Similar presentations:

User Manual

1.

A4 SeriesUser Manual

2.

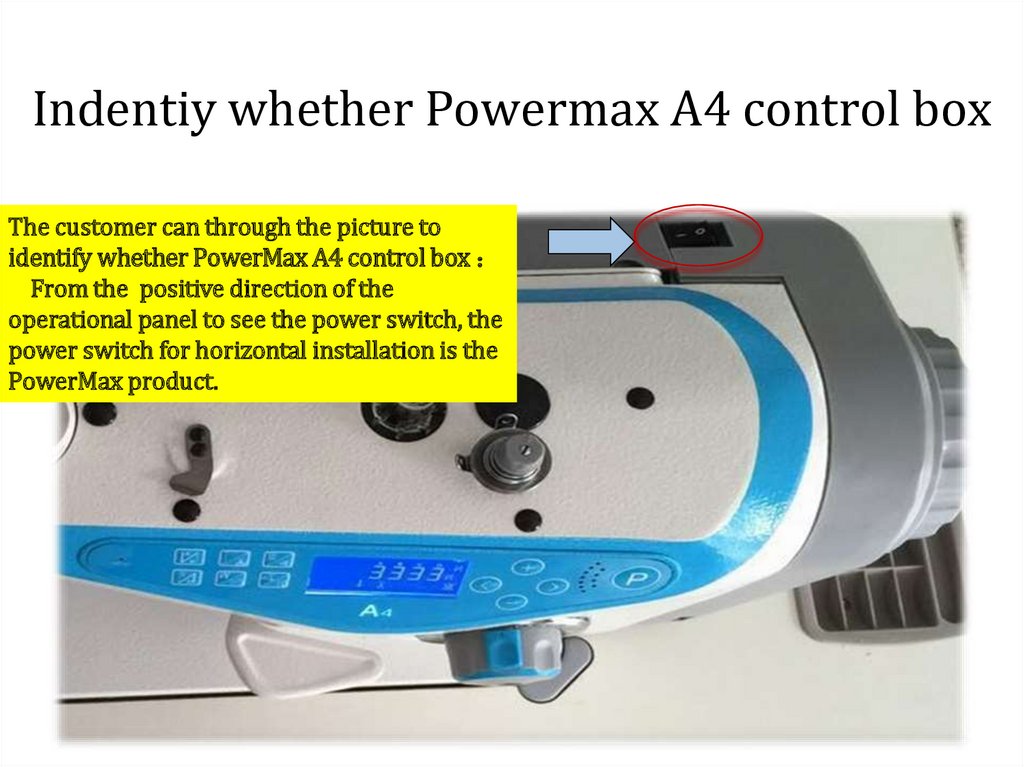

Indentiy whether Powermax A4 control boxThe customer can through the picture to

identify whether PowerMax A4 control box

From the positive direction of the

operational panel to see the power switch, the

power switch for horizontal installation is the

PowerMax product.

3.

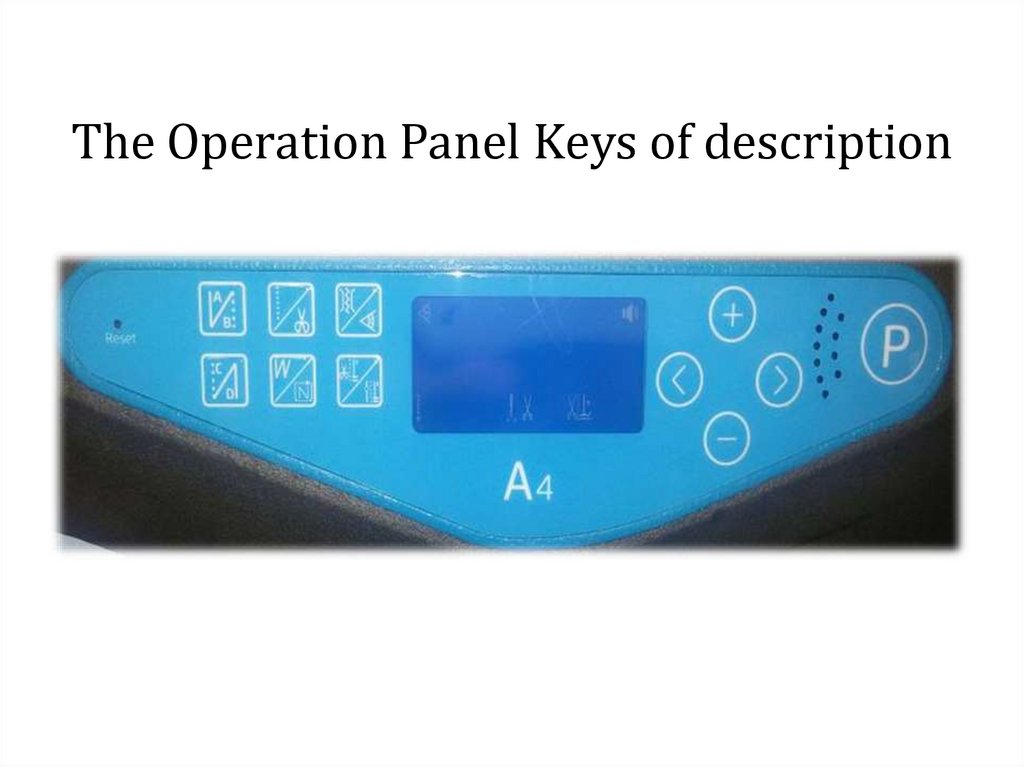

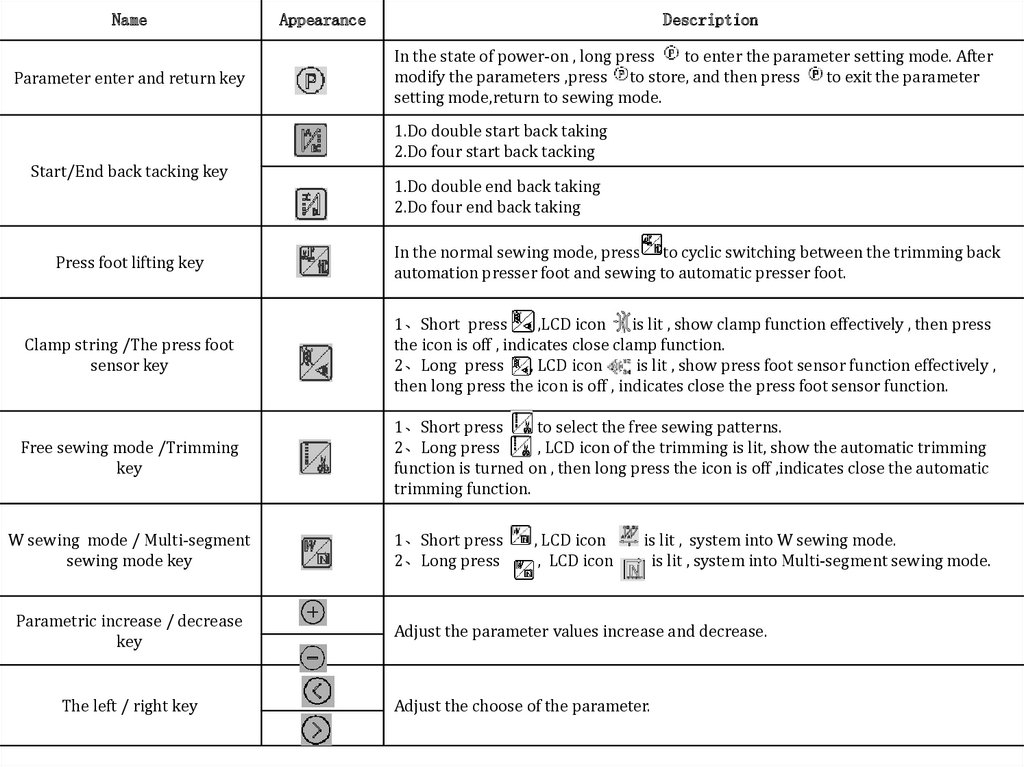

The Operation Panel Keys of description4.

NameParameter enter and return key

Appearance

Description

In the state of power-on , long press

to enter the parameter setting mode. After

modify the parameters ,press to store, and then press

to exit the parameter

setting mode,return to sewing mode.

1.Do double start back taking

2.Do four start back tacking

Start/End back tacking key

1.Do double end back taking

2.Do four end back taking

Press foot lifting key

In the normal sewing mode, press to cyclic switching between the trimming back

automation presser foot and sewing to automatic presser foot.

Clamp string /The press foot

sensor key

1、Short press

,LCD icon

is lit , show clamp function effectively , then press

the icon is off , indicates close clamp function.

2、Long press

, LCD icon

is lit , show press foot sensor function effectively ,

then long press the icon is off , indicates close the press foot sensor function.

Free sewing mode /Trimming

key

1、Short press

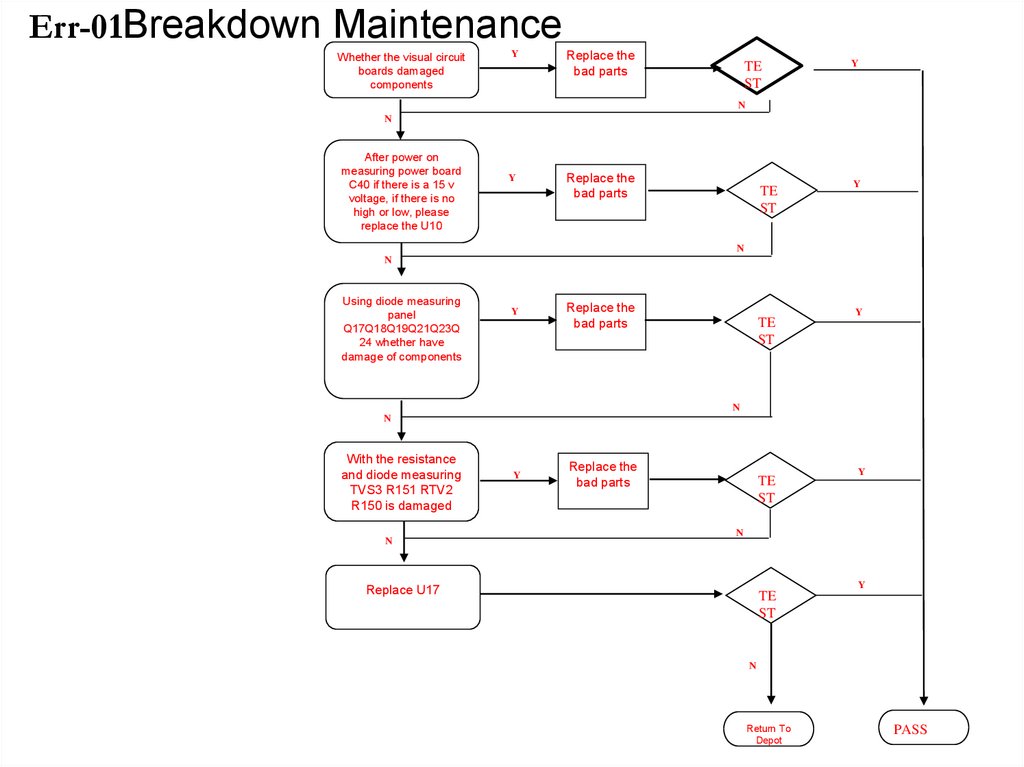

to select the free sewing patterns.

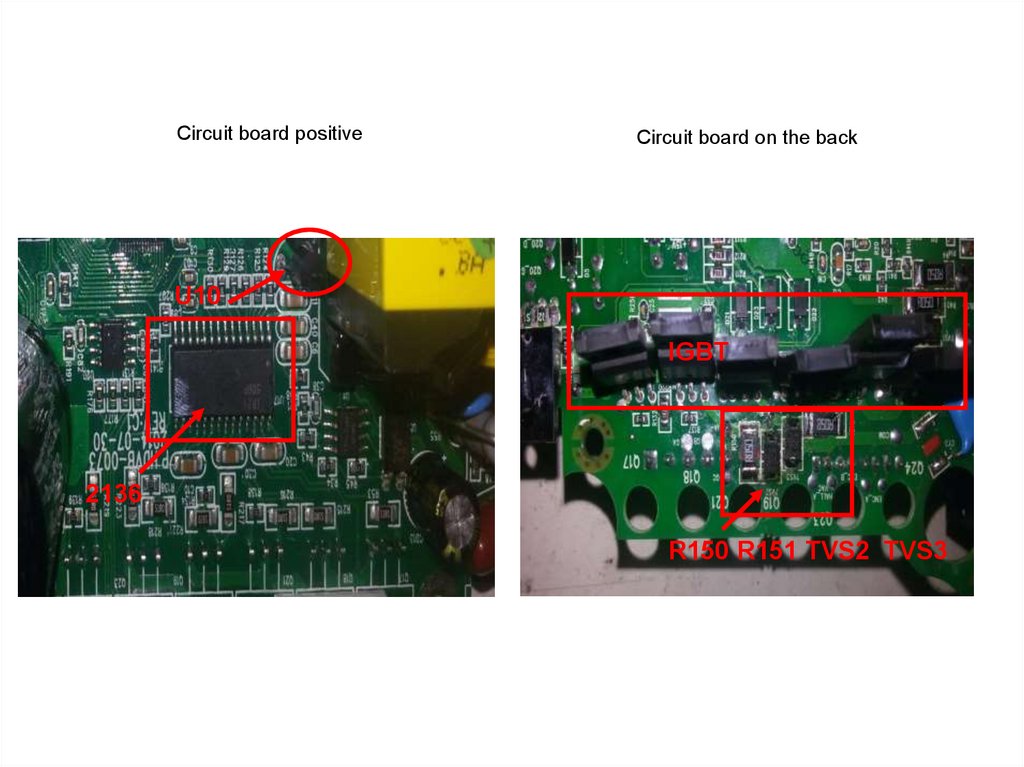

2、Long press

, LCD icon of the trimming is lit, show the automatic trimming

function is turned on , then long press the icon is off ,indicates close the automatic

trimming function.

W sewing mode / Multi-segment

sewing mode key

Parametric increase / decrease

key

The left / right key

1、Short press

2、Long press

, LCD icon

, LCD icon

is lit , system into W sewing mode.

is lit , system into Multi-segment sewing mode.

Adjust the parameter values increase and decrease.

Adjust the choose of the parameter.

5.

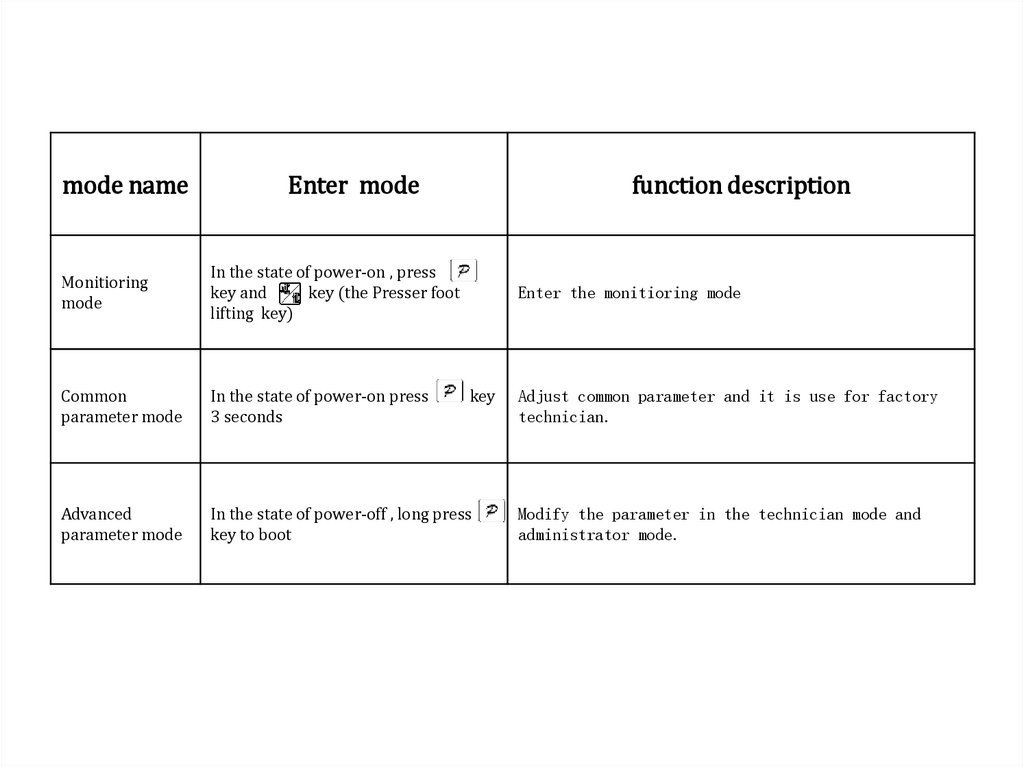

mode nameEnter mode

function description

Monitioring

mode

In the state of power-on , press

key and

key (the Presser foot

lifting key)

Common

parameter mode

In the state of power-on press

3 seconds

Advanced

parameter mode

In the state of power-off , long press

key to boot

Enter the monitioring mode

key

Adjust common parameter and it is use for factory

technician.

Modify the parameter in the technician mode and

administrator mode.

6.

Motor Introduction7.

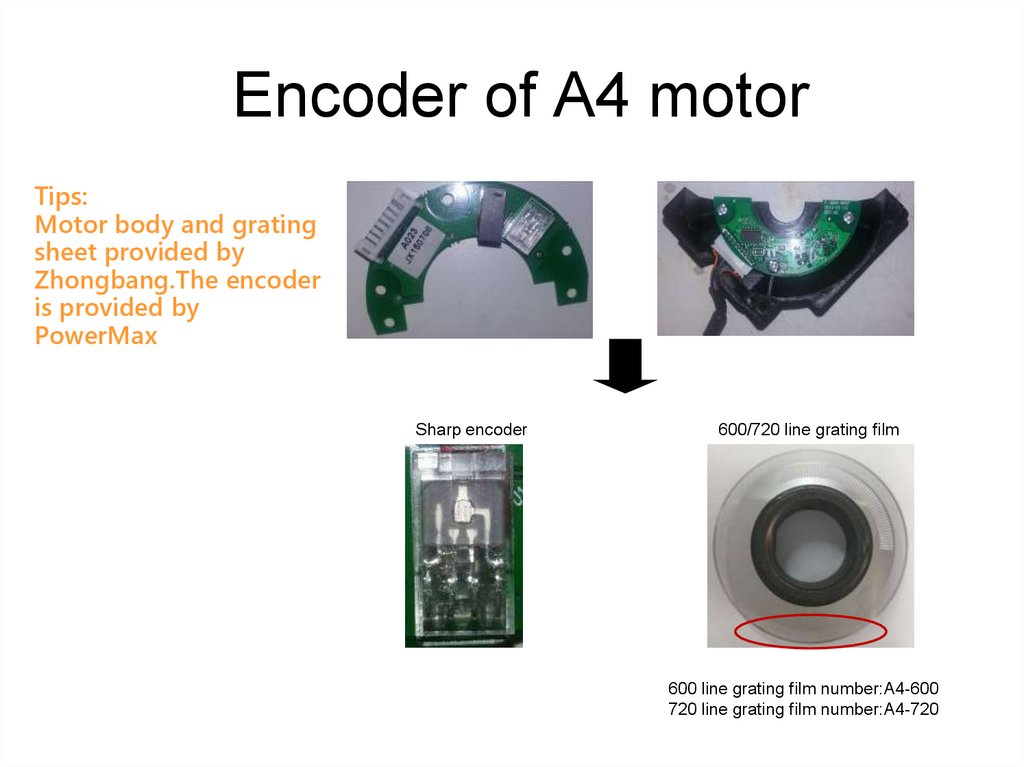

Encoder of A4 motorTips:

Motor body and grating

sheet provided by

Zhongbang.The encoder

is provided by

PowerMax

Sharp encoder

600/720 line grating film

600 line grating film number:A4-600

720 line grating film number:A4-720

8.

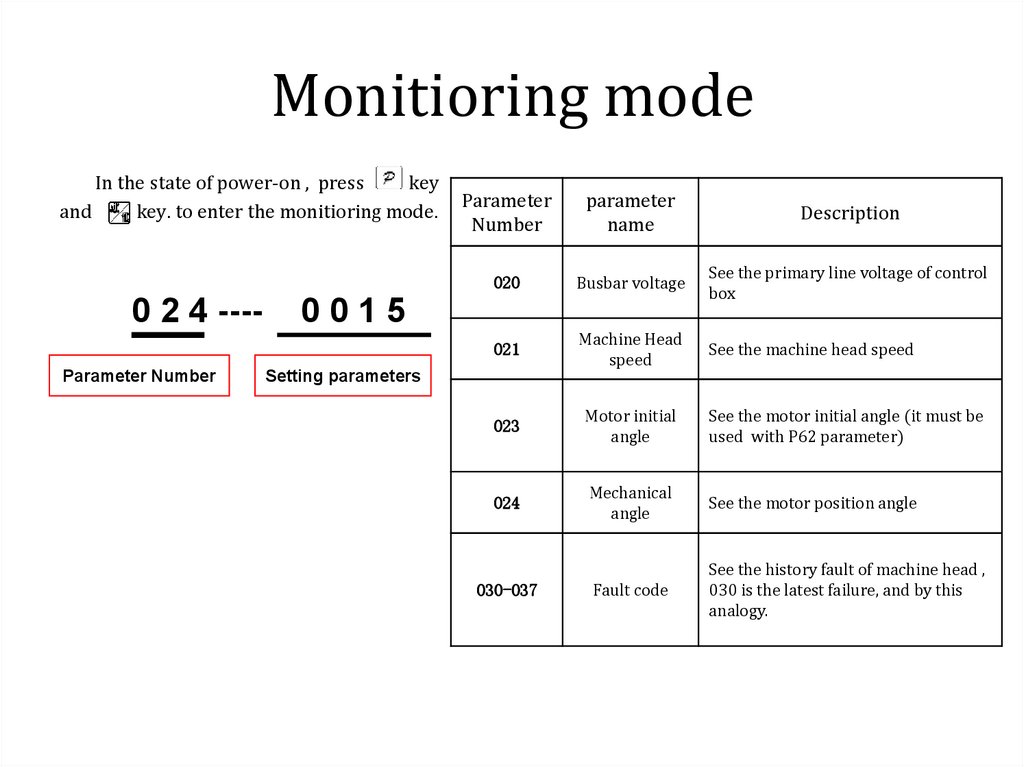

Monitioring modeIn the state of power-on , press

key

and

key. to enter the monitioring mode.

0 2 4 ---Parameter Number

Parameter

Number

parameter

name

Description

020

Busbar voltage

See the primary line voltage of control

box

021

Machine Head

speed

See the machine head speed

023

Motor initial

angle

See the motor initial angle (it must be

used with P62 parameter)

024

Mechanical

angle

See the motor position angle

030-037

Fault code

See the history fault of machine head ,

030 is the latest failure, and by this

analogy.

0015

Setting parameters

9.

Common mode parametersSpeed parameter adjustment

Speed locking

Restore Factory

Upper stop position adjust

A key to save the parameter setting

Constant sewing function setting

Motor initial angle measurement

language selection

10.

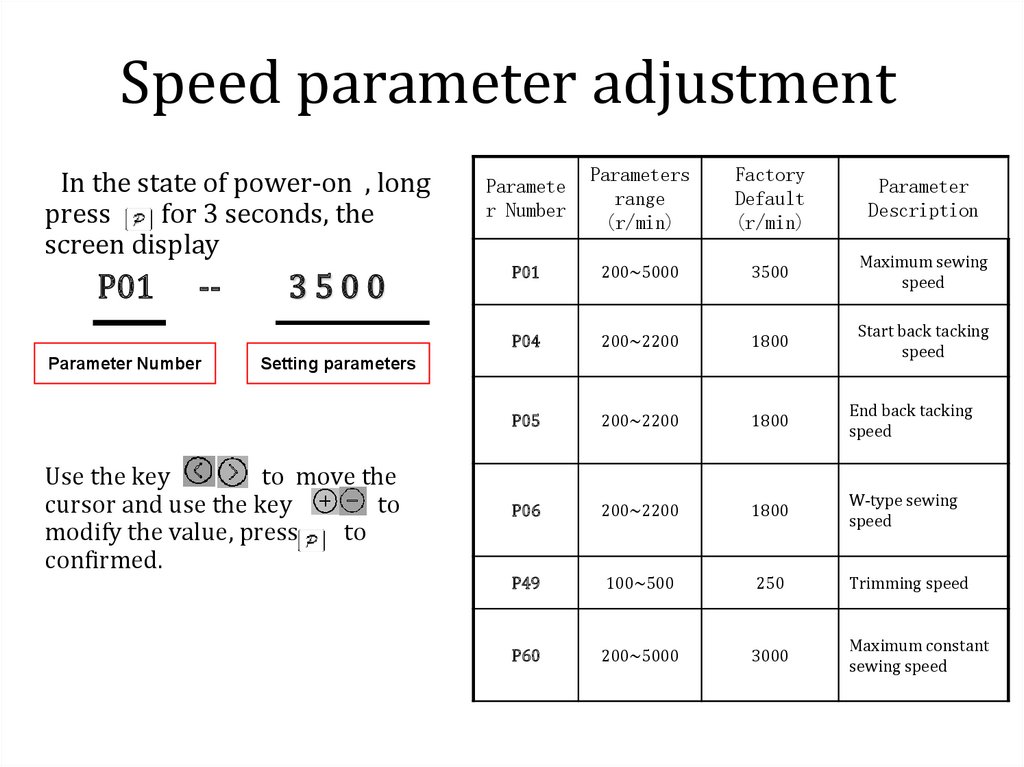

Speed parameter adjustmentIn the state of power-on , long

press

for 3 seconds, the

screen display

P01

--

Parameter Number

3500

Paramete

r Number

Parameters

range

(r/min)

Factory

Default

(r/min)

Parameter

Description

P01

200~5000

3500

Maximum sewing

speed

P04

200~2200

1800

Start back tacking

speed

P05

200~2200

1800

End back tacking

speed

P06

200~2200

1800

W-type sewing

speed

P49

100~500

250

Trimming speed

P60

200~5000

3000

Maximum constant

sewing speed

Setting parameters

Use the key

to move the

cursor and use the key

to

modify the value, press

to

confirmed.

11.

Lock speed settingIn the state of power-on ,long

press

for 3 seconds to enter

the parameter adjustment .

P68 -P68 parameter

is the maximum

lock speed

0000

Setting the maximum lock

speed

After setting press

take effect

to confirm, re-switch

Parameter

Number

Parameter

Range

Factory

Default

Parameter

Description

P68

0~5000

3500

The

maximum

speed lock

12.

Restore factoryUse needle-like object to click the hole which under the “Reset” on the left

monitor for one second and the screen display:

8888888

And then return to the standby monitor indicates restore factory is

successed.

Note: If "Reset" button is damaged, you can reference the advanced

parameters to Restore factory settings

13.

Upper stop position adjustStep one:first press

key ,then press

key , enter into monitor mode . The

default is 024,monitoring parameters , LCD screen displays the current point

of view.

Step Two:turn the hand wheel , let the thread take-up lever to the needle stop

position or hope appropriate position adjusting to ,the liquid crystal display

screen adjustment of needle position.

Step three: first press

key , then press

key , make the mechanical

deflection angle is zero , on needle position . Finally, according to the key

exit .

to

14.

A key to save machine head parameterFunction: users can save any changes for the parameters into the system by following

these steps.

Step one:First press

key ,then press

024 , monitoring parameters.

Step two; Long press

parameters.

key , enter into monitor mode ; the default is

key for more then 3 seconds ,start a key to save machine head

Note: Press “Reset” will restore the most recently saved parameters after saving

parameters

15.

Constant sewing function settingFunction: fixed-length slit open after the trigger function, touch the pedal is automatically set in

accordance with the fixed length of the complete stitch sewing process parameters, the process is

not completed before the middle of the parking impact

Step:

Step one: long key

three seconds, the screen shows P01-01-16 set the total number of multi-seam section

P01

The total number

of segments set

-

01

-

16

Each pin

number

Number of

segments

Step Two: Press the panel button

after setting the top right corner of the screen

display

, shows the trigger function to play。

Step Three: After a light step on the foot controller automatically complete fixed slit

16.

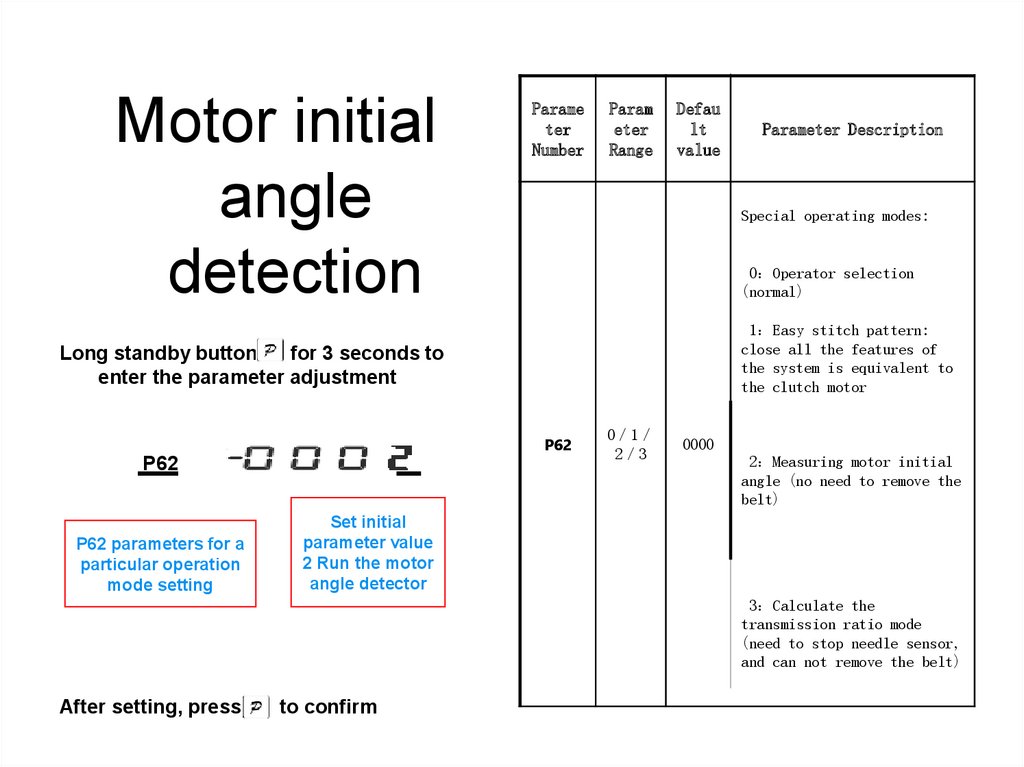

Motor initialangle

detection

Parame

ter

Number

Param

eter

Range

Defau

lt

value

Special operating modes:

0 Operator selection

(normal)

1 Easy stitch pattern:

close all the features of

the system is equivalent to

the clutch motor

Long standby button

for 3 seconds to

enter the parameter adjustment

P62

P62

P62 parameters for a

particular operation

mode setting

Parameter Description

0 1

2 3

0000

2 Measuring motor initial

angle (no need to remove the

belt)

Set initial

parameter value

2 Run the motor

angle detector

3 Calculate the

transmission ratio mode

(need to stop needle sensor,

and can not remove the belt)

After setting, press

to confirm

17.

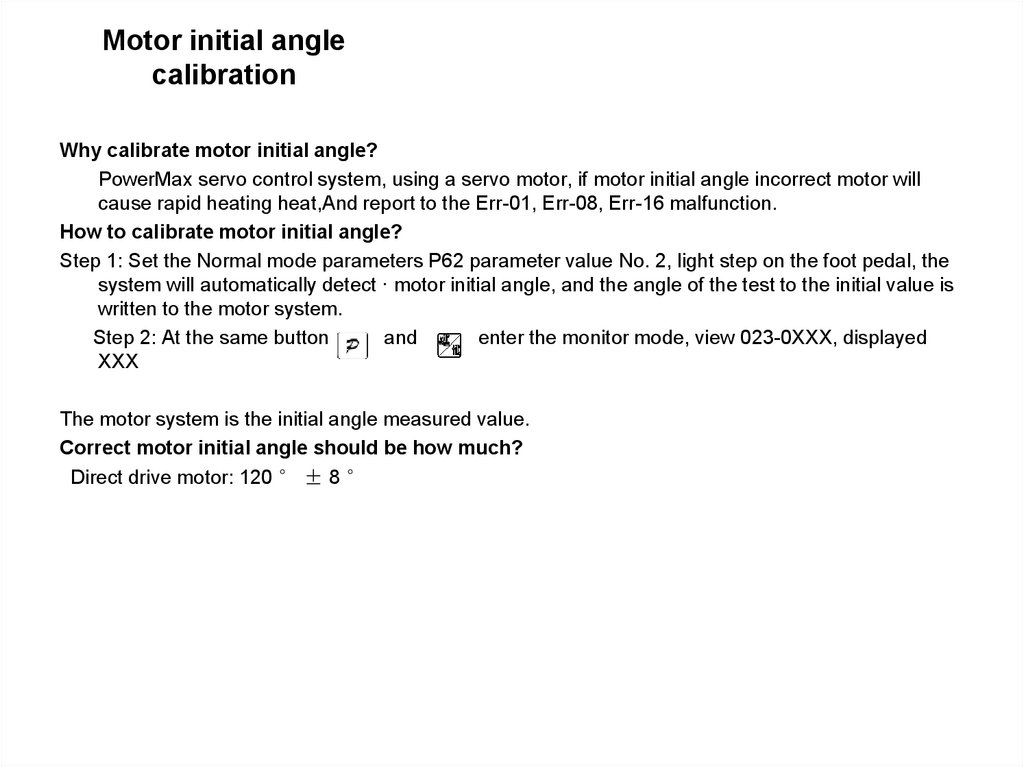

Motor initial anglecalibration

Why calibrate motor initial angle?

PowerMax servo control system, using a servo motor, if motor initial angle incorrect motor will

cause rapid heating heat,And report to the Err-01, Err-08, Err-16 malfunction.

How to calibrate motor initial angle?

Step 1: Set the Normal mode parameters P62 parameter value No. 2, light step on the foot pedal, the

system will automatically detect · motor initial angle, and the angle of the test to the initial value is

written to the motor system.

Step 2: At the same button

and

enter the monitor mode, view 023-0XXX, displayed

XXX

The motor system is the initial angle measured value.

Correct motor initial angle should be how much?

Direct drive motor: 120 ° ± 8 °

18.

languageselection

Paramet

er

Number

Paramete

r Range

Defaul

t

value

Parameter Description

Long standby button

for 3 seconds to

enter the parameter setting

P99 ----- 0001

0000 shut down

P99

P99 parameter

selection

parameters for

the language

After setting, press

Language

according to

their needs

to confirm

0/1/2

1

0001 Chines

0002 English

19.

Advanced parameter setting• Acceleration

sensitivity setting

• Pedal response

control settings

• reset

20.

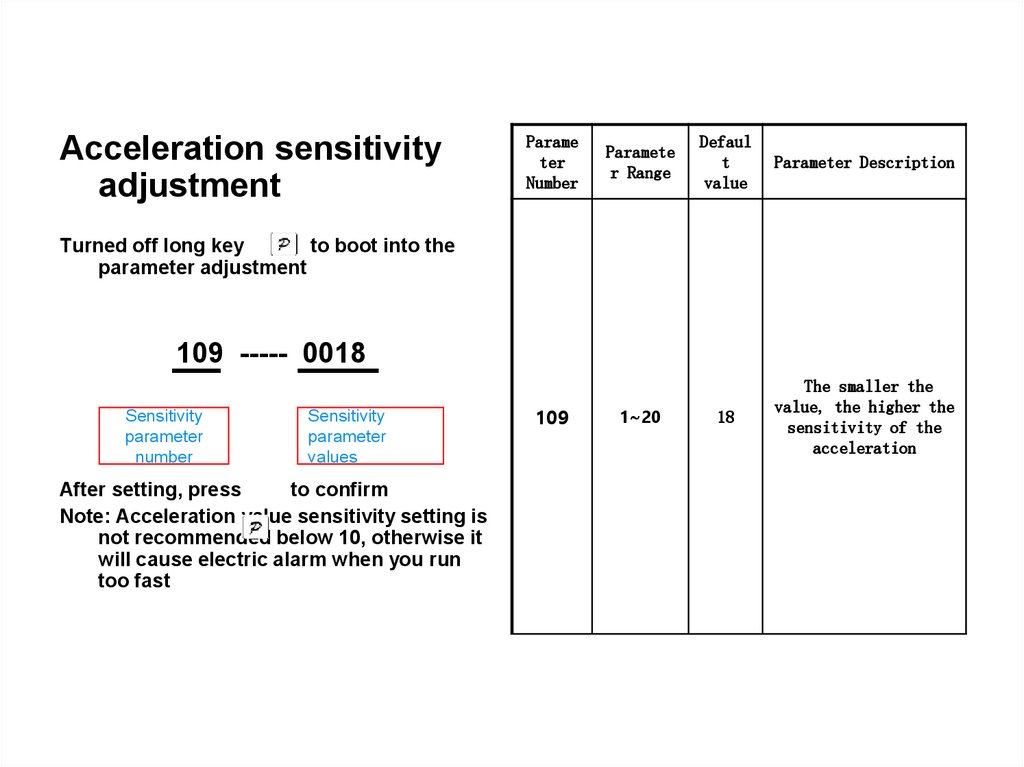

Acceleration sensitivityadjustment

Parame

ter

Number

Paramete

r Range

Defaul

t

value

Parameter Description

18

The smaller the

value, the higher the

sensitivity of the

acceleration

Turned off long key

to boot into the

parameter adjustment

109 ----- 0018

Sensitivity

parameter

number

Sensitivity

parameter

values

After setting, press

to confirm

Note: Acceleration value sensitivity setting is

not recommended below 10, otherwise it

will cause electric alarm when you run

too fast

109

1~20

21.

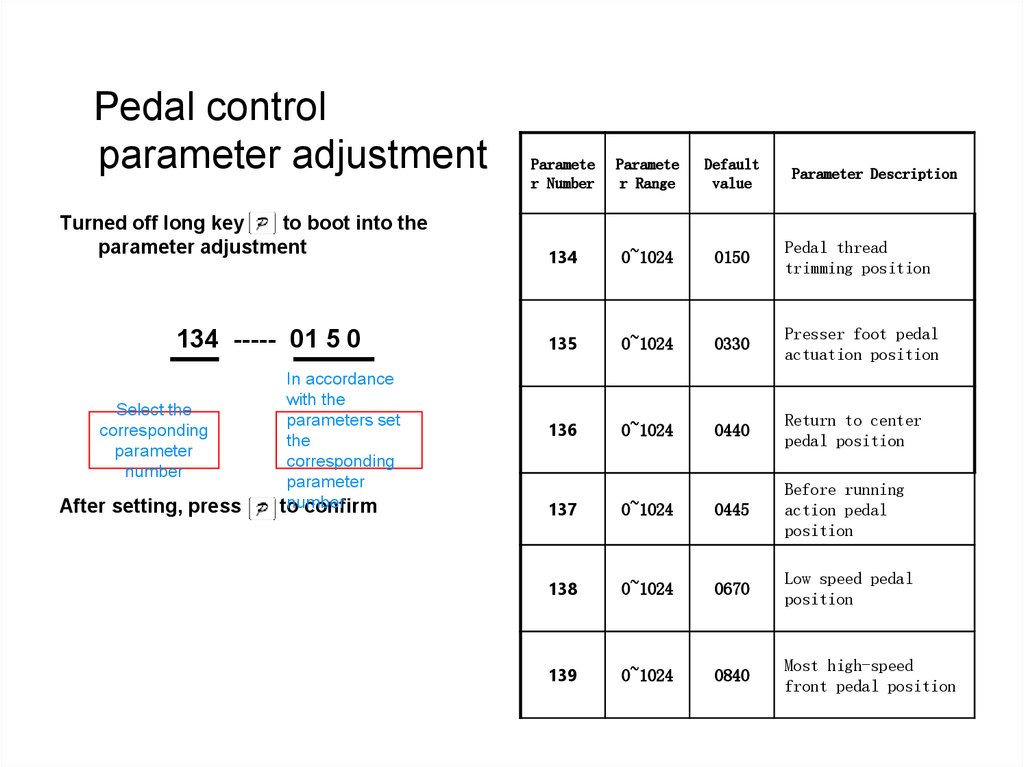

Pedal controlparameter adjustment

Turned off long key

to boot into the

parameter adjustment

134 ----- 01 5 0

Select the

corresponding

parameter

number

After setting, press

In accordance

with the

parameters set

the

corresponding

parameter

number

to

confirm

Paramete

r Number

Paramete

r Range

Default

value

134

0~1024

0150

Pedal thread

trimming position

135

0~1024

0330

Presser foot pedal

actuation position

136

0~1024

0440

Return to center

pedal position

Parameter Description

137

0~1024

0445

Before running

action pedal

position

138

0~1024

0670

Low speed pedal

position

139

0~1024

0840

Most high-speed

front pedal position

22.

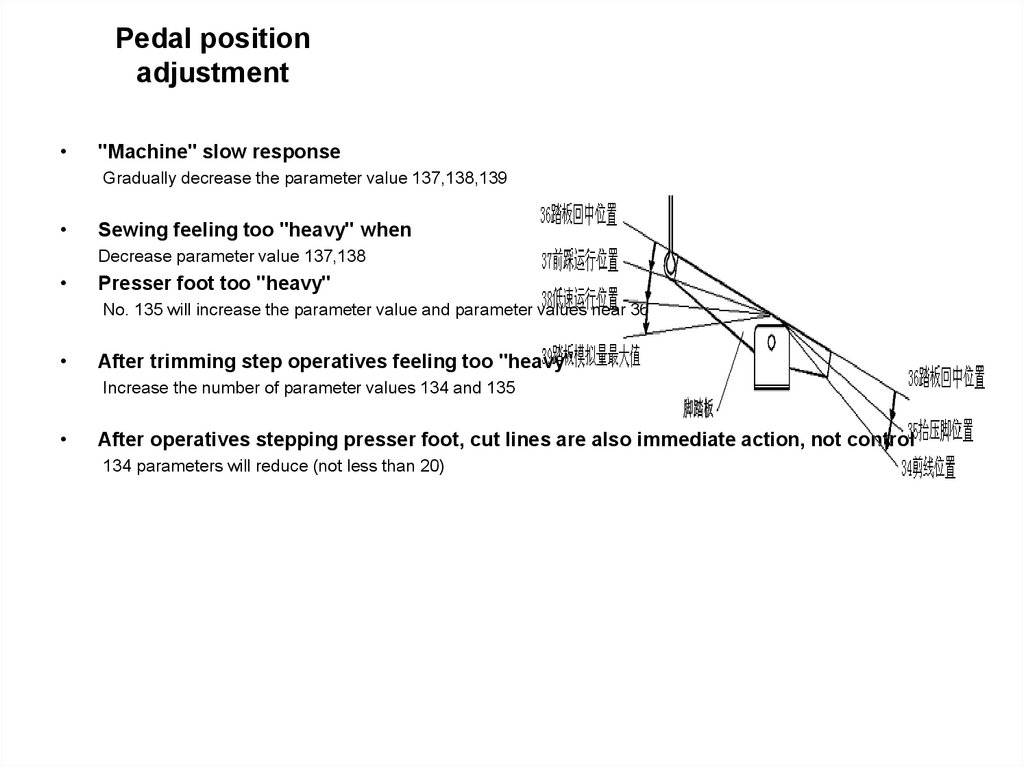

Pedal positionadjustment

"Machine" slow response

Gradually decrease the parameter value 137,138,139

Sewing feeling too "heavy" when

Decrease parameter value 137,138

Presser foot too "heavy"

No. 135 will increase the parameter value and parameter values near 36

After trimming step operatives feeling too "heavy"

Increase the number of parameter values 134 and 135

After operatives stepping presser foot, cut lines are also immediate action, not control

134 parameters will reduce (not less than 20)

23.

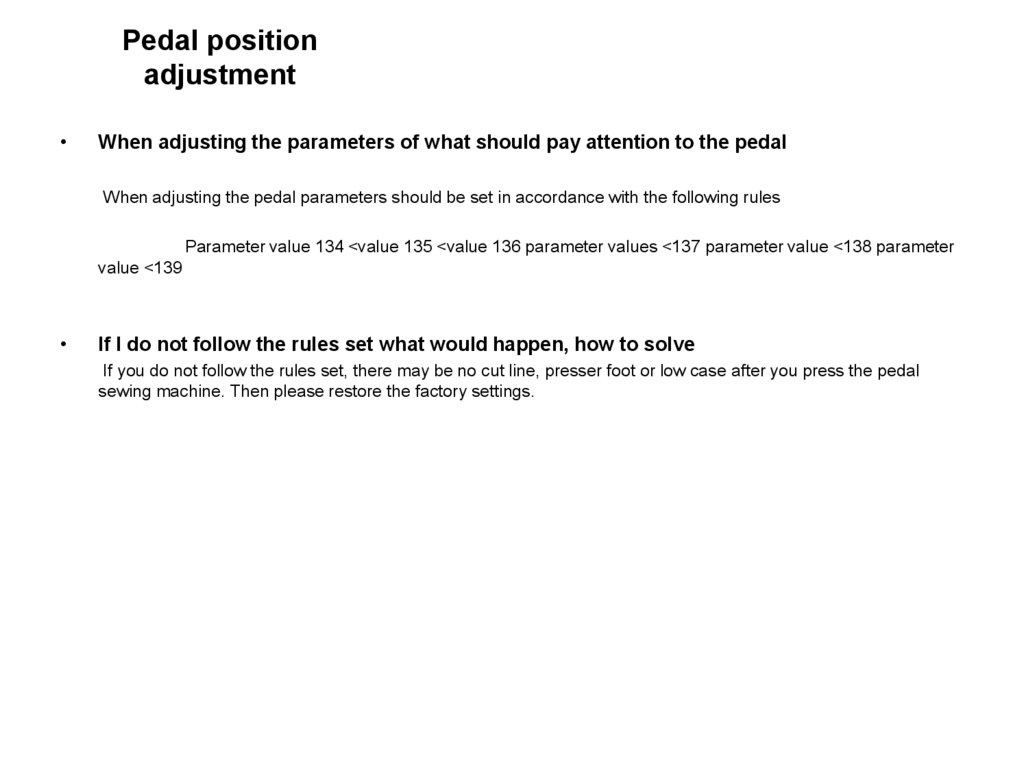

Pedal positionadjustment

When adjusting the parameters of what should pay attention to the pedal

When adjusting the pedal parameters should be set in accordance with the following rules

Parameter value 134 <value 135 <value 136 parameter values <137 parameter value <138 parameter

value <139

If I do not follow the rules set what would happen, how to solve

If you do not follow the rules set, there may be no cut line, presser foot or low case after you press the pedal

sewing machine. Then please restore the factory settings.

24.

Restore the factoryTurned off until the power button

long to enter the parameter setting

interface, adjusted to

162

162

parameters to

restore

factory

settings

–

0002

0002 to

restore

factory value

After completion of the setting press

key

three seconds after reverse

stitching restore factory

Note: This feature is under "Reset" button

in case of damage

25.

Fault code• Err-01 (Hardware overcurrent

• Err-03 (System Brown

• Err-04 (When parking

overvoltage)

• Err-05 (Run-time overvoltage)

• Err-07 (Current detection fault)

• Err-08 (Motor stall)

• Err-09 (Brake circuit fault)

• Err-10 (Communication

breakdown)

• Err-13 (Motor fault HALL)

• Err-15(Overspeed fault)

• Err-16 (Motor reverse

fault)

• Err-18 (Motor overload)

• Err-23 (Motor stall

• UP fault Total lift switch

failure

26.

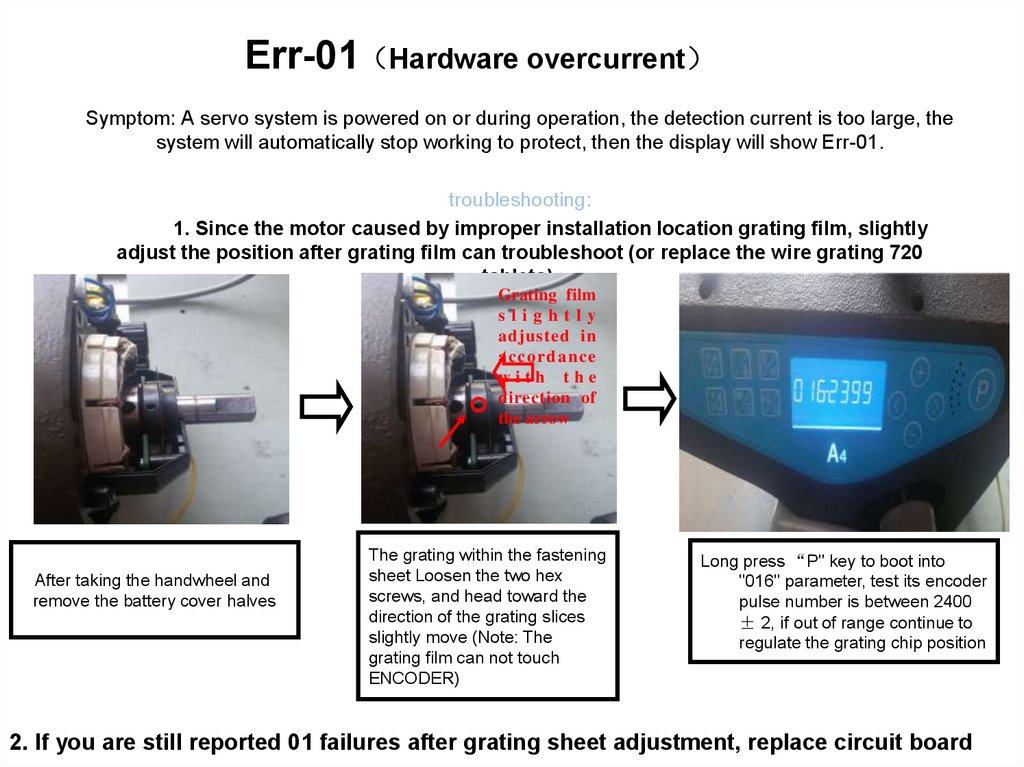

Err-01 Hardware overcurrentSymptom: A servo system is powered on or during operation, the detection current is too large, the

system will automatically stop working to protect, then the display will show Err-01.

troubleshooting:

1. Since the motor caused by improper installation location grating film, slightly

adjust the position after grating film can troubleshoot (or replace the wire grating 720

tablets).

Grating film

slightly

adjusted in

acco rd an ce

with the

direction of

the arrow

After taking the handwheel and

remove the battery cover halves

The grating within the fastening

sheet Loosen the two hex

screws, and head toward the

direction of the grating slices

slightly move (Note: The

grating film can not touch

ENCODER)

Long press “P" key to boot into

"016" parameter, test its encoder

pulse number is between 2400

± 2, if out of range continue to

regulate the grating chip position

2. If you are still reported 01 failures after grating sheet adjustment, replace circuit board

27.

Err-03 System BrownSymptom: A servo system detects if the input voltage is below the normal operating

voltage, the system will automatically stop working to protect the operating panel

displays Err-03 at startup.

troubleshooting:

1. City network voltage is too low

With a multimeter to check the power supply voltage is less

than 220V ± 20%. If the voltage is too low recommendations to

improve the grid voltage.

2. System board component damage

If the grid voltage is normal, it is a system board components

are damaged, replace the system board.

28.

Err-04 When parking overvoltageFault description: detects when the servo system is turned on input voltage is higher than

the normal operating voltage, the system will automatically stop working to protect,

then the panel will show Err-04.

troubleshooting:

1. Check the City Network Voltage

With a multimeter to check the power supply voltage is higher than 220V ± 20%,

if the voltage is too high recommendations to improve the grid voltage.

2. System board component damage

If the grid voltage is normal, it is a system board components are damaged,

replace the system board。

29.

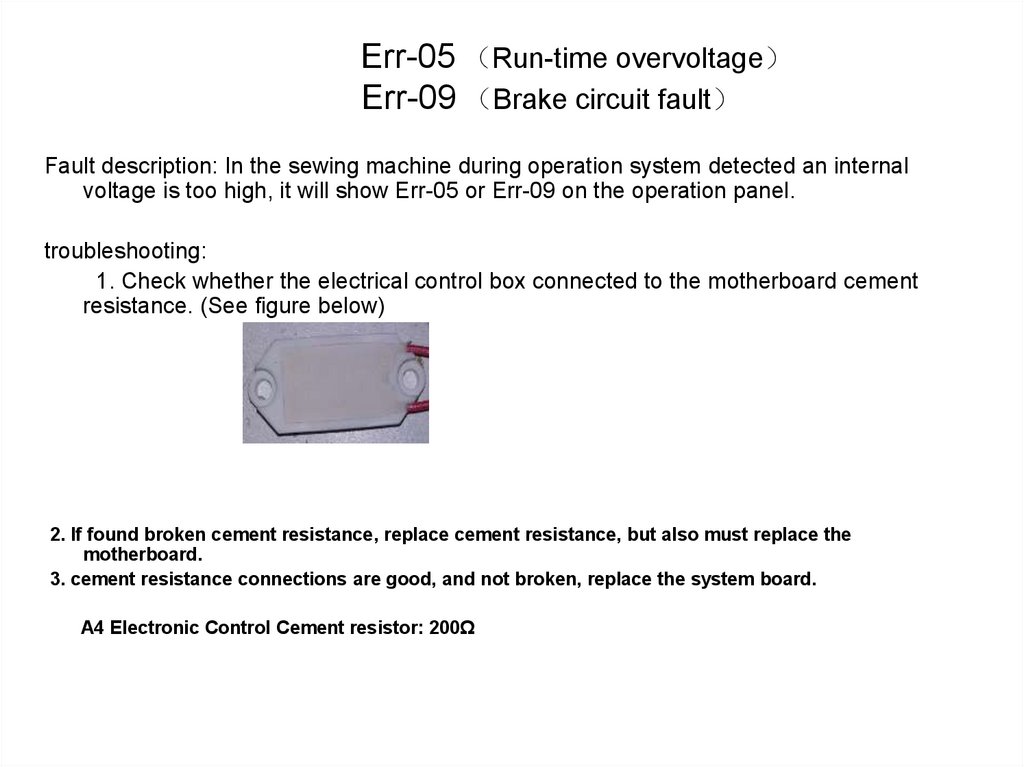

Err-05 Run-time overvoltageErr-09 Brake circuit fault

Fault description: In the sewing machine during operation system detected an internal

voltage is too high, it will show Err-05 or Err-09 on the operation panel.

troubleshooting:

1. Check whether the electrical control box connected to the motherboard cement

resistance. (See figure below)

2. If found broken cement resistance, replace cement resistance, but also must replace the

motherboard.

3. cement resistance connections are good, and not broken, replace the system board.

A4 Electronic Control Cement resistor: 200Ω

30.

Err-07 Current detection circuit faultFailure Description: The system detects when the machine is switched on or

run to the circuit board current sensor is damaged, Err-07 will be displayed

on the operator panel.

troubleshooting:

Replace the electric control box board.

31.

Err-08/ Err-23 Motor stallFault description: In the motor is driven, the system does not detect motor rotation or exceed its load capacity, it will

show Err-08 or Err-23 on the operation panel

troubleshooting:

1. turn on the power, they reported 08

A Check that the motor is dead foreign body stuck.

B according to Err-01 troubleshooting check sheet position raster

2. Restore factory restore factory settings as

3. Daily 08 during sewing

A test motor initial angle (refer to detect motor initial angle method)

B according to Err-01 troubleshooting check sheet position raster

4. If the above method does not resolve, replace the PCB

32.

Err-10 Communication breakdownSymptom: A communication system detected between the

control board and the operator panel is not normal, A4

operator panel displays Err-10.

troubleshooting:

Respectively replacement operation panel or circuit

board

33.

Err-13 motor HALL faultFailure Description: The system detects the motor encoder signal is not

synchronized with the sensor signal, the operation panel displays

Err-13.

troubleshooting:

1. Check the motor and the electronic control of the connection

socket is connected.

2. The motor encoder is damaged, replace encoder.

34.

Err-15 Overspeed faultErr-16 Motor reverse fault

Failure Description: The system detects the motor exceeds the set

value range or the occurrence of the reverse direction, the operator

panel displays Err-15 or Err-16 during operation.

troubleshooting:

1. Test motor initial angle

2. Replace the motor encoder.

35.

Err-18 Motor overloadFailure Description: The system detects motor load is too large, the operation panel

displays Err-18.

troubleshooting:

1. Test motor initial angle

2. Insert the needle position slightly elevated, or changing the trimming cam time

Trimming it slightly longer time

36.

Failure Description: The turn table switch defective Cause This error alarms.Troubleshooting:

1. Power status under long key P to enter the parameter setting

2. Set the parameter to "P66", the screen displays "P66-0002" change it to

"P66-0000".

3. Press the P button to confirm.

37.

No error Troubleshooting38.

Ⅰ. Depress the foot pedal and the motor without any response, whilenot being given the operation panel display

troubleshooting:

1. Check the pedal connected to the

control box is good

2. Replace the pedal.

39.

II. Pedal sewing machine no high-speed,error-free operation panel and display

troubleshooting:

1. Check speed parameter setting is

being modified

2. Replace the pedal.

40.

III. Display no displaytroubleshooting:

A first determine whether it is caused by

damage to the display, please replace the

display case

B as the display normal, replace circuit

board

41.

Circuit board repair42.

Err-01Breakdown MaintenanceWhether the visual circuit

boards damaged

components

Y

Replace the

bad parts

TE

ST

Y

N

N

After power on

measuring power board

C40 if there is a 15 v

voltage, if there is no

high or low, please

replace the U10

Y

Replace the

bad parts

TE

ST

Y

N

N

Using diode measuring

panel

Q17Q18Q19Q21Q23Q

24 whether have

damage of components

Y

Replace the

bad parts

Y

TE

ST

N

N

With the resistance

and diode measuring

TVS3 R151 RTV2

R150 is damaged

N

Y

Replace the

bad parts

TE

ST

Y

N

Y

Replace U17

TE

ST

N

Return To

Depot

PASS

43.

Circuit board positiveCircuit board on the back

U10

IGBT

2136

R150 R151 TVS2 TVS3

44.

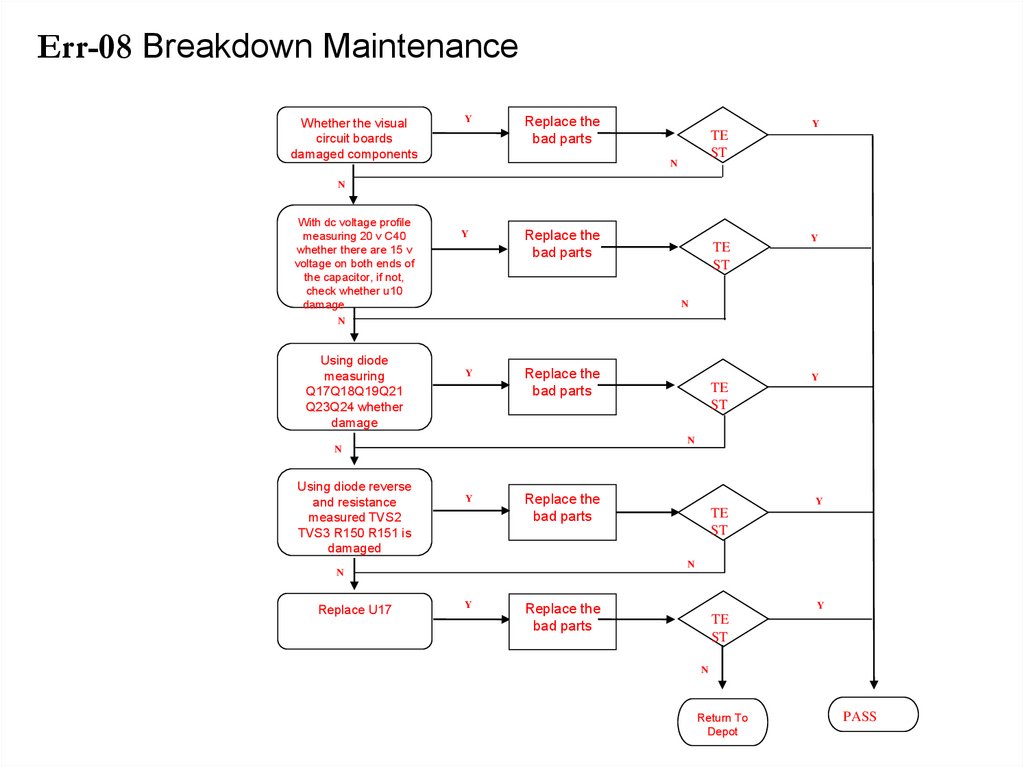

Err-08 Breakdown MaintenanceWhether the visual

circuit boards

damaged components

Y

Replace the

bad parts

Y

TE

ST

N

N

With dc voltage profile

measuring 20 v C40

whether there are 15 v

voltage on both ends of

the capacitor, if not,

check whether u10

damage

Y

Replace the

bad parts

TE

ST

Y

N

N

Using diode

measuring

Q17Q18Q19Q21

Q23Q24 whether

damage

Y

Replace the

bad parts

Y

TE

ST

N

N

Using diode reverse

and resistance

measured TVS2

TVS3 R150 R151 is

damaged

Y

Replace the

bad parts

N

N

Replace U17

Y

TE

ST

Y

Y

Replace the

bad parts

TE

ST

N

Return To

Depot

PASS

45.

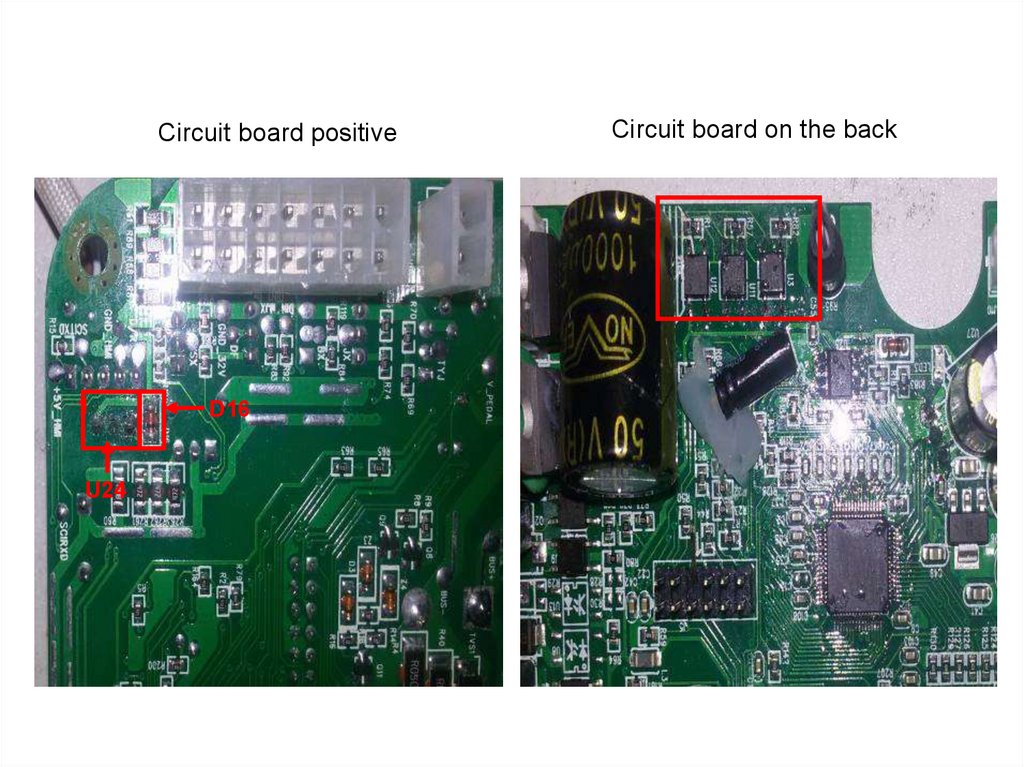

Circuit board positiveCircuit board on the back

U10

IGBT

2136

R150 R151 TVS2 TVS3

46.

Err-10 Breakdown MaintenanceWhether the visual

circuit boards

damaged components

Y

Replace

the bad

parts

TE

ST

Y

N

N

Voltage shift gears

was used to measure

the power plate U24

foot 1 and 2 feet 5 v

voltage output, U24

without replacement

Y

Replace

the bad

parts

TE

ST

Replace

the bad

parts

TE

ST

Y

N

Using diode

measuring panel D16

is damaged

Y

N

N

Measuring R57 R82

resistance is normal

Y

Y

Replace

the bad

parts

TE

ST

Y

N

Y

Replace U3 U11

TE

ST

N

Return

To Depot

PASS

47.

Circuit board positive1

U24

D16

Circuit board on the back

48.

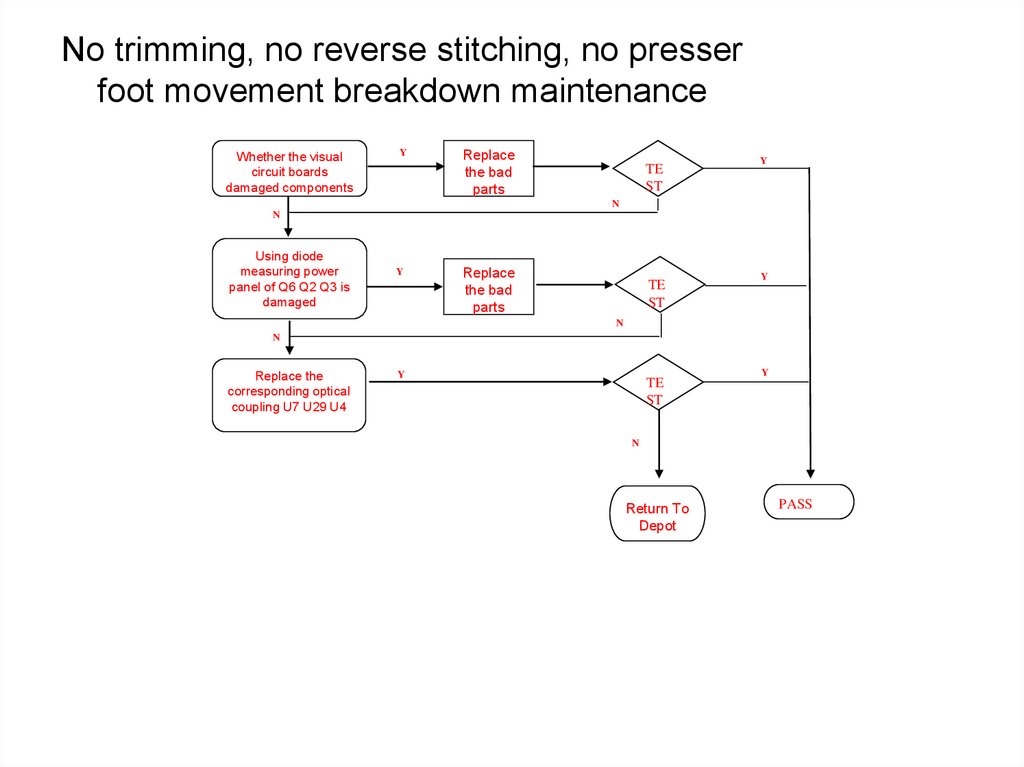

No trimming, no reverse stitching, no presserfoot movement breakdown maintenance

Whether the visual

circuit boards

damaged components

Y

Replace

the bad

parts

TE

ST

Y

N

N

Using diode

measuring power

panel of Q6 Q2 Q3 is

damaged

Y

Replace

the bad

parts

TE

ST

Y

N

N

Replace the

corresponding optical

coupling U7 U29 U4

Y

TE

ST

Y

N

Return To

Depot

PASS

49.

U29U7 U4

Reverse stitching

controlQ2

Shear line

controlQ6

Presser foot

controlQ3

electronics

electronics