Similar presentations:

Electro-mechanical Steering System

1. ELECTRO-MECHANICAL STEERING SYSTEM

SUBMITTED BYPAPPOO YADAVSR NO - 567/12

2. BRIEF HISTORY

The first automobiles weresteered with a tiller.

A steering wheel was first

used in Europe in 1894 .

Bicycles, Mobility scooters

are often using tiller

steering.

3. OTHER FEATURES…

It helps in swinging the wheels to the left or right.It converts the rotary movement of the steering wheel

into an angular turn of the front wheels.

It multiplies the effort of the driver by leverage in order

to make it fairly easy to turn the wheels.

It absorbs a major part of the road shocks thereby

preventing them to get transmitted to the hands of the

driver

4. BASIC STEERING MECHANISM

Ackerman steeringsystem

Davis steering system

Projected center lines of

all should meet on or

near the centre of the

rear axle.

5. TYPES OF STEERING SYTEM

RECIRCULATING OR PARALLELOGRAMSTEERING SYSTEM

RACK AND PINION TYPE STEERING SYSTEM

Any vehicle (heavy,small,medium) must have these two

steering system whether they have any type of power steering.

6. RECIRCULATING TYPE

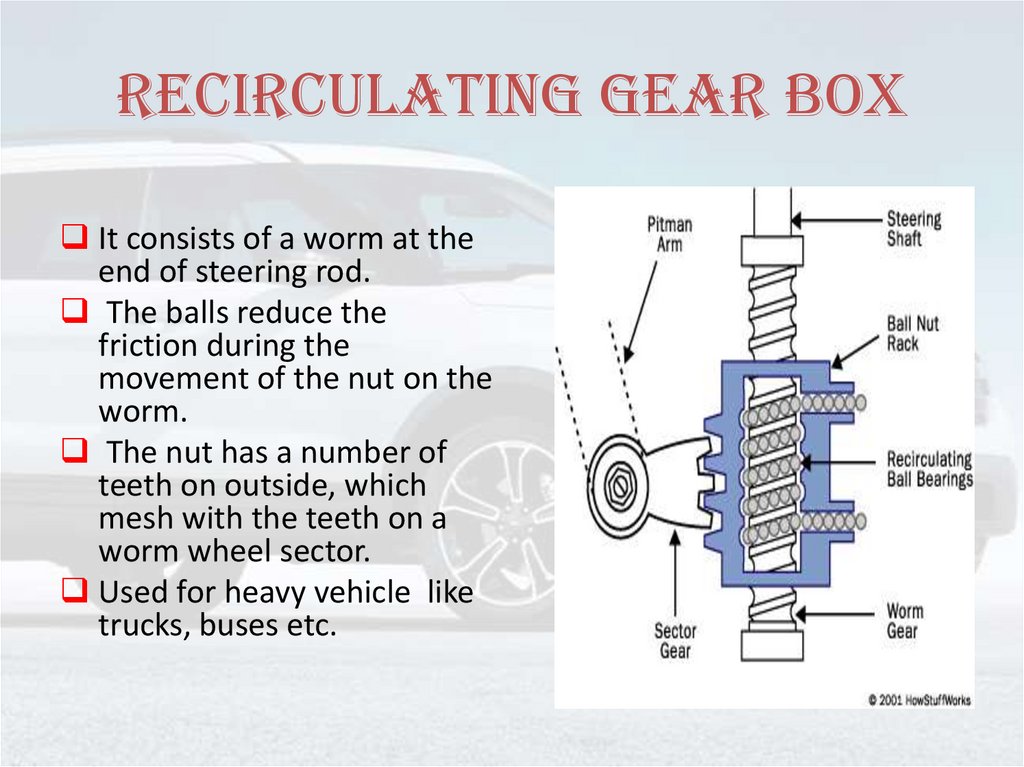

7. RECIRCULATING GEAR BOX

It consists of a worm at theend of steering rod.

The balls reduce the

friction during the

movement of the nut on the

worm.

The nut has a number of

teeth on outside, which

mesh with the teeth on a

worm wheel sector.

Used for heavy vehicle like

trucks, buses etc.

8. RACK AND PINION TYPE

9. RACK AND PINION GEAR BOX

• Some cars have variableratio steering, which uses arack-and-pinion gear set

that has a different tooth

pitch (number of teeth per

inch) in the center than it

has on the outside.

• This makes the car

respond quickly when

starting a turn (the rack is

near the center), and also

reduces effort near the

wheel's turning limit.

• Used in small and medium

vehicles like cars,suv,racing

cars etc.

10. WHEEL ALIGNMENT

CAMBER ANGLECASTER ANGLE

TOE-IN AND TOE-OUT

KING PIN INCLINATION

11. WHEEL ALIGNMMENT

Why is it necessary?Directional stability

Maintain straightness

Reduce uneven wear of tyres

Proper traction between tyres and road while

turning

12. POWER STEERING

1. Hydraulic power steering(HPS)2. Electro-mechanical steering system or electric

steering system (EPS)

3. Electro hydraulic steering system(EHPS)

4. Hydrostatic steering system (no mechanical

linkage, used in tractor, roller, bulldozer )

13. ELECTRO MECHANICAL STEERING SYSTEM

Why we need for this while we have manual aswell as hydraulics steering system?

14. PROS OF EPS

Less complicatedUsually less weighs

There is no such fluid needed thus it needs less

maintenance compared to hydraulic power

steering.

Better response at different speeds

It supports return of the steering wheel back to the

center position via the “active return”

function.

It consumes power from battery, but it consumes

less power compared to HPS. So a car having EPS

will give more mileage than one with HPS.

Straight-line stability function

No continuous power taking

15. EPS

• Electric Power Steering (EPS) is the latest system in whichthe electric motor (“E-motor”) is attached.

• Sensors detect the motion of the steering column and a

processor module applies assistive power via an electric

motor. This allows varying amounts of assistance depending

on driving conditions.

• With electronic systems becoming more and more common

in cars, EPS is the future power steering system that they

will use.

• EPS is active only during the actual steering process.

• The sum of the turning force on the steering wheel and the

assisting force is the effective force applied on the steering

gear to move the rack.

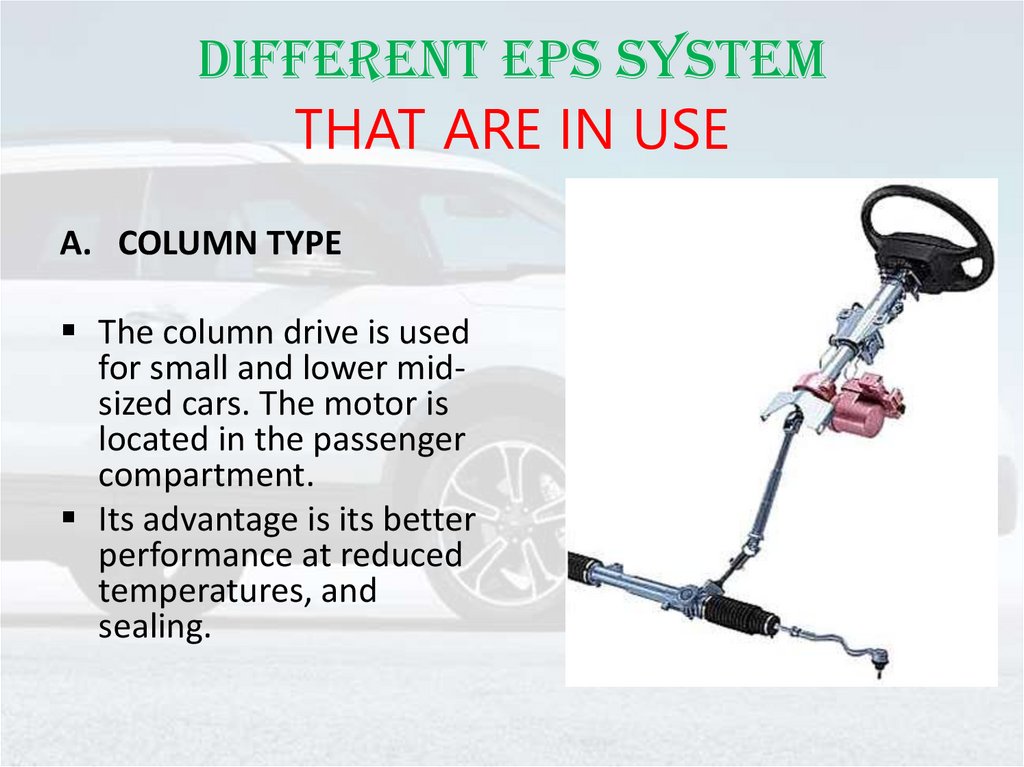

16. DIFFERENT EPS SYSTEM THAT ARE IN USE

A. COLUMN TYPEThe column drive is used

for small and lower midsized cars. The motor is

located in the passenger

compartment.

Its advantage is its better

performance at reduced

temperatures, and

sealing.

17. DIFFERENT EPS SYSTEM THAT ARE IN USE

B. DUAL PINION TYPE• The dual pinion drive is

used for mid-sized cars.

• This drive is located in

the engine

compartment

18. DIFFERENT EPS SYSTEM THAT ARE IN USE

C. RACK TYPEThis type is

appropriate for large

vehicles such as Sports

Utility Vehicles(SUVs)

and trucks

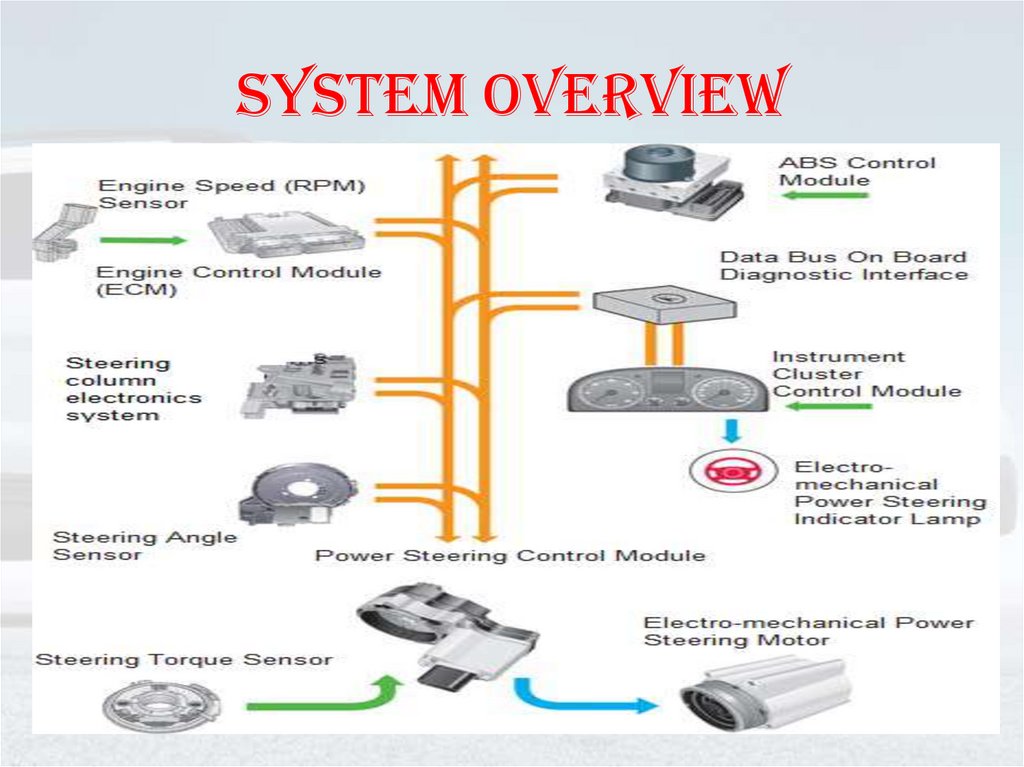

19. EPS COMPONENTS

1.2.

3.

4.

5.

6.

7.

8.

Steering wheel

Steering Angle Sensor

G85

Steering column

Steering Torque Sensor

G269

Steering gear

Electro-mechanical

Power Steering

Motor V187

Power Steering Control

Module J500

20. SYSTEM OVERVIEW

21. STEERING FUNCTION

1. The power steering assistance startswhen the driver uses force to turn the

steering wheel

2. The Steering Torque Sensor

detects the rotation and sends the

calculated steering force figure to the

Power Steering Control Module.

3. The Steering Angle Sensor reports

the current steering angle and steering

speed.

22. STEERING FUNCTION

4. Depending on the steering force, roadspeed, engine speed, steering angle,

steering speed and maps stored in Power

Steering Control Module , it calculates

the necessary assisting force and

actuates EMPS Motor.

5. The steering assistance comes from a

second pinion, which applies its energy

in parallel on the steering rack. This

pinion is driven by EMPS Motor.

6. The sum of the turning force on the

steering wheel and the assisting force

is the effective force applied on the

steering gear to move the rack.

23. STEERING FUNCTION

Electro-mechanical PowerSteering Indicator Lamp

EMPS Indicator Lamp light up

in two colors if functional

faults are detected.

If it lights up yellow, the

warning is of a lower priority.

If it lights up red, the vehicle

should be serviced

immediately

Once Power Steering Control

Module receives a signal,

indicating that all systems are

working correctly, EMPS

Indicator Lamp will go out.

24. CONTROL MAP CHARACTERISTICS

25. ENERGY COSUMPTION

10090

80

70

60

100

50

40

60

30

35

20

10

10

0

EPS

EHPS

HPS

HSPS

26. CONCLUSION

EPS reduces the human effort up to 80 percent soupcoming year of steering will be of EPS in all type of

vehicle.

EPS will become most efficient, safe and reliable power

steering system in the future .

The key to the success of EPS is an accurate and quick

response, so it will be used in F1 racing cars in upcoming

years.

Program for control module IC can be changed according

to need of assisting force. So it will be beneficial for

different types of road.

This year, in auto spa Delhi, mostly cars manufactured by

different company were launched with EPS.

27. REFERENCES

www.autoshop101.com/forms/Hybrid17.pdfhttp://www.volkspage.net/technik/ssp/ssp/SSP_225.pd

f self study program 259

http://www.howeperformance.com/rockcrawling.html

R.K.RAJPUT, 2009-10 , “AUTOMOBILE ENGINEERING”

M.F. Rehman, “ELECTRIC POWER ASSISTED STEERING

SYSTEM FOR AUTOMOBILES”, Electrical Engineering

Vol.3.

Ratan S., Tata McGraw Hills publication , “Theory of

Machines” Vol 1,

www.infineon.com/electric power steering.pdf/Edition

2008-10-23

mechanics

mechanics