Similar presentations:

Steel hardenability capacity and hardenability

1.

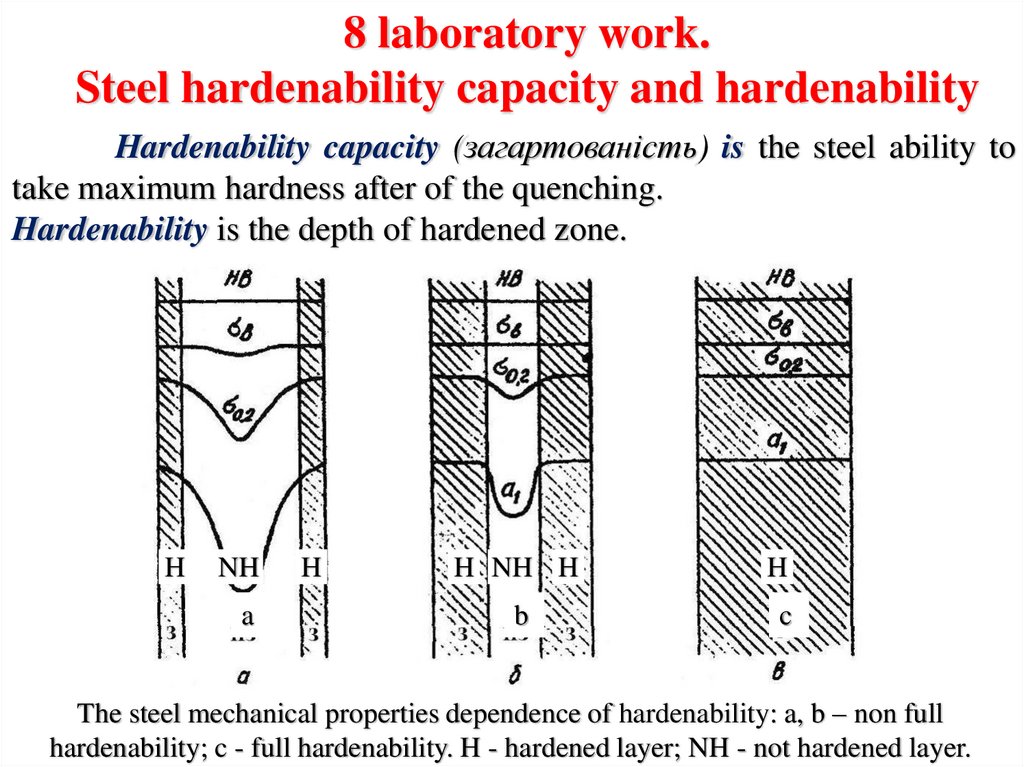

8 laboratory work.Steel hardenability capacity and hardenability

Hardenability capacity (загартованість) is the steel ability to

take maximum hardness after of the quenching.

Hardenability is the depth of hardened zone.

H

NH

a

H

H NH H

b

H

c

The steel mechanical properties dependence of hardenability: a, b – non full

hardenability; c - full hardenability. H - hardened layer; NH - not hardened layer.

2.

Steel hardenabilityThe part has not full hardenability, when the part cooling rate

(Vc) is less than the critical (Vcr) for steel, which manufactured the

product (slide 16 a, b). The hardened zone depth increases with

decreasing Vcr the material (slide 16 a, b). Part has full hardenability and

martensitic structure at Vc > Vcr (slide 16 c). If the part section has great

[greɪt-великі] sizes and it is impossible to reach critical cooling rate

even [‘iv(ə)n-навіть] on the surface, such a part does not quenched.

Parts working in conditions of high pressure and large dynamic

loads are made of steels with high hardenability. In the case of

incomplete hardenability mechanical properties differs significantly in

external and internal layers of parts (slide 16 a, b)., It is which reduces

The reliability operation [rɪlaɪə'bɪlətɪ ɔp(ə)'reɪʃ(ə)n-надійність

експлуатації] decreases in the case. For steels with a through

prohartovuvanistyu mechanical properties are practically identical (slide

16 c).

3.

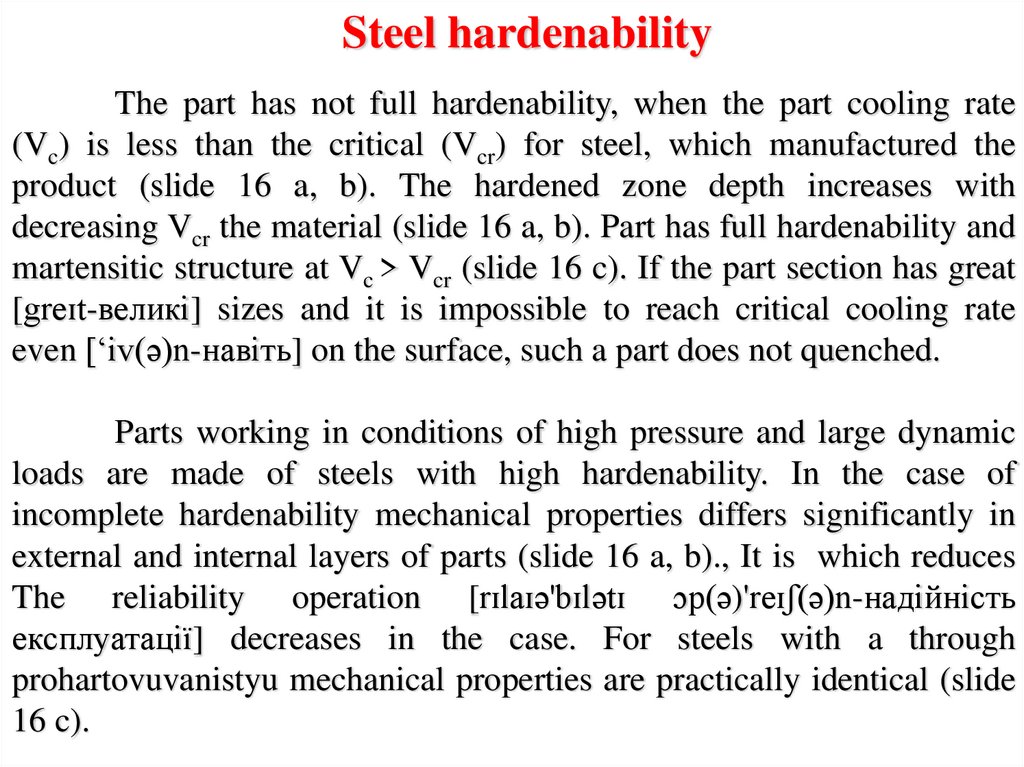

Steel hardenabilityHardenability criteria [kraɪ'tɪərɪə] is critical diameter (Dcr) and

the semi martensitic (50% martensite and 50% troostite) zone length.

Critical diameter (Dcr) is the maximum diameter of the cylindrical

sample that has full hardenability in the cooling environment

[ɪn'vaɪər(ə)nmənt].

The ideal critical

diameter

(D )

corresponds

[kɔrɪ'spɔndвідповідає] to the

Dcr

Quenching in oil

Dcr

maximum part cross

section that has full

hardenability in ideal

Quenching in water

cooling

environment

with

infinitely

Hardenability of different diameter samples at ['ɪnfɪnətlɪ-безкінечно]

cooling in water and oil: Shaded

high (великою)

of

[ʹʃeıdıd-заштрихована] area – non quenching. cooling rate.

4.

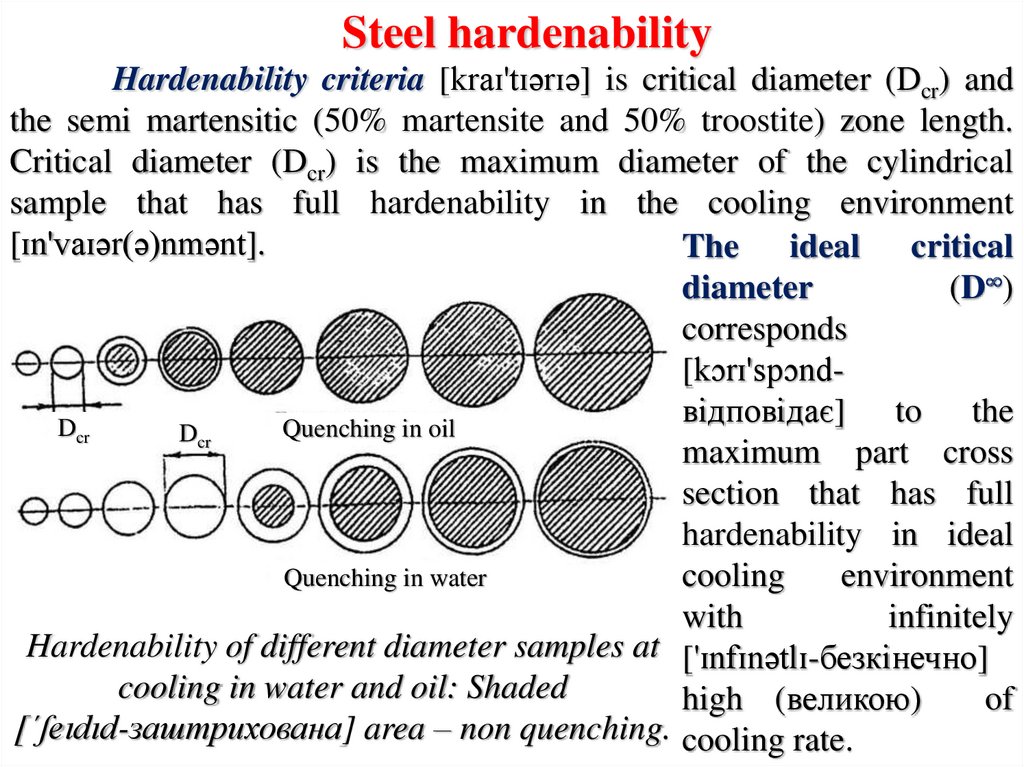

Steel hardenabilityAt the transition [træn'zɪʃ(ə)n-перехід] of the semi (напів) martensitic

(50% martensite and 50% troostite) to the martensitic structure (100%

martensite) critical diameter (Dcr) decreases. Critical diameter (Dcr)

decreases at replacement [rɪ'pleɪsmənt-зміна] of a cooling environment

[ɪn'vaɪər(ə)nmənt-середовищe], for example of water to mineral oil

(slide 18).

If necessary mechanical properties are provided by semi (напів)

martensitic structure, for example structural steels, Dcr defined as D50.

Structural steel hardenability is determined as the layer thickness that

has semi martensitic structure. Semi martensitic structure hardness

depends of the carbon concentration in steel and is determined by tables

or graphs draw [drɔ-побудованими] in the coordinates of the “Carbon

concentration, % - Hardness of semi martensitic zone, НRС”.

Tool steel hardenability is determined by the thickness of the hardened

layer with martensitic structure. Hardness is НRС 60.

5.

Determination [dɪtɜmɪ'neɪʃ(ə)n-визначення]of the steel hardenability

Steel hardenability is determined [dɪ'tɜ mɪnd] by the hardness

changing after end (face) quenching. The normalized samples are heated

in furnace up to of 820 to 900 oC (temperature depends of the carbon

content in steel). Sample holding time is a 30 minutes ['mɪnɪts]. Sample

quenching carried out in the installation located from furnace at a

distance then (таким чином) that the time of sample transfer from

furnace to the cooling does not exceed 5 s.

The sample end is cooled by water jet after

setting of heated sample in the device. Sample

end has quenching and opposite end normalization. When whole [həul-весь]

sample is cooled up to room temperature, the

sample both sides are polished on the length

of 100 mm, depth of 0.5 mm and two parallel

Water

planes are formed. The hardness is measured

Sample and scheme [skim-схема]

of quenched to normalized of the ends.

of end (face) quenching

6.

Walter E. Jominy (1893-1976)7.

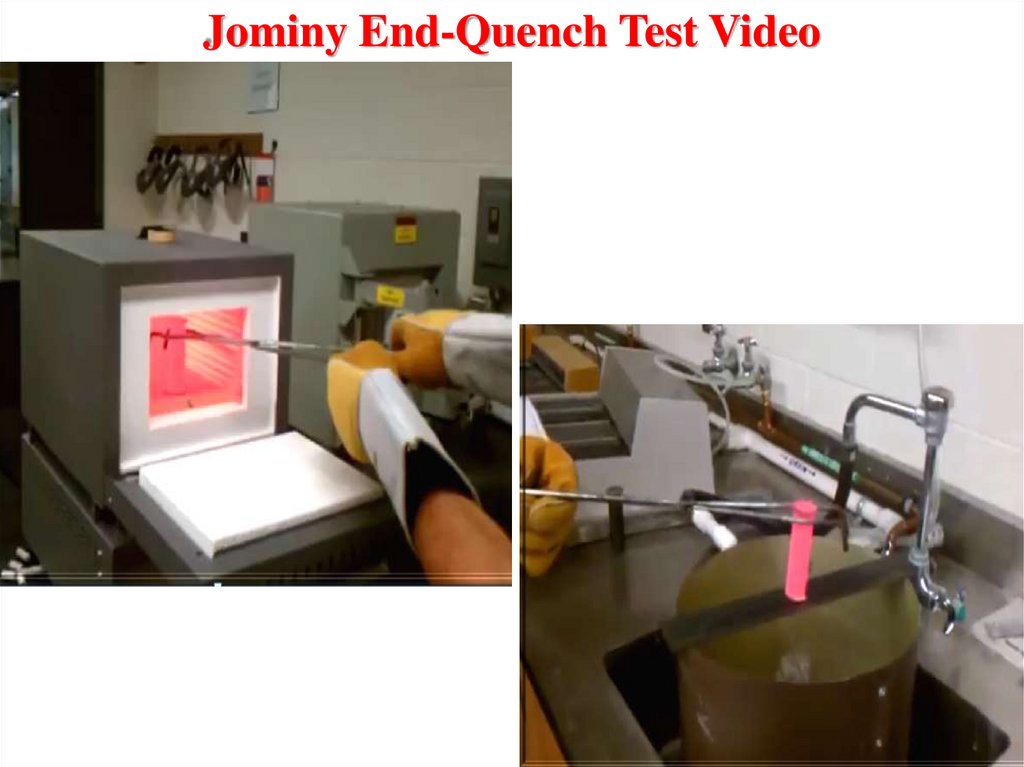

Jominy End-Quench Test Video8.

Jominy End-Quench Test Video9.

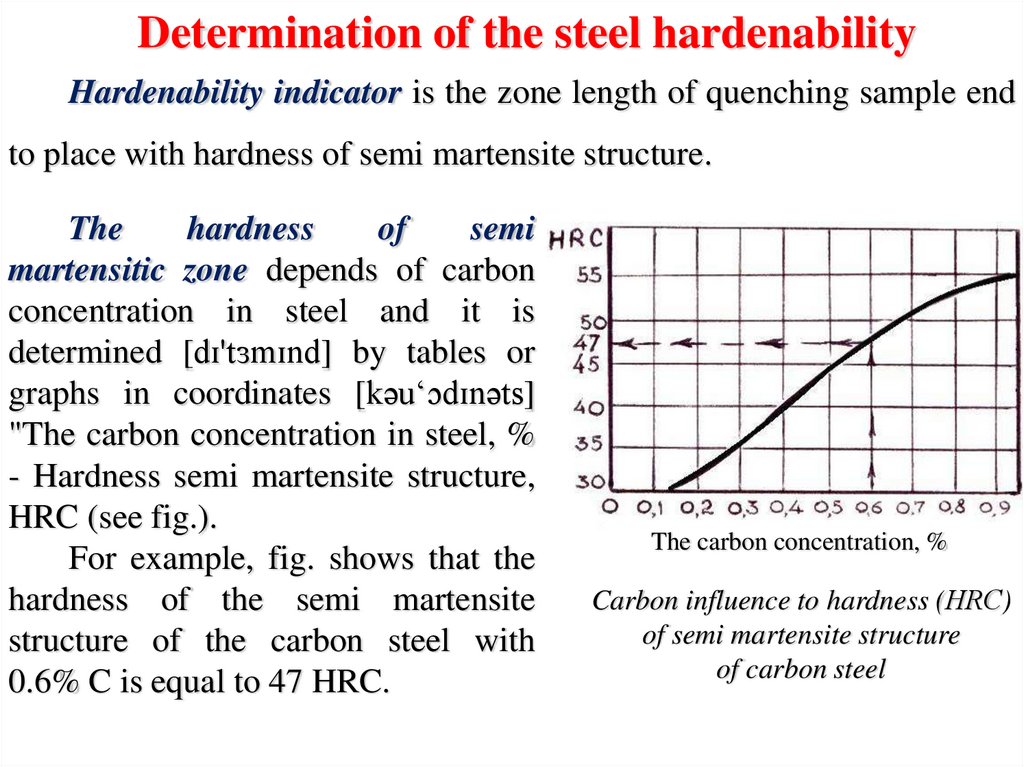

Determination of the steel hardenabilityHardenability indicator is the zone length of quenching sample end

to place with hardness of semi martensite structure.

The

hardness

of

semi

martensitic zone depends of carbon

concentration in steel and it is

determined [dɪ'tɜmɪnd] by tables or

graphs in coordinates [kəu‘ɔdɪnəts]

"The carbon concentration in steel, %

- Hardness semi martensite structure,

HRC (see fig.).

For example, fig. shows that the

hardness of the semi martensite

structure of the carbon steel with

0.6% C is equal to 47 HRC.

The carbon concentration, %

Carbon influence to hardness (НRС)

of semi martensite structure

of carbon steel

10.

Determination of the steel hardenabilityHardenability steel curve draws in the coordinates [kəu‘ɔdɪnəts]

"Distance of quenching sample end, mm - Hardness, НRС". The semi

martensitic zone [zəun] hardness is defined and ploted on graph [grɑːf].

Hardness of semi martensitic zone

Distance of quenching sample end, mm

Hardenability curve and hardness of

semi martensitic zone [zəun]

For example, fig. (slide 21)

shows that the hardness of the

semi martensite structure of the

carbon steel with 0,3% C is

equal to 35 HRC. Hardenability

steel with 0,3% C is equal 3,5

mm (see figure ['fɪgə]).

Nomograms are existed for

determination of the cooling rate

and hardenability of parts by

simple

geometric

shapes

(cylinder ['sɪlɪndə], sphere [sfɪə],

square [skweə], parallelepiped

[ˌpærəle'lepɪped]).

11.

Steel hardenability nomogram [nɒməgram]Distance of quenching sample end to semi martensitic zone

mm

Ideal critical diameter (D )

mm

Cylinder ['sɪlɪndə] or

parallelepiped

[ˌpærəle'lepɪped]).

Cooling rate

оС/s

Sphere

Size (sphere [sfɪə] diameter or cylinder ['sɪlɪndə] (D) and square [skweə] (a)), mm

industry

industry