Similar presentations:

For Internal Use Only. Для амбиций о устойчивого пивоварения

1.

For Internal Use OnlyДля амбиций

экологичног

о

устойчивого

пивоварения

2. Простая и естественная стабилизация пива

BREWERS CLAREX®Константин Кляритский

Февраль 2020, Алматы

BRIGHT SCIENCE. BRIGHTER LIVING.

3. Простая и естественная стабилизация пива

Brewers Clarex® предупреждает мутностьрасщеплением белков

Наипростейшая стабилизация пива

– Жидкий препарат, готовый к использованию

– Без потерь от смешивания

Увеличение мощностей до ~20%

– Предотвращает формирование мутности

– Снижает время холодного кондиционирования

Бережет энергию

– Повышение температуры холодного

кондиционирования

от -2 °C до +6 °C

Экологичная стабилизация

– Снижение выбросов СО2

– Природный стабилизатор

Page 3

– Без химических веществ

– Без отходов из твердых частиц

For Internal Use Only

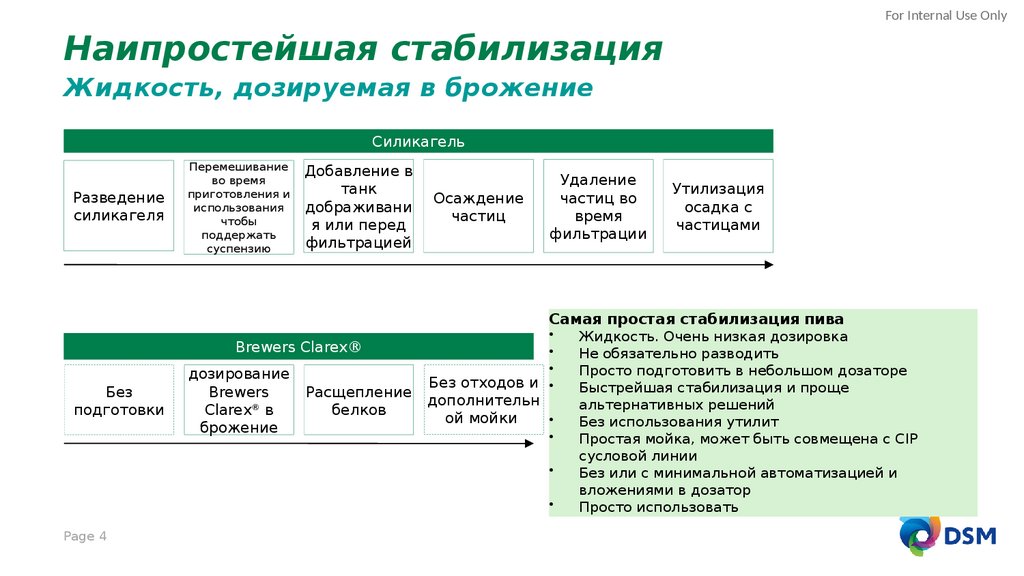

4. Наипростейшая стабилизация

For Internal Use OnlyНаипростейшая стабилизация

Жидкость, дозируемая в брожение

Силикагель

Разведение

силикагеля

Перемешивание

во время

приготовления и

использования

чтобы

поддержать

суспензию

Добавление в

танк

дображивани

я или перед

фильтрацией

Brewers Clarex®

Без

подготовки

Page 4

дозирование

Brewers

Clarex® в

брожение

Расщепление

белков

Осаждение

частиц

Удаление

частиц во

время

фильтрации

Утилизация

осадка с

частицами

Самая простая стабилизация пива

Жидкость. Очень низкая дозировка

Не обязательно разводить

Просто подготовить в небольшом дозаторе

Без отходов и

Быстрейшая стабилизация и проще

дополнительн

альтернативных решений

ой мойки

Без использования утилит

Простая мойка, может быть совмещена с СIP

сусловой линии

Без или с минимальной автоматизацией и

вложениями в дозатор

Просто использовать

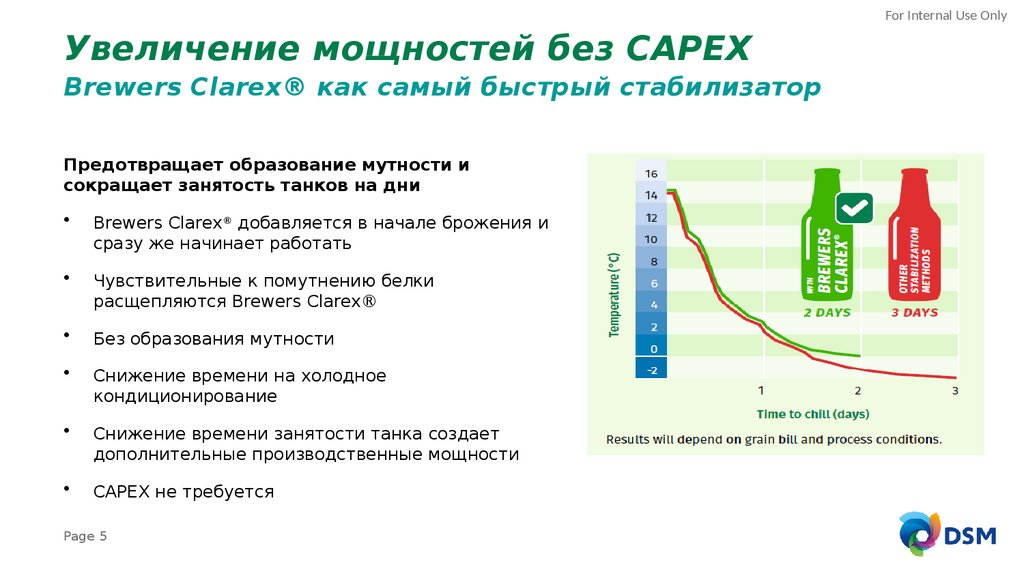

5. Увеличение мощностей без CAPEX

For Internal Use OnlyУвеличение мощностей без CAPEX

Brewers Clarex® как самый быстрый стабилизатор

Предотвращает образование мутности и

сокращает занятость танков на дни

Brewers Clarex® добавляется в начале брожения и

сразу же начинает работать

Чувствительные к помутнению белки

расщепляются Brewers Clarex®

Без образования мутности

Снижение времени на холодное

кондиционирование

Снижение времени занятости танка создает

дополнительные производственные мощности

CAPEX не требуется

Page 5

6. Снижение времени холодного кондиционирования за счет расщепления белков

For Internal Use OnlyСнижение времени холодного

кондиционирования за счет расщепления

Стабилизация пива с Brewers Clarex :

белков

Холодное кондиционирование (выдержка)

Фильтрация пива

Брожение

®

1.

2.

добавление Brewers

Clarex®

Brewers Clarex®

расщепляет

чувствительные к

помутнению белки

Осаждение дрожжевых клеток (7 °C)

Не нужна выжержка про температуре ниже 1 °C

из-за отсутствия белково-полифенольных

комплексов, мутности (расщеплена при

брожении)

Стабилизация пива с силикагелем

Брожение

Холодное кондиционирование

1.

2.

3.

4.

5.

Beer stabilization with PVPP

Брожение

Холодное кондиционирование

1.

2.

Фильтрация пива

Осаждение дрожжевых клеток(7 °C)

Перекачка в танк хранения

Дозирование силикагеля

Образование белково-полифенольных комплексов,

мути(1 °C, -1 °C)

Осаждение частиц мутности и силикагеля (1 °C, -1 °C)

Осаждение дрожжевых клеток (7 °C)

Образование белково-полифенольных комплексов,

мути(1 °C, -1 °C)

Стабилизация и фильтрация пива

1.

2.

3.

4.

Page 6

Добавление one-way PVPP с

кизельгуром,

Или добавление R-PVPP после

кизельгуровой фильтрации

PVPP удаляет полифенолы

Мутность расщепляется путем

удаления полифенолов

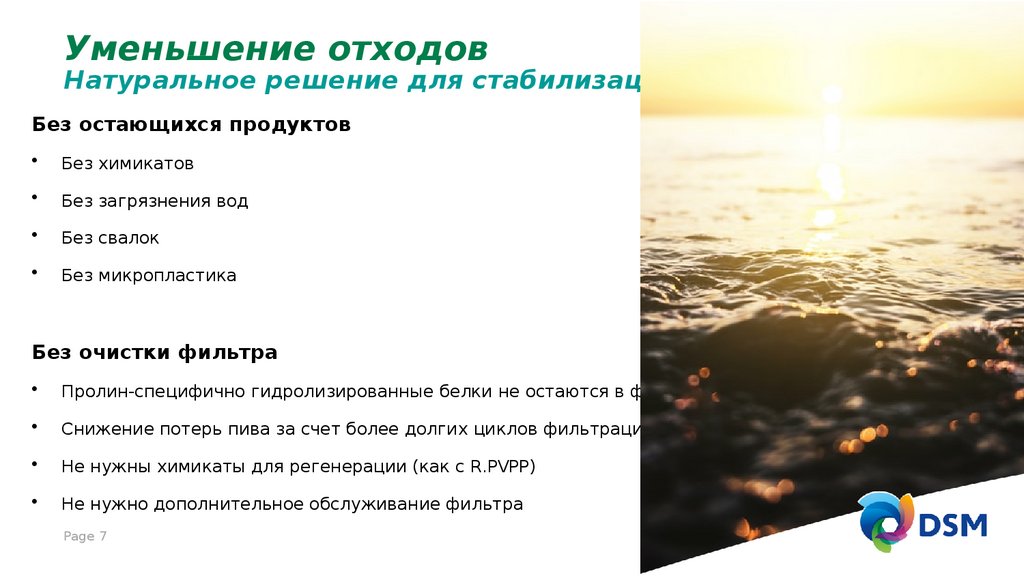

7. Уменьшение отходов

For Internal Use OnlyУменьшение отходов

Натуральное решение для стабилизации

Без остающихся продуктов

Без химикатов

Без загрязнения вод

Без свалок

Без микропластика

Без очистки фильтра

Пролин-специфично гидролизированные белки не остаются в фильтре

Снижение потерь пива за счет более долгих циклов фильтрации (~0.3%)

Не нужны химикаты для регенерации (как с R.PVPP)

Не нужно дополнительное обслуживание фильтра

Page 7

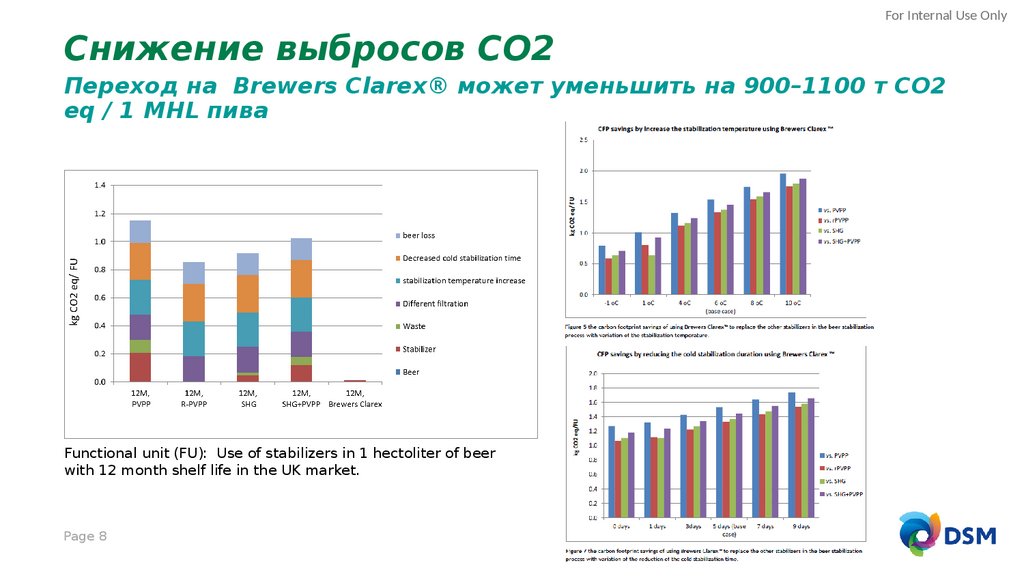

8. Снижение выбросов СО2

For Internal Use OnlyСнижение выбросов СО2

Переход на Brewers Clarex® может уменьшить на 900–1100 т CO2

eq / 1 MHL пива

Functional unit (FU): Use of stabilizers in 1 hectoliter of beer

with 12 month shelf life in the UK market.

Page 8

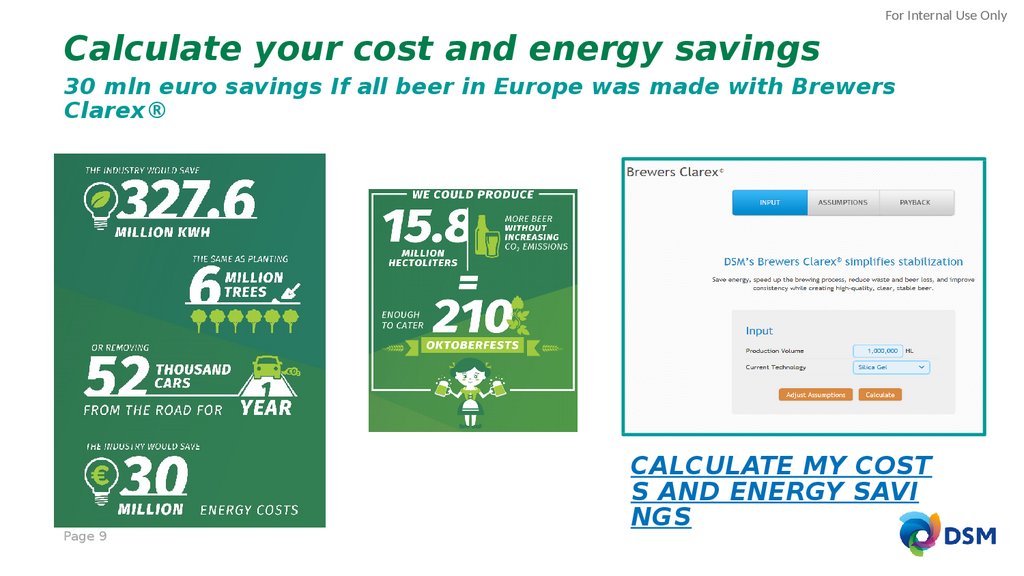

9. Calculate your cost and energy savings

For Internal Use OnlyCalculate your cost and energy savings

30 mln euro savings If all beer in Europe was made with Brewers

Clarex®

Page 9

CALCULATE MY COST

S AND ENERGY SAVI

NGS

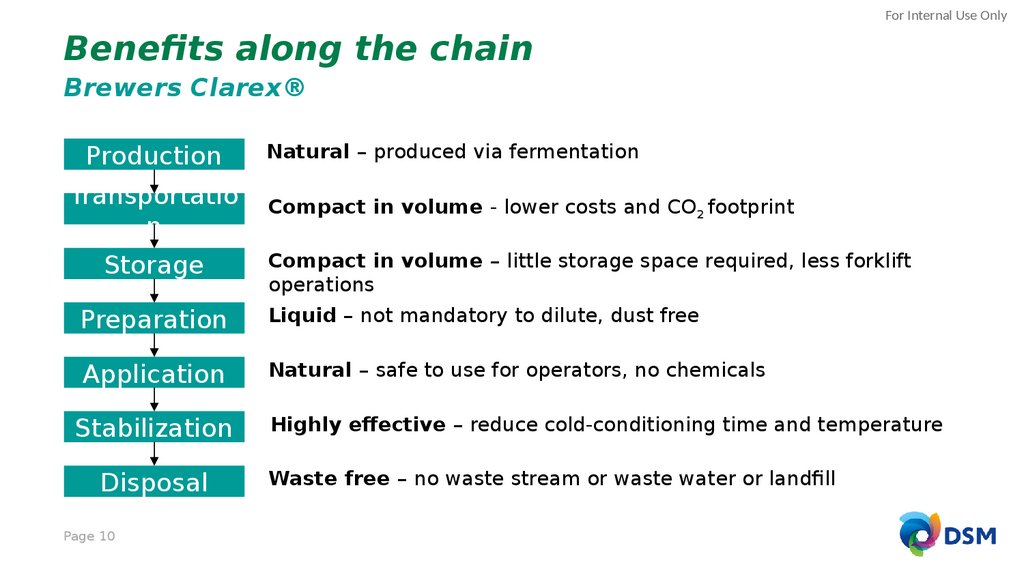

10. Benefits along the chain

For Internal Use OnlyBenefts along the chain

Brewers Clarex®

Production

Transportatio

n

Storage

Natural – produced via fermentation

Compact in volume - lower costs and CO2 footprint

Compact in volume – little storage space required, less forklift

operations

Preparation

Liquid – not mandatory to dilute, dust free

Application

Natural – safe to use for operators, no chemicals

Stabilization

Disposal

Page 10

Highly efective – reduce cold-conditioning time and temperature

Waste free – no waste stream or waste water or landfll

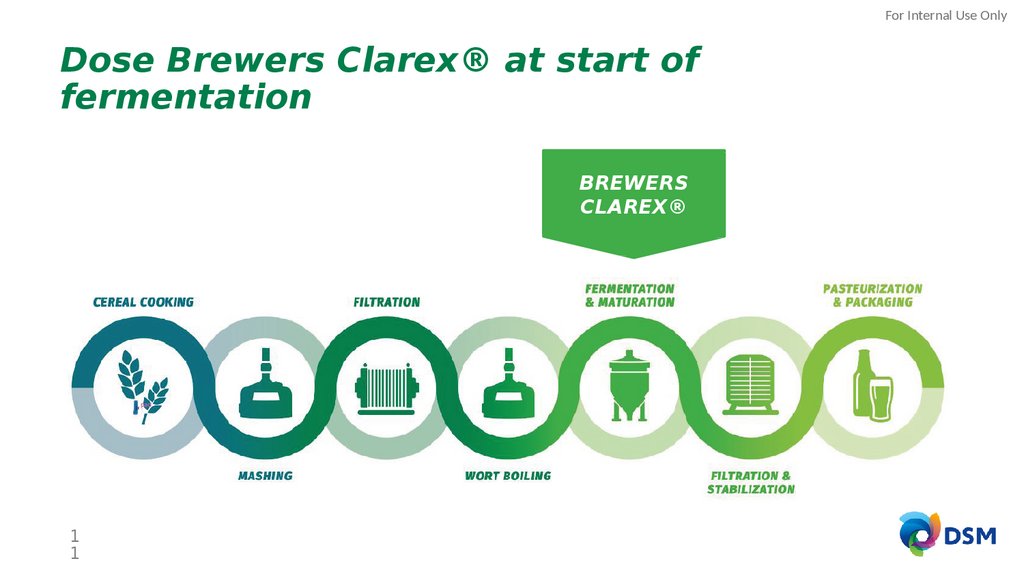

11. Dose Brewers Clarex® at start of fermentation

For Internal Use OnlyDose Brewers Clarex® at start of

fermentation

BREWERS

CLAREX®

1

1

12.

For Internal Use OnlyPrevent

colloidal haze

formation

Stabilize by specifcally

degrading haze sensitive

proteins

13.

For Internal Use OnlyBrewers

Clarex® into

action

Stabilize by specifcally

degrading haze sensitive

proteins

14.

For Internal Use OnlyHow Brewers

Clarex®

prevents

colloidal haze

in beer

Stabilize by specifcally degrading

haze sensitive proteins

15.

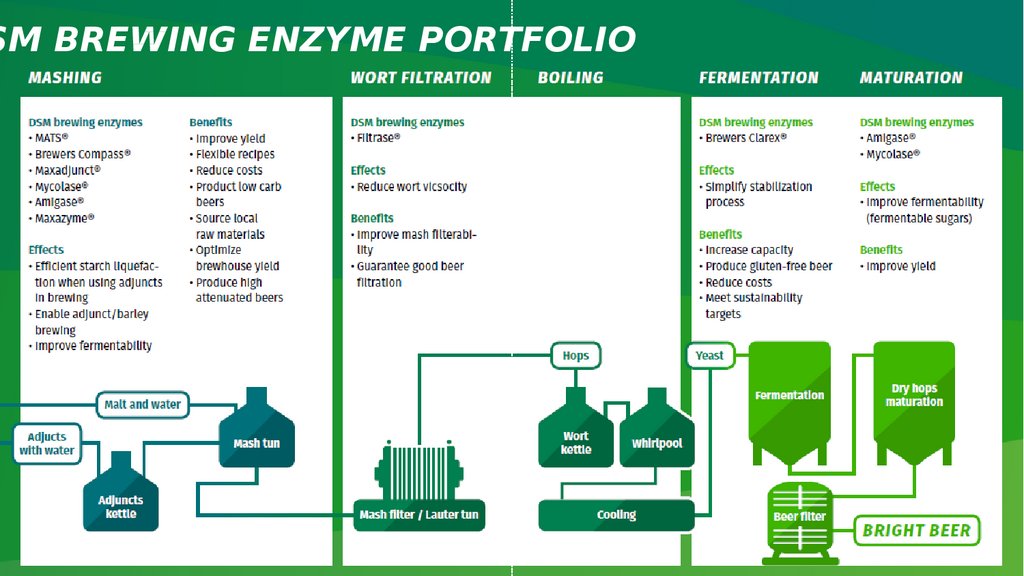

SM BREWING ENZYME PORTFOLIOFor Internal Use Only

16.

For Internal Use OnlyWITH OUR BREW MASTERS:

ACHIEVING

KPIs

.. AFTER IMPLEMENTING

KEEP SAME QUALITY BEER

BREWERS

SAVE

ENERGY CLAREX ® .

REDUCE CO2

INCREASE CAPACITY

17. Worldwide dedication to the brewers DSM Food Specialties – DSM Brewing

For Internal Use OnlyWorldwide dedication to the

brewers

DSM

Food Specialties – DSM Brewing

How we are doing this…

Japan

Europe

Global

Russia

North America

LOCAL experts with years of brewery

experience that speak your language for

TECHNICAL and TECHNOLOGICAL

SUPPORT ...

–

–

–

–

–

–

–

–

–

–

–

–

Marlos Fernandes, North America

Alberto Melgoza, Central America & Mexico

Marcelo Gallardo, South America

Torben Katzmann, Europe

Pierre Lambert Smal, Middle East & Africa

Denis Shirokovskiy, Middle East & Africa

Konstantin Klyaritski, Russia

Siaw Yon Miaw, Asia Pacifc

Hiro Furukawa, Japan

Sam Li, China

Jason Ma, China

Theo Wijsman, Global coordinator

17

Hiro

Furukawa

Marlos

Fernandes

CAM & Mexico

Theo

Wijsman

Torben

Katzmann

Konstantin

Klyaritsky

China

China

Sam Li

Jason

Ma

MEA

ME

A

Alberto

Melgoza

Denis

Shirokovskiy

South America

Pierre-Lambert

Smal

Marcelo

Gallardo

APA

Sam

Li

Siaw

Yon-Miaw

18.

For Internal Use OnlyCREATING

BRIGHTER LIVES.

FOR ALL.

CREATING VALUE FOR ALL OUR

CUSTOMERS, EMPLOYEES,

SHAREHOLDERS, AND

SOCIETY AT LARGE.

19.

BRIGHT SCIENCE. BRIGHTER LIVING.While making reasonable eforts to ensure that all information in this presentation is accurate and up to date,

DSM makes no representation or warranty of accuracy, reliability, or completeness of the information.

The information provided herein is for the informational purposes only.

This publication does not constitute or provide scientifc advice and is without warranty of any kind, express

or implied. In no event shall DSM be liable for any damage arising from the reader’s reliance upon, or use of,

this presentation.

The reader shall be solely responsible for any interpretation or use of the materials contained herein.

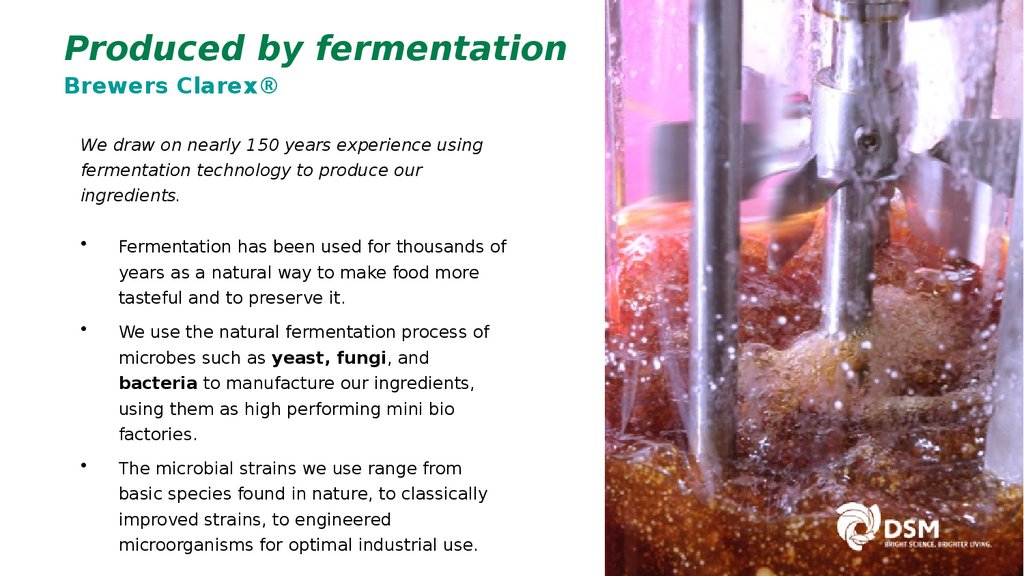

20. Produced by fermentation

For Internal Use OnlyProduced by fermentation

Brewers Clarex®

We draw on nearly 150 years experience using

fermentation technology to produce our

ingredients.

Fermentation has been used for thousands of

years as a natural way to make food more

tasteful and to preserve it.

We use the natural fermentation process of

microbes such as yeast, fungi, and

bacteria to manufacture our ingredients,

using them as high performing mini bio

factories.

The microbial strains we use range from

basic species found in nature, to classically

improved strains, to engineered

microorganisms for optimal industrial use.

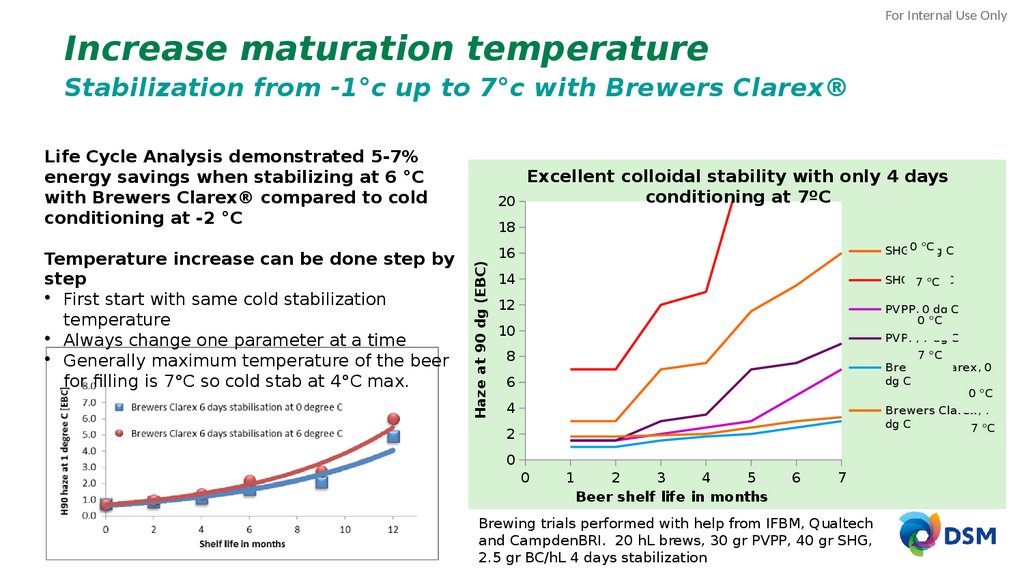

21. Increase maturation temperature

For Internal Use OnlyIncrease maturation temperature

Stabilization from -1°c up to 7°c with Brewers Clarex®

Life Cycle Analysis demonstrated 5-7%

energy savings when stabilizing at 6 °C

with Brewers Clarex® compared to cold

conditioning at -2 °C

18

Haze at 90 dg (EBC)

Temperature increase can be done step by

step

• First start with same cold stabilization

temperature

• Always change one parameter at a time

• Generally maximum temperature of the beer

for flling is 7°C so cold stab at 4°C max.

Excellent colloidal stability with only 4 days

conditioning at 7ºC

20

16

SHG,00°C

dg C

14

SHG, 77 °C

dg C

12

PVPP, 0 dg C

0 °C

10

PVPP, 7 dg C

7 °C

Brewers Clarex, 0

dg C

0 °C

8

6

4

Brewers Clarex, 7

dg C

7 °C

2

0

0

Page 21

1

2

3

4

5

Beer shelf life in months

6

7

Brewing trials performed with help from IFBM, Qualtech

and CampdenBRI. 20 hL brews, 30 gr PVPP, 40 gr SHG,

2.5 gr BC/hL 4 days stabilization

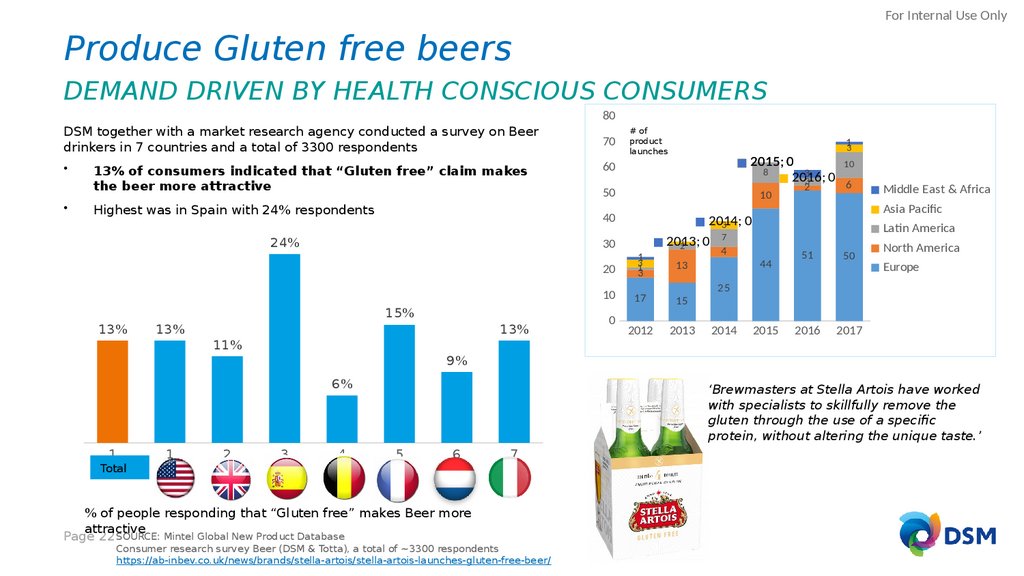

22. Produce Gluten free beers

For Internal Use OnlyProduce Gluten free beers

DEMAND DRIVEN BY HEALTH CONSCIOUS CONSUMERS

80

DSM together with a market research agency conducted a survey on Beer

drinkers in 7 countries and a total of 3300 respondents

13% of consumers indicated that “Gluten free” claim makes

the beer more attractive

Highest was in Spain with 24% respondents

# of

product

launches

15%

13%

11%

2015; 0

8

3

2016;

0

3

50

10

20

13

10

17

15

2012

2013

0

6

Middle East & Africa

Latn America

4

13

31

2

10

Asia Pacifc

2014;

0

3

7

2013;

0

1

2

30

13%

13

60

40

24%

13%

70

44

51

50

North America

Europe

25

2014

2015

2016

2017

9%

6%

1

Total

1

2

3

4

‘Brewmasters at Stella Artois have worked

with specialists to skillfully remove the

gluten through the use of a specifc

protein, without altering the unique taste.’

5

6

% of people responding that “Gluten free” makes Beer more

attractive

Page 22 SOURCE: Mintel Global New Product Database

7

Consumer research survey Beer (DSM & Totta), a total of ~3300 respondents

https://ab-inbev.co.uk/news/brands/stella-artois/stella-artois-launches-gluten-free-beer/

23.

For Internal Use OnlyMINIMAL IMPACT ON FILLING SPEED

INCREASE FILLING TEMPERATURE

% Loss in speed

20%

18%

16%

14%

12%

10%

8%

6%

4%

2%

0%

0

5

10

15

Filling temperature °C

20

25

Infuence flling temperature capacity botle fller Krones HES type

% Loss in speed

Infuence flling temperature capacity botle fller Krones HRS type

20%

18%

16%

14%

12%

10%

8%

6%

4%

2%

0%

0

5

10

15

Filling temperature °C

20

25

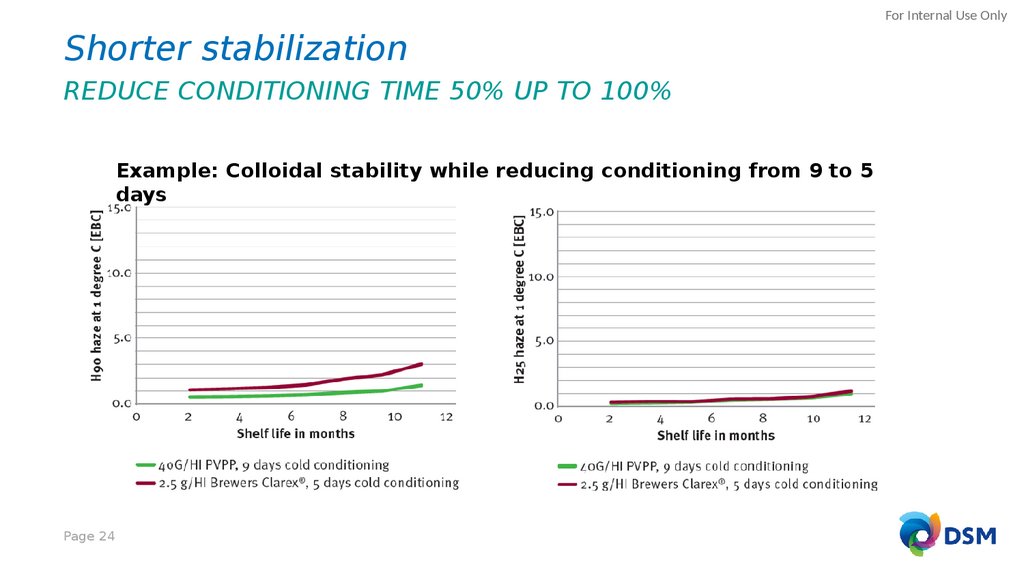

24. Shorter stabilization

For Internal Use OnlyShorter stabilization

REDUCE CONDITIONING TIME 50% UP TO 100%

Example: Colloidal stability while reducing conditioning from 9 to 5

days

Page 24

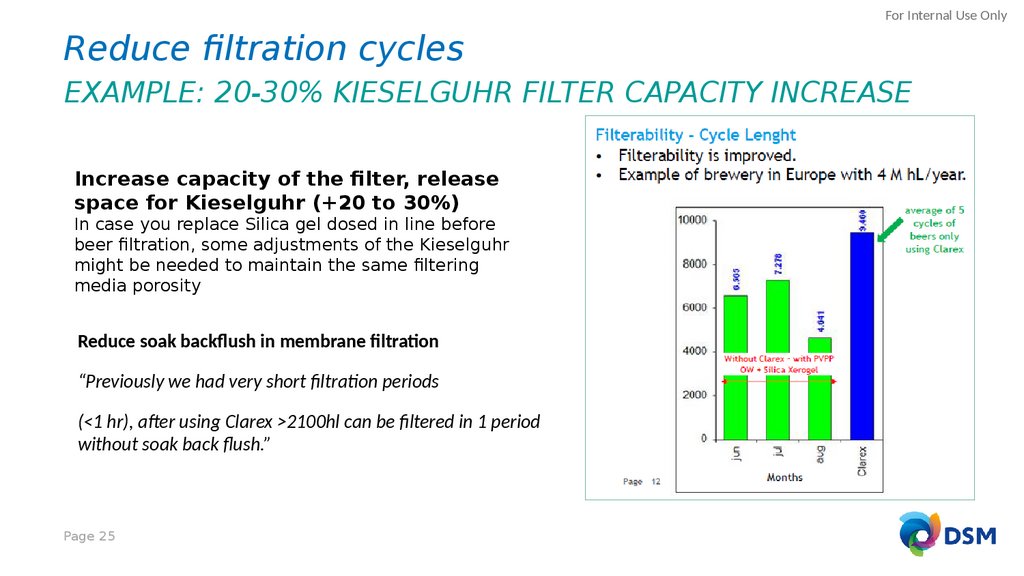

25. Reduce filtration cycles

For Internal Use OnlyReduce fltration cycles

EXAMPLE: 20-30% KIESELGUHR FILTER CAPACITY INCREASE

Increase capacity of the flter, release

space for Kieselguhr (+20 to 30%)

In case you replace Silica gel dosed in line before

beer fltration, some adjustments of the Kieselguhr

might be needed to maintain the same fltering

media porosity

Reduce soak backfuss in membrane fltraton

“Previously we had very short fltraton periods

(<1 hr), afer using Clarex >2100hl can be fltered in 1 period

without soak back fush.”

Page 25

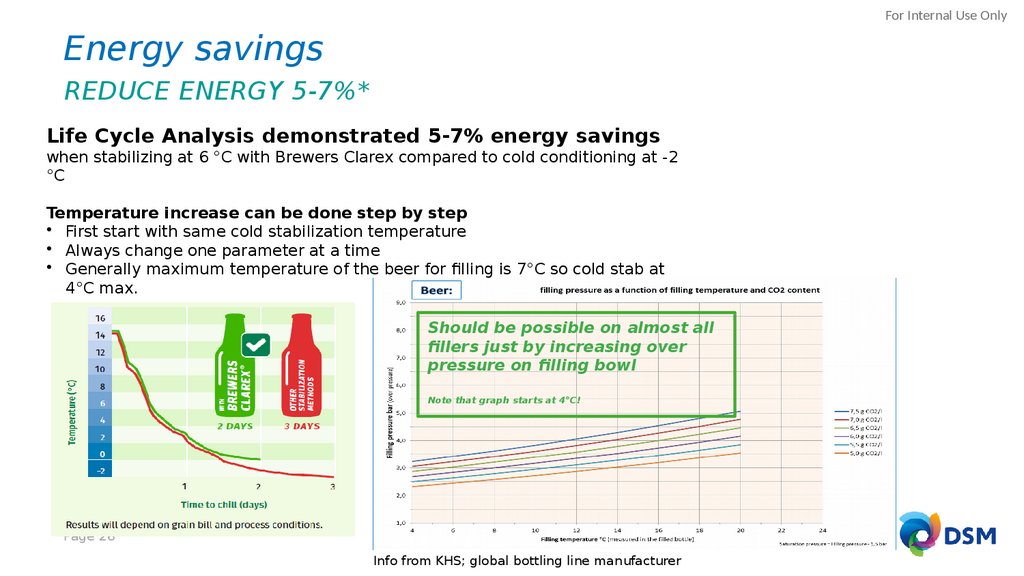

26. Energy savings

For Internal Use OnlyEnergy savings

REDUCE ENERGY 5-7%*

Life Cycle Analysis demonstrated 5-7% energy savings

when stabilizing at 6 °C with Brewers Clarex compared to cold conditioning at -2

°C

Temperature increase can be done step by step

• First start with same cold stabilization temperature

• Always change one parameter at a time

• Generally maximum temperature of the beer for flling is 7°C so cold stab at

4°C max.

Should be possible on almost all

fllers just by increasing over

pressure on flling bowl

Note that graph starts at 4°C!

Page 26

Info from KHS; global bottling line manufacturer

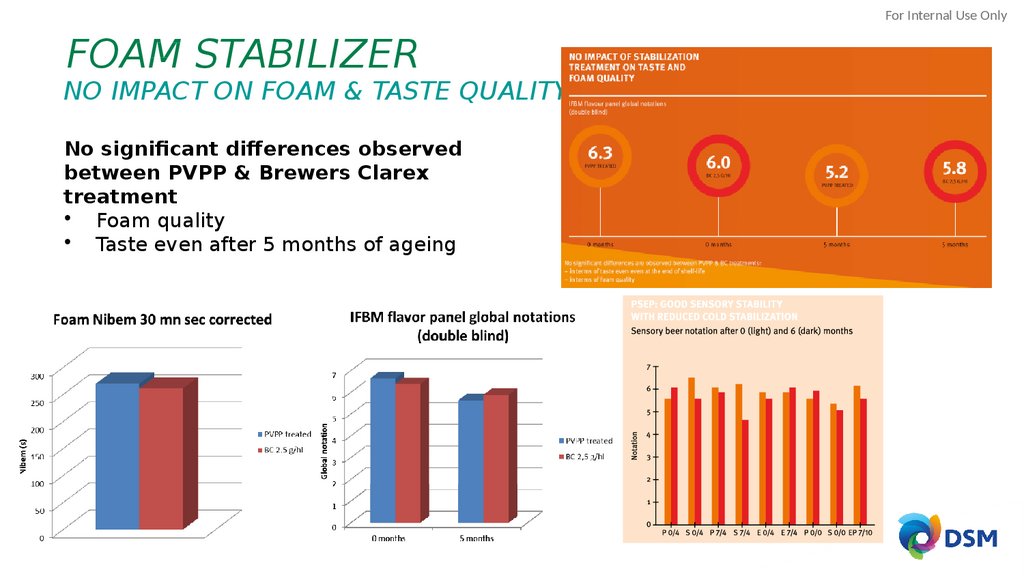

27. foam stabilizer

For Internal Use OnlyFOAM STABILIZER

NO IMPACT ON FOAM & TASTE QUALITY

No signifcant diferences observed

between PVPP & Brewers Clarex

treatment

• Foam quality

• Taste even after 5 months of ageing

Page 27

28.

For Internal Use OnlyBEER APPLICATION LAB, DELFT (NL) AND

TECHNICAL

CUSTOMER SERVICE

SHANGHAI

Focus on Mashing &

Filtration, Stabilization,

Microscopy,

Gluten and beer haze

analysis

28

29. Reduce transportation costs

For Internal Use OnlyReduce transportation costs

EXAMPLE 3 MLN HL BREWERY

Silica dosage 50 g/hL

= 150 t silicagel per year

Shipping costs 0.5 eur/kg

= 75000 eur / year ssipping costs silicagel

Clarex dosage 1.5 g/hL

Silica hydro gel contains ~65% water

= 97t water / year

= 48 500 eur / year shipping costs spend

on water shipment can be avoided

Silica xero gel contains ~10% water

=15t water / year

=7500 eur /year shipping costs spend on

water shipment can be avoided

= 4.5t Clarex / year

Shipping costs 0.5 eur/kg

=2500 eur / year ssipping costs Clarex

Shipping costs 0.5 eur/kg (Africa estimation)

Depending on distance shipped

Page 29

Waste treatment

50 eur / ton waste stream management

= 7500 eur / year waste stream

management can be saved

30. sustainable stabilization

For Internal Use Onlysustainable stabilization

STABILIZATION TECHNOLOGY OF THE FUTURE

Current users of Brewers Clarex name it ‘the stabilizaton tech of the future’

Natural soluton

Save energy

Reduce waste

No use of chemicals

Reduce carbon footprint

Page 30

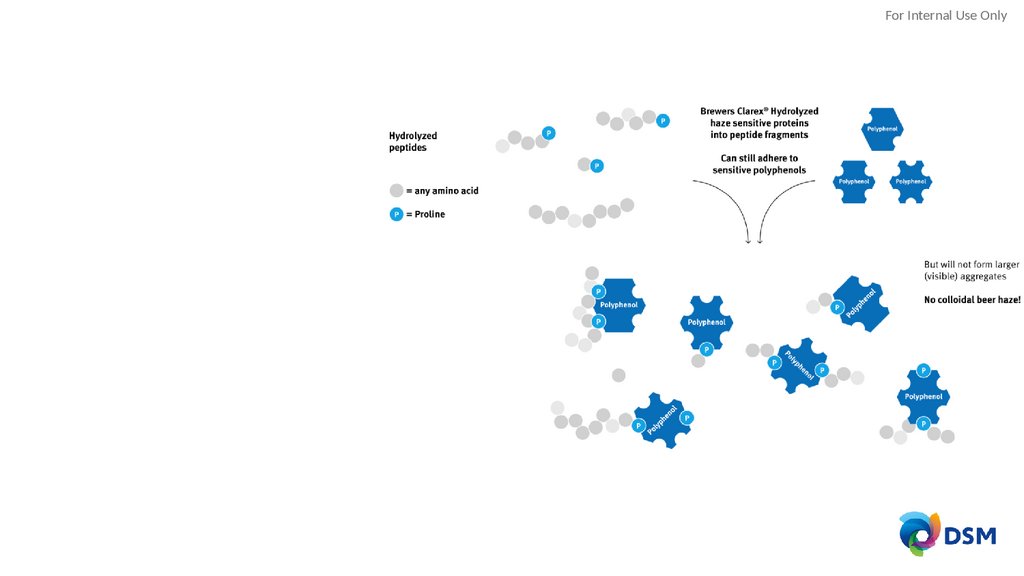

31. The principle

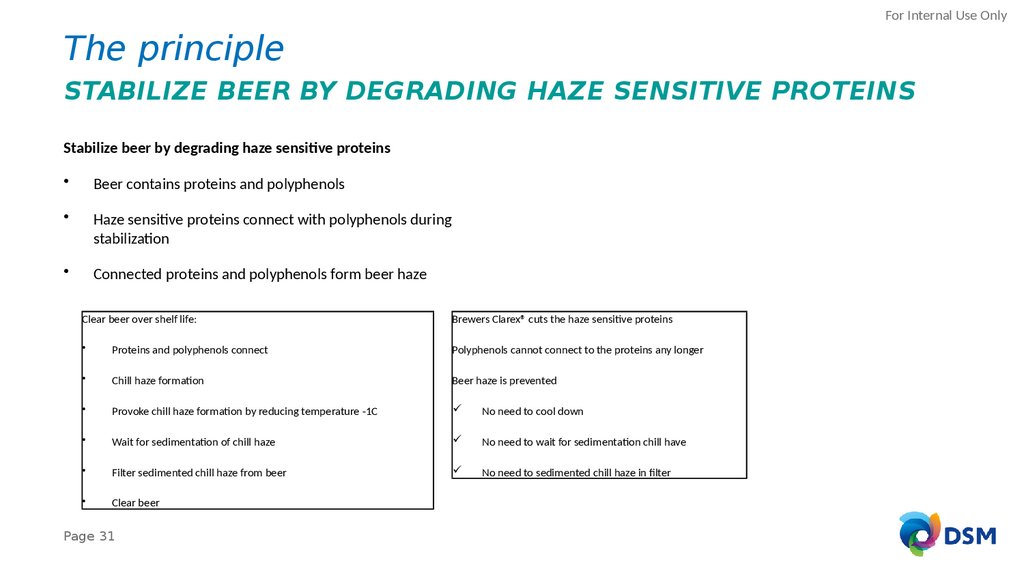

For Internal Use OnlyThe principle

STABILIZE BEER BY DEGRADING HAZE SENSITIVE PROTEINS

Stabilize beer by degrading saze sensitve proteins

Beer contains proteins and polyphenols

Haze sensitve proteins connect with polyphenols during

stabilizaton

Connected proteins and polyphenols form beer haze

Clear beer over shelf life:

Brewers Clarex® cuts the haze sensitve proteins

Proteins and polyphenols connect

Polyphenols cannot connect to the proteins any longer

Chill haze formaton

Beer haze is prevented

Provoke chill haze formaton by reducing temperature -1C

No need to cool down

Wait for sedimentaton of chill haze

No need to wait for sedimentaton chill have

Filter sedimented chill haze from beer

No need to sedimented chill haze in flter

Clear beer

Page 31

industry

industry