Similar presentations:

Medical coverage for closing wounds of various etiologies “OTRAN”

1. Medical coverage for closing wounds of various etiologies “OTRAN”

12. Текущее состояние

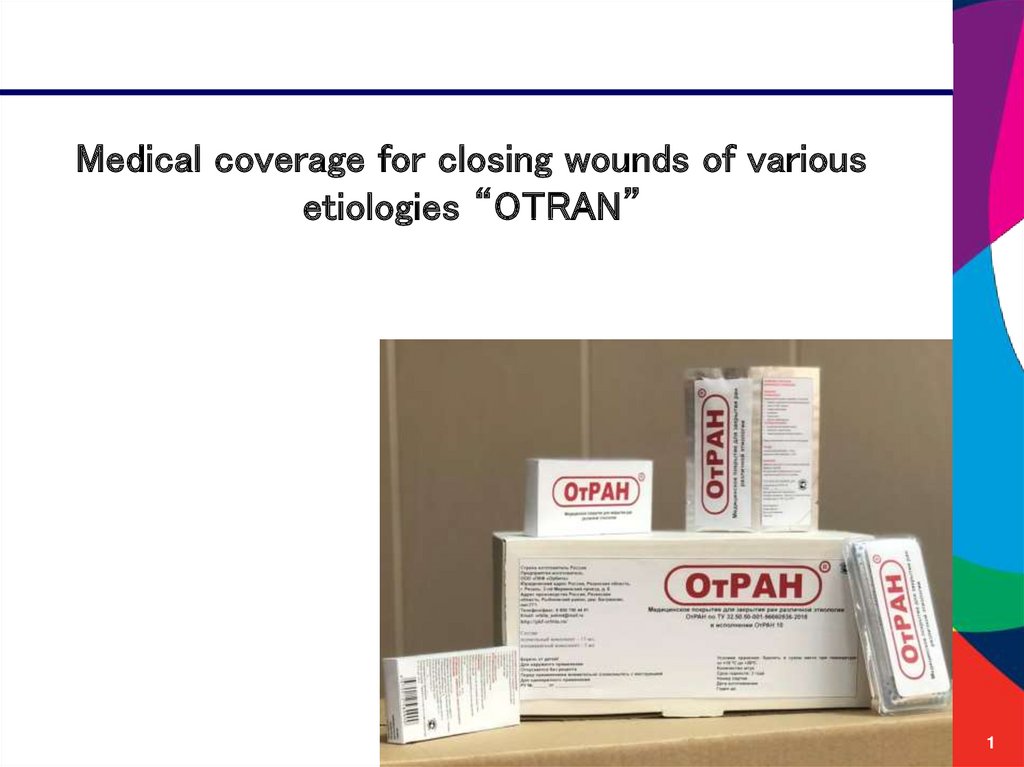

2) PatentsPatents were obtained for polyurethane

compositions for coating OTRAN, for the

1) Application

production technology of a number of

nanoparticles used for the Project’s

products.

The methodology of application has been

fully developed. Methodological

recommendations on application for medical

institutions and educational films have been

prepared.

At the moment, Medical coverage for the

closure of wounds of various etiologies.

OTRAN is at the stage of registration in the

Russian Federation.

4) Sales

The products have been

successfully tested in

medical institutions.

Идут переговоры с гос.

структурами РЖД, МЧС, ВС России и

другими ведомствами о закупках

«ОтРАН».

PKF ORBIT LLC

(Ryazan)

Contracts with 2

distributors of medical

products.

3) Production

Small-scale production was set up in the

amount of up to 50 thousand pieces. per month.

Worked out a plan to build mass production.

Selected technological equipment.

5) Development

Work is underway to further improve the coating and

packaging "OTRAN".

2

3. Продукция

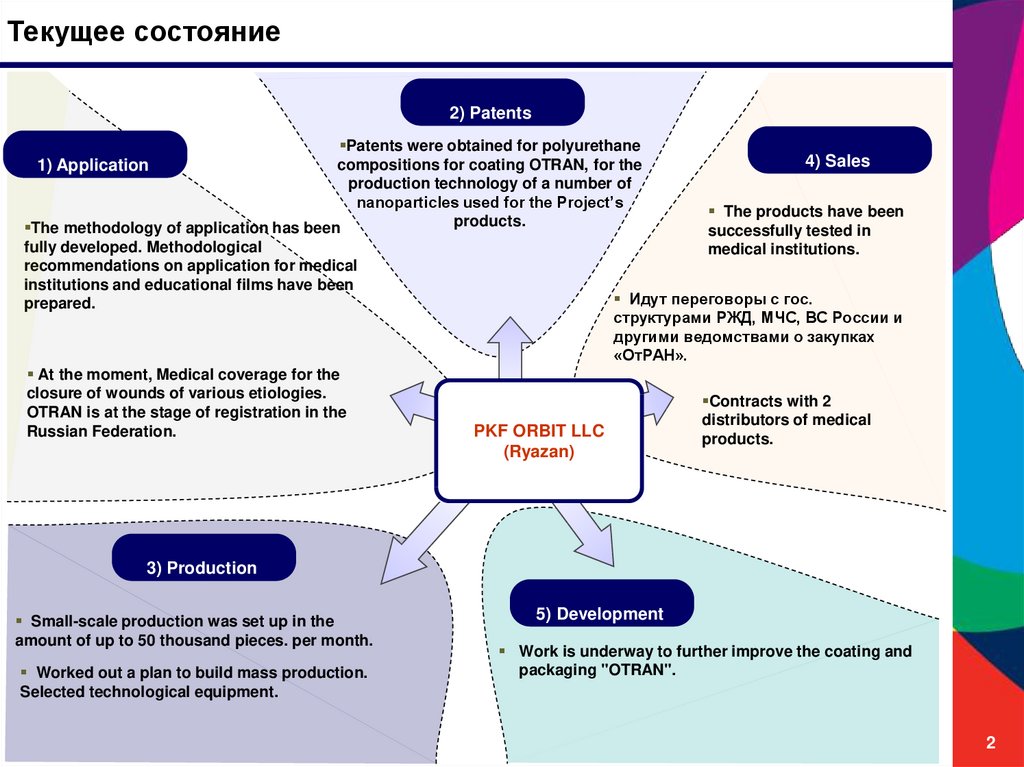

descriptionMedical coverage for closing wounds of various etiologies

intelligence

The coverage of “OTRAN” is currently at the registration stage.

base

composition

The coating is a two-component polyurethane foam composition in packaging of

aluminized polyethylene.

The coating is obtained by mixing two components:

• polyol (with the addition of nanocrystalline boehmite);

• isocyanate,

The foam mass, when applied to the wound, forms a fine-porous elastic coating

with a thickness of 0.8-1 cm. The coverage area depends on the volume of the

mixed components.

OTRAN 5 – 50 см2

OTRAN 10 – 100 см2

OTRAN 20 – 200 см2

Special:

application

hospitals;

Army, Ministry of Emergency

Situations, spec. services;

fleet;

fire services;

sports organizations;

traumatic production.

Veterinary, breeding farms and

livestock breeding.

Household:

for the treatment of any domestic

injuries and burns;

self-treatment of wounds;

fishing;

tourism;

home and car first aid kit;

sport, active rest;

Pets.

3

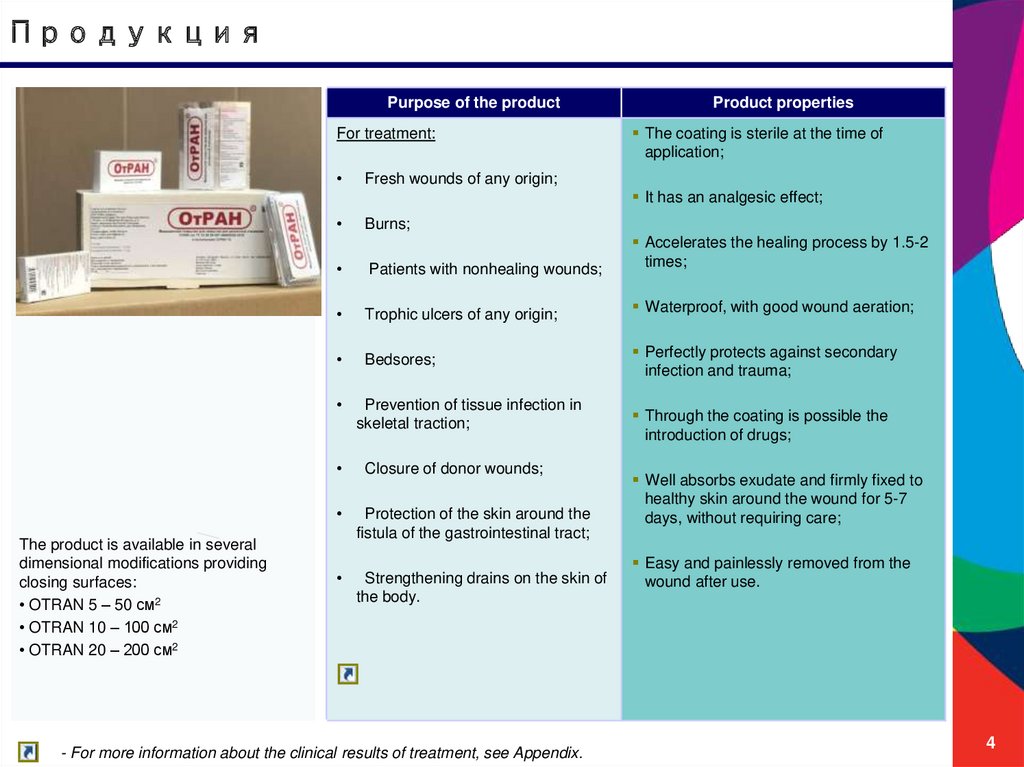

4. Продукция

Purpose of the productFor treatment:

10 см

Product properties

The coating is sterile at the time of

application;

Fresh wounds of any origin;

It has an analgesic effect;

15 см

Patients with nonhealing wounds;

Accelerates the healing process by 1.5-2

times;

Trophic ulcers of any origin;

Waterproof, with good wound aeration;

Bedsores;

The product is available in several

dimensional modifications providing

closing surfaces:

• OTRAN 5 – 50 см2

• OTRAN 10 – 100 см2

• OTRAN 20 – 200 см2

Burns;

Prevention of tissue infection in

skeletal traction;

Closure of donor wounds;

Protection of the skin around the

fistula of the gastrointestinal tract;

Strengthening drains on the skin of

the body.

- For more information about the clinical results of treatment, see Appendix.

Perfectly protects against secondary

infection and trauma;

Through the coating is possible the

introduction of drugs;

Well absorbs exudate and firmly fixed to

healthy skin around the wound for 5-7

days, without requiring care;

Easy and painlessly removed from the

wound after use.

4

5.

Photos of applicationHeel sore closure

Hip sore closure

Closing a donor wound

Heel wound closure

Closure of the sacrum sore

Abdominal wall burn closure

The photos were taken in the resuscitation department of the Research Institute of Emergency Care. N.V. Sklifosofskogo

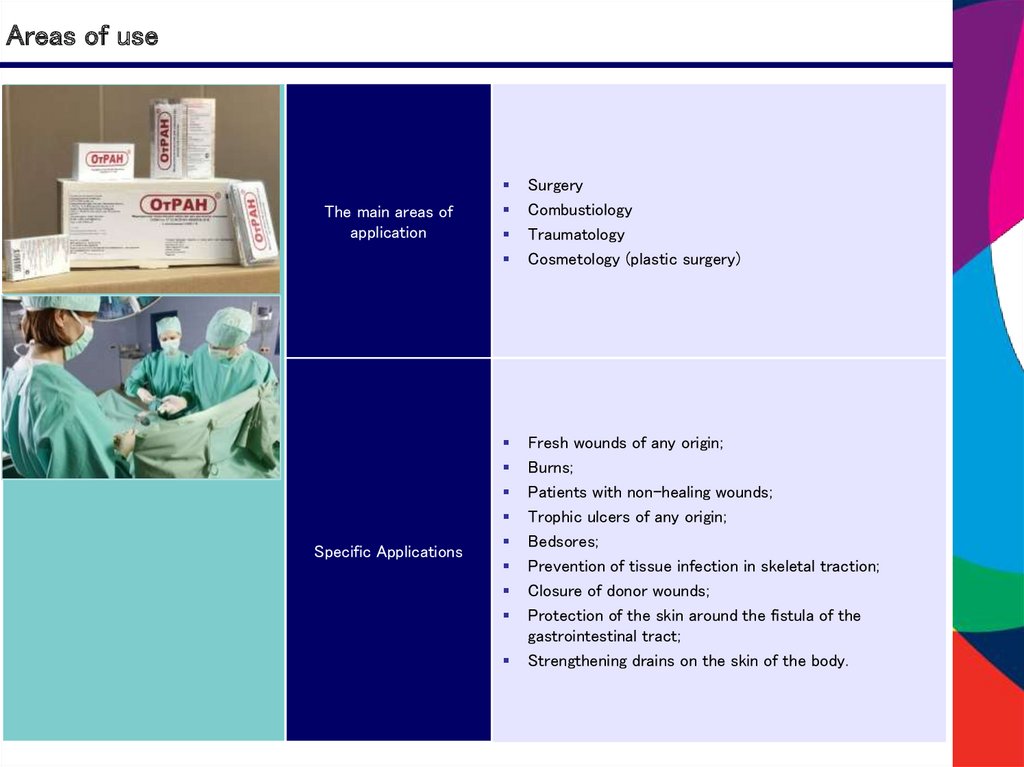

6.

Areas of useThe main areas of

application

Specific Applications

Surgery

Combustiology

Traumatology

Cosmetology (plastic surgery)

Fresh wounds of any origin;

Burns;

Patients with non-healing wounds;

Trophic ulcers of any origin;

Bedsores;

Prevention of tissue infection in skeletal traction;

Closure of donor wounds;

Protection of the skin around the fistula of the

gastrointestinal tract;

Strengthening drains on the skin of the body.

стр. 6

7.

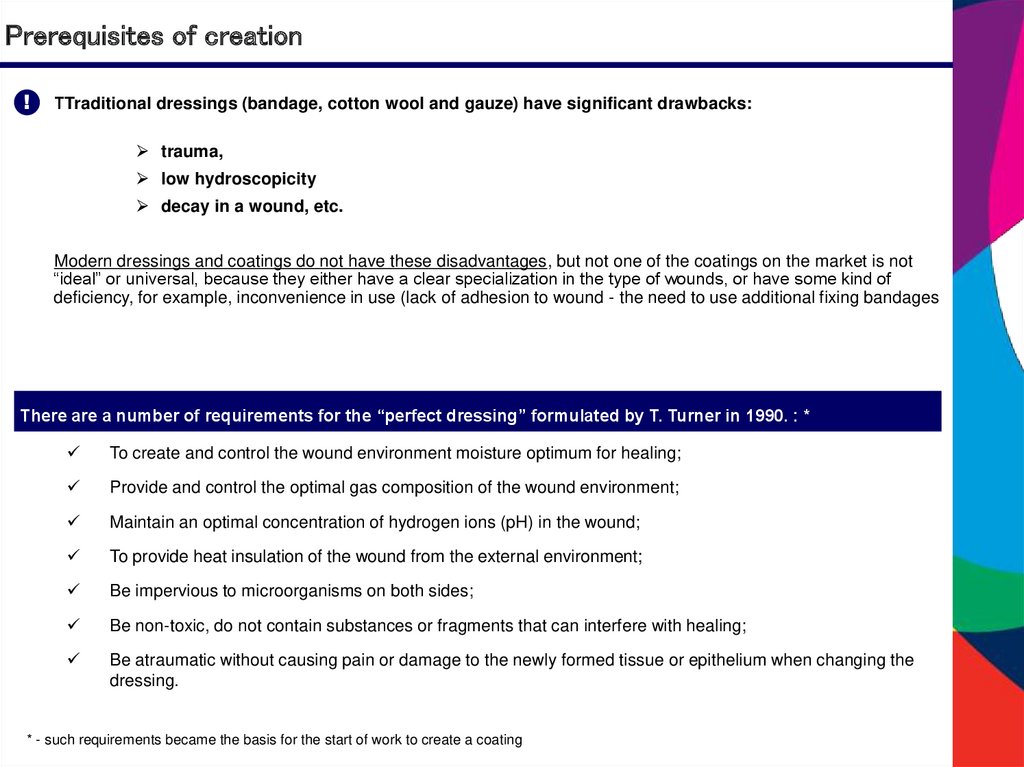

Prerequisites of creationТTraditional dressings (bandage, cotton wool and gauze) have significant drawbacks:

¡¡

trauma,

low hydroscopicity

decay in a wound, etc.

Modern dressings and coatings do not have these disadvantages, but not one of the coatings on the market is not

“ideal” or universal, because they either have a clear specialization in the type of wounds, or have some kind of

deficiency, for example, inconvenience in use (lack of adhesion to wound - the need to use additional fixing bandages

There are a number of requirements for the “perfect dressing” formulated by T. Turner in 1990. : *

To create and control the wound environment moisture optimum for healing;

Provide and control the optimal gas composition of the wound environment;

Maintain an optimal concentration of hydrogen ions (pH) in the wound;

To provide heat insulation of the wound from the external environment;

Be impervious to microorganisms on both sides;

Be non-toxic, do not contain substances or fragments that can interfere with healing;

Be atraumatic without causing pain or damage to the newly formed tissue or epithelium when changing the

dressing.

* - such requirements became the basis for the start of work to create a coating

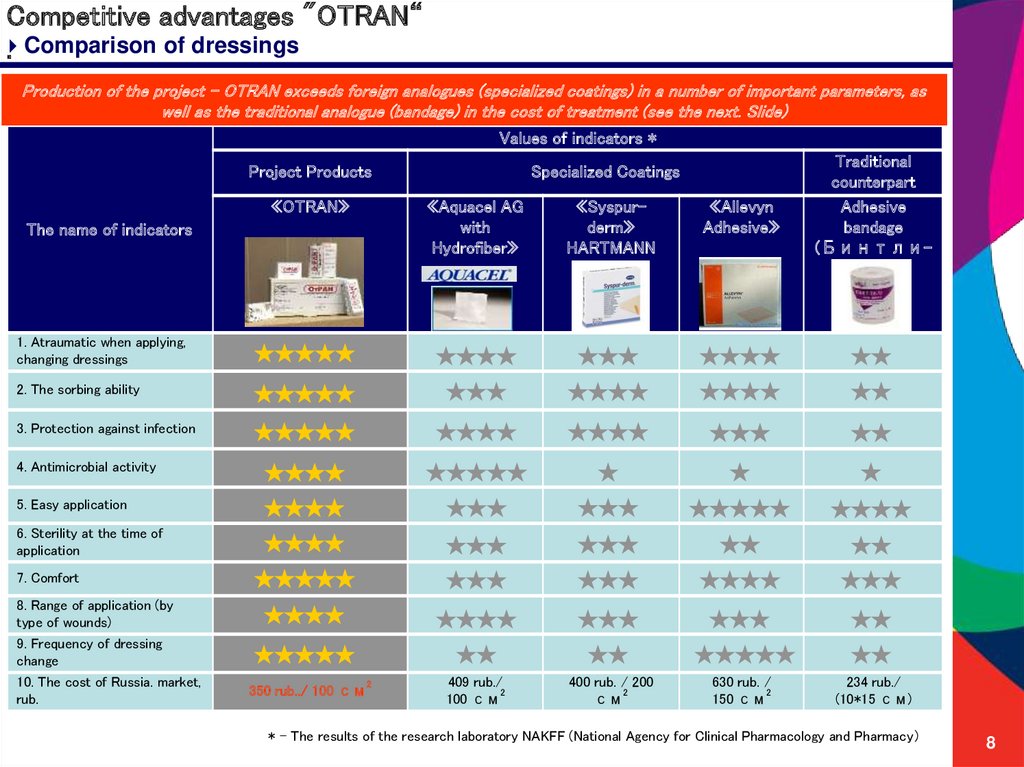

8. Competitive advantages "OTRAN“ .

Competitive advantages "OTRAN“Comparison

of dressings

.

Production of the project - OTRAN exceeds foreign analogues (specialized coatings) in a number of important parameters, as

well as the traditional analogue (bandage) in the cost of treatment (see the next. Slide)

Values of indicators *

«Aquacel AG

with

Hydrofiber»

«Syspurderm»

HARTMANN

«Allevyn

Adhesive»

Traditional

counterpart

Adhesive

bandage

(БинтлиМ)

409 rub./

2

100 см

400 rub. / 200

2

см

630 rub. /

2

150 см

234 rub./

(10*15 см)

Project Products

«OTRAN»

The name of indicators

Specialized Coatings

1. Atraumatic when applying,

changing dressings

2. The sorbing ability

3. Protection against infection

4. Antimicrobial activity

5. Easy application

6. Sterility at the time of

application

7. Comfort

8. Range of application (by

type of wounds)

9. Frequency of dressing

change

10. The cost of Russia. market,

rub.

350 rub../ 100 см

2

* - The results of the research laboratory NAKFF (National Agency for Clinical Pharmacology and Pharmacy)

8

9. Competitive advantages

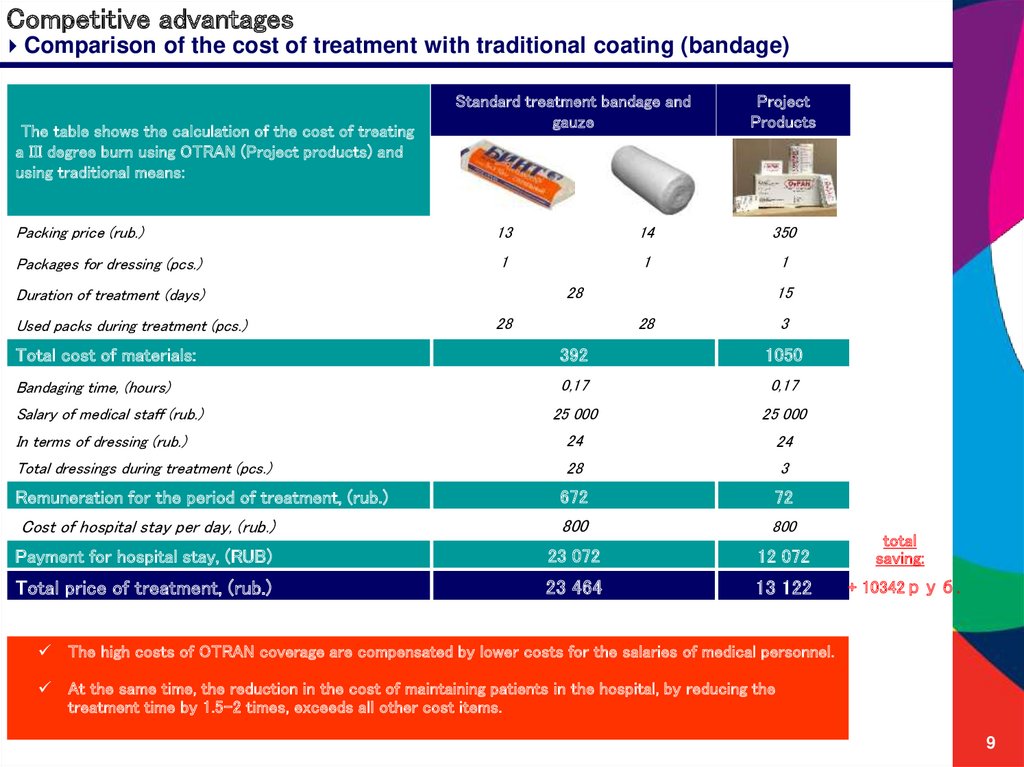

Comparison of the cost of treatment with traditional coating (bandage)The table shows the calculation of the cost of treating

a III degree burn using OTRAN (Project products) and

using traditional means:

Standard treatment bandage and

gauze

Project

Products

Packing price (rub.)

13

14

350

Packages for dressing (pcs.)

1

1

1

28

Duration of treatment (days)

Used packs during treatment (pcs.)

28

15

28

3

Total cost of materials:

392

1050

Bandaging time, (hours)

0,17

0,17

25 000

25 000

In terms of dressing (rub.)

24

24

Total dressings during treatment (pcs.)

28

3

Remuneration for the period of treatment, (rub.)

672

72

Cost of hospital stay per day, (rub.)

800

800

Payment for hospital stay, (RUB)

23 072

12 072

total

saving:

Total price of treatment, (rub.)

23 464

13 122

+ 10342руб.

Salary of medical staff (rub.)

The high costs of OTRAN coverage are compensated by lower costs for the salaries of medical personnel.

At the same time, the reduction in the cost of maintaining patients in the hospital, by reducing the

treatment time by 1.5–2 times, exceeds all other cost items.

9

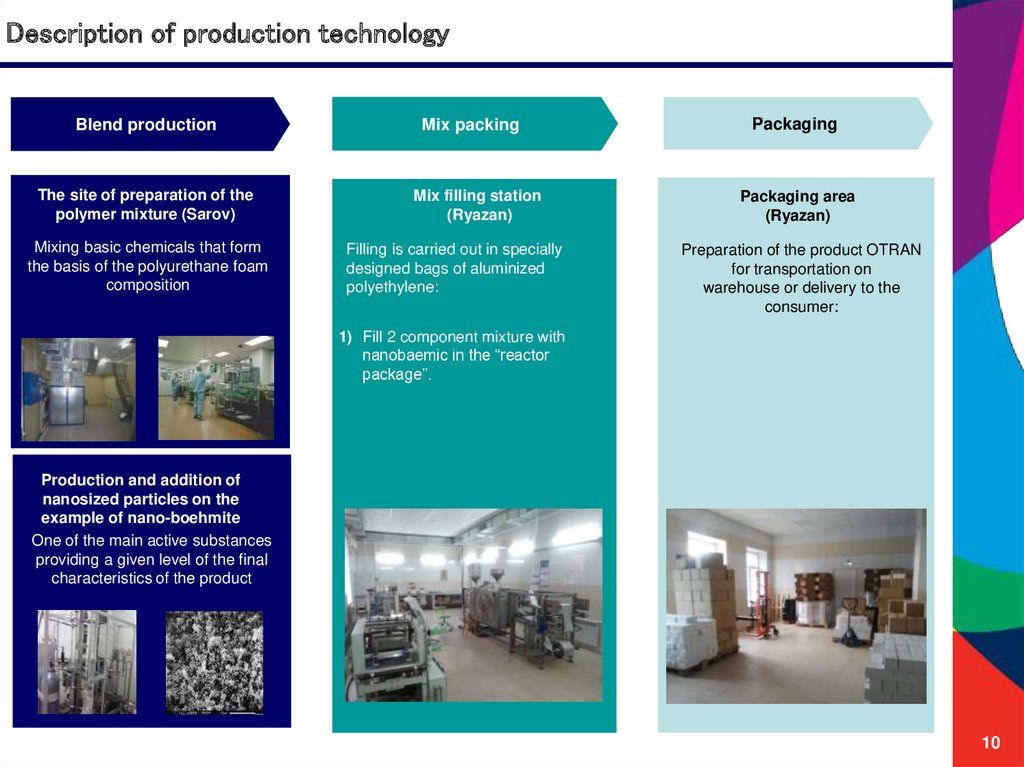

10. Description of production technology

Blend productionThe site of preparation of the

polymer mixture (Sarov)

Mixing basic chemicals that form

the basis of the polyurethane foam

composition

Mix packing

Mix filling station

(Ryazan)

Filling is carried out in specially

designed bags of aluminized

polyethylene:

Packaging

Packaging area

(Ryazan)

Preparation of the product OTRAN

for transportation on

warehouse or delivery to the

consumer:

1) Fill 2 component mixture with

nanobaemic in the “reactor

package”.

Production and addition of

nanosized particles on the

example of nano-boehmite

One of the main active substances

providing a given level of the final

characteristics of the product

10

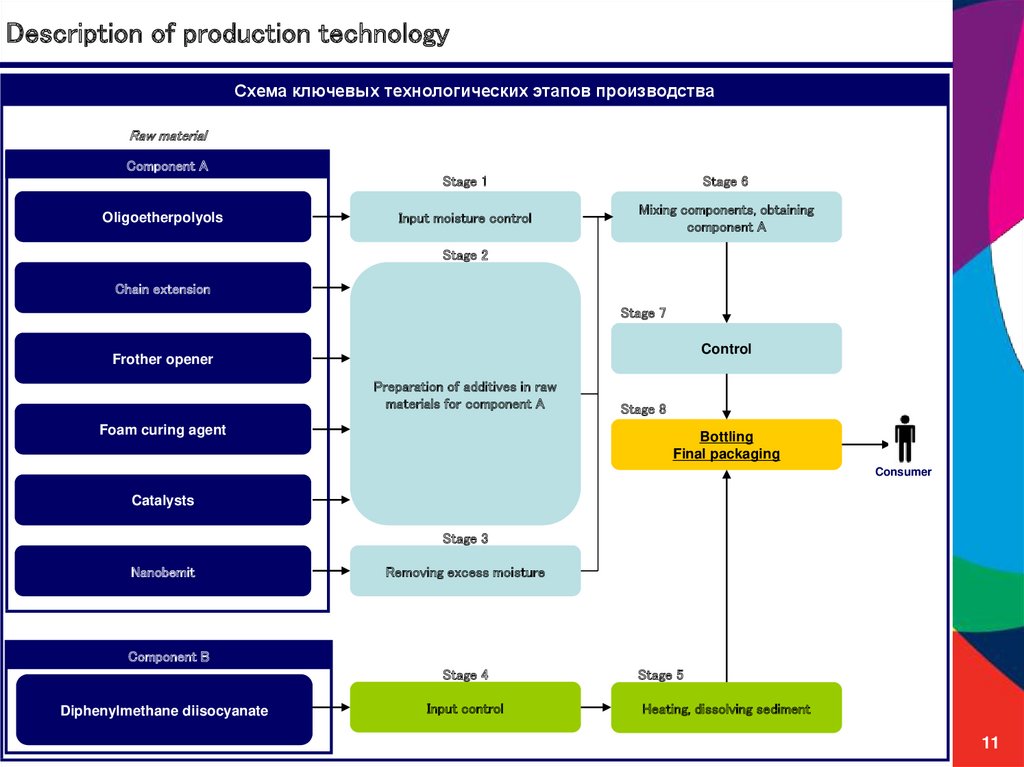

11. Description of production technology

Схема ключевых технологических этапов производстваRaw material

Component A

Oligoetherpolyols

Stage 1

Stage 6

Input moisture control

Mixing components, obtaining

component A

Stage 2

Chain extension

Stage 7

Control

Frother opener

Preparation of additives in raw

materials for component A

Foam curing agent

Stage 8

Bottling

Final packaging

Consumer

Catalysts

Stage 3

Nanobemit

Removing excess moisture

Component B

Stage 4

Diphenylmethane diisocyanate

Input control

Stage 5

Heating, dissolving sediment

11

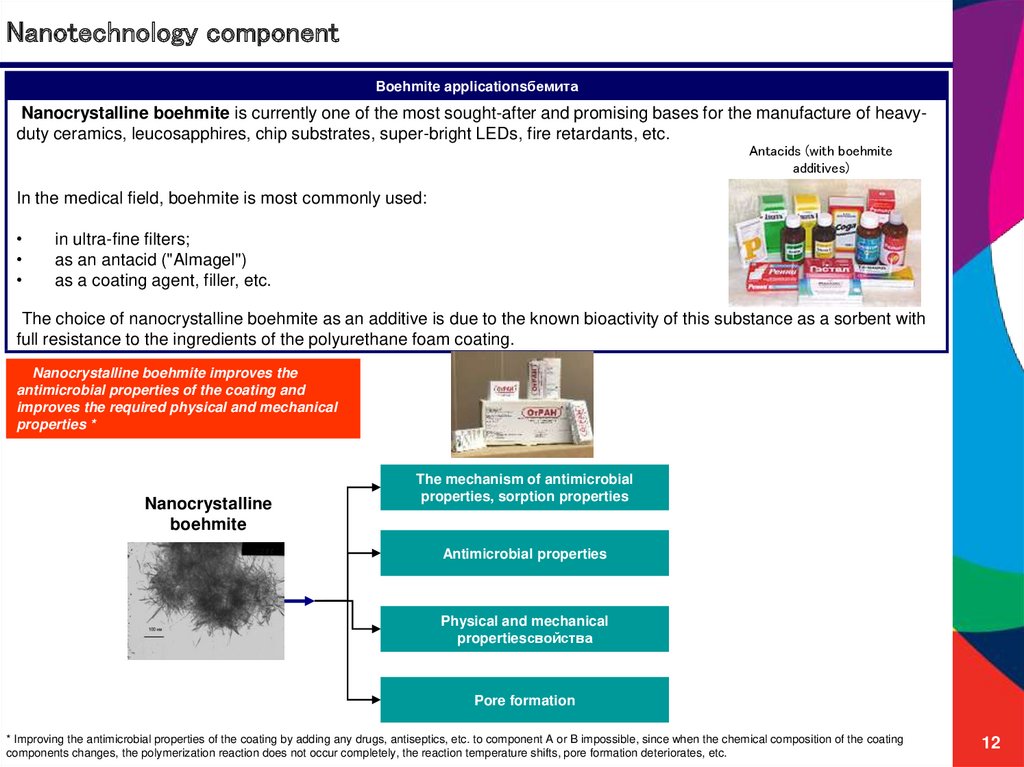

12. Nanotechnology component

Boehmite applicationsбемитаNanocrystalline boehmite is currently one of the most sought-after and promising bases for the manufacture of heavyduty ceramics, leucosapphires, chip substrates, super-bright LEDs, fire retardants, etc.

Antacids (with boehmite

additives)

In the medical field, boehmite is most commonly used:

in ultra-fine filters;

as an antacid ("Almagel")

as a coating agent, filler, etc.

The choice of nanocrystalline boehmite as an additive is due to the known bioactivity of this substance as a sorbent with

full resistance to the ingredients of the polyurethane foam coating.

Nanocrystalline boehmite improves the

antimicrobial properties of the coating and

improves the required physical and mechanical

properties *

Nanocrystalline

boehmite

The mechanism of antimicrobial

properties, sorption properties

Antimicrobial properties

Physical and mechanical

propertiesсвойства

Pore formation

* Improving the antimicrobial properties of the coating by adding any drugs, antiseptics, etc. to component A or B impossible, since when the chemical composition of the coating

components changes, the polymerization reaction does not occur completely, the reaction temperature shifts, pore formation deteriorates, etc.

12

13. Nanotechnology component

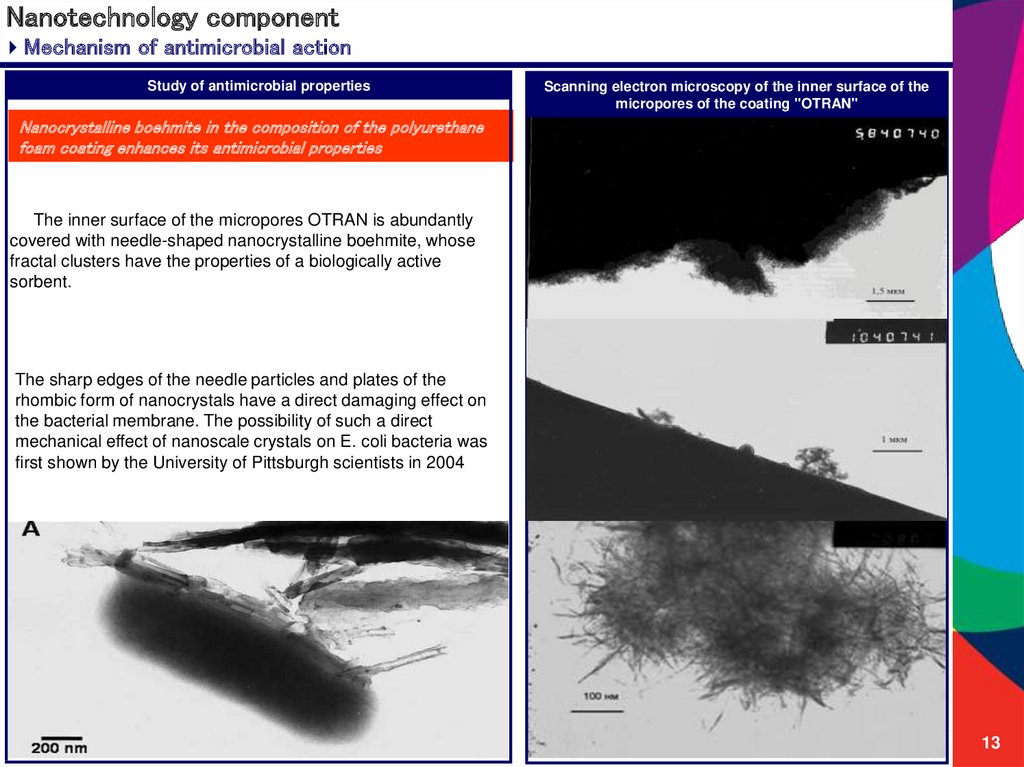

Mechanism of antimicrobial actionStudy of antimicrobial properties

Scanning electron microscopy of the inner surface of the

micropores of the coating "OTRAN"

Nanocrystalline boehmite in the composition of the polyurethane

foam coating enhances its antimicrobial properties

The inner surface of the micropores OTRAN is abundantly

covered with needle-shaped nanocrystalline boehmite, whose

fractal clusters have the properties of a biologically active

sorbent.

The sharp edges of the needle particles and plates of the

rhombic form of nanocrystals have a direct damaging effect on

the bacterial membrane. The possibility of such a direct

mechanical effect of nanoscale crystals on E. coli bacteria was

first shown by the University of Pittsburgh scientists in 2004

13

14. Nanotechnology component

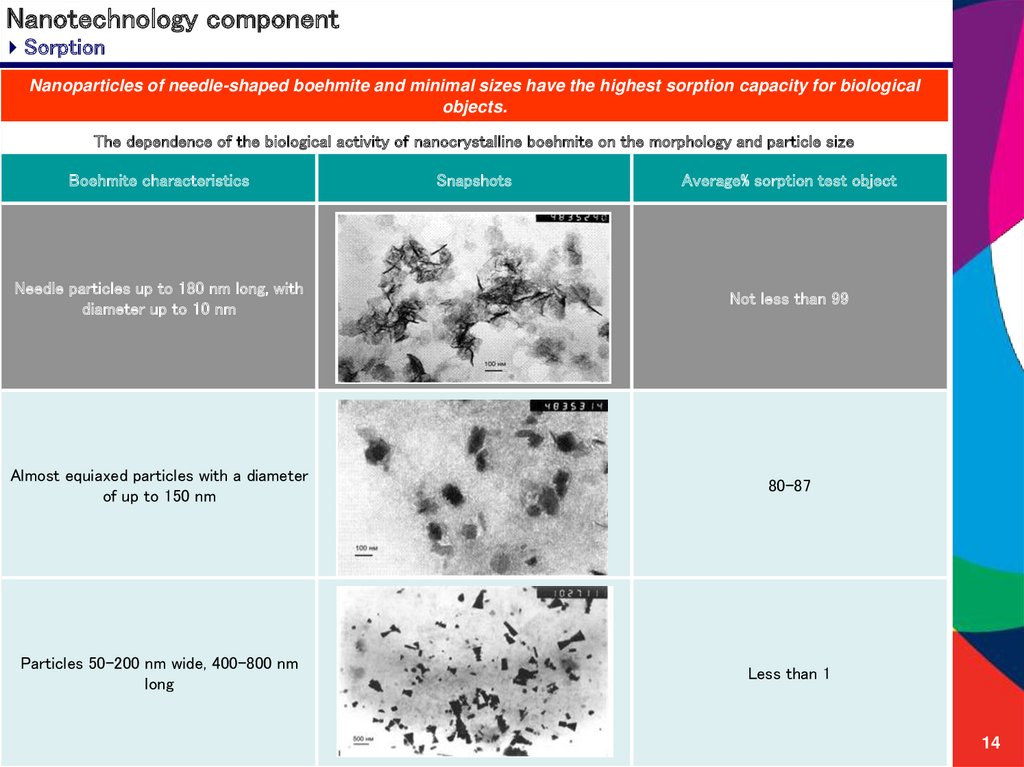

SorptionNanoparticles of needle-shaped boehmite and minimal sizes have the highest sorption capacity for biological

objects.

The dependence of the biological activity of nanocrystalline boehmite on the morphology and particle size

Boehmite characteristics

Snapshots

Average% sorption test object

Needle particles up to 180 nm long, with

diameter up to 10 nm

Not less than 99

Almost equiaxed particles with a diameter

of up to 150 nm

80-87

Particles 50-200 nm wide, 400-800 nm

long

Less than 1

14

15. Nanotechnology component

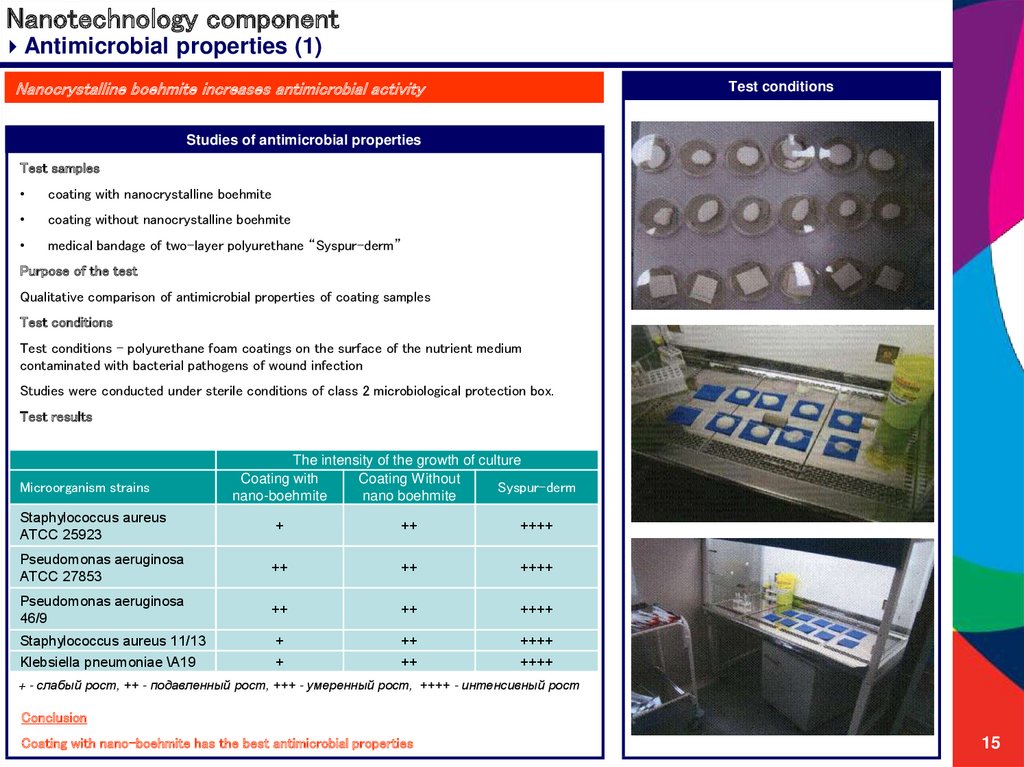

Antimicrobial properties (1)Nanocrystalline boehmite increases antimicrobial activity

Test conditions

Studies of antimicrobial properties

Test samples

coating with nanocrystalline boehmite

coating without nanocrystalline boehmite

medical bandage of two-layer polyurethane “Syspur-derm”

Purpose of the test

Qualitative comparison of antimicrobial properties of coating samples

Test conditions

Test conditions - polyurethane foam coatings on the surface of the nutrient medium

contaminated with bacterial pathogens of wound infection

Studies were conducted under sterile conditions of class 2 microbiological protection box.

Test results

Microorganism strains

The intensity of the growth of culture

Coating with

Coating Without

Syspur-derm

nano-boehmite

nano boehmite

Staphylococcus aureus

ATCC 25923

+

++

++++

Pseudomonas aeruginosa

ATCC 27853

++

++

++++

Pseudomonas aeruginosa

46/9

++

++

++++

Staphylococcus aureus 11/13

Klebsiella pneumoniae \A19

+

+

++

++

++++

++++

+ - слабый рост, ++ - подавленный рост, +++ - умеренный рост, ++++ - интенсивный рост

Conclusion

Coating with nano-boehmite has the best antimicrobial properties

15

16. Nanotechnology component

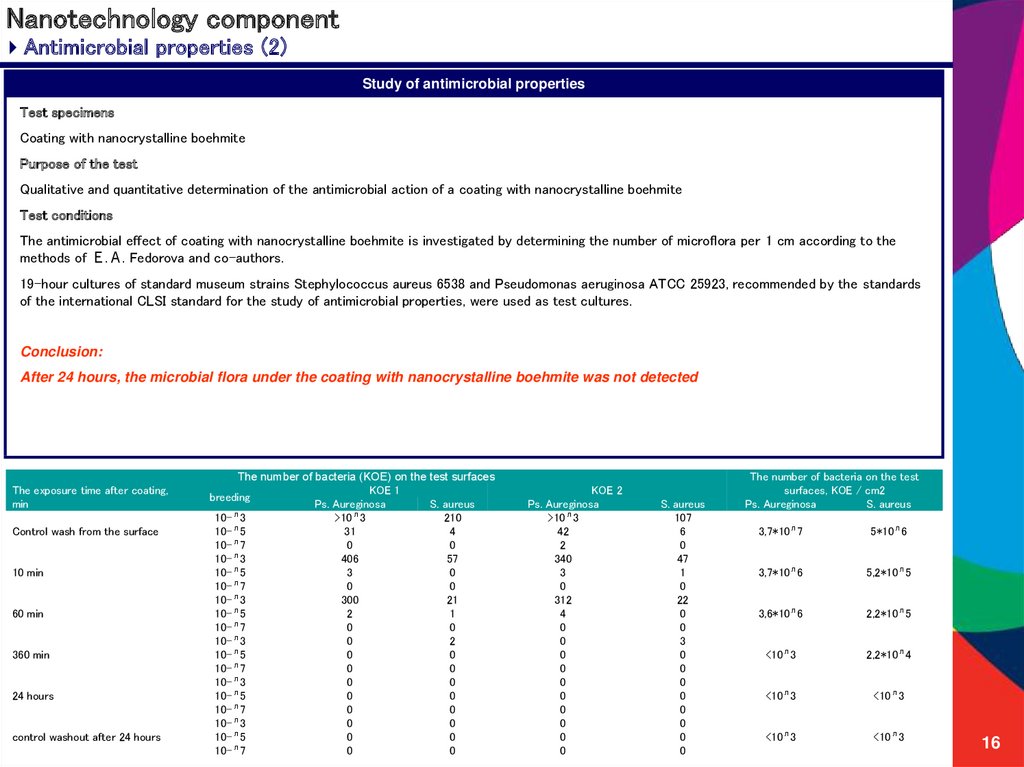

Antimicrobial properties (2)Study of antimicrobial properties

Test specimens

Coating with nanocrystalline boehmite

Purpose of the test

Qualitative and quantitative determination of the antimicrobial action of a coating with nanocrystalline boehmite

Test conditions

The antimicrobial effect of coating with nanocrystalline boehmite is investigated by determining the number of microflora per 1 cm according to the

methods of Е.А. Fedorova and co-authors.

19-hour cultures of standard museum strains Stephylococcus aureus 6538 and Pseudomonas aeruginosa ATCC 25923, recommended by the standards

of the international CLSI standard for the study of antimicrobial properties, were used as test cultures.

Conclusion:

After 24 hours, the microbial flora under the coating with nanocrystalline boehmite was not detected

The exposure time after coating,

min

Control wash from the surface

10 min

60 min

360 min

24 hours

control washout after 24 hours

The number of bacteria (KOE) on the test surfaces

KOE 1

breeding

Ps. Aureginosa

S. aureus

10-л3

>10л3

210

10-л5

31

4

10-л7

0

0

10-л3

406

57

10-л5

3

0

10-л7

0

0

10-л3

300

21

10-л5

2

1

10-л7

0

0

10-л3

0

2

10-л5

0

0

10-л7

0

0

10-л3

0

0

10-л5

0

0

10-л7

0

0

10-л3

0

0

10-л5

0

0

10-л7

0

0

KOE 2

Ps. Aureginosa

>10л3

42

2

340

3

0

312

4

0

0

0

0

0

0

0

0

0

0

S. aureus

107

6

0

47

1

0

22

0

0

3

0

0

0

0

0

0

0

0

The number of bacteria on the test

surfaces, KOE / cm2

Ps. Aureginosa

S. aureus

3,7*10л7

5*10л6

3,7*10л6

5,2*10л5

3,6*10л6

2,2*10л5

<10л3

2,2*10л4

<10л3

<10л3

<10л3

<10л3

16

17. Nanotechnology component

Physical and mechanical propertiesFrom the conducted research it follows that

nanocrystalline boehmite improves the demanded

physical and mechanical properties.

The study of physical and mechanical properties

Purpose: conducting physical and mechanical testing of

coatings with nanocrystalline boehmite

Samples: 5 samples of coating, approximately 250 * 250 * 60

mm in size (three coatings without boehmite and two coatings

with boehmite)

Test methods: work was carried out to determine the following

physicomechanical indicators — compressive stress at 40%

strain, relative elongation and breaking stress under tension,

tear strength, apparent density, relative residual strain.

Used equipment: machine for compressing and stretching

materials, die-cutting press, cutting machine / band saw, scales

(0.001 and 0.0001), caliper, micrometer, thickness gauge.

Sample to determine the strength of tear

Name of the indicator

tensile strength

tensile stress

Dimension

N/m

Sample coverage

No boehmite

Boehmite

98 (50 mm / min)

102 (50 mm / min)

133 (500 mm / min)

186 (500 mm / min)

kPa

64

63

elongation at break

%

115

88

compression stress

kPa

3,1

4,7

%

1,9

2,8

kg / m3

59,5

65,5

relative residual strain in compression

apparent density

17

18. Nanotechnology component

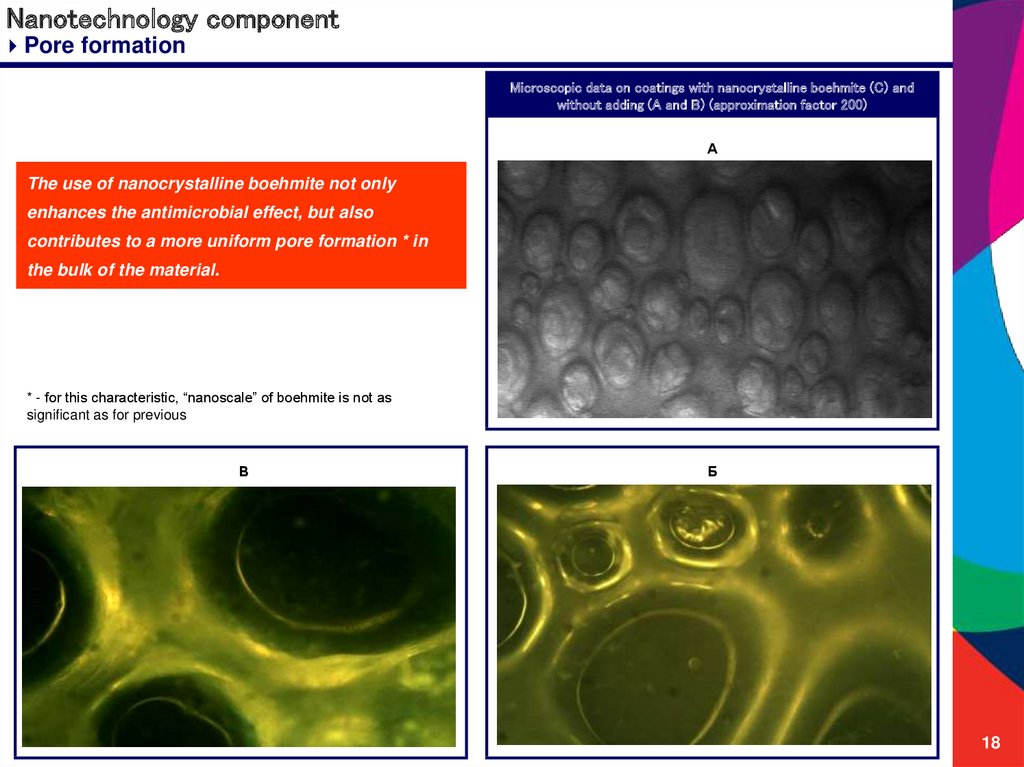

Pore formationMicroscopic data on coatings with nanocrystalline boehmite (C) and

without adding (A and B) (approximation factor 200)

А

The use of nanocrystalline boehmite not only

enhances the antimicrobial effect, but also

contributes to a more uniform pore formation * in

the bulk of the material.

* - for this characteristic, “nanoscale” of boehmite is not as

significant as for previous

В

Б

18

19. Classification of dressings

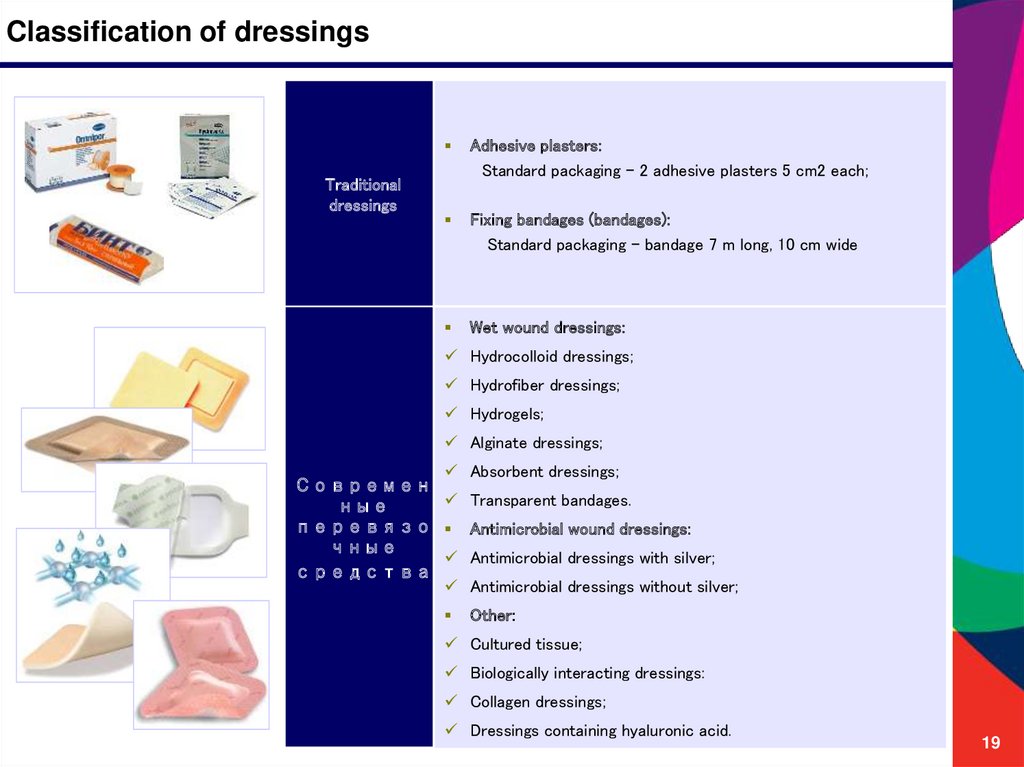

Traditionaldressings

Adhesive plasters:

Standard packaging - 2 adhesive plasters 5 cm2 each;

Fixing bandages (bandages):

Standard packaging - bandage 7 m long, 10 cm wide

Wet wound dressings:

Hydrocolloid dressings;

Hydrofiber dressings;

Hydrogels;

Alginate dressings;

Absorbent dressings;

Современ

Transparent bandages.

ные

перевязо Antimicrobial wound dressings:

чные

Antimicrobial dressings with silver;

средства

Antimicrobial dressings without silver;

Other:

Cultured tissue;

Biologically interacting dressings:

Collagen dressings;

Dressings containing hyaluronic acid.

19

20. Russian market *

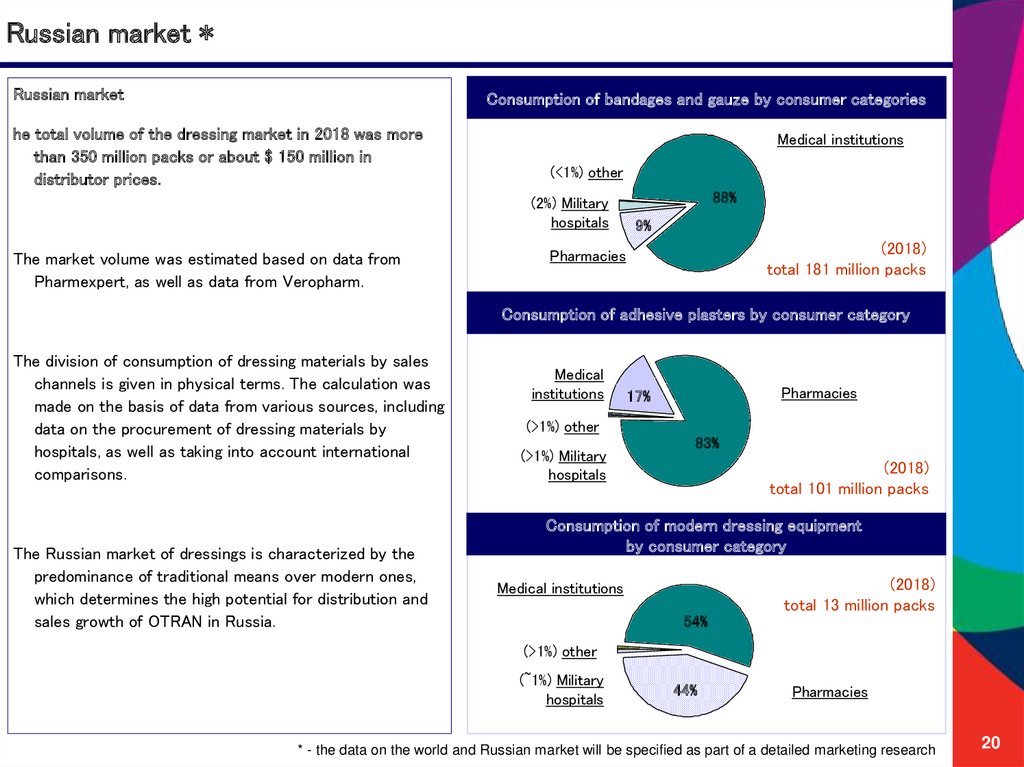

Russian marketConsumption of bandages and gauze by consumer categories

he total volume of the dressing market in 2018 was more

than 350 million packs or about $ 150 million in

distributor prices.

Medical institutions

(<1%) other

(2%) Military

hospitals

The market volume was estimated based on data from

Pharmexpert, as well as data from Veropharm.

88%

9%

(2018)

total 181 million packs

Pharmacies

Consumption of adhesive plasters by consumer category

The division of consumption of dressing materials by sales

channels is given in physical terms. The calculation was

made on the basis of data from various sources, including

data on the procurement of dressing materials by

hospitals, as well as taking into account international

comparisons.

The Russian market of dressings is characterized by the

predominance of traditional means over modern ones,

which determines the high potential for distribution and

sales growth of OTRAN in Russia.

Medical

institutions

Pharmacies

17%

(>1%) other

(>1%) Military

hospitals

83%

(2018)

total 101 million packs

Consumption of modern dressing equipment

by consumer category

(2018)

total 13 million packs

Medical institutions

54%

(>1%) other

(~1%) Military

hospitals

44%

Pharmacies

* - the data on the world and Russian market will be specified as part of a detailed marketing research

20

21. Certification

2122. Patents

2223.

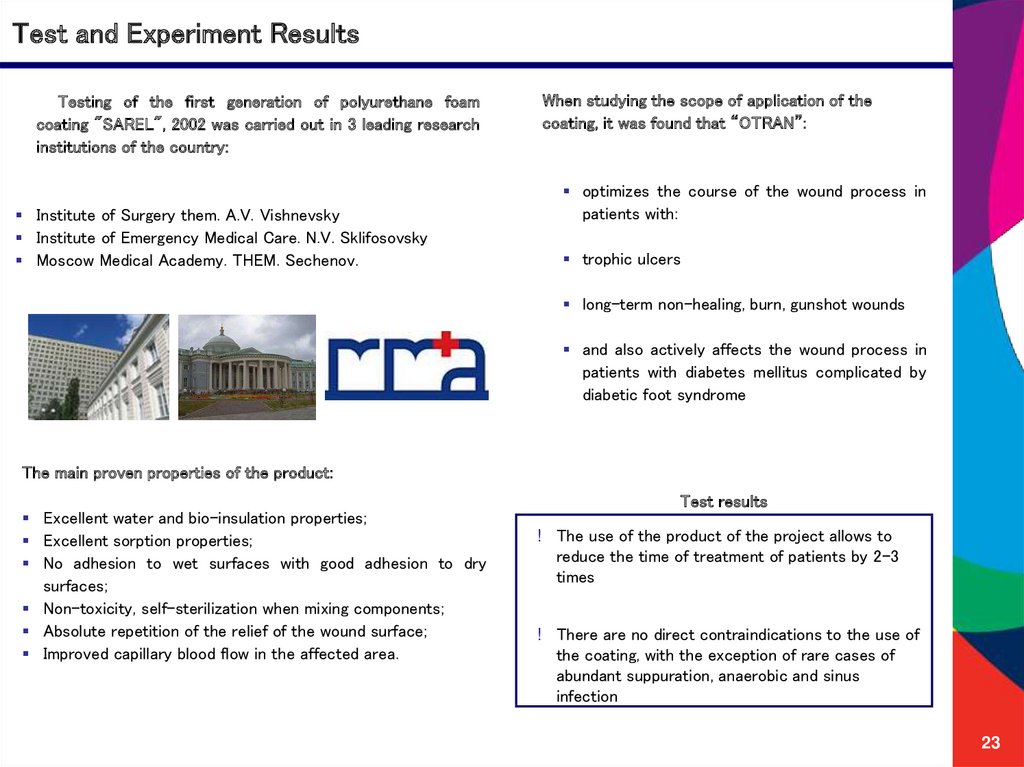

Test and Experiment ResultsTesting of the first generation of polyurethane foam

coating "SAREL", 2002 was carried out in 3 leading research

institutions of the country:

Institute of Surgery them. A.V. Vishnevsky

Institute of Emergency Medical Care. N.V. Sklifosovsky

Moscow Medical Academy. THEM. Sechenov.

When studying the scope of application of the

coating, it was found that “OTRAN”:

optimizes the course of the wound process in

patients with:

trophic ulcers

long-term non-healing, burn, gunshot wounds

and also actively affects the wound process in

patients with diabetes mellitus complicated by

diabetic foot syndrome

The main proven properties of the product:

Excellent water and bio-insulation properties;

Excellent sorption properties;

No adhesion to wet surfaces with good adhesion to dry

surfaces;

Non-toxicity, self-sterilization when mixing components;

Absolute repetition of the relief of the wound surface;

Improved capillary blood flow in the affected area.

Test results

! The use of the product of the project allows to

reduce the time of treatment of patients by 2-3

times

! There are no direct contraindications to the use of

the coating, with the exception of rare cases of

abundant suppuration, anaerobic and sinus

infection

23

24.

The results of experimental clinical studiesThe influence of OTRAN on the healing process of burn wounds;

The effect of OTRAN on the healing of nonhealing wounds, trophic ulcers,

and other injuries of the skin.

The main findings of the research:

1

Polyurethane foam formed on the wound is non-toxic and has

moderate antimicrobial properties for most microorganisms that

are sown from the surface of wounds.

5

2

6

When treating patients with the use of OTRAN, there is a

noticeable increase in the regenerative abilities of tissues, which

leads to a reduction in the healing time:

• nonhealing wounds - for 34 days;

• trophic ulcers - for 46 days.

3

High efficiency of OTRAN coating has been proven in the

treatment of patients with superficial burns, the healing of which

occurs under it:

• for burns of the II degree - for 3 days;

• IIIA degree burns - 7 days earlier.

4С

In order to create the best conditions for tissue regeneration

and enhance the antimicrobial effect under the coating, the use of

various drugs, in particular Ximenedon, in the form of 5-10%

powder with 90-95% talc is shown as a pad.

OTRAN coating enhances capillary blood flow at the

site of its application.

The possibility of effective use of coating OTRAN for:

treatment of patients with pressure sores;

closure of donor wounds;

prevention of inflammatory complications of the soft

tissues around the needles for skeletal traction;

skin protection around gastrointestinal fistulas;

strengthen drains and catheters.

7П

The coating of polyurethane foam can be successfully

applied in the military field conditions at the stages of

rendering the first medical, skilled and special assistance and

in emergency situations in the aftermath of disasters.

24

25.

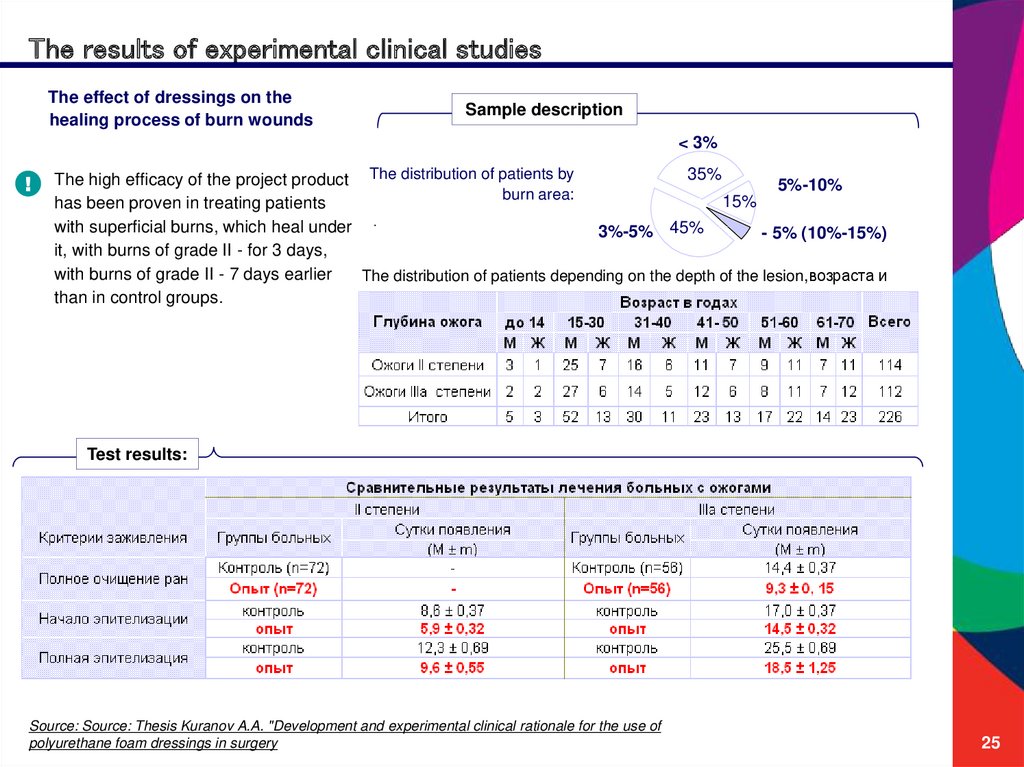

The results of experimental clinical studiesThe effect of dressings on the

healing process of burn wounds

Sample description

< 3%

35%

The high efficacy of the project product The distribution of patients by

5%-10%

burn area:

15%

has been proven in treating patients

with superficial burns, which heal under

3%-5% 45%

- 5% (10%-15%)

it, with burns of grade II - for 3 days,

with burns of grade II - 7 days earlier

The distribution of patients depending on the depth of the lesion,возраста и

пола:

than in control groups.

¡¡

Test results:

Source: Source: Thesis Kuranov A.A. "Development and experimental clinical rationale for the use of

polyurethane foam dressings in surgery

25

26.

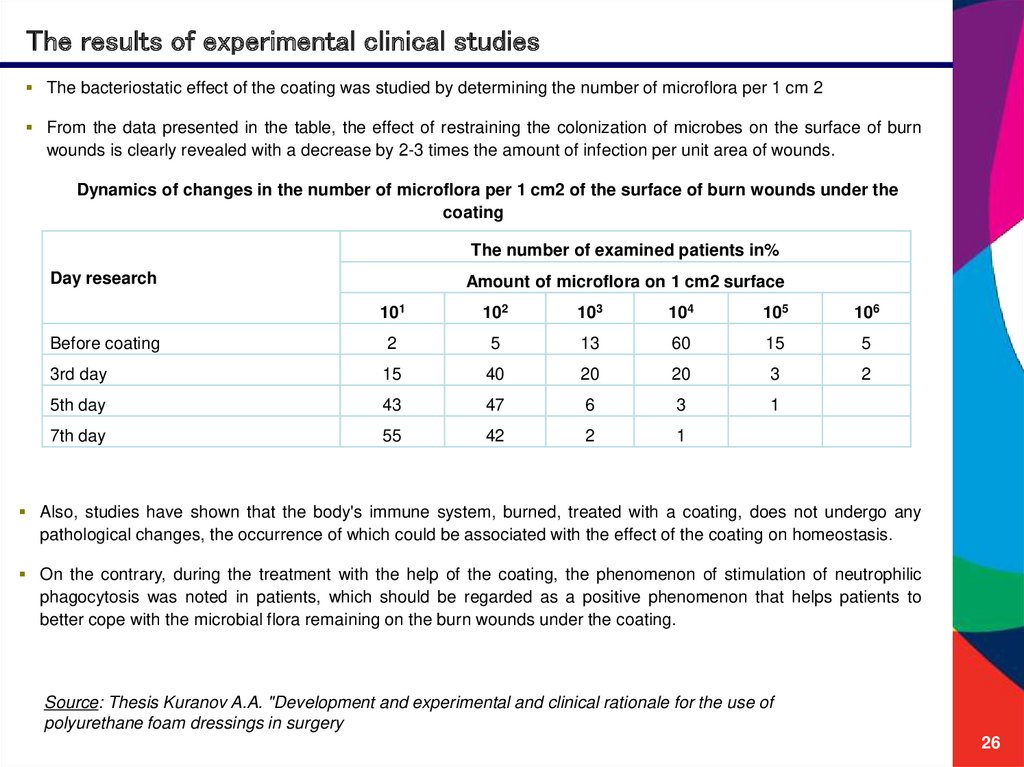

The results of experimental clinical studiesThe bacteriostatic effect of the coating was studied by determining the number of microflora per 1 cm 2

From the data presented in the table, the effect of restraining the colonization of microbes on the surface of burn

wounds is clearly revealed with a decrease by 2-3 times the amount of infection per unit area of wounds.

Dynamics of changes in the number of microflora per 1 cm2 of the surface of burn wounds under the

coating

The number of examined patients in%

Day research

Amount of microflora on 1 cm2 surface

101

102

103

104

105

106

Before coating

2

5

13

60

15

5

3rd day

15

40

20

20

3

2

5th day

43

47

6

3

1

7th day

55

42

2

1

Also, studies have shown that the body's immune system, burned, treated with a coating, does not undergo any

pathological changes, the occurrence of which could be associated with the effect of the coating on homeostasis.

On the contrary, during the treatment with the help of the coating, the phenomenon of stimulation of neutrophilic

phagocytosis was noted in patients, which should be regarded as a positive phenomenon that helps patients to

better cope with the microbial flora remaining on the burn wounds under the coating.

Source: Thesis Kuranov A.A. "Development and experimental and clinical rationale for the use of

polyurethane foam dressings in surgery

26

27.

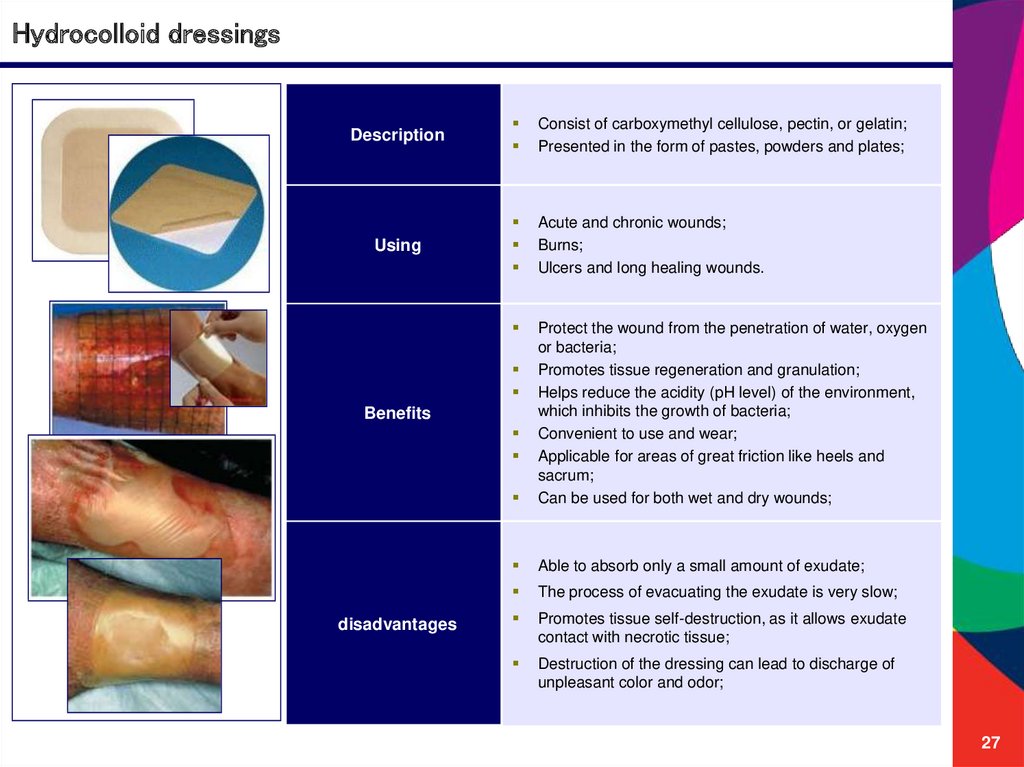

Hydrocolloid dressingsDescription

Consist of carboxymethyl cellulose, pectin, or gelatin;

Presented in the form of pastes, powders and plates;

Using

Acute and chronic wounds;

Burns;

Ulcers and long healing wounds.

Protect the wound from the penetration of water, oxygen

or bacteria;

Promotes tissue regeneration and granulation;

Helps reduce the acidity (pH level) of the environment,

which inhibits the growth of bacteria;

Convenient to use and wear;

Applicable for areas of great friction like heels and

sacrum;

Can be used for both wet and dry wounds;

Able to absorb only a small amount of exudate;

The process of evacuating the exudate is very slow;

Promotes tissue self-destruction, as it allows exudate

contact with necrotic tissue;

Destruction of the dressing can lead to discharge of

unpleasant color and odor;

Benefits

disadvantages

27

28.

Hydrofibre HandwrapsDescription

Using

Intended for wounds with medium and abundant

exudate content:

Wounds;

Burns;

Trophic ulcers;

Longing wounds;

Bedsores etc.

Protect the wound from the penetration of water, oxygen

or bacteria;

Promotes tissue regeneration and granulation;

Helps reduce the acidity (pH level) of the environment,

which inhibits the growth of bacteria;

Convenient to use and wear;

Applicable for areas of great friction like heels and

sacrum;

Can be used for both wet and dry wounds;

The process of evacuating the exudate is very slow;

Destruction of the dressing can lead to discharge of

unpleasant color and odor;

Benefits

disadvantages

Hydrocolloid fibers consist;

The fiber composition is carboxymethyl cellulose, pectin,

or gelatin;

May contain antimicrobial agents;

28

29.

Hydrogel dressingsDescription

Ready sorption gel, fixed on a transparent semipermeable membrane;

The gel keeps the wound moist and at the same time

absorbs excess fluid, maintaining optimal conditions for

its healing;

Hydrogel dressings are used when a vascular wound

bed is formed for the purpose of rehydration and

rejection of a dense necrotic scab or stimulation of

epithelialization of flat granulating (including donor)

wounds;

Wounds with poor content of exudate;

Using

Benefits

disadvantages

Due to the multi-layer structure of the gel with the

presence of a layer with pronounced sorption properties

and adjacent layers with high (up to 80%) moisture

content, these dressings can maintain the necessary

parameters of the wound environment for a long time

and stay on the wound surface for up to 14 days or

more;

Do not stick to the wound;

The outer surface is impermeable to microorganisms

and water;

The transparent structure of the dressing allows you to

visually monitor the condition of the wound at any time

without changing the dressing;

Relatively low sorption capacity

Therefore, secondary dressings are often required;

29

30.

Alginate dressingsThey consist of brown seaweed extracts and are formed

into nonwoven fabric in the form of sheets and ropes;

Able to absorb a large amount of drainage from a wound

by forming a gel that keeps the wound moist, speeding

healing;

Using

Wounds with abundant drainage content;

Benefits

Very high absorption rate;

Promotes the evacuation of exudate from the wound;

Promote tissue regeneration;

Limited scope - only wounds with abundant exudate

content;

Used as a primary dressing and should be covered with

a gauze pad or a compress to extract excreta;

Fixatives are needed to secure the dressing on the

wound;

Description

disadvantages

30

31.

Absorbent dressingsDescription

Able to absorb a large amount of drainage from a

wound;

Using

Wounds with varying levels of exudate from small to

heavy

Wounds

Ulcers

Bedsores and others

Benefits

disadvantages

They can maintain the necessary parameters of the

wound environment for a long time and stay on the

wound surface for up to 7 days;

They create the effect of heat insulation;

Maintain the required level of moisture and do not stick

to the wound;

Not applicable to dry wounds;

Requires combination with hydrogels, alginate or

hydrocolloid dressings;

31

32.

Transparent bandagesDescription

Wounds with low exudate content;

Wounds that are not subject to repeated mechanical

stress;

Ulcers of the first stage;

Most effective for superficial wounds;

Prevent the entry of contaminants into the wound;

Pass oxygen and water vapor;

Transparency, which allows you to control the processes

in the wound without removing the dressing;

Requires combination with primary dressings;

Not suitable for wounds in areas of body subject to great

friction;

Using

Benefits

disadvantages

They consist of a flexible, transparent film of various

types of polymer, which is a sticky, waterproof

membrane that prevents the penetration of pollutants,

allowing oxygen and water vapor to enter the wound;

Used as a secondary dressing;

32

33.

Antimicrobial wound dressingsDescription

Using

Benefits

disadvantages

Silver content

• Consist of several layers, one of which contains silver

(silver sulfadiazine and chlorhexidine);

• The base is a layer of nonwoven material;

Silver free

• The active substance is honey, iodine, and compounds

that mainly contain polyhexamethylene, biguanide,

chlorhexidine, gluconate;

Any wounds with the probability of infection;

Silver content

• Effective against staphylococcus and many other

microorganisms;

Silver free

• Greater availability;

• Pronounced antimicrobial properties;

Silver content

• High price;

33

34.

Other dressingsDescription

Using

Cultured tissue

• Skin replacement products that are involved in tissue

regeneration;

Biologically Interoperable Dressings

• The use of collagen and fibronectin;

• The use of hyaluronic acid;

Appointment - restoration of the skin;

Cultured tissue

• Involved in tissue regeneration and accelerating wound

healing;

Benefits

Biologically Interoperable Dressings

• Involved in tissue regeneration and accelerating wound

healing;

disadvantages

Use only in the final stages of healing in order to

accelerate tissue regeneration.

34

35.

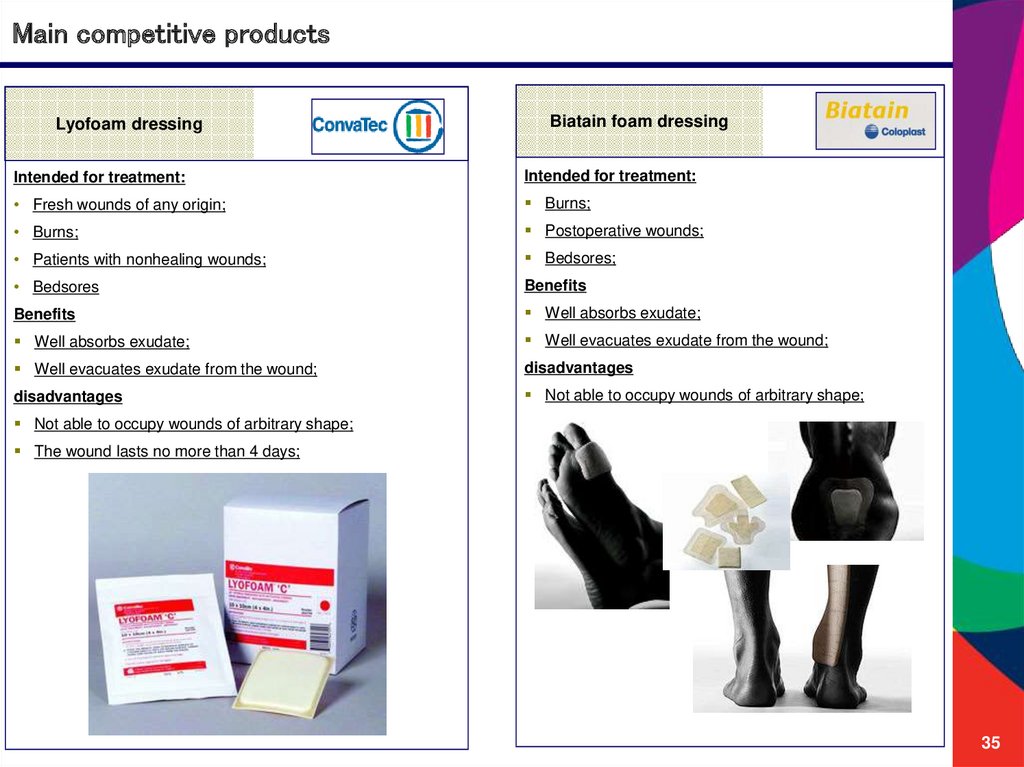

Main competitive productsLyofoam dressing

Biatain foam dressing

Intended for treatment:

Intended for treatment:

• Fresh wounds of any origin;

Burns;

• Burns;

Postoperative wounds;

• Patients with nonhealing wounds;

Bedsores;

• Bedsores

Benefits

Benefits

Well absorbs exudate;

Well absorbs exudate;

Well evacuates exudate from the wound;

Well evacuates exudate from the wound;

disadvantages

disadvantages

Not able to occupy wounds of arbitrary shape;

Not able to occupy wounds of arbitrary shape;

The wound lasts no more than 4 days;

35

36.

Main competitive productsHydrocolloid dressing

Cutinova

Hydrocolloid dressing

Granuflex

Intended for treatment:

Intended for treatment:

Fresh wounds of any origin with level; low to medium wound

exudate;

Granulating wounds;

Ulcers;

Bedsores;

Diabetic foot;

Superficial burns;

Benefits

Well absorbs exudate

Burns;

Ulcers;

Benefits

Impervious to exudate and HIV;

It provokes the rehydration of necrotic tissue;

disadvantages

Not able to occupy wounds of arbitrary shape;

Protects against moisture penetration

disadvantages

Not able to occupy wounds of arbitrary shape.

Not suitable for wounds with copious exudate

36

37.

Main competitive productsHydrofiber dressing

Allevyn

Intended for treatment:

Ran with any level of exudate from small to abundant;

Burns;

Bedsores;

Ulcers and diabetic foot;

Benefits

Well absorbs exudate;

Protects against moisture penetration;

Maintains optimum moisture;

disadvantages

Not able to occupy wounds of arbitrary shape;

Does not prevent from repeated mechanical damage;

Hydrogel dressing

Hydrosorb

Intended for treatment:

Ran with low exudate content;

Dry wounds;

Burns;

Benefits

It provokes the death of necrotic tissue;

Maintains optimum moisture;

Able to occupy wounds of arbitrary shape;

disadvantages

Does not prevent from repeated mechanical damage;

Not suitable for wounds with medium and abundant exudate

content;

37

38.

Main competitive productsAbsorbent dressing

Mepitel

Absorbent dressing

Mesorb

Intended for treatment:

Intended for treatment:

Wounds with any exudate content;

Run with any exudate content;

II degree burns;

Burns;

Skin lesions;

Benefits

Benefits

Absorbs and holds any amount of wound exudate;

Protects against moisture penetration;

disadvantages

Maintains optimum moisture;

Does not prevent from repeated mechanical damage;

disadvantages

Not able to occupy wounds of arbitrary shape;

Not able to occupy wounds of arbitrary shape;

Does not prevent from repeated mechanical damage;

38

39.

Main competitive products"Liquid Bandage"

BioCure Inc., (USA)

Foaming bandage

Designed to treat

Comfortable two-component silicone foaming bandage;

Ran;

Designed for the treatment of wounds in the form of

granulating cavities;

Burns;

Ulcers and pressure sores;

Benefits:

Accurately performs the wound cavity;

Simplifies deep wound management;

Protects sensitive postoperative structures;

Maintains a moist wound environment;

The product is under development.

Prevents premature closure of the edges of the skin wound;

Does not stick to the wound surface.

Product inferior to OTRANU by characteristics

39

medicine

medicine