Similar presentations:

Modernization of deaerator

1.

Good Practice name: Modernization of deaeratorZone: Europe

Idea

Submission

BU, Brewery: Ivanovo

Category:

Date: 03/06/2019

1

2.

SummaryДля снижения кислорода в питательной

воде для парогенератора в котельных

установлен деаэратор. в него поступает

конденсат и свежая вода и паром

происходит деаэрация. Пар в деаэратор

подается постояно, потому что он

соединён с атмосферой и условие подачи

пара это поддержание уставки по

далению в деаэраторе таким образом

деаэратор это постоянная составляющая

в потреблении тепла

Идея состоит в том, чтобы

модернизировать деаэратор,

использовать восстановленное тепло для

нагрева свежей питательной воды и

конденсата, а также открывать клапан

подачи пара в деаратор только в тот

момент, когда в него подается свежая

вода и не деаэрировать конденсат, в

котором нет кислорода

To reduce oxygen in the feed water for the

steam generator, a deaerator is installed in

the boiler rooms. condensate and fresh

water enter it and deaeration occurs with

steam. Steam to the deaerator is supplied

continuously, because it is connected to the

atmosphere and the condition for steam

supply is to maintain the set point in the

deaerator, so the deaerator is a constant

component in the heat consumption

The idea is to upgrade the deaerator,

use the recovered heat to heat fresh

feed water and condensate, and also

open the steam supply valve to the

deaerator only when fresh water is

supplied to it and not deaerate

condensate that is not oxygenated

BEFORE

IDEA

Результатом внедрения

данной инициативы

было большое

снижение потребления

тепла на деаэратор

The result of the

implementation of this

initiative was a large

reduction in heat

consumption at the

deaerator

RESULT

2

3.

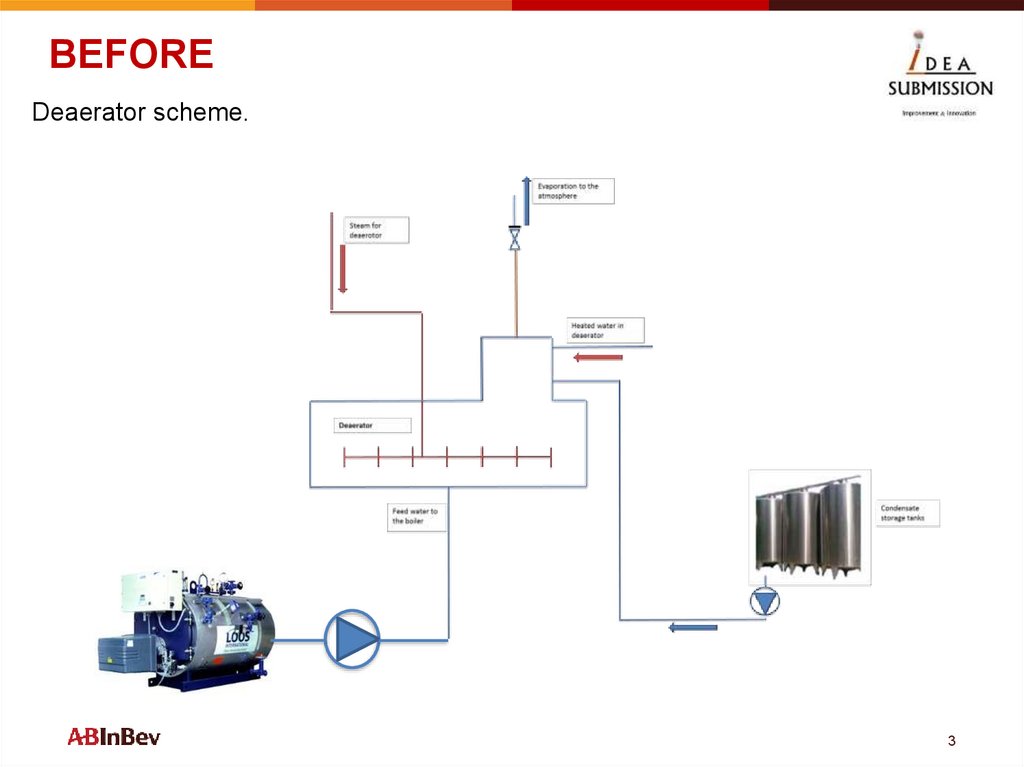

BEFOREDeaerator scheme.

3

4.

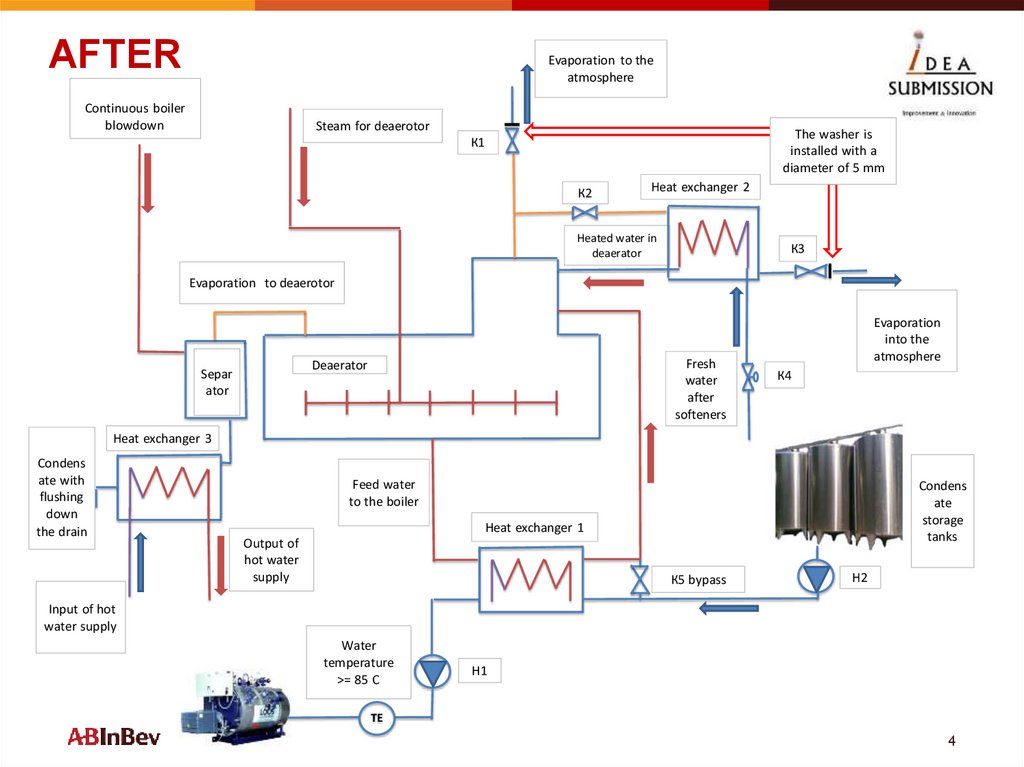

AFTEREvaporation to the

atmosphere

Continuous boiler

blowdown

Steam for deaerotor

The washer is

installed with a

diameter of 5 mm

К1

К2

Heat exchanger 2

Heated water in

deaerator

К3

Evaporation to deaerotor

Fresh

water

after

softeners

Deaerator

Separ

ator

Evaporation

into the

atmosphere

К4

Heat exchanger 3

Condens

ate with

flushing

down

the drain

Feed water

to the boiler

Condens

ate

storage

tanks

Heat exchanger 1

Output of

hot water

supply

К5 bypass

H2

Input of hot

water supply

Water

temperature

>= 85 С

Н1

TE

4

5.

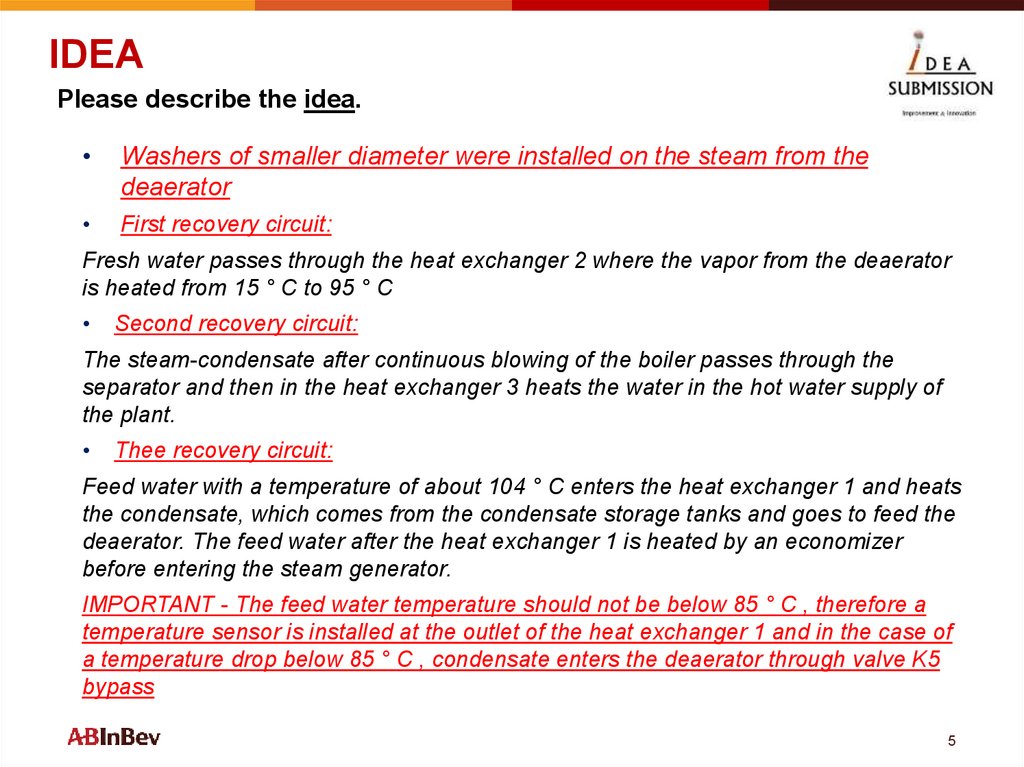

IDEAPlease describe the idea.

Washers of smaller diameter were installed on the steam from the

deaerator

First recovery circuit:

Fresh water passes through the heat exchanger 2 where the vapor from the deaerator

is heated from 15 ° C to 95 ° C

Second recovery circuit:

The steam-condensate after continuous blowing of the boiler passes through the

separator and then in the heat exchanger 3 heats the water in the hot water supply of

the plant.

Thee recovery circuit:

Feed water with a temperature of about 104 ° C enters the heat exchanger 1 and heats

the condensate, which comes from the condensate storage tanks and goes to feed the

deaerator. The feed water after the heat exchanger 1 is heated by an economizer

before entering the steam generator.

IMPORTANT - The feed water temperature should not be below 85 ° C , therefore a

temperature sensor is installed at the outlet of the heat exchanger 1 and in the case of

a temperature drop below 85 ° C , condensate enters the deaerator through valve K5

bypass

5

6.

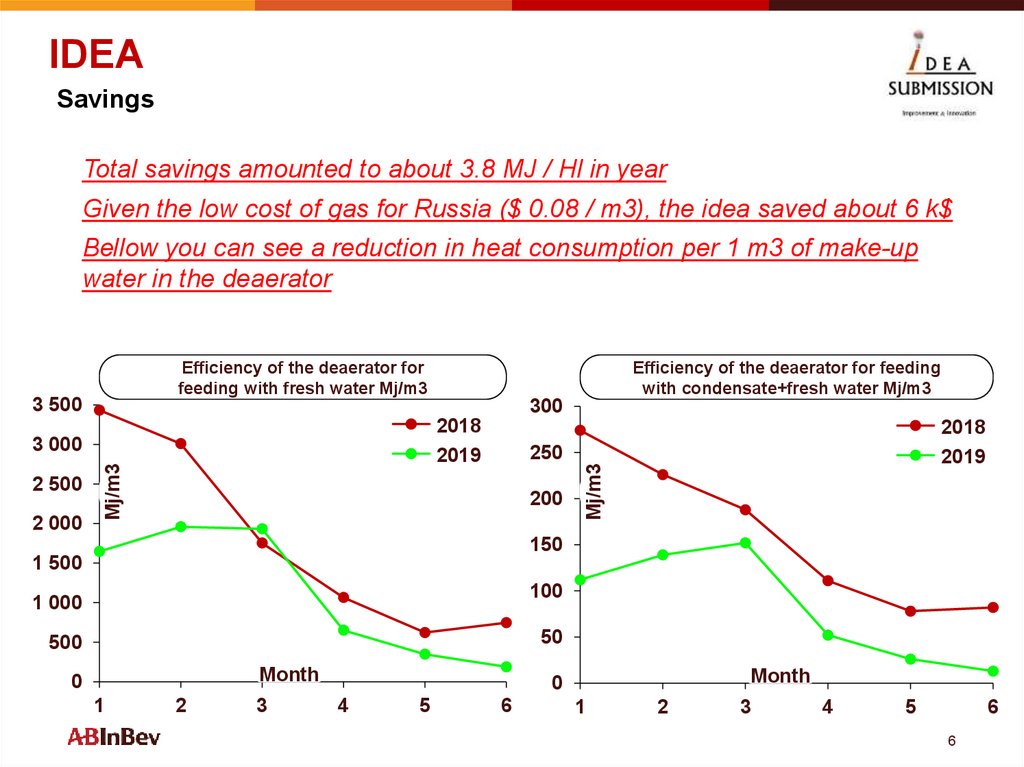

IDEASavings

Total savings amounted to about 3.8 MJ / Hl in year

Given the low cost of gas for Russia ($ 0.08 / m3), the idea saved about 6 k$

Bellow you can see a reduction in heat consumption per 1 m3 of make-up

water in the deaerator

Efficiency of the deaerator for

feeding with fresh water Mj/m3

3 500

Efficiency of the deaerator for feeding

with condensate+fresh water Mj/m3

300

2018

2019

2 500

2 000

2018

2019

250

Mj/m3

Mj/m3

3 000

200

150

1 500

100

1 000

50

500

Month

0

1

2

3

Month

0

4

5

6

1

2

3

4

5

6

6

7.

AFTERPlease select the achieved improvement(s) or innovation(s).

[x]

Type of improvement

Explanation

Improved Communication

Improved Customer relations

[x]

Savings of energy, materials or resources

The result of the implementation of this initiative was a large

reduction in heat consumption at the deaerator

Improved workplace organization

Increased Market share

Improved POC execution

Improved processes

Improved productivity

Improved quality

Improved environment, health or safety

Improved supplier relations

7

8.

Idea OwnerIdea Ownership

Name of idea owner

Function

Department, Brewery

Alexey Moskalenko, Vlasov Viktor, Kalenov Sergey,

Gavrilov Alexey

Supply

Technical Service

Recognition

Contact person in case of selection

Alexey Moskalenko

8

industry

industry