Similar presentations:

Ball mill dynamics. Grinding

1. Ball Mill Dynamics

GRINDING I – Training Session2. Content

Ball Mill DynamicsContent

• Size reduction mechanism

• Release point and internal dynamics 1st and 2nd

chamber

• 1st chamber liners

• 2nd chamber liners

• Fastening types

• Balls

• Mill head liners

• Material transport

KUJ - July 2012 – Grinding I - 2

3. Content

Ball Mill DynamicsContent

• Size reduction mechanism

• Release point and internal dynamics 1st and 2nd

chamber

• 1st chamber liners

• 2nd chamber liners

• Fastening types

• Balls

• Mill head liners

• Material transport

KUJ - July 2012 – Grinding I - 3

4. 3 mechanisms of size reduction

Ball Mill Dynamics3 mechanisms of size reduction

• Fractures

• Crushing

• Chipping

• Crushing and some fines

• Abrasion

• Fine grinding

KUJ - July 2012 – Grinding I - 4

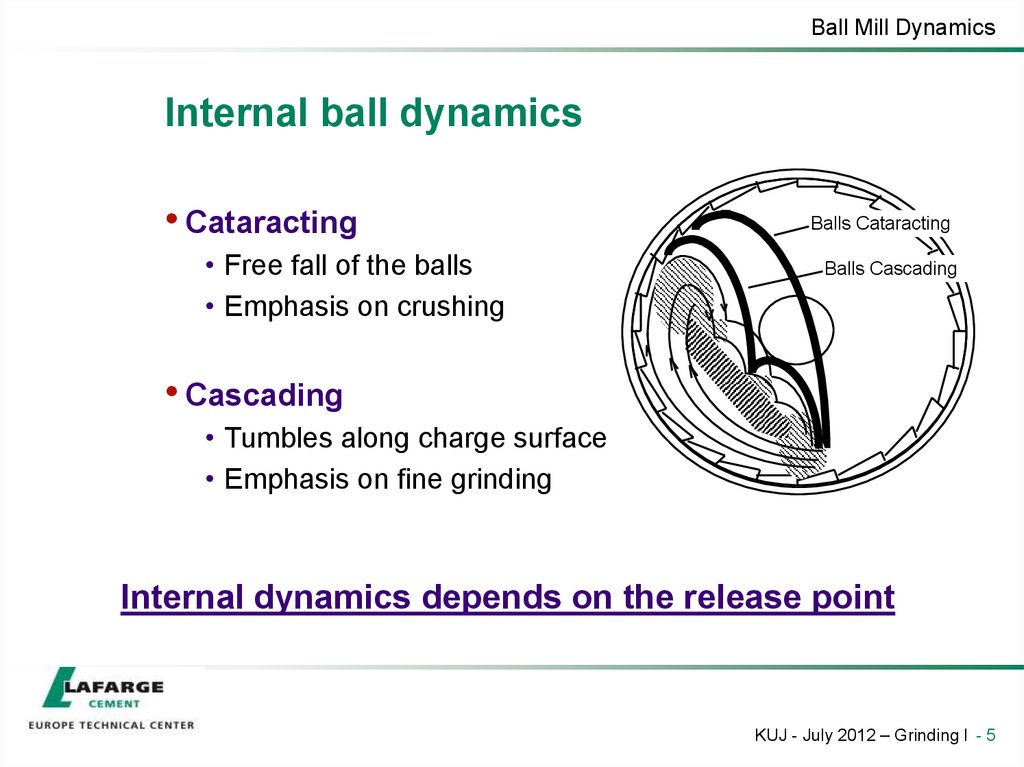

5. Internal ball dynamics

Ball Mill DynamicsInternal ball dynamics

• Cataracting

• Free fall of the balls

• Emphasis on crushing

Balls Cataracting

Balls Cascading

• Cascading

• Tumbles along charge surface

• Emphasis on fine grinding

Internal dynamics depends on the release point

KUJ - July 2012 – Grinding I - 5

6. Content

Ball Mill DynamicsContent

• Size reduction mechanism

• Release point and internal dynamics 1st and 2nd

chamber

• 1st chamber liners

• 2nd chamber liners

• Fastening types

• Mill head liners

• Material transport

KUJ - July 2012 – Grinding I - 6

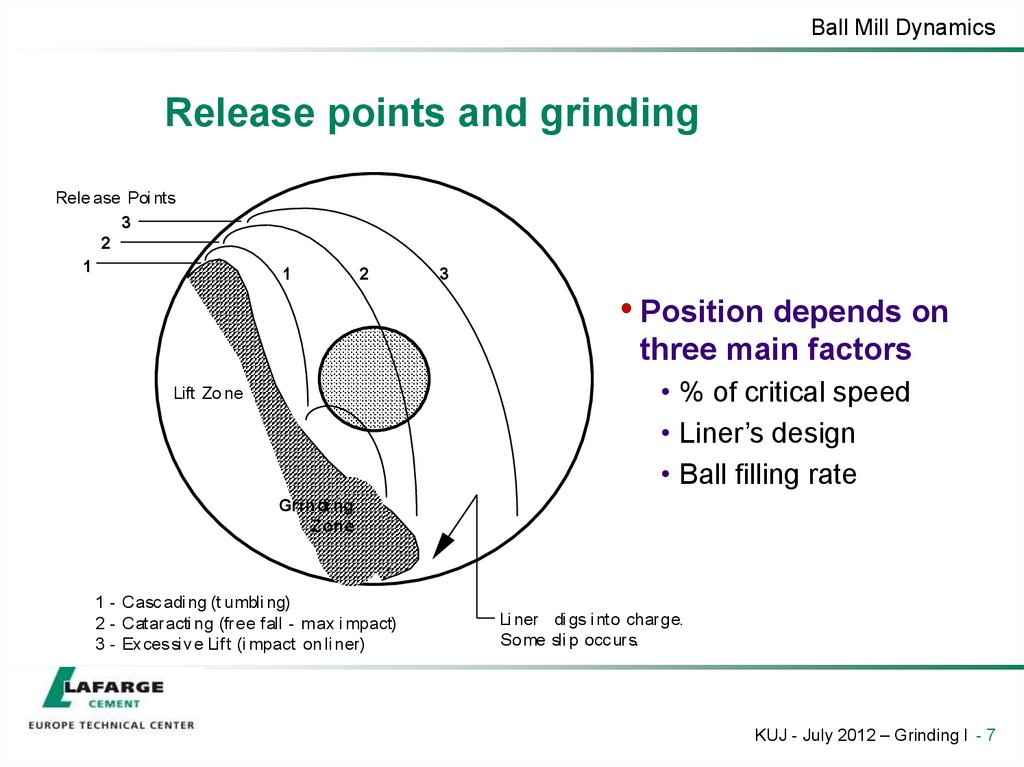

7. Release points and grinding

Ball Mill DynamicsRelease points and grinding

Rele ase Poi nts

3

2

1

1

2

3

• Position depends on

three main factors

• % of critical speed

• Liner’s design

• Ball filling rate

Lift Zo ne

Grindi ng

Zone

1 - Casc adi ng (t umbli ng)

2 - Catar acti ng (fr ee fall - max i mpact)

3 - Excessi ve Lift (i mpact on li ner)

Li ner di gs i nto charge.

Some sli p occurs.

KUJ - July 2012 – Grinding I - 7

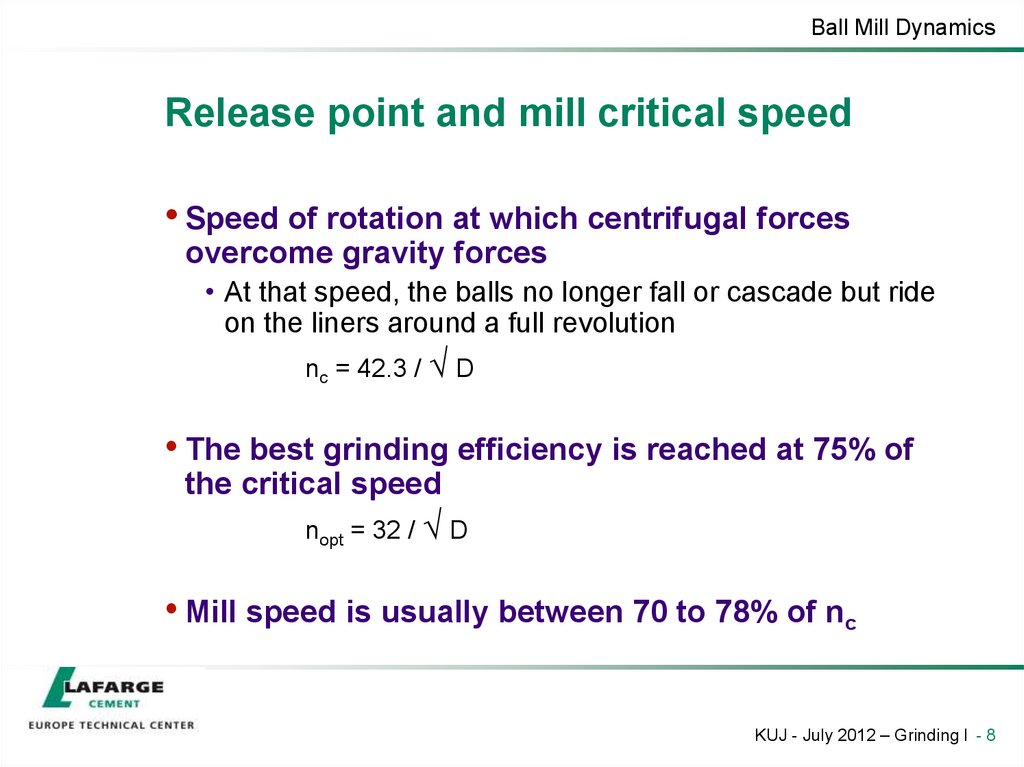

8. Release point and mill critical speed

Ball Mill DynamicsRelease point and mill critical speed

• Speed of rotation at which centrifugal forces

overcome gravity forces

• At that speed, the balls no longer fall or cascade but ride

on the liners around a full revolution

nc = 42.3 / D

• The best grinding efficiency is reached at 75% of

the critical speed

nopt = 32 / D

• Mill speed is usually between 70 to 78% of nc

KUJ - July 2012 – Grinding I - 8

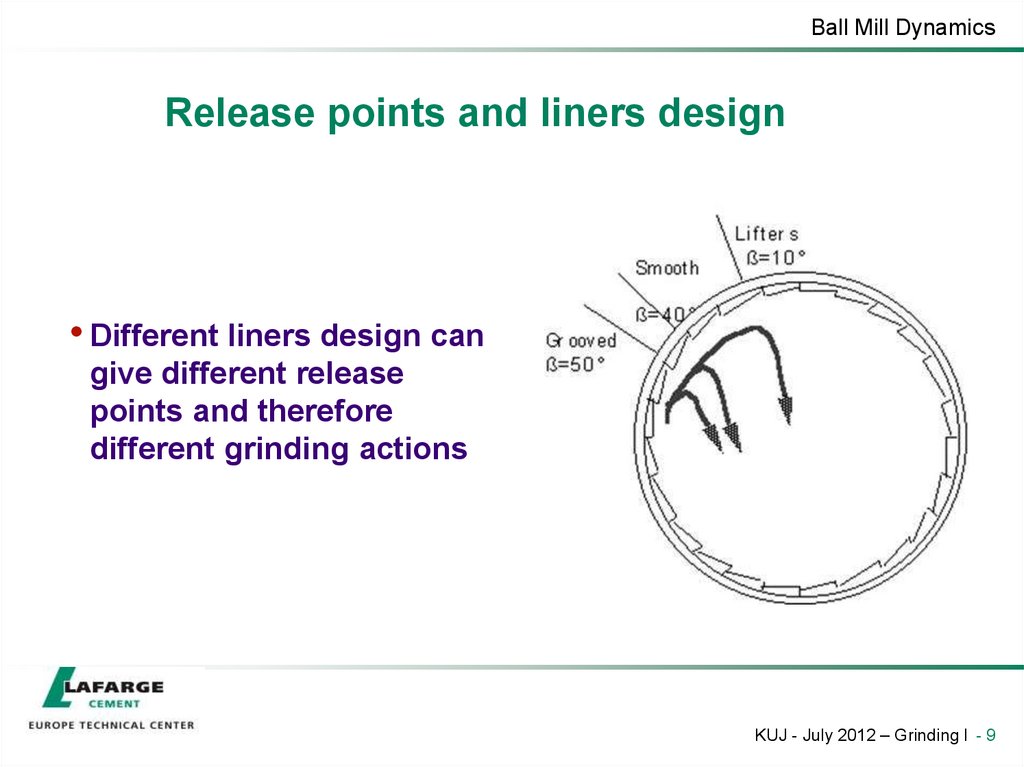

9. Release points and liners design

Ball Mill DynamicsRelease points and liners design

• Different liners design can

give different release

points and therefore

different grinding actions

KUJ - July 2012 – Grinding I - 9

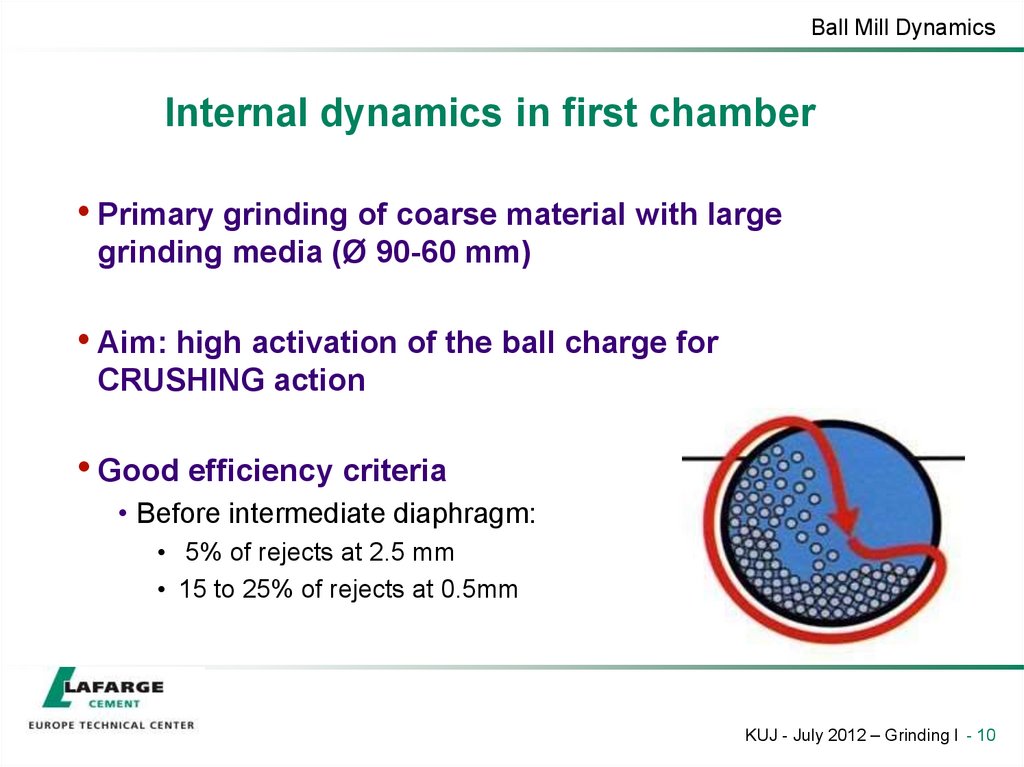

10. Internal dynamics in first chamber

Ball Mill DynamicsInternal dynamics in first chamber

• Primary grinding of coarse material with large

grinding media (Ø 90-60 mm)

• Aim: high activation of the ball charge for

CRUSHING action

• Good efficiency criteria

• Before intermediate diaphragm:

• 5% of rejects at 2.5 mm

• 15 to 25% of rejects at 0.5mm

KUJ - July 2012 – Grinding I - 10

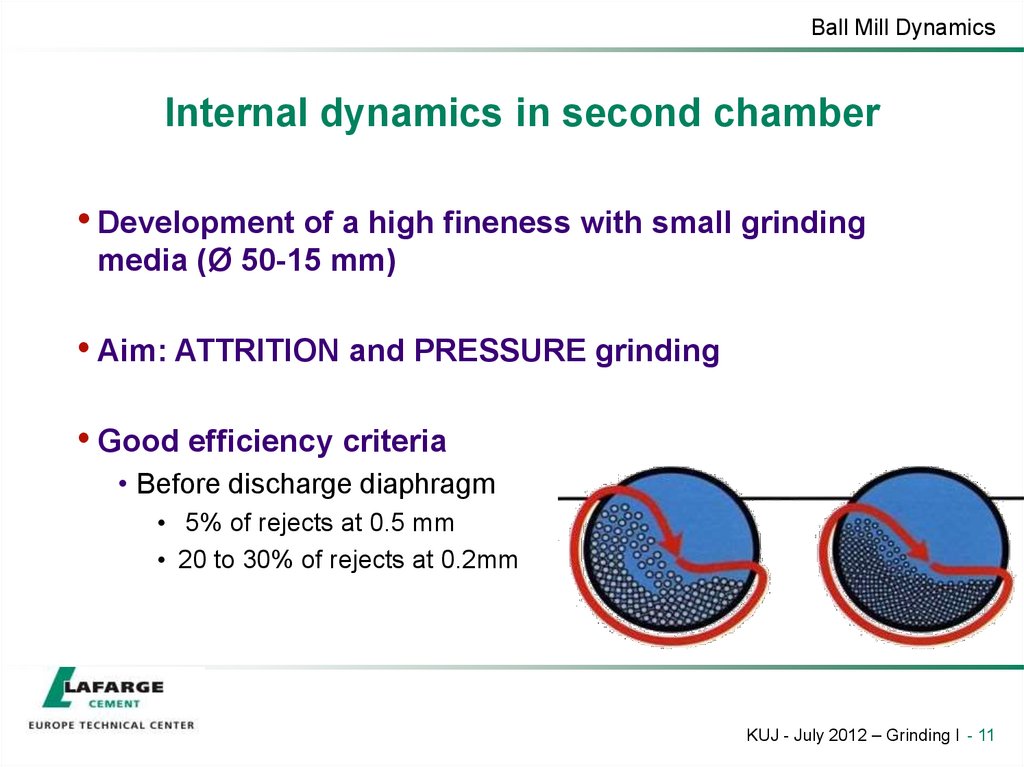

11. Internal dynamics in second chamber

Ball Mill DynamicsInternal dynamics in second chamber

• Development of a high fineness with small grinding

media (Ø 50-15 mm)

• Aim: ATTRITION and PRESSURE grinding

• Good efficiency criteria

• Before discharge diaphragm

• 5% of rejects at 0.5 mm

• 20 to 30% of rejects at 0.2mm

KUJ - July 2012 – Grinding I - 11

12. Content

Ball Mill DynamicsContent

• Size reduction mechanism

• Release point and internal dynamics 1st and 2nd

chamber

• 1st chamber liners

• 2nd chamber liners

• Fastening types

• Balls

• Mill head liners

• Material transport

KUJ - July 2012 – Grinding I - 12

13. Purpose of a liner’s design

Ball Mill DynamicsPurpose of a liner’s design

• Each liner is designed to ensure:

• Lowest specific energy consumption

• Highest production capacity for a shell design

• Protect mill shell and ensure efficient grinding

action

• With lowest possible specific cost for liners

KUJ - July 2012 – Grinding I - 13

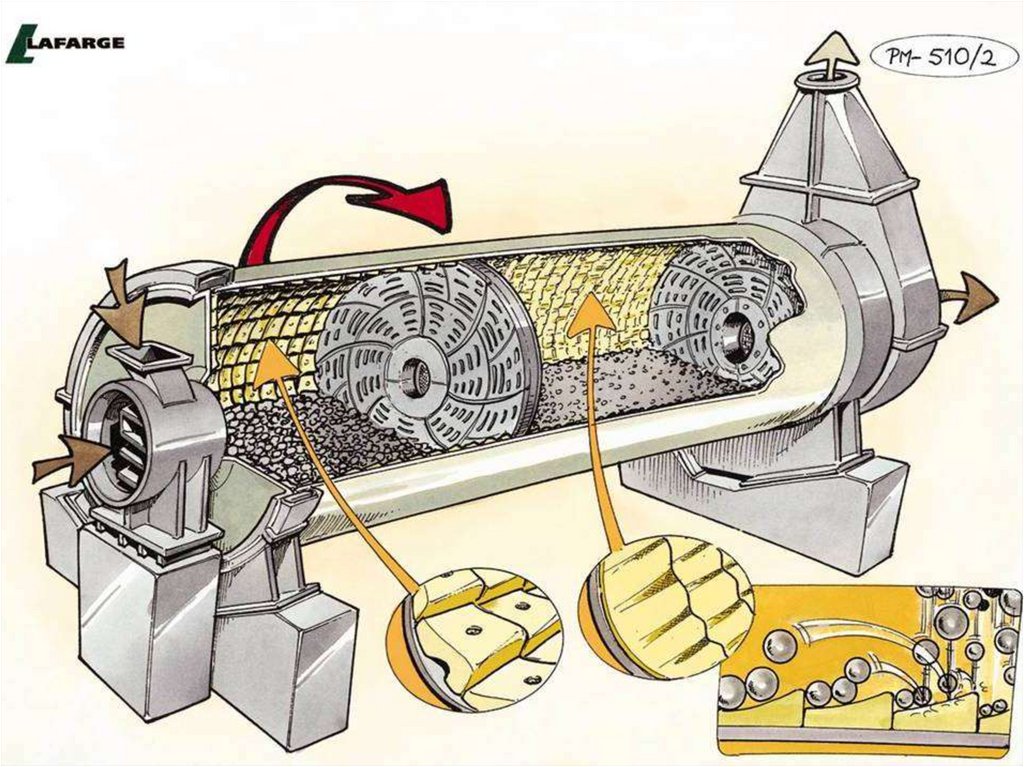

14.

Ball Mill DynamicsKUJ - July 2012 – Grinding I - 14

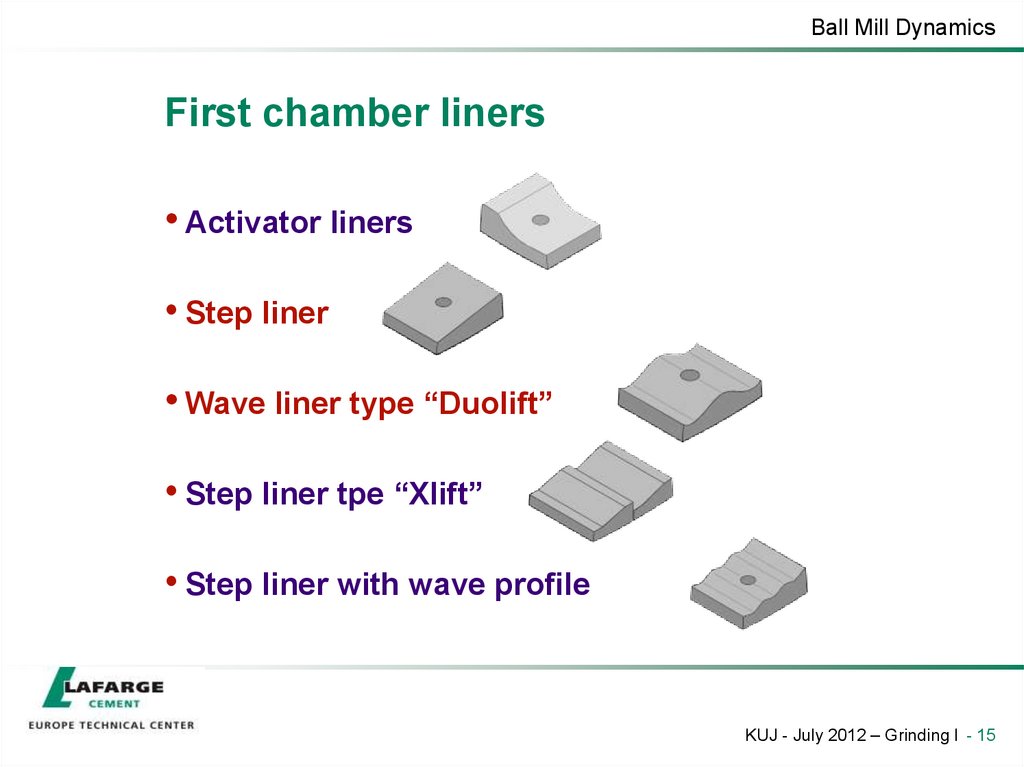

15. First chamber liners

Ball Mill DynamicsFirst chamber liners

• Activator liners

• Step liner

• Wave liner type “Duolift”

• Step liner tpe “Xlift”

• Step liner with wave profile

KUJ - July 2012 – Grinding I - 15

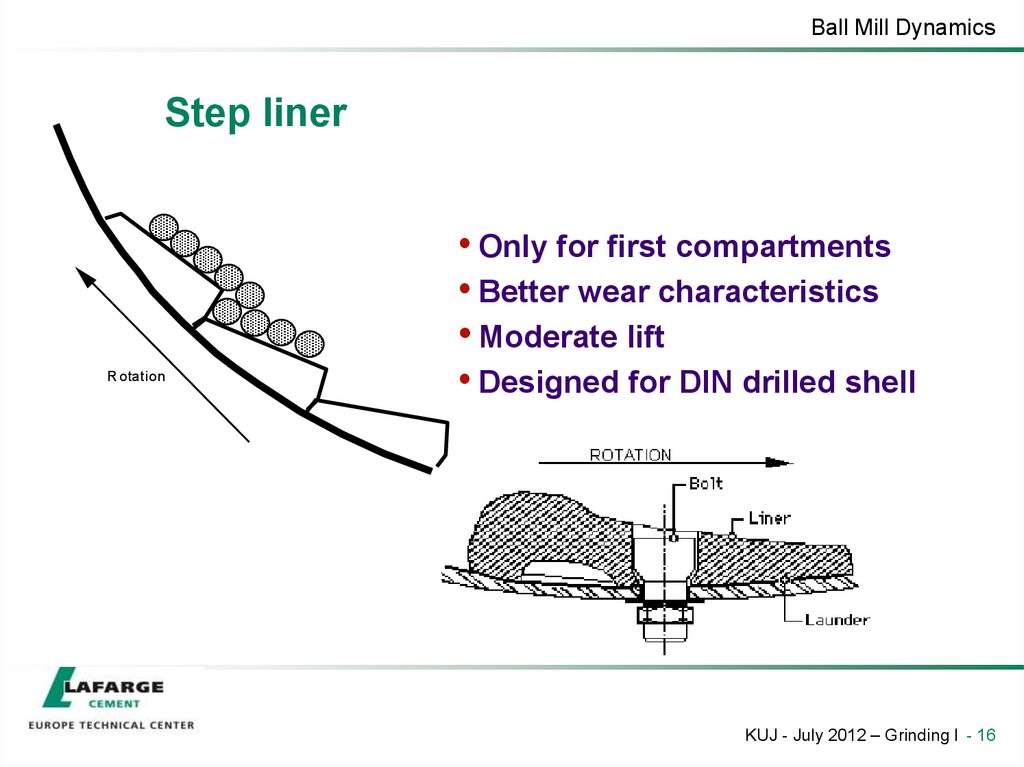

16. Step liner

Ball Mill DynamicsStep liner

R otation

• Only for first compartments

• Better wear characteristics

• Moderate lift

• Designed for DIN drilled shell

KUJ - July 2012 – Grinding I - 16

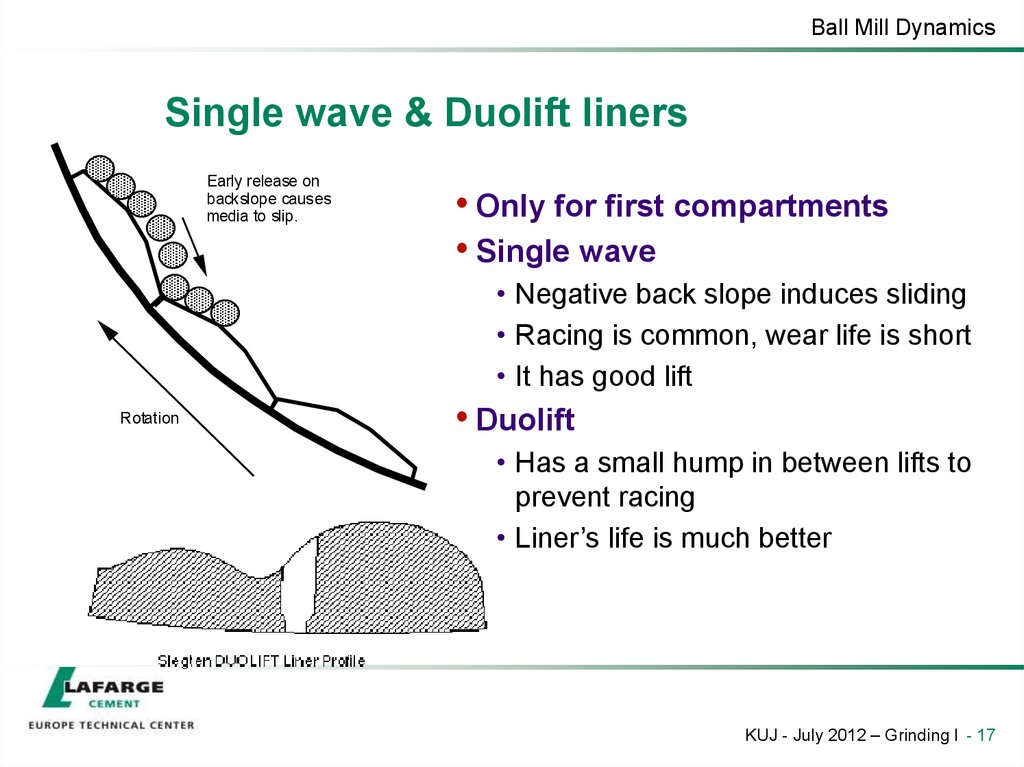

17. Single wave & Duolift liners

Ball Mill DynamicsSingle wave & Duolift liners

Early release on

backslope causes

media to slip.

• Only for first compartments

• Single wave

• Negative back slope induces sliding

• Racing is common, wear life is short

• It has good lift

Rotation

• Duolift

• Has a small hump in between lifts to

prevent racing

• Liner’s life is much better

KUJ - July 2012 – Grinding I - 17

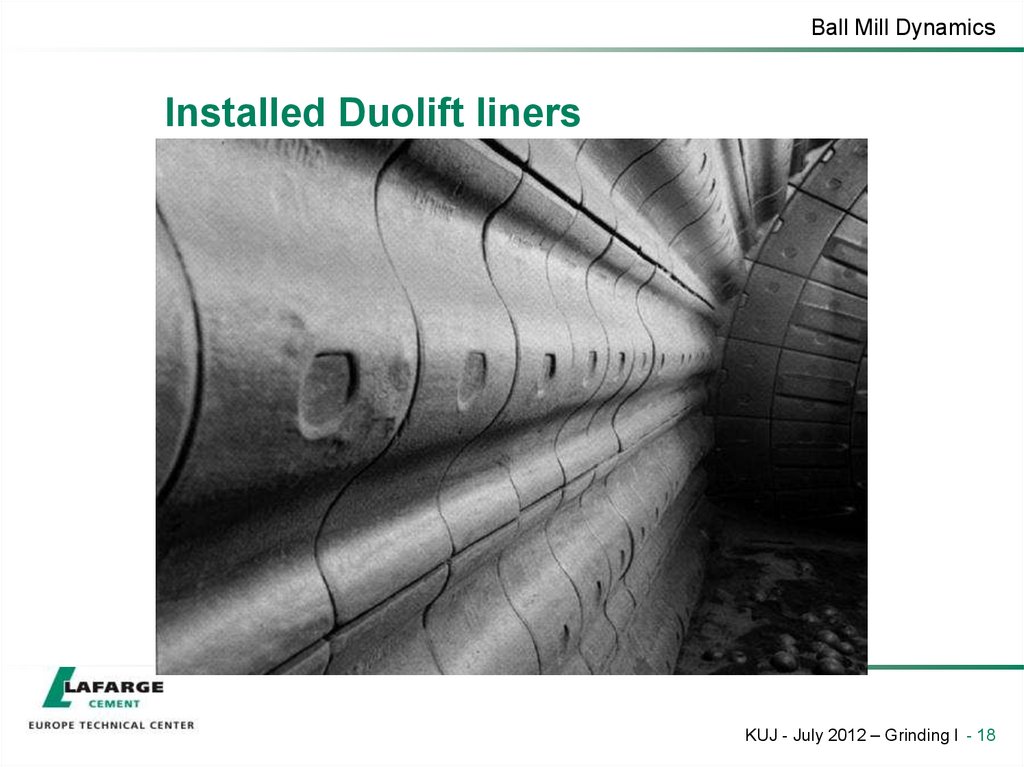

18. Installed Duolift liners

Ball Mill DynamicsInstalled Duolift liners

KUJ - July 2012 – Grinding I - 18

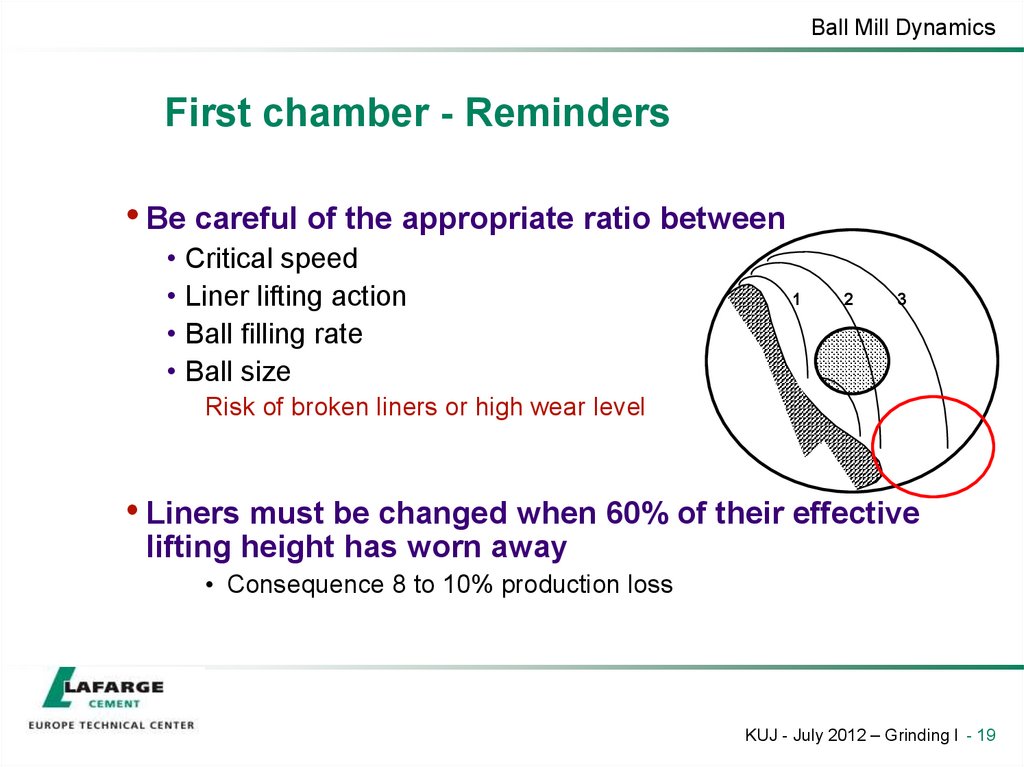

19. First chamber - Reminders

Ball Mill DynamicsFirst chamber - Reminders

• Be careful of the appropriate ratio between

Critical speed

Liner lifting action

Ball filling rate

Ball size

1

2

3

Risk of broken liners or high wear level

• Liners must be changed when 60% of their effective

lifting height has worn away

• Consequence 8 to 10% production loss

KUJ - July 2012 – Grinding I - 19

20. Content

Ball Mill DynamicsContent

• Size reduction mechanism

• Release point and internal dynamics 1st and 2nd

chamber

• 1st chamber liners

• 2nd chamber liners

• Fastening types

• Balls

• Mill head liners

• Material transport

KUJ - July 2012 – Grinding I - 20

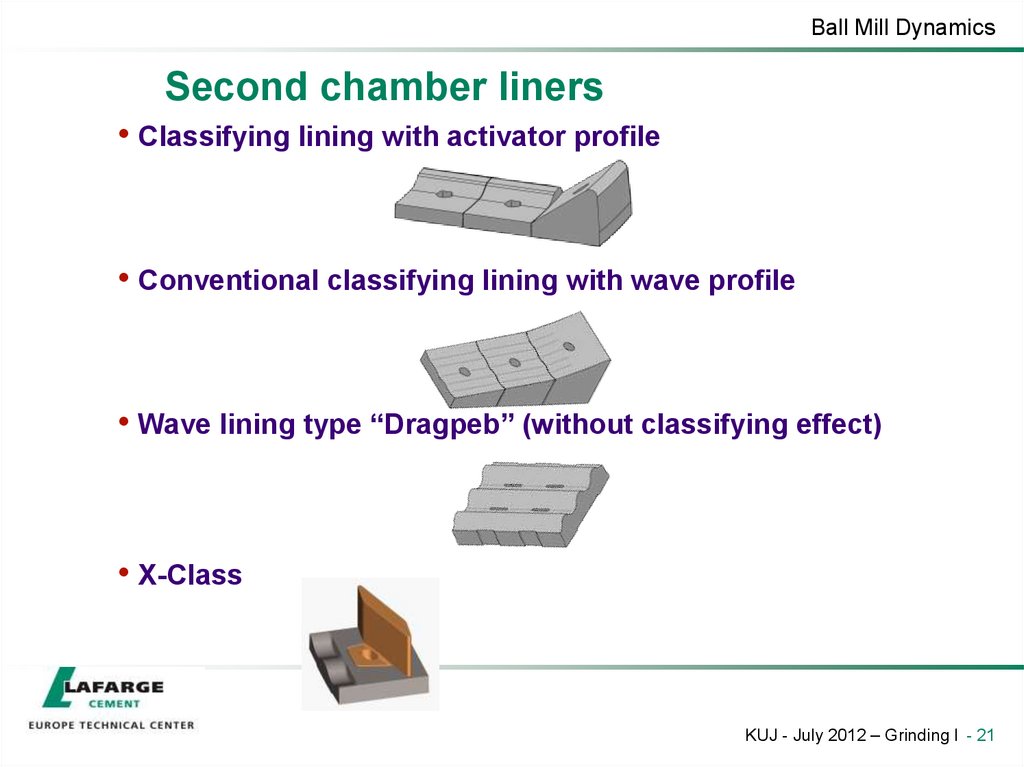

21. Second chamber liners

Ball Mill DynamicsSecond chamber liners

• Classifying lining with activator profile

• Conventional classifying lining with wave profile

• Wave lining type “Dragpeb” (without classifying effect)

• X-Class

KUJ - July 2012 – Grinding I - 21

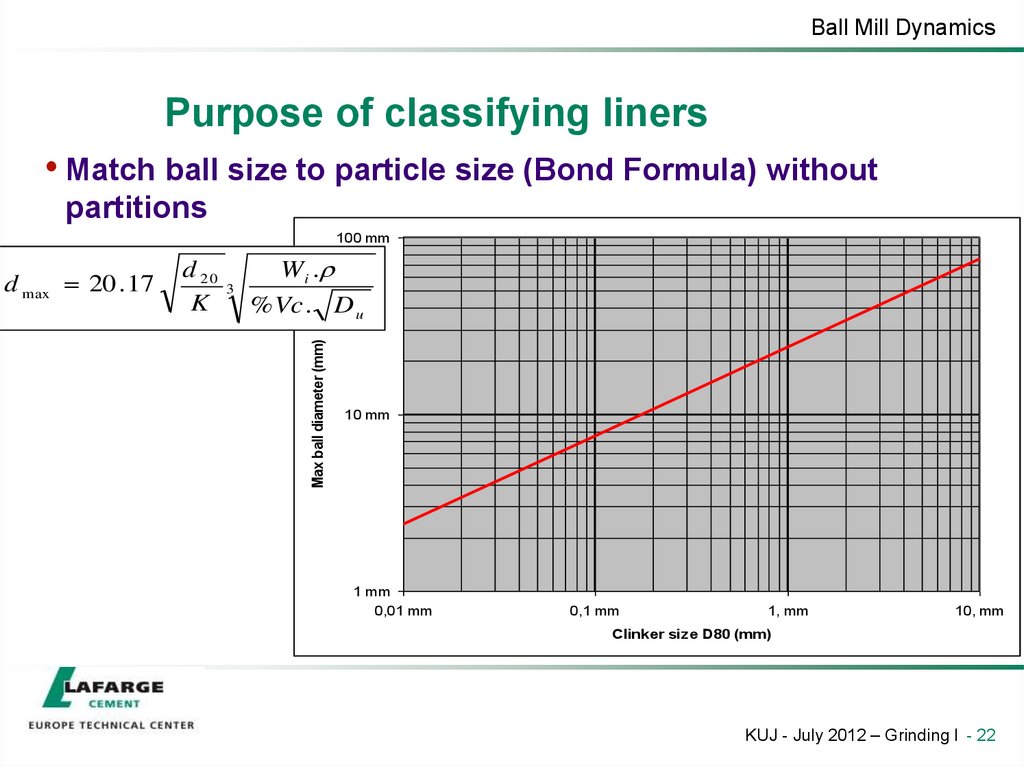

22. Purpose of classifying liners

Ball Mill DynamicsPurpose of classifying liners

• Match ball size to particle size (Bond Formula) without

partitions

100 mm

d 20

K

3

W i .

% Vc . D u

Max ball diameter (mm)

d max 20 . 17

10 mm

1 mm

0,01 mm

0,1 mm

1, mm

10, mm

Clinker size D80 (mm)

KUJ - July 2012 – Grinding I - 22

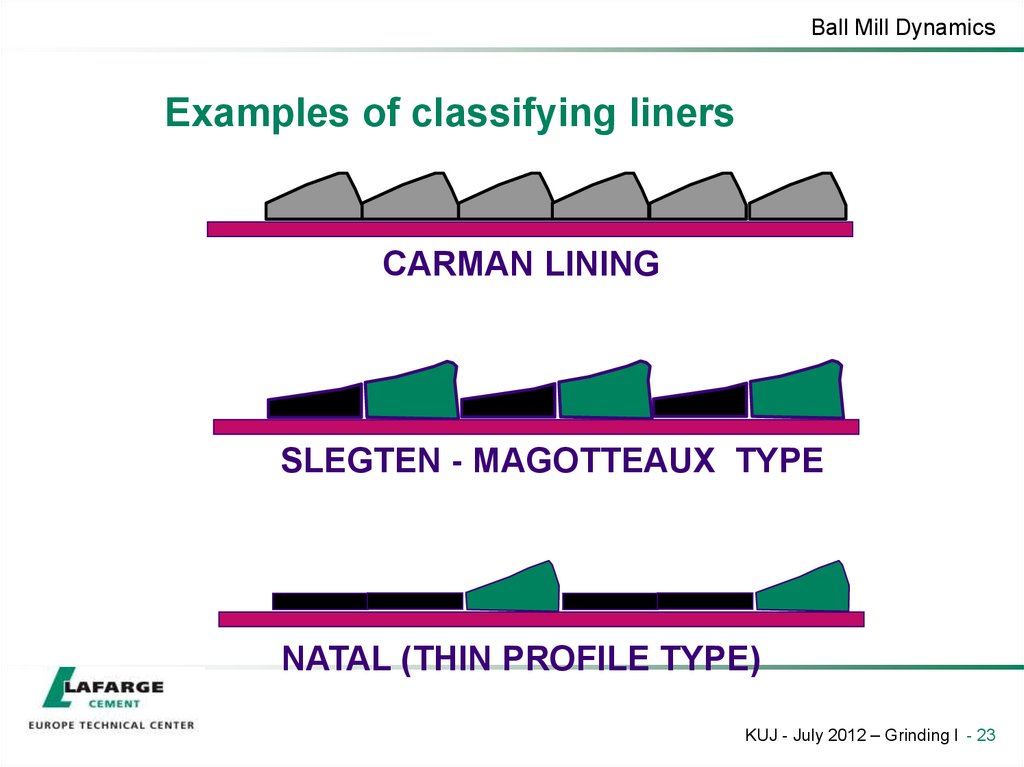

23. Examples of classifying liners

Ball Mill DynamicsExamples of classifying liners

CARMAN LINING

SLEGTEN - MAGOTTEAUX TYPE

NATAL (THIN PROFILE TYPE)

KUJ - July 2012 – Grinding I - 23

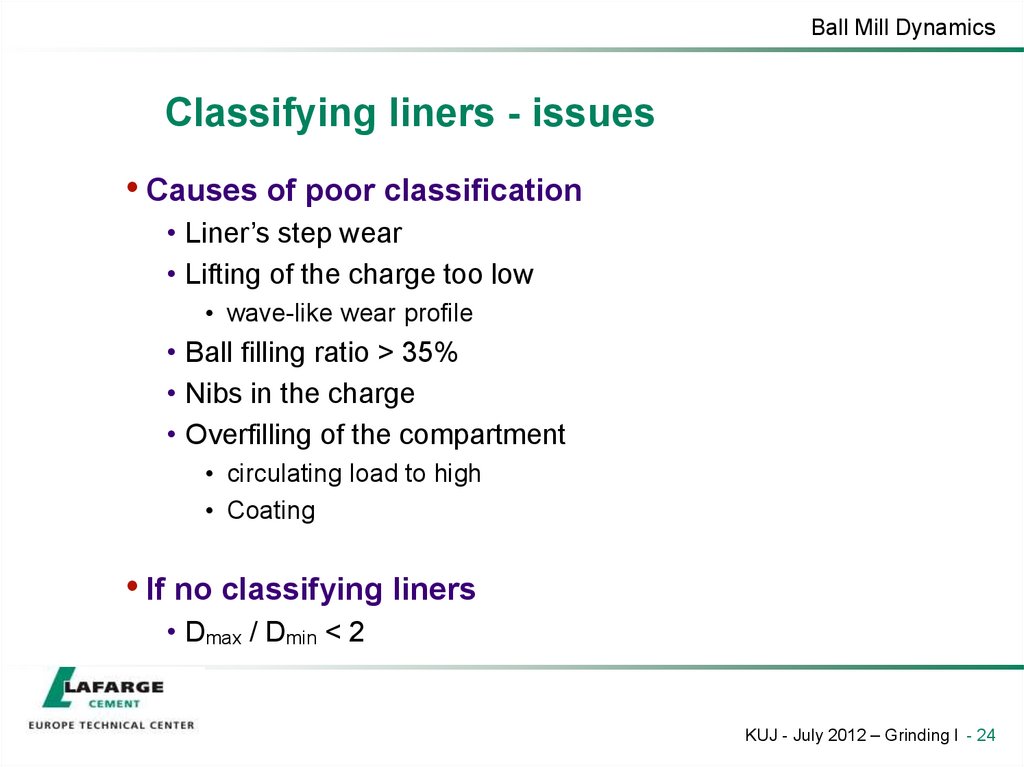

24. Classifying liners - issues

Ball Mill DynamicsClassifying liners - issues

• Causes of poor classification

• Liner’s step wear

• Lifting of the charge too low

• wave-like wear profile

• Ball filling ratio > 35%

• Nibs in the charge

• Overfilling of the compartment

• circulating load to high

• Coating

• If no classifying liners

• Dmax / Dmin < 2

KUJ - July 2012 – Grinding I - 24

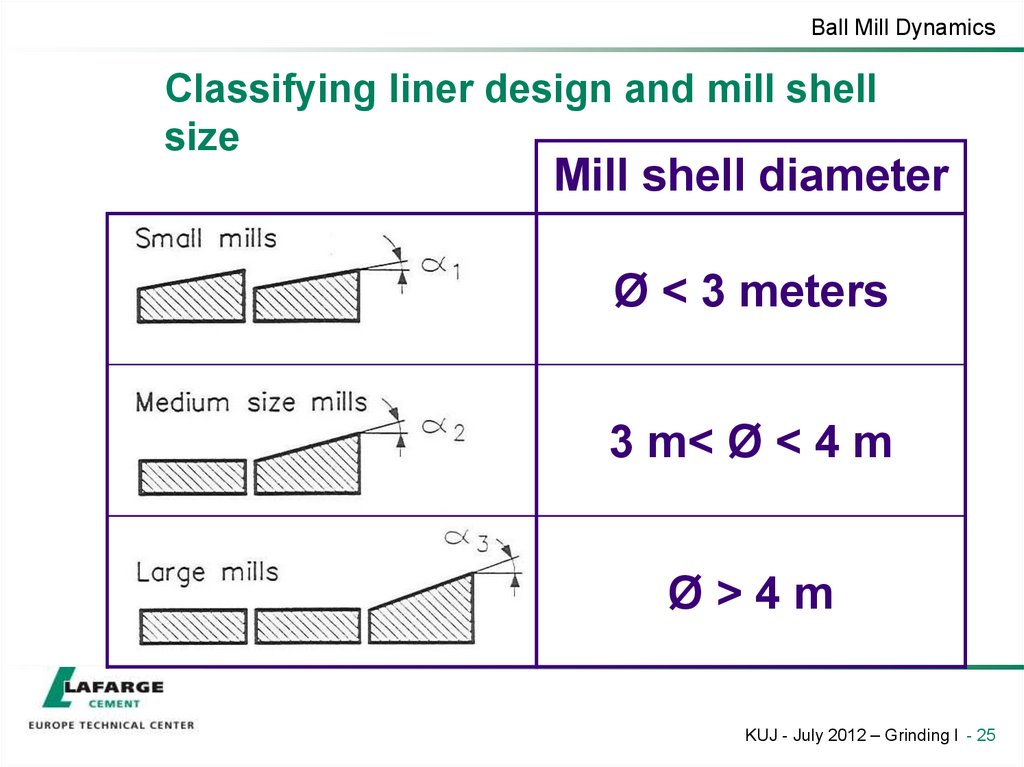

25. Classifying liner design and mill shell size

Ball Mill DynamicsClassifying liner design and mill shell

size

Mill shell diameter

Ø < 3 meters

3 m< Ø < 4 m

Ø>4m

KUJ - July 2012 – Grinding I - 25

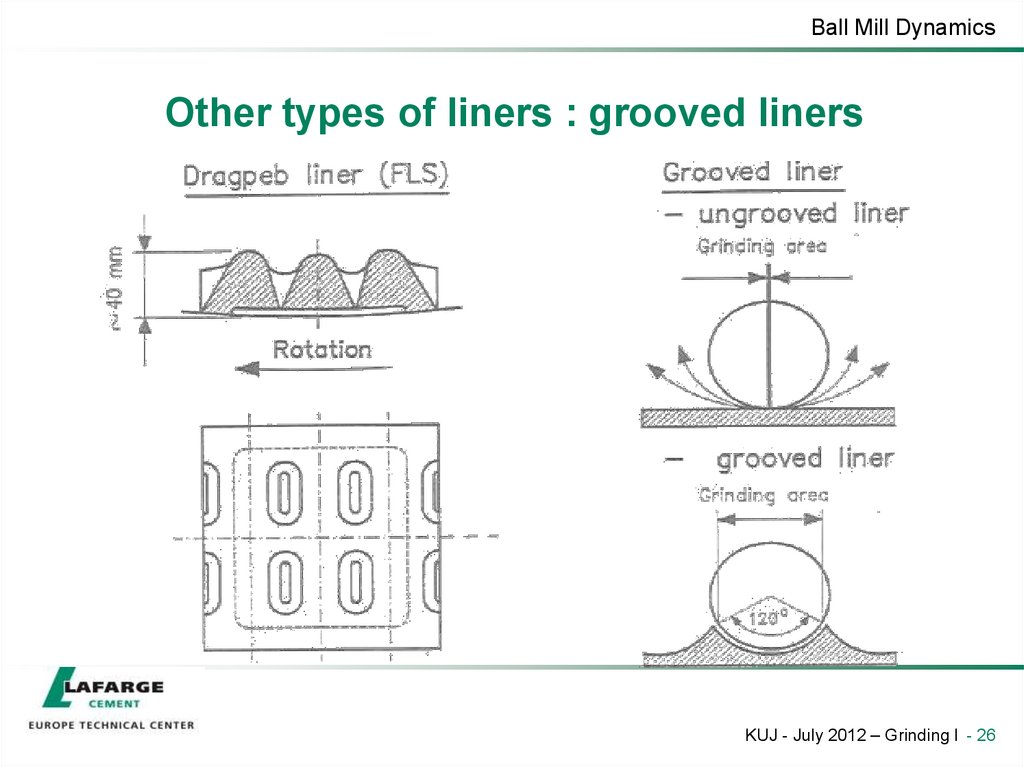

26. Other types of liners : grooved liners

Ball Mill DynamicsOther types of liners : grooved liners

KUJ - July 2012 – Grinding I - 26

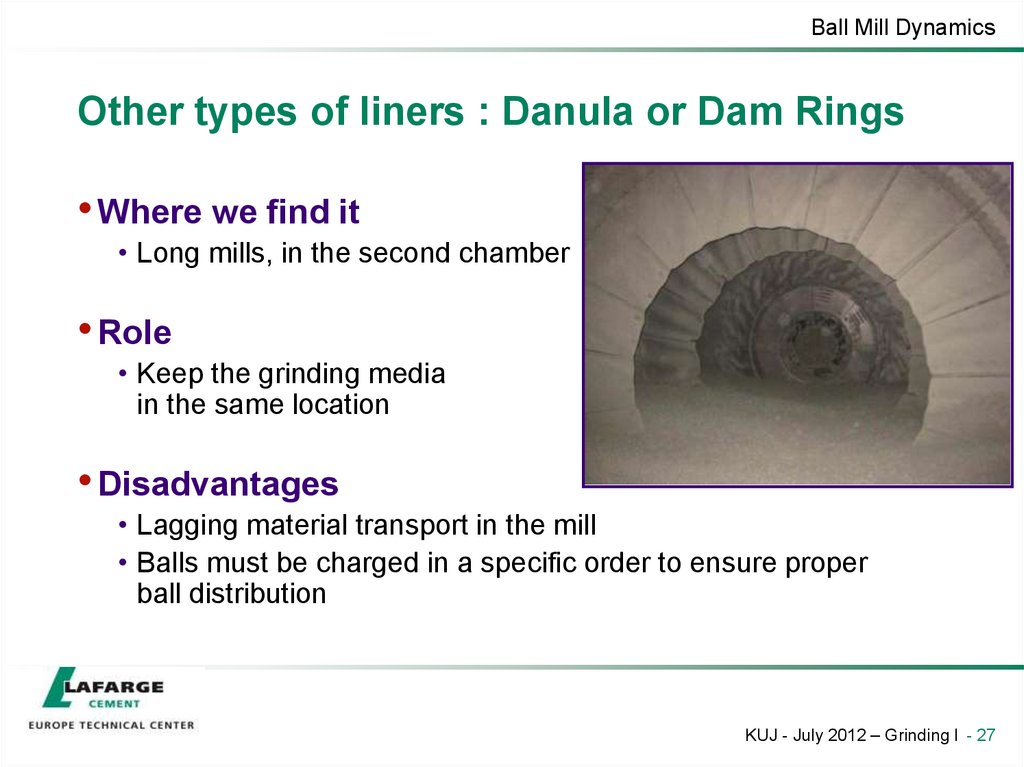

27. Other types of liners : Danula or Dam Rings

Ball Mill DynamicsOther types of liners : Danula or Dam Rings

• Where we find it

• Long mills, in the second chamber

• Role

• Keep the grinding media

in the same location

• Disadvantages

• Lagging material transport in the mill

• Balls must be charged in a specific order to ensure proper

ball distribution

KUJ - July 2012 – Grinding I - 27

28. Second chamber - Reminders

Ball Mill DynamicsSecond chamber - Reminders

• Classifying liners

• Causes for poor classification

• Liner step wear

• Lifting of the charge too low

• Liner wave wear

• Ball filling ratio > 35%

• Nibs in the charge

• Overfilling of the compartment

• Circulating load too high

• Coating

• Without classifying liners

• Dmax / Dmin < 2

KUJ - July 2012 – Grinding I - 28

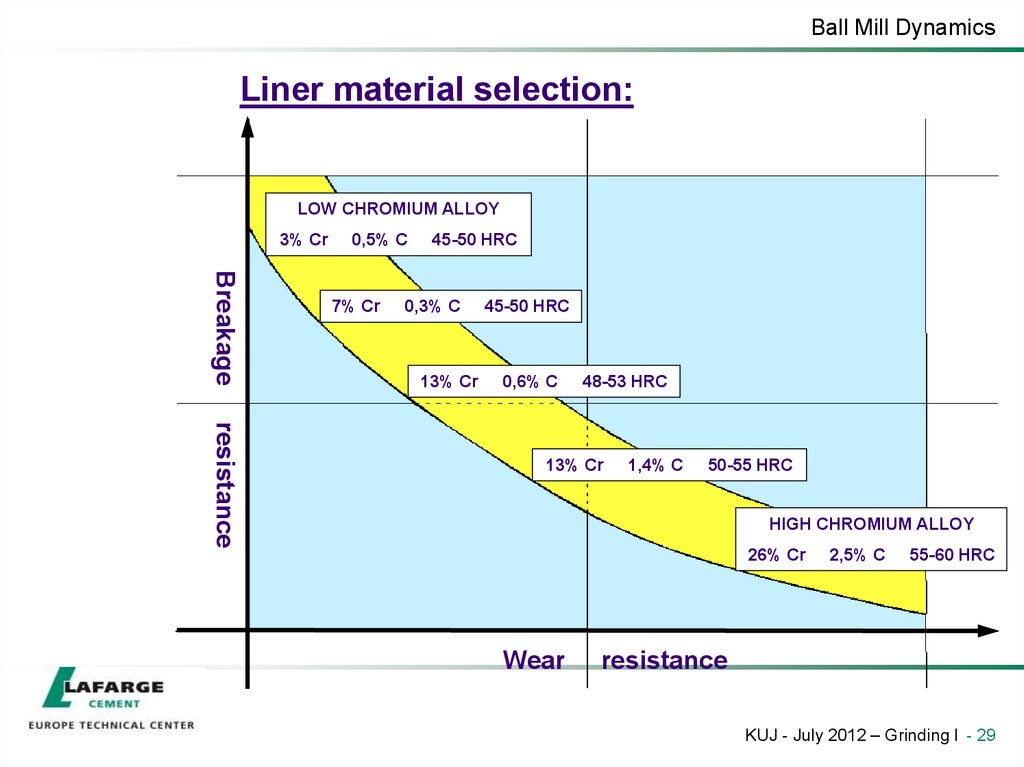

29.

Ball Mill DynamicsLiner material selection:

LOW CHROMIUM ALLOY

3% Cr

0,5% C

Breakage

7% Cr

45-50 HRC

0,3% C

13% Cr

45-50 HRC

0,6% C

48-53 HRC

resistance

13% Cr

1,4% C

50-55 HRC

HIGH CHROMIUM ALLOY

26% Cr

Wear

2,5% C

55-60 HRC

resistance

KUJ - July 2012 – Grinding I - 29

30. Content

Ball Mill DynamicsContent

• Size reduction mechanism

• Release point and internal dynamics 1st and 2nd

chamber

• 1st chamber liners

• 2nd chamber liners

• Fastening types

• Balls

• Mill head liners

• Material transport

KUJ - July 2012 – Grinding I - 30

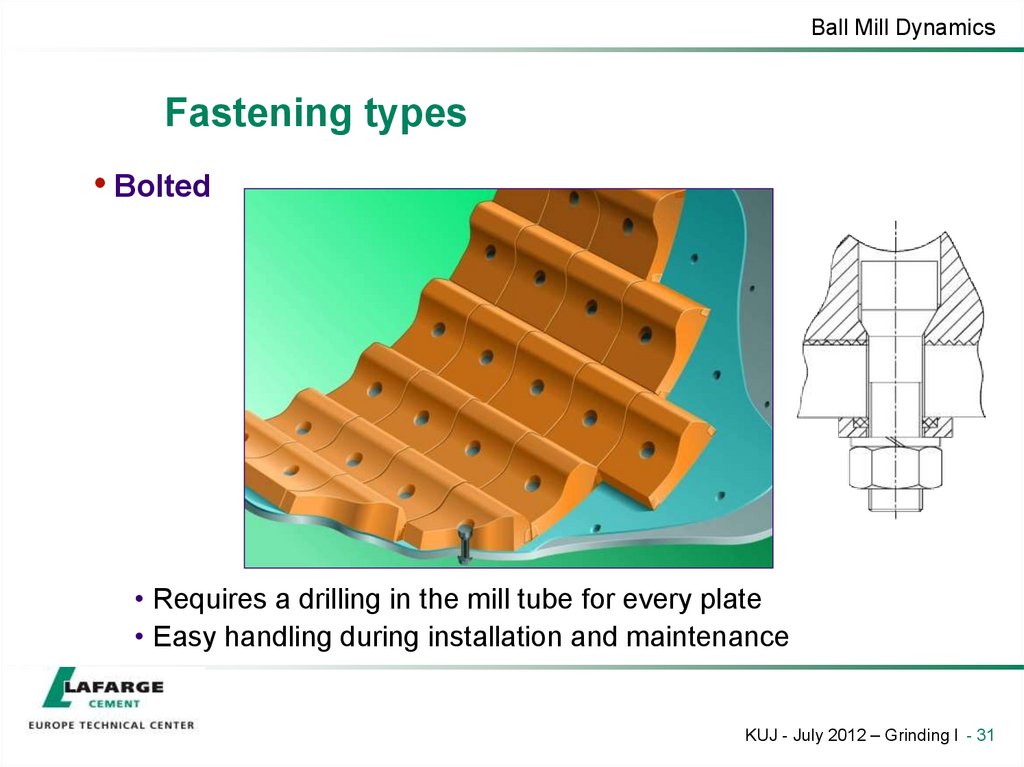

31. Fastening types

Ball Mill DynamicsFastening types

• Bolted

• Requires a drilling in the mill tube for every plate

• Easy handling during installation and maintenance

KUJ - July 2012 – Grinding I - 31

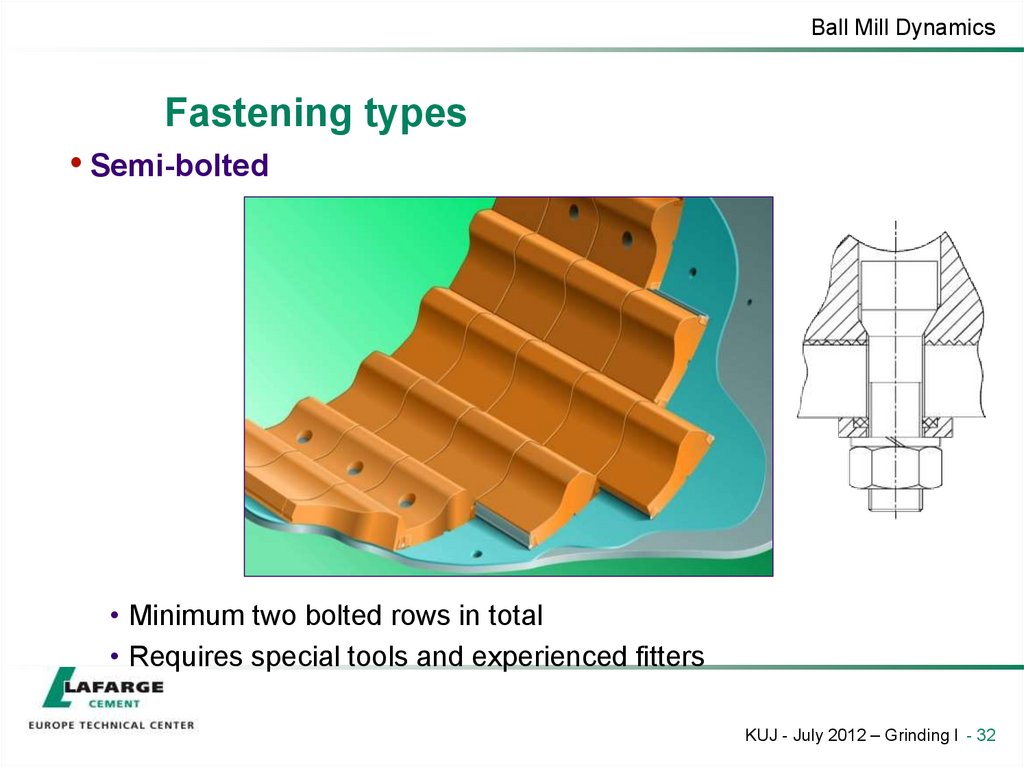

32. Fastening types

Ball Mill DynamicsFastening types

• Semi-bolted

• Minimum two bolted rows in total

• Requires special tools and experienced fitters

KUJ - July 2012 – Grinding I - 32

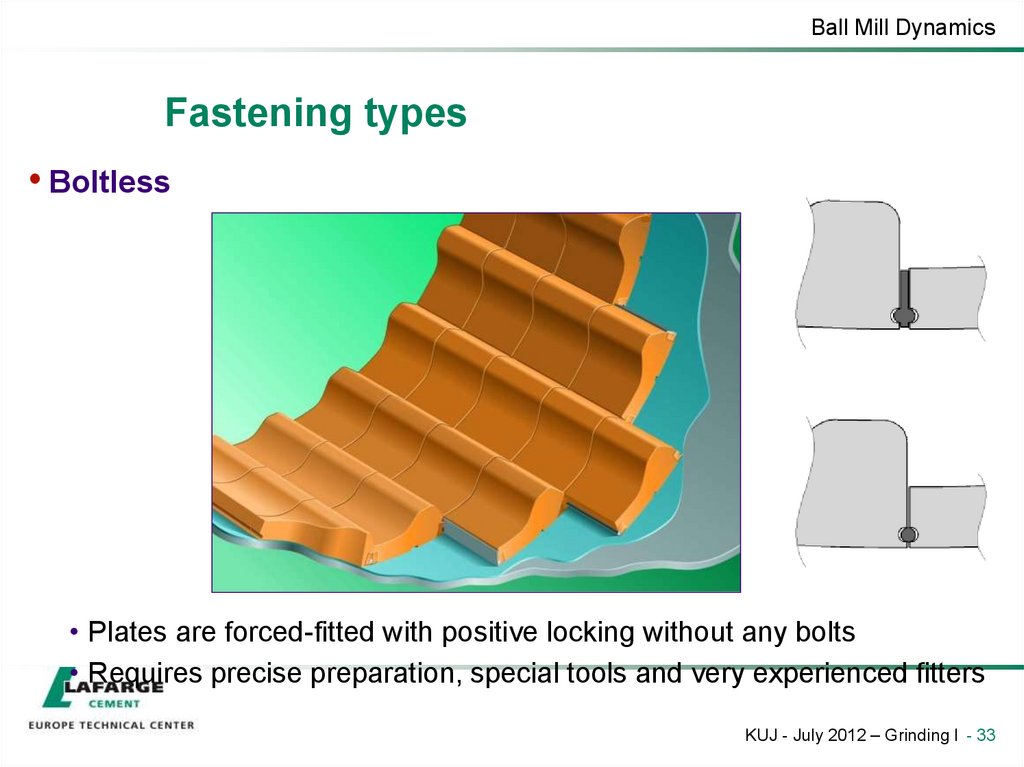

33. Fastening types

Ball Mill DynamicsFastening types

• Boltless

• Plates are forced-fitted with positive locking without any bolts

• Requires precise preparation, special tools and very experienced fitters

KUJ - July 2012 – Grinding I - 33

34. Liners’ wear management

Ball Mill DynamicsLiners’ wear management

• Liner wear optimisation

• Avoid metal / metal contact

• Minimise purge duration

• Look for optimal material filling rate

• Bolt holes can result in casting flaws: failures occur

there first.

• Boltless liners wear better, but require careful

installation

KUJ - July 2012 – Grinding I - 34

35. Content

Ball Mill DynamicsContent

• Size reduction mechanism

• Release point and internal dynamics 1st and 2nd

chamber

• 1st chamber liners

• 2nd chamber liners

• Fastening types

• Balls

• Mill head liners

• Material transport

KUJ - July 2012 – Grinding I - 35

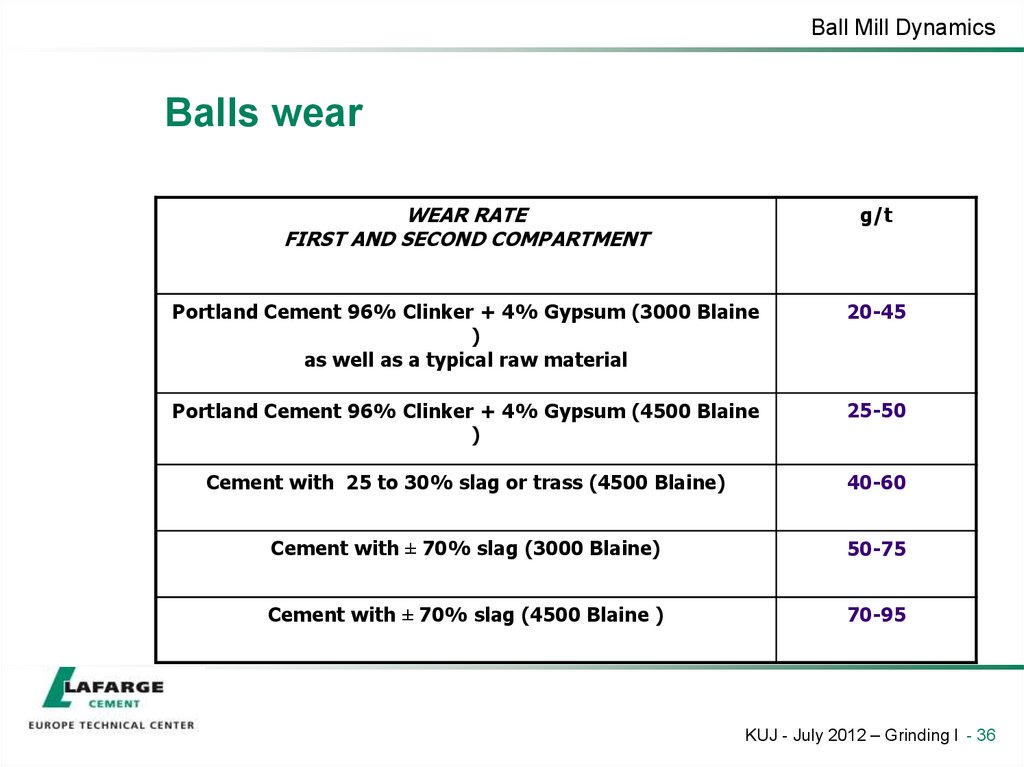

36. Balls wear

Ball Mill DynamicsBalls wear

WEAR RATE

FIRST AND SECOND COMPARTMENT

g/t

Portland Cement 96% Clinker + 4% Gypsum (3000 Blaine

)

as well as a typical raw material

20-45

Portland Cement 96% Clinker + 4% Gypsum (4500 Blaine

)

25-50

Cement with 25 to 30% slag or trass (4500 Blaine)

40-60

Cement with ± 70% slag (3000 Blaine)

50-75

Cement with ± 70% slag (4500 Blaine )

70-95

KUJ - July 2012 – Grinding I - 36

37. Content

Ball Mill DynamicsContent

• Size reduction mechanism

• Release point and internal dynamics 1st and 2nd

chamber

• 1st chamber liners

• 2nd chamber liners

• Fastening types

• Mill head liners

• Material transport

KUJ - July 2012 – Grinding I - 37

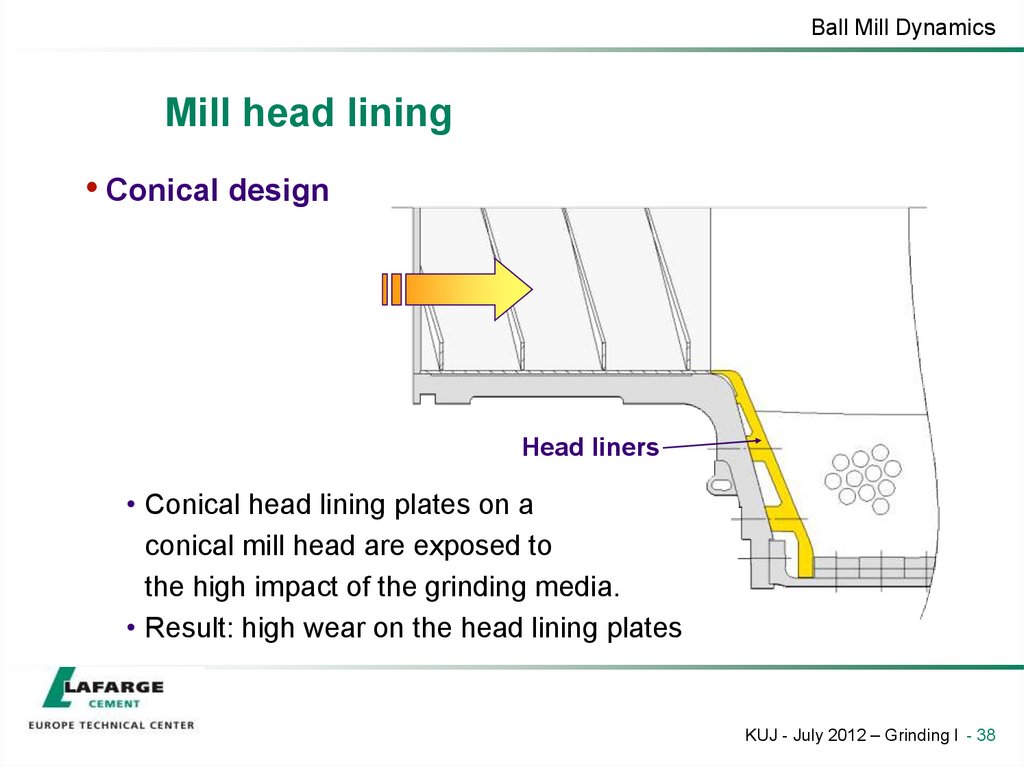

38. Mill head lining

Ball Mill DynamicsMill head lining

• Conical design

Head liners

• Conical head lining plates on a

conical mill head are exposed to

the high impact of the grinding media.

• Result: high wear on the head lining plates

KUJ - July 2012 – Grinding I - 38

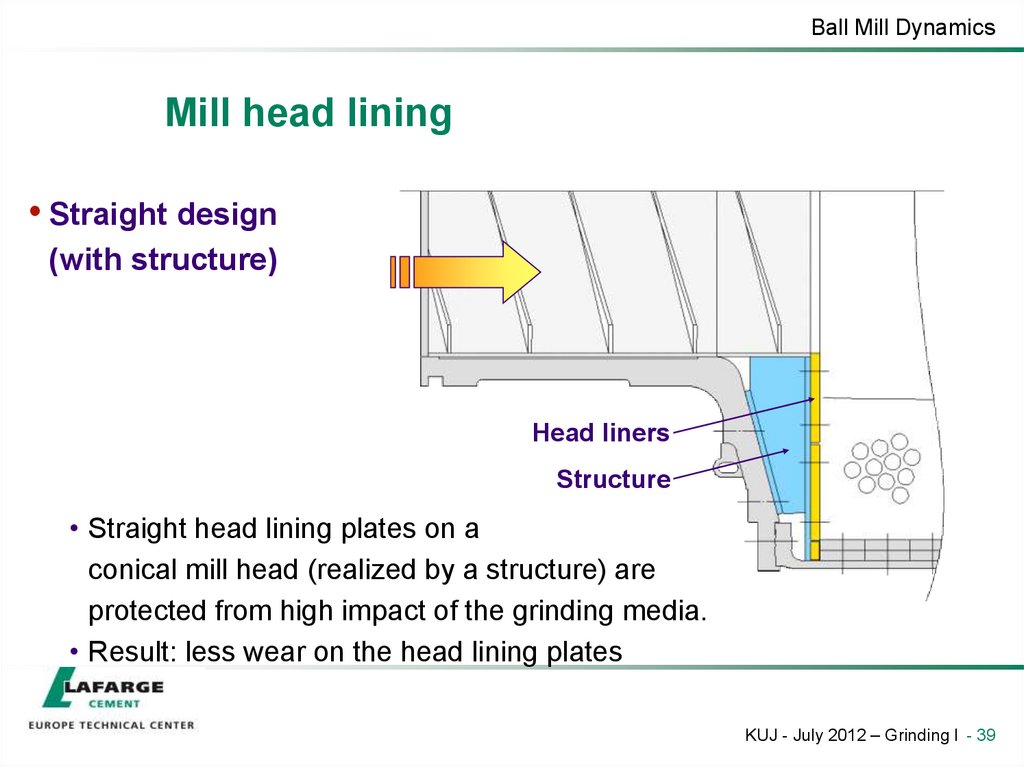

39. Mill head lining

Ball Mill DynamicsMill head lining

• Straight design

(with structure)

Head liners

Structure

• Straight head lining plates on a

conical mill head (realized by a structure) are

protected from high impact of the grinding media.

• Result: less wear on the head lining plates

KUJ - July 2012 – Grinding I - 39

40. Content

Ball Mill DynamicsContent

• Size reduction mechanism

• Release point and internal dynamics 1st and 2nd

chamber

• 1st chamber liners

• 2nd chamber liners

• Fastening types

• Balls

• Mill head liners

• Material transport

KUJ - July 2012 – Grinding I - 40

41. Mass transport

Ball Mill DynamicsMass transport

• Reason for mass transport in the mill shell

• Mill inlet feed pushes the material ahead

• Mill sweeping

• Pumping actions of the partition and discharge wall

• The mill retention time is about 10 to 15 minutes in

closed circuit

(20-30 min in open circuit)

KUJ - July 2012 – Grinding I - 41

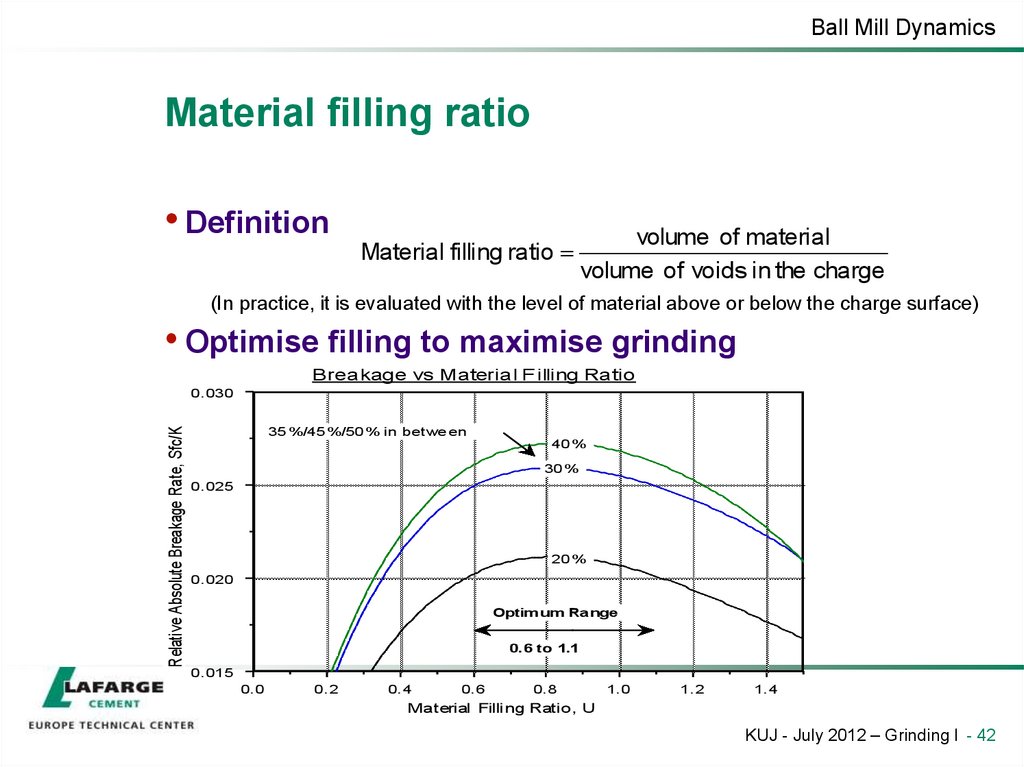

42. Material filling ratio

Ball Mill DynamicsMaterial filling ratio

• Definition

Material filling ratio

volume of material

volume of voids in the charge

(In practice, it is evaluated with the level of material above or below the charge surface)

• Optimise filling to maximise grinding

Breakage vs Material Filling Ratio

Relative Absolute Breakage Rate, Sfc/K

0.030

35 %/45 %/50 % in betwe en

40 %

30 %

0.025

20 %

0.020

Optim um Ra nge

0.6 to 1.1

0.015

0.0

0.2

0.4

0.6

0.8

1.0

1.2

1.4

Material Filli ng Ratio, U

KUJ - July 2012 – Grinding I - 42

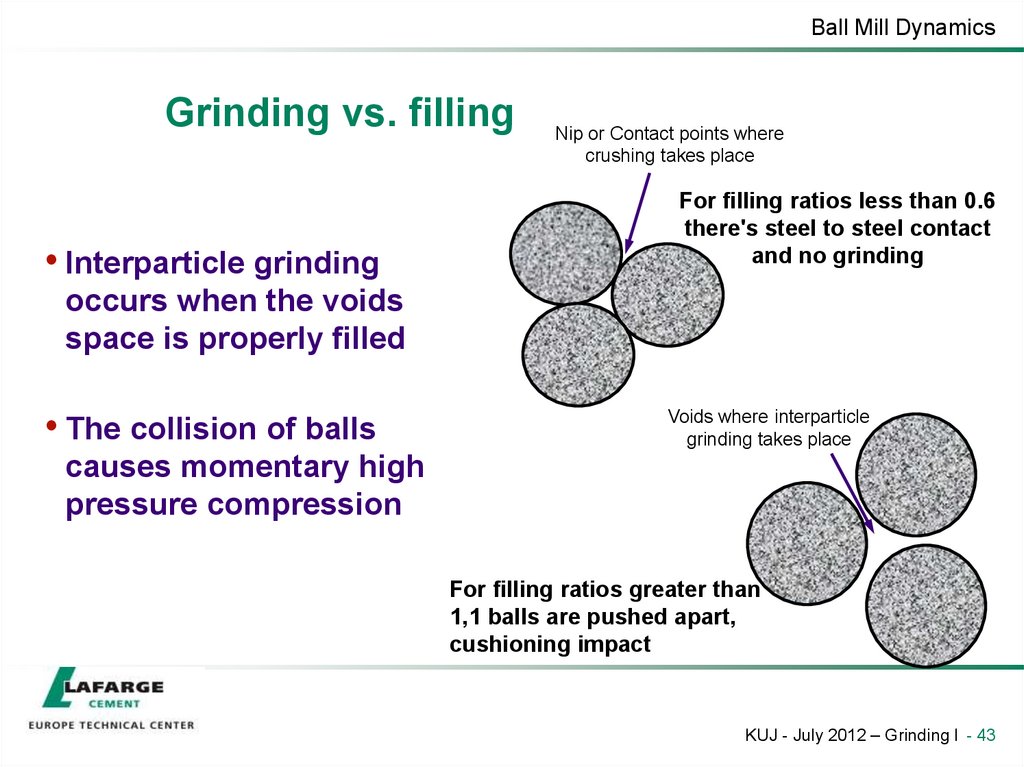

43. Grinding vs. filling

Ball Mill DynamicsGrinding vs. filling

• Interparticle grinding

Nip or Contact points where

crushing takes place

For filling ratios less than 0.6

there's steel to steel contact

and no grinding

occurs when the voids

space is properly filled

• The collision of balls

Voids where interparticle

grinding takes place

causes momentary high

pressure compression

For filling ratios greater than

1,1 balls are pushed apart,

cushioning impact

KUJ - July 2012 – Grinding I - 43

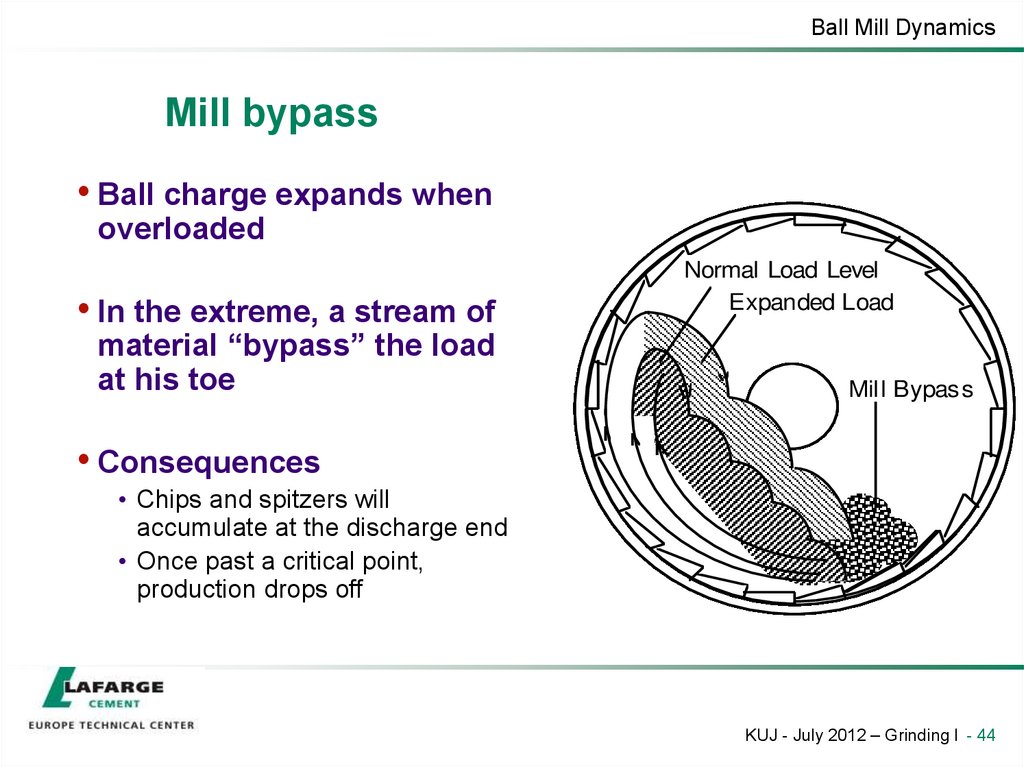

44. Mill bypass

Ball Mill DynamicsMill bypass

• Ball charge expands when

overloaded

• In the extreme, a stream of

material “bypass” the load

at his toe

Normal Load Level

Expanded Load

Mill Bypas s

• Consequences

• Chips and spitzers will

accumulate at the discharge end

• Once past a critical point,

production drops off

KUJ - July 2012 – Grinding I - 44

45. How to manage the material filling rate

Ball Mill DynamicsHow to manage the material filling rate

• Ball charge design

• The charge permeability depends on ball size

• Circulating load level

• Tuning of the partition drain effect

KUJ - July 2012 – Grinding I - 45

mechanics

mechanics