Similar presentations:

Ball mill internals

1. Ball Mill Internals

GRINDING I – Training Session2. Content

Ball Mill InternalsContent

• Partitions

• Single wall diaphragm

• Full liftered double wall diaphragm

• Adjustable double wall diaphragm

• Outlet partitions

• Slots design

• Ventilation screens

KUJ – July 2012 – Grinding I - 2

3. Content

Ball Mill InternalsContent

• Partitions

• Single wall diaphragm

• Full liftered double wall diaphragm

• Adjustable double wall diaphragm

• Outlet partitions

• Slots design

• Ventilation screens

KUJ – July 2012 – Grinding I - 3

4. Different types of partitions

Ball Mill InternalsDifferent types of partitions

• Partition between chambers

• Single wall diaphragm

• Double wall diaphragm full lifting

• Double wall diaphragm with adjustable blade

• Outlet partition

KUJ – July 2012 – Grinding I - 4

5. Purposes of a partition

Ball Mill InternalsPurposes of a partition

• Main partition roles

• Keep grinding media in several compartments

• Material flow control (double wall)

• Help air flow (lowest pressure drop)

• Specific roles

• For intermediate partitions: control the compartment

output material size

KUJ – July 2012 – Grinding I - 5

6. Content

Ball Mill InternalsContent

• Partitions

• Single wall diaphragm

• Full liftered double wall diaphragm

• Adjustable double wall diaphragm

• Outlet partitions

• Slots design

• Ventilation screens

KUJ – July 2012 – Grinding I - 6

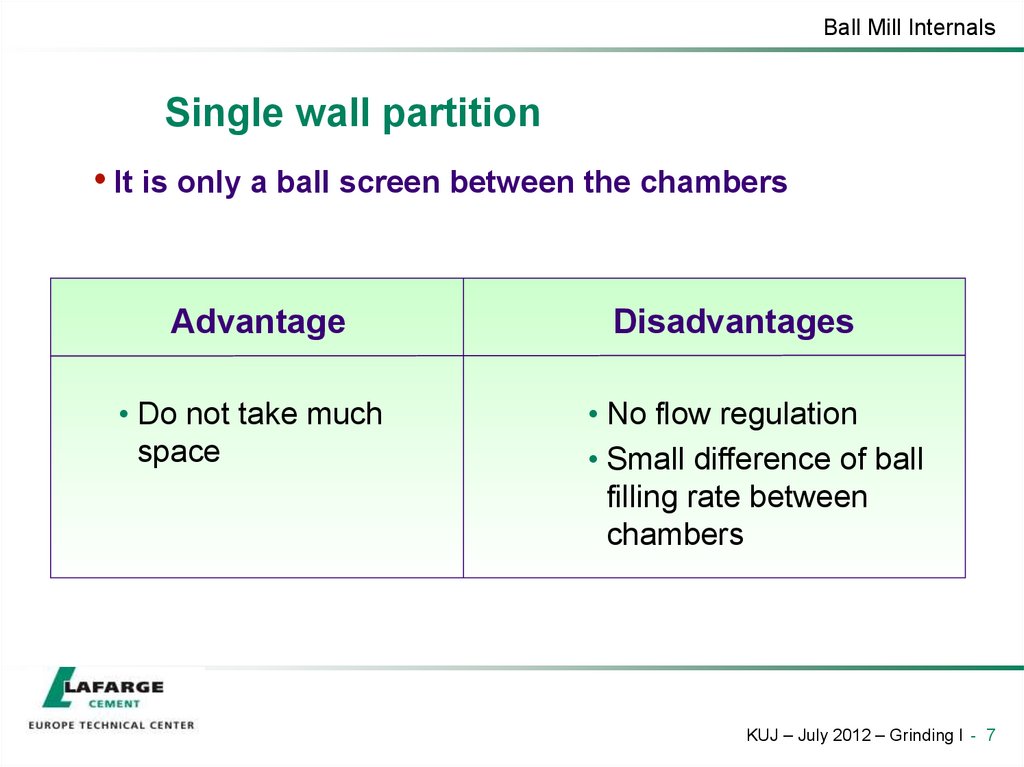

7. Single wall partition

Ball Mill InternalsSingle wall partition

• It is only a ball screen between the chambers

Advantage

• Do not take much

space

Disadvantages

• No flow regulation

• Small difference of ball

filling rate between

chambers

KUJ – July 2012 – Grinding I - 7

8. Content

Ball Mill InternalsContent

• Partitions

• Single wall diaphragm

• Full liftered double wall diaphragm

• Adjustable double wall diaphragm

• Outlet partitions

• Slots design

• Ventilation screens

KUJ – July 2012 – Grinding I - 8

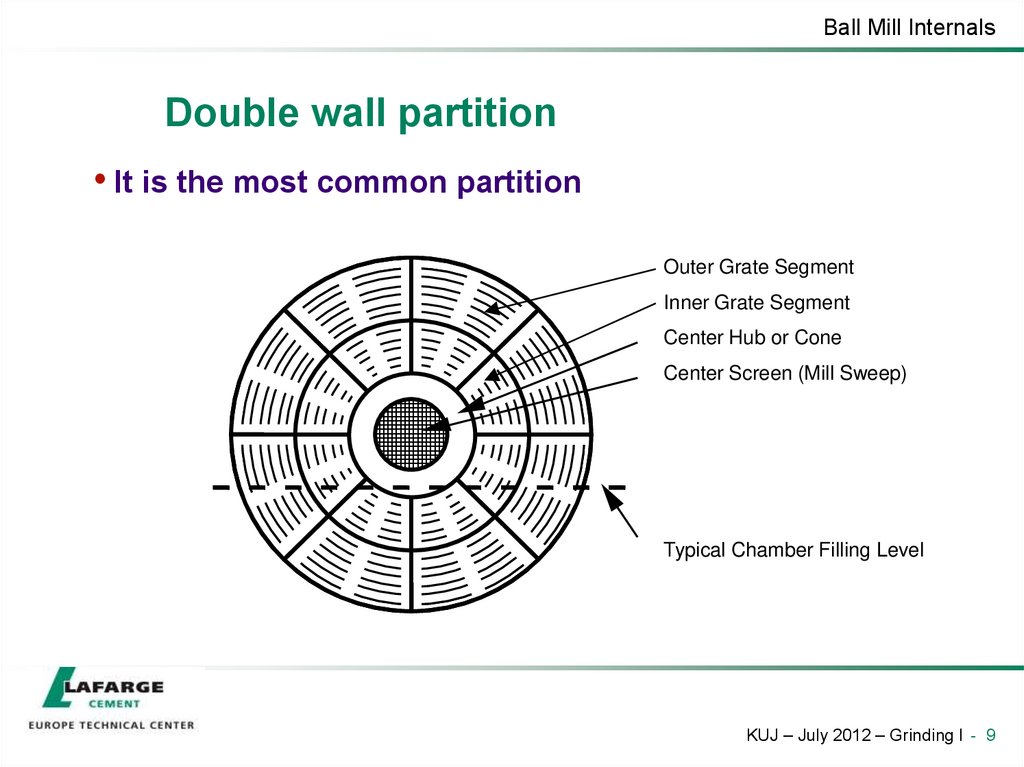

9. Double wall partition

Ball Mill InternalsDouble wall partition

• It is the most common partition

Outer Grate Segment

Inner Grate Segment

Center Hub or Cone

Center Screen (Mill Sweep)

Typical Chamber Filling Level

KUJ – July 2012 – Grinding I - 9

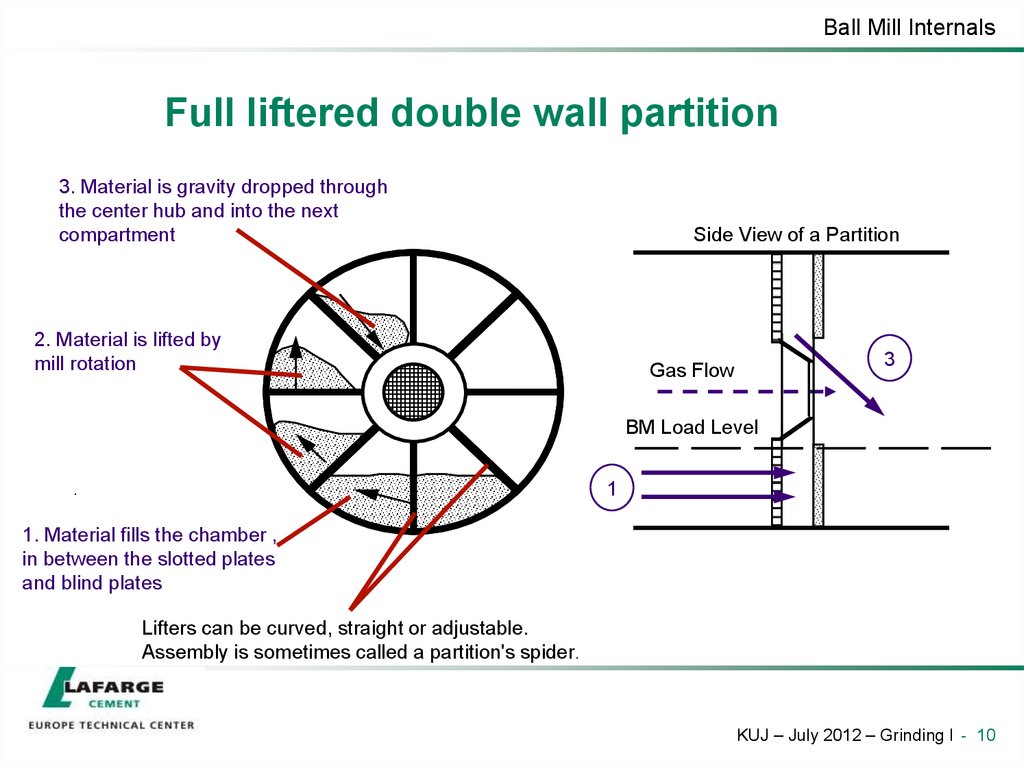

10. Full liftered double wall partition

Ball Mill InternalsFull liftered double wall partition

3. Material is gravity dropped through

the center hub and into the next

compartment

Side View of a Partition

2. Material is lifted by

mill rotation

3

Gas Flow

BM Load Level

1

.

1. Material fills the chamber ,

in between the slotted plates

and blind plates

Lifters can be curved, straight or adjustable.

Assembly is sometimes called a partition's spider.

KUJ – July 2012 – Grinding I - 10

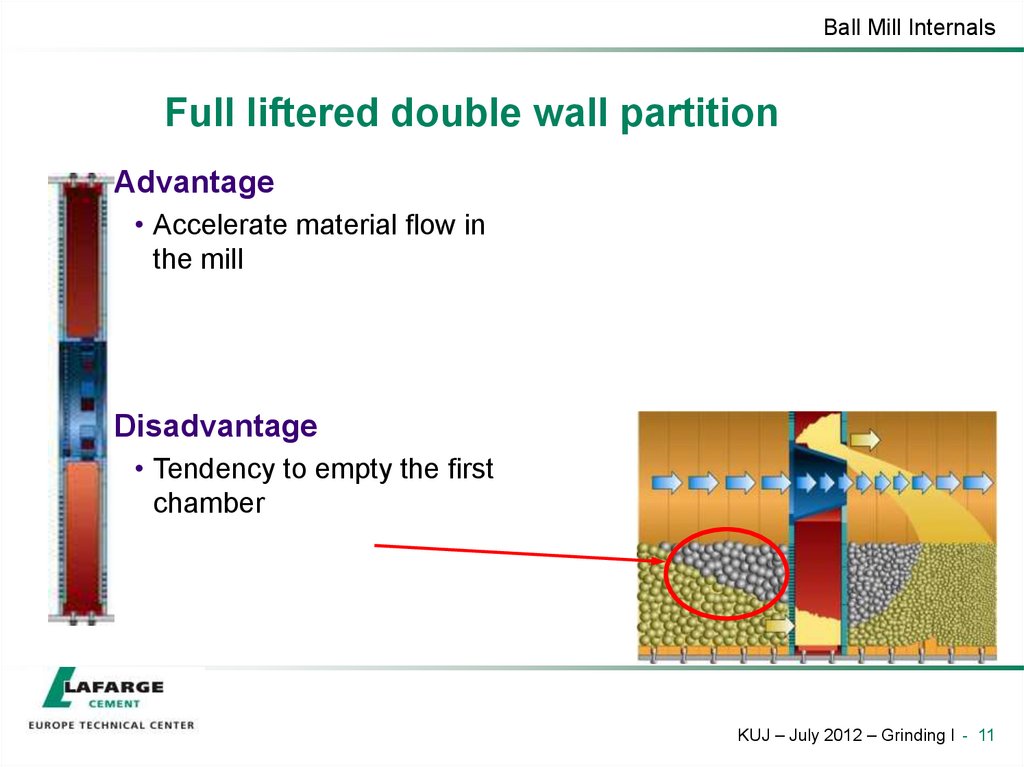

11. Full liftered double wall partition

Ball Mill InternalsFull liftered double wall partition

• Advantage

• Accelerate material flow in

the mill

• Disadvantage

• Tendency to empty the first

chamber

KUJ – July 2012 – Grinding I - 11

12. Content

Ball Mill InternalsContent

• Partitions

• Single wall diaphragm

• Full liftered double wall diaphragm

• Adjustable double wall diaphragm

• Outlet partitions

• Slots design

• Ventilation screens

KUJ – July 2012 – Grinding I - 12

13. Adjustable double wall partition

Ball Mill InternalsAdjustable double wall partition

• Purpose

• Control the empty zone before the partition by

regulating the material level in the partition

• Control different filling rates in both chambers

KUJ – July 2012 – Grinding I - 13

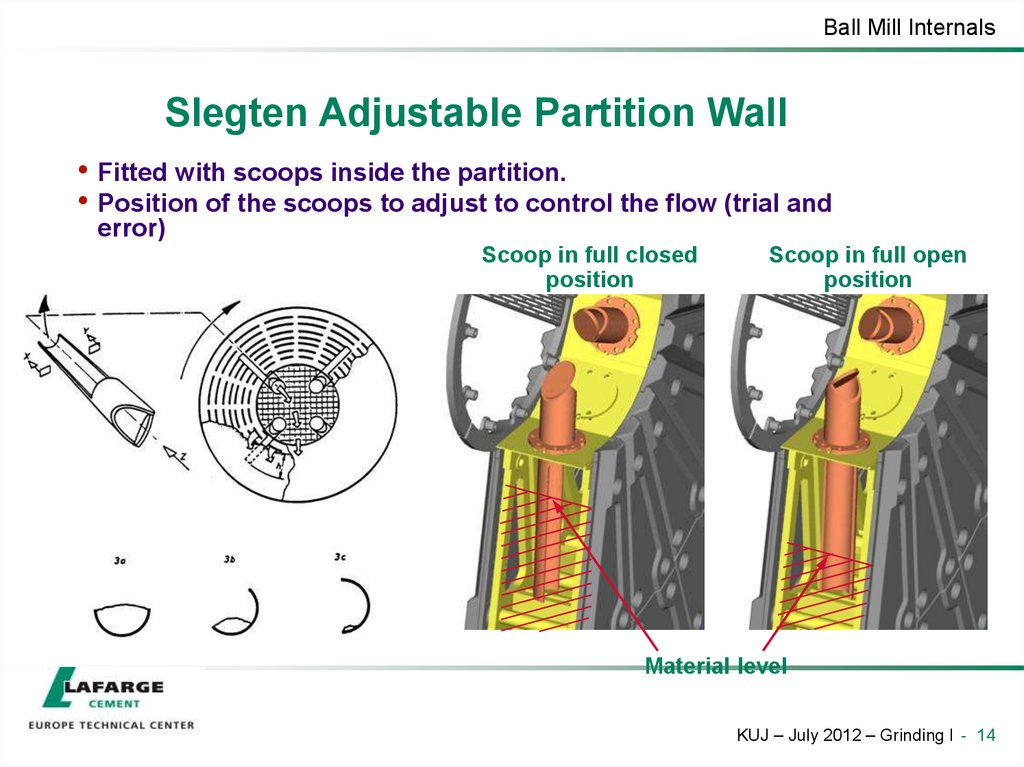

14. Slegten Adjustable Partition Wall

Ball Mill InternalsSlegten Adjustable Partition Wall

• Fitted with scoops inside the partition.

• Position of the scoops to adjust to control the flow (trial and

error)

Scoop in full closed

position

Scoop in full open

position

Material level

KUJ – July 2012 – Grinding I - 14

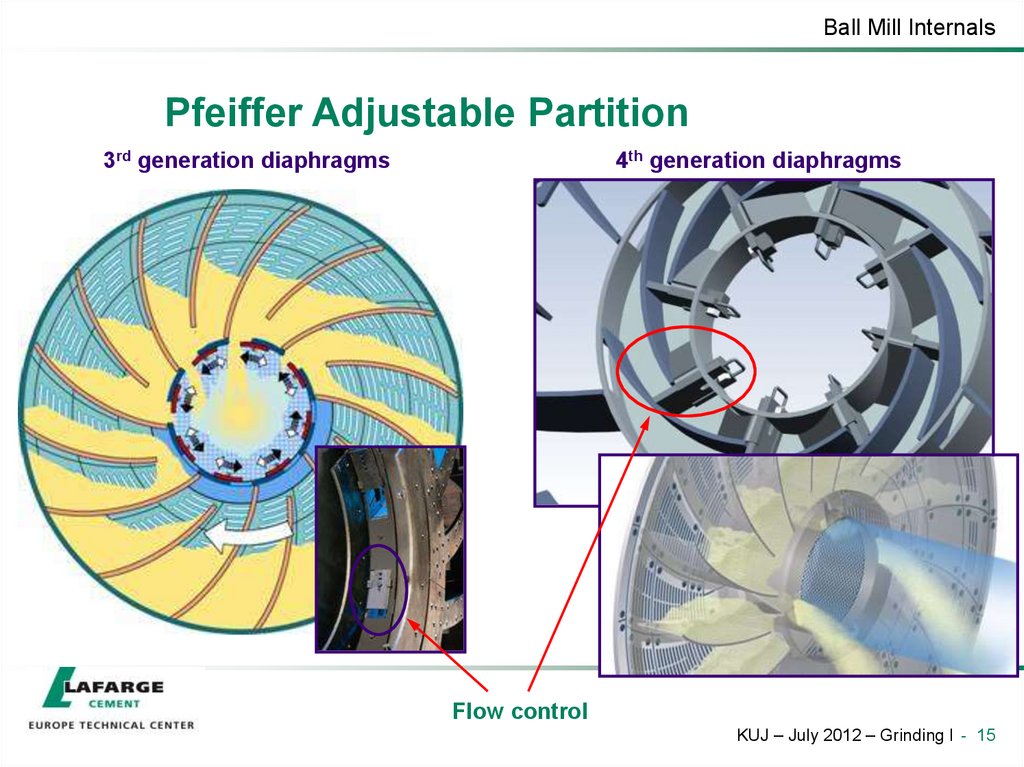

15. Pfeiffer Adjustable Partition

Ball Mill InternalsPfeiffer Adjustable Partition

3rd generation diaphragms

4th generation diaphragms

Flow control

KUJ – July 2012 – Grinding I - 15

16. Content

Ball Mill InternalsContent

• Partitions

• Single wall diaphragm

• Full liftered double wall diaphragm

• Adjustable double wall diaphragm

• Outlet partitions

• Slots design

• Ventilation screens

KUJ – July 2012 – Grinding I - 16

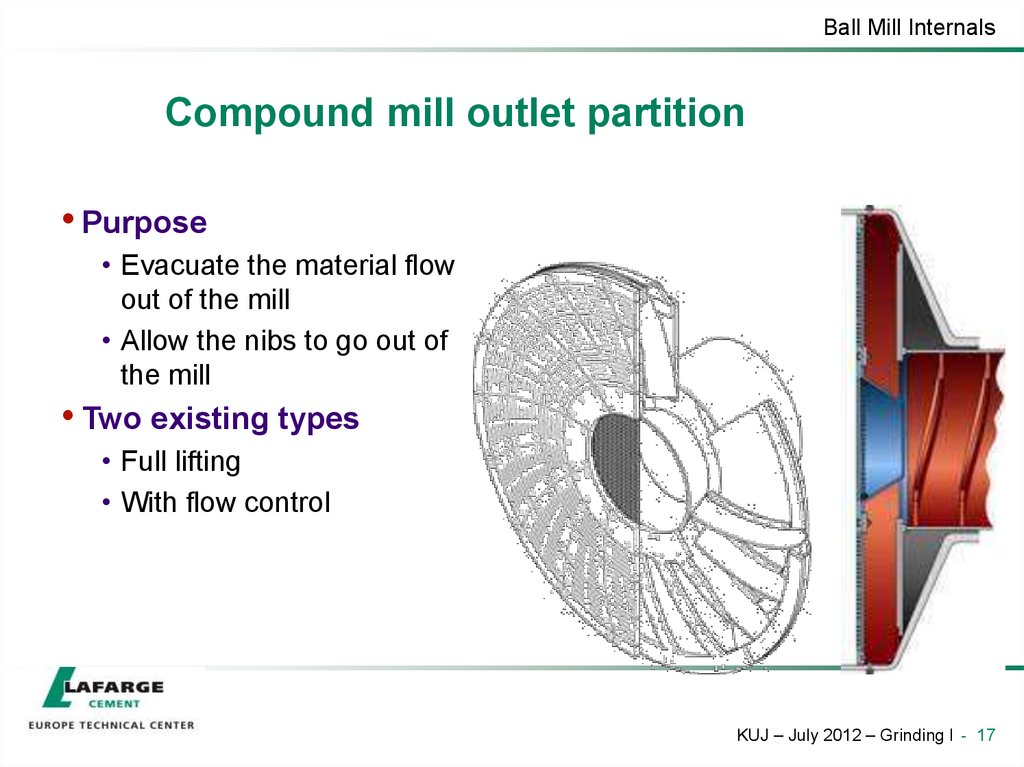

17. Compound mill outlet partition

Ball Mill InternalsCompound mill outlet partition

• Purpose

• Evacuate the material flow

out of the mill

• Allow the nibs to go out of

the mill

• Two existing types

• Full lifting

• With flow control

KUJ – July 2012 – Grinding I - 17

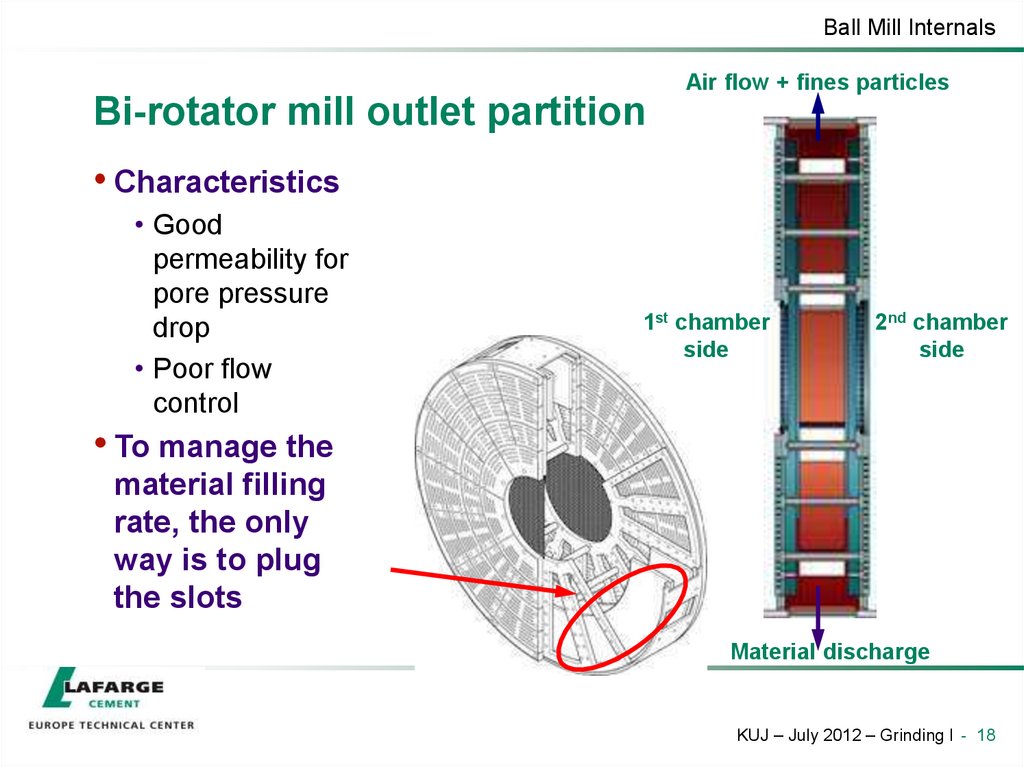

18. Bi-rotator mill outlet partition

Ball Mill InternalsAir flow + fines particles

Bi-rotator mill outlet partition

• Characteristics

• Good

permeability for

pore pressure

drop

• Poor flow

control

1st chamber

side

2nd chamber

side

• To manage the

material filling

rate, the only

way is to plug

the slots

Material discharge

KUJ – July 2012 – Grinding I - 18

19. Content

Ball Mill InternalsContent

• Partitions

• Single wall diaphragm

• Full liftered double wall diaphragm

• Adjustable double wall diaphragm

• Outlet partitions

• Slots design

• Ventilation screens

KUJ – July 2012 – Grinding I - 19

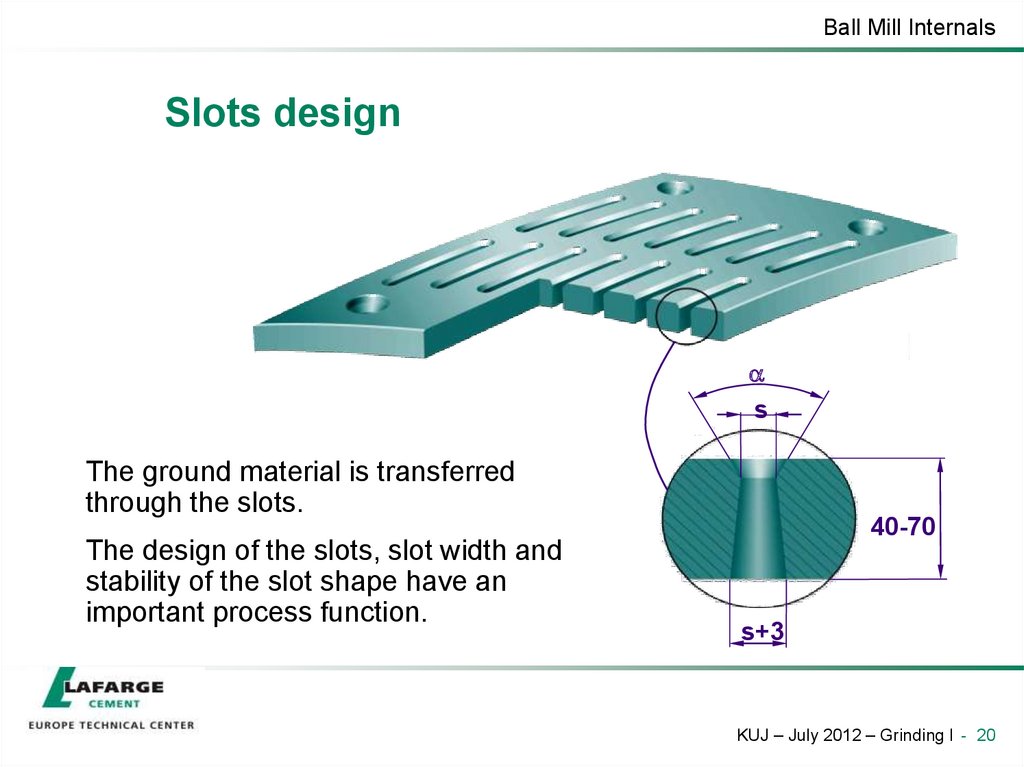

20. Slots design

Ball Mill InternalsSlots design

s

The ground material is transferred

through the slots.

The design of the slots, slot width and

stability of the slot shape have an

important process function.

40-70

s+3

KUJ – July 2012 – Grinding I - 20

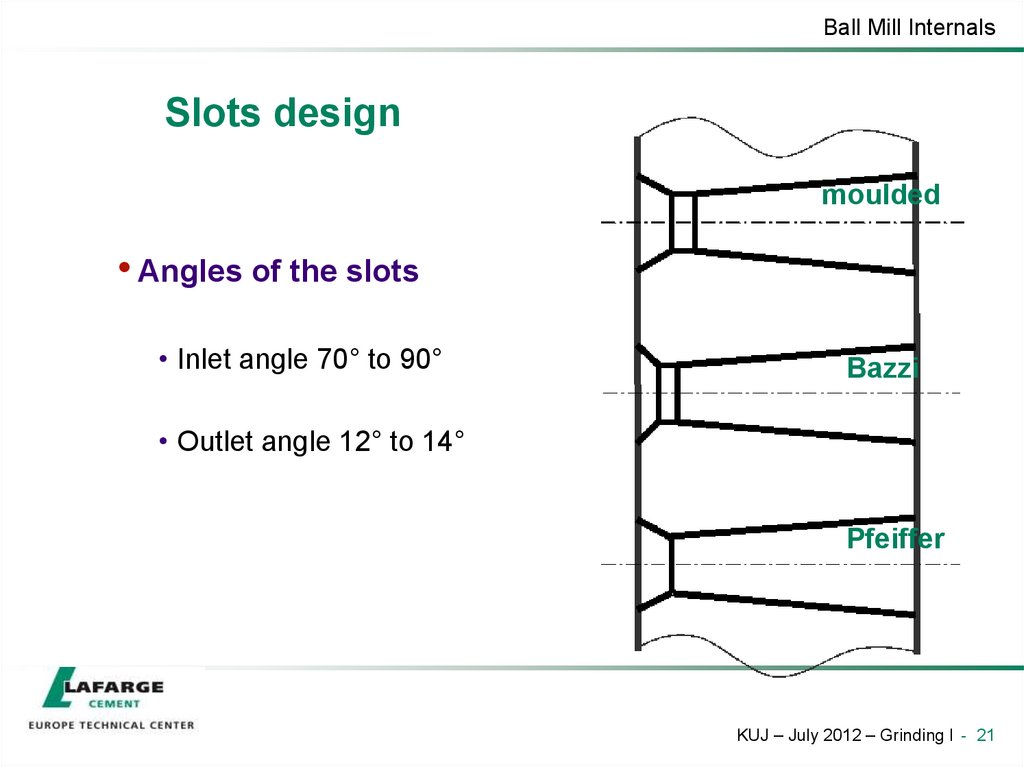

21. Slots design

Ball Mill InternalsSlots design

moulded

• Angles of the slots

• Inlet angle 70° to 90°

Bazzi

• Outlet angle 12° to 14°

Pfeiffer

KUJ – July 2012 – Grinding I - 21

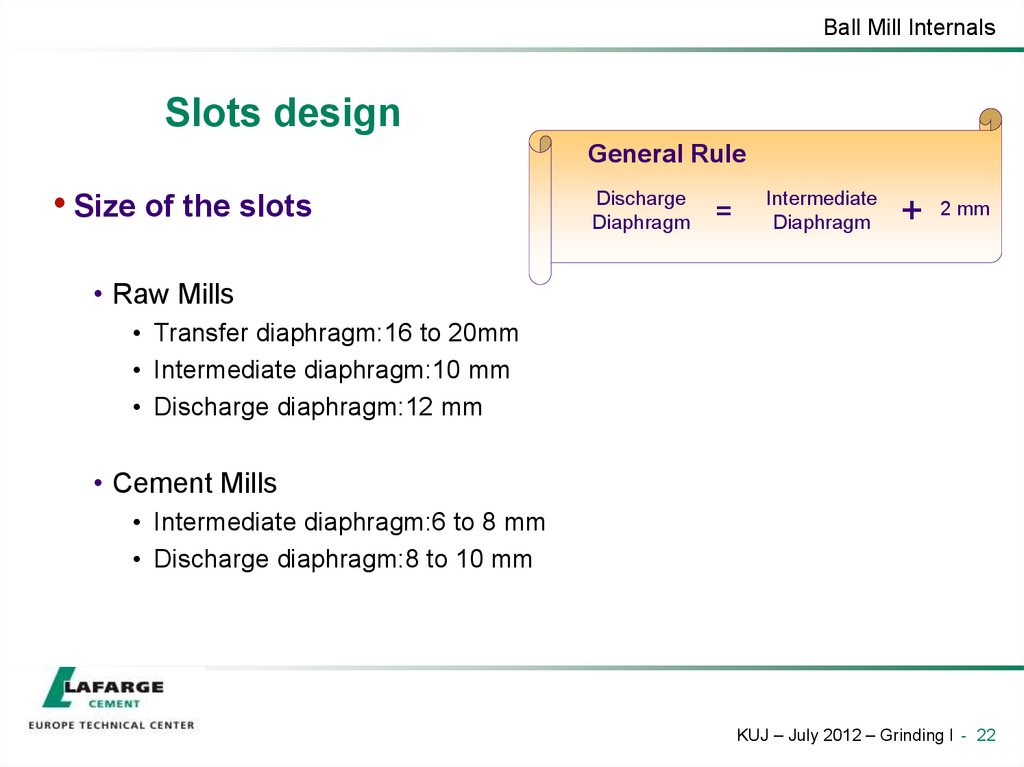

22. Slots design

Ball Mill InternalsSlots design

General Rule

• Size of the slots

Discharge

Diaphragm

=

Intermediate

Diaphragm

+

2 mm

• Raw Mills

• Transfer diaphragm:16 to 20mm

• Intermediate diaphragm:10 mm

• Discharge diaphragm:12 mm

• Cement Mills

• Intermediate diaphragm:6 to 8 mm

• Discharge diaphragm:8 to 10 mm

KUJ – July 2012 – Grinding I - 22

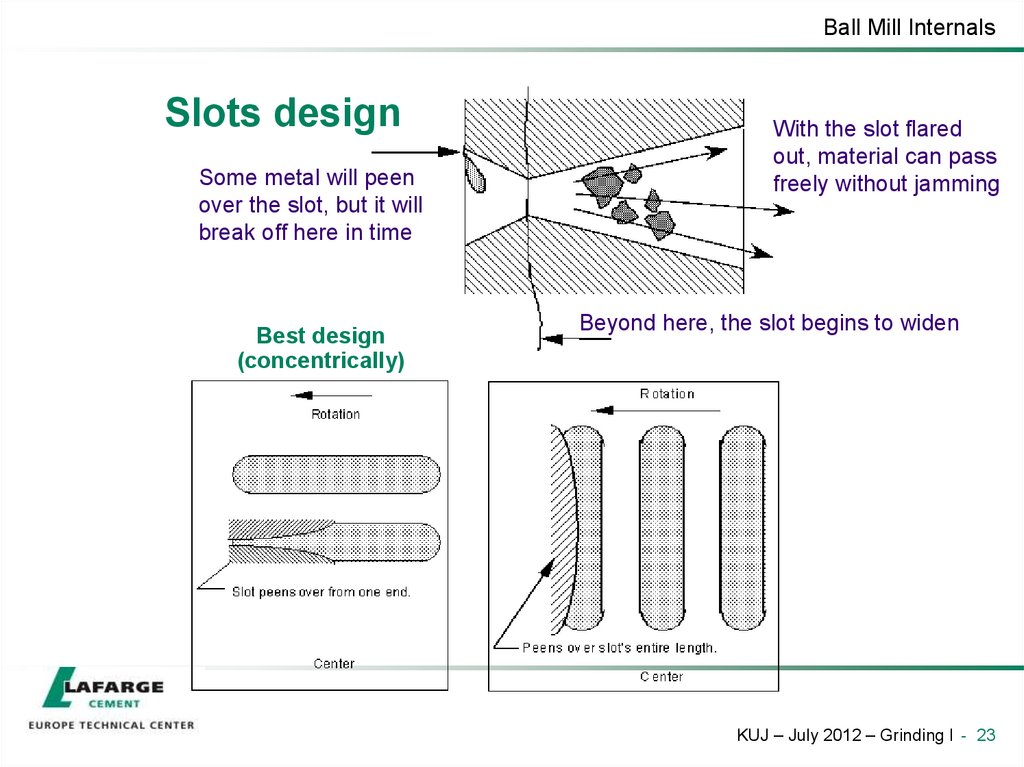

23. Slots design

Ball Mill InternalsSlots design

Some metal will peen

over the slot, but it will

break off here in time

Best design

(concentrically)

With the slot flared

out, material can pass

freely without jamming

Beyond here, the slot begins to widen

KUJ – July 2012 – Grinding I - 23

24. Slots design

Ball Mill InternalsSlots design

• Peening of slots

• Consequence: slots

have to be opened by

manual grinding

KUJ – July 2012 – Grinding I - 24

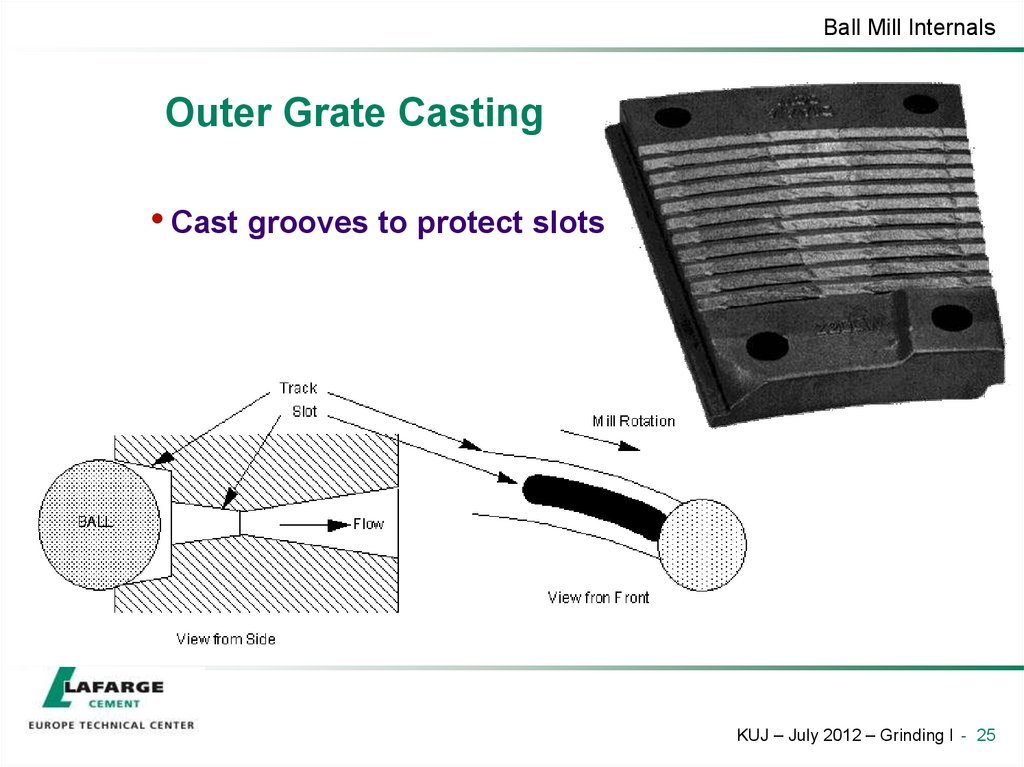

25. Outer Grate Casting

Ball Mill InternalsOuter Grate Casting

• Cast grooves to protect slots

KUJ – July 2012 – Grinding I - 25

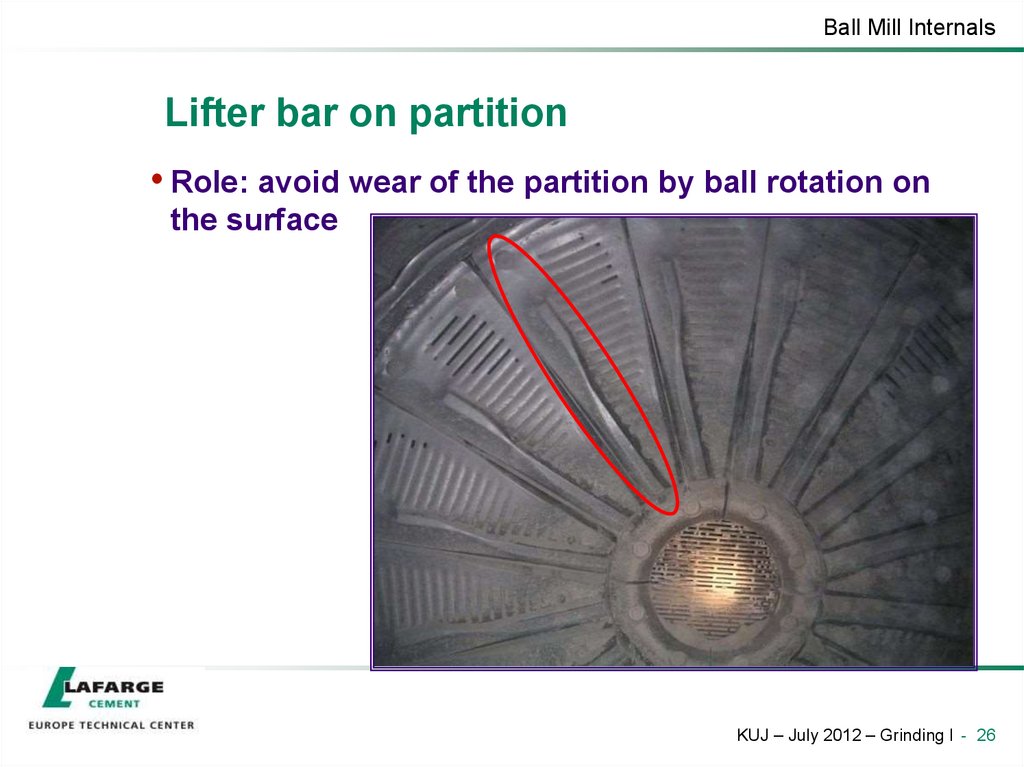

26. Lifter bar on partition

Ball Mill InternalsLifter bar on partition

• Role: avoid wear of the partition by ball rotation on

the surface

KUJ – July 2012 – Grinding I - 26

27. Content

Ball Mill InternalsContent

• Partitions

• Single wall diaphragm

• Full liftered double wall diaphragm

• Adjustable double wall diaphragm

• Outlet partitions

• Slots design

• Ventilation screens

KUJ – July 2012 – Grinding I - 27

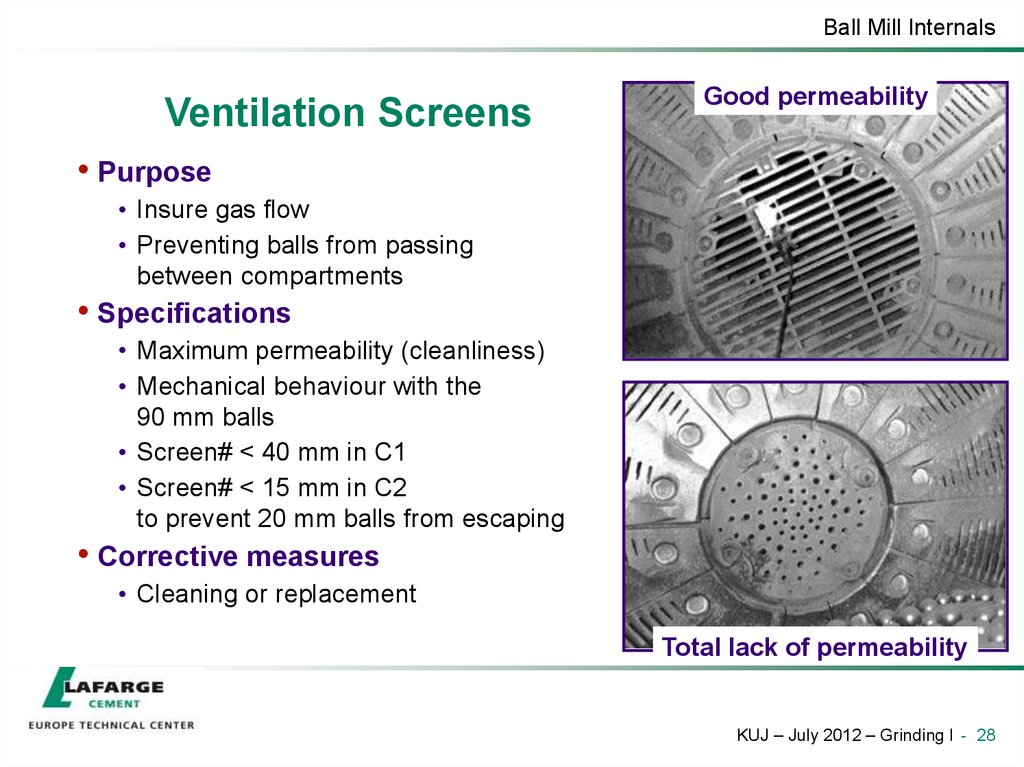

28. Ventilation Screens

Ball Mill InternalsVentilation Screens

Good permeability

• Purpose

• Insure gas flow

• Preventing balls from passing

between compartments

• Specifications

• Maximum permeability (cleanliness)

• Mechanical behaviour with the

90 mm balls

• Screen# < 40 mm in C1

• Screen# < 15 mm in C2

to prevent 20 mm balls from escaping

• Corrective measures

• Cleaning or replacement

Total lack of permeability

KUJ – July 2012 – Grinding I - 28

29. Partition control - Reminders

Ball Mill InternalsPartition control - Reminders

• Wear control

• Slot size and dimensions

• Lifter of the step partition

Discharge

Diaphragm

=

Intermediate

Diaphragm

+

2 mm

• Cleaning actions

• Nibs in the slots

• Foreign materials on central screen (raw mill essentially)

• Maintenance action

• Remove slot peens with a disc grinder

KUJ – July 2012 – Grinding I - 29

mechanics

mechanics