Similar presentations:

Light RTM (LRTM) Moulding “Mould build technology"

1. Light RTM (LRTM) Moulding

“Mould build technology"Presented By

Alan Harper, Managing Director, Plastech TT. UK.

Plastech TT Ltd.,

1

2. Master Model

OrientationFlange

Surface

Draft

angle

Release agent

Plastech TT Ltd.,

2

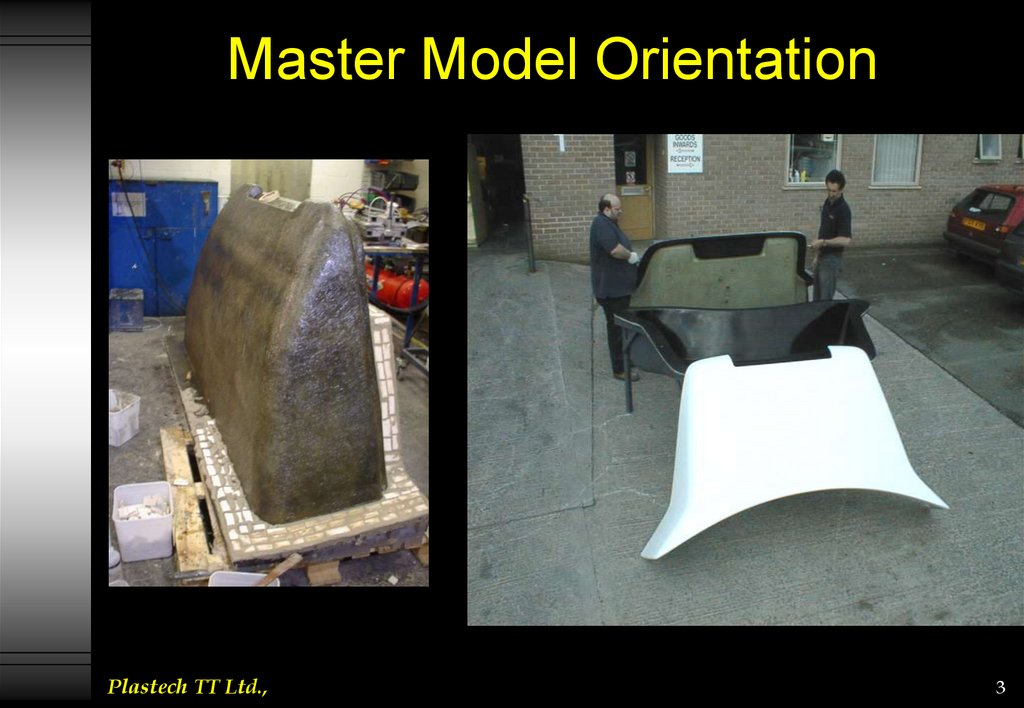

3. Master Model Orientation

Plastech TT Ltd.,3

4. Lounger pattern Flange

Dual level flangingSimple flange

Plastech TT Ltd.,

4

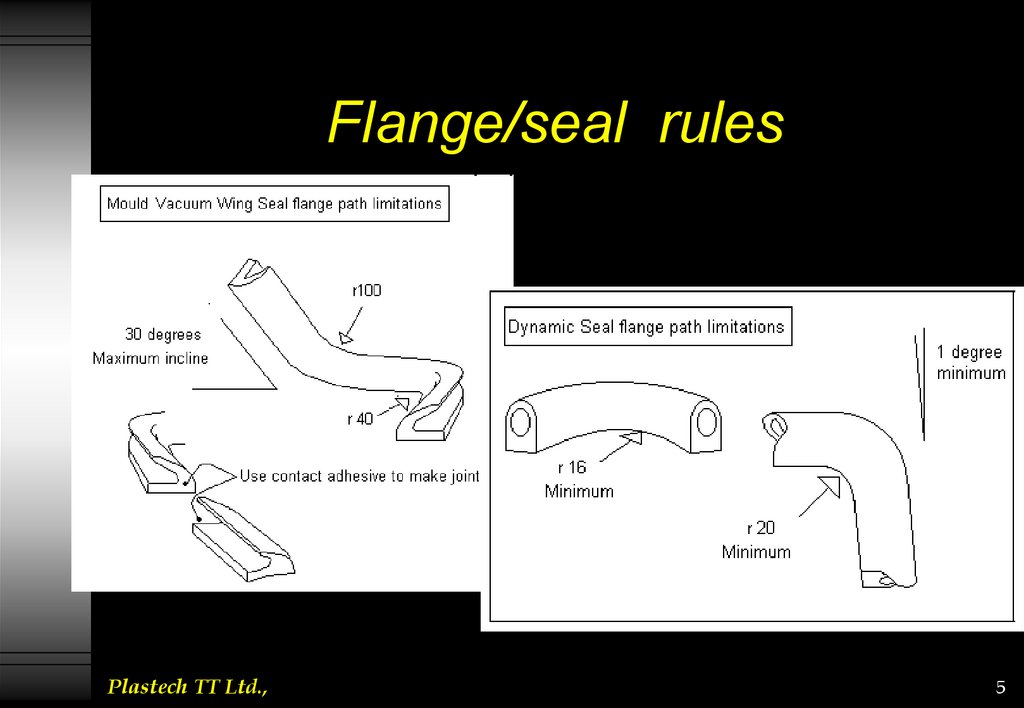

5. Flange/seal rules

Plastech TT Ltd.,5

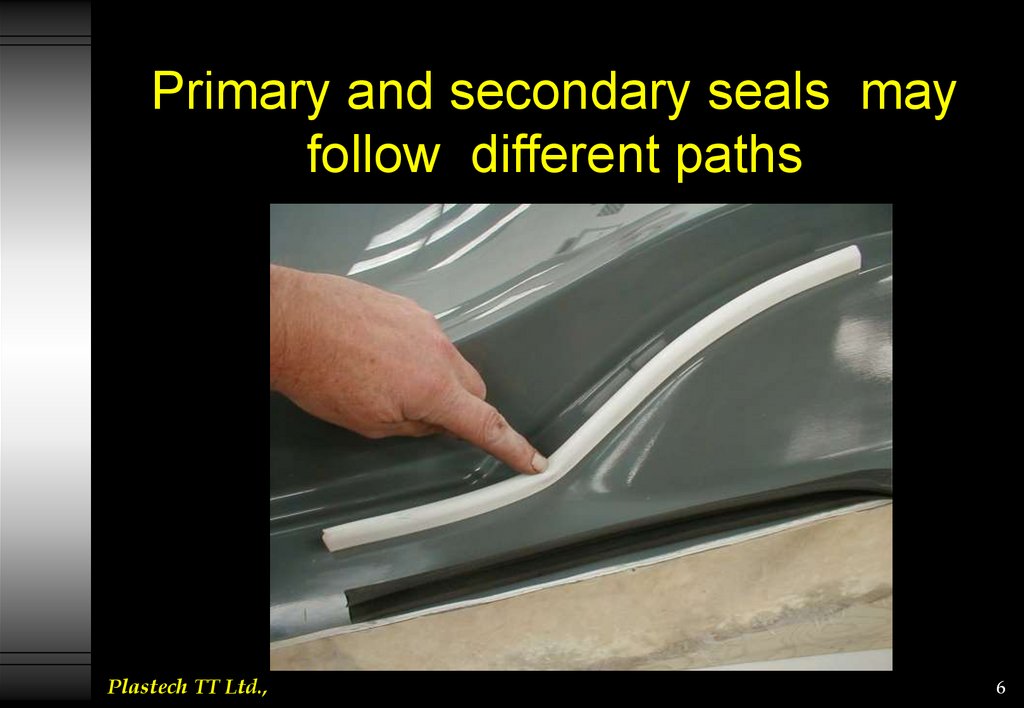

6. Primary and secondary seals may follow different paths

Plastech TT Ltd.,6

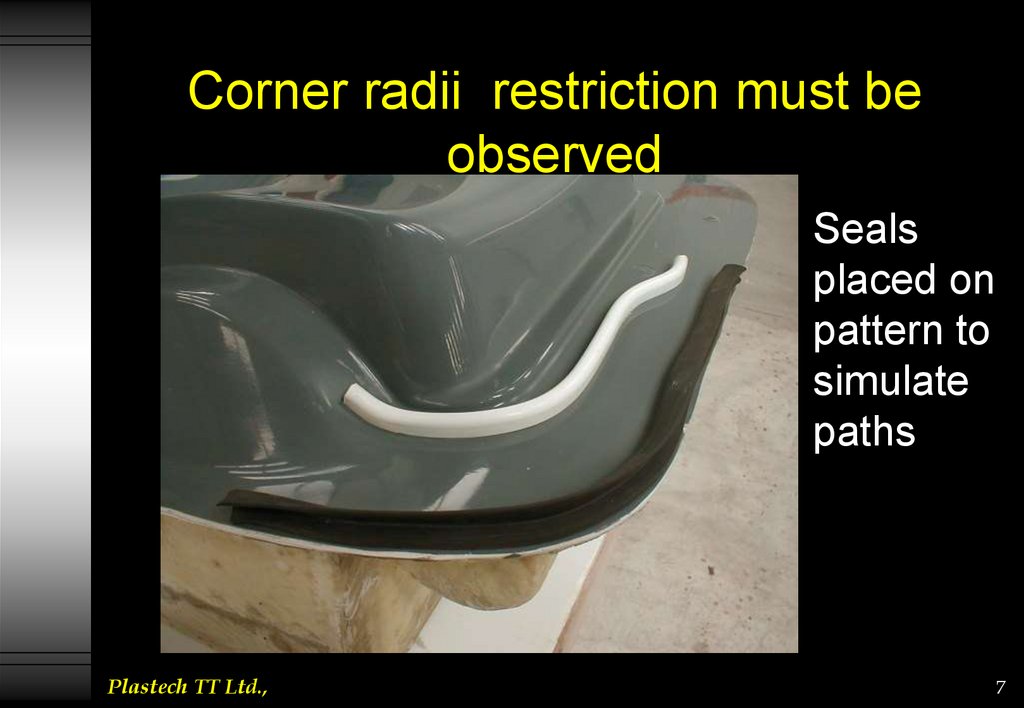

7. Corner radii restriction must be observed

Sealsplaced on

pattern to

simulate

paths

Plastech TT Ltd.,

7

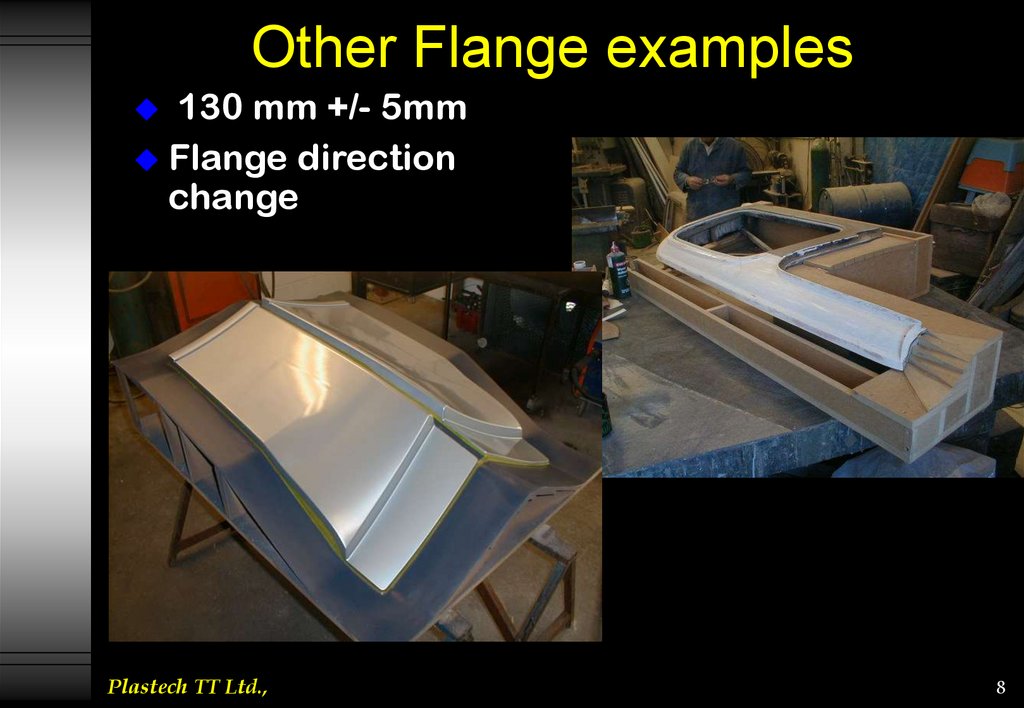

8. Other Flange examples

130 mm +/- 5mmFlange direction

change

Plastech TT Ltd.,

8

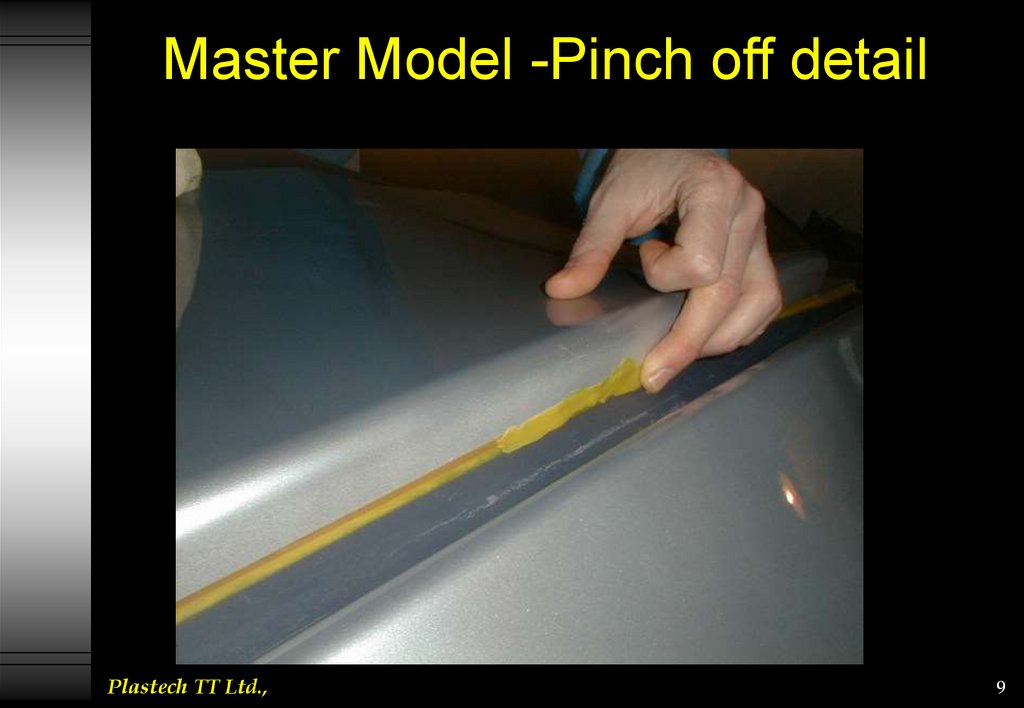

9. Master Model -Pinch off detail

Plastech TT Ltd.,9

10. Inserts in the first mould flange

Flangevacuum

Injection port

Alternatives

Autosprue

10mm pipe

Plastech TT Ltd.,

10

11. Location of inserts on master pattern

Plastech TT Ltd.,11

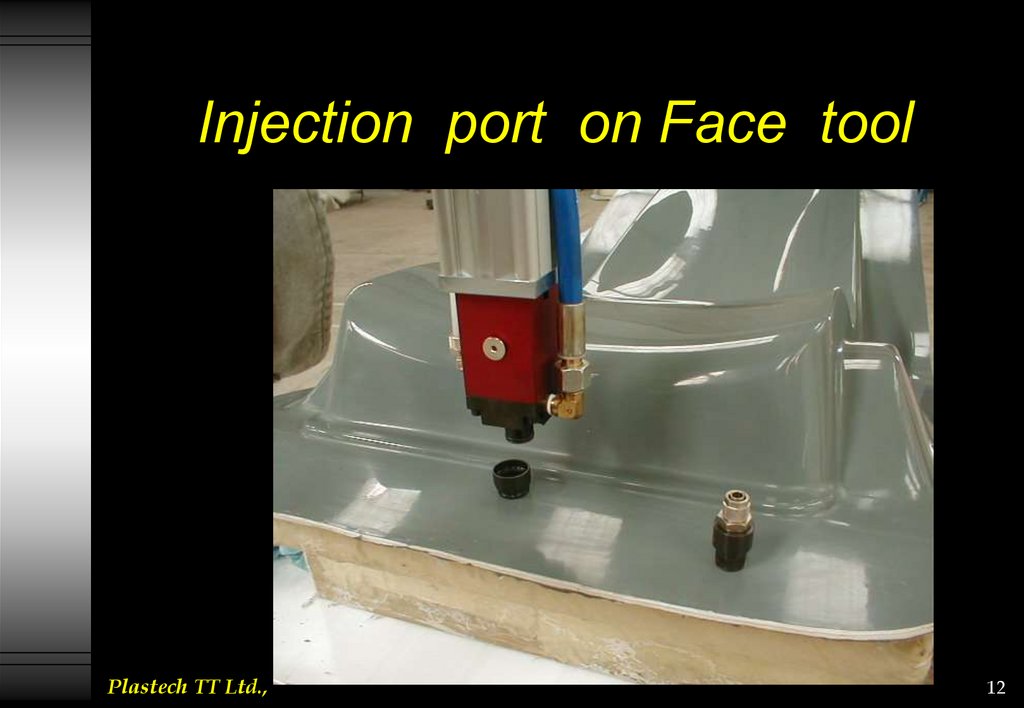

12. Injection port on Face tool

Plastech TT Ltd.,12

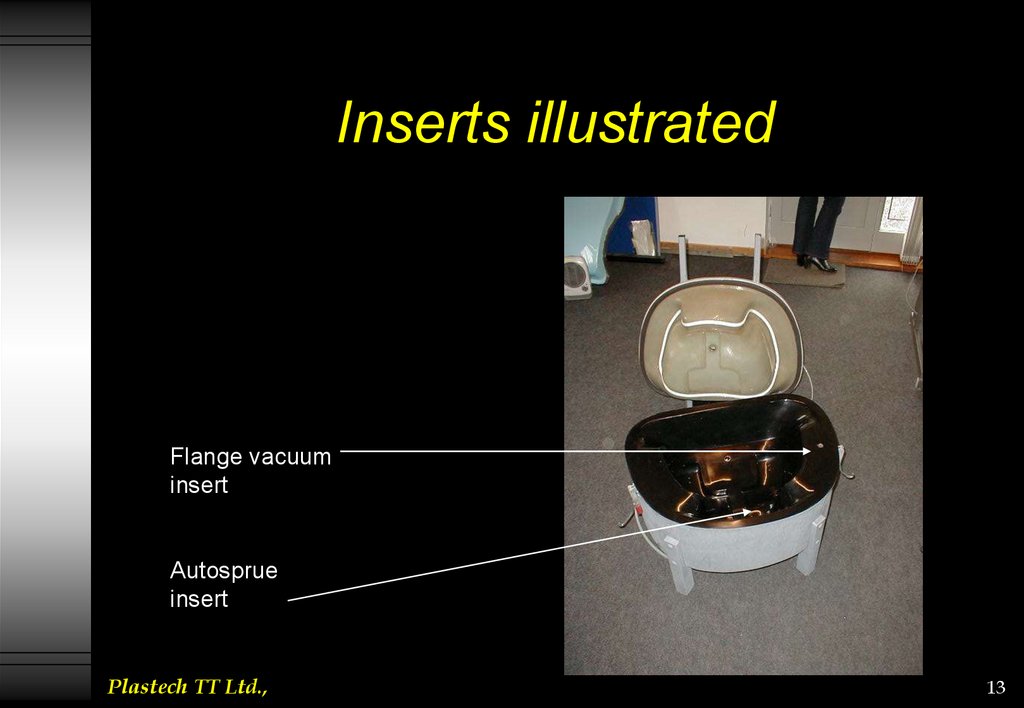

13. Inserts illustrated

Flange vacuuminsert

Autosprue

insert

Plastech TT Ltd.,

13

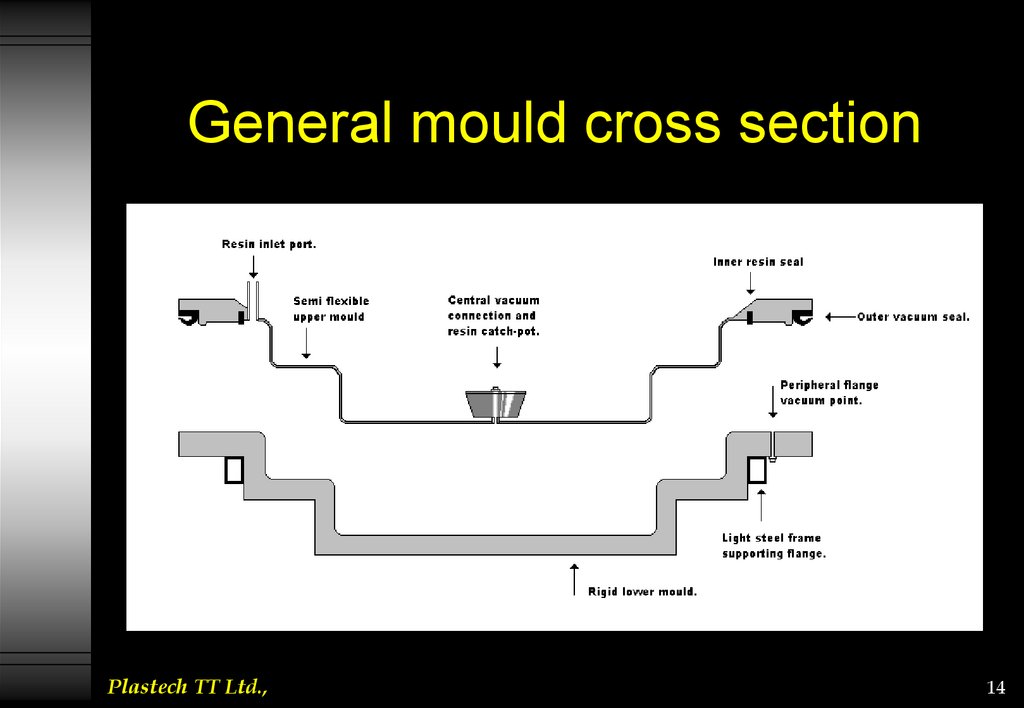

14. General mould cross section

Plastech TT Ltd.,14

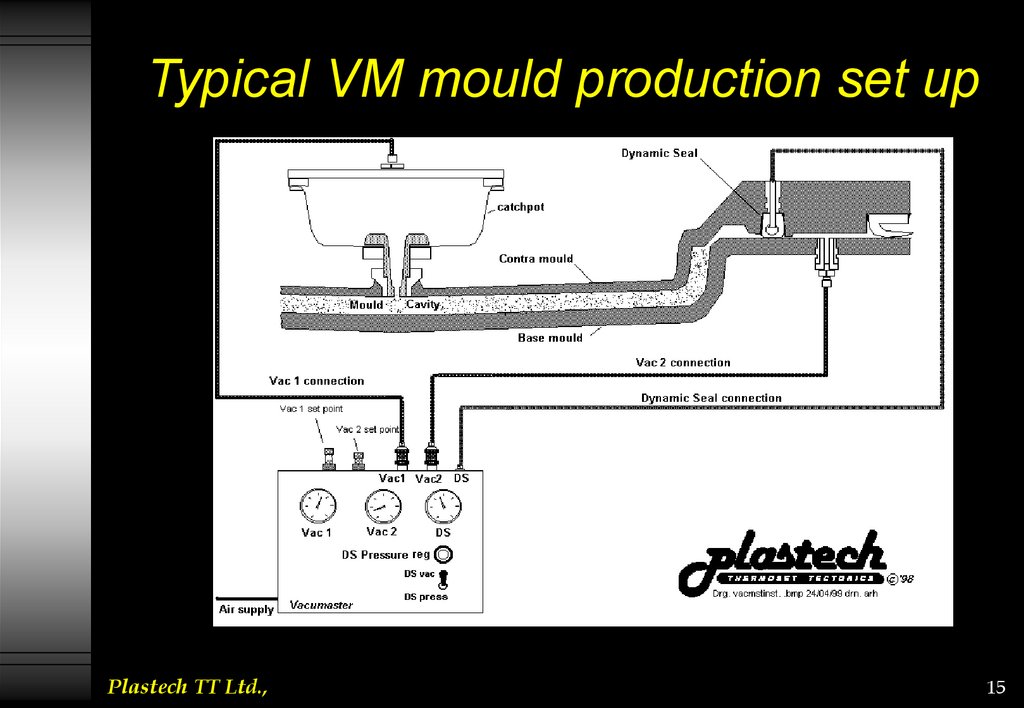

15. Typical VM mould production set up

Plastech TT Ltd.,15

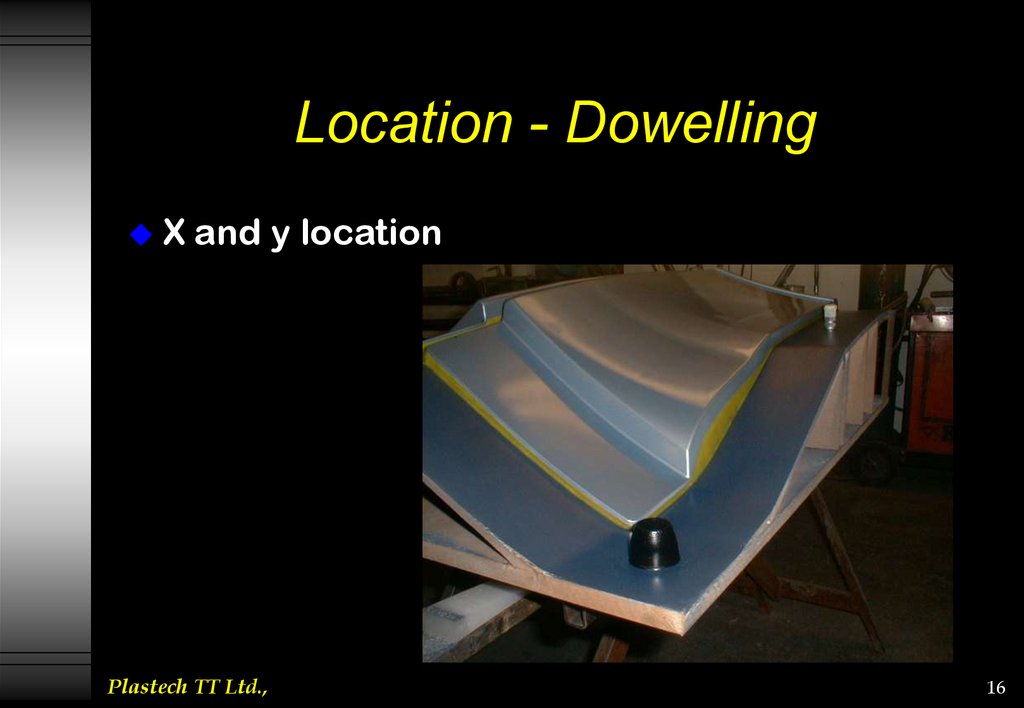

16. Location - Dowelling

Xand y location

Plastech TT Ltd.,

16

17. Peripheral Fill

Resinmould flow designed to find initial

easy path around cavity.

Ideal - path fills before cavity starts to fill.

Theory to practise example………

Plastech TT Ltd.,

17

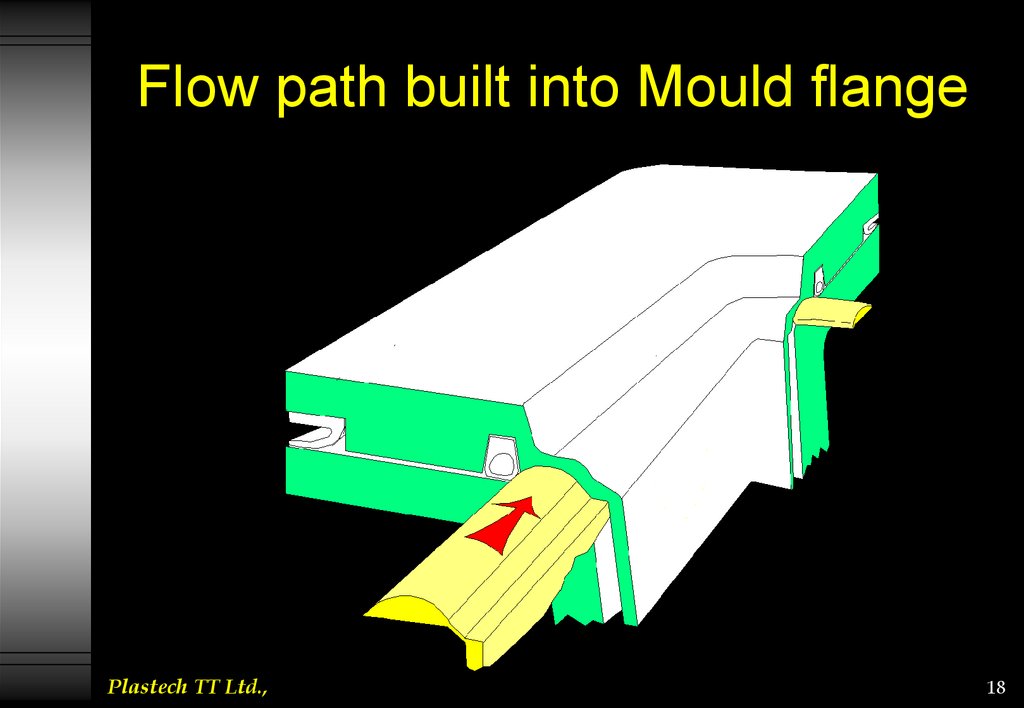

18. Flow path built into Mould flange

Plastech TT Ltd.,18

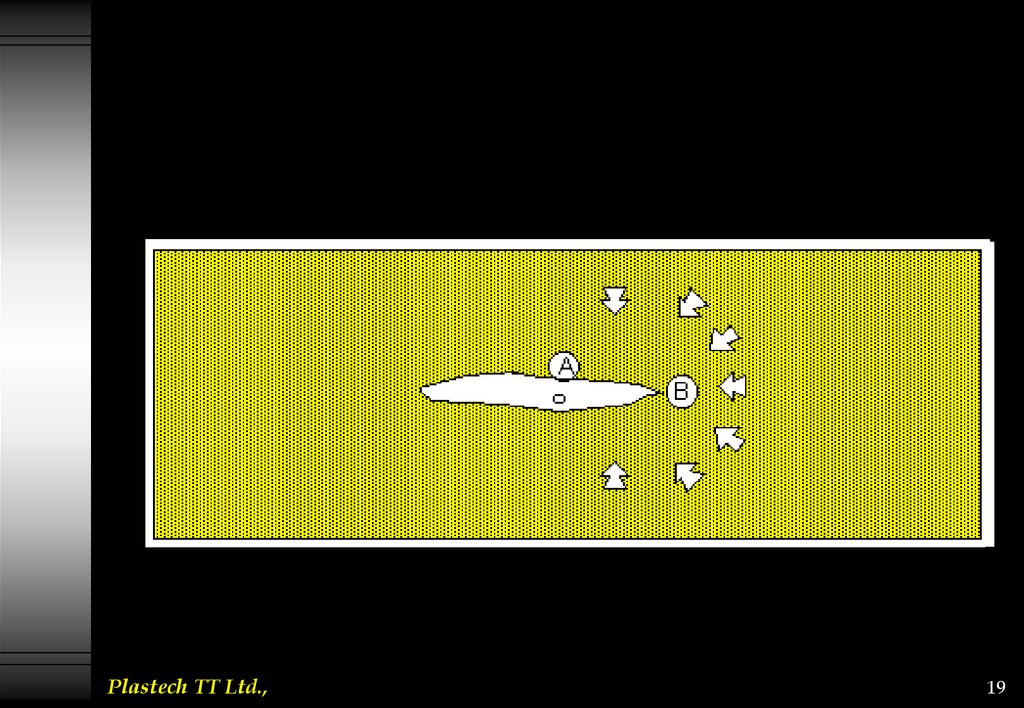

19.

Plastech TT Ltd.,19

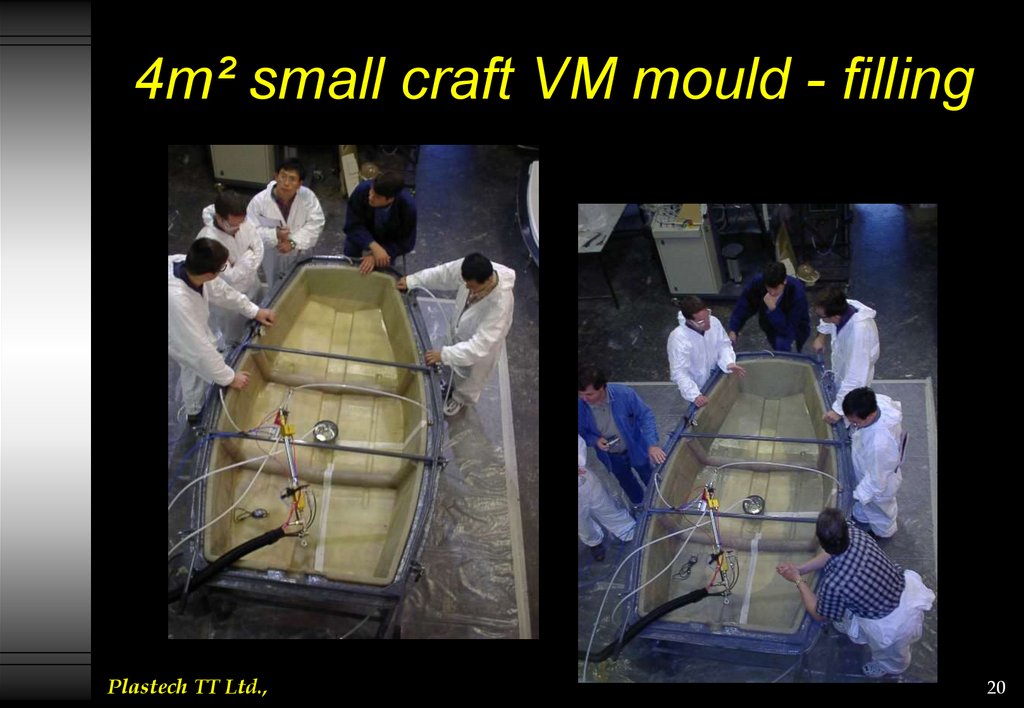

20. 4m² small craft VM mould - filling

Plastech TT Ltd.,20

21. Reality

Plastech TT Ltd.,21

22. More Flow shots

Plastech TT Ltd.,22

23. Face tool Lay up

Releaseagent

Tooling gel coat VE

Tissue + VE

First layer 450 g/m² CSM + VE

Second 3 x 450 g/m² CSM + LP

Frame – wood or light steel

Plastech TT Ltd.,

23

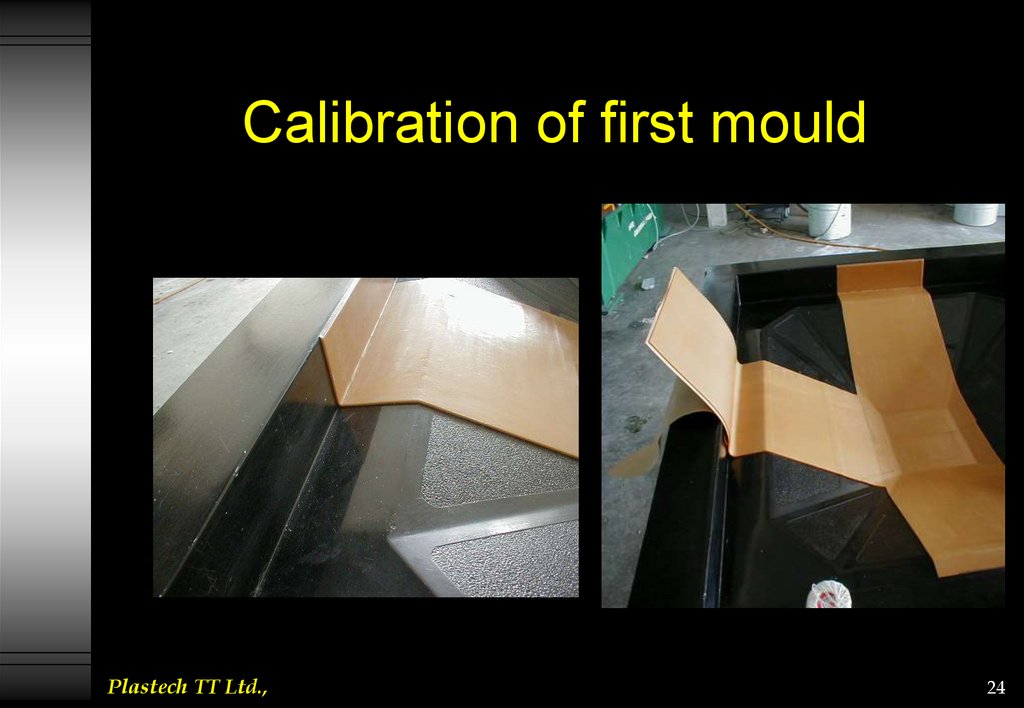

24. Calibration of first mould

Plastech TT Ltd.,24

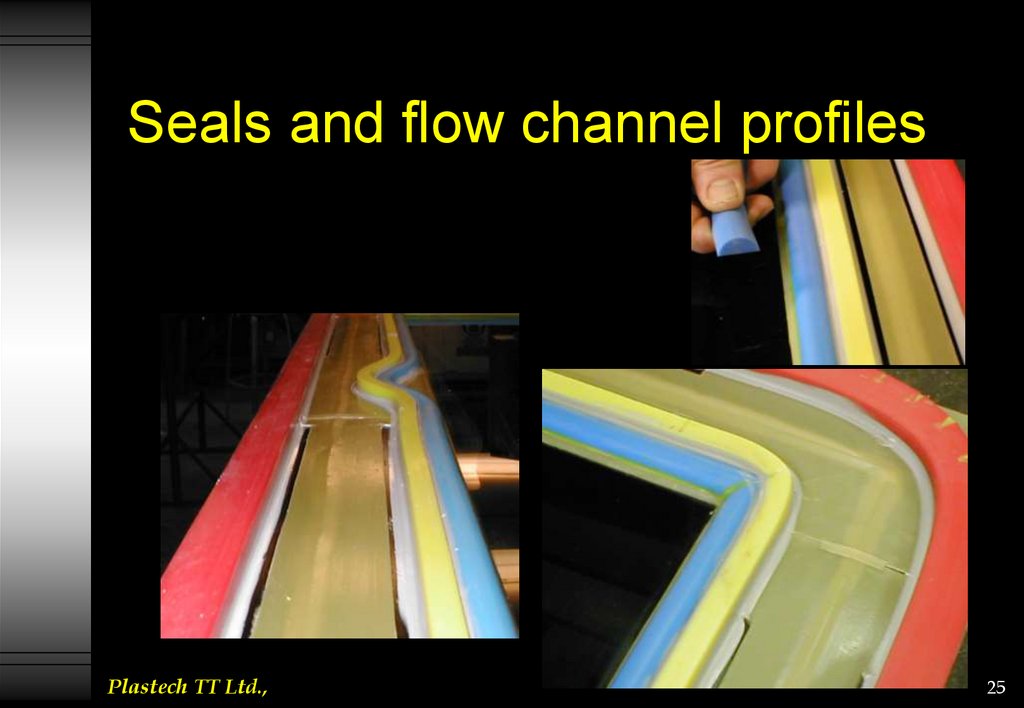

25. Seals and flow channel profiles

Plastech TT Ltd.,25

26. Seals and profiles

Plastech TT Ltd.,26

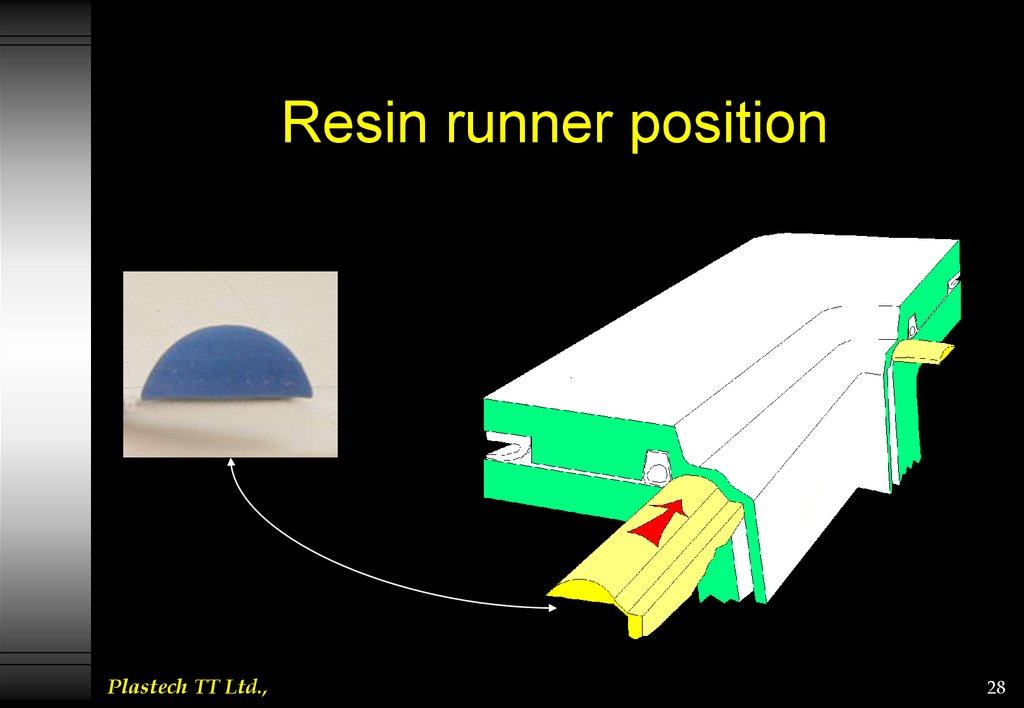

27. Resin Runner Profile

In facemould

or

contra

mould

Plastech TT Ltd.,

27

28. Resin runner position

Plastech TT Ltd.,28

29. Two vacuum levels

Vacuum1 to clamp mould flange.

At least 85% providing 1 tonne/linear m.

Vacuum 2 to clamp cavity and assist fill.

55% provides 0.55kg/cm ² clamping.

Plastech TT Ltd.,

29

30. Air driven vacuum control

Plastech TT Ltd.,30

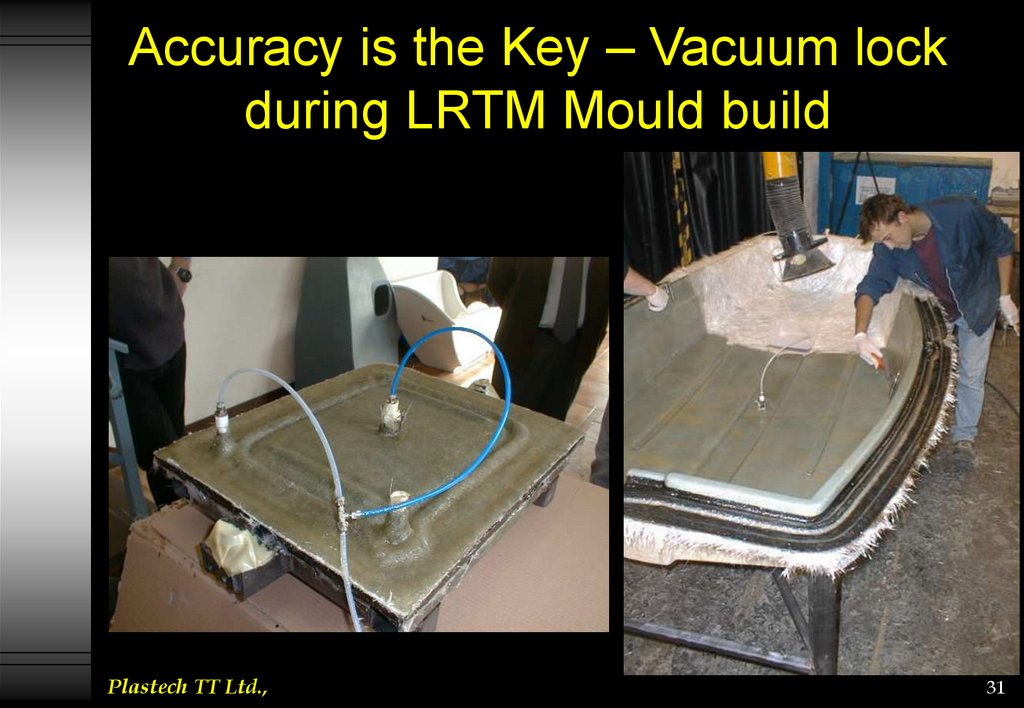

31. Accuracy is the Key – Vacuum lock during LRTM Mould build

Plastech TT Ltd.,31

32. Total Cost of moulds

Mould material costs £340 / m²Labour costs average 30 hrs /m²

Comparison, LRTM tooling is less than

50% the cost of conventional RTM

tooling

Plastech TT Ltd.,

32

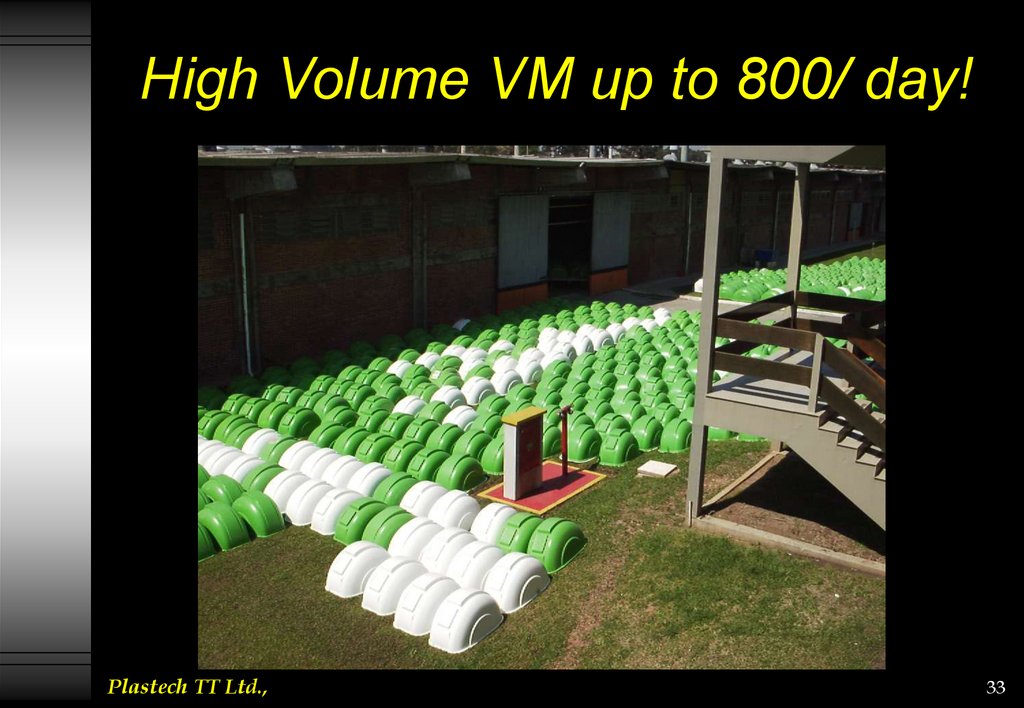

33. High Volume VM up to 800/ day!

Plastech TT Ltd.,33

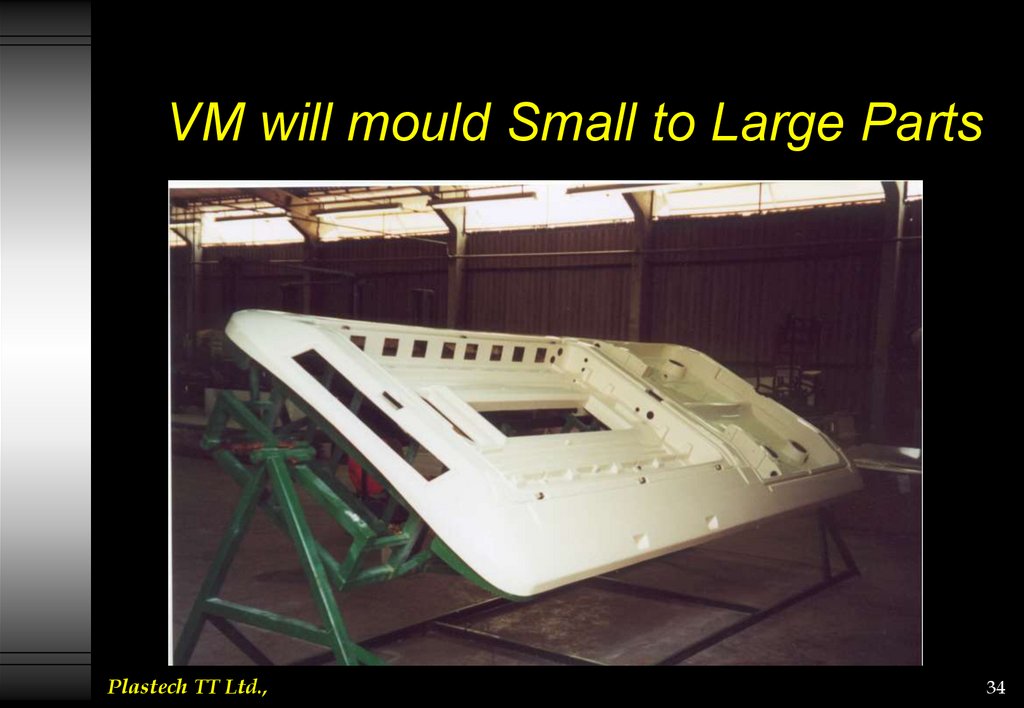

34. VM will mould Small to Large Parts

Plastech TT Ltd.,34

35. LRTM can go big and complicated

Plastech TT Ltd.,35

36. Wind Turbine housing – approx. 100 m2 surface area

Plastech TT Ltd.,36

37.

Plastech TT Ltd.,37

38.

Difference between RTM and LRTMMoulding Speed

Moulding accuracy

Equipment requirements

Plastech TT Ltd.,

38

39. “RTM” and complimentary “LRTM” closed moulding for composites

Difference between RTM and LRTMMoulding Speed

Plastech TT Ltd.,

39

40. Moulding Speed

LRTMinjects the fibre pack at

approximately 1/3 the speed of RTM

LRTM cannot be speeded up by using

higher injection pressure

RTM is able to inject 2 to 4 times faster

Optimised RTM 6 times faster

Plastech TT Ltd.,

40

41. “RTM” and complimentary “LRTM” closed moulding for composites

Difference between RTM and LRTMMoulding Speed

Moulding accuracy

Plastech TT Ltd.,

41

42. Moulding Accuracy

moulds within +/- 0.025”at bestRTM moulds within +/- 0.002” at best

LRTM mould accuracy governed by fibre

pack and vacuum level- unpredictable

RTM mould set accuracy controlled by

design - predictable

LRTM

Plastech TT Ltd.,

42

43. “RTM” and complimentary “LRTM” closed moulding for composites

Difference between RTM and LRTMMoulding Speed

Moulding accuracy

Equipment requirements

Plastech TT Ltd.,

43

44. Equipment requirements

RTMneeds a low pressure meter mix

machine and tool manipulator.

LRTM needs a VERY low pressure meter

mix machine and two vacuum sources

Plastech TT Ltd.,

44

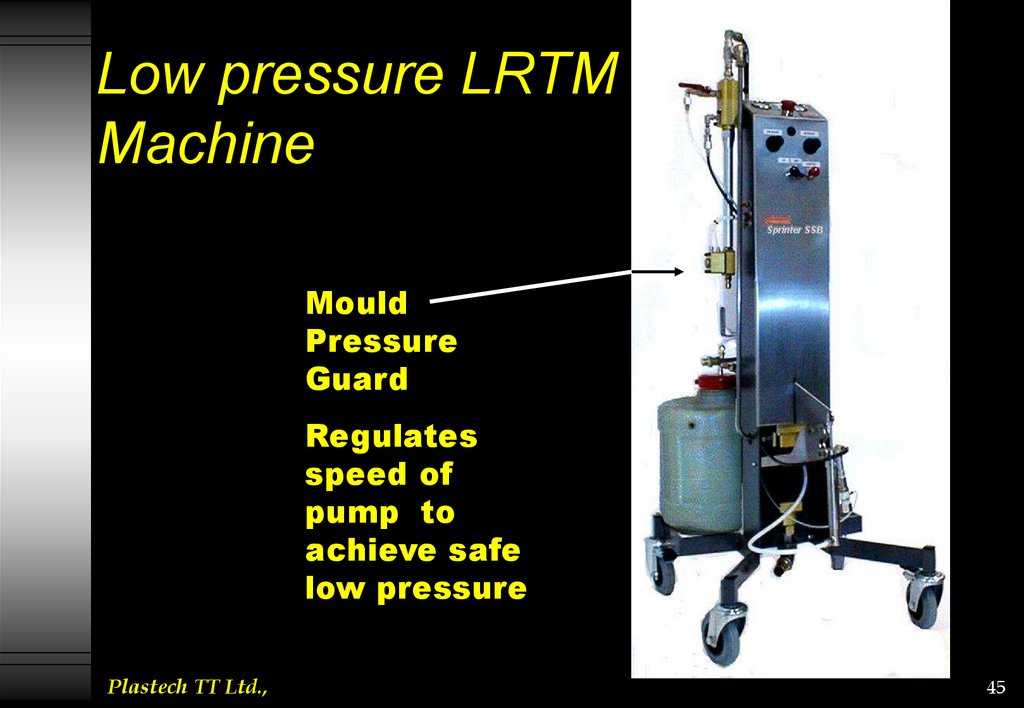

45. Low pressure LRTM Machine

MouldPressure

Guard

Regulates

speed of

pump to

achieve safe

low pressure

Plastech TT Ltd.,

45

46. More Application examples

Plastech TT Ltd.,46

47. Sunlounger

Plastech TT Ltd.,47

48. Pacific Composites - Australia

PacificComposites Australia

Plastech TT Ltd.,

48

49. Invalid Bath

Plastech TT Ltd.,49

50. 10mm thick 80kg VE resin

Plastech TT Ltd.,50

51.

Plastech TT Ltd.,51

52.

Plastech TT Ltd.,52

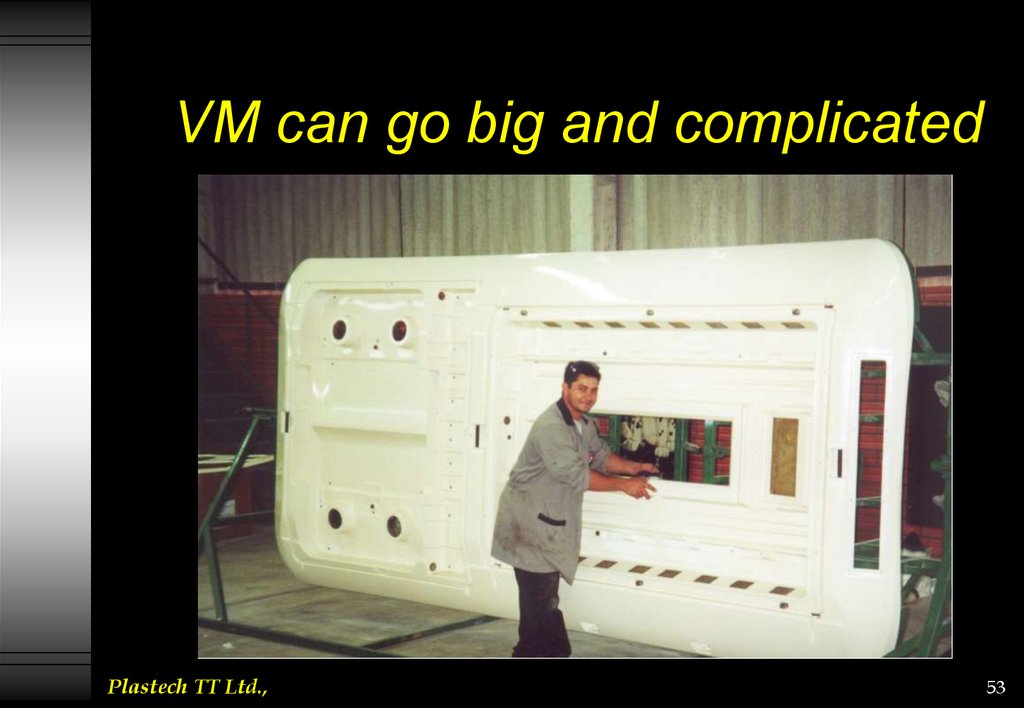

53. VM can go big and complicated

Plastech TT Ltd.,53

54.

Plastech TT Ltd.,54

55.

Plastech TT Ltd.,55

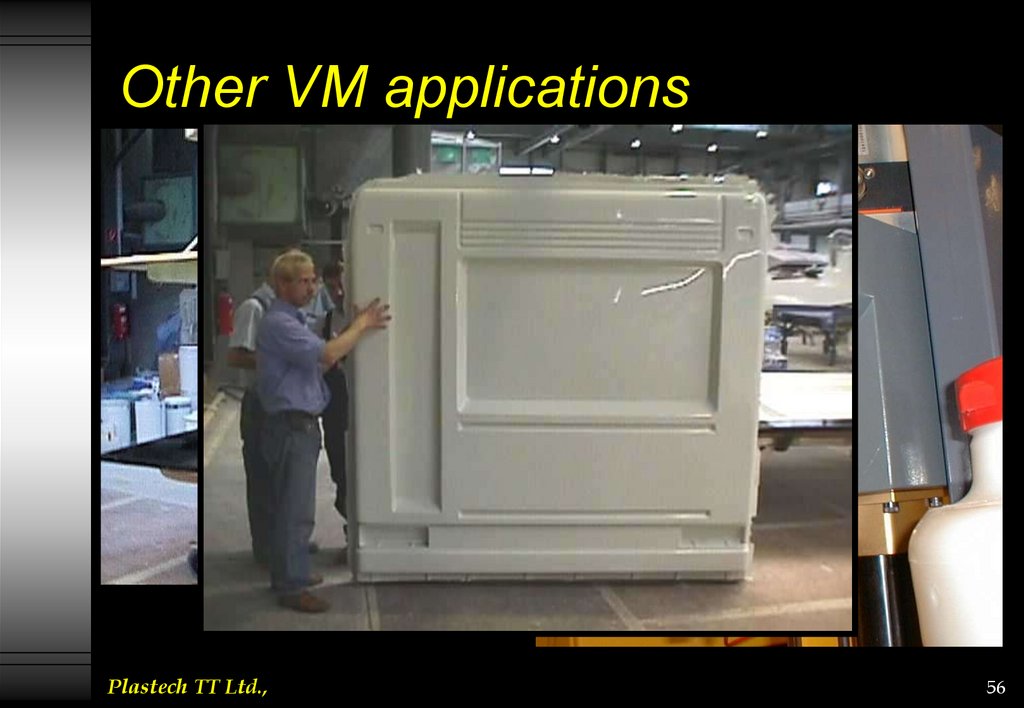

56. Other VM applications

Plastech TT Ltd.,56

57. Conclusions

LRTMis a viable lower cost system

complimentary to RTM.

Tooling manufacture must be accurate

Material selection, resin, fibre critical.

Operating procedures must be

consistent for success.

Plastech TT Ltd.,

57

58. Heating /Temperature control

Plastech TT Ltd.,58

59.

Electrical Heater-Cloth Application.Plastech TT Ltd.,

59

60.

Plastech TT Ltd.,60

61.

Plastech TT Ltd.,61

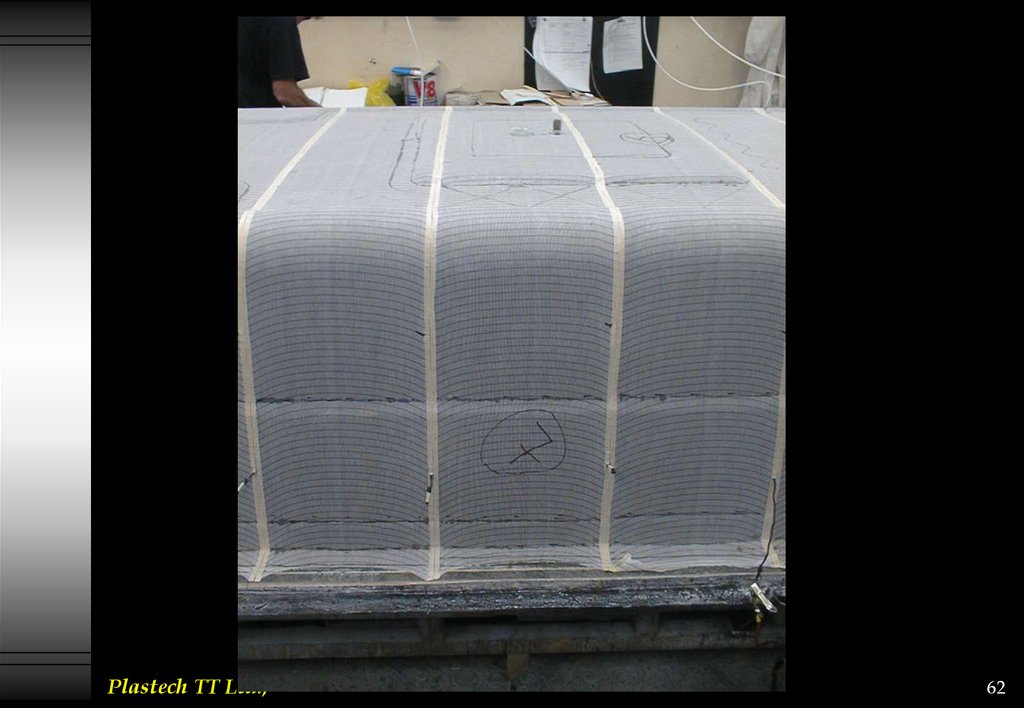

62.

Plastech TT Ltd.,62

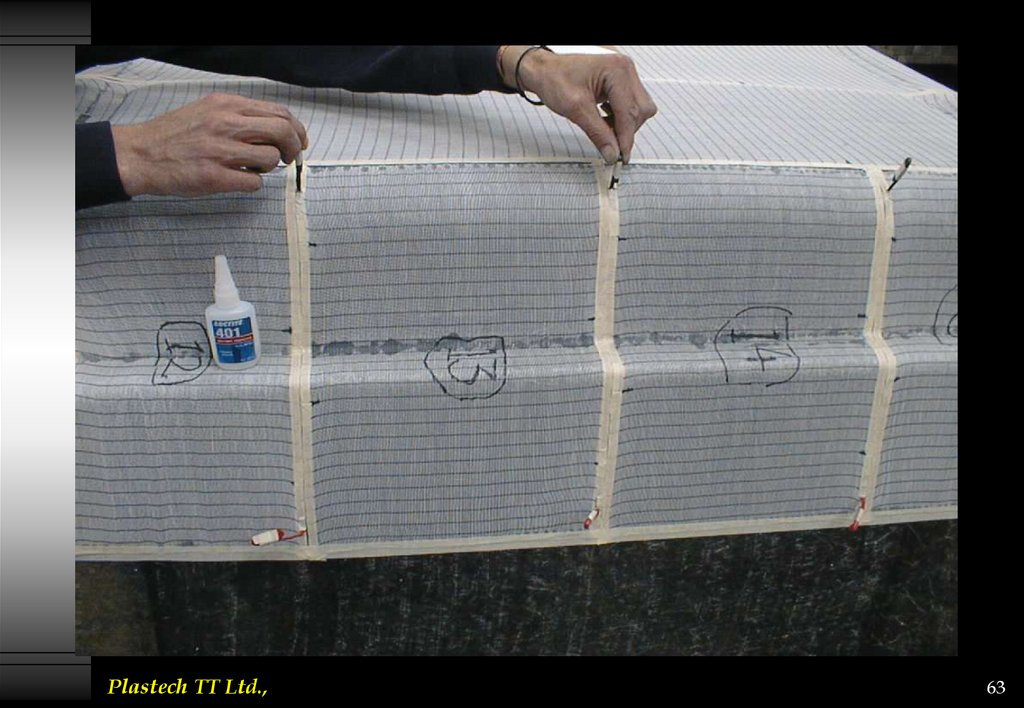

63.

Plastech TT Ltd.,63

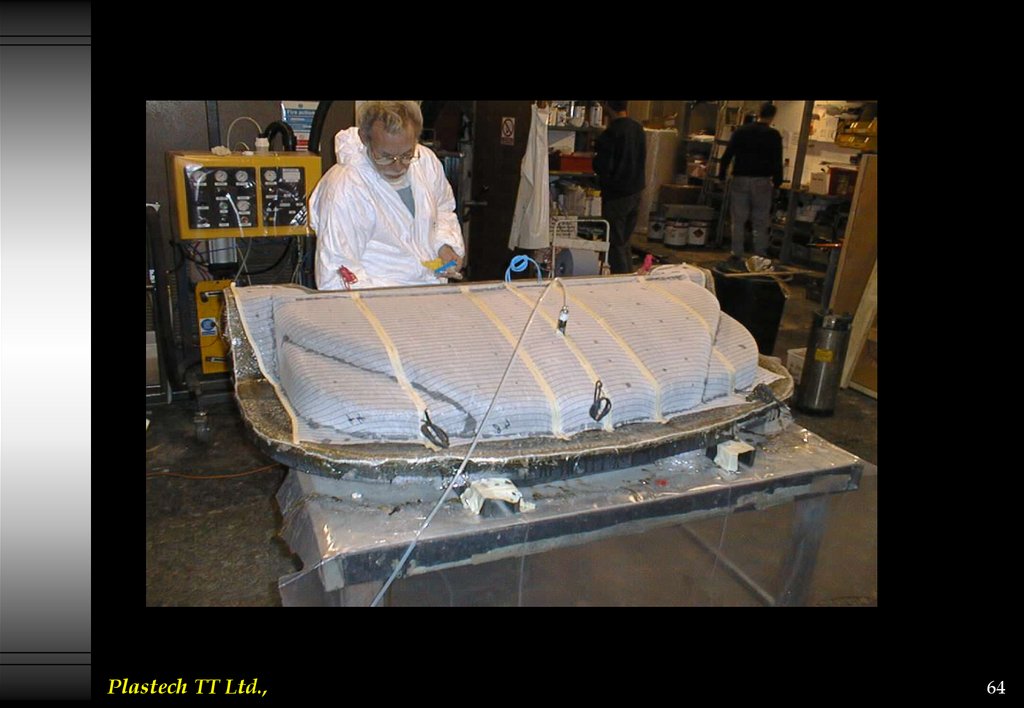

64.

Plastech TT Ltd.,64

65.

Plastech TT Ltd.,65

66.

Plastech TT Ltd.,66

67.

Plastech TT Ltd.,67

68.

Plastech TT Ltd.,68

69.

Plastech TT Ltd.,69

70.

Plastech TT Ltd.,70

71.

Plastech TT Ltd.,71

72.

Plastech TT Ltd.,72

73.

Plastech TT Ltd.,73

74.

Plastech TT Ltd.,74

75.

Plastech TT Ltd.,75

industry

industry