Similar presentations:

Modern construction materials

1.

MODERNCONSTRUCTION

MATERIALS

2.

COMPANY PRESENTATIONPENOPLEX

COMPANY

is a major Russian manufacturer of

construction, decorative and finishing

materials based on polymeric compounds.

It started operations in 1998

with the launch of the first Russian production line

manufacturing heat insulation

materials from extruded polystyrene foam

under PENOPLEX® trademark.

COMPANY MISSION:

Continuous innovation-driven development in the field of

production and application of polymer

construction materials.

3.

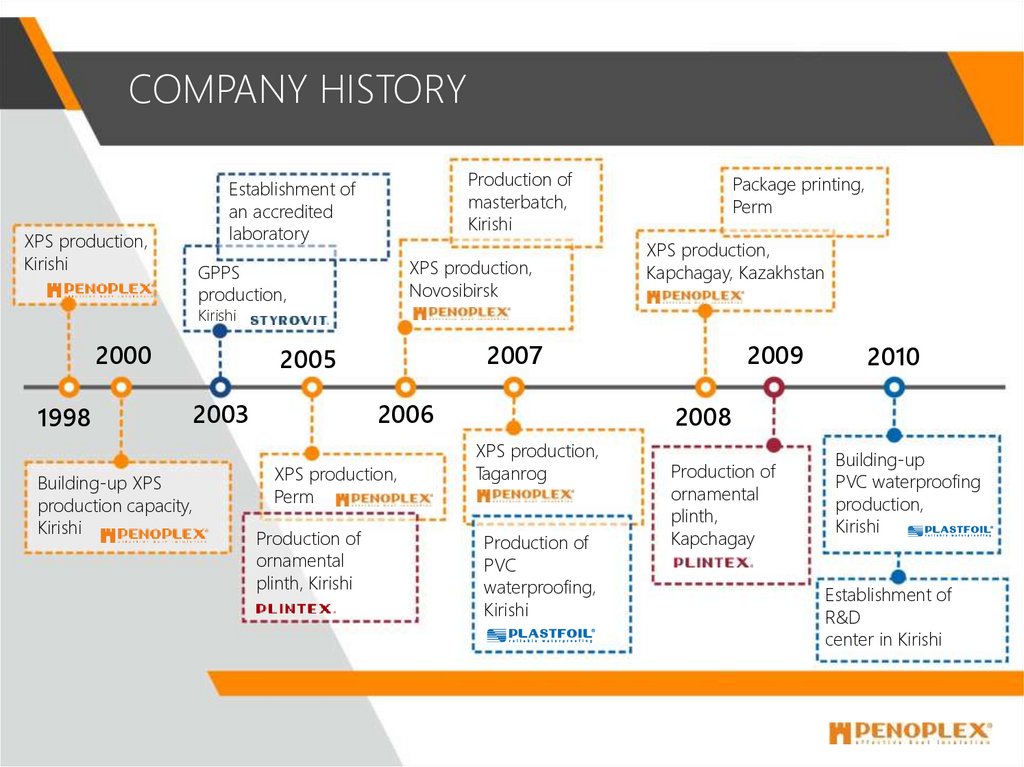

COMPANY HISTORYXPS production,

Kirishi

Production of

masterbatch,

Kirishi

Establishment of

an accredited

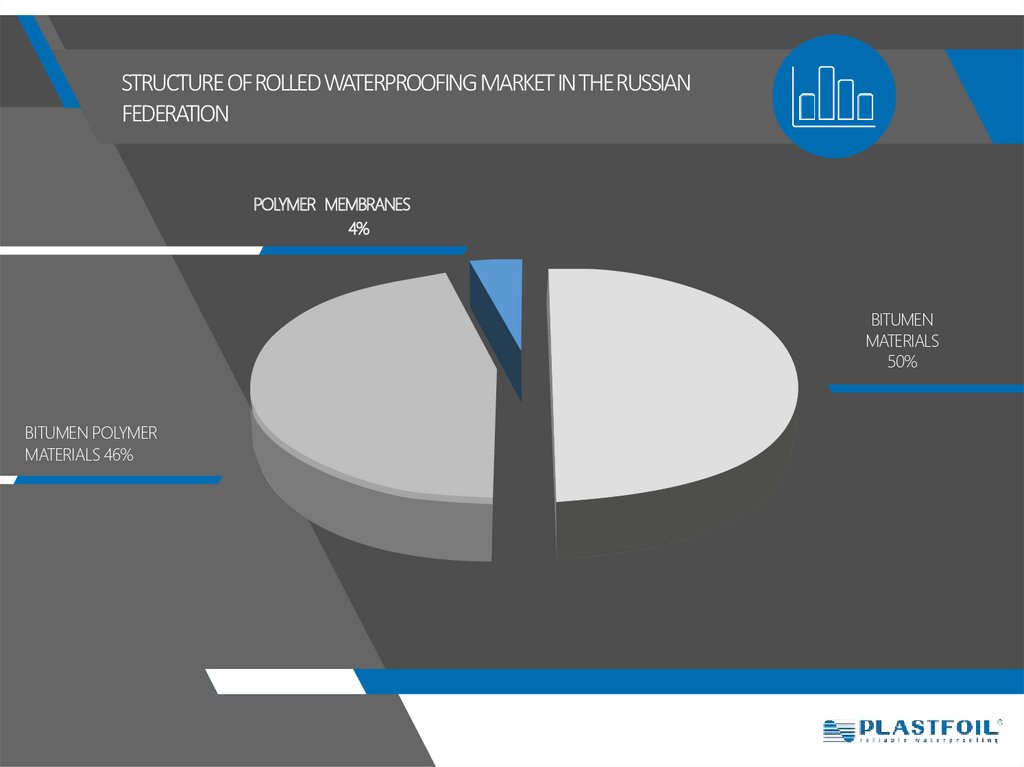

laboratory

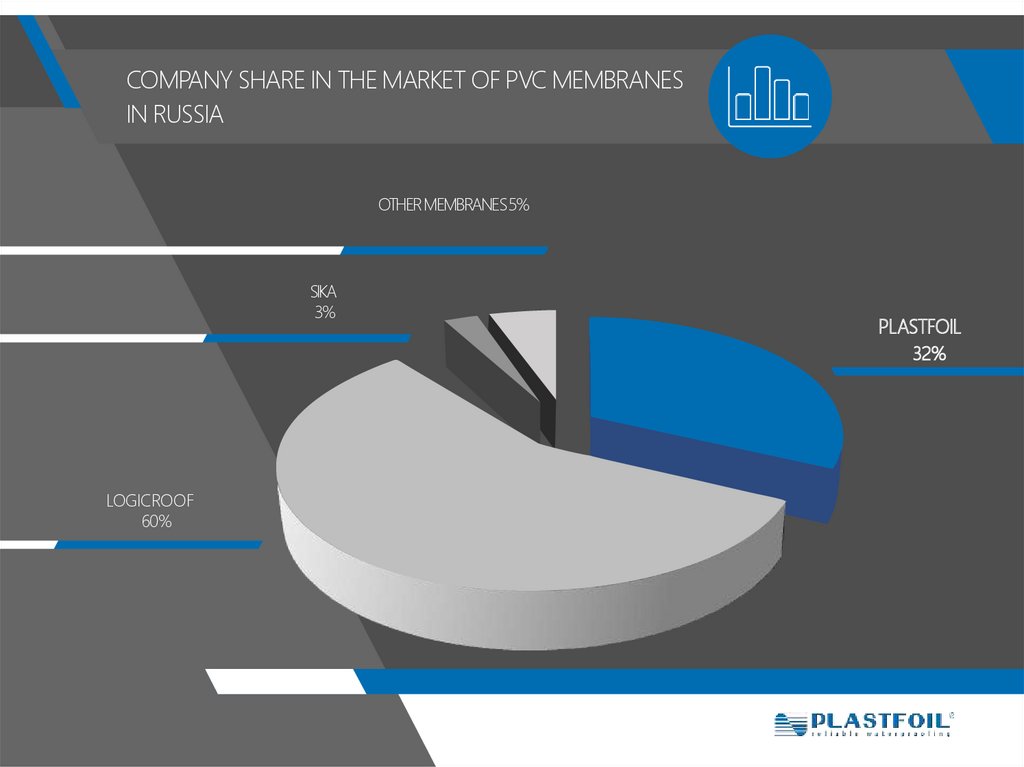

XPS production,

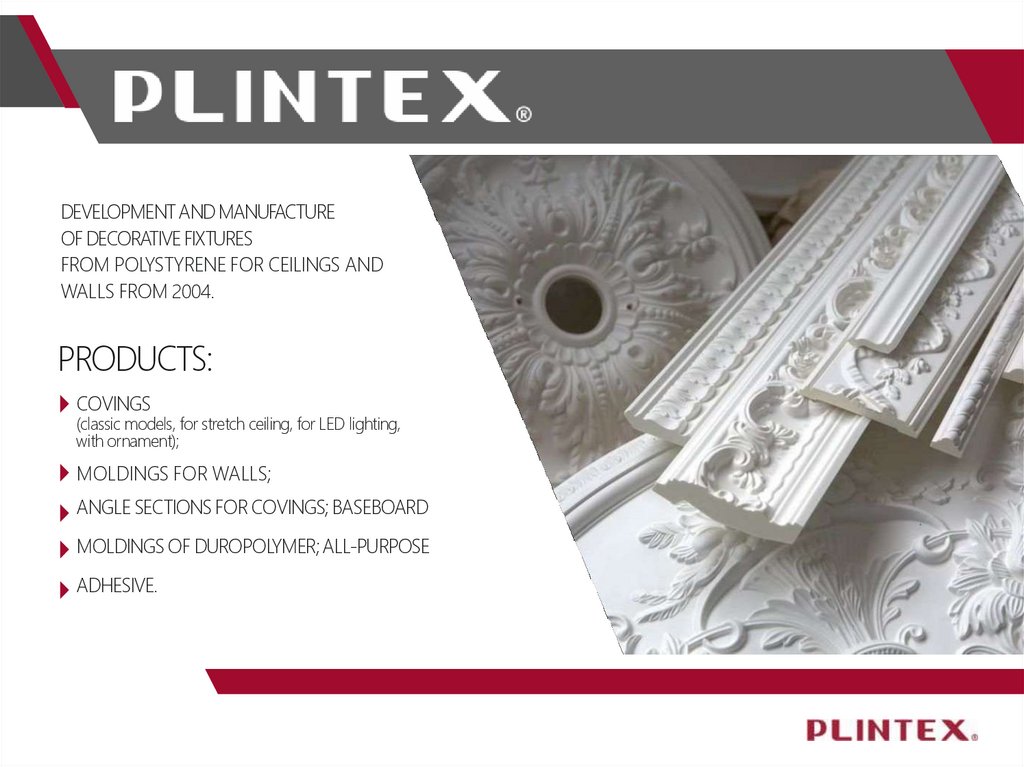

Novosibirsk

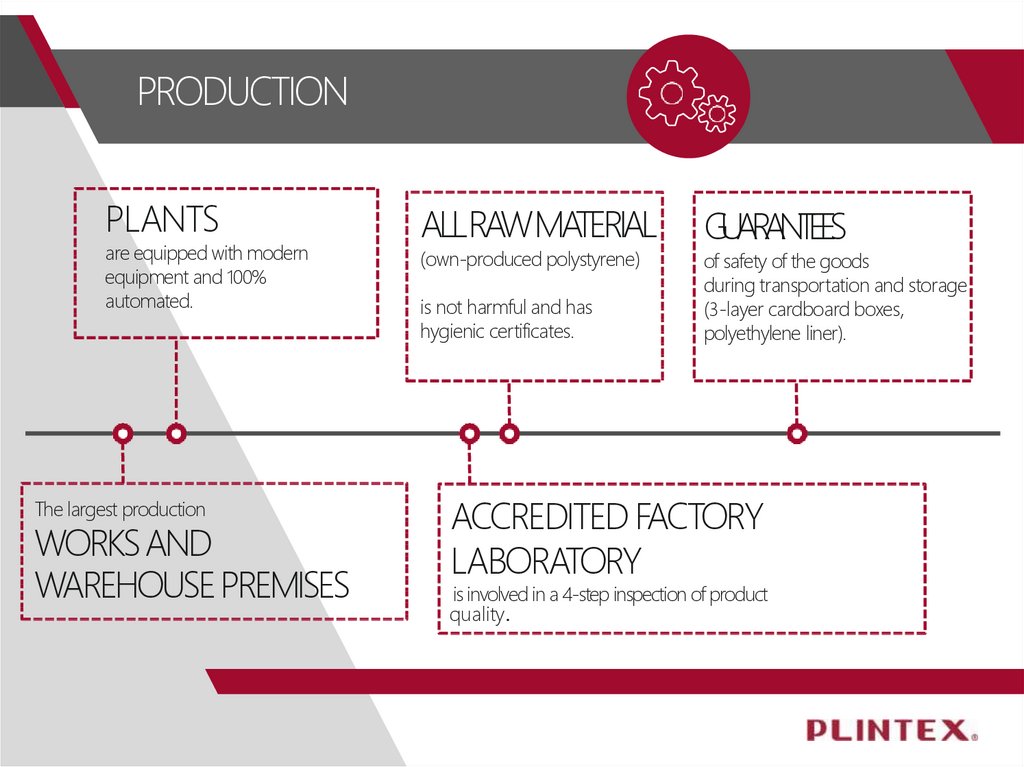

GPPS

production,

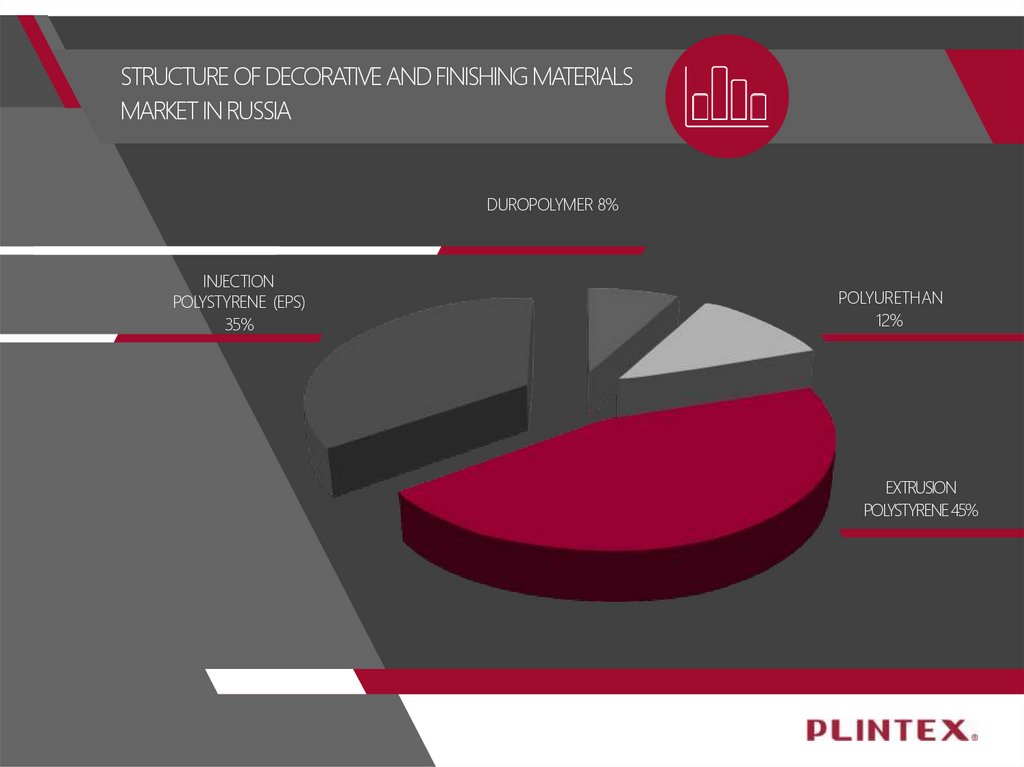

Package printing,

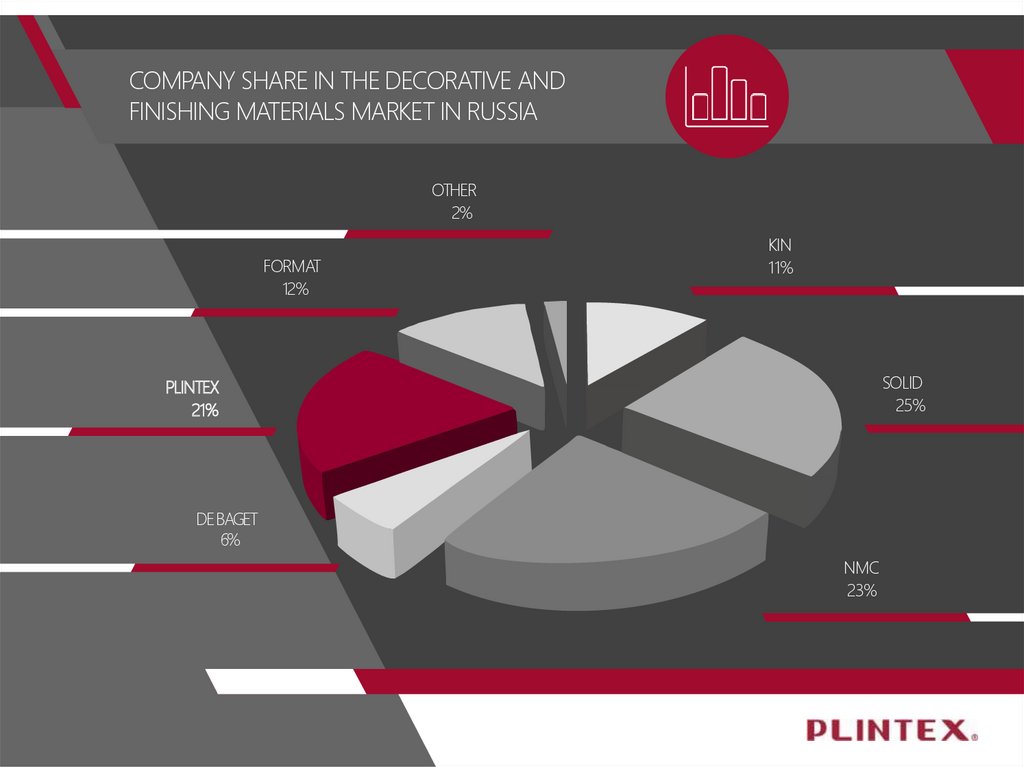

Perm

XPS production,

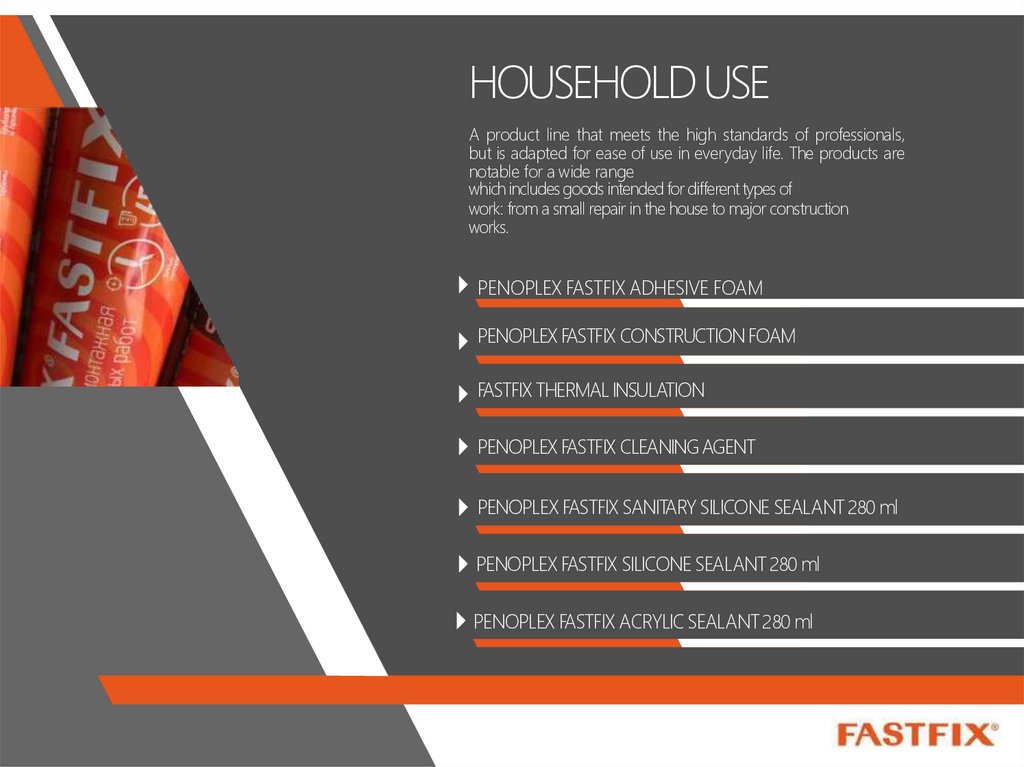

Kapchagay, Kazakhstan

Kirishi

2000

1998

Building-up XPS

production capacity,

Kirishi

2007

2005

2003

2006

XPS production,

Perm

Production of

ornamental

plinth, Kirishi

2009

2010

2008

XPS production,

Taganrog

Production of

PVC

waterproofing,

Kirishi

Production of

ornamental

plinth,

Kapchagay

Building-up

PVC waterproofing

production,

Kirishi

Establishment of

R&D

center in Kirishi

4.

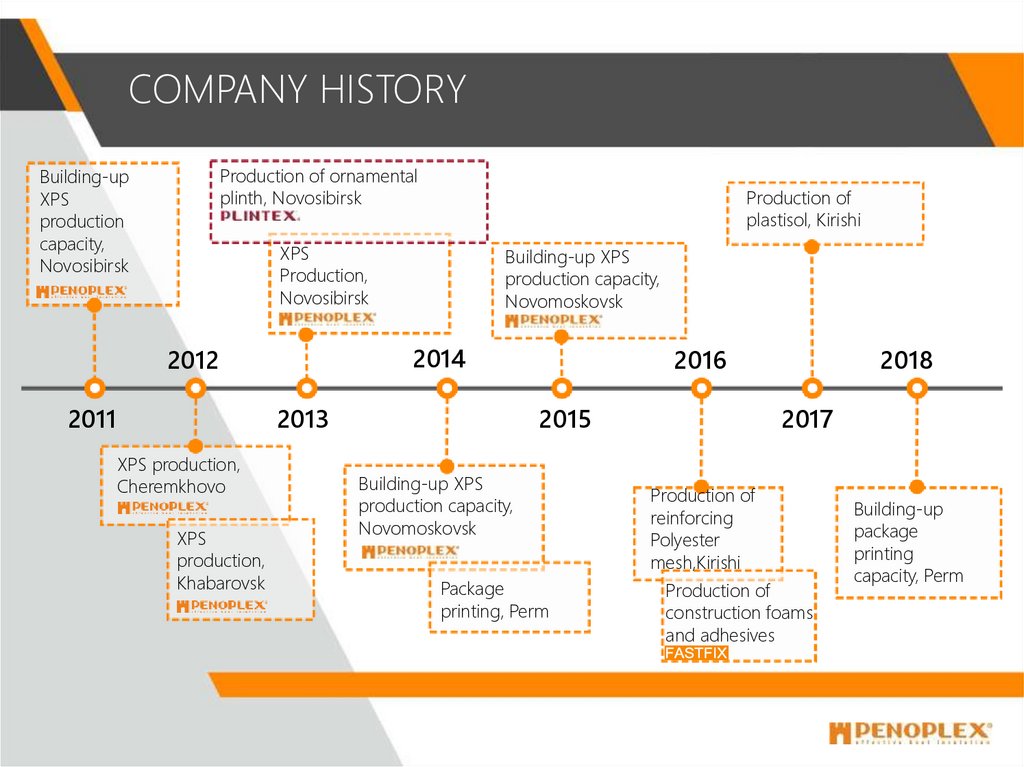

COMPANY HISTORYProduction of ornamental

plinth, Novosibirsk

Building-up

XPS

production

capacity,

Novosibirsk

Production of

plastisol, Kirishi

XPS

Production,

Novosibirsk

2014

2012

2011

Building-up XPS

production capacity,

Novomoskovsk

2013

XPS production,

Cheremkhovo

XPS

production,

Khabarovsk

2016

2015

Building-up XPS

production capacity,

Novomoskovsk

Package

printing, Perm

2018

2017

Production of

reinforcing

Polyester

mesh,Kirishi

Production of

construction foams

and adhesives

Building-up

package

printing

capacity, Perm

5.

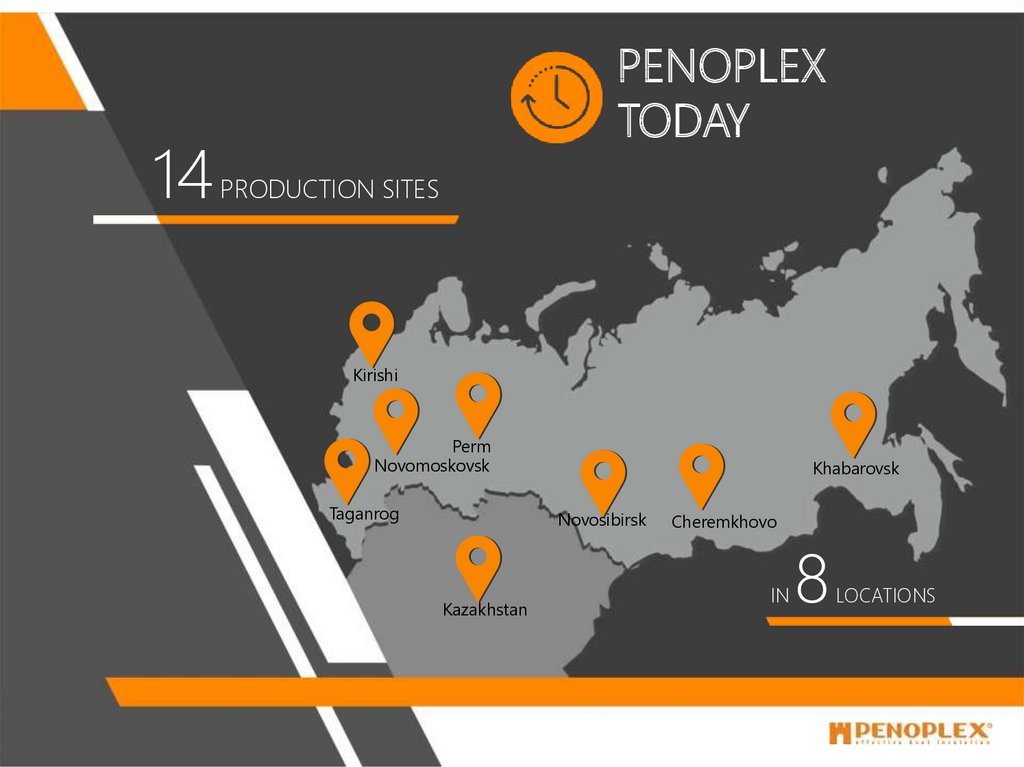

14PENOPLEX

TODAY

PRODUCTION SITES

Kirishi

Perm

Novomoskovsk

Taganrog

Khabarovsk

Novosibirsk

Kazakhstan

Cheremkhovo

IN

8

LOCATIONS

6.

14PRODUCTION SITES

IN

1700

20

8

EMPLOYEES

YEARS

of innovation activities in

Russian market

PENOPLEX

TODAY

WIDE DISTRIBUTION NETWORK

in all regions of Russia,

CIS countries and Europe

EQUIPMENT FROM LEADING

EUROPEAN MANUFACTURERS

R&D CENTER

with unique R&D

projects and products

LOCATIONS

7.

THE COMPANY IS REPRESENTEDBY THE FOLLOWING

BUSINESS LINES:

HEAT-INSULATING

MATERIALS

WATERPROOFING

MATERIALS

GENERAL PURPOSE

POLYSTYRENE

POLYSTYRENE DECORATIVE

AND FINISHING MATERIALS

CONSTRUCTION FOAMS, ADHESIVES,

JOINT FILLERS

8.

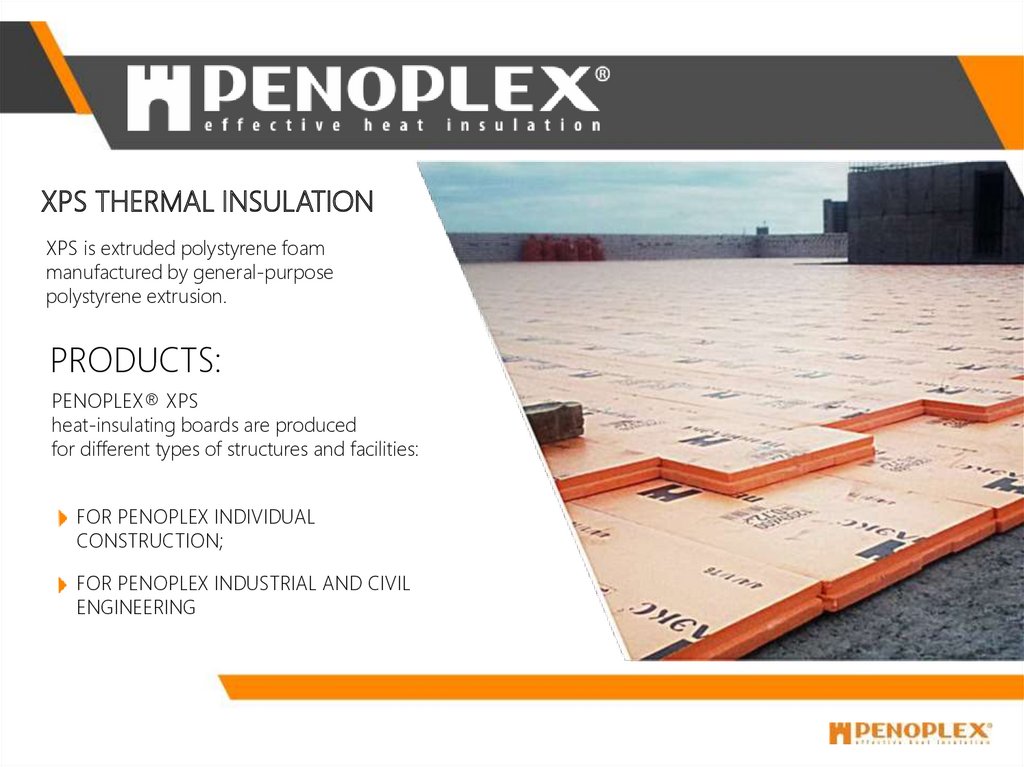

XPS THERMAL INSULATIONXPS is extruded polystyrene foam

manufactured by general-purpose

polystyrene extrusion.

PRODUCTS:

PENOPLEX® XPS

heat-insulating boards are produced

for different types of structures and facilities:

FOR PENOPLEX INDIVIDUAL

CONSTRUCTION;

FOR PENOPLEX INDUSTRIAL AND CIVIL

ENGINEERING

9.

PRODUCTSFOR INDIVIDUAL

CONSTRUCTION

COMFORT®

FOUNDATION®

Thermal insulation for pitched

roofs, walls and base course

Thermal insulation for buried

structures:

foundations, paths, septic tanks

PITCHED

ROOF®

WALLS

Thermal insulation for pitched

roof

Thermal insulation of walls, partitions,

facade systems

10.

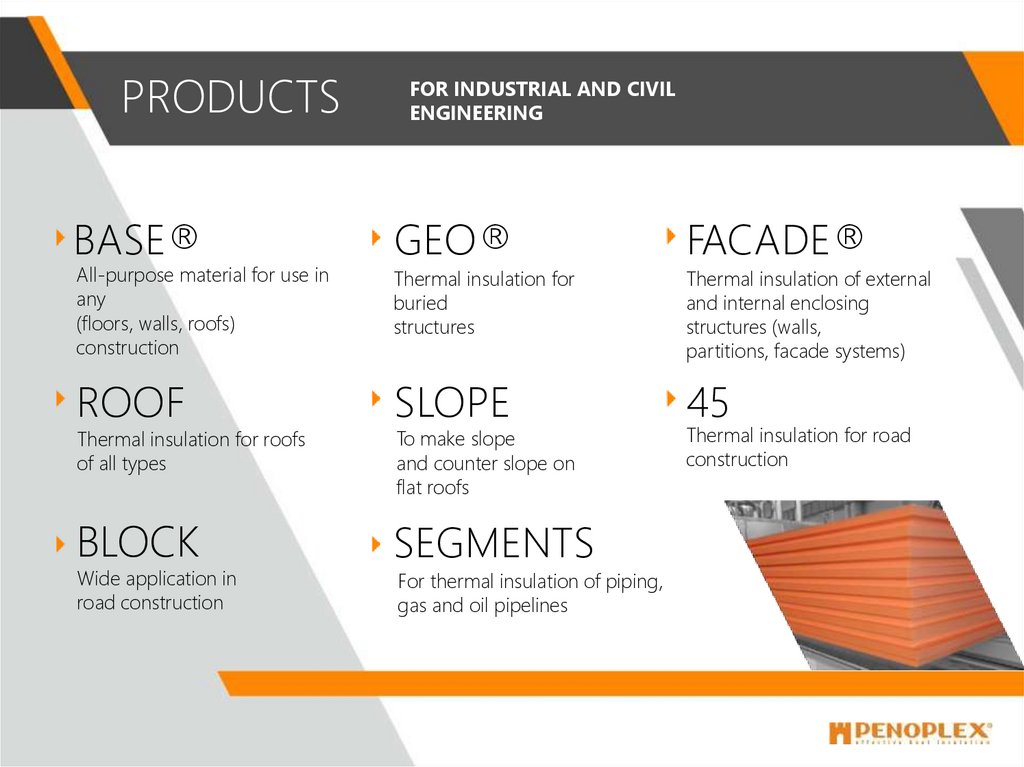

PRODUCTSBASE®

FOR INDUSTRIAL AND CIVIL

ENGINEERING

All-purpose material for use in

any

(floors, walls, roofs)

construction

GEO®

FACADE®

Thermal insulation for

buried

structures

Thermal insulation of external

and internal enclosing

structures (walls,

partitions, facade systems)

ROOF

SLOPE

45

BLOCK

SEGMENTS

Thermal insulation for roofs

of all types

Wide application in

road construction

To make slope

and counter slope on

flat roofs

For thermal insulation of piping,

gas and oil pipelines

Thermal insulation for road

construction

11.

ADVANTAGES OFMATERIAL:

HIGH COMPRESSIVE

STRENGTH:

at least 25 tons per square meter

ZERO

WATER ABSORPTION

(λ=0,032 W/mK).

LIGHT WEIGHT BOARDS,

ABSOLUTELY

EXPEDIENT SHAPE,

BIOPROOF

AND ENVIRONMENTALLY FRIENDLY.

for tight connections,

at least 25 tons per square meter

CONSISTENTLY LOW

THERMAL

CONDUCTIVITY

DURABILITY

OF MATERIAL over 50 years.

12.

MOSCOW METRO(main line tunnel "Filatov Lug")

VTB Ice Palace

MIRNY Antarctic Station

REFERENCE

PROJECTS:

DYNAMO STADIUM

renovation

Chekhov Moscow Art Theater

VDNKh (Exhibition of National Economy Achievements)

GUM-skating rink

NEW TERMINAL

at "Domodedovo" airport

EIGHTEDGES Business Center

Gazprom

"Zaryadie" PARK

13.

CERTIFICATESGOST R. (PENOPLEX 45, 45S, 75):

PROOF ROOFING SYSTEM:

GOST R. (PENOPLEX BASE, GEO,

FACADE, ROOF, COMFORT, FOUNDATION):

PENOPLEX BLOCK:

Certificate of Conformity.

Certificate of Conformity.

PENOPLEX (SEZ) PENOPLEX 45C, 45, 75:

Fire Safety Certificate.

Certificate of Conformity.

SEGMENTS, SEMI-CYLINDERS, BLOCK-SEGMENTS:

Expert Opinion.

Certificate of Conformity.

FZ 123 (PENOPLEX GEO, BASE,

COMFORT, FOUNDATION):

PENOPLEX NIISPh RAASN:

Declaration of Conformity.

FZ 123 (PENOPLEX ROOF, FACADE):

Durability Test Certificate.

SAINT PETERSBURG STATE UNIVERSITY REPORT, ANTS

Declaration of Conformity.

ENVIRONMENTAL COMPLIANCE CERTIFICATE

FZ 123 (PENOPLEX 45, 45 C, 75)

ACOUSTIC TESTS. FLOORS

Declaration of Conformity.

STANDARD ROOFING SYSTEM:

Fire Safety Certificate.

ACOUSTIC TESTS OF SEGMENTS

14.

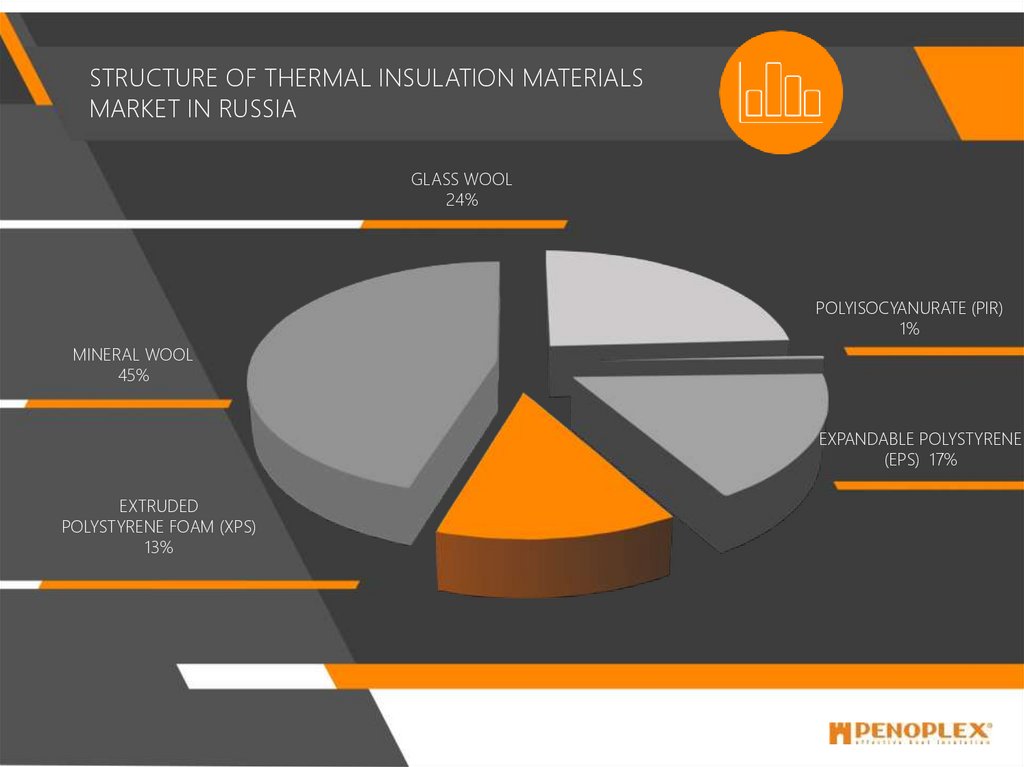

STRUCTURE OF THERMAL INSULATION MATERIALSMARKET IN RUSSIA

GLASS WOOL

24%

POLYISOCYANURATE (PIR)

1%

MINERAL WOOL

45%

EXPANDABLE POLYSTYRENE

(EPS) 17%

EXTRUDED

POLYSTYRENE FOAM (XPS)

13%

15.

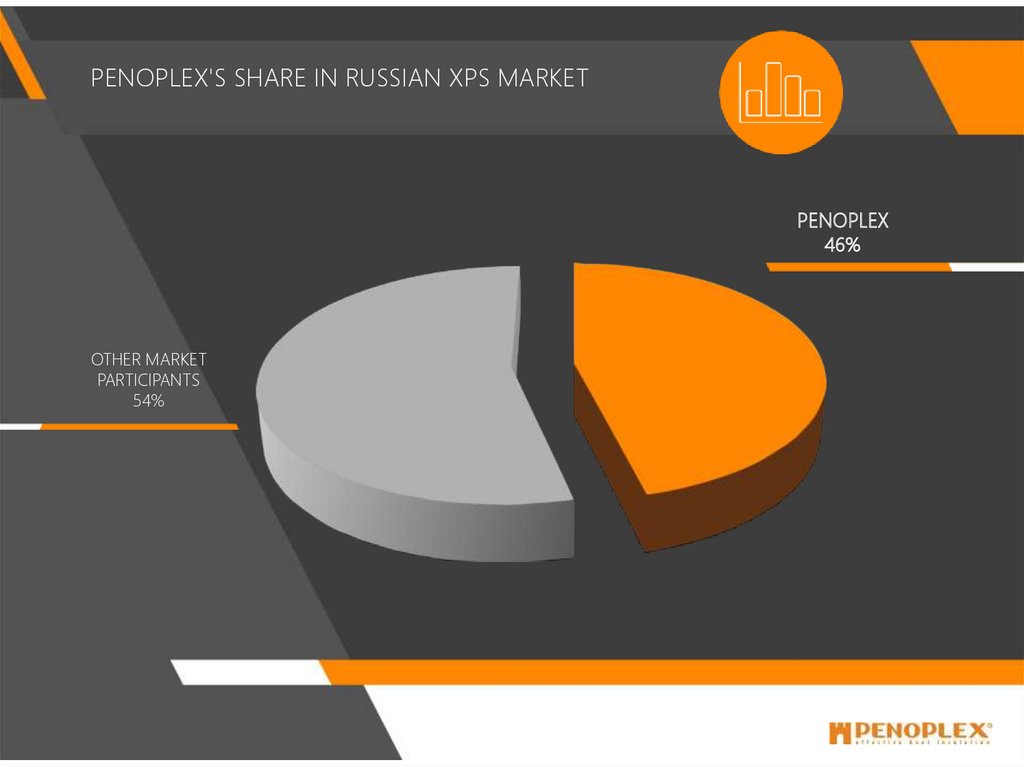

PENOPLEX'S SHARE IN RUSSIAN XPS MARKETPENOPLEX

46%

OTHER MARKET

PARTICIPANTS

54%

16.

GENERAL PURPOSE POLYSTYRENE(GPPS) is manufactured under

STYROVIT® trademark

DISTINCTIVE

QUALITY

Low residual monomer content

Stability of all parameters

Increased heat resistance

High transparency

Lightfastness

ISO

17.

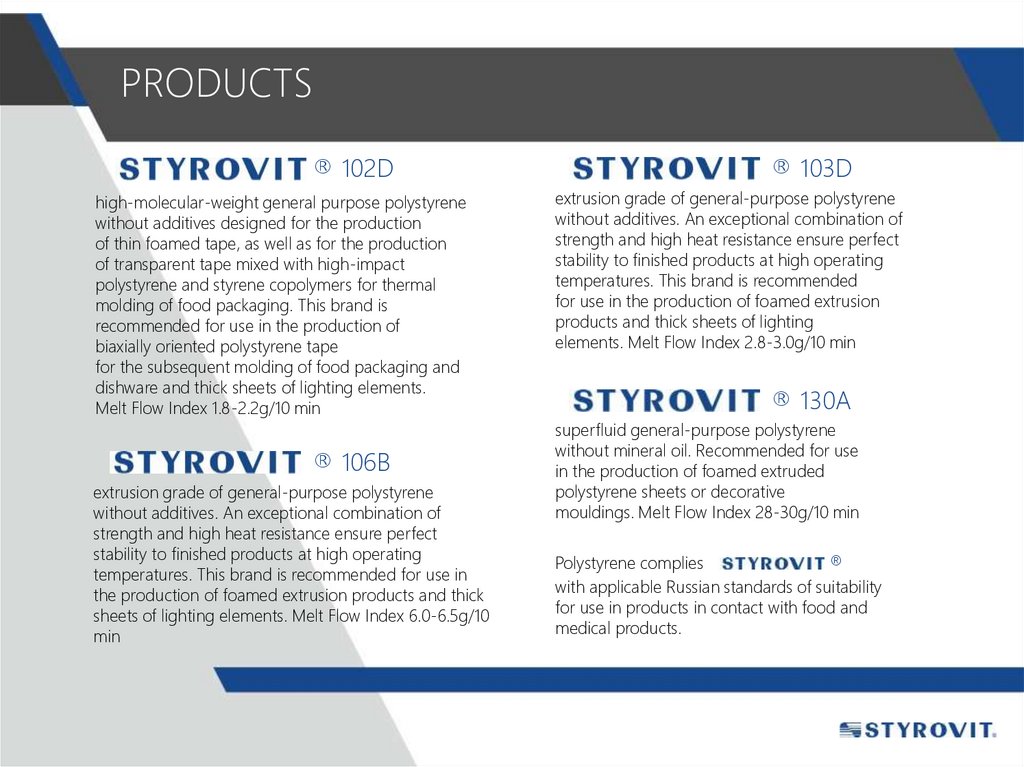

PRODUCTS® 102D

high-molecular-weight general purpose polystyrene

without additives designed for the production

of thin foamed tape, as well as for the production

of transparent tape mixed with high-impact

polystyrene and styrene copolymers for thermal

molding of food packaging. This brand is

recommended for use in the production of

biaxially oriented polystyrene tape

for the subsequent molding of food packaging and

dishware and thick sheets of lighting elements.

Melt Flow Index 1.8-2.2g/10 min

® 106В

extrusion grade of general-purpose polystyrene

without additives. An exceptional combination of

strength and high heat resistance ensure perfect

stability to finished products at high operating

temperatures. This brand is recommended for use in

the production of foamed extrusion products and thick

sheets of lighting elements. Melt Flow Index 6.0-6.5g/10

min

® 103D

extrusion grade of general-purpose polystyrene

without additives. An exceptional combination of

strength and high heat resistance ensure perfect

stability to finished products at high operating

temperatures. This brand is recommended

for use in the production of foamed extrusion

products and thick sheets of lighting

elements. Melt Flow Index 2.8-3.0g/10 min

® 130А

superfluid general-purpose polystyrene

without mineral oil. Recommended for use

in the production of foamed extruded

polystyrene sheets or decorative

mouldings. Melt Flow Index 28-30g/10 min

®

Polystyrene complies

with applicable Russian standards of suitability

for use in products in contact with food and

medical products.

18.

APPLICATIONSINDUSTRIAL AND

FOOD PACKAGING

SMALL AND LARGE

HOUSEHOLD APPLIANCES

THERMAL INSULATION

OF BUILDINGS

ELECTRICAL AND

ELECTRONIC

EQUIPMENT

AUTOMOTIVE

COMPONENTS

TOYS

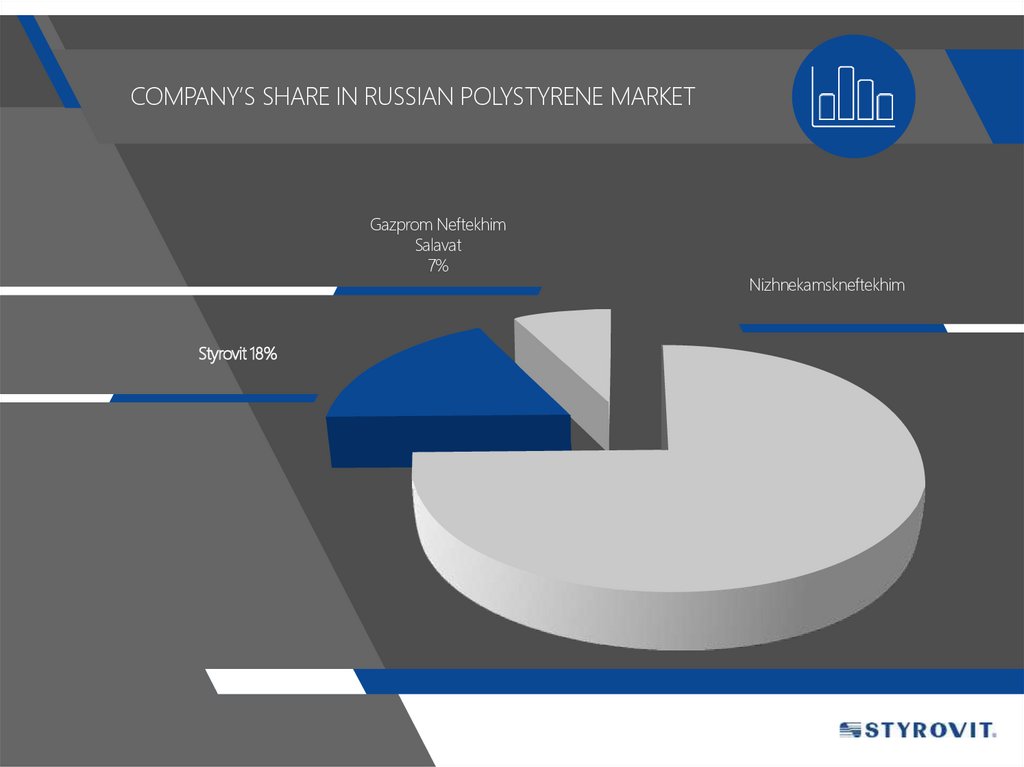

19. COMPANY’S SHARE IN RUSSIAN POLYSTYRENE MARKET

Gazprom NeftekhimSalavat

7%

Styrovit 18%

Nizhnekamskneftekhim

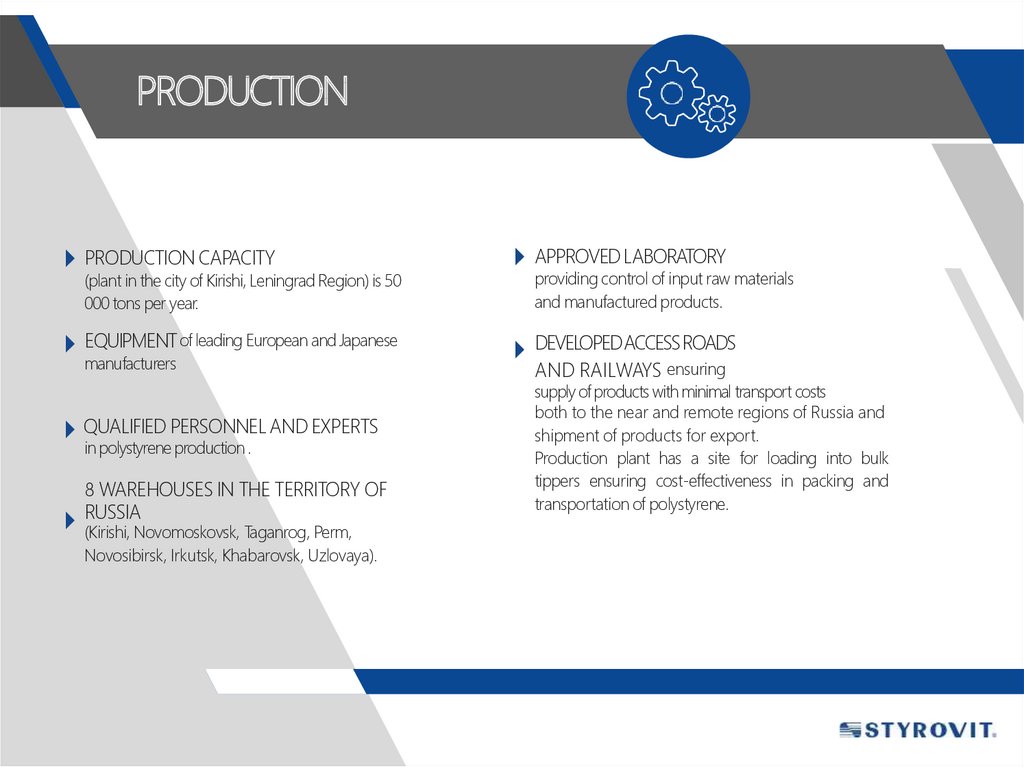

20. PRODUCTION

PRODUCTION CAPACITYAPPROVED LABORATORY

(plant in the city of Kirishi, Leningrad Region) is 50

000 tons per year.

providing control of input raw materials

and manufactured products.

EQUIPMENT of leading European and Japanese

DEVELOPED ACCESS ROADS

AND RAILWAYS ensuring

manufacturers

QUALIFIED PERSONNEL AND EXPERTS

in polystyrene production .

8 WAREHOUSES IN THE TERRITORY OF

RUSSIA

(Kirishi, Novomoskovsk, Taganrog, Perm,

Novosibirsk, Irkutsk, Khabarovsk, Uzlovaya).

supply of products with minimal transport costs

both to the near and remote regions of Russia and

shipment of products for export.

Production plant has a site for loading into bulk

tippers ensuring cost-effectiveness in packing and

transportation of polystyrene.

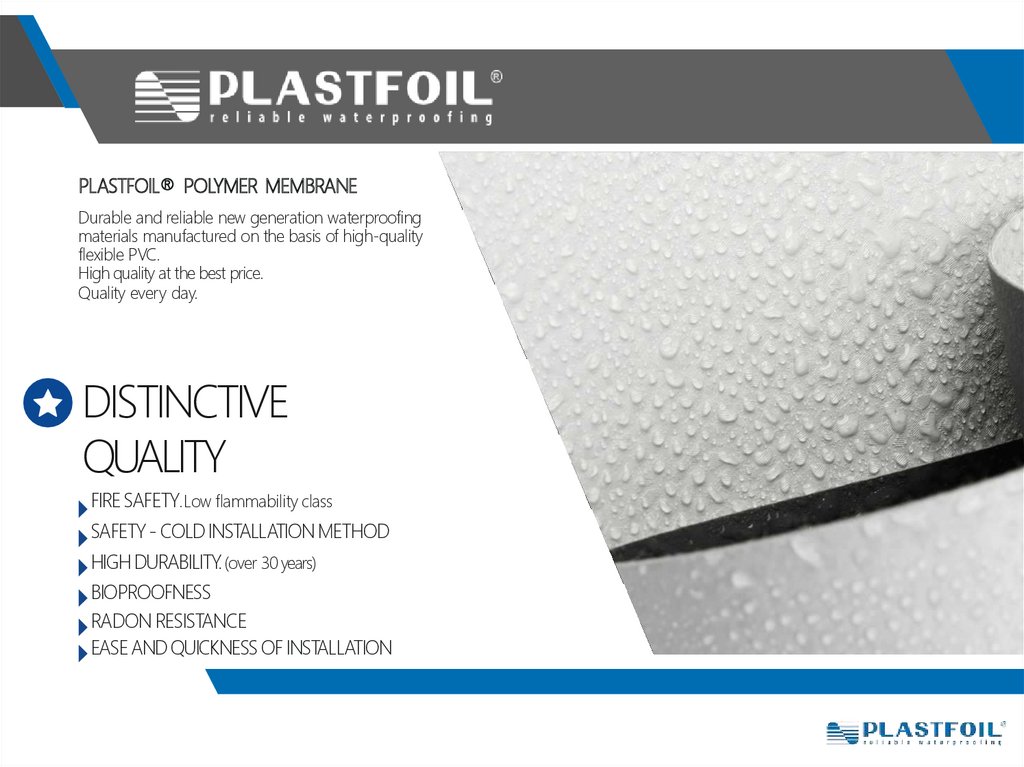

21. PLASTFOIL® POLYMER MEMBRANE

Durable and reliable new generation waterproofingmaterials manufactured on the basis of high-quality

flexible PVC.

High quality at the best price.

Quality every day.

DISTINCTIVE

QUALITY

FIRE SAFETY. Low flammability class

SAFETY - COLD INSTALLATION METHOD

HIGH DURABILITY. (over 30 years)

BIOPROOFNESS

RADON RESISTANCE

EASE AND QUICKNESS OF INSTALLATION

22. PRODUCTS AND SERVICES

ROOFWATERPROOFING

MATERIALS

WATERPROOFING

FOR UNDERGROUND

FACILITIES

Plastfoil Eco, Classic, Polar, Lay, Fl, Art

Plastfoil Geo

ROOF WALKWAYS

TRAINING FOR

ROOFING

COMPANIES

work with PVC, installation supervision at sites,

inspection of existing roofs with the issuance of

an opinion, etc.

23. APPLICATIONS

ROOF WATERPROOFINGFOUNDATIONS

TUNNELS

PIPELINES

UNDERGROUND STRUCTURES

WATERS AND POOLS

24. OBJECTIVES AND PROSPECTS

IMPROVMENT THE QUALITY OF CONSTRUCTIONIn the Russian Federation through the use of modern waterproofing materials.

INCREASE OF SHARE OF POLYMER MEMBRANES

in the market of waterproofing for roofs and underground structures and in private housing construction.

TAKING A LEADING POSITION AT GLOBAL LEVEL

in the production of waterproofing materials.

INCREASE OF PVC SHARE IN THE RUSSIAN FEDERATION

due to the transition from obsolescent bitumen materials to modern polymer

materials.

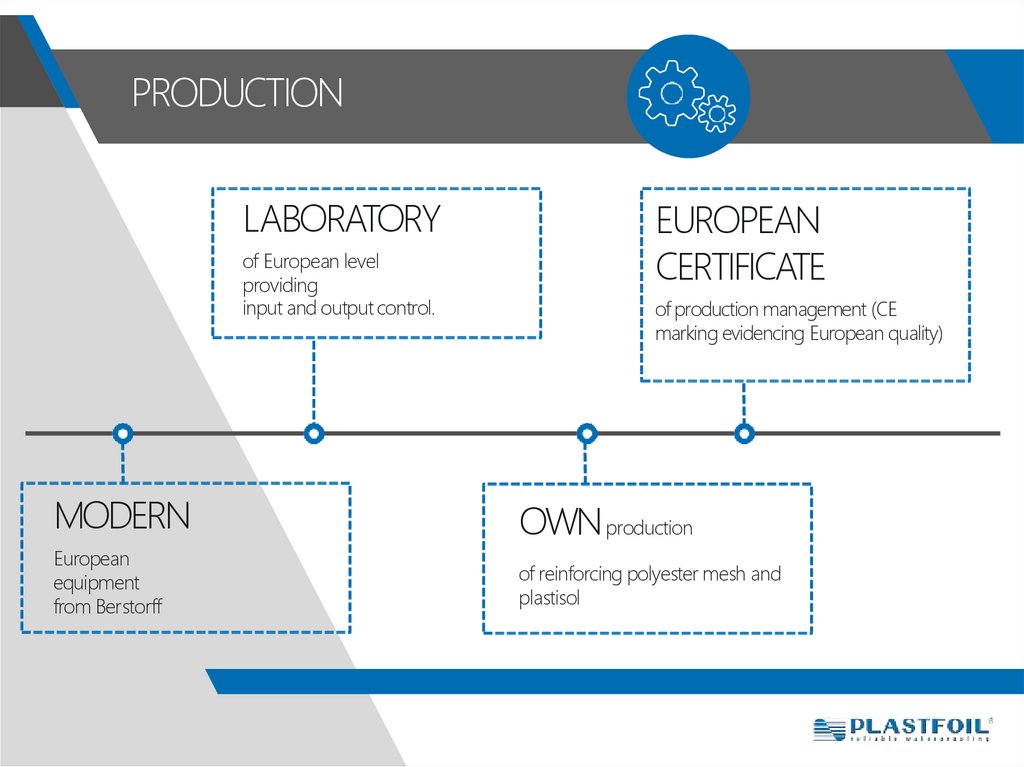

25. PRODUCTION

LABORATORYof European level

providing

input and output control.

EUROPEAN

CERTIFICATE

of production management (CE

marking evidencing European quality)

MODERN

OWN production

European

equipment

from Berstorff

of reinforcing polyester mesh and

plastisol

26. CERTIFICATES

RAASN NIISPh:conclusion on the study to determine the effective life of PLASTFOIL PVC membranes (Roofing

membranes 50 years, Plastfoil Geo - 100 years).

Tambov State Technical University:

conclusion on the study on the possibility of using PLASTFOIL PVC membranes in livestock breeding units.

Federal Budgetary Institution of Science St. Petersburg

Scientific Research Institute of Radiation Hygiene named after Professor P.V. Ramzaev: conclusion on the study

to determine the radiation protective properties of PLASTFOIL Geo waterproofing polymer material for

PLASTFOIL Geo.

Rosatom:

PLASTFOIL PVC membranes are included in the "RosatomRegister of Innovative Solutions".

ISS GRAND-StroyInfo:

PLASTFOIL PVC membranes are included in the electronic library of the cost estimator in construction.

CERTIFIFCATES CE, BROOF (T1, T2, T3), ETAG

CERTIFICATE OF LIABILITY INSURANCE

for the amount of 55 million rubles

27. COMPLETED PROJECTS

Foreign projects:Pig Farm in Germany, Building material store “PRAKTIS” in Bulgaria, Stock of

Gorenje in Czech Republic, Music House in Croatia, Port “ Sillamae” in Estonia,

Shopping moll “ATUT” in Poland, Factory “IKEA” in Belarus, Factory “Carlsberg” in

Kazakhstan and others.

Russian projects:

Supermarket "Lenta", Sports Complex "Olympus" Nevinnomyssk, Troitsk power

plant, Cheboksary Dairy Plant, Kuzbass Agro-industrial Plant, Tibet KAMAZ

Plant, Tobolsk Oil Refinery, "Evalar" Plant, "Ekaterinburg Arena" Stadium,

"Volgabus" Plant and others.

28. STRUCTURE OF ROLLED WATERPROOFING MARKET IN THE RUSSIAN FEDERATION

POLYMER MEMBRANES4%

BITUMEN

MATERIALS

50%

BITUMEN POLYMER

MATERIALS 46%

29. COMPANY SHARE IN THE MARKET OF PVC MEMBRANES IN RUSSIA

OTHER MEMBRANES 5%SIKA

3%

LOGICROOF

60%

PLASTFOIL

32%

30.

DEVELOPMENT AND MANUFACTUREOF DECORATIVE FIXTURES

FROM POLYSTYRENE FOR CEILINGS AND

WALLS FROM 2004.

PRODUCTS:

COVINGS

(classic models, for stretch ceiling, for LED lighting,

with ornament);

MOLDINGS FOR WALLS;

ANGLE SECTIONS FOR COVINGS; BASEBOARD

MOLDINGS OF DUROPOLYMER; ALL-PURPOSE

ADHESIVE.

31. PRODUCTION

PLANTSare equipped with modern

equipment and 100%

automated.

The largest production

WORKS AND

WAREHOUSE PREMISES

ALLRAWMATERIAL

(own-produced polystyrene)

is not harmful and has

hygienic certificates.

GUARANTEES

of safety of the goods

during transportation and storage

(3-layer cardboard boxes,

polyethylene liner).

ACCREDITED FACTORY

LABORATORY

is involved in a 4-step inspection of product

quality.

32. STRATEGIC OBJECTIVES:

EXPANSIONin the market of Russia

and neighboring

countries. Entering new

markets;

INCREASING

the range of products.

Production of unique models.

Production of related products.

Introduction of new stock item

group;

IMPROVING

the quality of customer

service

33. STRUCTURE OF DECORATIVE AND FINISHING MATERIALS MARKET IN RUSSIA

DUROPOLYMER 8%INJECTION

POLYSTYRENE (EPS)

35%

POLYURETHAN

12%

EXTRUSION

POLYSTYRENE 45%

34. COMPANY SHARE IN THE DECORATIVE AND FINISHING MATERIALS MARKET IN RUSSIA

OTHER2%

FORMAT

12%

KIN

11%

SOLID

25%

PLINTEX

21%

DE BAGET

6%

NMC

23%

35.

FASTFIX BUSINESS LINE ISREPRESENTED BY THE

FOLLOWING RANGE OF

PRODUCTS:

CONSTRUCTION FOAM, ADHESIVE,

JOINT FILLERS AND SPRAY-ON THERMAL INSULATION

FOR INSULATION,

SEALING AND CONNECTING VARIOUS

BUILDING AND HOUSEHOLD MATERIALS

36. HOUSEHOLD USE

A product line that meets the high standards of professionals,but is adapted for ease of use in everyday life. The products are

notable for a wide range

which includes goods intended for different types of

work: from a small repair in the house to major construction

works.

PENOPLEX FASTFIX ADHESIVE FOAM

PENOPLEX FASTFIX CONSTRUCTION FOAM

FASTFIX THERMAL INSULATION

PENOPLEX FASTFIX CLEANING AGENT

PENOPLEX FASTFIX SANITARY SILICONE SEALANT 280 ml

PENOPLEX FASTFIX SILICONE SEALANT 280 ml

PENOPLEX FASTFIX ACRYLIC SEALANT 280 ml

37. PROFESSIONAL USE

A range of products for use primarily in theprofessional

construction industry.

Products are characterized by a unique set of

properties and technical characteristics and

show a consistently excellent result in any

operating environment

by professionals.

PENOPLEX FASTFIX ADHESIVE FOAM

PENOPLEX FASTFIX PROFESSIONAL CONSTRUCTION FOAM 65 l

PENOPLEX FASTFIX PROFESSIONAL CONSTRUCTION FOAM 45 l

PENOPLEX FASTFIX 4 PROFESSIONAL CONSTRUCTION FOAM (WINTER)

FASTFIX THERMAL INSULATION

FASTFIX SANITARY SEALANT 750 ml

PENOPLEX FASTFIX SILICONE SEALANT 750 ml

PENOPLEX FASTFIX ACRYLIC SEALANT 750 ml

38.

THANK YOUFOR YOUR ATTENTION

industry

industry