Similar presentations:

Power Industry

1.

Power IndustryMining

Cement Industry

Harbour

Terminals

Chemical Industry

Iron &

Steel

2.

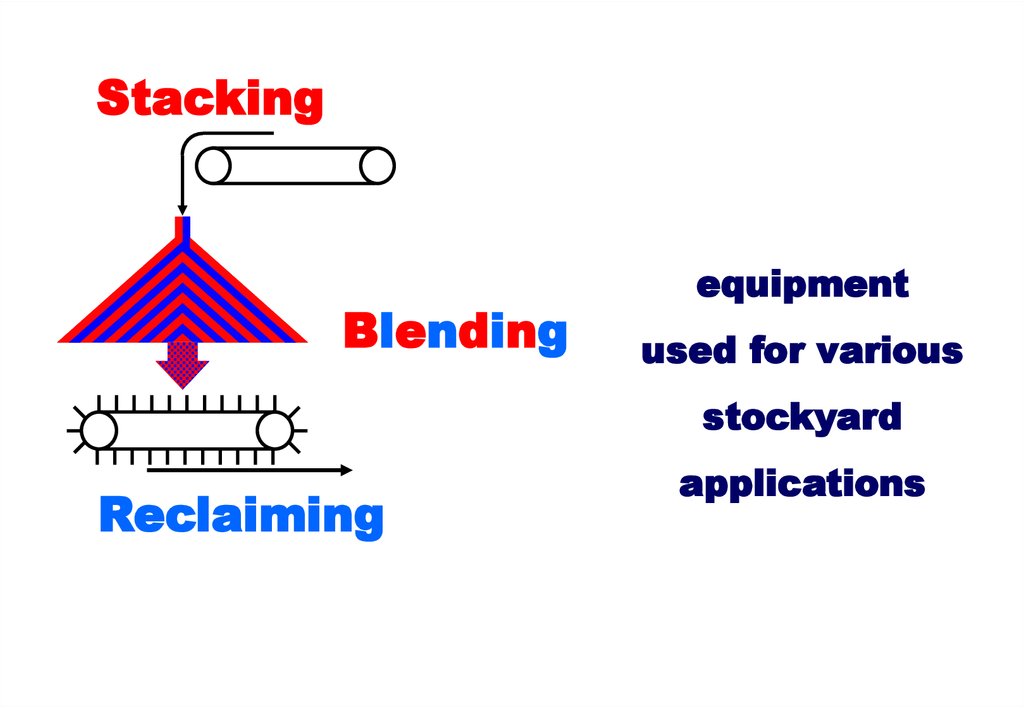

StackingBlending

equipment

used for various

stockyard

Reclaiming

applications

3.

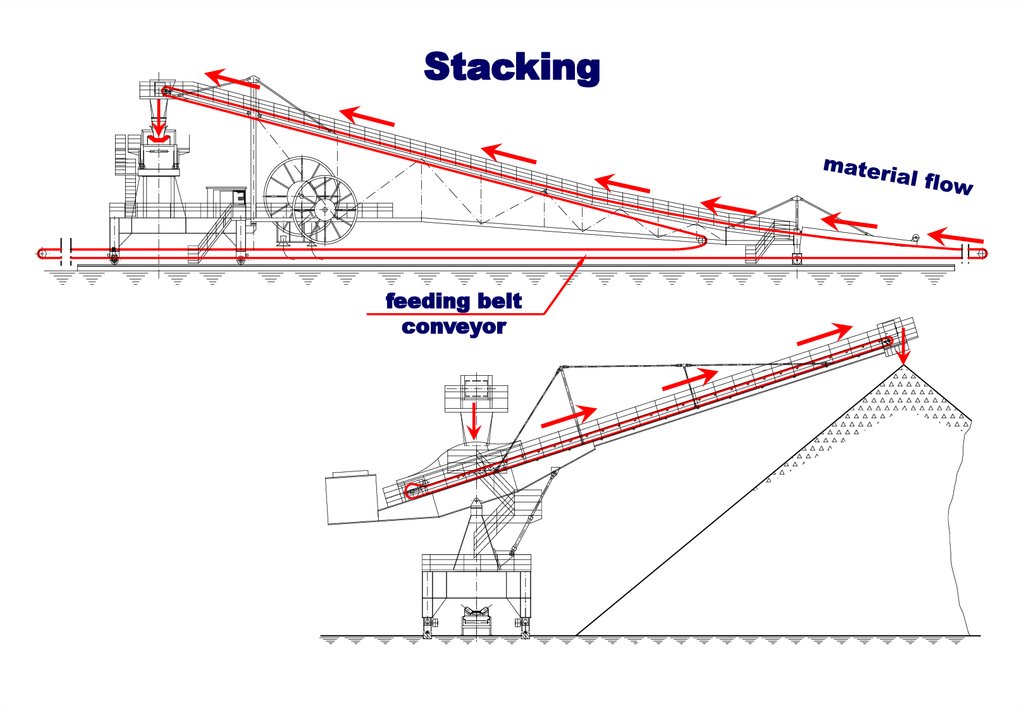

Stackingfeeding belt

conveyor

4.

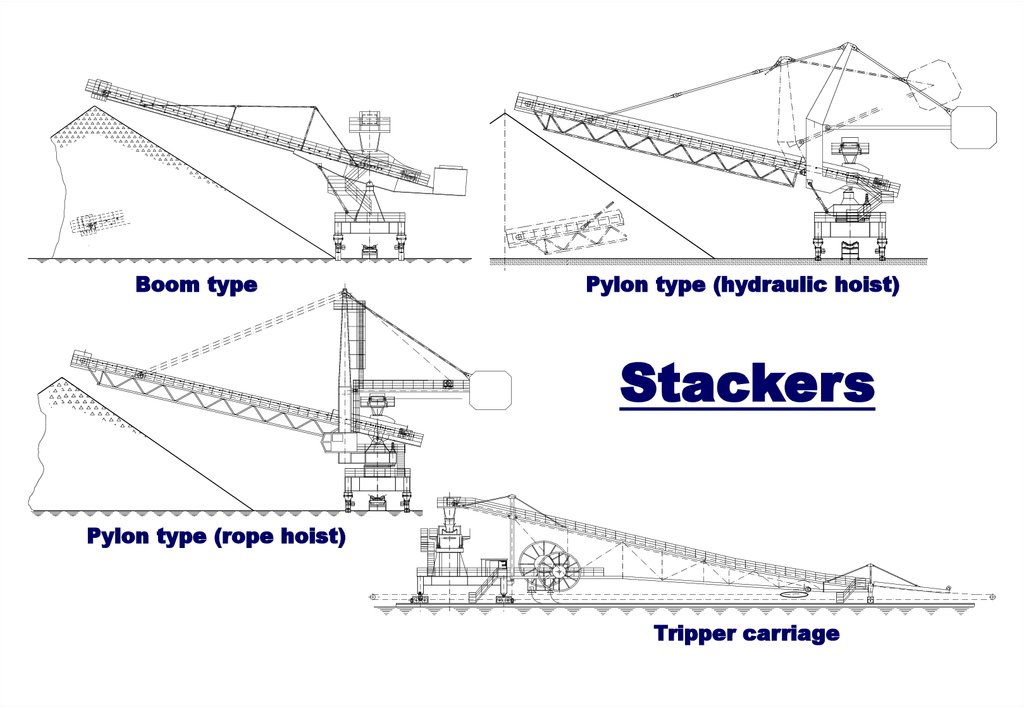

Boom typePylon type (hydraulic hoist)

Stackers

Pylon type (rope hoist)

Tripper carriage

5.

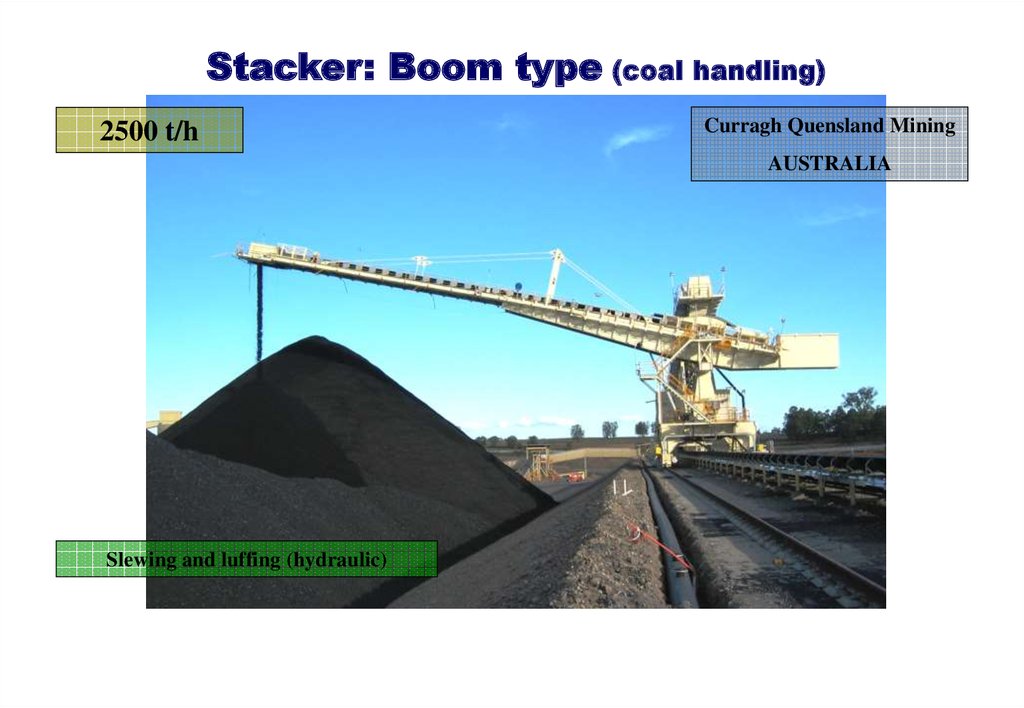

Stacker: Boom type (coal handling)2500 t/h

Curragh Quensland Mining

AUSTRALIA

Slewing and luffing (hydraulic)

6.

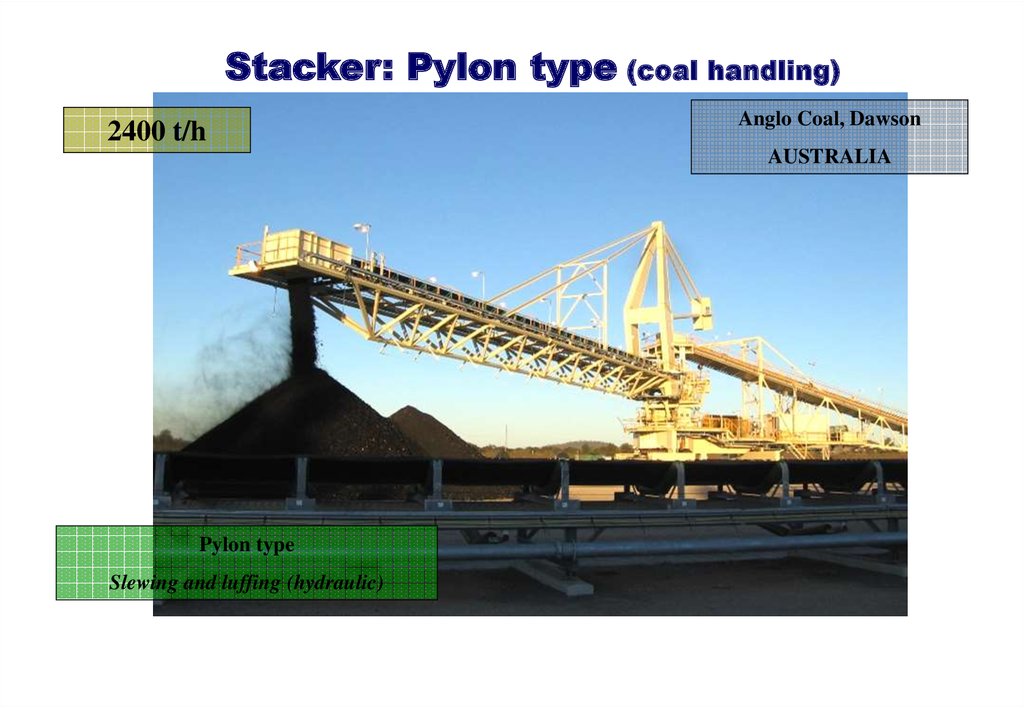

Stacker: Pylon type (coal handling)2400 t/h

Anglo Coal, Dawson

AUSTRALIA

Pylon type

Slewing and luffing (hydraulic)

7.

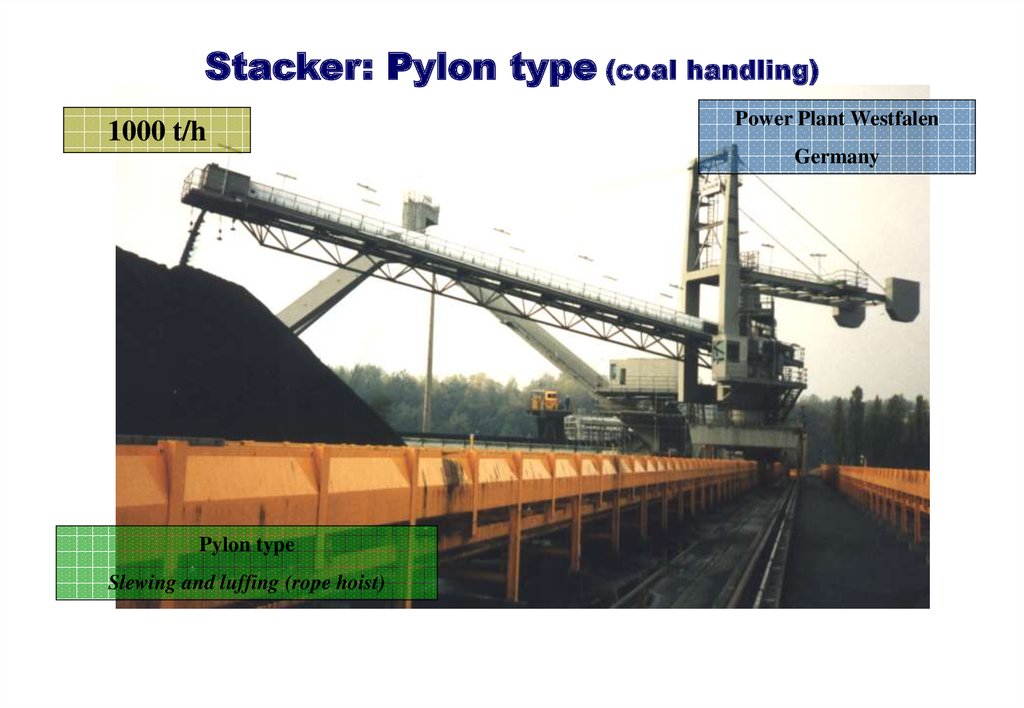

Stacker: Pylon type (coal handling)1000 t/h

Power Plant Westfalen

Germany

Pylon type

Slewing and luffing (rope hoist)

8.

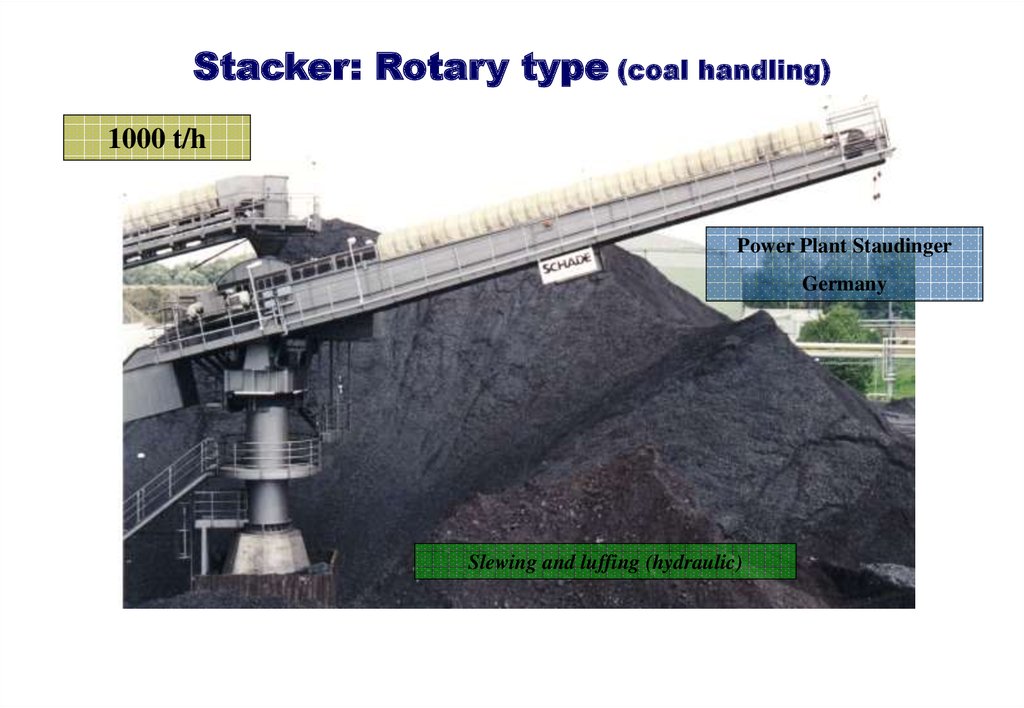

Stacker: Rotary type (coal handling)1000 t/h

Power Plant Staudinger

Germany

Slewing and luffing (hydraulic)

9.

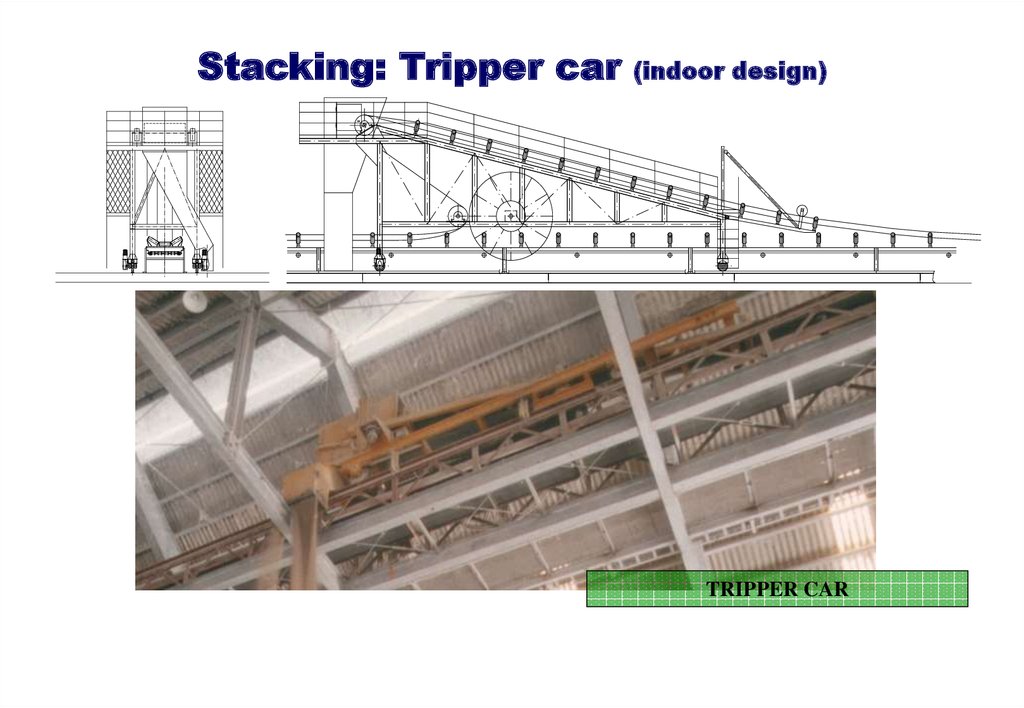

Stacking: Tripper car(indoor design)

TRIPPER CAR

10.

Stacking MethodsChevron

(mainly for blending purpose)

reclaiming

11.

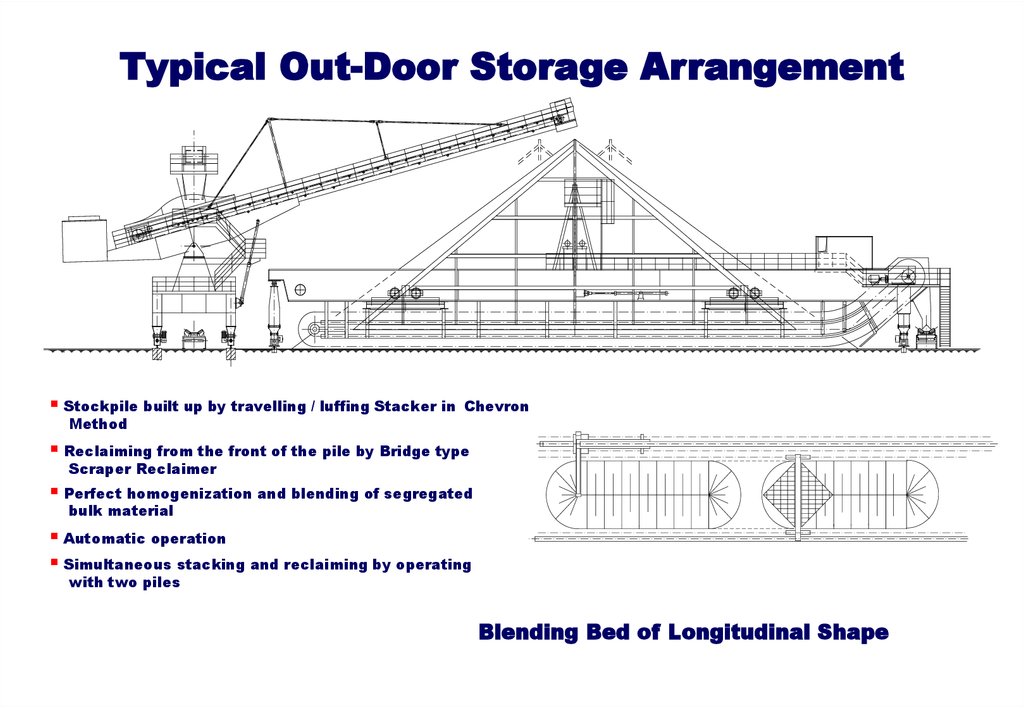

Typical Out-Door Storage ArrangementStockpile built up by travelling / luffing Stacker in

Method

Chevron

Reclaiming from the front of the pile by Bridge type

Scraper Reclaimer

Perfect homogenization and blending of segregated

bulk material

Automatic operation

Simultaneous stacking and reclaiming by operating

with two piles

Blending Bed of Longitudinal Shape

12.

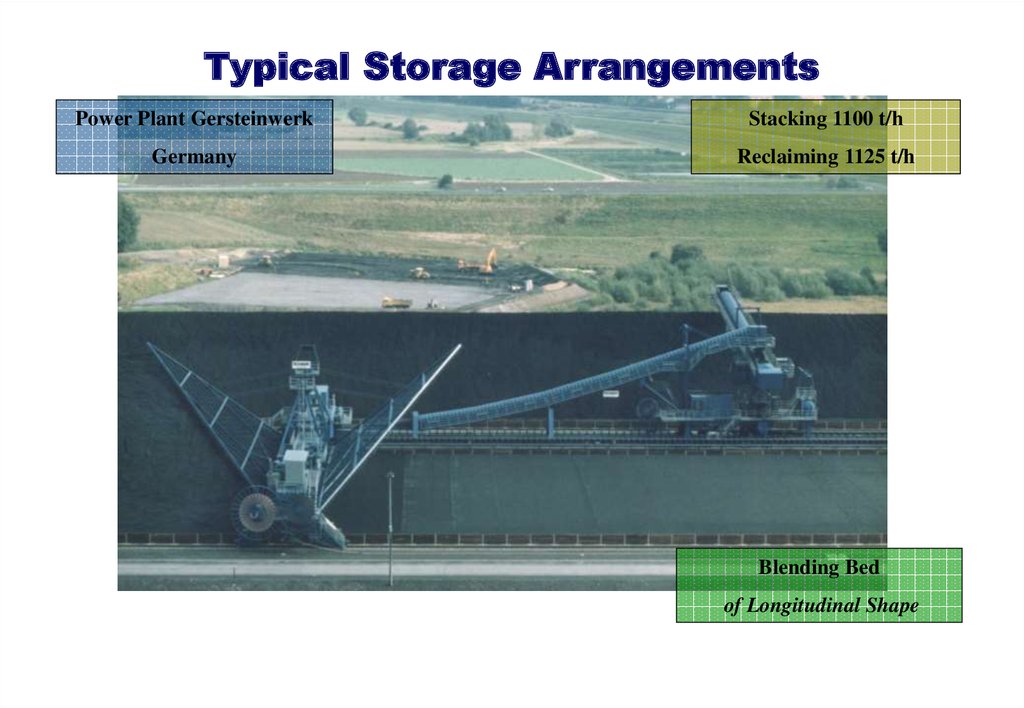

Typical Storage ArrangementsPower Plant Gersteinwerk

Stacking 1100 t/h

Germany

Reclaiming 1125 t/h

Blending Bed

of Longitudinal Shape

13.

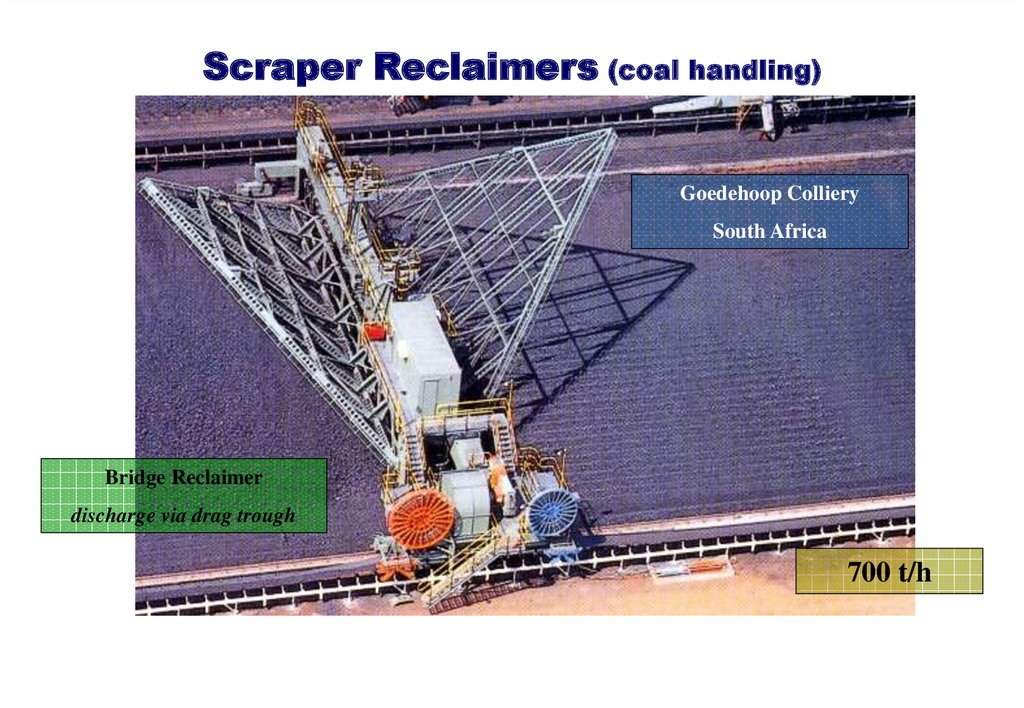

Scraper Reclaimers (coal handling)Goedehoop Colliery

South Africa

Bridge Reclaimer

discharge via drag trough

700 t/h

14.

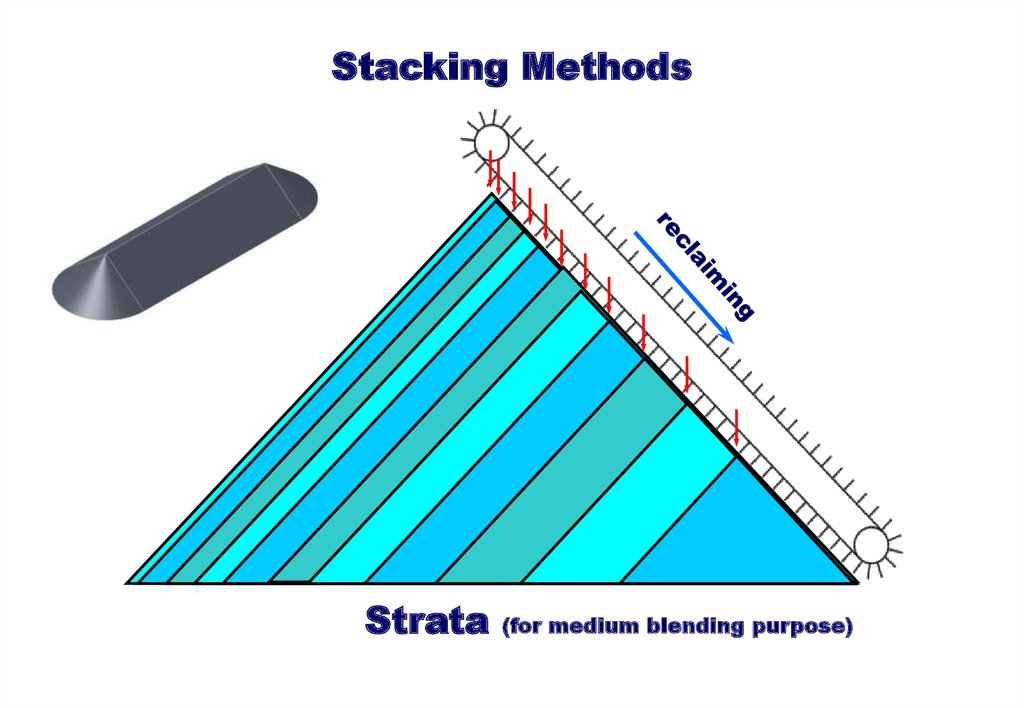

Stacking MethodsStrata

(for medium blending purpose)

15.

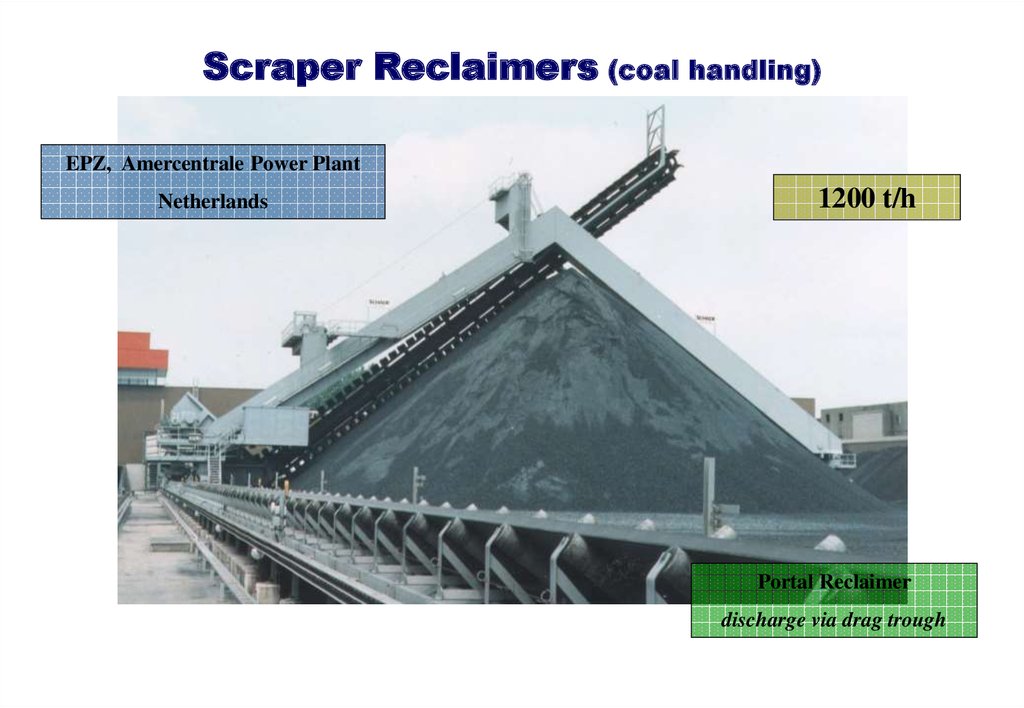

Scraper Reclaimers (coal handling)EPZ, Amercentrale Power Plant

Netherlands

1200 t/h

Portal Reclaimer

discharge via drag trough

16.

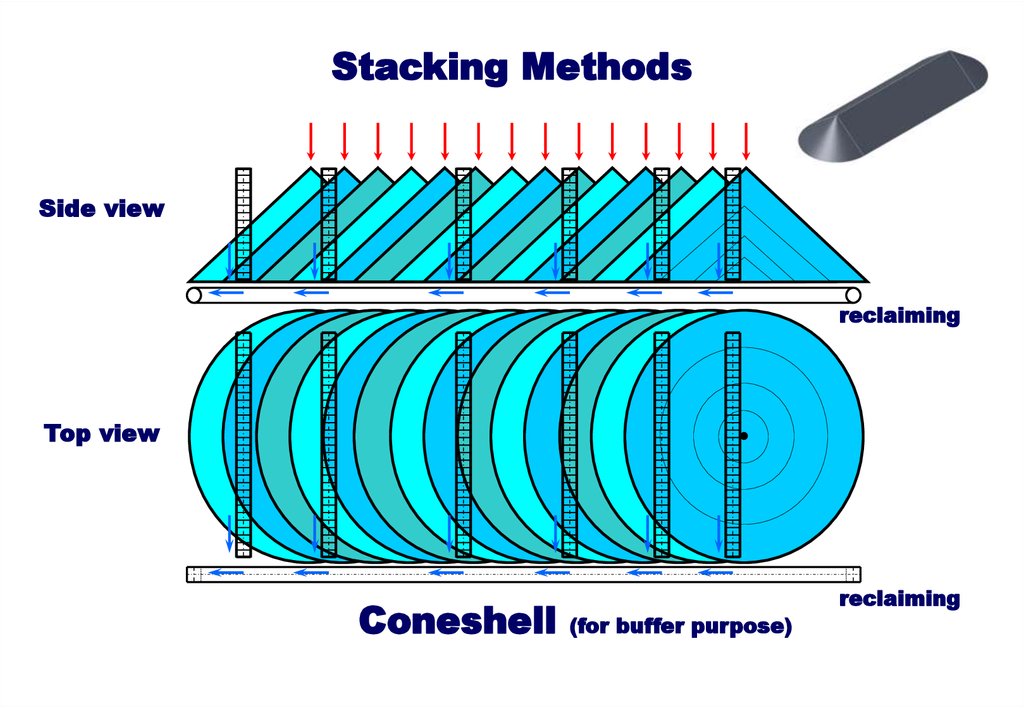

Stacking MethodsSide view

reclaiming

Top view

Coneshell

(for buffer purpose)

reclaiming

17.

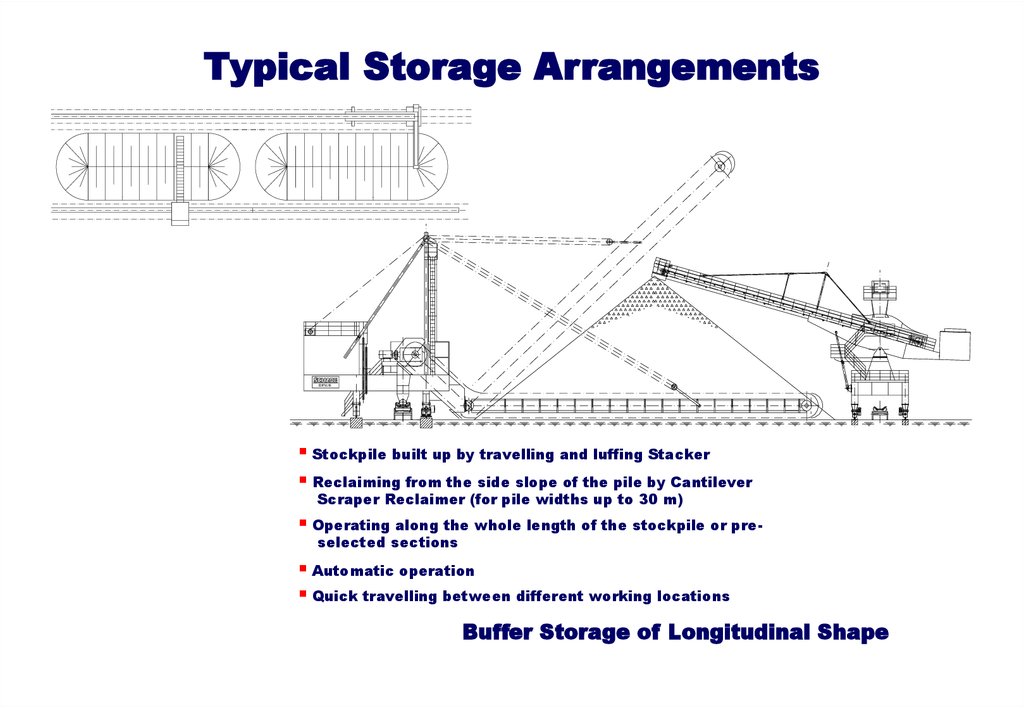

Typical Storage ArrangementsDORTMUND

Stockpile built up by travelling and luffing Stacker

Reclaiming from the side slope of the pile by Cantilever

Scraper Reclaimer (for pile widths up to 30 m)

Operating along the whole length of the stockpile or preselected sections

Automatic operation

Quick travelling between different working locations

Buffer Storage of Longitudinal Shape

18.

Scraper Reclaimers (coal handling)Steweag, Power Plant Mellach

250 t/h

Austria

Cantilever Reclaimer

discharge via drag trough

19.

Scraper Reclaimers (limestone handling)Kawasaki for Celik Holding

Turkmenistan

200 t/h

Cantilever Reclaimer

discharge via concrete ramp

20.

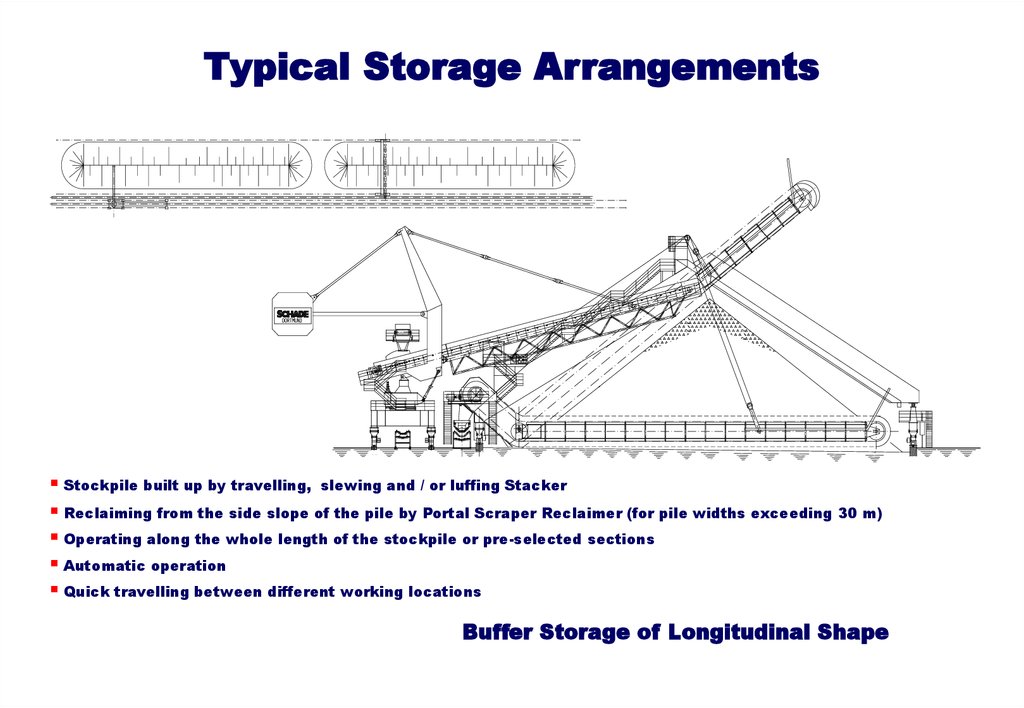

Typical Storage ArrangementsStockpile built up by travelling, slewing and / or luffing Stacker

Reclaiming from the side slope of the pile by Portal Scraper Reclaimer (for pile widths exceeding 30 m)

Operating along the whole length of the stockpile or pre-selected sections

Automatic operation

Quick travelling between different working locations

Buffer Storage of Longitudinal Shape

21.

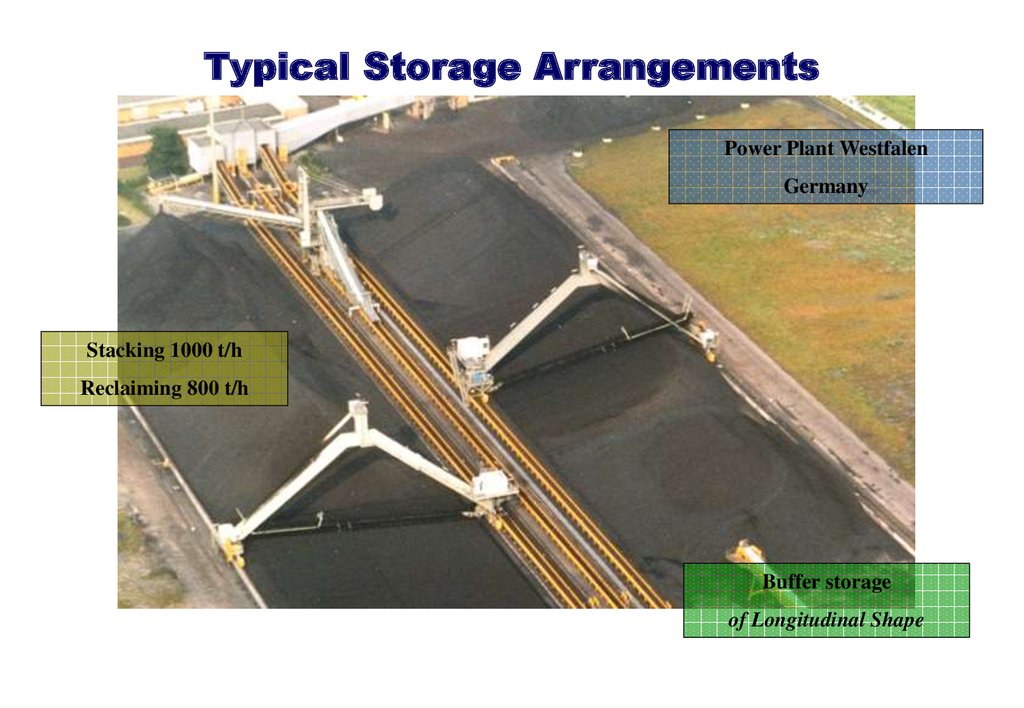

Typical Storage ArrangementsPower Plant Westfalen

Germany

Stacking 1000 t/h

Reclaiming 800 t/h

Buffer storage

of Longitudinal Shape

22.

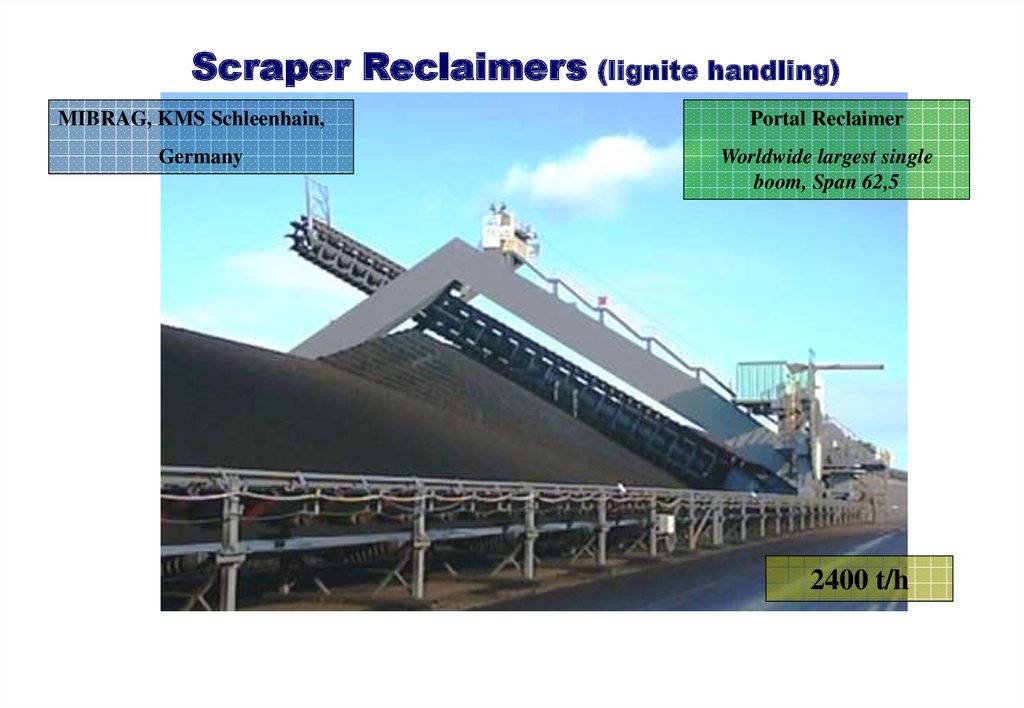

Scraper Reclaimers (lignite handling)MIBRAG, KMS Schleenhain,

Germany

Portal Reclaimer

Worldwide largest single

boom, Span 62,5

2400 t/h

23.

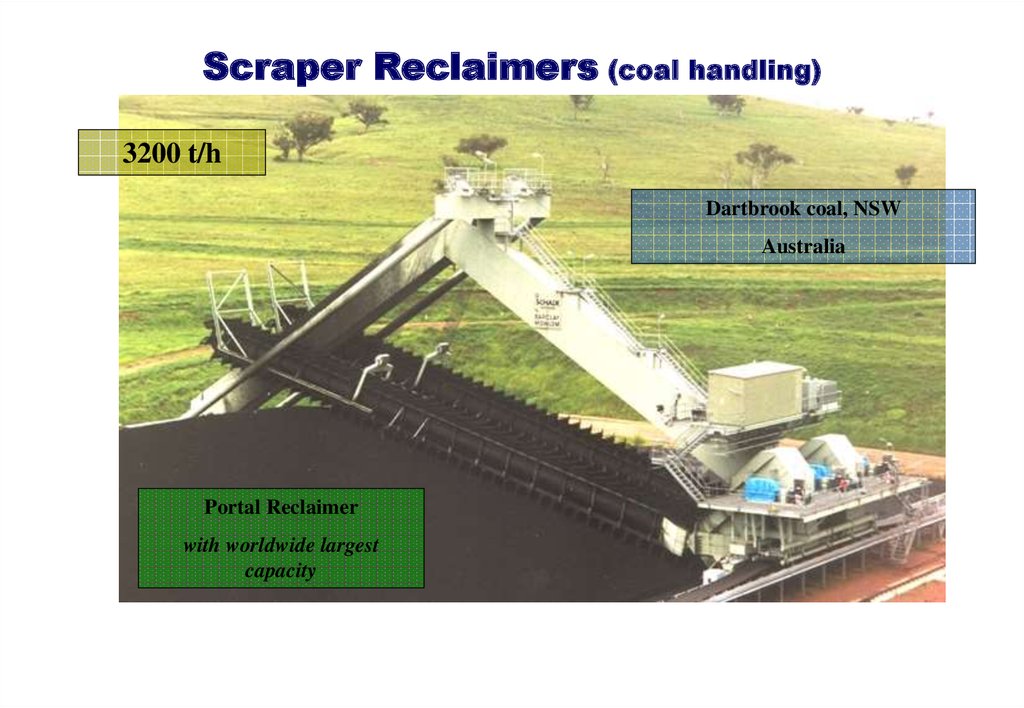

Scraper Reclaimers (coal handling)3200 t/h

Dartbrook coal, NSW

Australia

Portal Reclaimer

with worldwide largest

capacity

24.

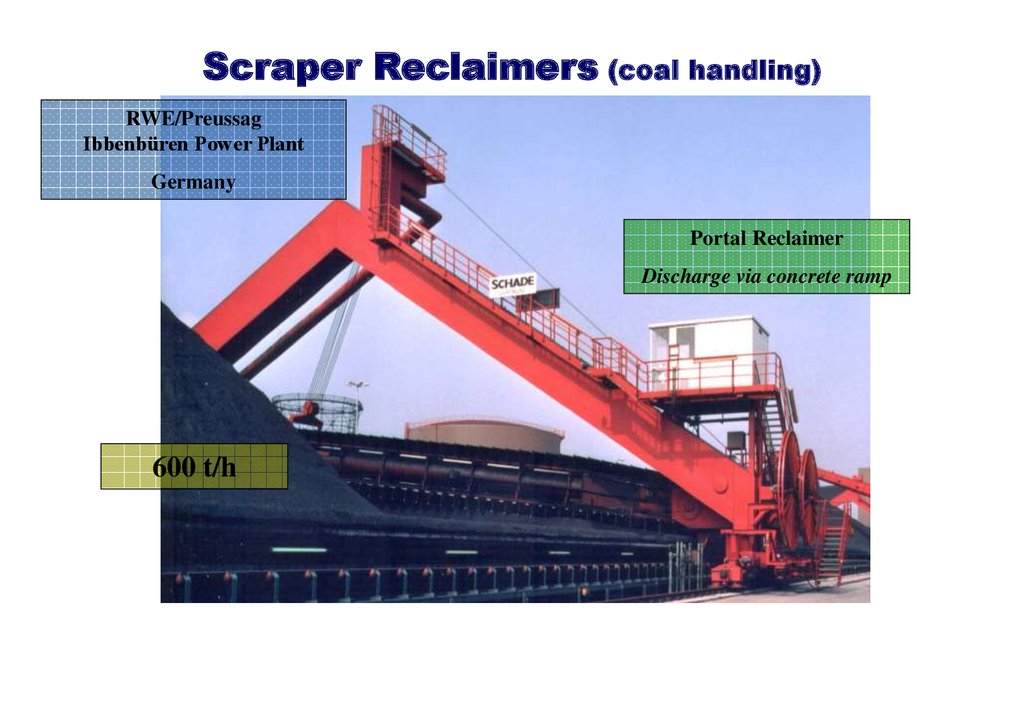

Scraper Reclaimers (coal handling)RWE/Preussag

Ibbenbüren Power Plant

Germany

Portal Reclaimer

Discharge via concrete ramp

600 t/h

25.

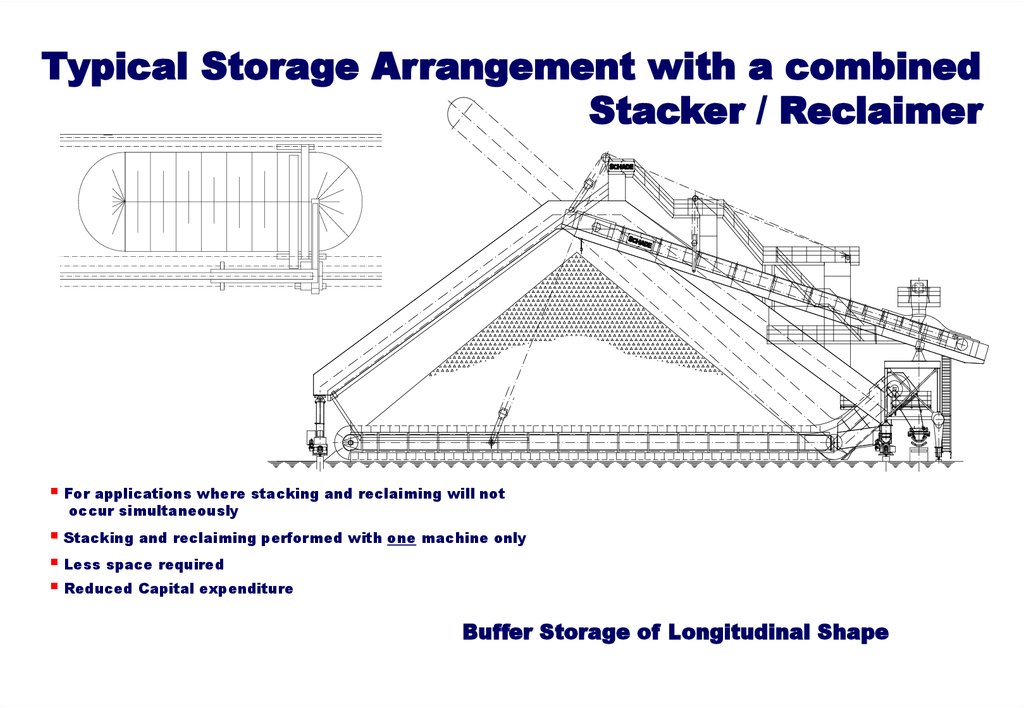

Typical Storage Arrangement with a combinedStacker / Reclaimer

For applications where stacking and reclaiming will not

occur simultaneously

Stacking and reclaiming performed with one machine only

Less space required

Reduced Capital expenditure

Buffer Storage of Longitudinal Shape

26.

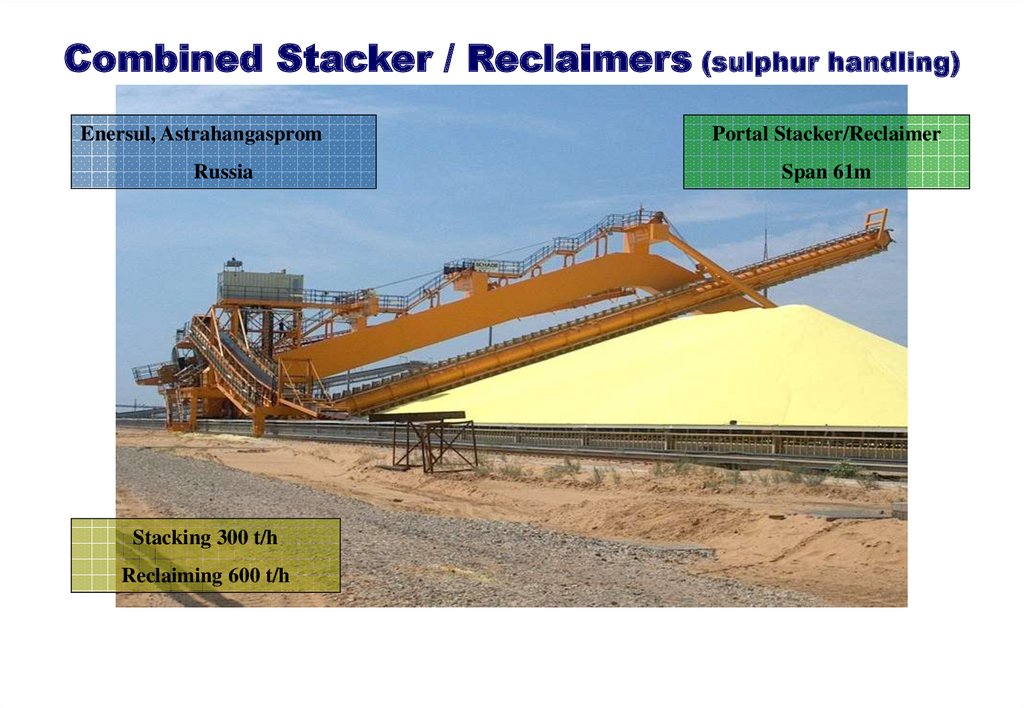

Combined Stacker / Reclaimers (sulphur handling)Enersul, Astrahangasprom

Russia

Stacking 300 t/h

Reclaiming 600 t/h

Portal Stacker/Reclaimer

Span 61m

27.

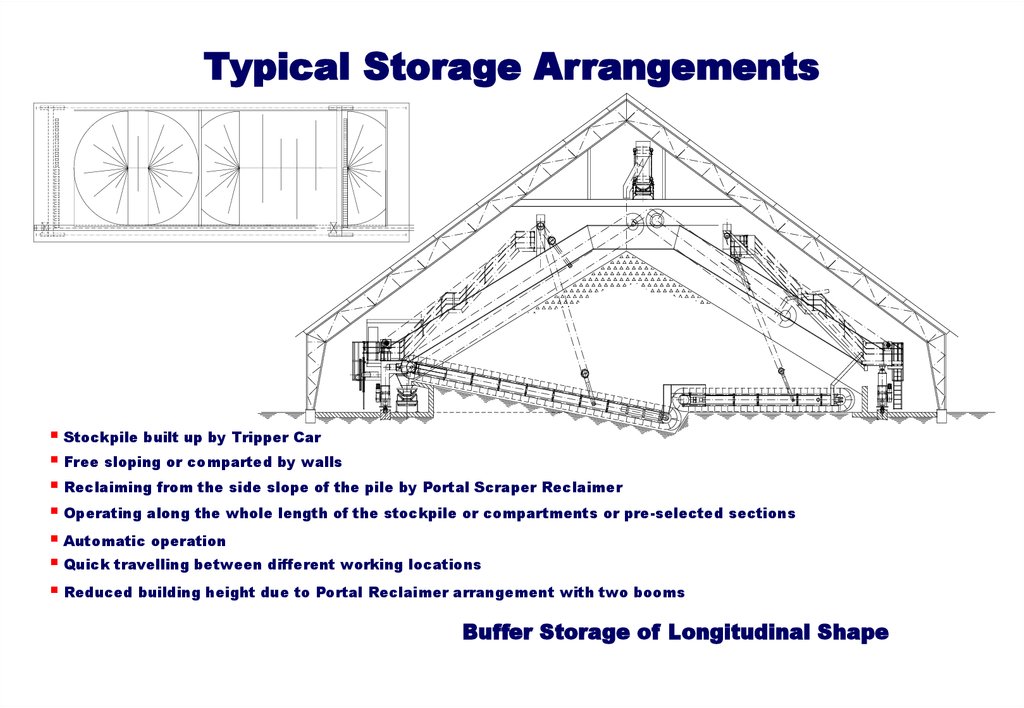

Typical Storage ArrangementsStockpile built up by Tripper Car

Free sloping or comparted by walls

Reclaiming from the side slope of the pile by Portal Scraper Reclaimer

Operating along the whole length of the stockpile or compartments or pre-selected sections

Automatic operation

Quick travelling between different working locations

Reduced building height due to Portal Reclaimer arrangement with two booms

Buffer Storage of Longitudinal Shape

28.

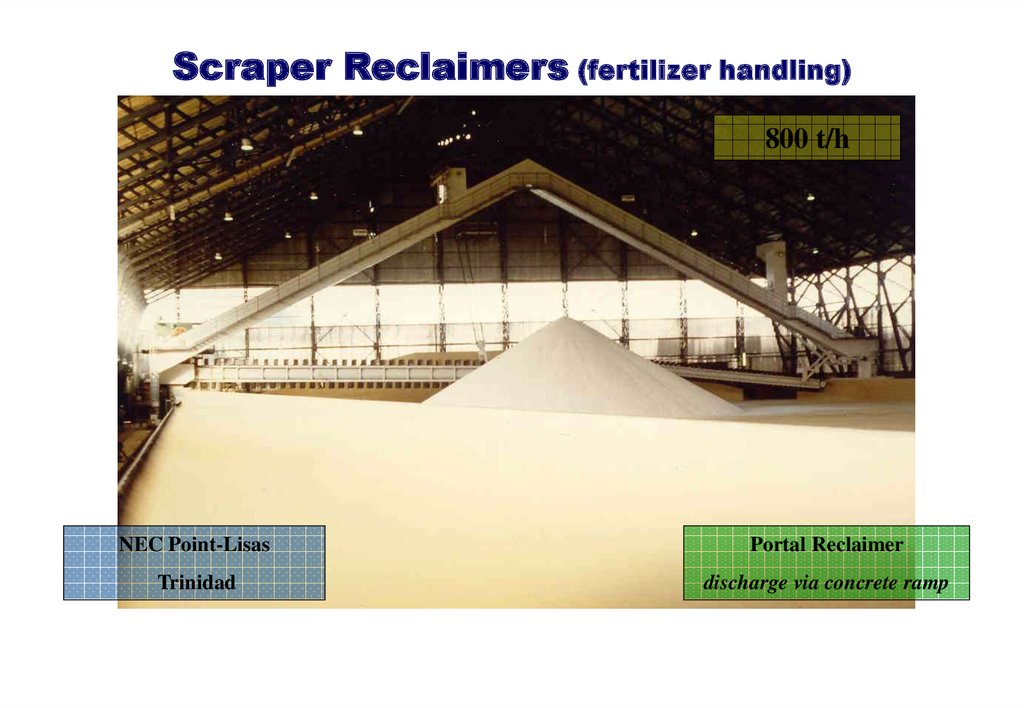

Scraper Reclaimers (fertilizer handling)800 t/h

NEC Point-Lisas

Portal Reclaimer

Trinidad

discharge via concrete ramp

29.

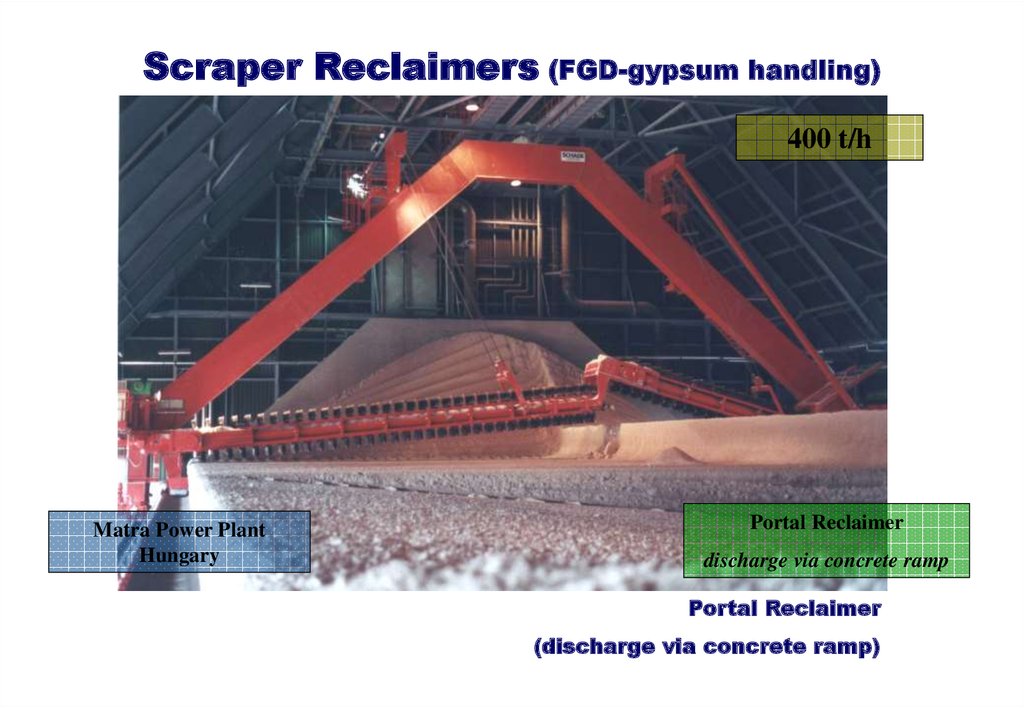

Scraper Reclaimers (FGD-gypsum handling)400 t/h

Matra Power Plant

Hungary

Portal Reclaimer

discharge via concrete ramp

Portal Reclaimer

(discharge via concrete ramp)

30.

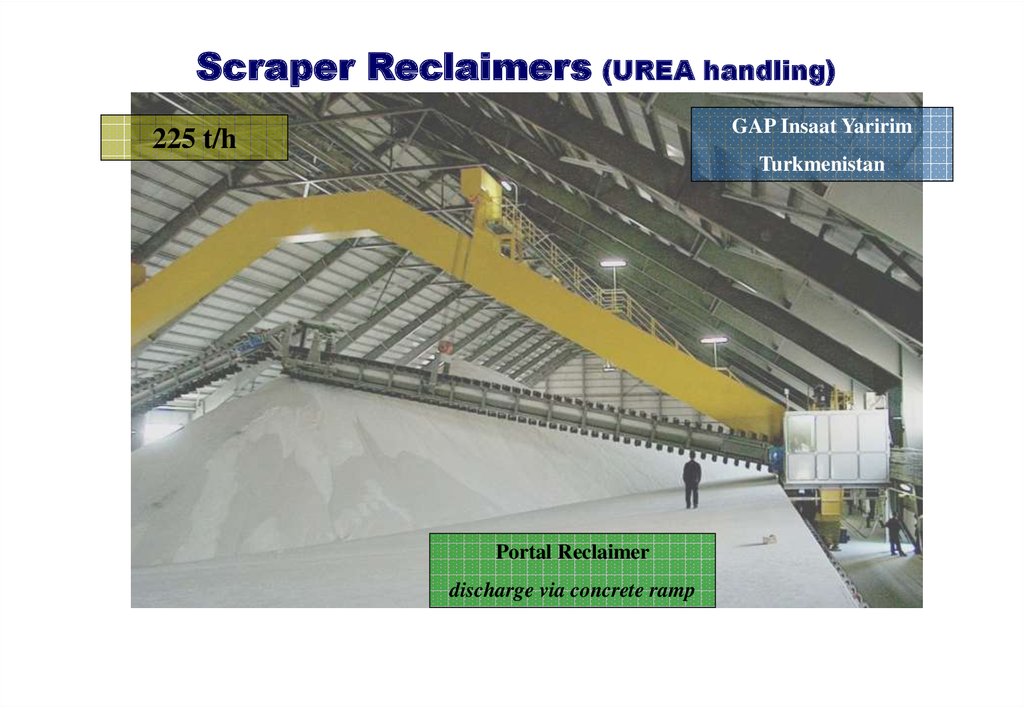

Scraper Reclaimers (UREA handling)GAP Insaat Yaririm

225 t/h

Turkmenistan

Portal Reclaimer

discharge via concrete ramp

31.

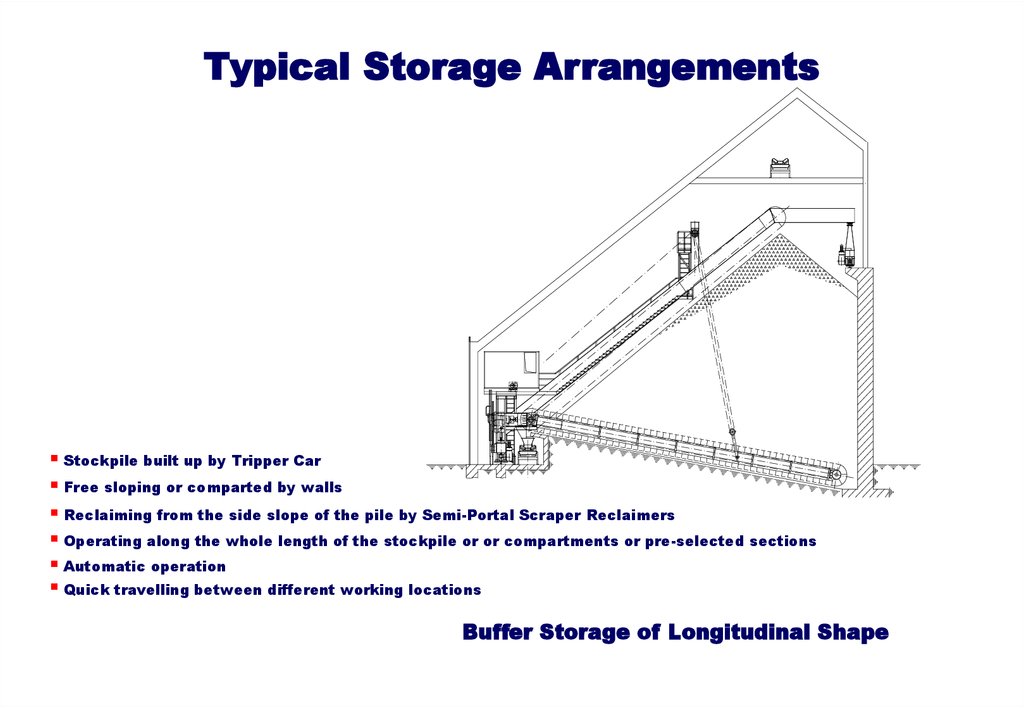

Typical Storage ArrangementsStockpile built up by Tripper Car

Free sloping or comparted by walls

Reclaiming from the side slope of the pile by Semi-Portal Scraper Reclaimers

Operating along the whole length of the stockpile or or compartments or pre-selected sections

Automatic operation

Quick travelling between different working locations

Buffer Storage of Longitudinal Shape

32.

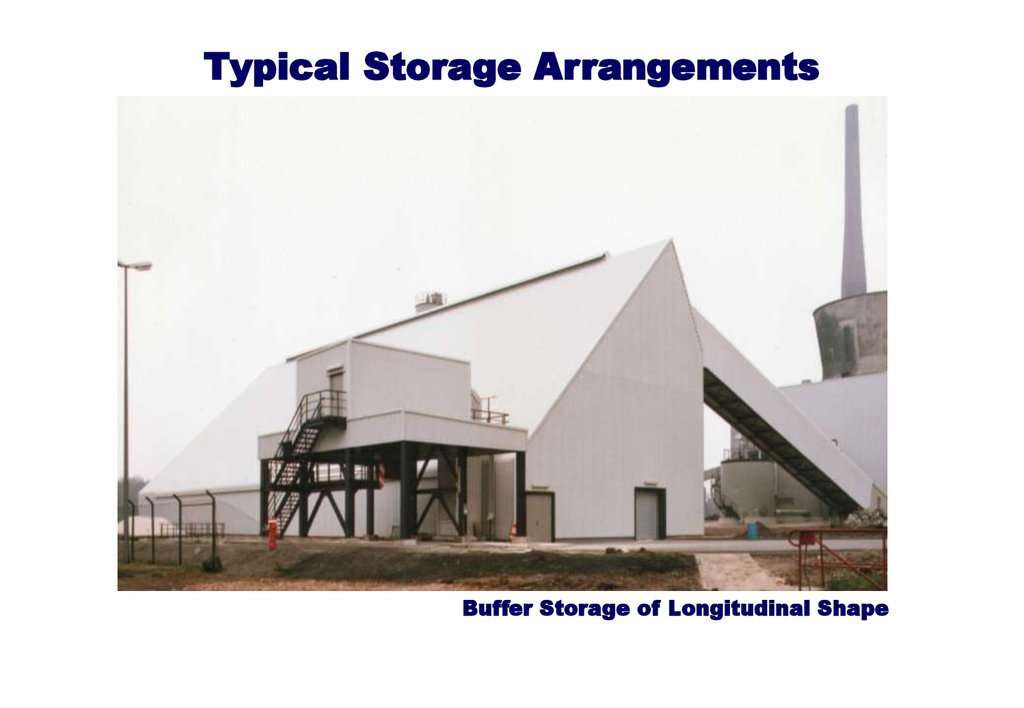

Typical Storage ArrangementsBuffer Storage of Longitudinal Shape

33.

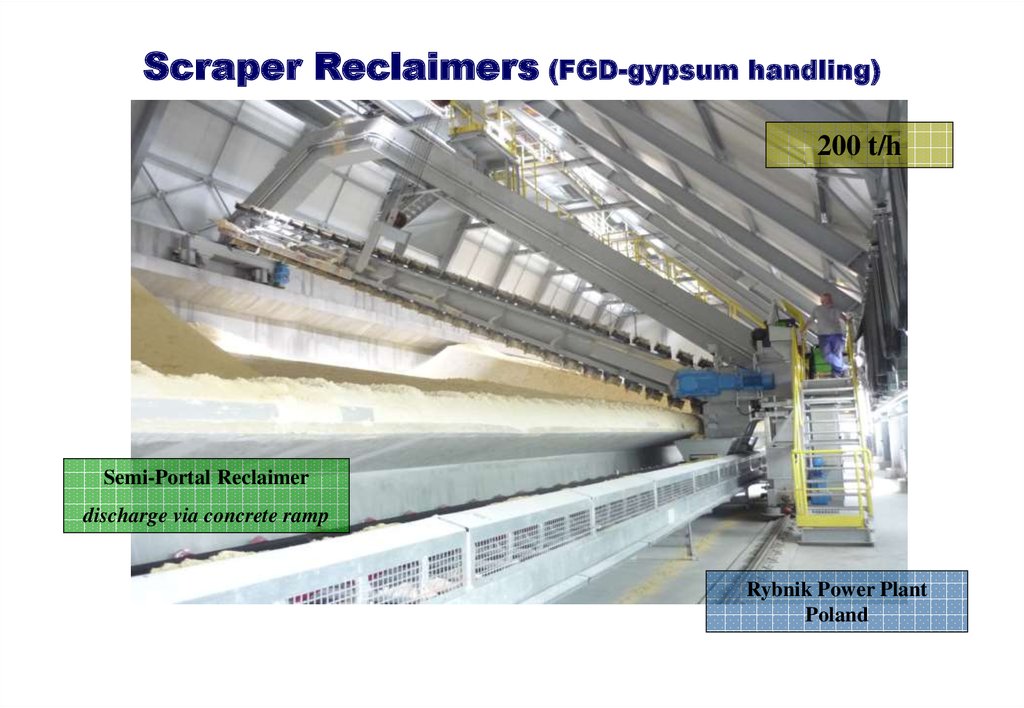

Scraper Reclaimers (FGD-gypsum handling)200 t/h

Semi-Portal Reclaimer

discharge via concrete ramp

Rybnik Power Plant

Poland

34.

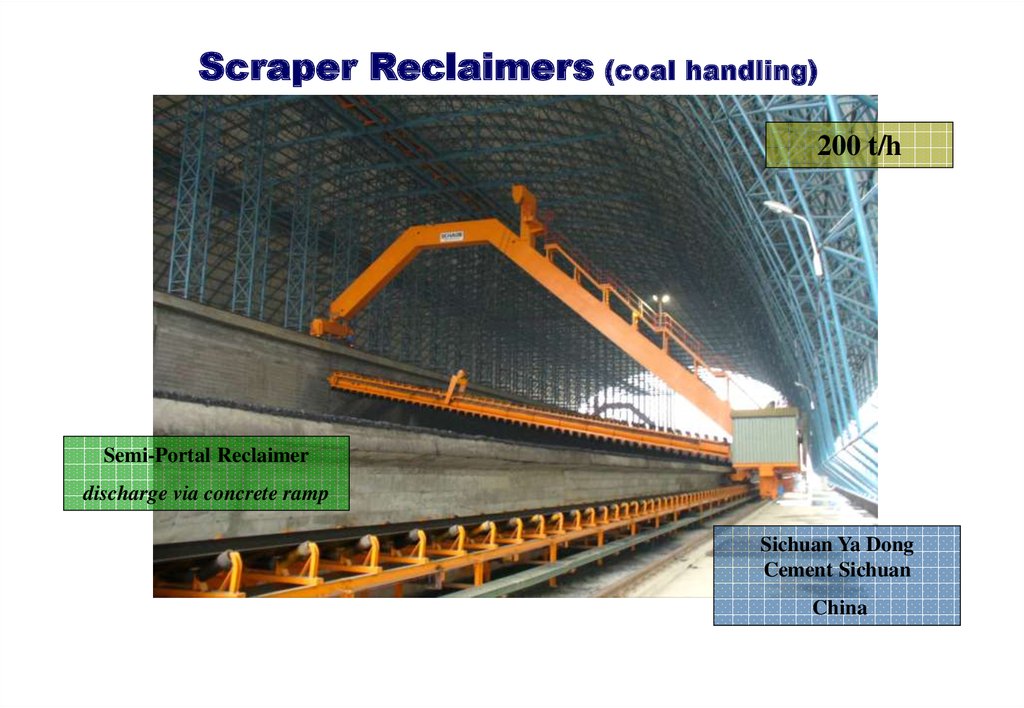

Scraper Reclaimers (coal handling)200 t/h

Semi-Portal Reclaimer

discharge via concrete ramp

Sichuan Ya Dong

Cement Sichuan

China

35.

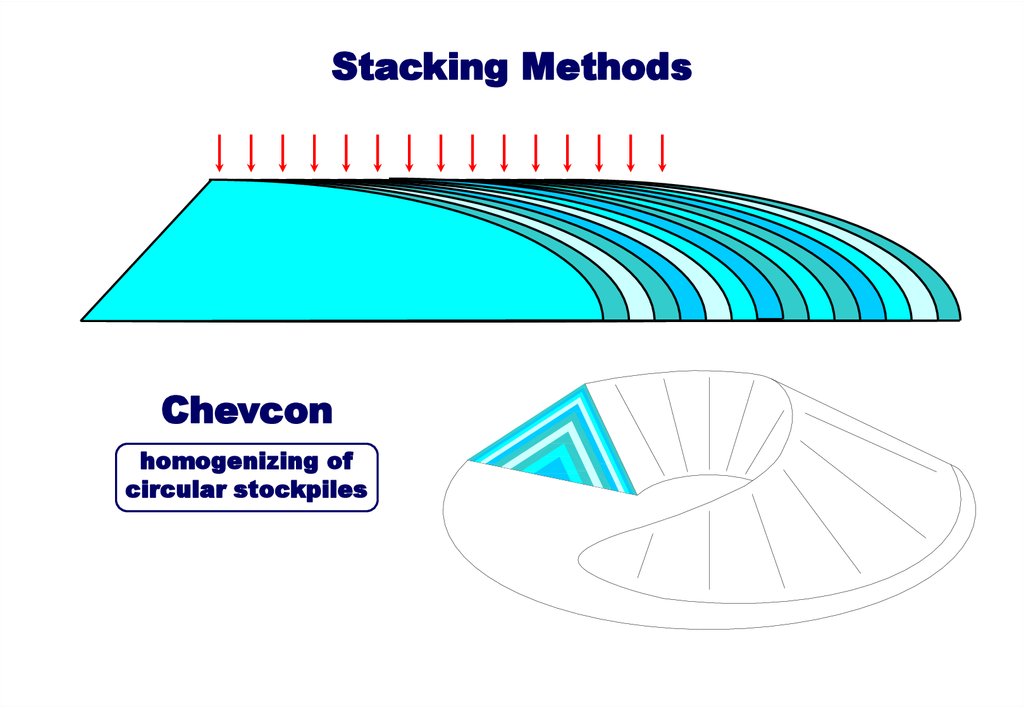

Stacking MethodsChevcon

homogenizing of

circular stockpiles

36.

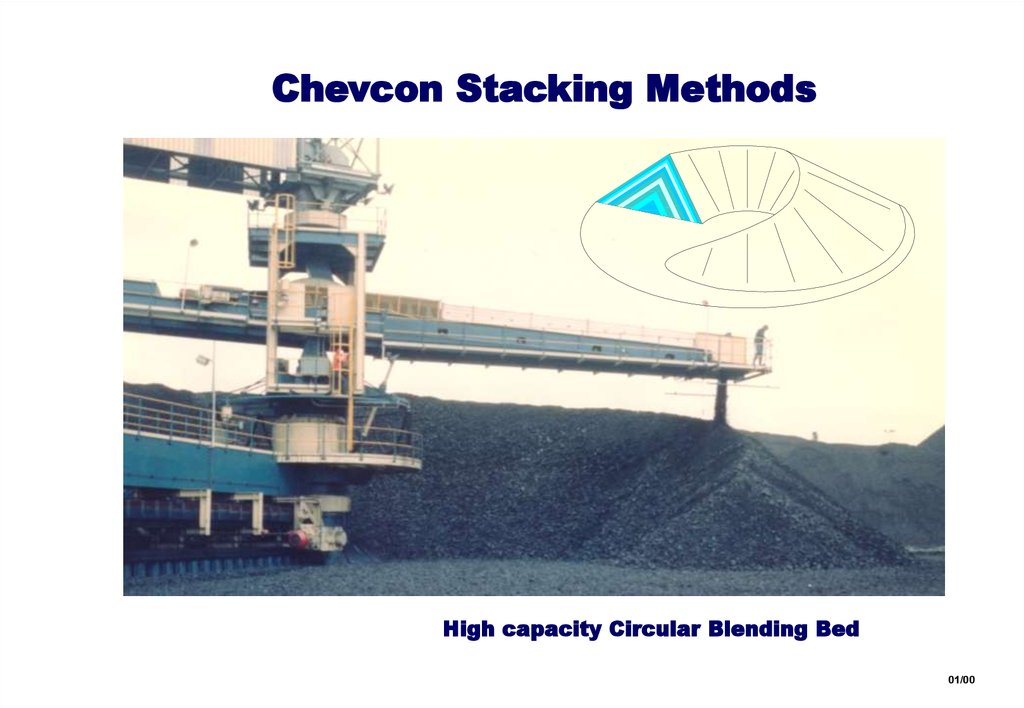

Chevcon Stacking MethodsHigh capacity Circular Blending Bed

01/00

37.

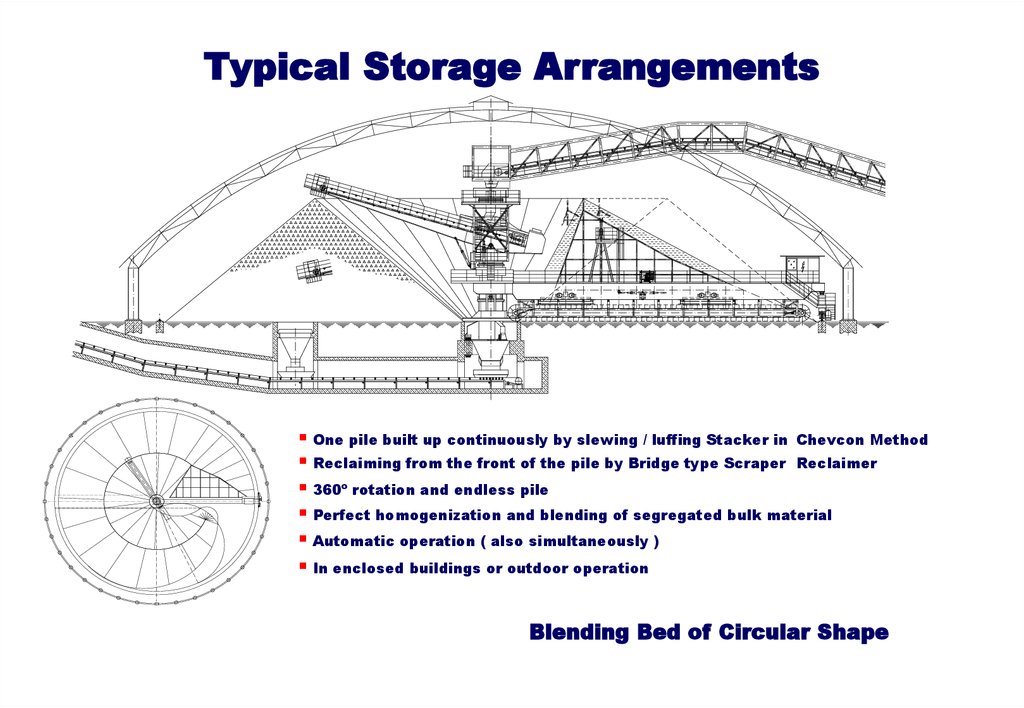

Typical Storage ArrangementsOne pile built up continuously by slewing / luffing Stacker in Chevcon Method

Reclaiming from the front of the pile by Bridge type Scraper Reclaimer

360º rotation and endless pile

Perfect homogenization and blending of segregated bulk material

Automatic operation ( also simultaneously )

In enclosed buildings or outdoor operation

Blending Bed of Circular Shape

38.

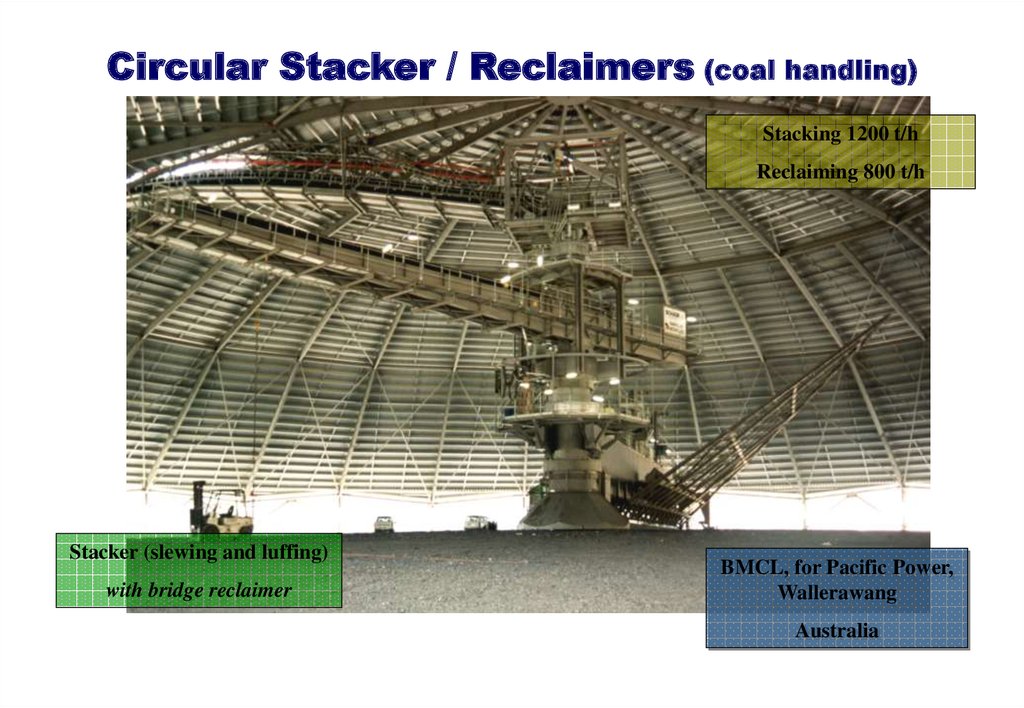

Circular Stacker / Reclaimers (coal handling)Stacking 1200 t/h

Reclaiming 800 t/h

Stacker (slewing and luffing)

with bridge reclaimer

BMCL, for Pacific Power,

Wallerawang

Australia

39.

Circular Stacker / Reclaimers (coal handling)JCI Arthur Taylor Collieries

Stacking 1200 t/h

South-Africa

Reclaiming 1200 t/h

Stacker (slewing and luffing)

with bridge reclaimer

40.

Typical Storage ArrangementsLess space required as with storages of longitudinal shape

Large storage capacities on small base area

Stockpile built up by Slewing Stacker

Reclaiming from the inner side slope of the pile by slewing/luffing scraper

boom

Automatic operation ( also simultaneously )

Buffer Storage of Circular Shape

41.

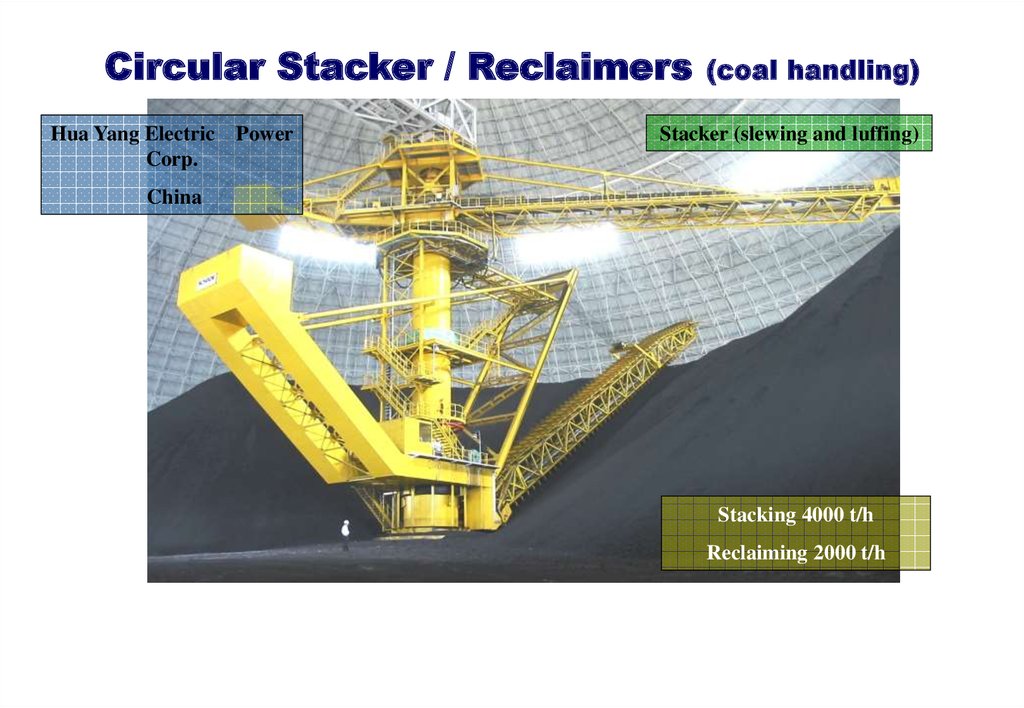

Circular Stacker / ReclaimersHua Yang Electric

Corp.

Power

(coal handling)

Stacker (slewing and luffing)

China

Stacking 4000 t/h

Reclaiming 2000 t/h

42.

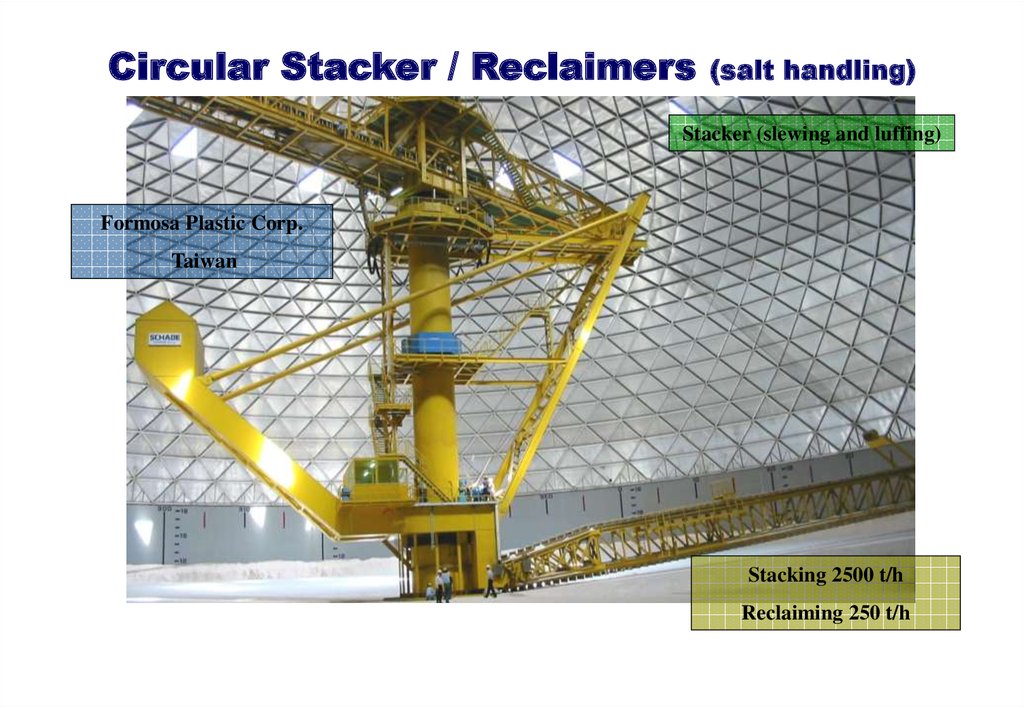

Circular Stacker / Reclaimers(salt handling)

Stacker (slewing and luffing)

Formosa Plastic Corp.

Taiwan

Stacking 2500 t/h

Reclaiming 250 t/h

43.

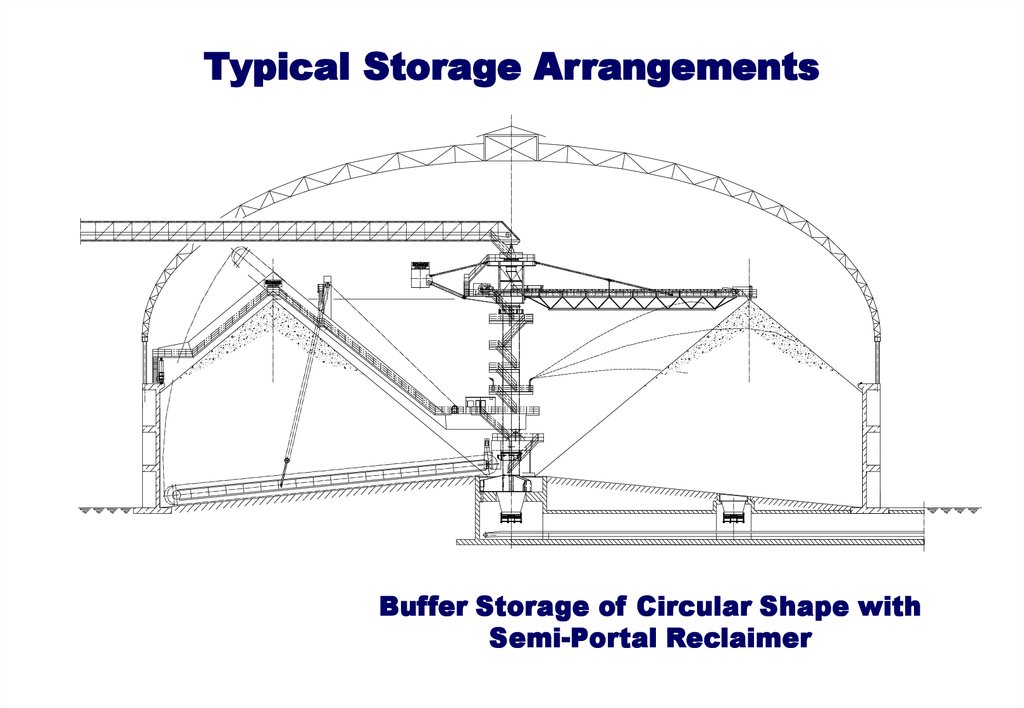

Typical Storage ArrangementsBuffer Storage of Circular Shape with

Semi-Portal Reclaimer

44.

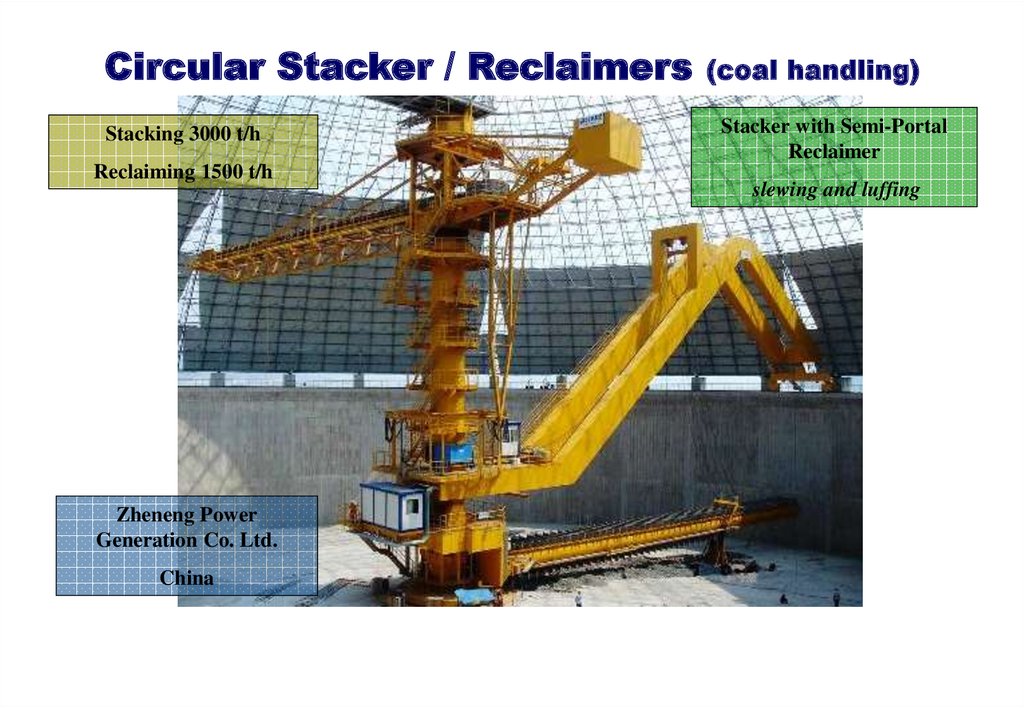

Circular Stacker / ReclaimersStacking 3000 t/h

Reclaiming 1500 t/h

Zheneng Power

Generation Co. Ltd.

China

(coal handling)

Stacker with Semi-Portal

Reclaimer

slewing and luffing

45.

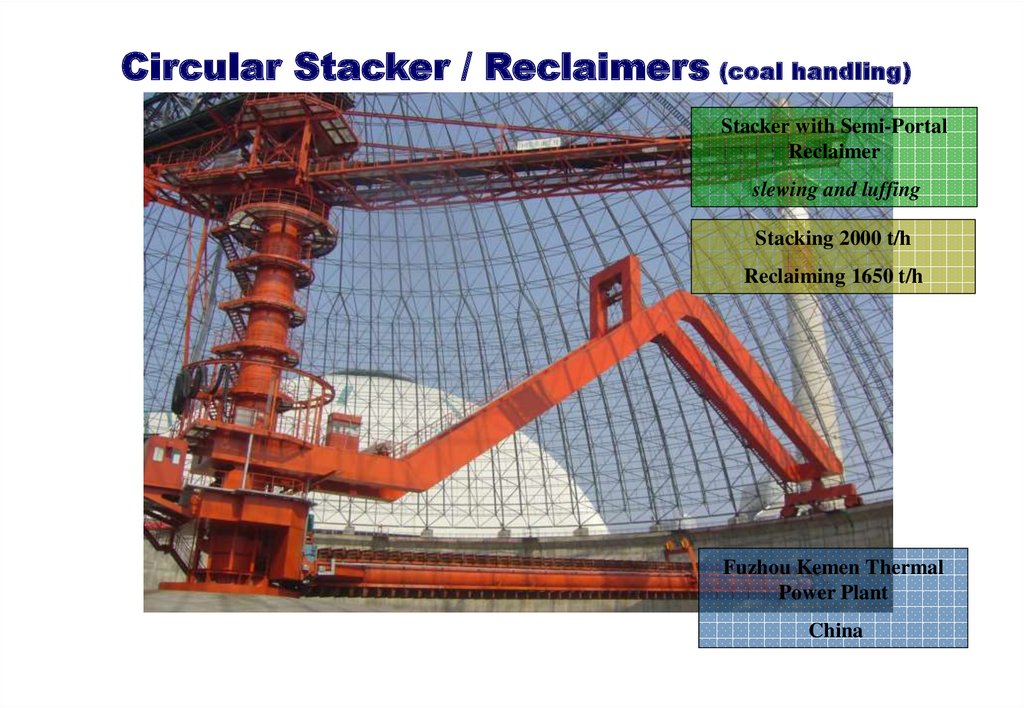

Circular Stacker / Reclaimers (coal handling)Stacker with Semi-Portal

Reclaimer

slewing and luffing

Stacking 2000 t/h

Reclaiming 1650 t/h

Fuzhou Kemen Thermal

Power Plant

China

46.

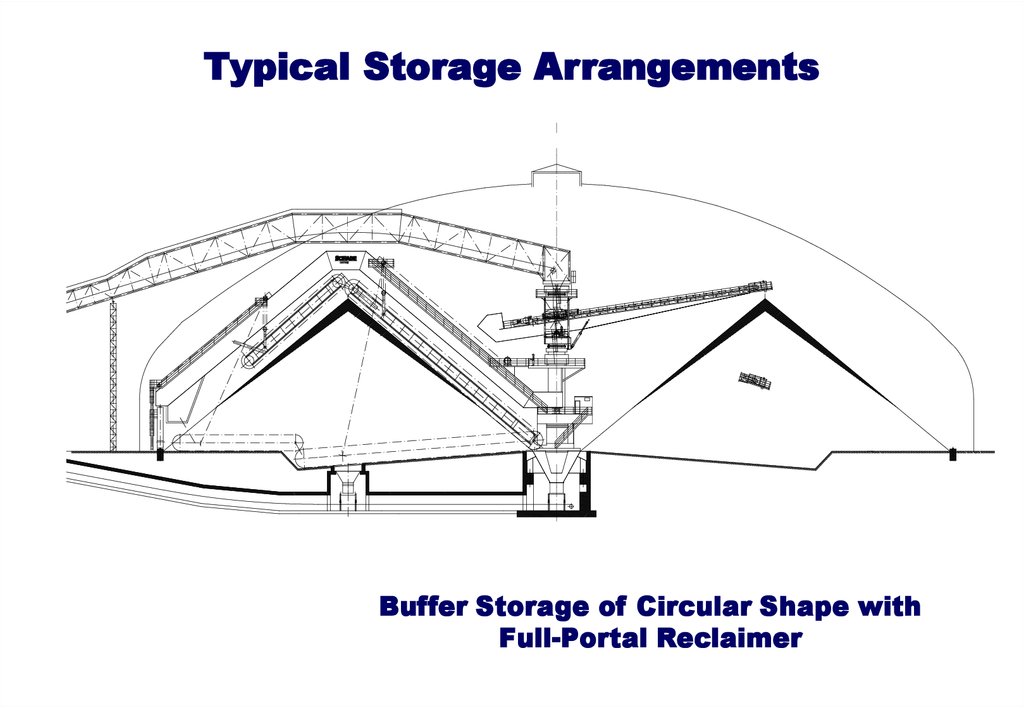

Typical Storage ArrangementsBuffer Storage of Circular Shape with

Full-Portal Reclaimer

47.

Typical Storage ArrangementsCircular Storages

FPC – Mai Liao Plant

Taiwan

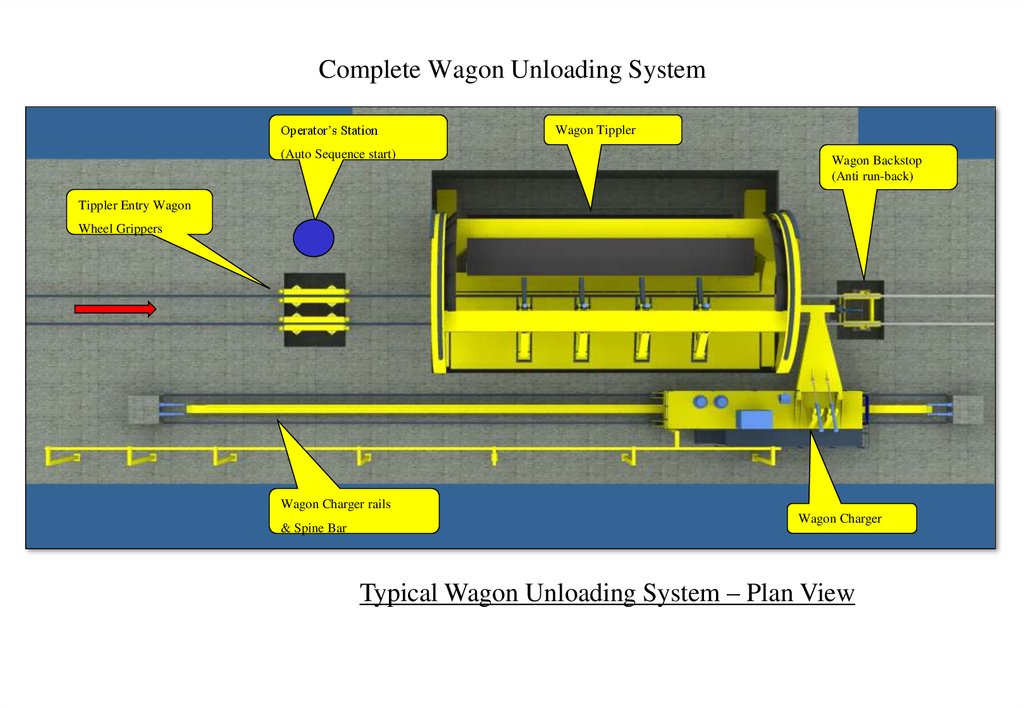

48. Complete Wagon Unloading System

Operator’s Station(Auto Sequence start)

Wagon Tippler

Wagon Backstop

(Anti run-back)

Tippler Entry Wagon

Wheel Grippers

Wagon Charger rails

& Spine Bar

Wagon Charger

Typical Wagon Unloading System – Plan View

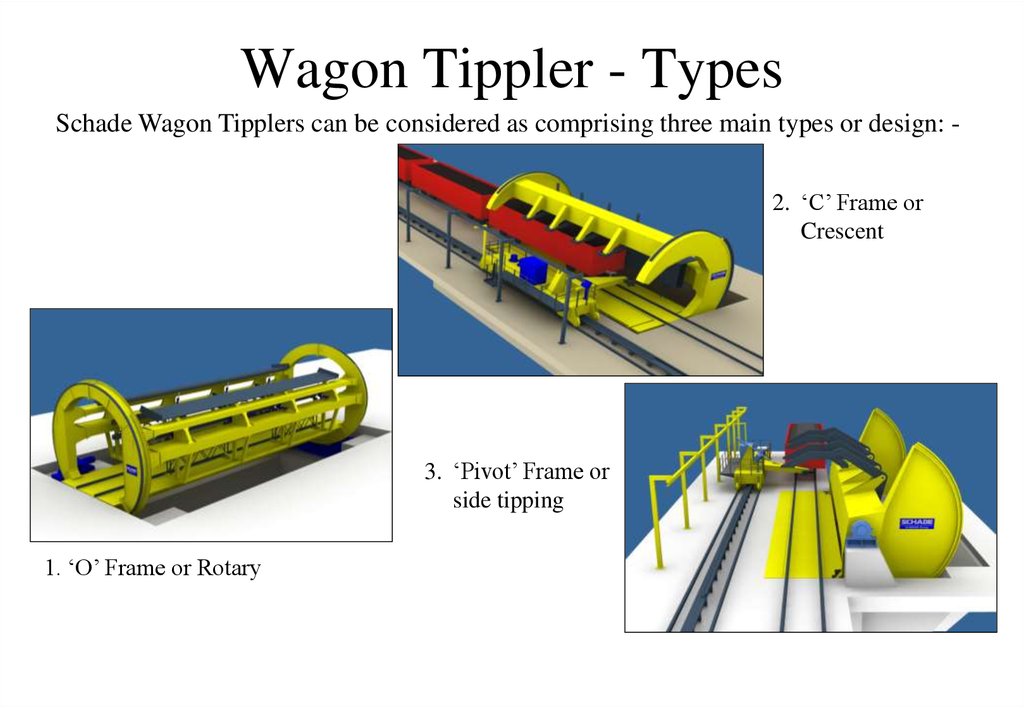

49. Wagon Tippler - Types

Schade Wagon Tipplers can be considered as comprising three main types or design: 2. ‘C’ Frame orCrescent

3. ‘Pivot’ Frame or

side tipping

1. ‘O’ Frame or Rotary

industry

industry