Similar presentations:

Solid waste biotreatment. Ethanol production from lignocellulosic materials. Lecture 4

1.

BIOPROCESS TECHNOLOGYDr. TERESA FERNANDEZ ALDAMA

“SAMARA UNIVERSITY”

1

2.

LECTURE No. 4. SOLID WASTEBIOTREATMENT/Ethanol production

from lignocellulosic materials (I)

2

3.

LCM are promissing feedstock for ethanolproduction without affecting the food

sector

3

4.

ObjectiveTo describe components of lignocellulosic

materials, their characteristics and how to

prepare them for ethanol production.

4

5.

OutlineLignocellulosic materials (LCM) for ethanol

production

LCM. Composition

Characteristics of cellulose, hemicellulose and

lignin

Hydrolysis of cellulose and hemicellulose

Pretreatment methods

5

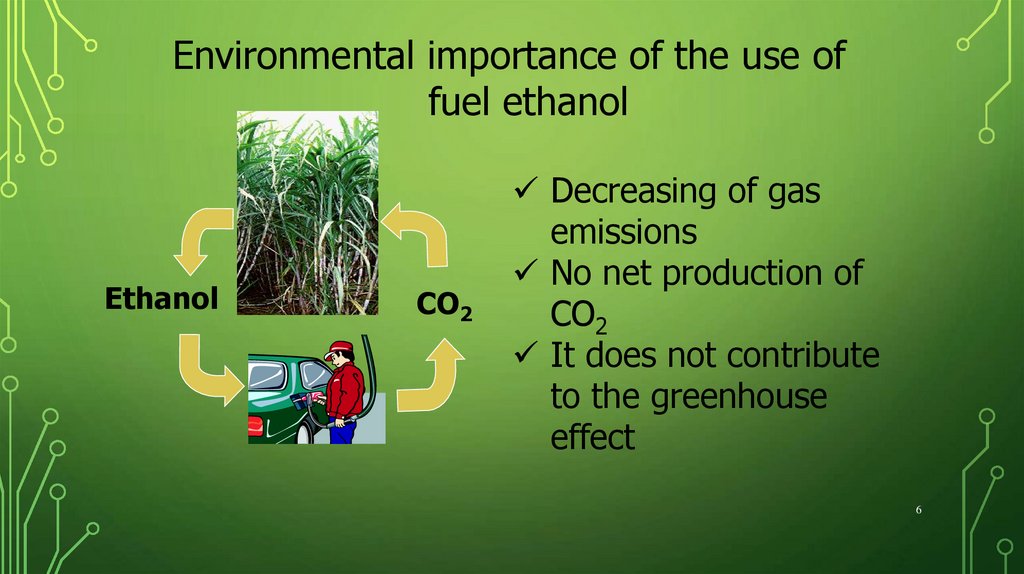

6.

Environmental importance of the use offuel ethanol

Ethanol

CO2

Decreasing of gas

emissions

No net production of

CO2

It does not contribute

to the greenhouse

effect

6

7.

Lignocellulosic materialsForest residues

Agricultural and food industry residues

Municipal solid wastes (Recycled paper)

Energy crops

7

8.

Sugarcane bagasseCassava stems

Rice husks

Peanut shells

8

9.

Alternative for production of ethanolSecond generation

biofuel

9

10.

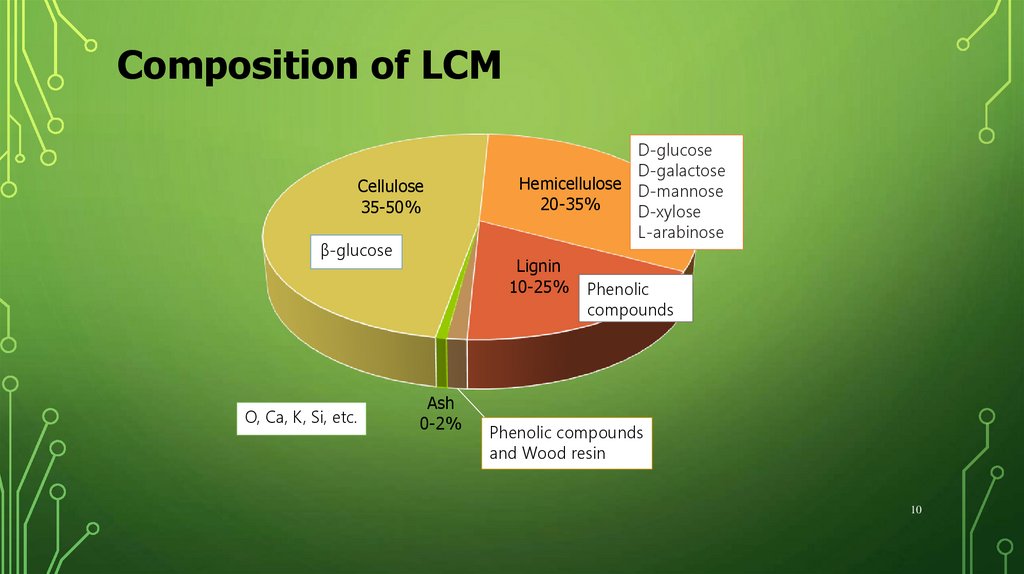

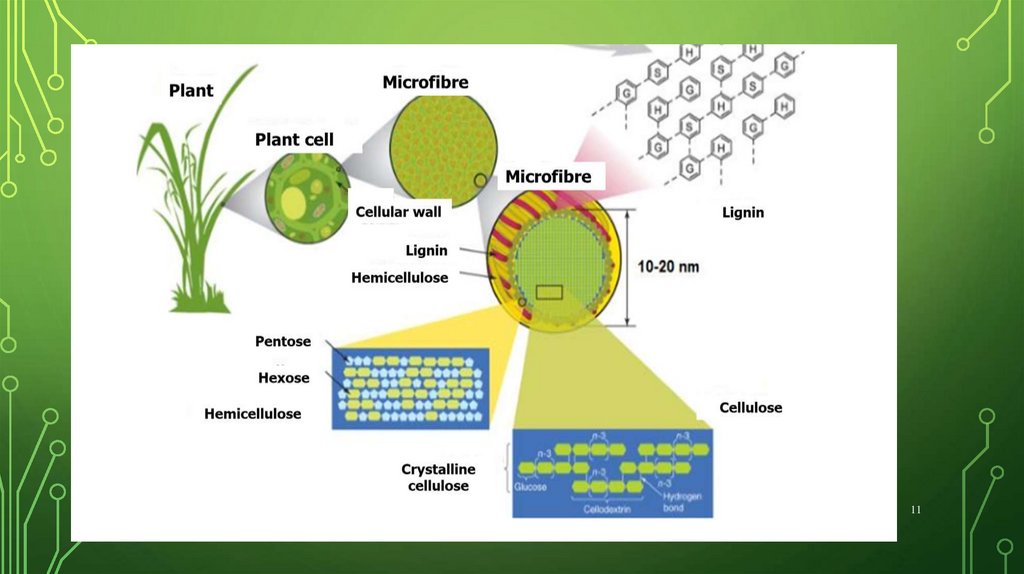

Composition of LCMCellulose

35-50%

β-glucose

O, Ca, K, Si, etc.

D-glucose

D-galactose

Hemicellulose D-mannose

20-35%

D-xylose

L-arabinose

Lignin

10-25%

Ash

0-2%

Phenolic

compounds

Extractives

Phenolic

compounds

1-5%resin

and Wood

10

11.

1112.

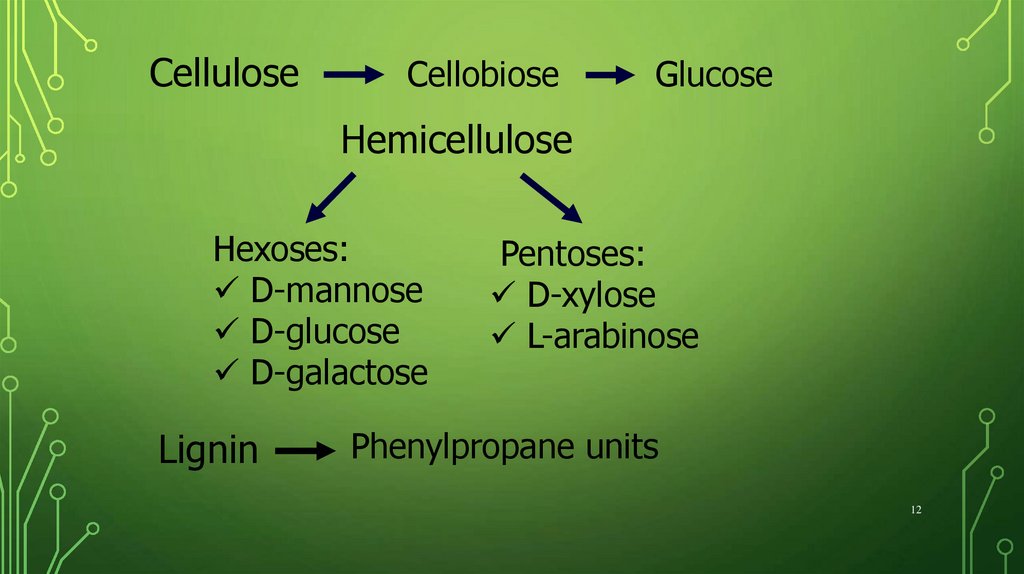

CelluloseCellobiose

Glucose

Hemicellulose

Hexoses:

D-mannose

D-glucose

D-galactose

Lignin

Pentoses:

D-xylose

L-arabinose

Phenylpropane units

12

13.

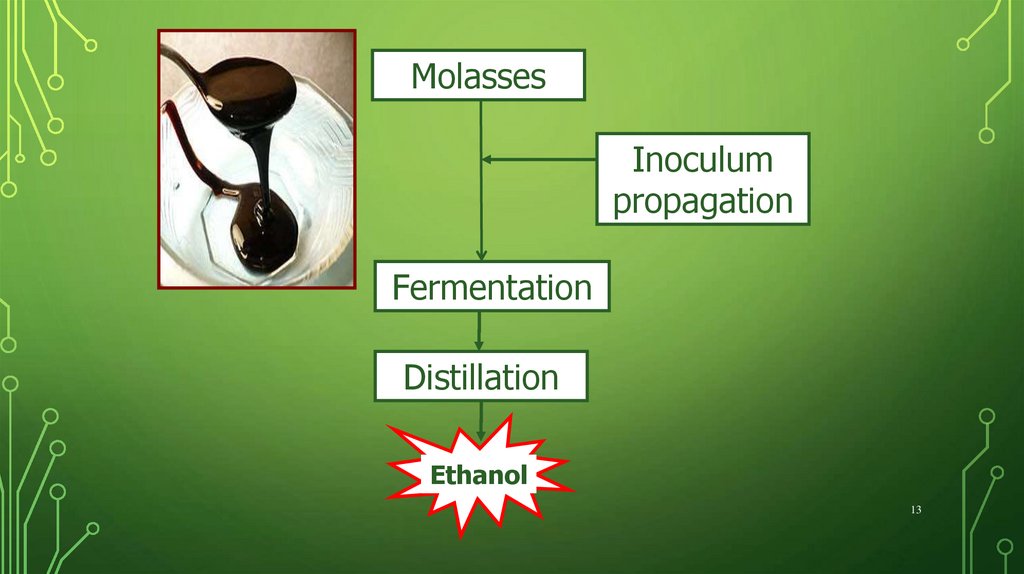

MolassesInoculum

propagation

Fermentation

Distillation

Ethanol

13

14.

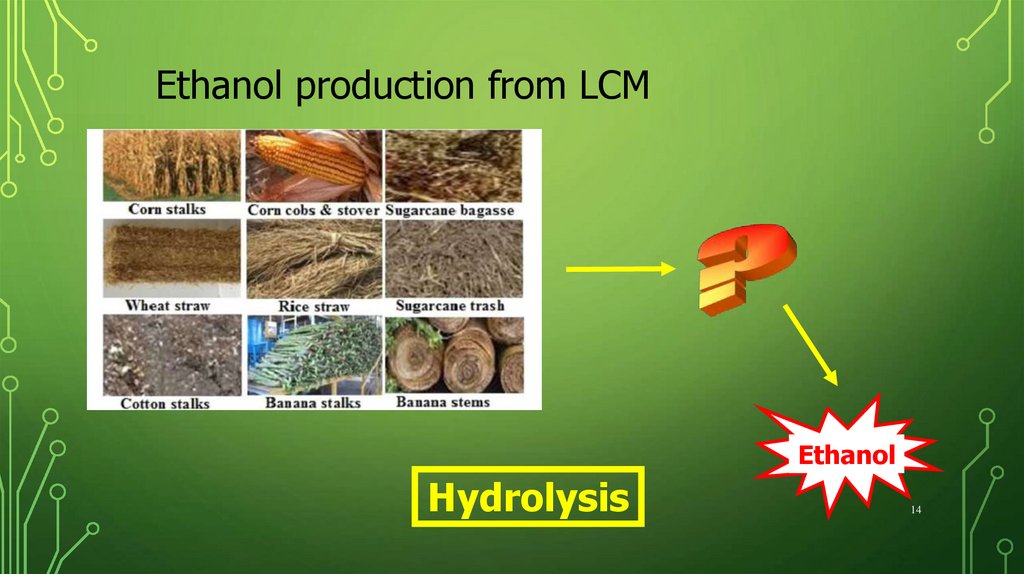

Ethanol production from LCMEthanol

Hydrolysis

14

15.

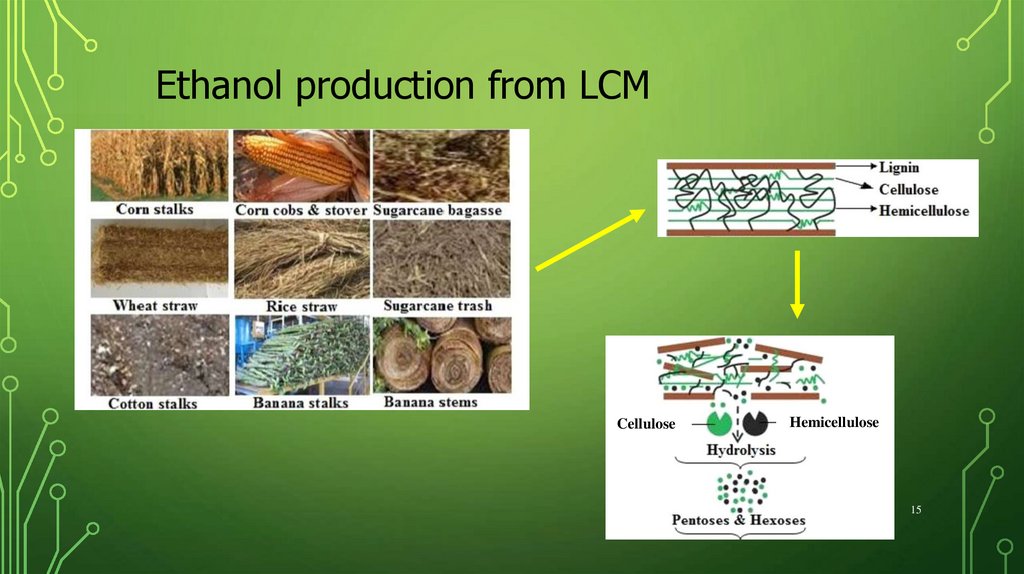

Ethanol production from LCMCellulose

Hemicellulose

15

16.

Hydrolysis of celluloseAcid hydrolysis

With concentrated acids

With diluted acids

Enzymatic hydrolysis

With cellulases and hemicellulases

16

17.

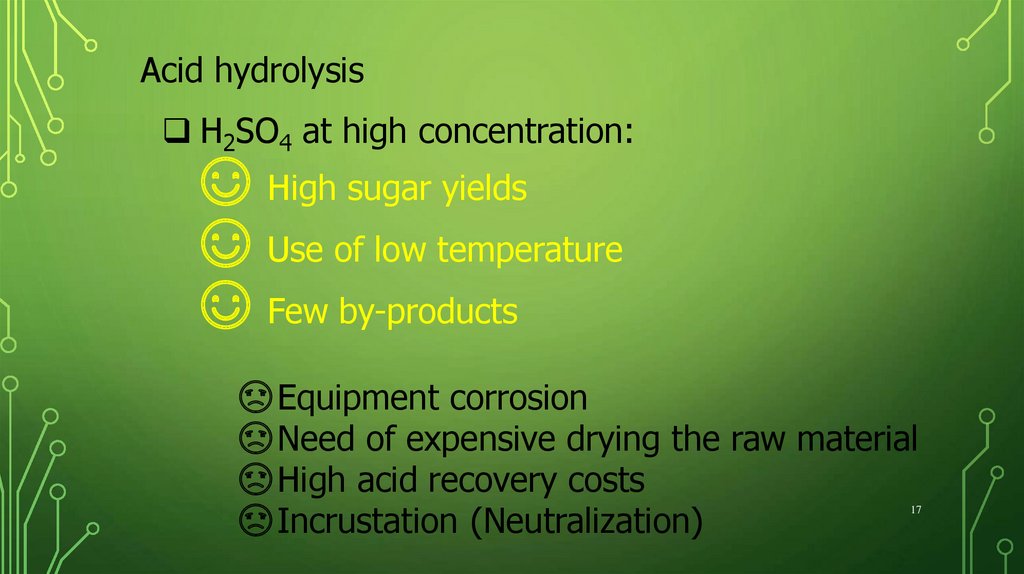

Acid hydrolysisH2SO4 at high concentration:

☺

☺

☺

High sugar yields

Use of low temperature

Few by-products

☹ Equipment corrosion

☹ Need of expensive drying the raw material

☹ High acid recovery costs

☹ Incrustation (Neutralization)

17

18.

Acid hydrolysisDilute-acid Hydrolysis

☺ Lower requirement of acid (compared with

the previous one)

☹ High temperatures

☹ Sugar degradation

☹ Formation of by-products

☹ Equipment corrosion

18

19.

Enzymatic hydrolysisBacterial cellulases (Clostridium and Bacillus)

Fungal cellulases (Trichoderma, Aspergillus,

Penicillium)

Endoglucanase (EC 3.2.1.4)

Cellobiohydrolase (EC 3.2.1.91)

-glicosidase (EC 3.2.1.21)

19

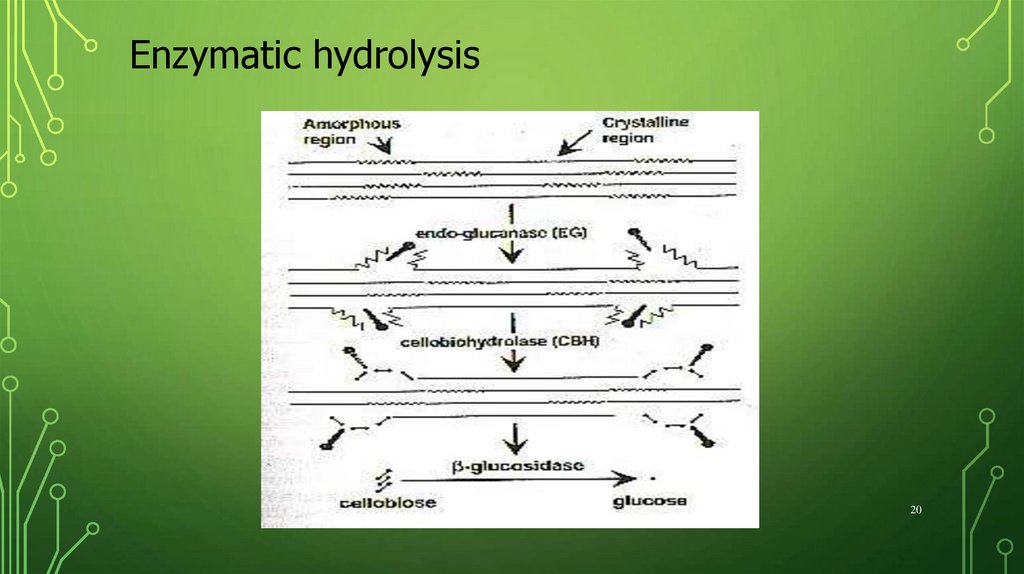

20.

Enzymatic hydrolysis20

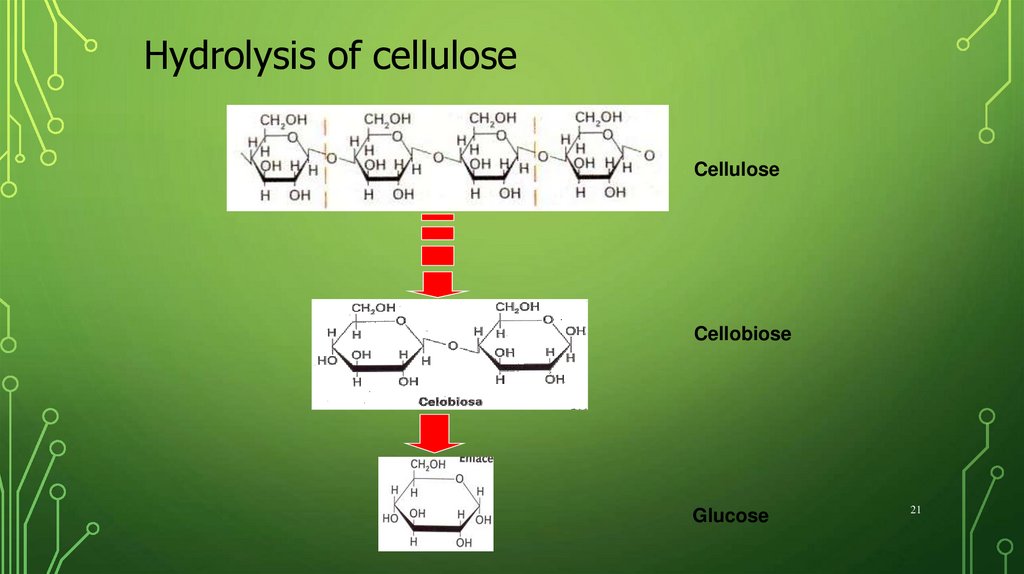

21.

Hydrolysis of celluloseCellulose

Cellobiose

Glucose

21

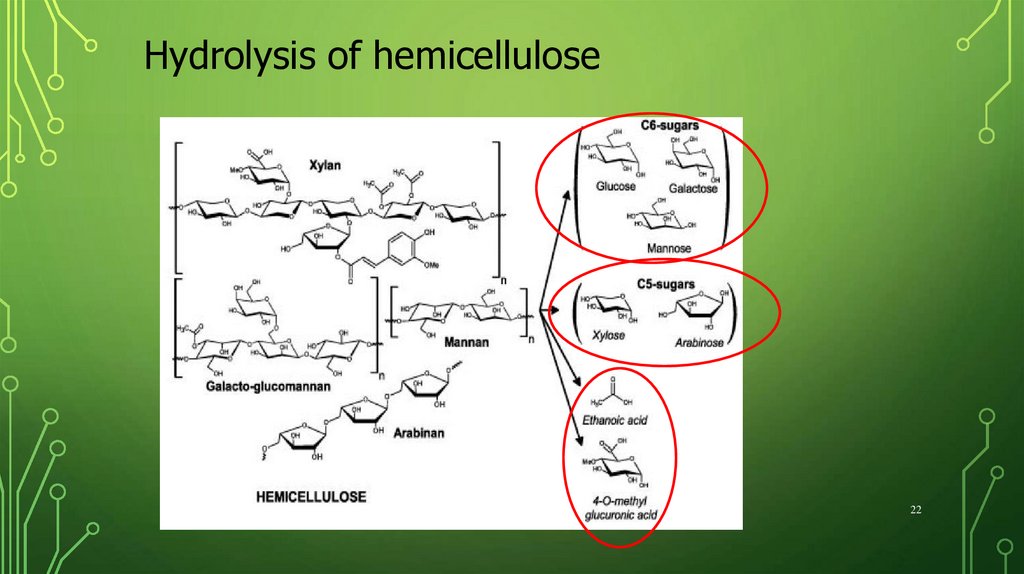

22.

Hydrolysis of hemicellulose22

23.

Enzymatic hydrolysis☺ High conversion yield

90-100% for cellulose

70-75% for hemicelluloses

☺ No sugar degradation

☹ High cost of enzymes

☹ Slow process

23

24.

Enzymatic hydrolysisThe cellulases must be able to:

Reach and adsorb onto cellulose

surface (Accessibility)

Find, or make, reactive ends of

cellulose chain (Reactivity)

24

25.

Enzymatic hydrolysis☹ Low accessibility (Association with

hemicelluloses and lignin)

☹ Low reactivity (High degree of crystallinity)

PRETREATMENT

25

26.

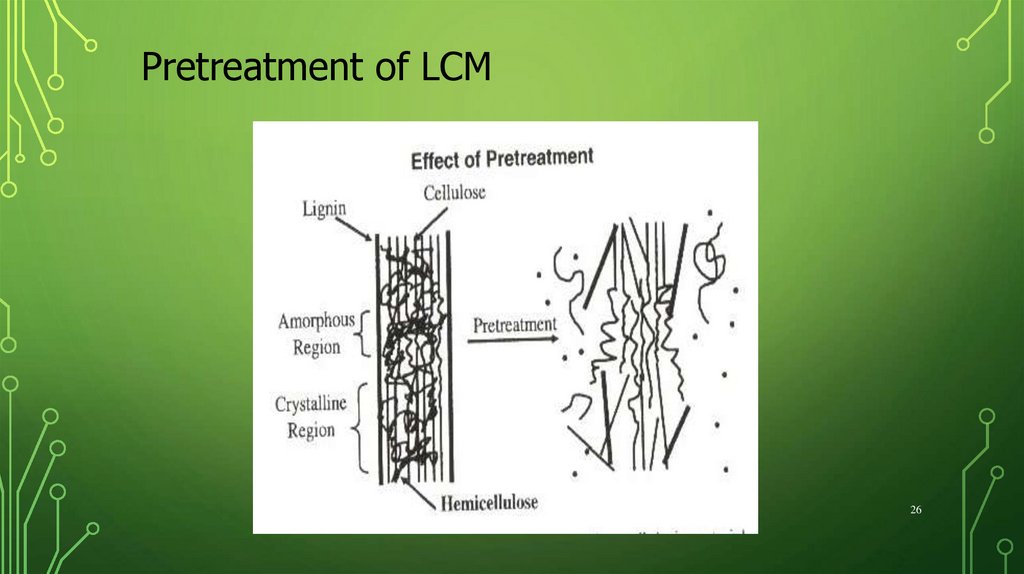

Pretreatment of LCM26

27.

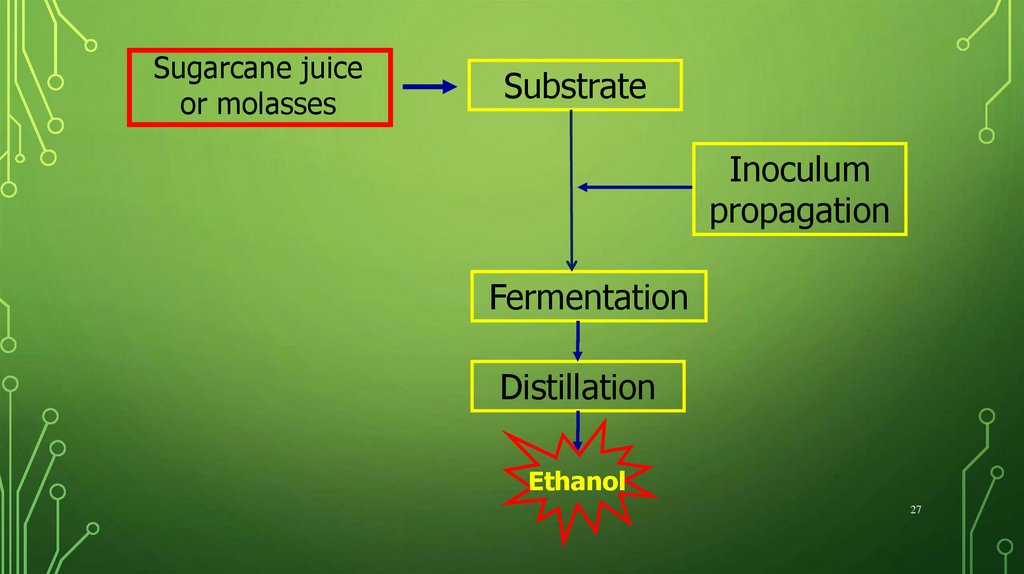

Sugarcane juiceor molasses

Substrate

Inoculum

propagation

Fermentation

Distillation

Ethanol

27

28.

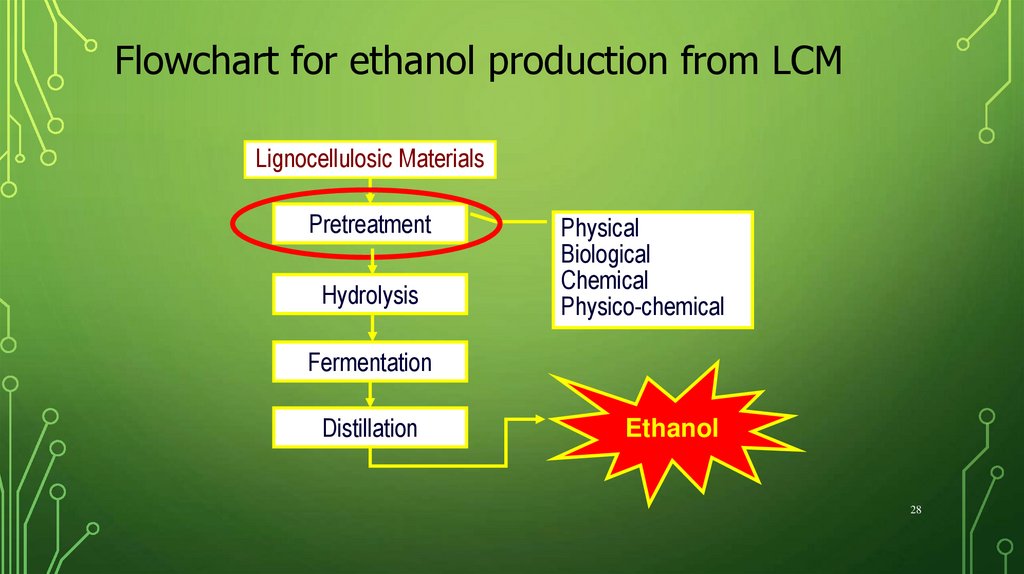

Flowchart for ethanol production from LCMLignocellulosic Materials

Pretreatment

Hydrolysis

Physical

Biological

Chemical

Physico-chemical

Fermentation

Distillation

Ethanol

28

29.

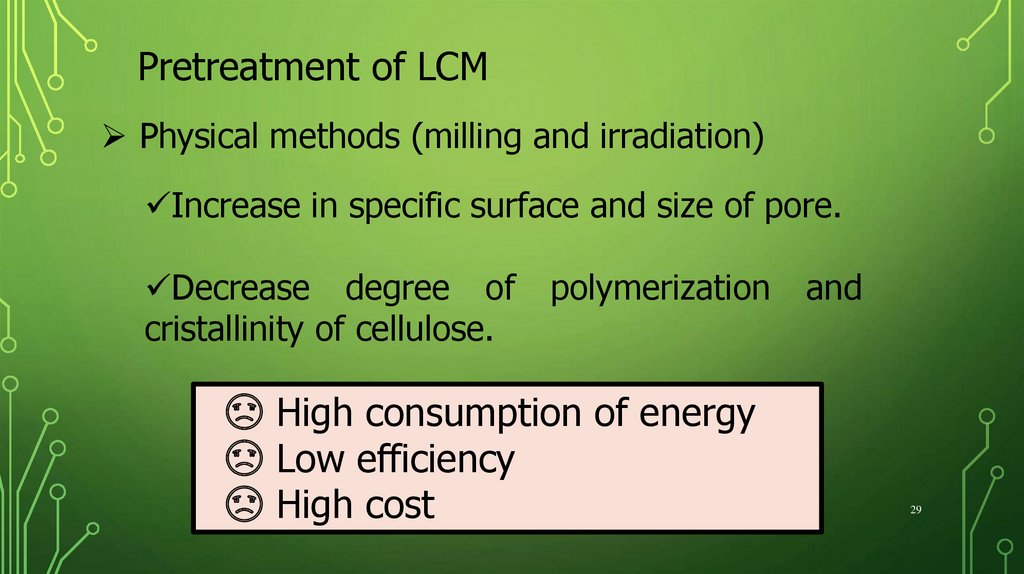

Pretreatment of LCMPhysical methods (milling and irradiation)

Increase in specific surface and size of pore.

Decrease degree of

cristallinity of cellulose.

polymerization

☹ High consumption of energy

☹ Low efficiency

☹ High cost

and

29

30.

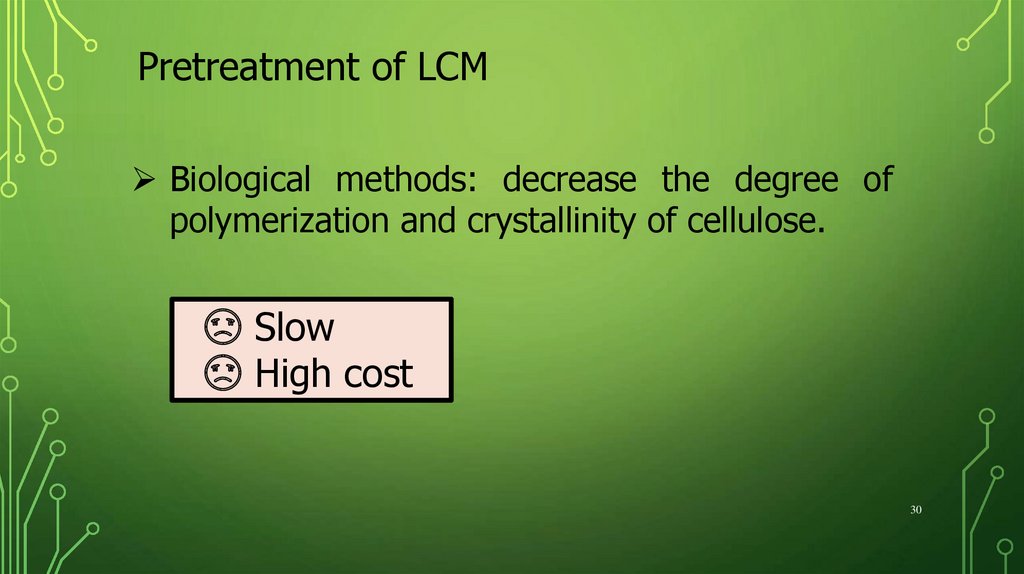

Pretreatment of LCMBiological methods: decrease the degree of

polymerization and crystallinity of cellulose.

☹ Slow

☹ High cost

30

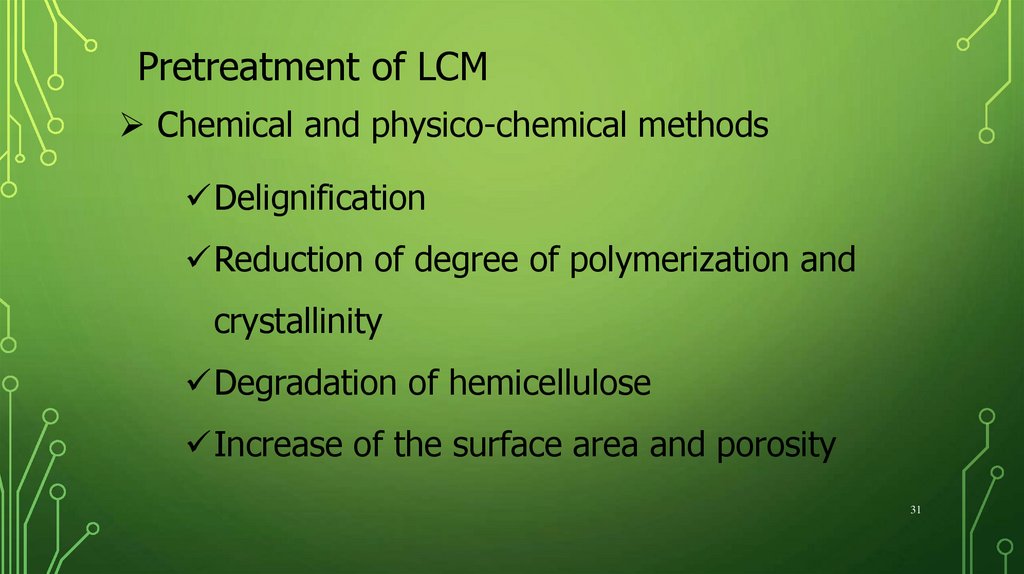

31.

Pretreatment of LCMChemical and physico-chemical methods

Delignification

Reduction of degree of polymerization and

crystallinity

Degradation of hemicellulose

Increase of the surface area and porosity

31

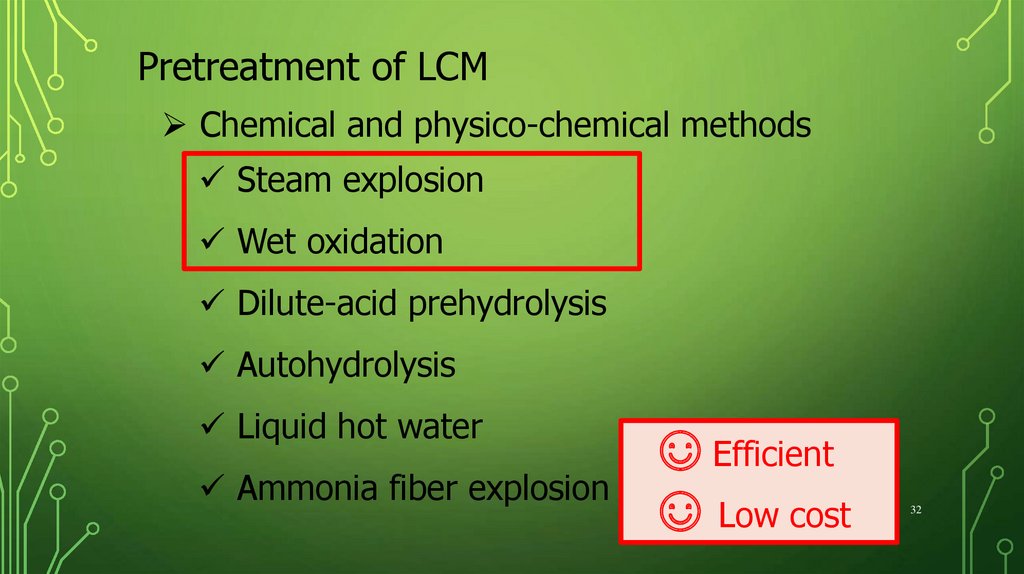

32.

Pretreatment of LCMChemical and physico-chemical methods

Steam explosion

Wet oxidation

Dilute-acid prehydrolysis

Autohydrolysis

Liquid hot water

Ammonia fiber explosion

☺ Efficient

☺ Low cost

32

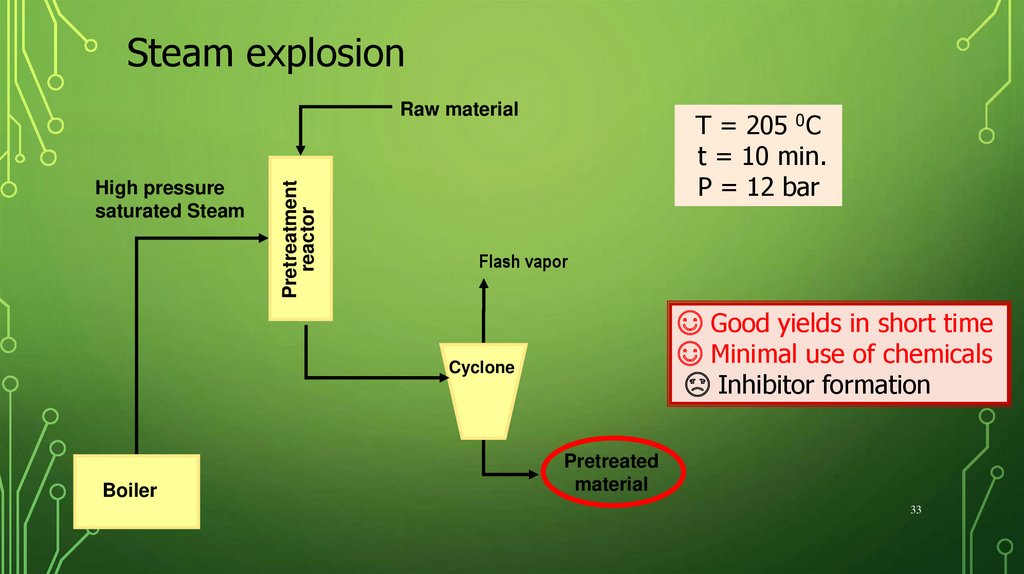

33.

Steam explosionHigh pressure

saturated Steam

Pretreatment

reactor

Raw material

T = 205 0C

t = 10 min.

P = 12 bar

Flash vapor

☺ Good yields in short time

☺ Minimal use of chemicals

☹ Inhibitor formation

Cyclone

Boiler

Pretreated

material

33

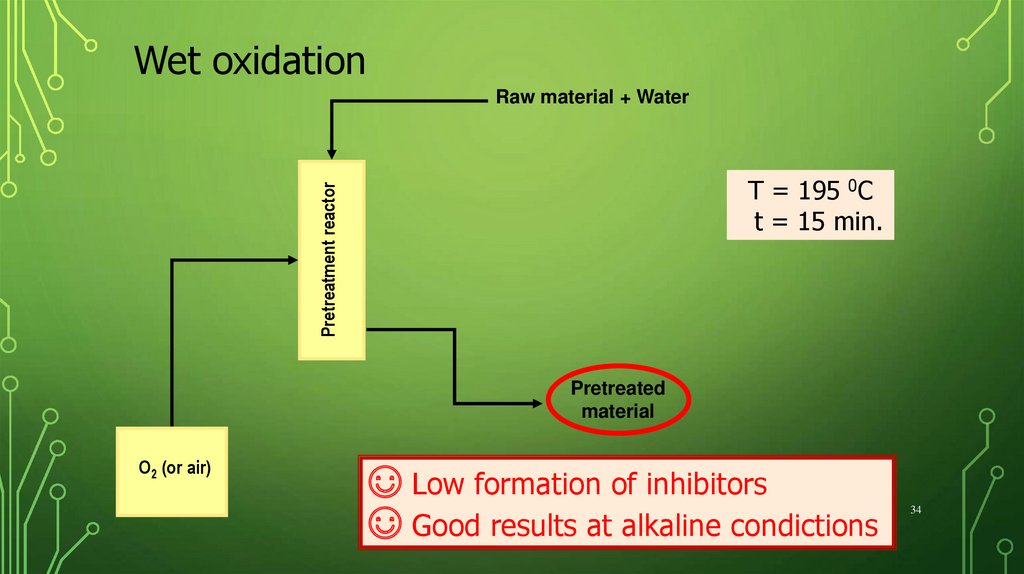

34.

Wet oxidationRaw material + Water

Pretreatment reactor

T = 195 0C

t = 15 min.

Pretreated

material

O2 (or air)

☺ Low formation of inhibitors

☺ Good results at alkaline condictions

34

35.

Control questions1. Describe the composition of lignocellulosic materials.

2. What characteristics distinguish cellulose from

hemicelluloses?

3. Mention the hydrolysis methods that can be used to obtain

fermentable sugars. Explain one of them.

4. Why is necessary to pretreat lignocellulosic materials before

their use for ethanol production.

5. Describe one pretreatment that can be used before

hydrolysis of lignocellulosic materials. Specify the most

important goals to achieve an efficient pretreatment?

35

36.

Suggested literature- Harmsen P., Huijgen W., Bermudez L., Bakker R. Literature

review of physical and chemical pretreatment processes for

lignocellulosic biomass. Biosynergy, September 2010, Report

1184. ISBN 978-90-8585-757-0.

- Zoghlami A., Paës G. Lignocellulosic Biomass:

Understanding Recalcitrance and Predicting Hydrolysis.

Frontiers in Chemistry, 2019, Volume 7, Article 874.

- Galbe M., Zacchi G. A review of the production of ethanol

from softwood. Appl Microbiol Biotechnol, 2002, 59:618–628.

36

37.

THANK YOU FOR YOURATTENTION!

37

chemistry

chemistry industry

industry