Similar presentations:

The First Full Inorganic Packaging of UV LED in China

1.

The First Full Inorganic Packaging of UV LED in ChinaConfidential business information, disclosure prohibited

2.

OutlineCompany profile

Product technology

Quality assurance

Market application

2

3.

1.Company profile3

4.

1.1 Company profile4

Hongli Zhihui Group Co., Ltd.

Founding date:2004

Registered capital:710 million Yuan

Legal representative:Guo Ping LI

Stock code:300219.

Hongli Zhihui is a listed enterprise and it is also

known as a National Torch Plan key high-tech

enterprise, who is advance in researching , producing

and marketing for LED packaged devices in

worldwide.

Bytech Electronics Co.,Ltd.

Start-up time: 2013

Registered capital: 11.458 million Yuan

Legal representative Qian WU

BYTECH is the first enterprise who set foot in Full

Inorganic Packaging of UV LED in China. In an

Inorganic Packaging field, BYTECH has the complete

intellectual property in substrate, glass cover, laser

sealing process, and laser sealing equipments. The

company's current products including UV LED, VCSEL

and other OEM products.

5.

1.2 Events of BYTECHIn 2013

BYTECH

was

established

on

December

3th, 2013.

5

In 2014

In April,

BYTECH

launched the

first Full

Inorganic

Packaging UV

LED.

In 2015

In 2016

Won the "excellent

In June 2016 ,

enterprise"

we joined the

in the 4th innovation

Hong Li Zhihui

entrepreneurship

Group and

competition and was

become its

awarded the second prize affiliate.

in"Pearl River Angel Cup".

In October, BYTECH

obtained the certification

of ISO9001 quality

management system.

In 2017

In November,

BYTECH was

titled as a

National

High-tech

Enterprise.

In 2018

Registered as a sciencebased small and mediumsized enterprises of

Guangdong province.

In June 2018, the

company was voted as a

member of Ministry of

Industry and Information

Technology for

semiconductor lighting

technology.

6.

1.3 Science and technology projects for governmentScience and technology projects for government

The capital project in 2014 for business incubation in Zhongshan Torch Hi-tech

Industrial Development Zone: ''application modules of high efficient UVLED based

sterilization in drinking water''.

The Start-up Capital Project in 2014 in Pioneering Park for overseas students in

Zhongshan, China.

The technology innovation project in 2014 for small and medium-sized technologybased enterprises in Zhongshan city -- "UV LED packaging technology and

application".

Guangdong provincial special fund for frontier and key technology innovation

technology project in 2014, for small and medium-sized enterprises of science and

technology -- "UV LED and module for disinfection of drinking water".

2015 Guangdong province application-oriented science and technology research and

development special fund project -- "packaging technology and industrialization of

highly reliable uv LED light source with full inorganic".

National Key Research and Development Project in 2015 "strategic advanced

electronic materials" for research and development plan -- "key technology of thirdgeneration semiconductor solid-state ultraviolet light source materials and devices".

6

The holding subsidiary lasitong laser was supported by the sixth batch of innovation

and entrepreneurship research team projects in 2017 in Zhongshan (already

publicized).

7.

1.4 Setting the industry standardParticipated in drafting the National

Standard for Press and Publication

Industry -- “Control Requirements and

Inspection Methods for Paper during UV

curing process".

Participated in drafting the National

Standard for Press and Publication

Industry -- "The Requirements and an

Inspection Methods during Printing

Process of UV Flexo-Printing".

Participated in rafting the Local Standard

of Guangdong Province--"Technical

Requirements and Testing Methods for

UV LED".

7

8.

2. Product technology8

9.

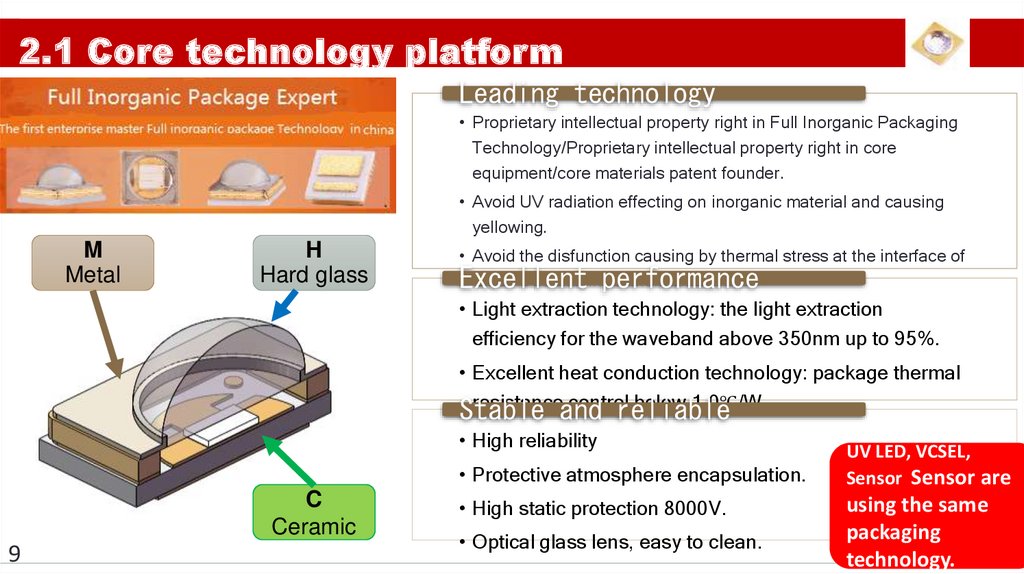

2.1 Core technology platformLeading technology

• Proprietary intellectual property right in Full Inorganic Packaging

Technology/Proprietary intellectual property right in core

equipment/core materials patent founder.

• Avoid UV radiation effecting on inorganic material and causing

yellowing.

M

Metal

H

Hard glass

• Avoid the disfunction causing by thermal stress at the interface of

organic packaging materials.

Excellent performance

• Light extraction technology: the light extraction

efficiency for the waveband above 350nm up to 95%.

• Excellent heat conduction technology: package thermal

resistance control below 1.0℃/W.

Stable and reliable

• High reliability

• Protective atmosphere encapsulation.

C

Ceramic

9

• High static protection 8000V.

• Optical glass lens, easy to clean.

UV LED, VCSEL,

Sensor Sensor are

using the same

packaging

technology.

10.

2.2 Core intellectual propertyItem

pcs

material

2

method

7

application

5

equipment

6

10 Total

20

Patent for

invention

11

Utility

model

7

11.

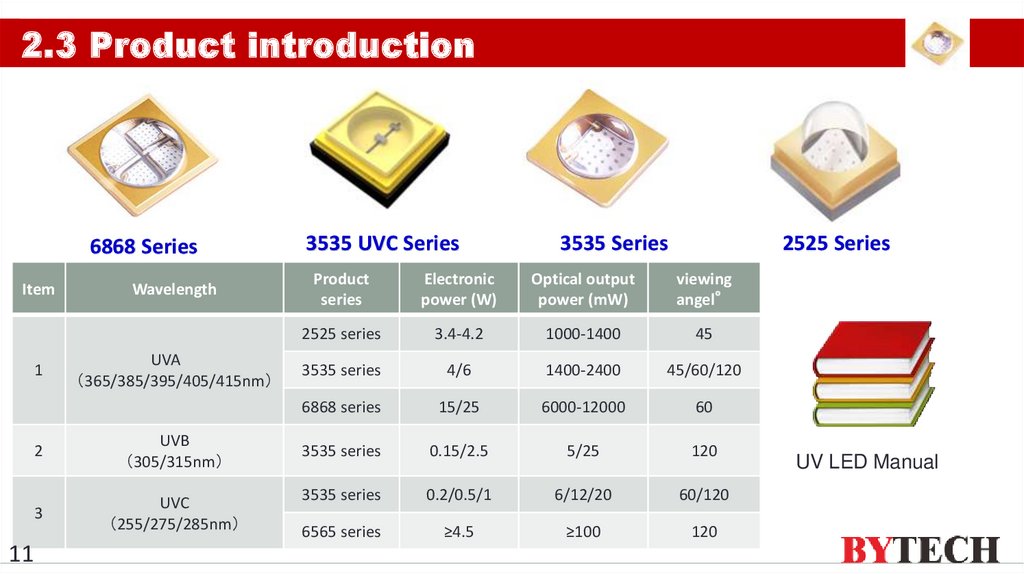

2.3 Product introduction6868 Series

Item

1

Wavelength

UVA

365/385/395/405/415nm

2

UVB

305/315nm

3

UVC

255/275/285nm

11

3535 UVC Series

3535 Series

2525 Series

Product

series

Electronic

power (W)

Optical output

power (mW)

viewing

angel°

2525 series

3.4-4.2

1000-1400

45

3535 series

4/6

1400-2400

45/60/120

6868 series

15/25

6000-12000

60

3535 series

0.15/2.5

5/25

120

3535 series

0.2/0.5/1

6/12/20

60/120

6565 series

≥4.5

≥100

120

UV LED Manual

12.

2.4 Module product introductionCustomized/solution services

Module

design

SMT service

Lamp bead

selection

Thermal

design

Temperature

monitoring

Lamp bead

configuration

Optical design

Void rate

control

Stress Test of

the Insulation

The power

supply

UV LED Module

Instruction Manual

UV LED MODULE

Protective

ascension

12

IPX4

13.

3.Quality assurance13

14.

3.1 Quality system and patent protection14

15.

3.2 Research and development facility14

16.

3.3 Research and development facility14

17.

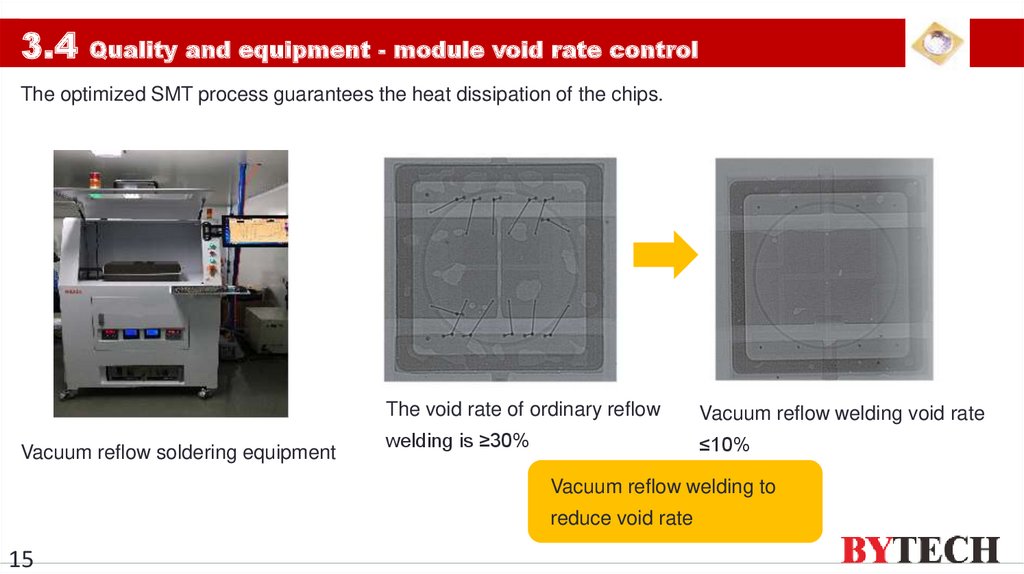

3.4Quality and equipment - module void rate control

The optimized SMT process guarantees the heat dissipation of the chips.

Vacuum reflow soldering equipment

The void rate of ordinary reflow

Vacuum reflow welding void rate

welding is ≥30%

≤10%

Vacuum reflow welding to

reduce void rate

15

18.

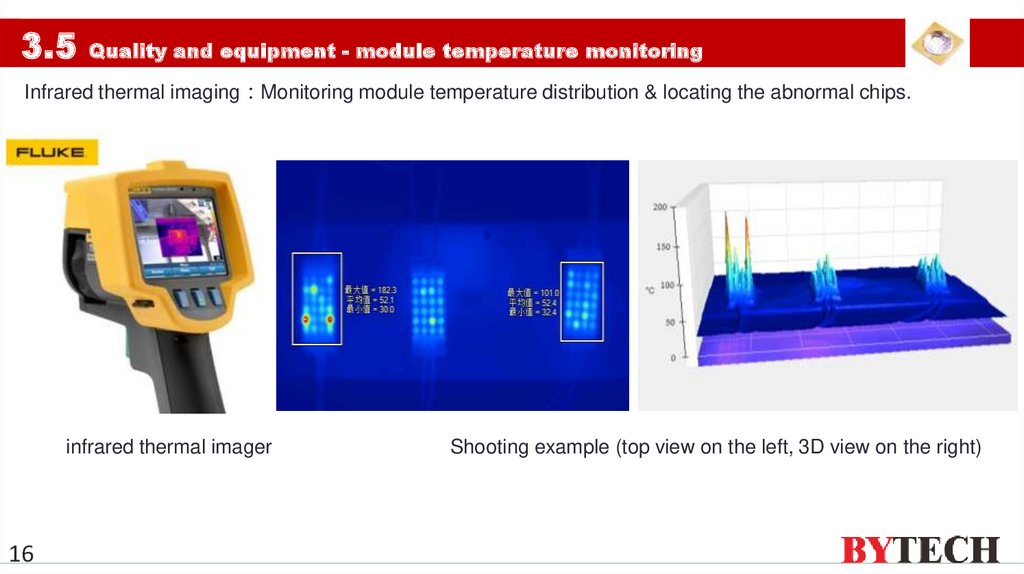

3.5Quality and equipment - module temperature monitoring

Infrared thermal imaging Monitoring module temperature distribution & locating the abnormal chips.

infrared thermal imager

16

Shooting example (top view on the left, 3D view on the right)

19.

3.6 Quality and equipment - module waterproof level upgradeThrough a special process, the UV LED module's waterproof grade can up to IPX4

Solve the problem of "condensate water"

IP waterproof rating

IP waterproof grade test

equipment

17

IPX4 experiment of UVLED module

20.

4. Market application18

21.

4.1 Application case - printing industryApplication: exposure machine, offset press,

inkjet printer, etc.

19

22.

4.2 Application case - coating industry20

23.

4.3 Application case - semiconductor equipmentLithography

machine,

exposure

machine

21

24.

4.4 Application case - identification systemRemote infrared

monitoring

Intelligent driving

Face recognition

23

25.

4.5 Application case - air purificationAir purification

UV LED tube

24

26.

4.6 Application case -UVC sterilization25

industry

industry