Similar presentations:

Arc Welding Function

1.

Arc Welding FunctionSpecial Training

2.

CONTENTS01

Welding function instruction and programming operation

02

Welding power parameter setting

03

Multilayer and multichannel function

04

Touch sense function

让智造更简单

MAKING SMART MORE SIMPLE

3.

PART 01Welding Function Instruction and

Programming Operation

让智造更简单

MAKING SMART MORE SIMPLE

4.

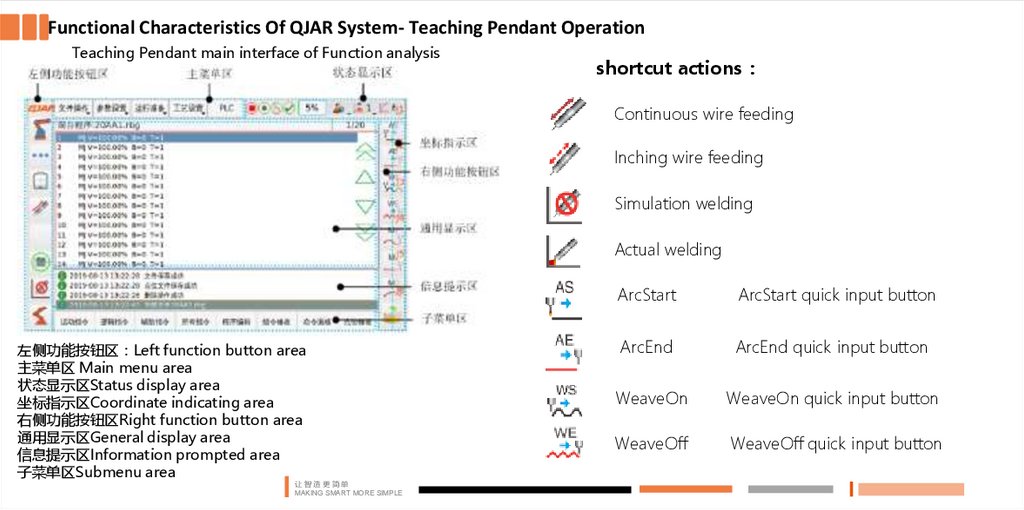

Functional Characteristics Of QJAR System- Teaching Pendant OperationTeaching Pendant main interface of Function analysis

shortcut actions

Continuous wire feeding

Inching wire feeding

Simulation welding

Actual welding

左侧功能按钮区 Left function button area

主菜单区 Main menu area

状态显示区Status display area

坐标指示区Coordinate indicating area

右侧功能按钮区Right function button area

通用显示区General display area

信息提示区Information prompted area

子菜单区Submenu area

让智造更简单

MAKING SMART MORE SIMPLE

ArcStart

ArcStart quick input button

ArcEnd

ArcEnd quick input button

WeaveOn

WeaveOn quick input button

WeaveOff

WeaveOff quick input button

5.

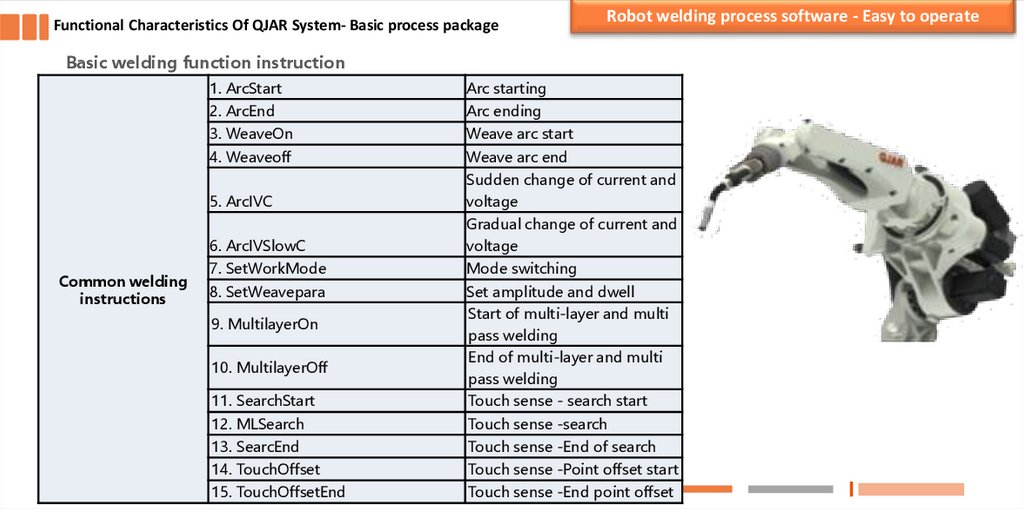

Functional Characteristics Of QJAR System- Basic process packageRobot welding process software - Easy to operate

Basic welding function instruction

Common welding

instructions

1. ArcStart

Arc starting

2. ArcEnd

Arc ending

3. WeaveOn

Weave arc start

4. Weaveoff

Weave arc end

5. ArcIVC

Sudden change of current and

voltage

6. ArcIVSlowC

Gradual change of current and

voltage

7. SetWorkMode

Mode switching

8. SetWeavepara

Set amplitude and dwell

Start of multi-layer and multi

pass welding

End of multi-layer and multi

pass welding

9. MultilayerOn

10. MultilayerOff

11. SearchStart

Touch sense - search start

12. MLSearch

Touch sense -search

13. SearcEnd

Touch sense -End of search

14. TouchOffset

Touch sense -Point offset start

让智造更简单

MAKING SMART MORE SIMPLE

15. TouchOffsetEnd

Touch sense -End point offset

6.

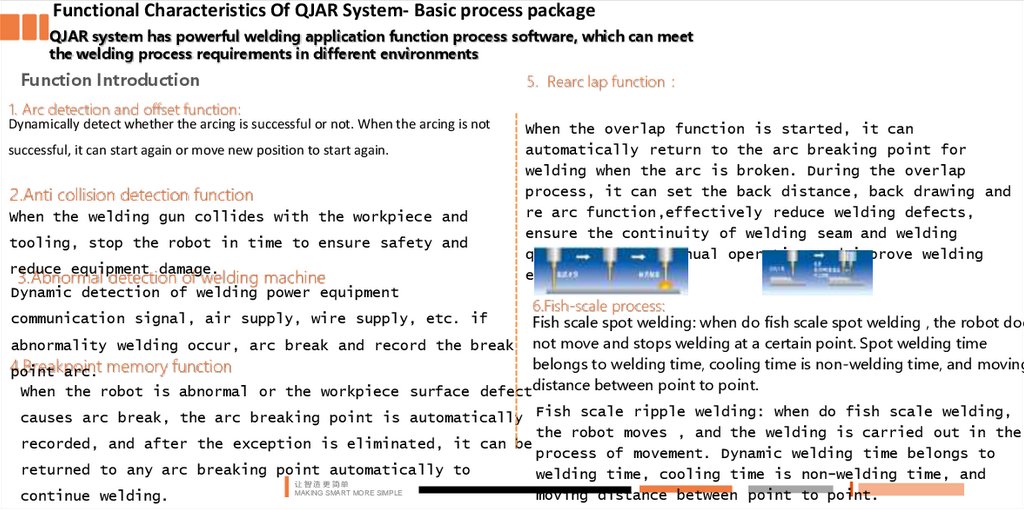

Functional Characteristics Of QJAR System- Basic process packageQJAR system has powerful welding application function process software, which can meet

the welding process requirements in different environments

Function Introduction

1. Arc detection and offset function:

Dynamically detect whether the arcing is successful or not. When the arcing is not

successful, it can start again or move new position to start again.

2.Anti collision detection function

When the welding gun collides with the workpiece and

tooling, stop the robot in time to ensure safety and

reduce equipment damage.

3.Abnormal detection of welding machine

Dynamic detection of welding power equipment

5. Rearc lap function

When the overlap function is started, it can

automatically return to the arc breaking point for

welding when the arc is broken. During the overlap

process, it can set the back distance, back drawing and

re arc function,effectively reduce welding defects,

ensure the continuity of welding seam and welding

quality, reduce manual operation and improve welding

efficiency.

6.Fish-scale process:

Fish scale spot welding: when do fish scale spot welding , the robot doe

abnormality welding occur, arc break and record the break not move and stops welding at a certain point. Spot welding time

belongs to welding time, cooling time is non-welding time, and moving

4.Breakpoint

point arc. memory function

When the robot is abnormal or the workpiece surface defectdistance between point to point.

causes arc break, the arc breaking point is automatically Fish scale ripple welding: when do fish scale welding,

the robot moves , and the welding is carried out in the

recorded, and after the exception is eliminated, it can be

process of movement. Dynamic welding time belongs to

returned to any arc breaking point automatically to

welding time, cooling time is non-welding time, and

让智造更简单

MAKING SMART MORE SIMPLE

moving distance between point to point.

continue welding.

communication signal, air supply, wire supply, etc. if

7.

Functional Characteristics Of QJAR System- Basic process packageFunction Introduction

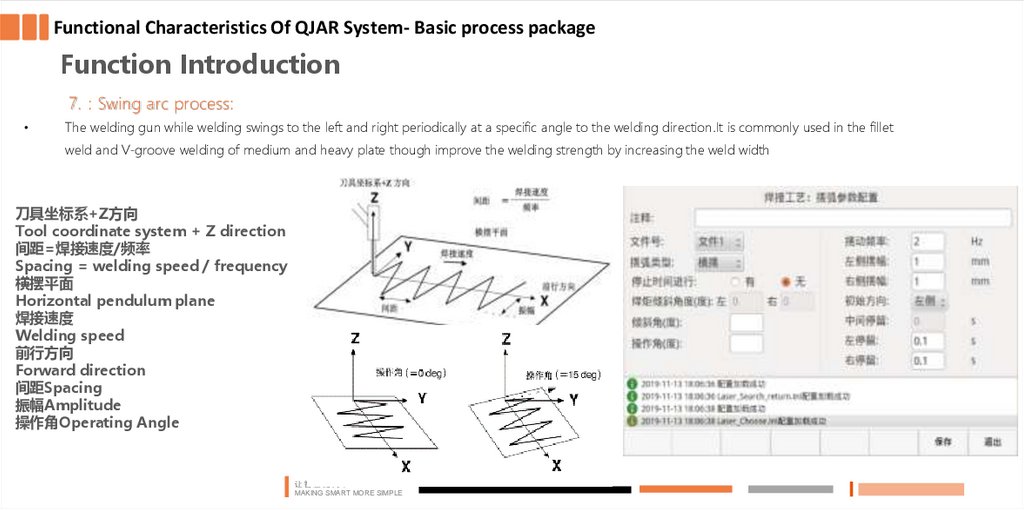

7. Swing arc process:

The welding gun while welding swings to the left and right periodically at a specific angle to the welding direction.It is commonly used in the fillet

weld and V-groove welding of medium and heavy plate though improve the welding strength by increasing the weld width

刀具坐标系+Z方向

Tool coordinate system + Z direction

间距=焊接速度/频率

Spacing = welding speed / frequency

横摆平面

Horizontal pendulum plane

焊接速度

Welding speed

前行方向

Forward direction

间距Spacing

振幅Amplitude

操作角Operating Angle

让智造更简单

MAKING SMART MORE SIMPLE

8.

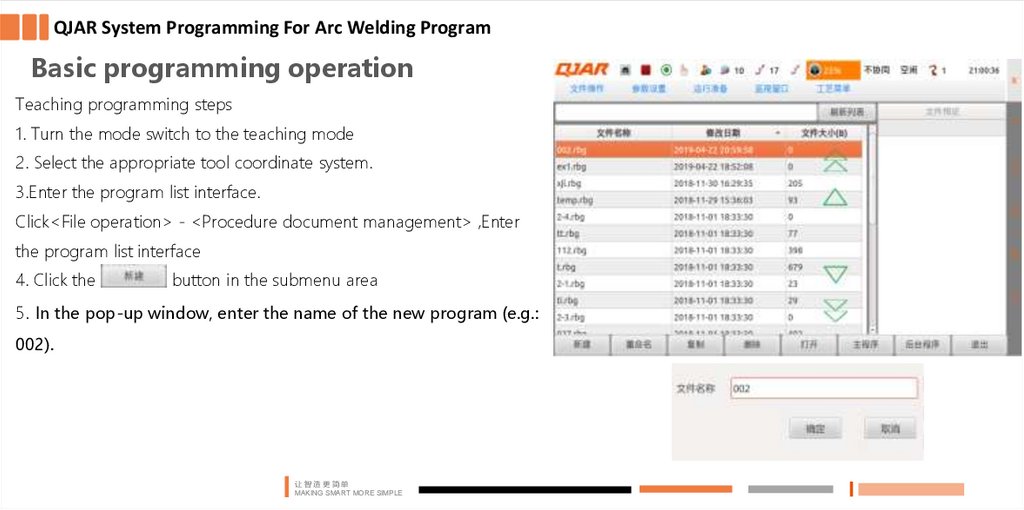

QJAR System Programming For Arc Welding ProgramBasic programming operation

Teaching programming steps

1. Turn the mode switch to the teaching mode

2. Select the appropriate tool coordinate system.

3.Enter the program list interface.

Click<File operation> - <Procedure document management> ,Enter

the program list interface

4. Click the

button in the submenu area

5. In the pop-up window, enter the name of the new program (e.g.:

002).

让智造更简单

MAKING SMART MORE SIMPLE

9.

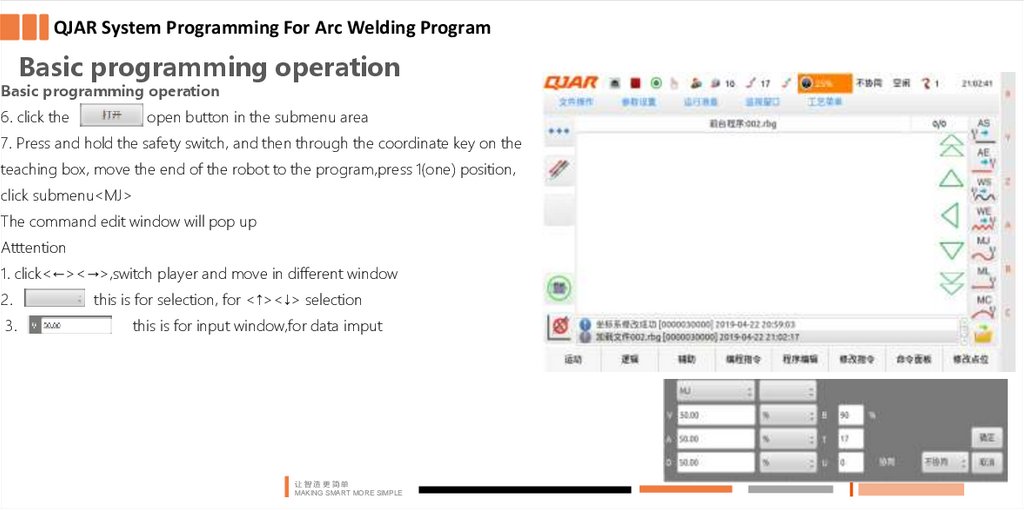

QJAR System Programming For Arc Welding ProgramBasic programming operation

Basic programming operation

6. click the

open button in the submenu area

7. Press and hold the safety switch, and then through the coordinate key on the

teaching box, move the end of the robot to the program,press 1(one) position,

click submenu<MJ>

The command edit window will pop up

Atttention

1. click<←><→>,switch player and move in different window

2.

3.

this is for selection, for <↑><↓> selection

this is for input window,for data imput

让智造更简单

MAKING SMART MORE SIMPLE

10.

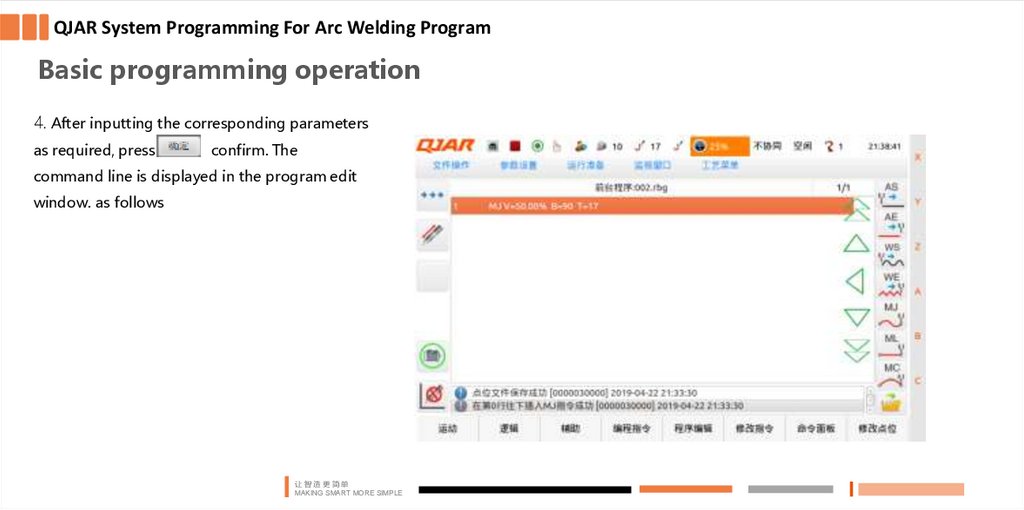

QJAR System Programming For Arc Welding ProgramBasic programming operation

4. After inputting the corresponding parameters

as required, press

confirm. The

command line is displayed in the program edit

window. as follows

让智造更简单

MAKING SMART MORE SIMPLE

11.

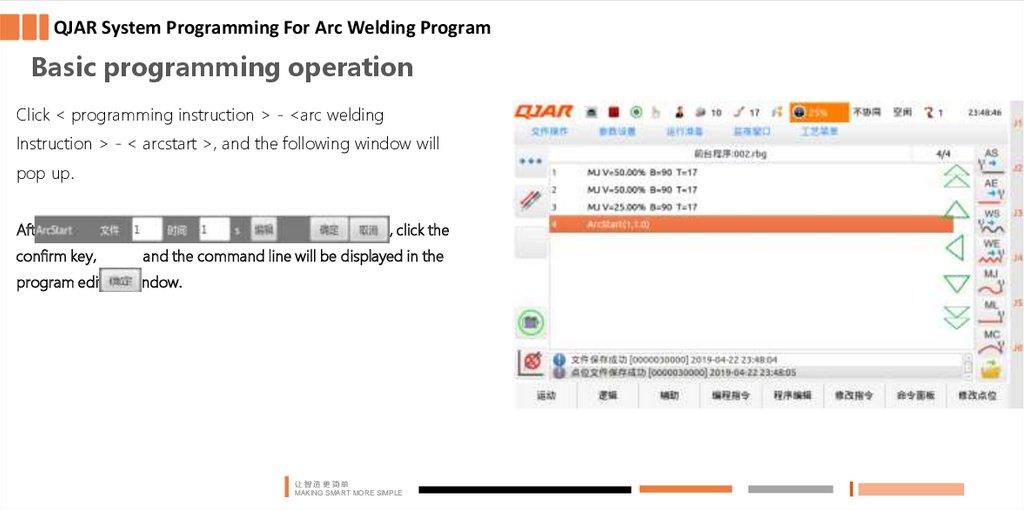

QJAR System Programming For Arc Welding ProgramBasic programming operation

Click < programming instruction > - <arc welding

Instruction > - < arcstart >, and the following window will

pop up.

After entering the corresponding parameters as required, click the

confirm key,

and the command line will be displayed in the

program editing window.

让智造更简单

MAKING SMART MORE SIMPLE

12.

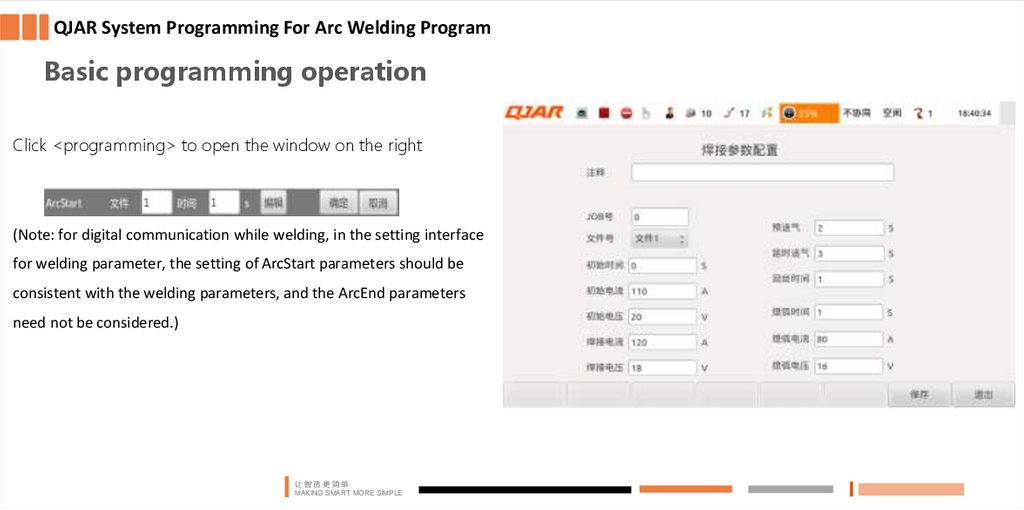

QJAR System Programming For Arc Welding ProgramBasic programming operation

Click <programming> to open the window on the right

(Note: for digital communication while welding, in the setting interface

for welding parameter, the setting of ArcStart parameters should be

consistent with the welding parameters, and the ArcEnd parameters

need not be considered.)

让智造更简单

MAKING SMART MORE SIMPLE

13.

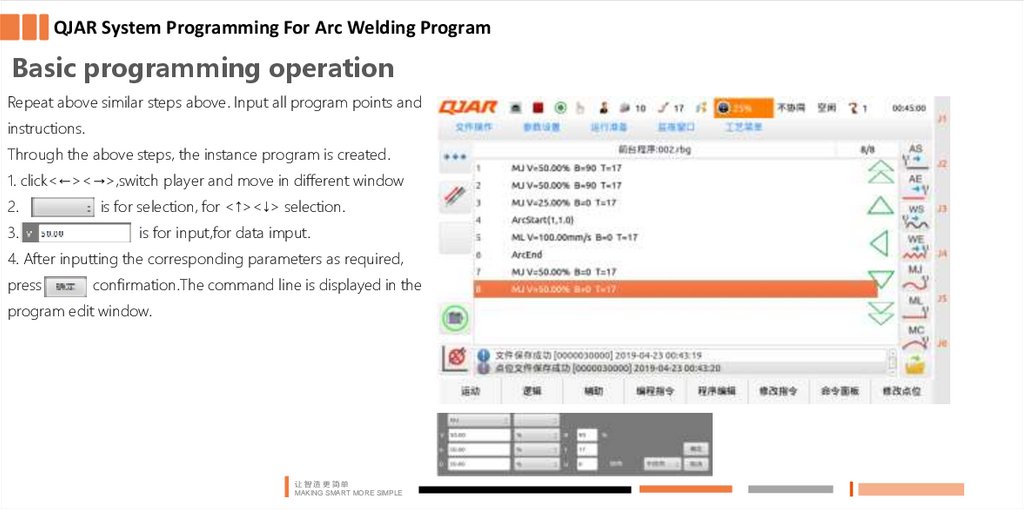

QJAR System Programming For Arc Welding ProgramBasic programming operation

Repeat above similar steps above. Input all program points and

instructions.

Through the above steps, the instance program is created.

1. click<←><→>,switch player and move in different window

2.

is for selection, for <↑><↓> selection.

3.

is for input,for data imput.

4. After inputting the corresponding parameters as required,

press

confirmation.The command line is displayed in the

program edit window.

让智造更简单

MAKING SMART MORE SIMPLE

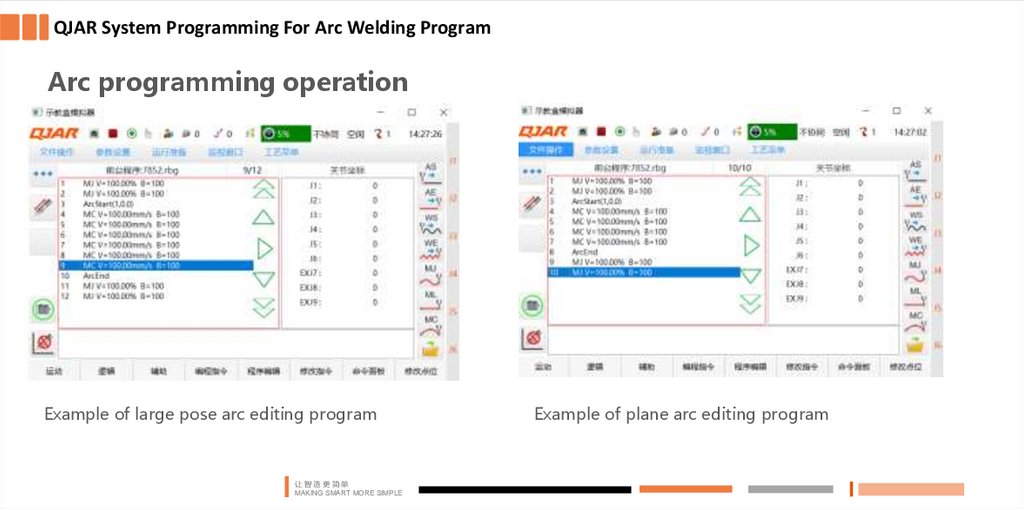

14.

QJAR System Programming For Arc Welding ProgramArc programming operation

Example of large pose arc editing program

让智造更简单

MAKING SMART MORE SIMPLE

Example of plane arc editing program

15.

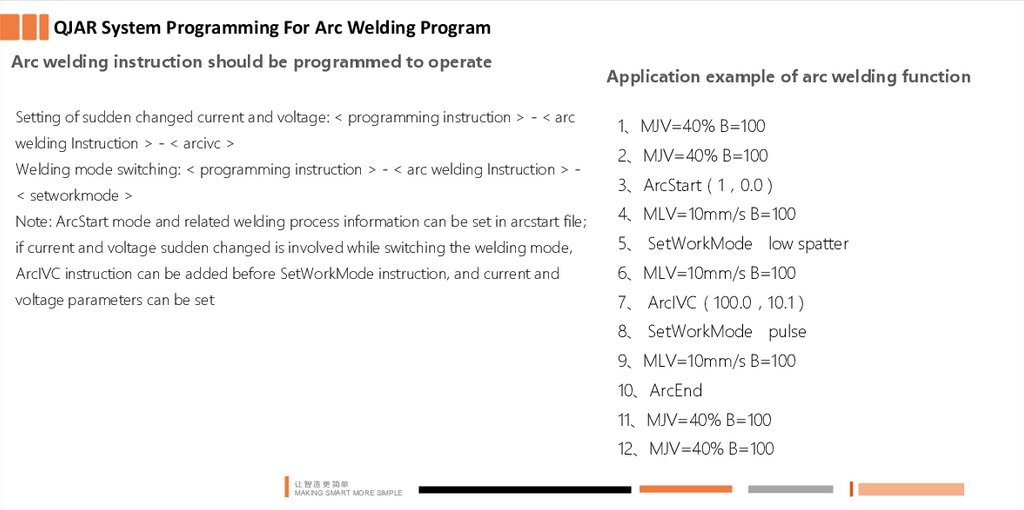

QJAR System Programming For Arc Welding ProgramArc welding instruction should be programmed to operate

Setting of sudden changed current and voltage: < programming instruction > - < arc

welding Instruction > - < arcivc >

Welding mode switching: < programming instruction > - < arc welding Instruction > < setworkmode >

Application example of arc welding function

1、MJV=40% B=100

2、MJV=40% B=100

3、ArcStart 1 0.0

Note: ArcStart mode and related welding process information can be set in arcstart file;

4、MLV=10mm/s B=100

if current and voltage sudden changed is involved while switching the welding mode,

5、 SetWorkMode low spatter

ArcIVC instruction can be added before SetWorkMode instruction, and current and

6、MLV=10mm/s B=100

voltage parameters can be set

7、 ArcIVC 100.0 10.1

8、 SetWorkMode pulse

9、MLV=10mm/s B=100

10、ArcEnd

11、MJV=40% B=100

12、MJV=40% B=100

让智造更简单

MAKING SMART MORE SIMPLE

16.

PART 02Arc welding power source

communication and application setting

让智造更简单

MAKING SMART MORE SIMPLE

17.

Communication And Application Of Arc Welding Power SourceAnalog / digital welding power management:

Support Aotai and Megmeet and other

analog/digital welding source.

The welding source configuration can be settled

and configured by pressing the button to select the

model.The operation is simple and fast.

Analog welding power, current and voltage is set

with ten gear value with multiple intervals, which

can more accurately match the current and voltage

Analog communication

让智造更简单

MAKING SMART MORE SIMPLE

Digital communication

18.

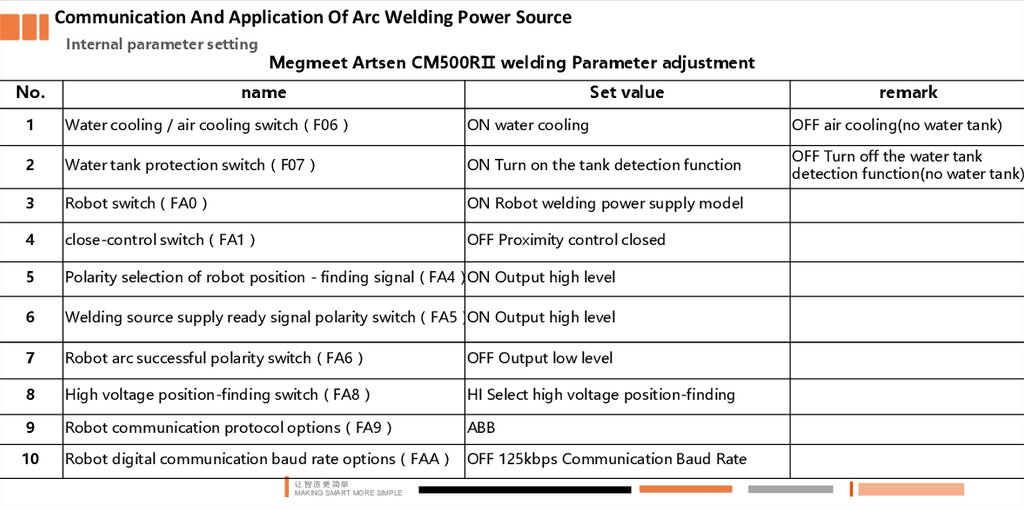

Communication And Application Of Arc Welding Power SourceInternal parameter setting

No.

Megmeet Artsen CM500RⅡ welding Parameter adjustment

name

Set value

remark

1

Water cooling / air cooling switch F06

ON water cooling

OFF air cooling(no water tank)

2

Water tank protection switch F07

ON Turn on the tank detection function

OFF Turn off the water tank

detection function(no water tank)

3

Robot switch FA0

ON Robot welding power supply model

4

close-control switch FA1

OFF Proximity control closed

5

Polarity selection of robot position - finding signal FA4 ON Output high level

6

Welding source supply ready signal polarity switch FA5 ON Output high level

7

Robot arc successful polarity switch FA6

OFF Output low level

8

High voltage position-finding switch FA8

HI Select high voltage position-finding

9

Robot communication protocol options FA9

ABB

10

Robot digital communication baud rate options FAA OFF 125kbps Communication Baud Rate

让智造更简单

MAKING SMART MORE SIMPLE

19.

PART 03Multilayer and multipass arc welding

function

让智造更简单

MAKING SMART MORE SIMPLE

20.

Multilayer and multipass arc welding functionMultilayer and multichannel arc welding function introduction

The multi-layer welding function has the following two functions

Memory and reproduction function of welding path: This is a function of

storing the compensation data obtained by tracking sensors such as arc

sensor in the memory called "path data", which should be used for the

second welding after the first time.

Welding path offset function: This is a function based on the data of the

position register to offset the welding path after the second layer on the

whole. At this time, the offset method is a special method for multi-layer

welding function.

让智造更简单

MAKING SMART MORE SIMPLE

21.

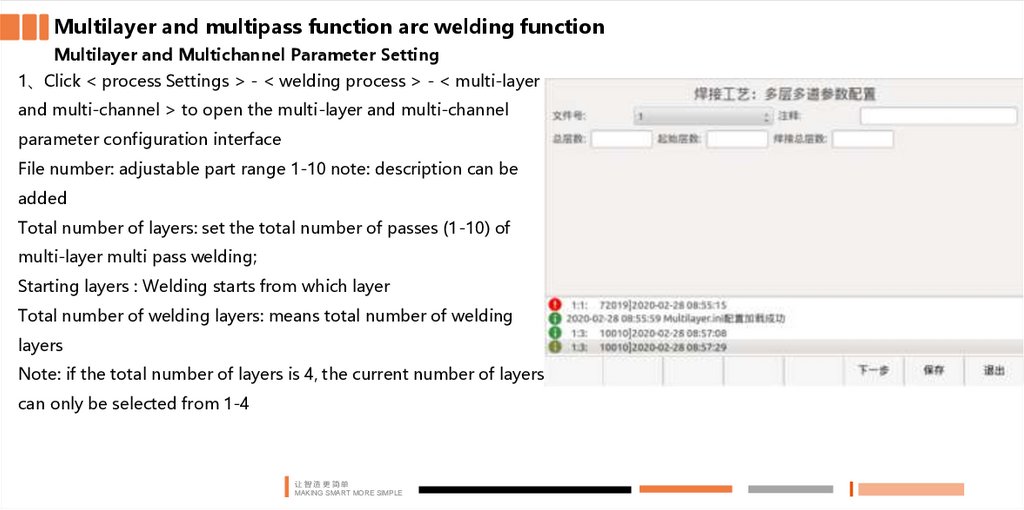

Multilayer and multipass function arc welding functionMultilayer and Multichannel Parameter Setting

1、Click < process Settings > - < welding process > - < multi-layer

and multi-channel > to open the multi-layer and multi-channel

parameter configuration interface

File number: adjustable part range 1-10 note: description can be

added

Total number of layers: set the total number of passes (1-10) of

multi-layer multi pass welding;

Starting layers : Welding starts from which layer

Total number of welding layers: means total number of welding

layers

Note: if the total number of layers is 4, the current number of layers

can only be selected from 1-4

让智造更简单

MAKING SMART MORE SIMPLE

22.

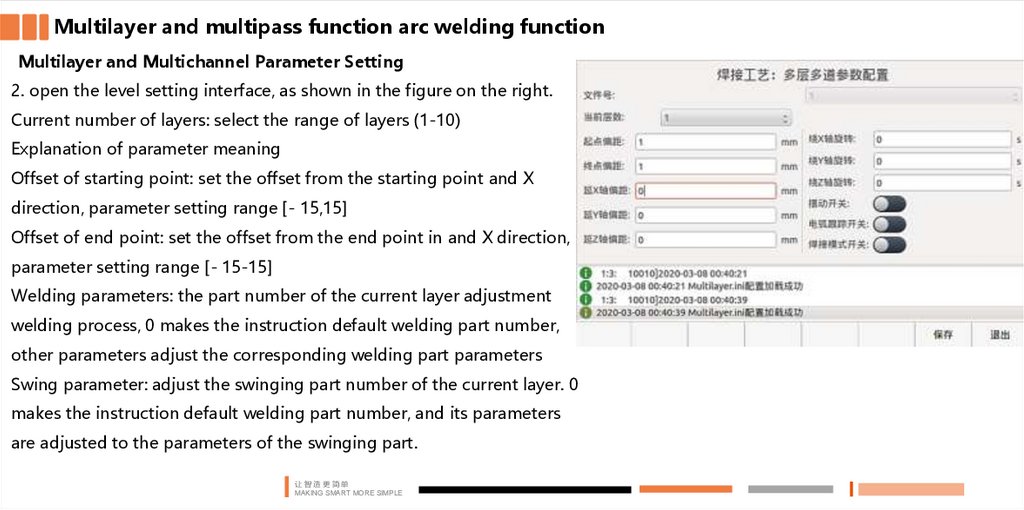

Multilayer and multipass function arc welding functionMultilayer and Multichannel Parameter Setting

2. open the level setting interface, as shown in the figure on the right.

Current number of layers: select the range of layers (1-10)

Explanation of parameter meaning

Offset of starting point: set the offset from the starting point and X

direction, parameter setting range [- 15,15]

Offset of end point: set the offset from the end point in and X direction,

parameter setting range [- 15-15]

Welding parameters: the part number of the current layer adjustment

welding process, 0 makes the instruction default welding part number,

other parameters adjust the corresponding welding part parameters

Swing parameter: adjust the swinging part number of the current layer. 0

makes the instruction default welding part number, and its parameters

are adjusted to the parameters of the swinging part.

让智造更简单

MAKING SMART MORE SIMPLE

23.

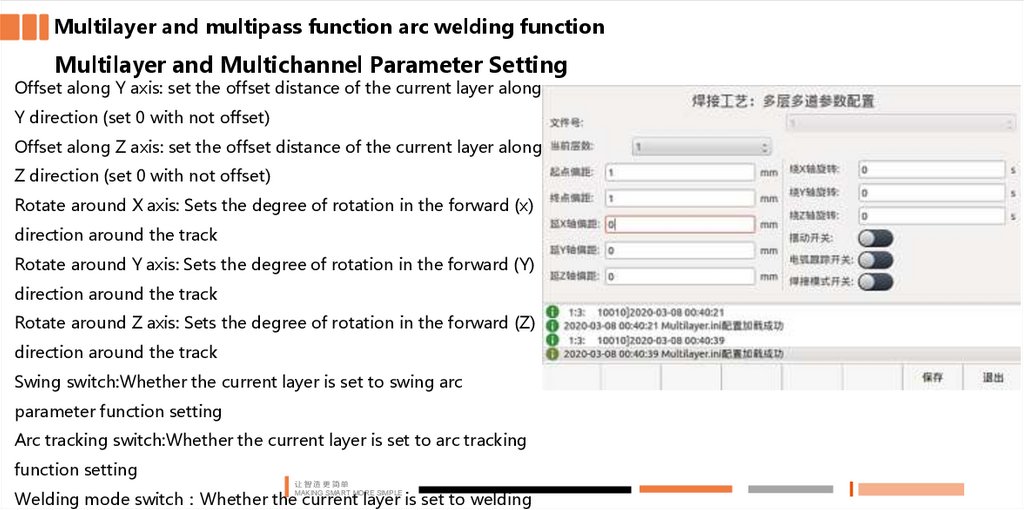

Multilayer and multipass function arc welding functionMultilayer and Multichannel Parameter Setting

Offset along Y axis: set the offset distance of the current layer along

Y direction (set 0 with not offset)

Offset along Z axis: set the offset distance of the current layer along

Z direction (set 0 with not offset)

Rotate around X axis: Sets the degree of rotation in the forward (x)

direction around the track

Rotate around Y axis: Sets the degree of rotation in the forward (Y)

direction around the track

Rotate around Z axis: Sets the degree of rotation in the forward (Z)

direction around the track

Swing switch:Whether the current layer is set to swing arc

parameter function setting

Arc tracking switch:Whether the current layer is set to arc tracking

function setting

让智造更简单

MAKING SMART MORE SIMPLE

Welding mode switch Whether the current layer is set to welding

24.

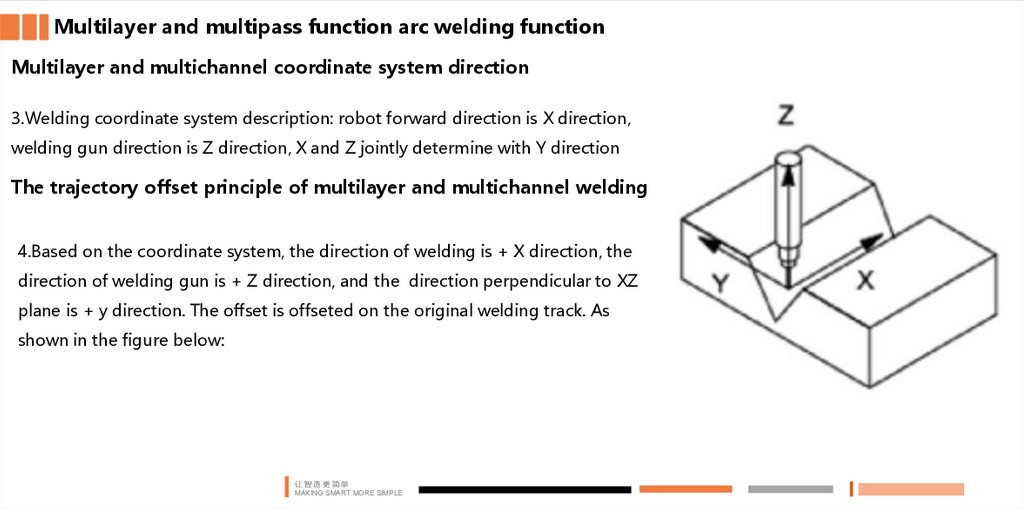

Multilayer and multipass function arc welding functionMultilayer and multichannel coordinate system direction

3.Welding coordinate system description: robot forward direction is X direction,

welding gun direction is Z direction, X and Z jointly determine with Y direction

The trajectory offset principle of multilayer and multichannel welding

4.Based on the coordinate system, the direction of welding is + X direction, the

direction of welding gun is + Z direction, and the direction perpendicular to XZ

plane is + y direction. The offset is offseted on the original welding track. As

shown in the figure below:

让智造更简单

MAKING SMART MORE SIMPLE

25.

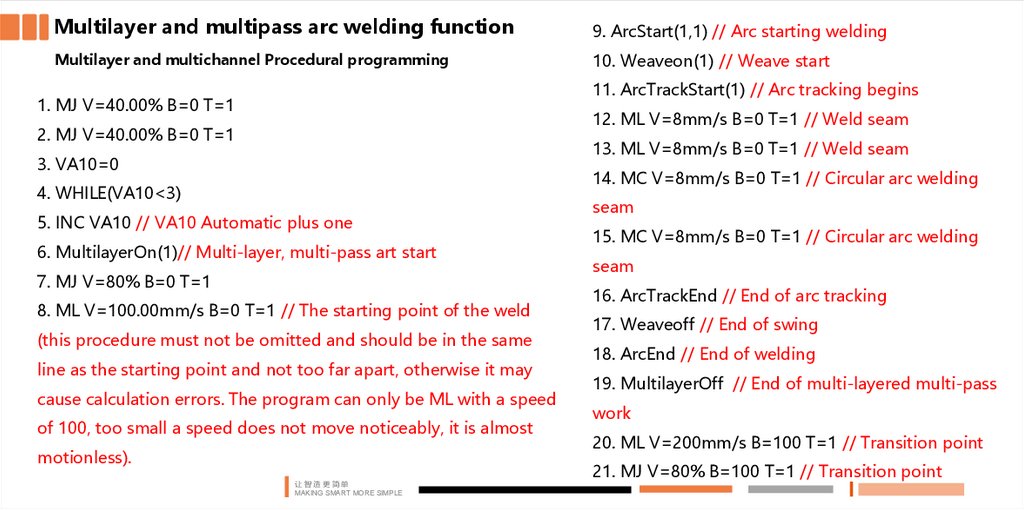

Multilayer and multipass arc welding function9. ArcStart(1,1) // Arc starting welding

Multilayer and multichannel Procedural programming

10. Weaveon(1) // Weave start

11. ArcTrackStart(1) // Arc tracking begins

1. MJ V=40.00% B=0 T=1

12. ML V=8mm/s B=0 T=1 // Weld seam

2. MJ V=40.00% B=0 T=1

13. ML V=8mm/s B=0 T=1 // Weld seam

3. VA10=0

14. MC V=8mm/s B=0 T=1 // Circular arc welding

4. WHILE(VA10<3)

5. INC VA10 // VA10 Automatic plus one

6. MultilayerOn(1)// Multi-layer, multi-pass art start

7. MJ V=80% B=0 T=1

8. ML V=100.00mm/s B=0 T=1 // The starting point of the weld

(this procedure must not be omitted and should be in the same

line as the starting point and not too far apart, otherwise it may

cause calculation errors. The program can only be ML with a speed

of 100, too small a speed does not move noticeably, it is almost

motionless).

让智造更简单

MAKING SMART MORE SIMPLE

seam

15. MC V=8mm/s B=0 T=1 // Circular arc welding

seam

16. ArcTrackEnd // End of arc tracking

17. Weaveoff // End of swing

18. ArcEnd // End of welding

19. MultilayerOff // End of multi-layered multi-pass

work

20. ML V=200mm/s B=100 T=1 // Transition point

21. MJ V=80% B=100 T=1 // Transition point

26.

Multilayer and multipass arc welding functionMultilayer and multichannel Procedural programming

22. MJ V=80% B=0 T=1 // Transition point

23. ENDWHILE

Note: In this program, the coordinate system follows the x-axis (x+) in the direction of the weld, the y-axis (y+)

perpendicular to the weld and the z-axis (z+) in the direction of the gun lift. When teaching, the number of layers is set

to the current number of layers, then the number of layers shown during teaching is the current set number of layers.

让智造更简单

MAKING SMART MORE SIMPLE

27.

PART 04Touch Sense

Function

让智造更简单

MAKING SMART MORE SIMPLE

28.

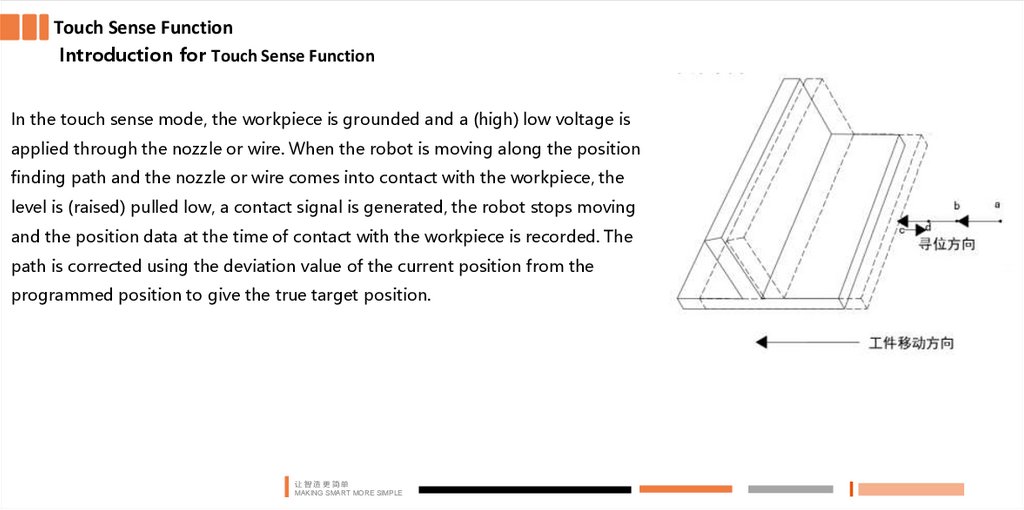

Touch Sense FunctionIntroduction for Touch Sense Function

In the touch sense mode, the workpiece is grounded and a (high) low voltage is

applied through the nozzle or wire. When the robot is moving along the position

finding path and the nozzle or wire comes into contact with the workpiece, the

level is (raised) pulled low, a contact signal is generated, the robot stops moving

and the position data at the time of contact with the workpiece is recorded. The

path is corrected using the deviation value of the current position from the

programmed position to give the true target position.

让智造更简单

MAKING SMART MORE SIMPLE

29.

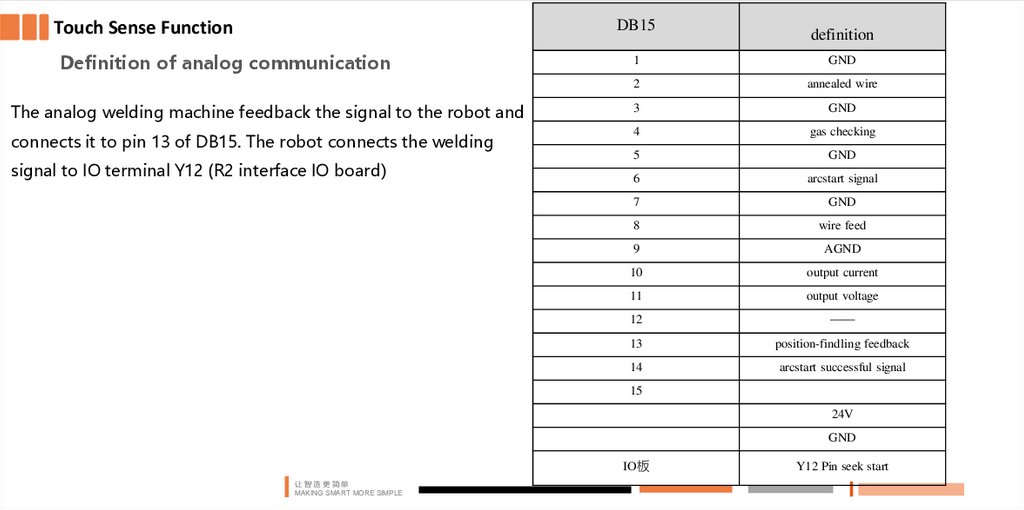

Touch Sense FunctionDB15

Definition of analog communication

definition

1

GND

2

annealed wire

The analog welding machine feedback the signal to the robot and

3

GND

connects it to pin 13 of DB15. The robot connects the welding

4

gas checking

signal to IO terminal Y12 (R2 interface IO board)

5

GND

6

arcstart signal

7

GND

8

wire feed

9

AGND

10

output current

11

output voltage

12

——

13

position-findling feedback

14

arcstart successful signal

15

24V

GND

IO板

让智造更简单

MAKING SMART MORE SIMPLE

Y12 Pin seek start

30.

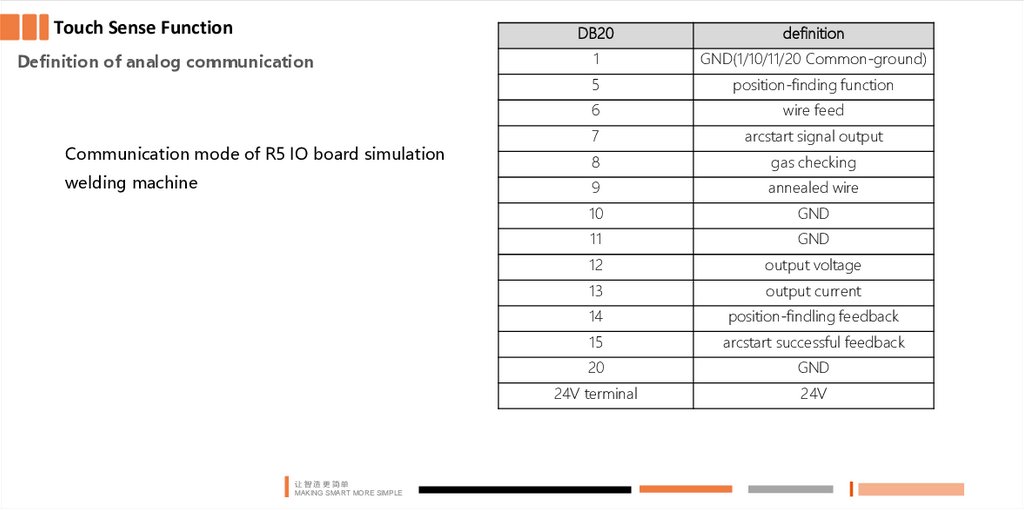

Touch Sense FunctionDefinition of analog communication

Communication mode of R5 IO board simulation

welding machine

让智造更简单

MAKING SMART MORE SIMPLE

DB20

definition

1

GND(1/10/11/20 Common-ground)

5

position-finding function

6

wire feed

7

arcstart signal output

8

gas checking

9

annealed wire

10

GND

11

GND

12

output voltage

13

output current

14

position-findling feedback

15

arcstart successful feedback

20

GND

24V terminal

24V

31.

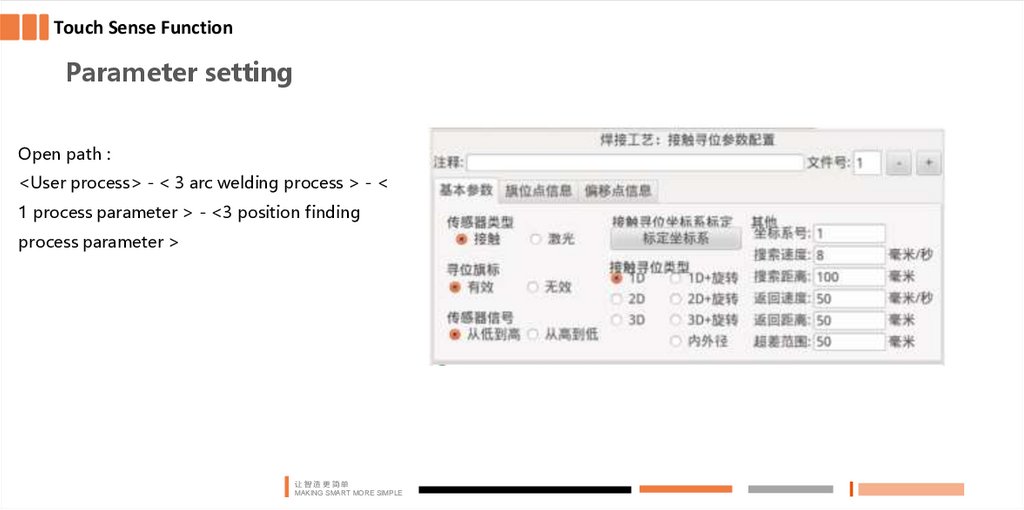

Touch Sense FunctionParameter setting

Open path :

<User process> - < 3 arc welding process > - <

1 process parameter > - <3 position finding

process parameter >

让智造更简单

MAKING SMART MORE SIMPLE

32.

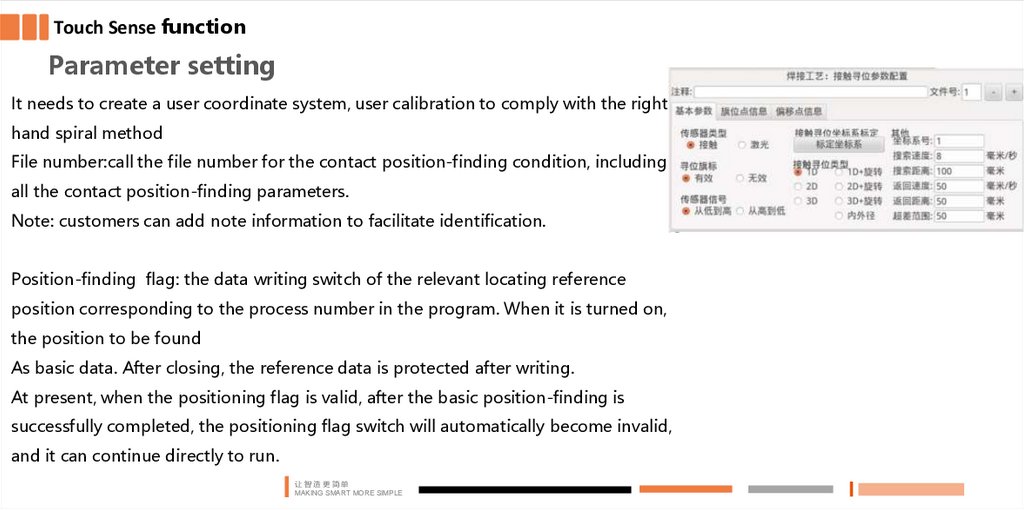

Touch Sense functionParameter setting

It needs to create a user coordinate system, user calibration to comply with the righthand spiral method

File number:call the file number for the contact position-finding condition, including

all the contact position-finding parameters.

Note: customers can add note information to facilitate identification.

Position-finding flag: the data writing switch of the relevant locating reference

position corresponding to the process number in the program. When it is turned on,

the position to be found

As basic data. After closing, the reference data is protected after writing.

At present, when the positioning flag is valid, after the basic position-finding is

successfully completed, the positioning flag switch will automatically become invalid,

and it can continue directly to run.

让智造更简单

MAKING SMART MORE SIMPLE

33.

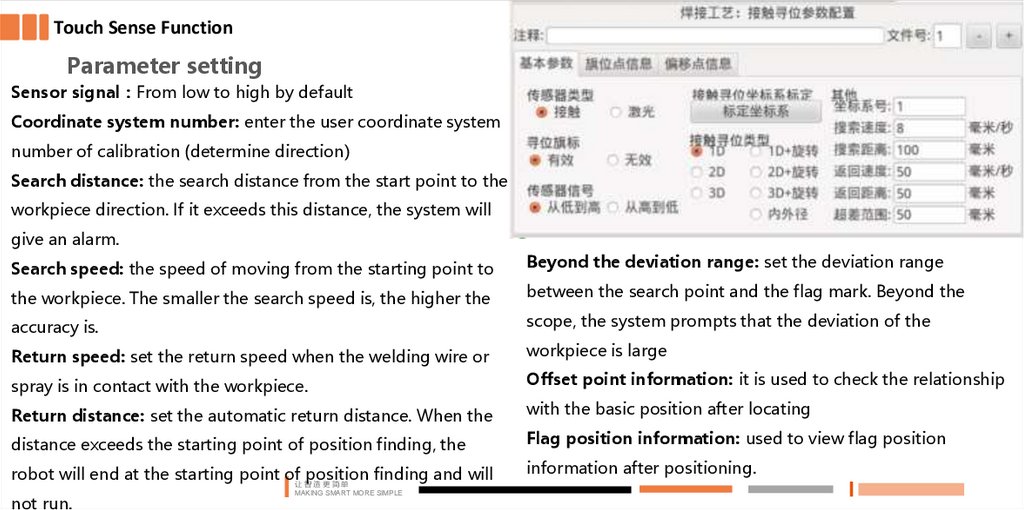

Touch Sense FunctionParameter setting

Sensor signal From low to high by default

Coordinate system number: enter the user coordinate system

number of calibration (determine direction)

Search distance: the search distance from the start point to the

workpiece direction. If it exceeds this distance, the system will

give an alarm.

Search speed: the speed of moving from the starting point to

Beyond the deviation range: set the deviation range

the workpiece. The smaller the search speed is, the higher the

between the search point and the flag mark. Beyond the

accuracy is.

scope, the system prompts that the deviation of the

Return speed: set the return speed when the welding wire or

workpiece is large

spray is in contact with the workpiece.

Offset point information: it is used to check the relationship

Return distance: set the automatic return distance. When the

with the basic position after locating

distance exceeds the starting point of position finding, the

Flag position information: used to view flag position

robot will end at the starting point of让 智position

finding and will

造更简单

information after positioning.

not run.

MAKING SMART MORE SIMPLE

34.

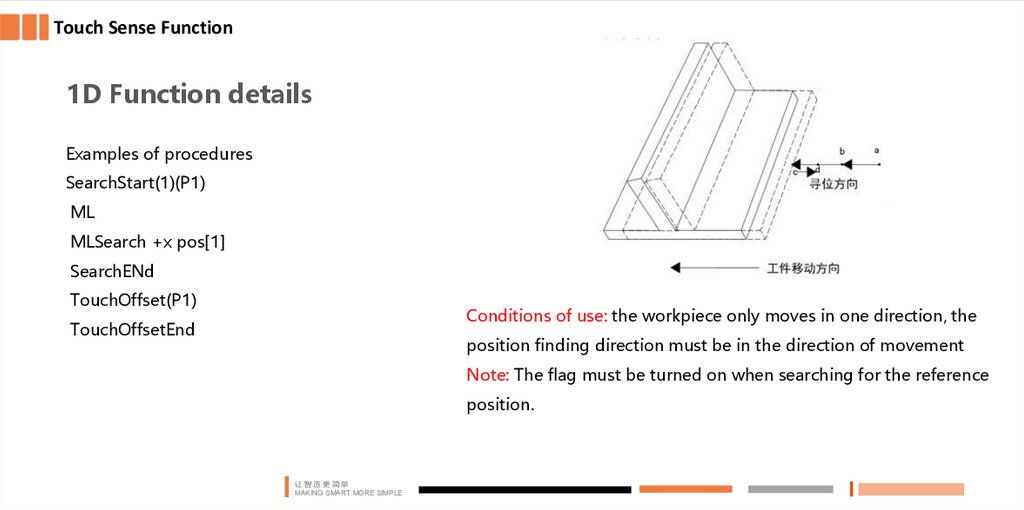

Touch Sense Function1D Function details

Examples of procedures

SearchStart(1)(P1)

ML

MLSearch +x pos[1]

SearchENd

TouchOffset(P1)

Conditions of use: the workpiece only moves in one direction, the

TouchOffsetEnd

position finding direction must be in the direction of movement

Note: The flag must be turned on when searching for the reference

position.

让智造更简单

MAKING SMART MORE SIMPLE

35.

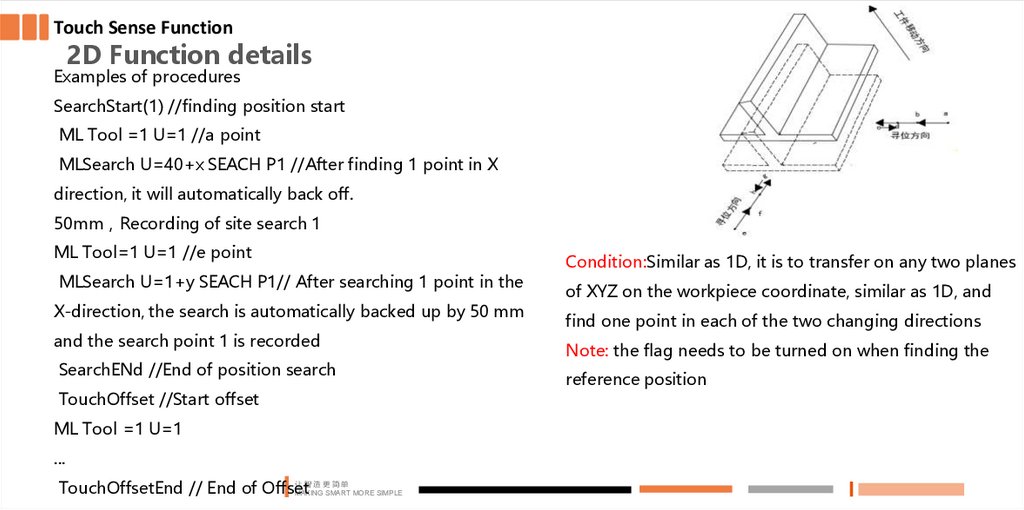

Touch Sense Function2D Function details

Examples of procedures

SearchStart(1) //finding position start

ML Tool =1 U=1 //a point

MLSearch U=40+x SEACH P1 //After finding 1 point in X

direction, it will automatically back off.

50mm Recording of site search 1

ML Tool=1 U=1 //e point

MLSearch U=1+y SEACH P1// After searching 1 point in the

X-direction, the search is automatically backed up by 50 mm

and the search point 1 is recorded

SearchENd //End of position search

TouchOffset //Start offset

ML Tool =1 U=1

...

让智造更简单

TouchOffsetEnd // End of Offset

MAKING SMART MORE SIMPLE

Condition:Similar as 1D, it is to transfer on any two planes

of XYZ on the workpiece coordinate, similar as 1D, and

find one point in each of the two changing directions

Note: the flag needs to be turned on when finding the

reference position

36.

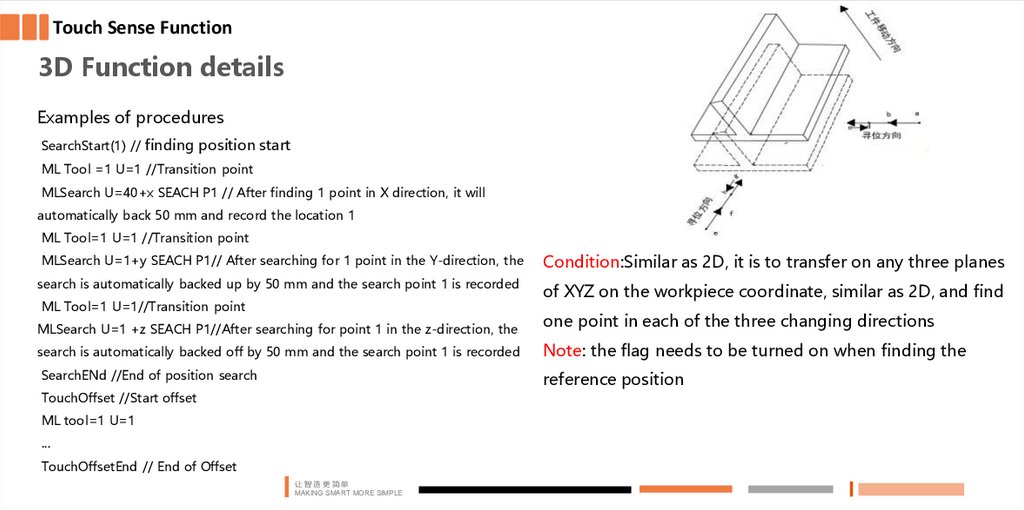

Touch Sense Function3D Function details

Examples of procedures

SearchStart(1) // finding position start

ML Tool =1 U=1 //Transition point

MLSearch U=40+x SEACH P1 // After finding 1 point in X direction, it will

automatically back 50 mm and record the location 1

ML Tool=1 U=1 //Transition point

MLSearch U=1+y SEACH P1// After searching for 1 point in the Y-direction, the

search is automatically backed up by 50 mm and the search point 1 is recorded

ML Tool=1 U=1//Transition point

MLSearch U=1 +z SEACH P1//After searching for point 1 in the z-direction, the

search is automatically backed off by 50 mm and the search point 1 is recorded

SearchENd //End of position search

Condition:Similar as 2D, it is to transfer on any three planes

of XYZ on the workpiece coordinate, similar as 2D, and find

one point in each of the three changing directions

Note: the flag needs to be turned on when finding the

reference position

TouchOffset //Start offset

ML tool=1 U=1

...

TouchOffsetEnd // End of Offset

让智造更简单

MAKING SMART MORE SIMPLE

37.

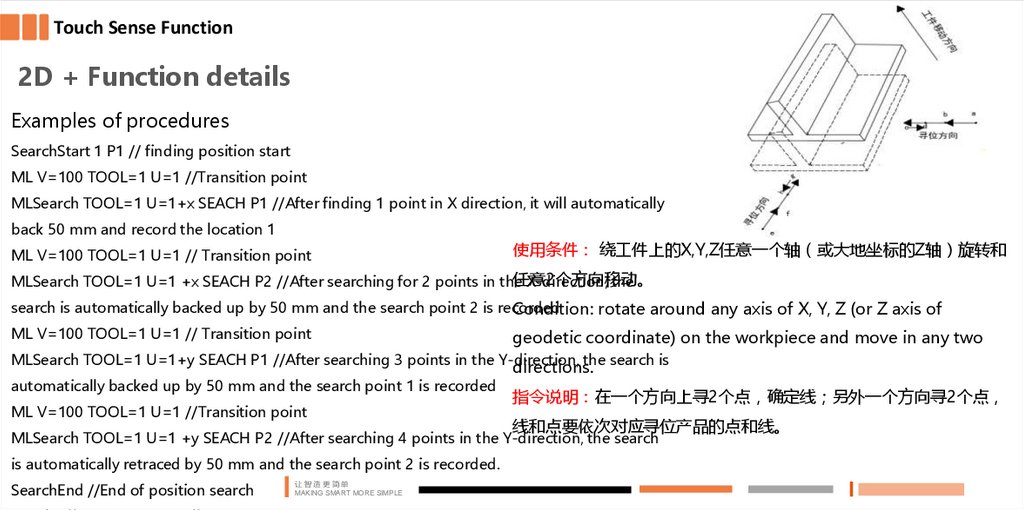

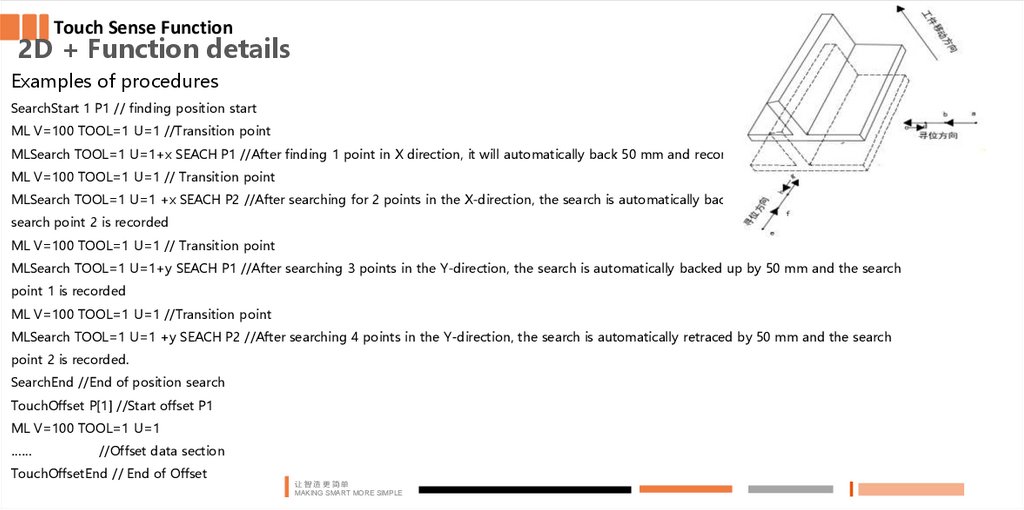

Touch Sense Function2D + Function details

Examples of procedures

SearchStart 1 P1 // finding position start

ML V=100 TOOL=1 U=1 //Transition point

MLSearch TOOL=1 U=1+x SEACH P1 //After finding 1 point in X direction, it will automatically

back 50 mm and record the location 1

ML V=100 TOOL=1 U=1 // Transition point

使用条件 绕工件上的X,Y,Z任意一个轴 或大地坐标的Z轴 旋转和

任意2个方向移动。

MLSearch TOOL=1 U=1 +x SEACH P2 //After searching for 2 points in the

X-direction, the

search is automatically backed up by 50 mm and the search point 2 is recorded

Condition: rotate around any axis of X, Y, Z (or Z axis of

ML V=100 TOOL=1 U=1 // Transition point

geodetic coordinate) on the workpiece and move in any two

MLSearch TOOL=1 U=1+y SEACH P1 //After searching 3 points in the Y-direction, the search is

automatically backed up by 50 mm and the search point 1 is recorded

ML V=100 TOOL=1 U=1 //Transition point

directions.

指令说明 在一个方向上寻2个点 确定线 另外一个方向寻2个点

线和点要依次对应寻位产品的点和线。

MLSearch TOOL=1 U=1 +y SEACH P2 //After searching 4 points in the Y-direction, the search

is automatically retraced by 50 mm and the search point 2 is recorded.

SearchEnd //End of position search

让智造更简单

MAKING SMART MORE SIMPLE

38.

Touch Sense Function2D + Function details

Examples of procedures

SearchStart 1 P1 // finding position start

ML V=100 TOOL=1 U=1 //Transition point

MLSearch TOOL=1 U=1+x SEACH P1 //After finding 1 point in X direction, it will automatically back 50 mm and record the location 1

ML V=100 TOOL=1 U=1 // Transition point

MLSearch TOOL=1 U=1 +x SEACH P2 //After searching for 2 points in the X-direction, the search is automatically backed up by 50 mm and the

search point 2 is recorded

ML V=100 TOOL=1 U=1 // Transition point

MLSearch TOOL=1 U=1+y SEACH P1 //After searching 3 points in the Y-direction, the search is automatically backed up by 50 mm and the search

point 1 is recorded

ML V=100 TOOL=1 U=1 //Transition point

MLSearch TOOL=1 U=1 +y SEACH P2 //After searching 4 points in the Y-direction, the search is automatically retraced by 50 mm and the search

point 2 is recorded.

SearchEnd //End of position search

TouchOffset P[1] //Start offset P1

ML V=100 TOOL=1 U=1

……

//Offset data section

TouchOffsetEnd // End of Offset

让智造更简单

MAKING SMART MORE SIMPLE

39.

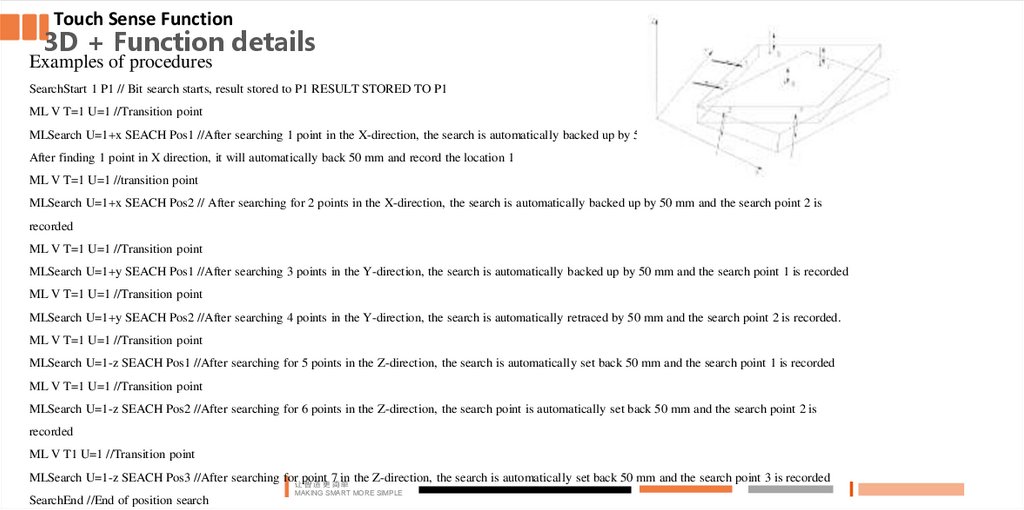

Touch Sense Function3D + Function details

Examples of procedures

SearchStart 1 P1 // Bit search starts, result stored to P1 RESULT STORED TO P1

ML V T=1 U=1 //Transition point

MLSearch U=1+x SEACH Pos1 //After searching 1 point in the X-direction, the search is automatically backed up by 50 mm and the search point 1 is recorded

After finding 1 point in X direction, it will automatically back 50 mm and record the location 1

ML V T=1 U=1 //transition point

MLSearch U=1+x SEACH Pos2 // After searching for 2 points in the X-direction, the search is automatically backed up by 50 mm and the search point 2 is

recorded

ML V T=1 U=1 //Transition point

MLSearch U=1+y SEACH Pos1 //After searching 3 points in the Y-direction, the search is automatically backed up by 50 mm and the search point 1 is recorded

ML V T=1 U=1 //Transition point

MLSearch U=1+y SEACH Pos2 //After searching 4 points in the Y-direction, the search is automatically retraced by 50 mm and the search point 2 is recorded.

ML V T=1 U=1 //Transition point

MLSearch U=1-z SEACH Pos1 //After searching for 5 points in the Z-direction, the search is automatically set back 50 mm and the search point 1 is recorded

ML V T=1 U=1 //Transition point

MLSearch U=1-z SEACH Pos2 //After searching for 6 points in the Z-direction, the search point is automatically set back 50 mm and the search point 2 is

recorded

ML V T1 U=1 //Transition point

MLSearch U=1-z SEACH Pos3 //After searching for让point

7 in the Z-direction, the search is automatically set back 50 mm and the search point 3 is recorded

智造更简单

SearchEnd //End of position search

MAKING SMART MORE SIMPLE

40.

Touch Sense Function3D + Function details

Conditions of use: Rotate or translate anywhere around X,Y,Z

Position finding conditions: find 3 points in one direction to determine the face; find 2 points in another direction to

determine the line; find 2 points in the last direction to find the position.

Note: The flag is to be turned on when locating the reference position.

让智造更简单

MAKING SMART MORE SIMPLE

41.

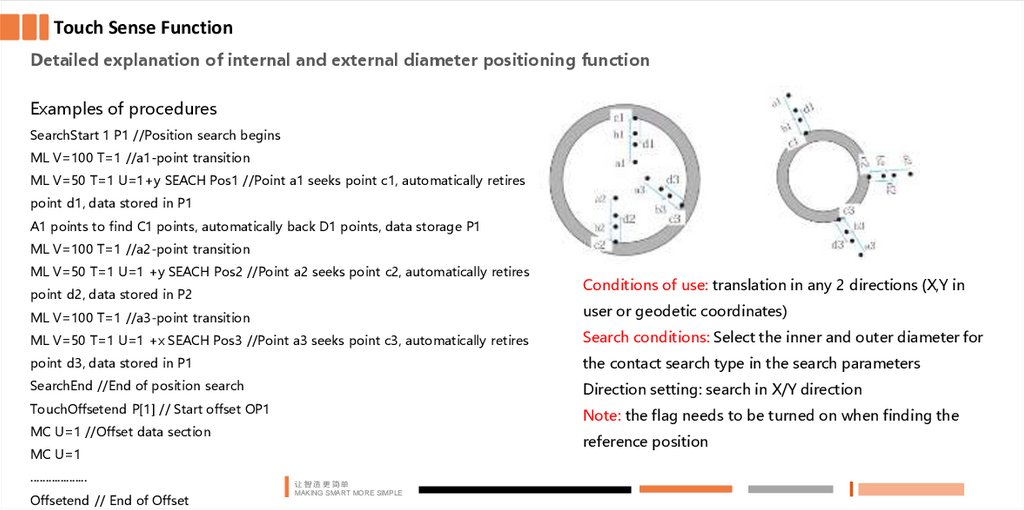

Touch Sense FunctionDetailed explanation of internal and external diameter positioning function

Examples of procedures

SearchStart 1 P1 //Position search begins

ML V=100 T=1 //a1-point transition

ML V=50 T=1 U=1+y SEACH Pos1 //Point a1 seeks point c1, automatically retires

point d1, data stored in P1

A1 points to find C1 points, automatically back D1 points, data storage P1

ML V=100 T=1 //a2-point transition

ML V=50 T=1 U=1 +y SEACH Pos2 //Point a2 seeks point c2, automatically retires

point d2, data stored in P2

Conditions of use: translation in any 2 directions (X,Y in

ML V=100 T=1 //a3-point transition

user or geodetic coordinates)

ML V=50 T=1 U=1 +x SEACH Pos3 //Point a3 seeks point c3, automatically retires

Search conditions: Select the inner and outer diameter for

point d3, data stored in P1

the contact search type in the search parameters

SearchEnd //End of position search

Direction setting: search in X/Y direction

TouchOffsetend P[1] // Start offset OP1

Note: the flag needs to be turned on when finding the

MC U=1 //Offset data section

reference position

MC U=1

...................

Offsetend // End of Offset

让智造更简单

MAKING SMART MORE SIMPLE

42.

感谢大家的聆听让智造更简单

MAKING SMART MORE SIMPLE

Thanks for your listening!

industry

industry