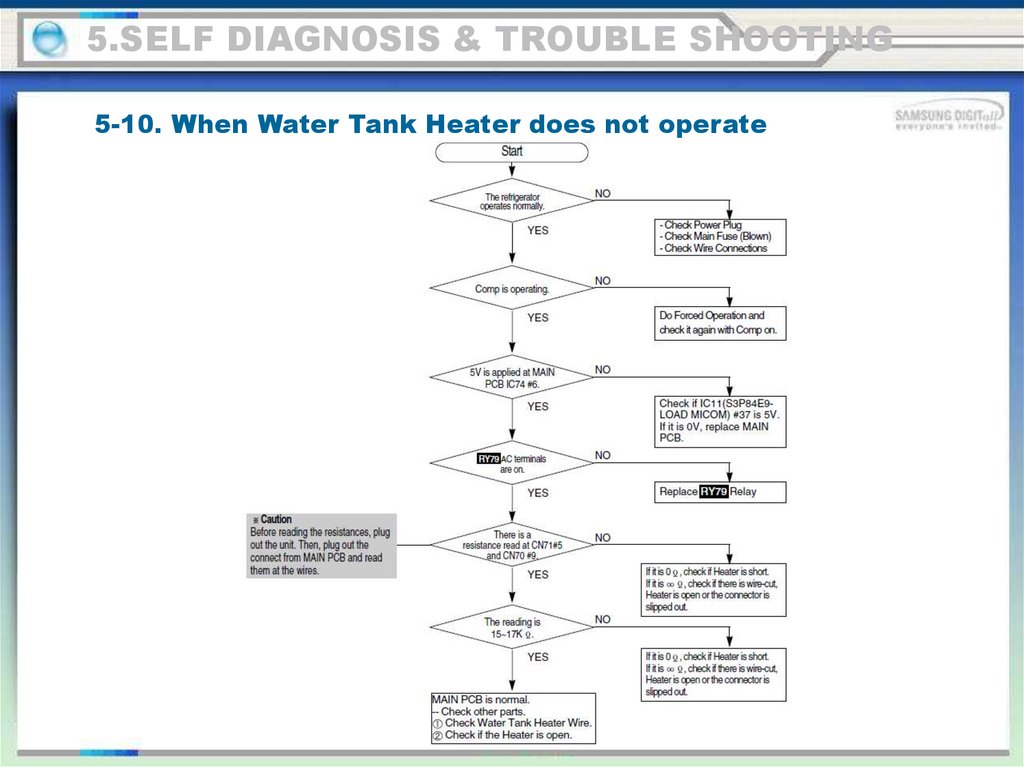

5.SELF DIAGNOSIS & TROUBLE SHOOTING5-10. When Water Tank Heater does not operate

107.

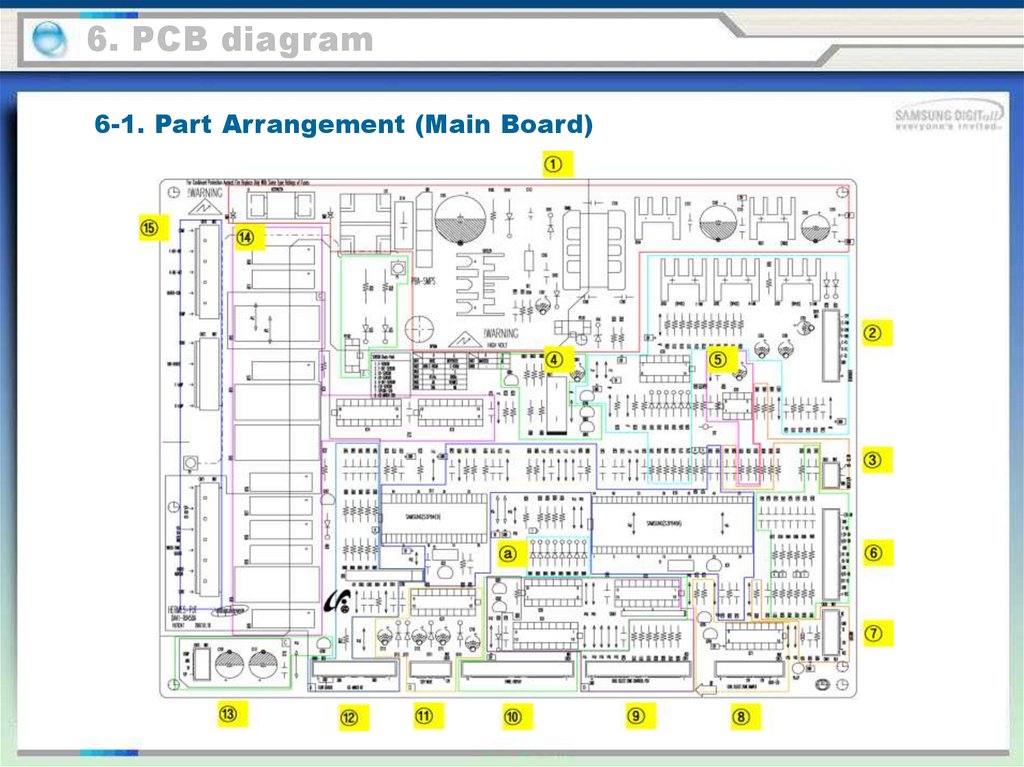

6. PCB diagram6-1. Part Arrangement (Main Board)

108.

6. PCB diagram6-1. Part Arrangement (Main Board)

1. SMPS Circuit: With input AC voltage, it outputs DC12V and 5V.

2. It supplies 8.3V~10V to Deodorizer & Fan Motors.

3. Dispenser Ice & Water (Freezer Home Bar) S/W

4. Buzzer

5. EEPROM : Data Storing

6. Receives various sensor voltages and door operation signals, and filter their noises.

Then, send them to MICOM.

7. PLC Circuit (PLC Input/Output) - PLC (Power Line communication)

8. Cool Select Zone Damper and its Heater/LED

9. Cool Select Zone Display Driver :LED Display, Button Signalling

10. Display Control (MAIN ➝ PANEL PCB)

11. Step-Valve Control (3-Way Valve)

12. Ice-Maker Kit Control

13. PCB & Inverter Comp Driver: DC12V, 5V and GND are input (Applied to Inverter Model).

14. AC Load Control Relay - It operates with Micom driving signals being receipt through Sink IC.

15. AC Load Connector

a. Diode Option Setting

109.

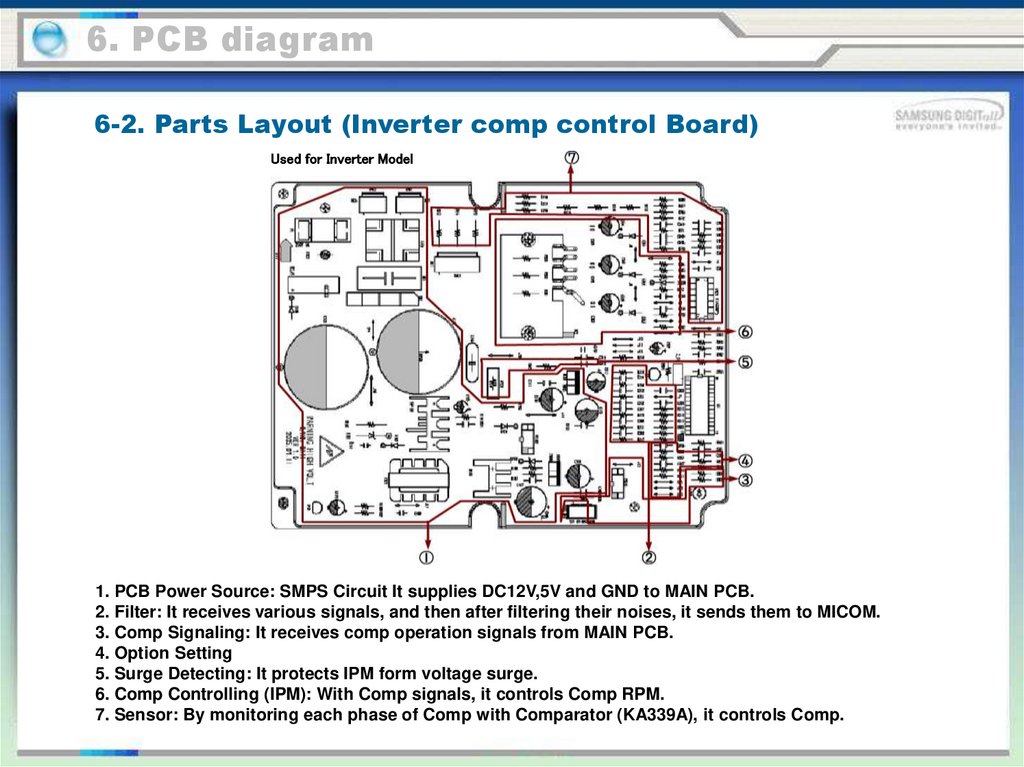

6. PCB diagram6-2. Parts Layout (Inverter comp control Board)

Used for Inverter Model

1. PCB Power Source: SMPS Circuit It supplies DC12V,5V and GND to MAIN PCB.

2. Filter: It receives various signals, and then after filtering their noises, it sends them to MICOM.

3. Comp Signaling: It receives comp operation signals from MAIN PCB.

4. Option Setting

5. Surge Detecting: It protects IPM form voltage surge.

6. Comp Controlling (IPM): With Comp signals, it controls Comp RPM.

7. Sensor: By monitoring each phase of Comp with Comparator (KA339A), it controls Comp.

110.

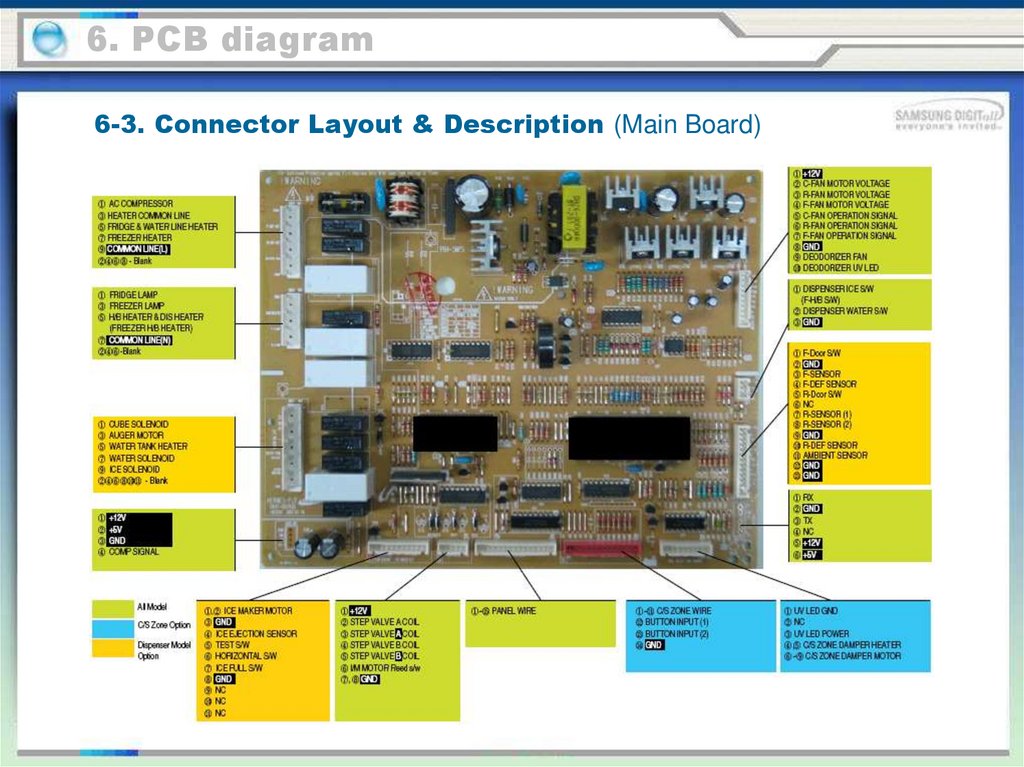

6. PCB diagram6-3. Connector Layout & Description (Main Board)

111.

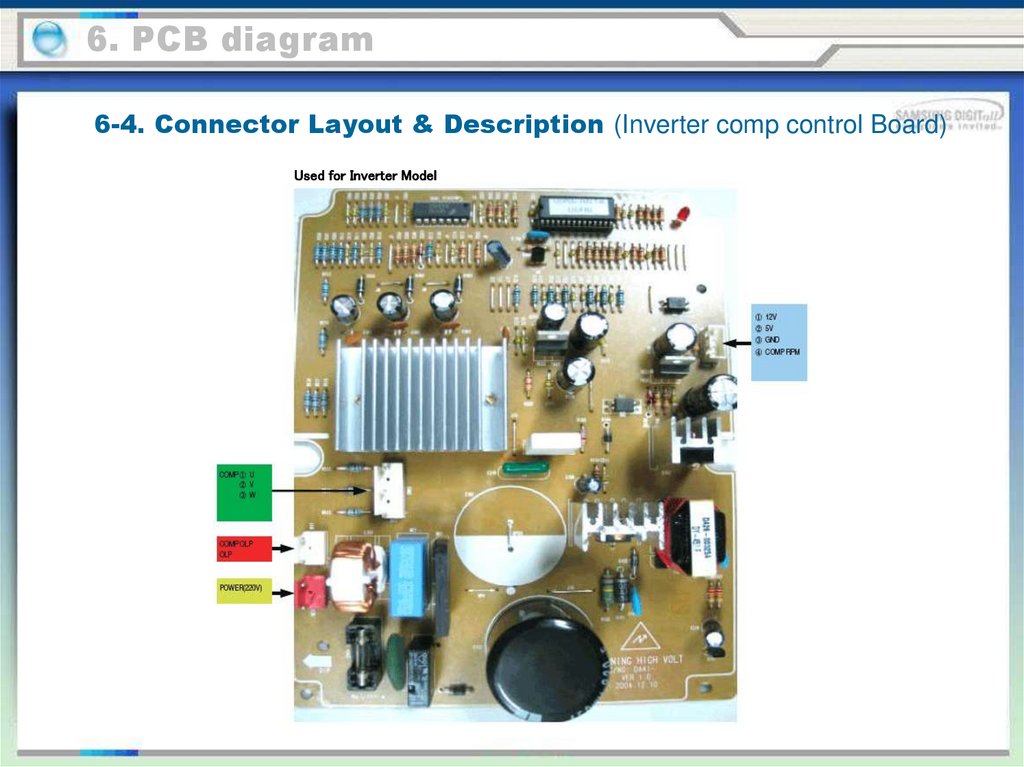

6. PCB diagram6-4. Connector Layout & Description (Inverter comp control Board)

Used for Inverter Model

112.

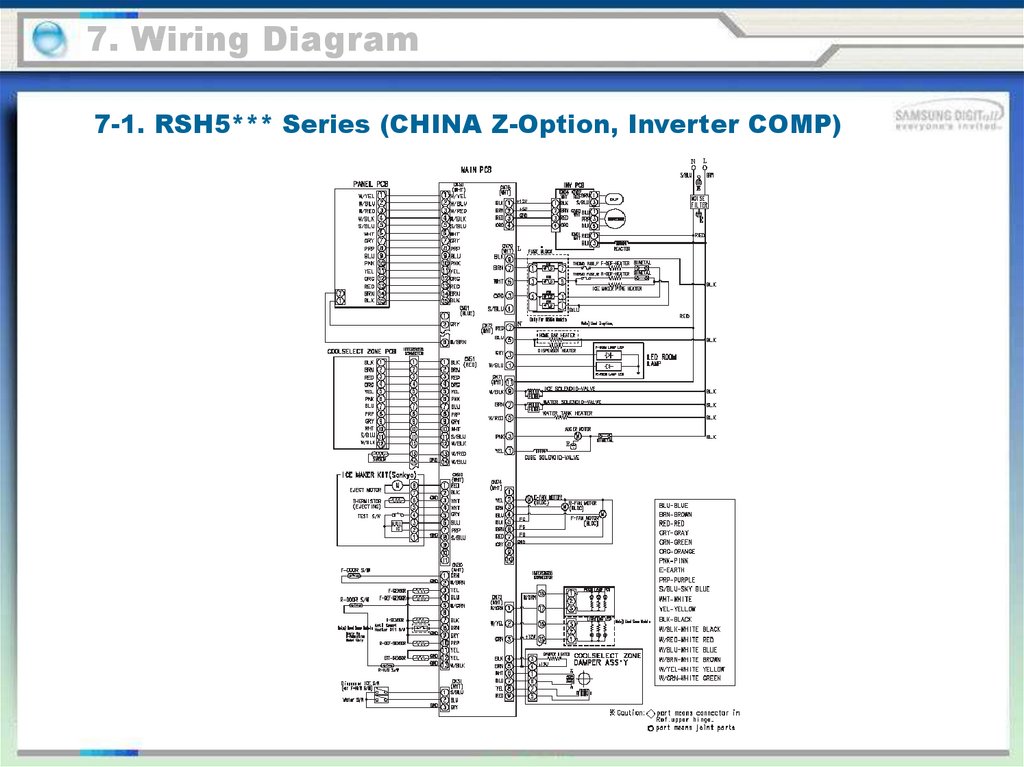

7. Wiring Diagram7-1. RSH5*** Series (CHINA Z-Option, Inverter COMP)

113.

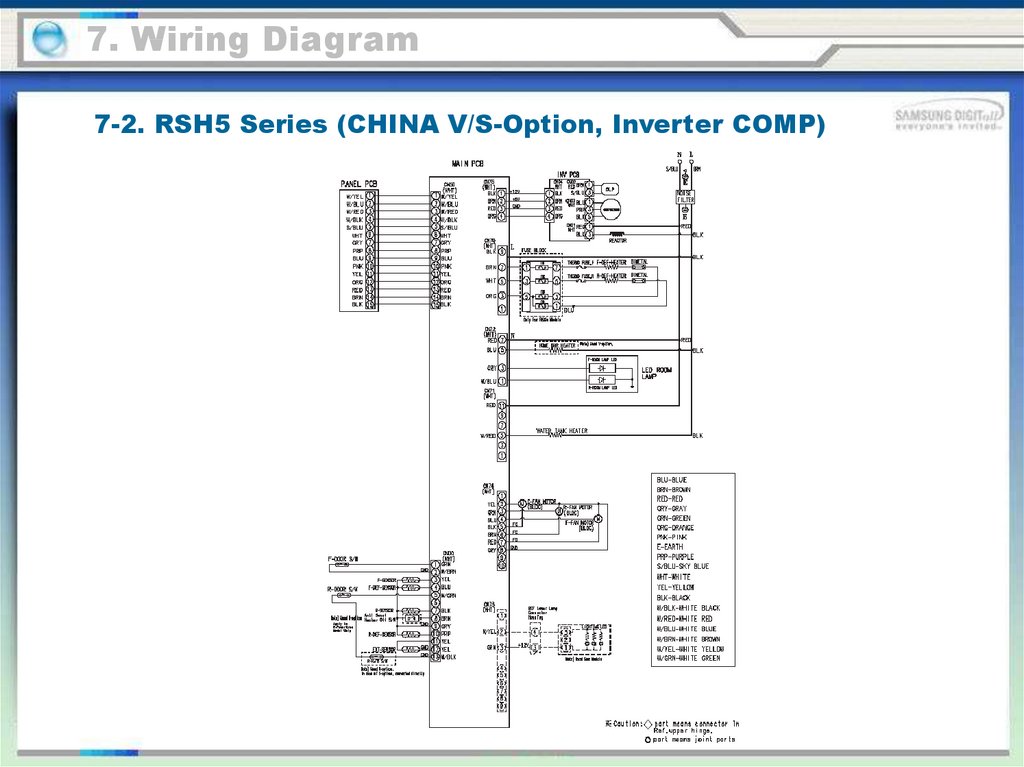

7. Wiring Diagram7-2. RSH5 Series (CHINA V/S-Option, Inverter COMP)

114.

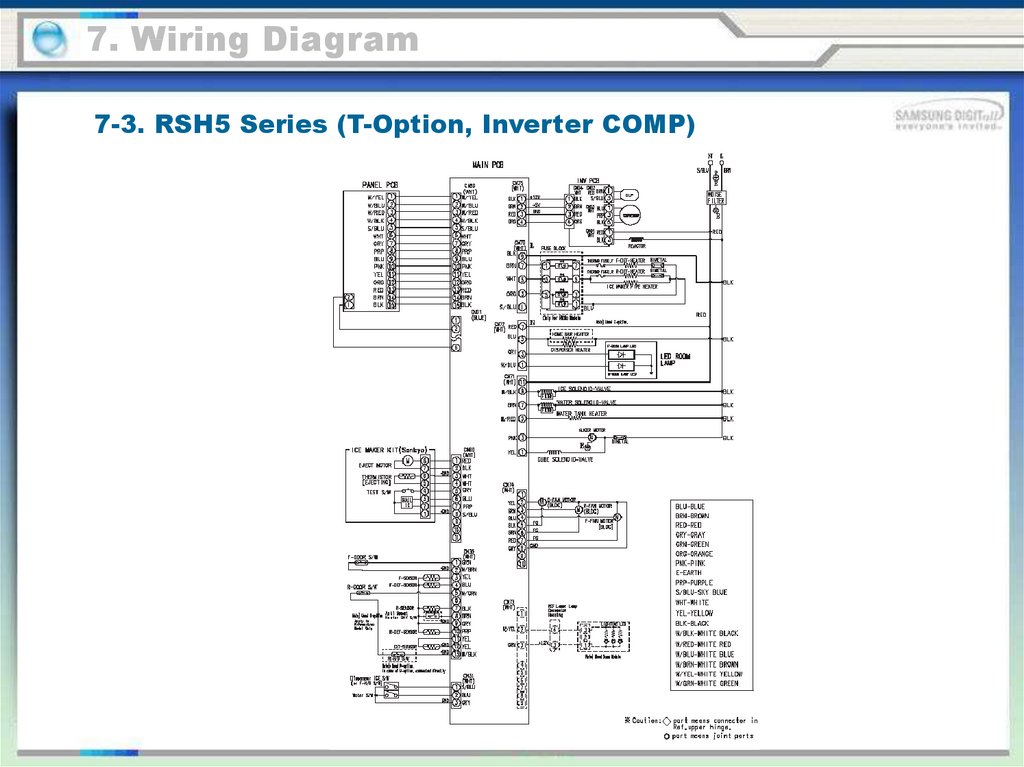

7. Wiring Diagram7-3. RSH5 Series (T-Option, Inverter COMP)

115.

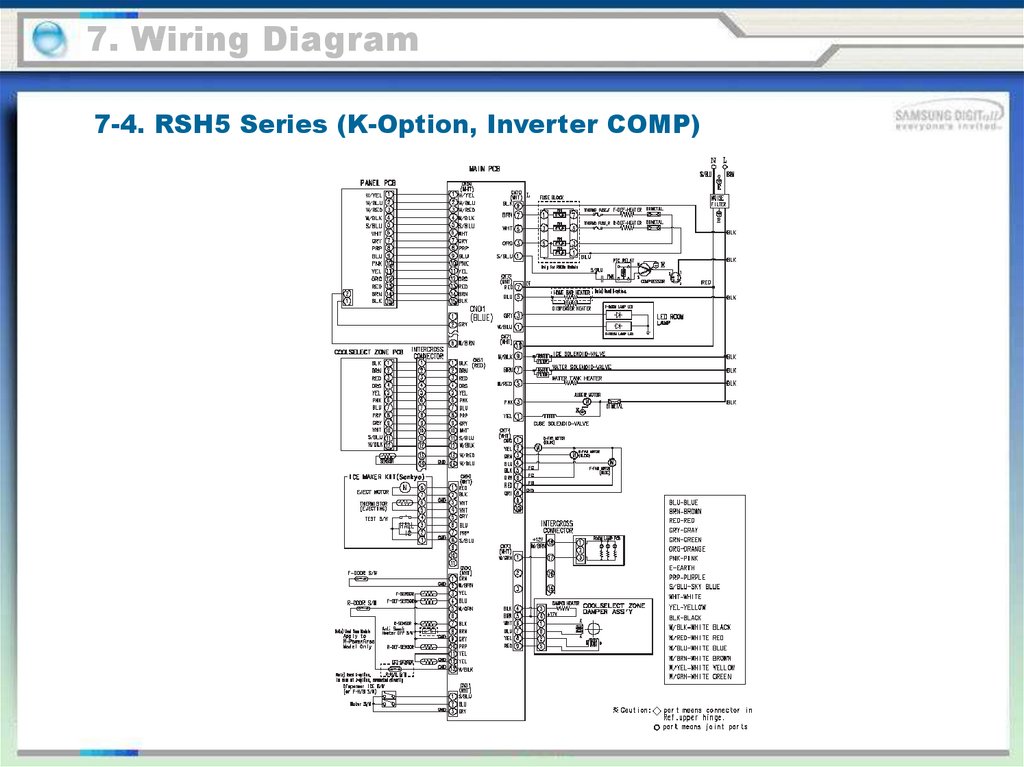

7. Wiring Diagram7-4. RSH5 Series (K-Option, Inverter COMP)

116.

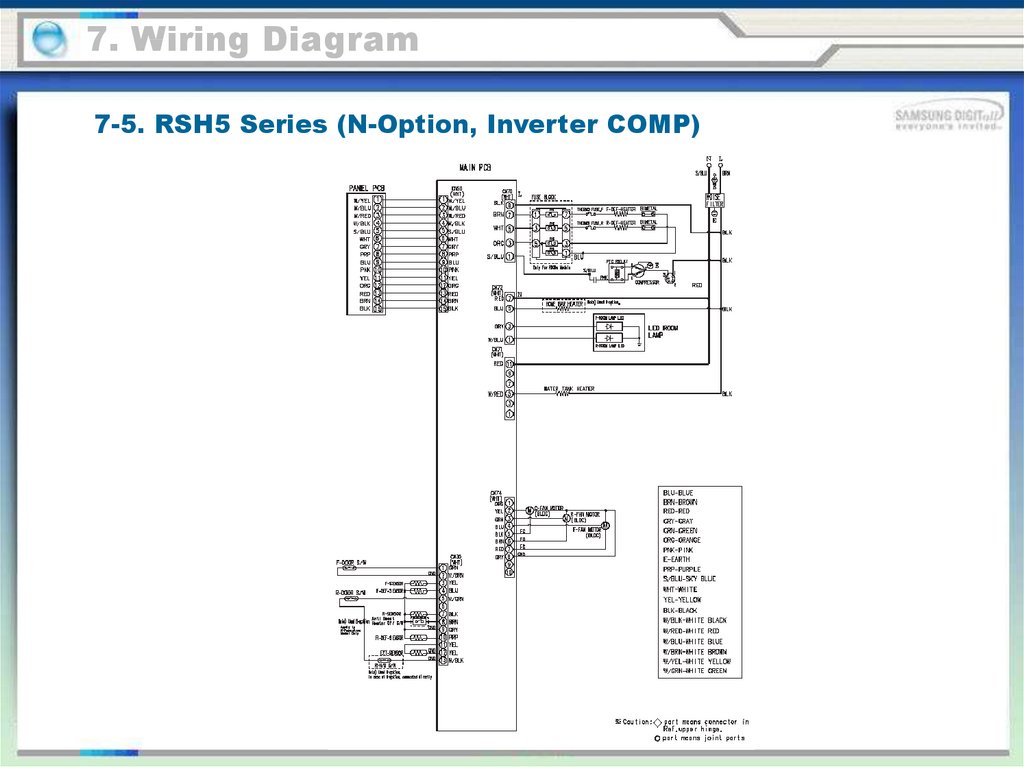

7. Wiring Diagram7-5. RSH5 Series (N-Option, Inverter COMP)

117.

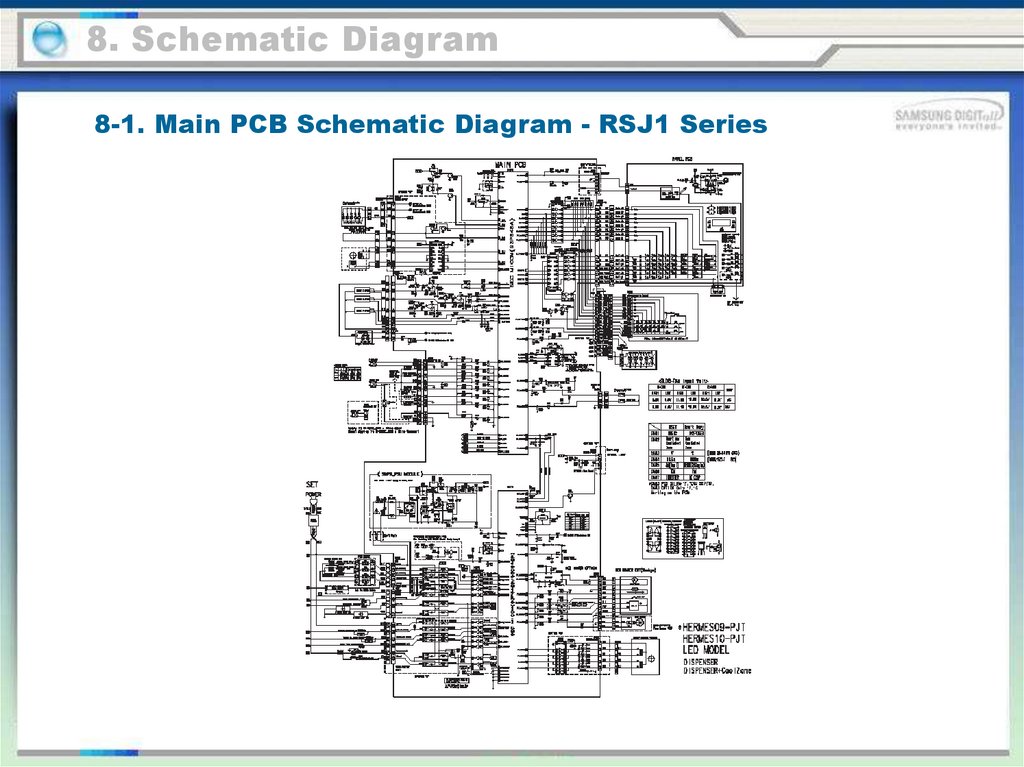

8. Schematic Diagram8-1. Main PCB Schematic Diagram - RSJ1 Series

118.

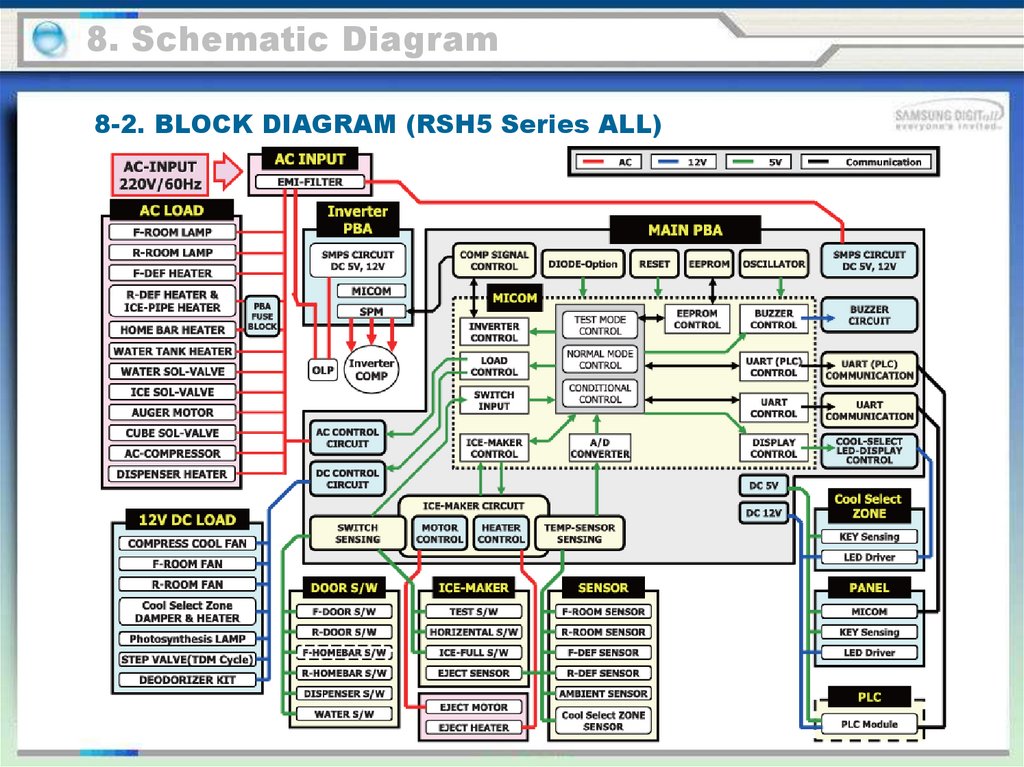

8. Schematic Diagram8-2. BLOCK DIAGRAM (RSH5 Series ALL)

119.

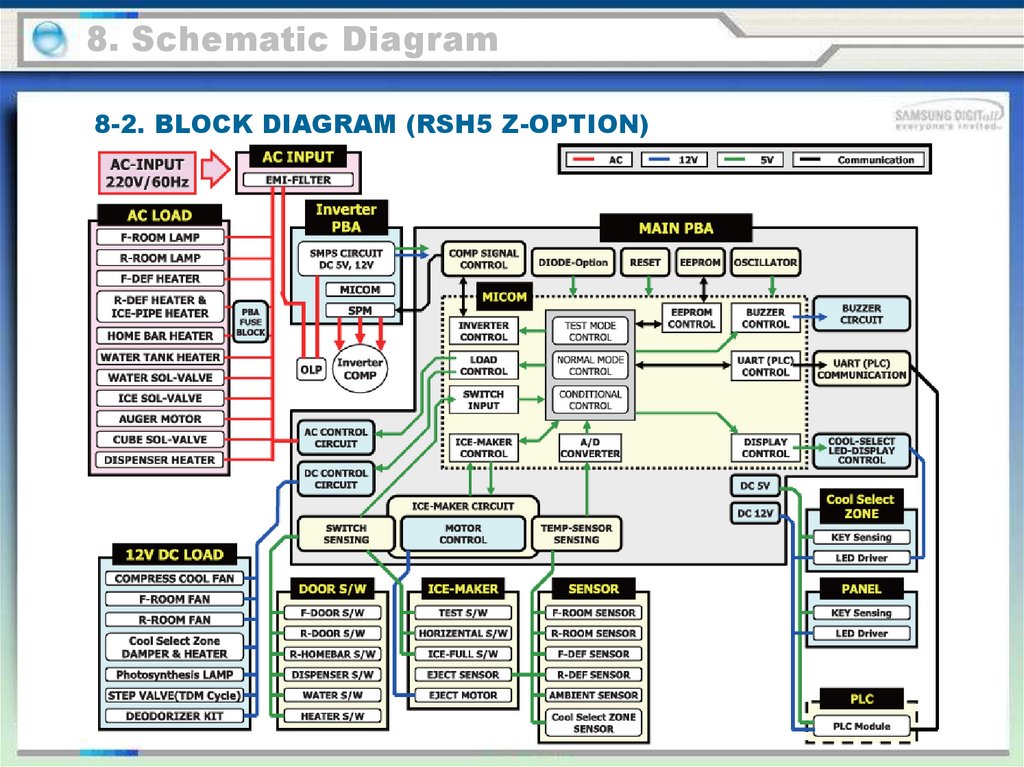

8. Schematic Diagram8-2. BLOCK DIAGRAM (RSH5 Z-OPTION)

120.

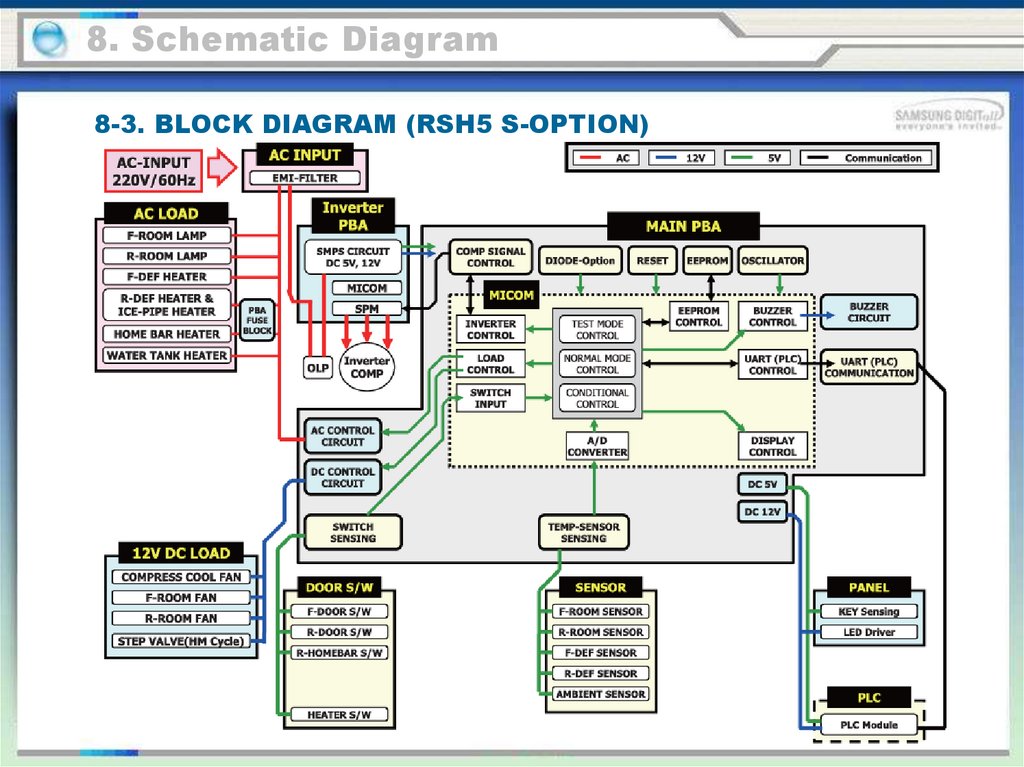

8. Schematic Diagram8-3. BLOCK DIAGRAM (RSH5 S-OPTION)

121.

8. Schematic Diagram8-4. BLOCK DIAGRAM (RSH5 T/R-OPTION)

122.

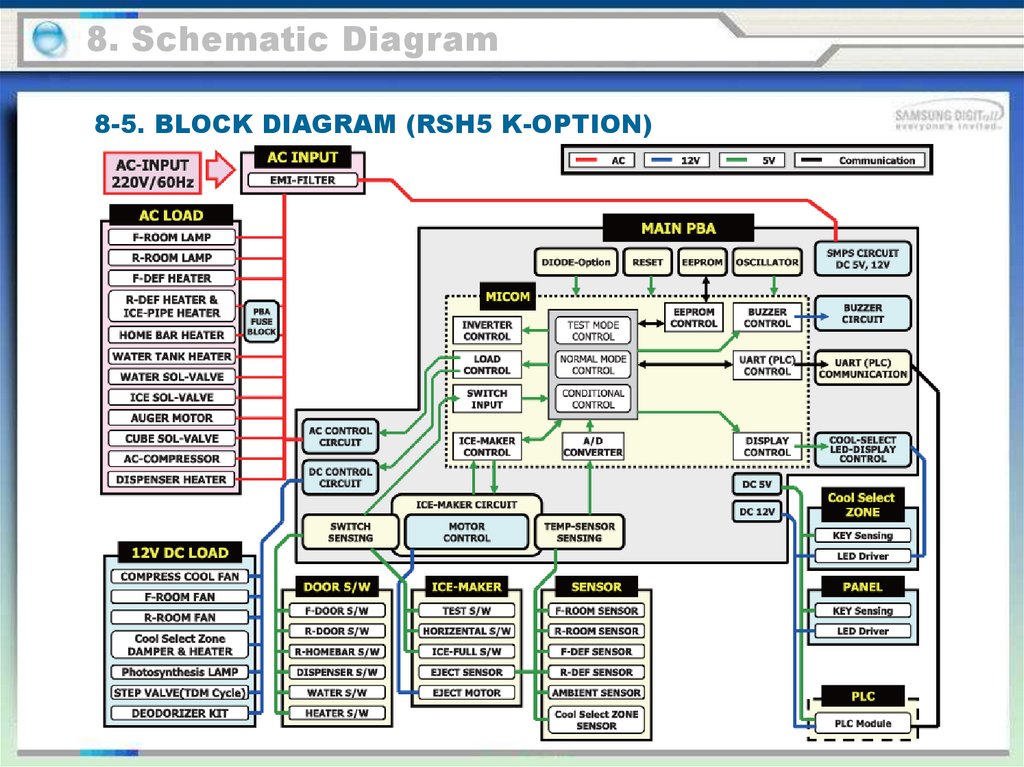

8. Schematic Diagram8-5. BLOCK DIAGRAM (RSH5 K-OPTION)

123.

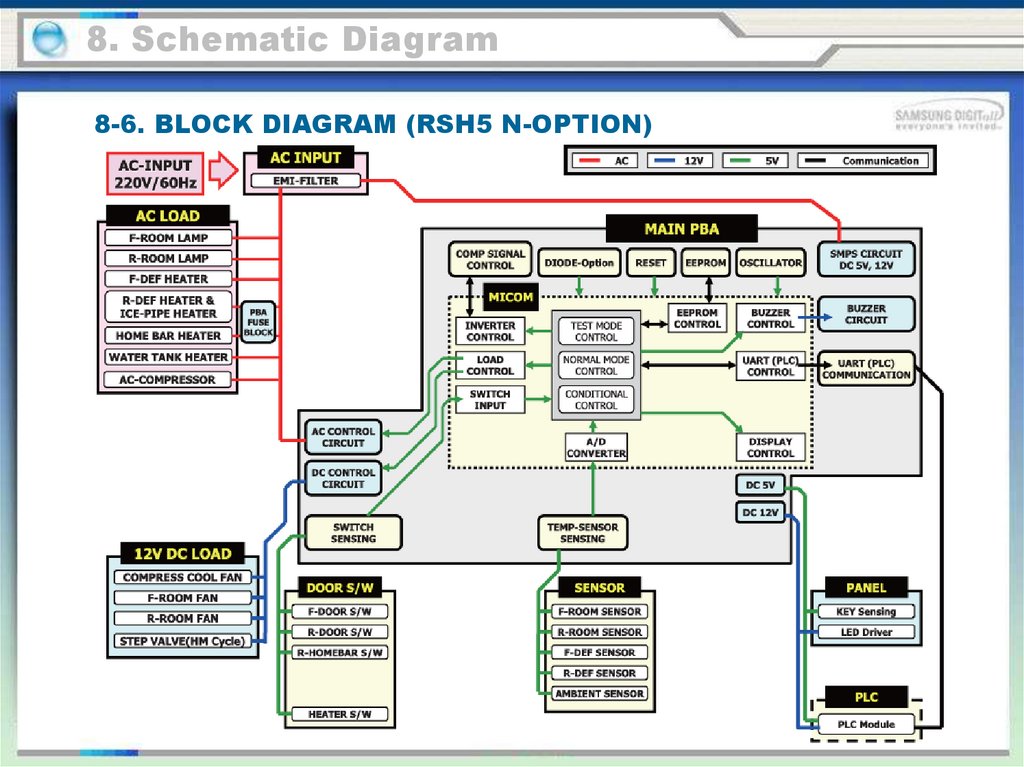

8. Schematic Diagram8-6. BLOCK DIAGRAM (RSH5 N-OPTION)

124.

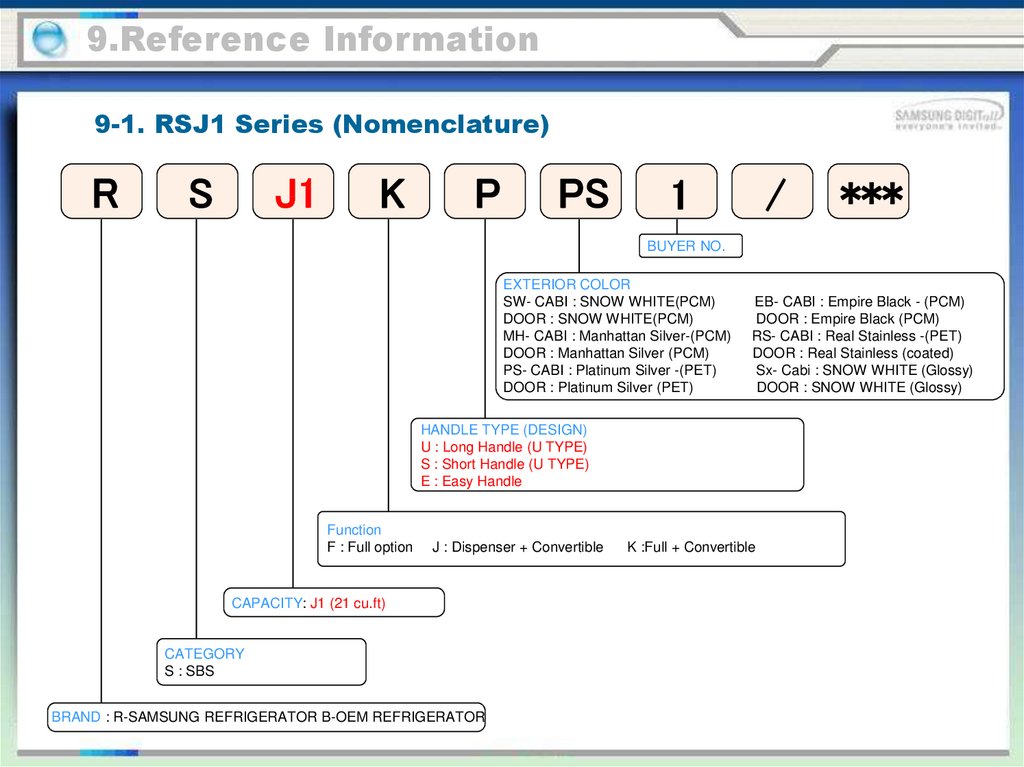

9.Reference Information9-1. RSJ1 Series (Nomenclature)

R

S

J1

K

P

PS

1

/

***

BUYER NO.

EXTERIOR COLOR

SW- CABI : SNOW WHITE(PCM)

DOOR : SNOW WHITE(PCM)

MH- CABI : Manhattan Silver-(PCM)

DOOR : Manhattan Silver (PCM)

PS- CABI : Platinum Silver -(PET)

DOOR : Platinum Silver (PET)

EB- CABI : Empire Black - (PCM)

DOOR : Empire Black (PCM)

RS- CABI : Real Stainless -(PET)

DOOR : Real Stainless (coated)

Sx- Cabi : SNOW WHITE (Glossy)

DOOR : SNOW WHITE (Glossy)

HANDLE TYPE (DESIGN)

U : Long Handle (U TYPE)

S : Short Handle (U TYPE)

E : Easy Handle

Function

F : Full option

J : Dispenser + Convertible

CAPACITY: J1 (21 cu.ft)

CATEGORY

S : SBS

BRAND : R-SAMSUNG REFRIGERATOR B-OEM REFRIGERATOR

K :Full + Convertible

125.

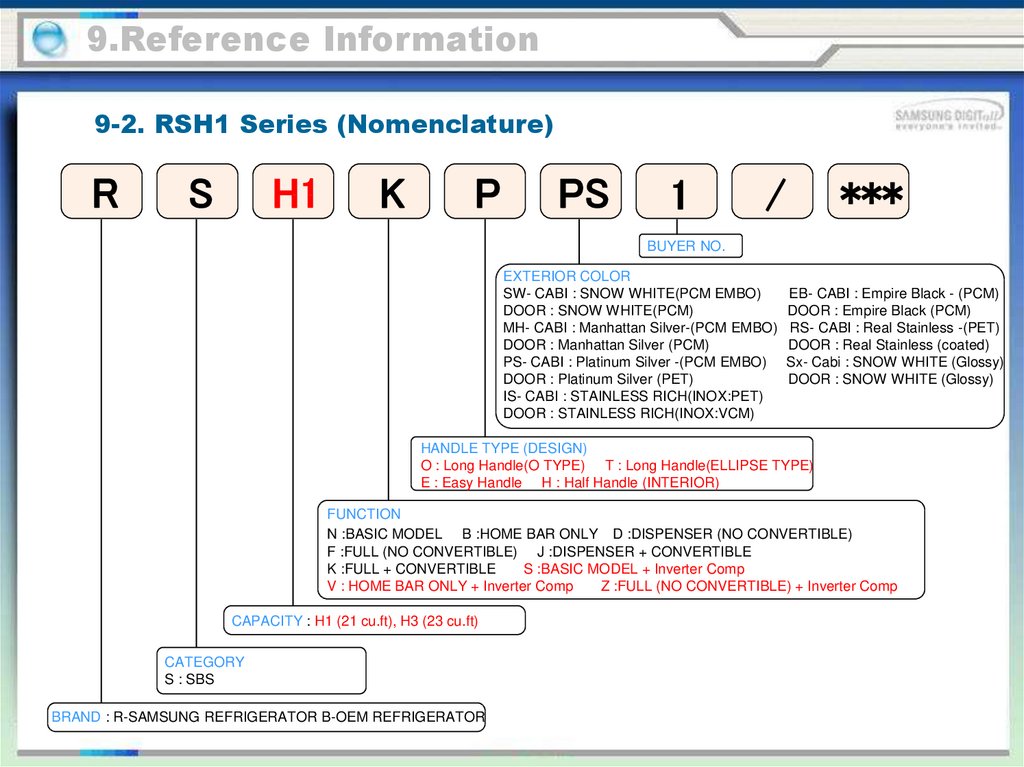

9.Reference Information9-2. RSH1 Series (Nomenclature)

R

S

H1

K

P

PS

1

***

/

BUYER NO.

EXTERIOR COLOR

SW- CABI : SNOW WHITE(PCM EMBO)

DOOR : SNOW WHITE(PCM)

MH- CABI : Manhattan Silver-(PCM EMBO)

DOOR : Manhattan Silver (PCM)

PS- CABI : Platinum Silver -(PCM EMBO)

DOOR : Platinum Silver (PET)

IS- CABI : STAINLESS RICH(INOX:PET)

DOOR : STAINLESS RICH(INOX:VCM)

EB- CABI : Empire Black - (PCM)

DOOR : Empire Black (PCM)

RS- CABI : Real Stainless -(PET)

DOOR : Real Stainless (coated)

Sx- Cabi : SNOW WHITE (Glossy)

DOOR : SNOW WHITE (Glossy)

HANDLE TYPE (DESIGN)

O : Long Handle(O TYPE) T : Long Handle(ELLIPSE TYPE)

E : Easy Handle H : Half Handle (INTERIOR)

FUNCTION

N :BASIC MODEL B :HOME BAR ONLY D :DISPENSER (NO CONVERTIBLE)

F :FULL (NO CONVERTIBLE) J :DISPENSER + CONVERTIBLE

K :FULL + CONVERTIBLE

S :BASIC MODEL + Inverter Comp

V : HOME BAR ONLY + Inverter Comp

Z :FULL (NO CONVERTIBLE) + Inverter Comp

CAPACITY : H1 (21 cu.ft), H3 (23 cu.ft)

CATEGORY

S : SBS

BRAND : R-SAMSUNG REFRIGERATOR B-OEM REFRIGERATOR

126.

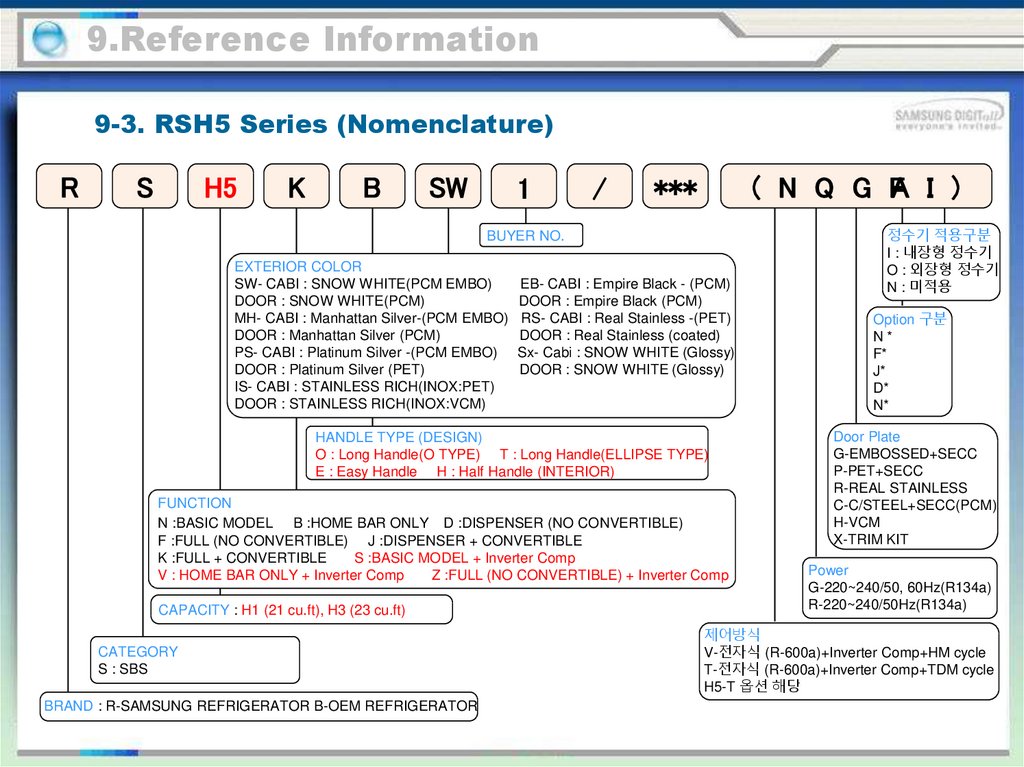

9.Reference Information9-3. RSH5 Series (Nomenclature)

R

S

H5

K

B

SW

1

/

***

( N Q G FA I )

BUYER NO.

EXTERIOR COLOR

SW- CABI : SNOW WHITE(PCM EMBO)

DOOR : SNOW WHITE(PCM)

MH- CABI : Manhattan Silver-(PCM EMBO)

DOOR : Manhattan Silver (PCM)

PS- CABI : Platinum Silver -(PCM EMBO)

DOOR : Platinum Silver (PET)

IS- CABI : STAINLESS RICH(INOX:PET)

DOOR : STAINLESS RICH(INOX:VCM)

EB- CABI : Empire Black - (PCM)

DOOR : Empire Black (PCM)

RS- CABI : Real Stainless -(PET)

DOOR : Real Stainless (coated)

Sx- Cabi : SNOW WHITE (Glossy)

DOOR : SNOW WHITE (Glossy)

HANDLE TYPE (DESIGN)

O : Long Handle(O TYPE) T : Long Handle(ELLIPSE TYPE)

E : Easy Handle H : Half Handle (INTERIOR)

FUNCTION

N :BASIC MODEL B :HOME BAR ONLY D :DISPENSER (NO CONVERTIBLE)

F :FULL (NO CONVERTIBLE) J :DISPENSER + CONVERTIBLE

K :FULL + CONVERTIBLE

S :BASIC MODEL + Inverter Comp

V : HOME BAR ONLY + Inverter Comp

Z :FULL (NO CONVERTIBLE) + Inverter Comp

CAPACITY : H1 (21 cu.ft), H3 (23 cu.ft)

CATEGORY

S : SBS

BRAND : R-SAMSUNG REFRIGERATOR B-OEM REFRIGERATOR

정수기 적용구분

I : 내장형 정수기

O : 외장형 정수기

N : 미적용

Option 구분

N*

F*

J*

D*

N*

Door Plate

G-EMBOSSED+SECC

P-PET+SECC

R-REAL STAINLESS

C-C/STEEL+SECC(PCM)

H-VCM

X-TRIM KIT

Power

G-220~240/50, 60Hz(R134a)

R-220~240/50Hz(R134a)

제어방식

V-전자식 (R-600a)+Inverter Comp+HM cycle

T-전자식 (R-600a)+Inverter Comp+TDM cycle

H5-T 옵션 해당

127.

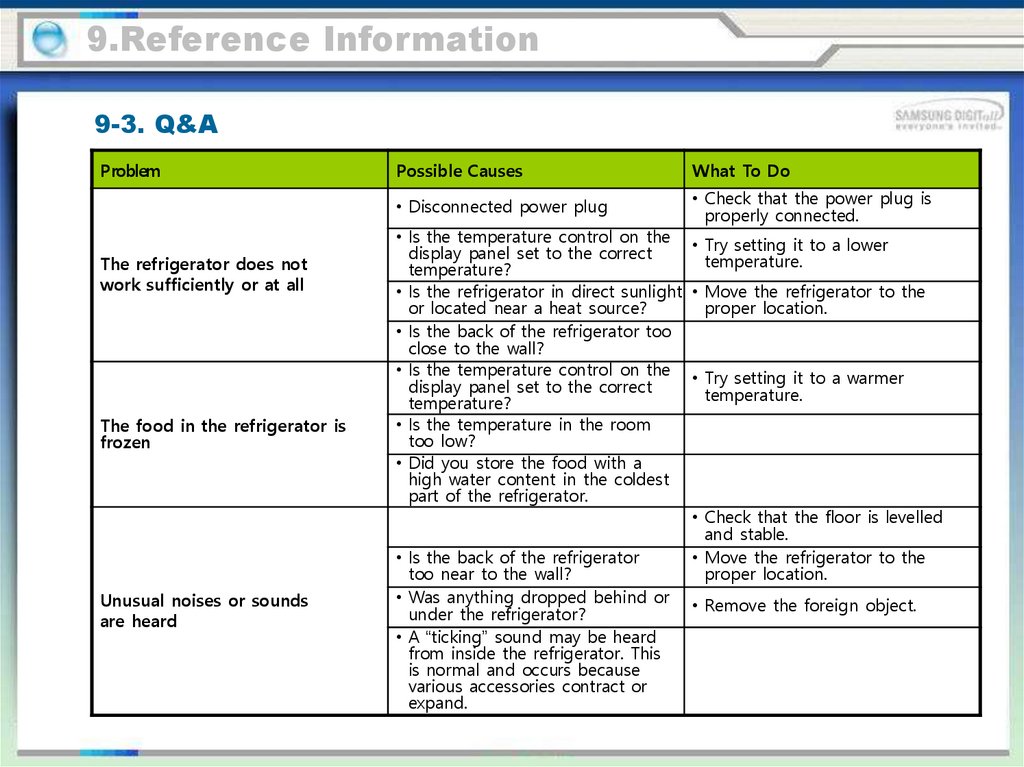

9.Reference Information9-3. Q&A

Problem

The refrigerator does not

work sufficiently or at all

The food in the refrigerator is

frozen

Unusual noises or sounds

are heard

Possible Causes

What To Do

• Disconnected power plug

• Check that the power plug is

properly connected.

• Is the temperature control on the • Try setting it to a lower

display panel set to the correct

temperature.

temperature?

• Is the refrigerator in direct sunlight • Move the refrigerator to the

or located near a heat source?

proper location.

• Is the back of the refrigerator too

close to the wall?

• Is the temperature control on the • Try setting it to a warmer

display panel set to the correct

temperature.

temperature?

• Is the temperature in the room

too low?

• Did you store the food with a

high water content in the coldest

part of the refrigerator.

• Check that the floor is levelled

and stable.

• Is the back of the refrigerator

• Move the refrigerator to the

too near to the wall?

proper location.

• Was anything dropped behind or • Remove the foreign object.

under the refrigerator?

• A “ticking” sound may be heard

from inside the refrigerator. This

is normal and occurs because

various accessories contract or

expand.

128.

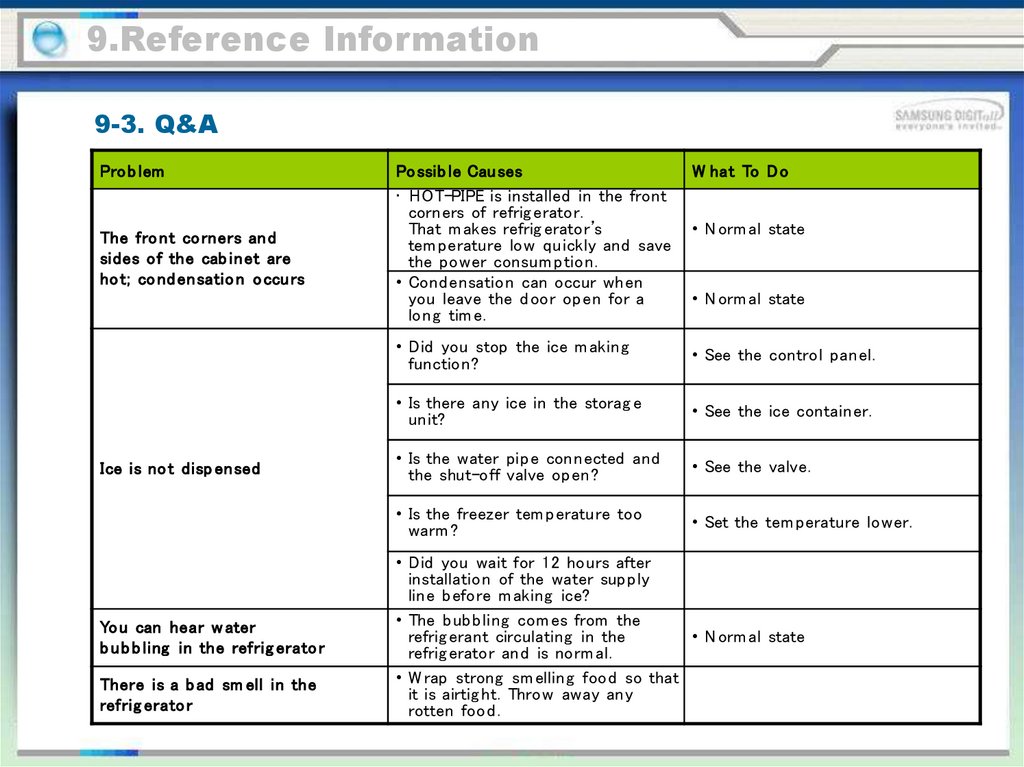

9.Reference Information9-3. Q&A

Pro b lem

The fro nt co rners an d

sides of the cab inet are

ho t; co nd ensatio n o ccu rs

Ice is no t disp ensed

Yo u can hear w ater

b u b b ling in the refrig erato r

There is a b ad sm ell in the

refrig erato r

Po ssib le Cau ses

• HOT-PIPE is installed in the front

corners of refrig erator.

That m akes refrig erator’s

tem perature low quickly and save

the po wer consum ption.

• Cond ensatio n can occur when

you leave the d oor op en for a

long tim e.

W hat To D o

• Did you stop the ice m aking

function?

• See the control panel.

• Is there any ice in the storag e

unit?

• See the ice container.

• Is the water pip e connected and

the shut-off valve op en?

• See the valve.

• Is the freezer tem perature too

warm ?

• Set the tem perature lower.

• N orm al state

• N orm al state

• Did you wait for 12 ho urs after

installation of the water sup p ly

line b efore m aking ice?

• The b ub b ling com es from the

• N orm al state

refrig erant circulating in the

refrig erator and is norm al.

• W rap strong sm elling food so that

it is airtig ht. Throw away any

rotten food .

129.

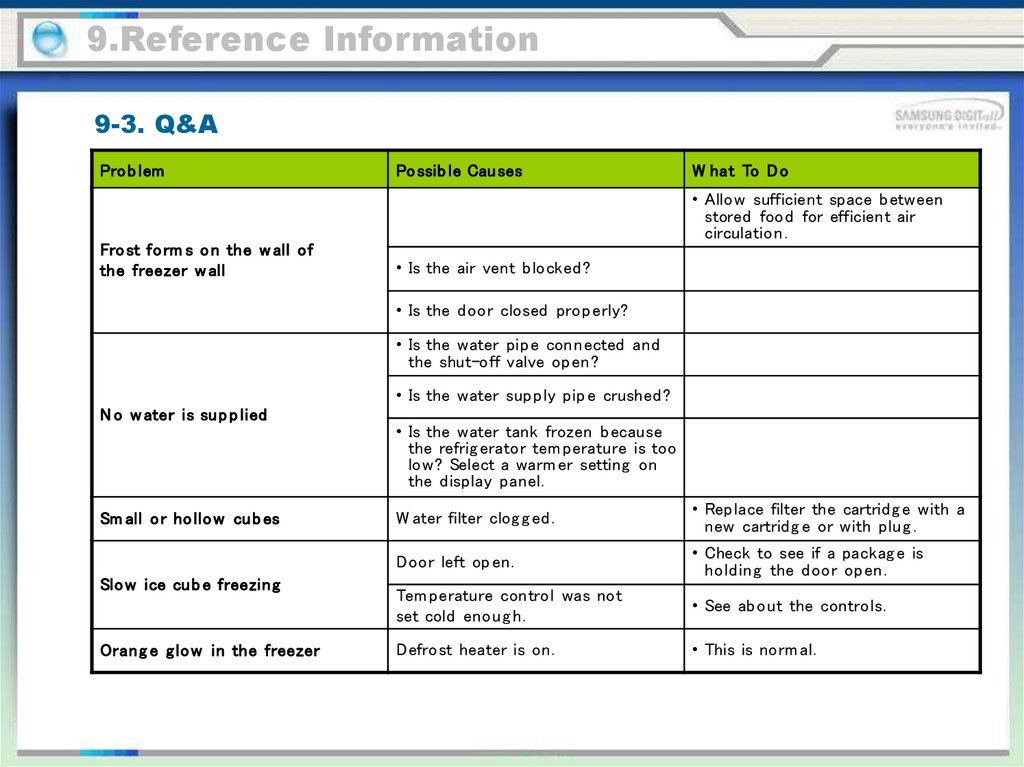

9.Reference Information9-3. Q&A

Pro b lem

Po ssib le Cau ses

W hat To D o

• Allo w sufficient space b etween

stored food for efficient air

circulation.

Fro st fo rm s o n the w all of

the freezer w all

• Is the air vent b locked ?

• Is the d oor closed pro p erly?

• Is the water pip e connected and

the shut-off valve op en?

• Is the water sup p ly pip e crushed ?

N o w ater is su p p lied

Sm all o r ho llo w cu b es

Slo w ice cu b e freezing

Orang e g lo w in the freezer

• Is the water tank frozen b ecause

the refrig erator tem perature is too

low? Select a warm er setting on

the d isplay panel.

W ater filter clog g ed .

• Replace filter the cartrid g e with a

new cartrid g e or with plug .

Door left op en.

• Check to see if a packag e is

ho ld ing the d oor op en.

Tem perature control was not

set cold eno ug h.

• See ab out the controls.

Defrost heater is on.

• This is norm al.

130.

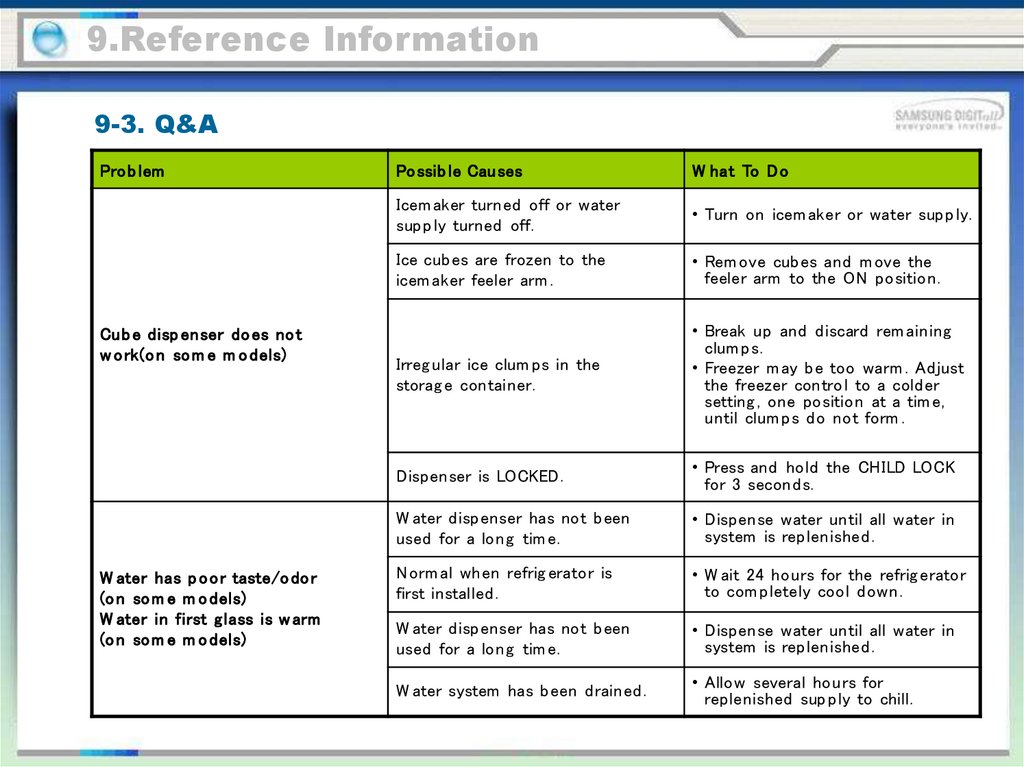

9.Reference Information9-3. Q&A

Pro b lem

Cub e disp enser do es no t

w o rk(o n so m e m o dels)

W ater has p o o r taste/o do r

(o n so m e m o dels)

W ater in first glass is w arm

(o n so m e m o dels)

Po ssib le Cau ses

W hat To D o

Icem aker turned off or water

sup p ly turned off.

• Turn on icem aker or water sup p ly.

Ice cub es are frozen to the

icem aker feeler arm .

• Rem ove cub es and m ove the

feeler arm to the ON position.

Irreg ular ice clum ps in the

storag e container.

• Break up and d iscard rem aining

clum ps.

• Freezer m ay b e too warm . Ad just

the freezer contro l to a cold er

setting , one position at a tim e,

until clum ps d o not form .

Dispenser is LOCKED.

• Press and ho ld the CHILD LOCK

for 3 second s.

W ater d ispenser has not b een

used for a long tim e.

• Dispense water until all water in

system is replenished .

N orm al when refrig erator is

first installed .

• W ait 24 hours for the refrig erator

to com p letely cool d own.

W ater d ispenser has not b een

used for a long tim e.

• Dispense water until all water in

system is replenished .

W ater system has b een d rained .

• Allo w several ho urs for

replenished sup p ly to chill.

131.

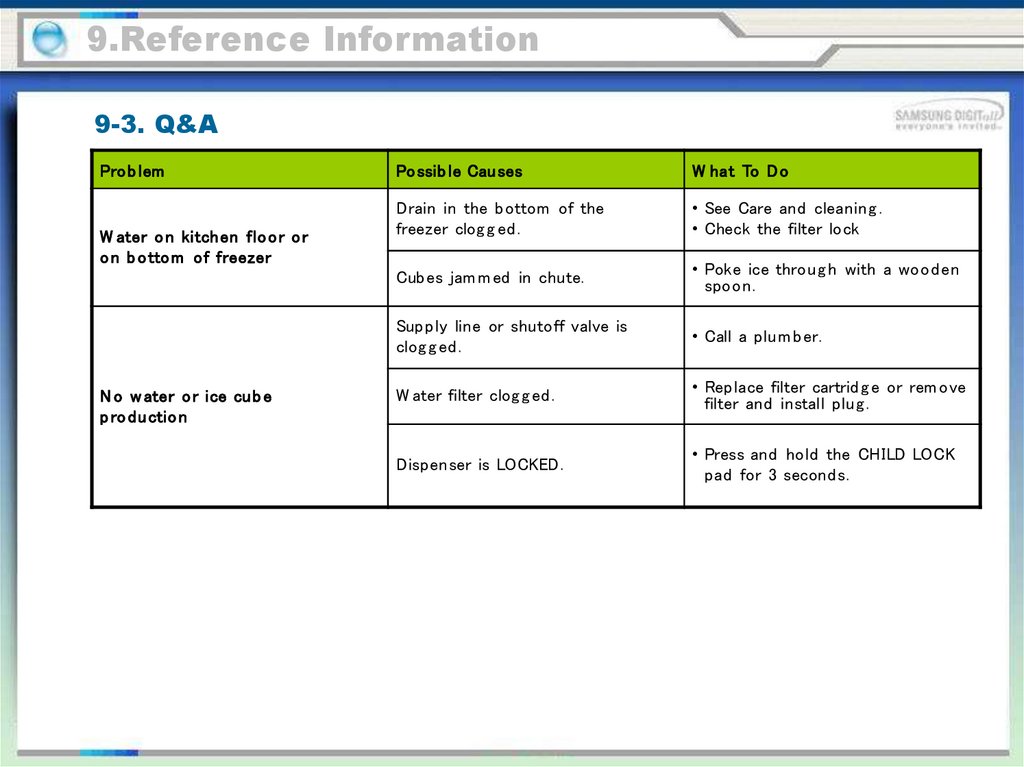

9.Reference Information9-3. Q&A

Pro b lem

W ater disp enser do es no t

w o rk(o n so m e m o dels)

W ater sp u rtin g fro m disp enser

(o n so m e m o dels)

W ater is no t disp ensed