Similar presentations:

VHMS technology as monitoring condition’s instrument aid

1.

VHMS TECHNOLOGY AS MONITORINGCONDITION’S INSTRUMENT AID

1

2.

CONTENTSГЛАВА I: СИСТЕМА VHMS

НАЧАЛЬНАЯ БУКВА ДИСПЕТЧЕРА VHMS, УСТАНАВЛИВАЮЩАЯ … … … … … …

… … … … … … … … …..... 5

ЗАГРУЗКА ДАННЫХ VHMS … … … … … … … … … … … … … … … … … … … … …

….. 28

РУЧНАЯ ЗАГРУЗКА … … … … … … … … … … … … … … … … … … … … ….. 29

БЕСПРОВОДНАЯ ЗАГРУЗКА … … … … … … … … … … … … … … … … … … … …...

48

ГЛАВА II: VHMS BAGUS ЗАЯВЛЕНИЕ

VHMS BAGUS ПРОГРАММНОЕ ОБЕСПЕЧЕНИЕ … … … … … … … … … … … … …

… … … … … … … … … … 66

i. INSTALATION, АКТИВАЦИЯ … … … … … … … … … … … … … … … … … … …

….. 67

ii. СТРУКТУРА … … … … … … … … … … … … … … … … … … … … … … … …

… … …... 70

iii. ДОБАВЛЯЯ КЛИЕНТА, УЧАСТОК РАБОТЫ, МАШИНУ, ДАННЫЕ

ЗАГРУЖАЮТ. … … … … ….. 71

КОНТРОЛЬ УСЛОВИЯ ЕДИНИЦЫ ЧЕРЕЗ VHMS BAGUS ЗАЯВЛЕНИЕ. 76

СОЗДАНИЕ СООБЩЕНИЯ … … … … … … … … … … … … … … … … … … … … …

… … … … … 98

ГЛАВА III: VHMS BAGUS ADMIN ФУНКЦИЯ И ОБСЛУЖИВАНИЕ БАЗЫ ДАННЫХ

1. СОЗДАНИЕ ПРОФИЛЯ ШАГ ЗА ШАГОМ (ЗАЯВЛЕНИЕ ADMIN) … … … … … … …

… 101

2

3.

CHAPTER IVHMS SYSTEM

3

4.

НАЧАЛЬНАЯ БУКВА ДИСПЕТЧЕРА VHMS,УСТАНАВЛИВАЮЩАЯ ДЛЯ ВСЕХ МАШИН

С VHMS

4

5.

УРЕГУЛИРОВАНИЕ НАЧАЛЬНОЙБУКВЫ

ДИСПЕТЧЕРА VHMS

General Objectives

:

Настраивать Машинную Идентификацию (Машина S/N, Двигатель S/N,

Передача S/N) в диспетчера VHMS и к часовому поясу установки,

приспособленному к местоположению единицы.

Начальное Урегулирование выполнено:

Для Новой Поставки Единицы, какое урегулирование Диспетчера VHMS не

было выполнено.

Когда Удаляют и Устанавливают Двигатель и или Передача выполнена,

где регистрационный номер компонента изменился.

Когда единица перемещена в другое местоположение с другим Часовым

поясом.

Изменяя Диспетчера VHMS, в котором данные от старого диспетчера

VHMS перемещены в нового диспетчера.

5

6.

VHMS INITIAL SETTINGНачальный Процесс Урегулирования:

В основном начальный процесс урегулирования включает:

1. часовой пояс изменения:

- По Гринвичу (Время Гринвичского меридиана)

- Начальное урегулирование, выполняющее время

2. заполнитесь в единице данных:

- Единица регистрационного номера

- Машинный регистрационный номер

- Регистрационный номер передачи

Начальный процесс Урегулирования для HD 465/605-7, HD785-7, D375A-5 & D475A5 может быть выполнена в 2 (два) местоположения:

Выполненный в каюте.

Соединитель Загрузки расположен в каюте позади пассажирского места

Выполненный вне каюты.

Соединитель Загрузки расположен на лево-стороне машины помимо

гидравлического резервуара HD465/605-7, перед единицей направо для

HD785-7 и для D375A/D475A-5 в спине налево помимо Лампы Работы Тыла

ЛЮФТГАНЗЫ; это предназначено, чтобы упростить процесс загрузки, в

котором никто не должен подняться6вверх по каюте.

7.

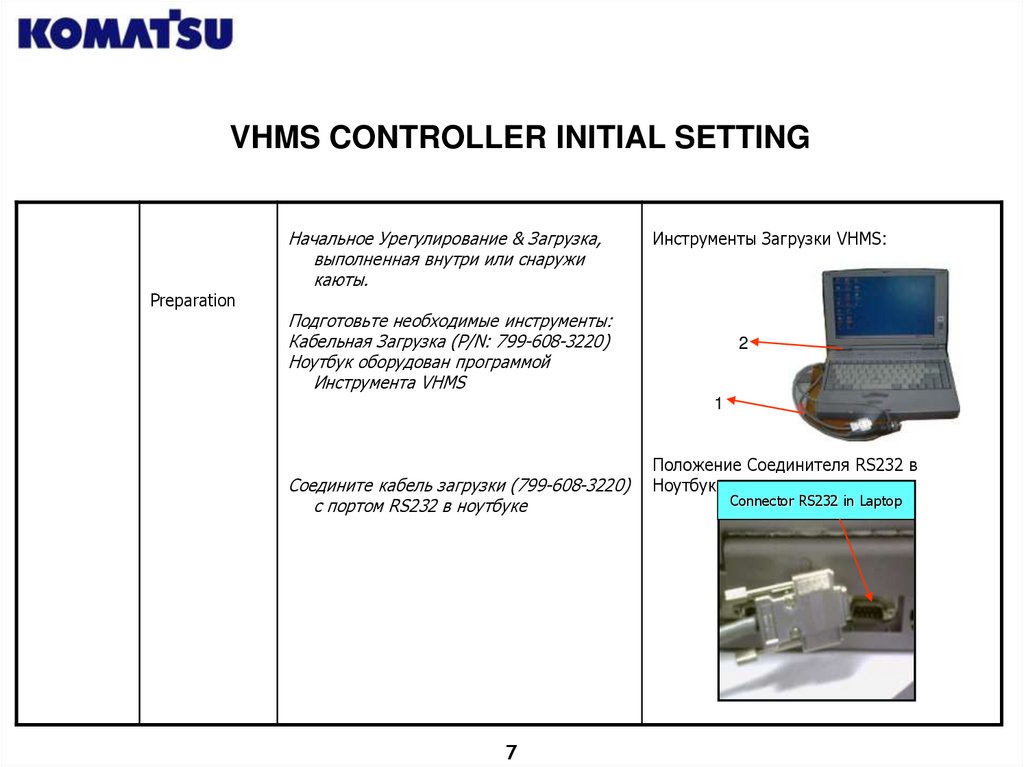

VHMS CONTROLLER INITIAL SETTINGPreparation

Начальное Урегулирование & Загрузка,

выполненная внутри или снаружи

каюты.

Инструменты Загрузки VHMS:

Подготовьте необходимые инструменты:

Кабельная Загрузка (P/N: 799-608-3220)

Ноутбук оборудован программой

Инструмента VHMS

2

1

Соедините кабель загрузки (799-608-3220)

с портом RS232 в ноутбуке

7

Положение Соединителя RS232 в

Ноутбуке:

Connector RS232 in Laptop

8.

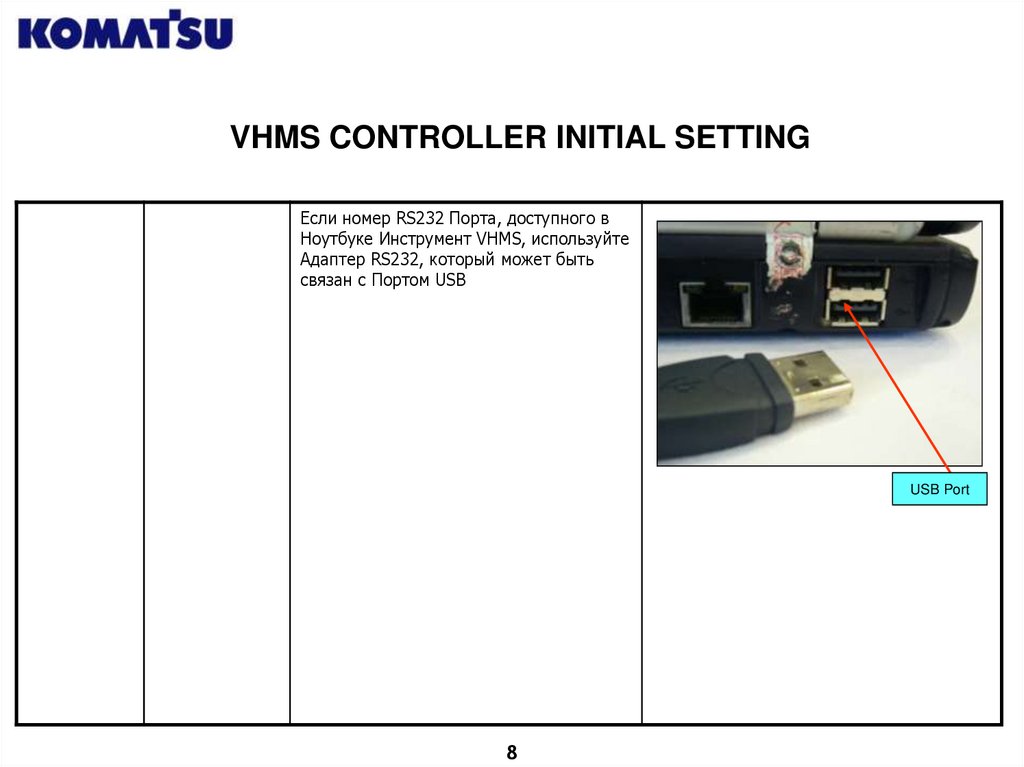

VHMS CONTROLLER INITIAL SETTINGЕсли номер RS232 Порта, доступного в

Ноутбуке Инструмент VHMS, используйте

Адаптер RS232, который может быть

связан с Портом USB

USB Port

8

9.

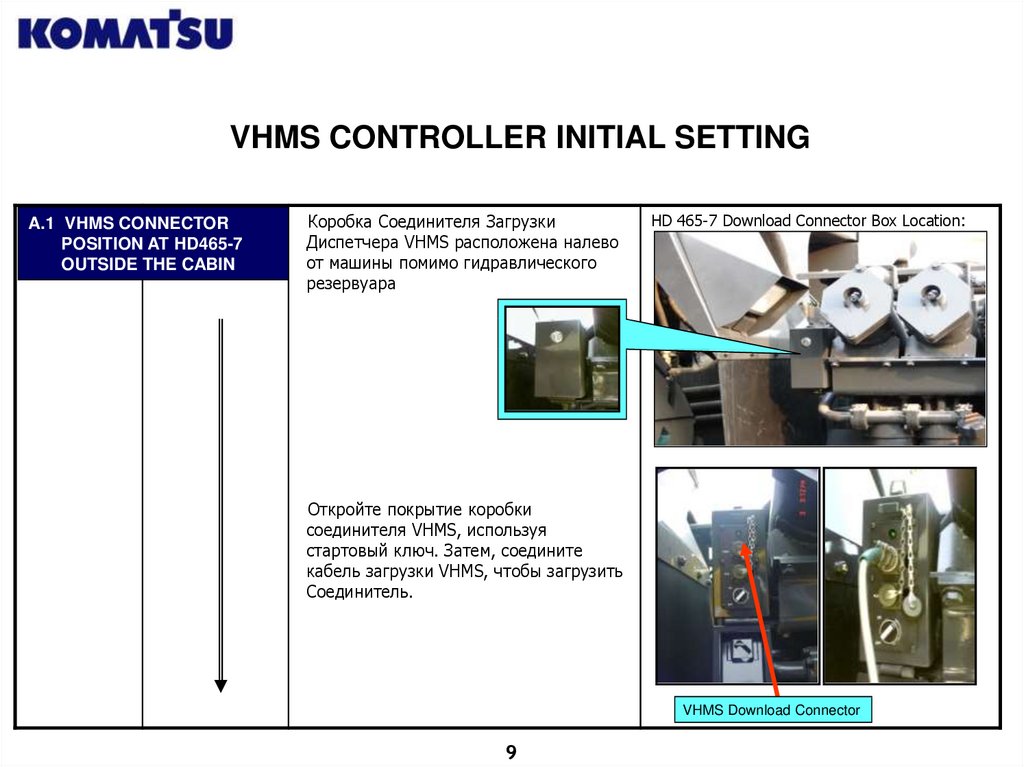

VHMS CONTROLLER INITIAL SETTINGA.1 VHMS CONNECTOR

POSITION AT HD465-7

OUTSIDE THE CABIN

Коробка Соединителя Загрузки

Диспетчера VHMS расположена налево

от машины помимо гидравлического

резервуара

HD 465-7 Download Connector Box Location:

Откройте покрытие коробки

соединителя VHMS, используя

стартовый ключ. Затем, соедините

кабель загрузки VHMS, чтобы загрузить

Соединитель.

VHMS Download Connector

9

10.

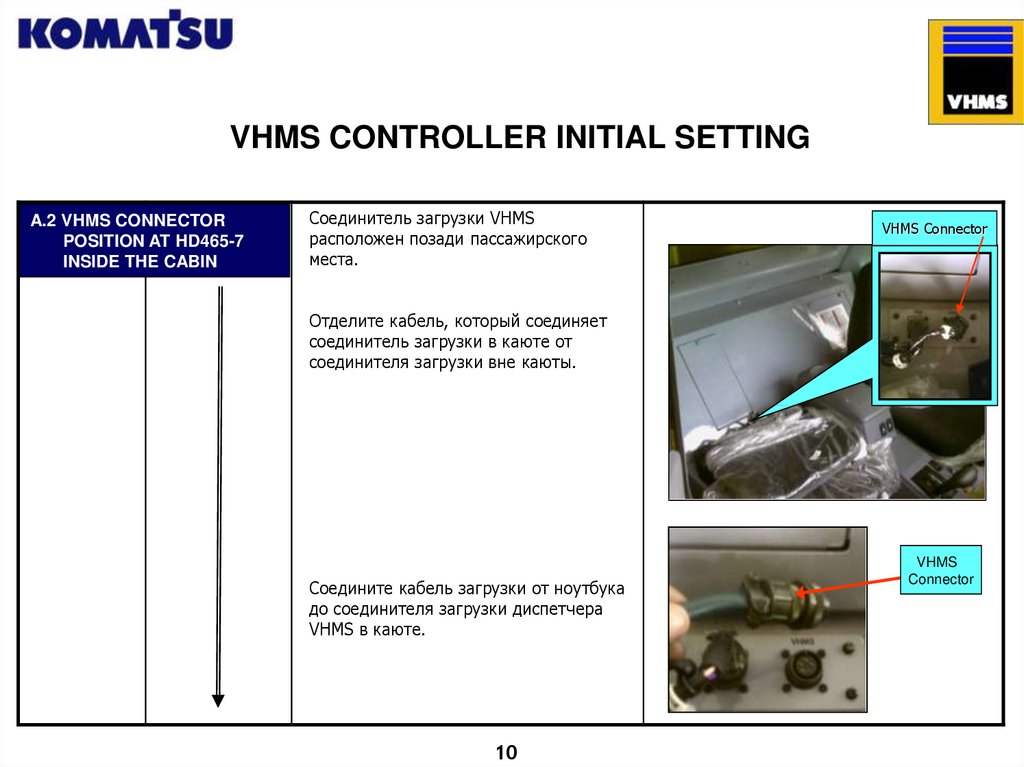

VHMS CONTROLLER INITIAL SETTINGA.2 VHMS CONNECTOR

POSITION AT HD465-7

INSIDE THE CABIN

Соединитель загрузки VHMS

расположен позади пассажирского

места.

VHMS Connector

Отделите кабель, который соединяет

соединитель загрузки в каюте от

соединителя загрузки вне каюты.

Соедините кабель загрузки от ноутбука

до соединителя загрузки диспетчера

VHMS в каюте.

10

VHMS

Connector

11.

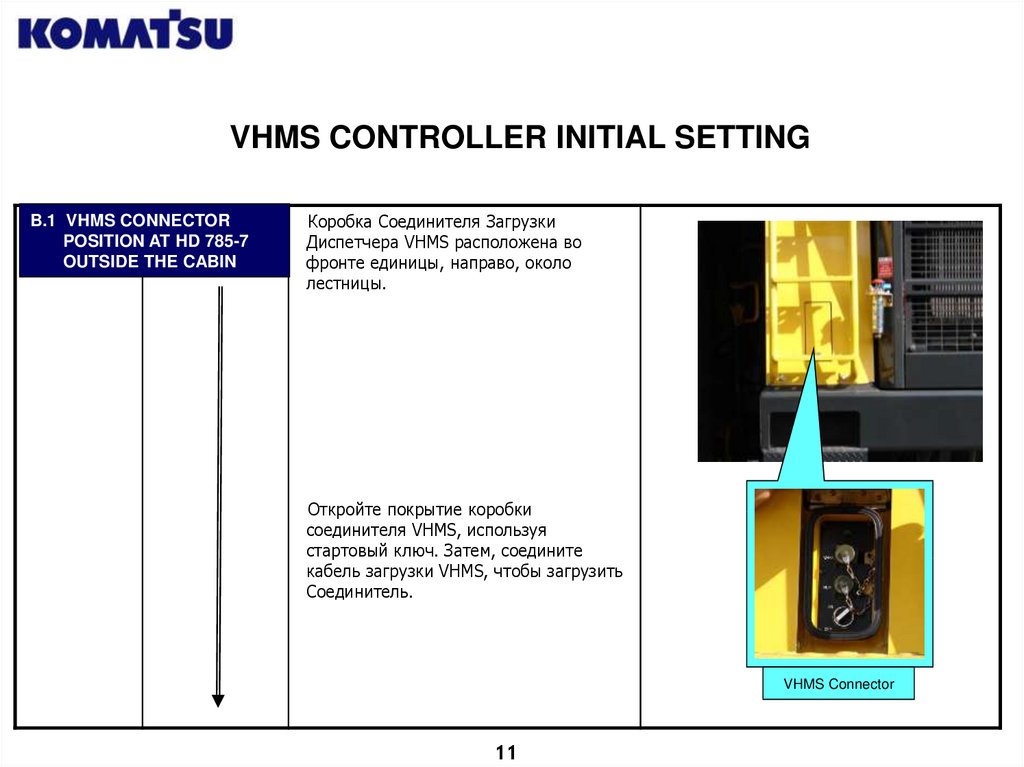

VHMS CONTROLLER INITIAL SETTINGB.1 VHMS CONNECTOR

POSITION AT HD 785-7

OUTSIDE THE CABIN

Коробка Соединителя Загрузки

Диспетчера VHMS расположена во

фронте единицы, направо, около

лестницы.

Откройте покрытие коробки

соединителя VHMS, используя

стартовый ключ. Затем, соедините

кабель загрузки VHMS, чтобы загрузить

Соединитель.

VHMS Connector

11

12.

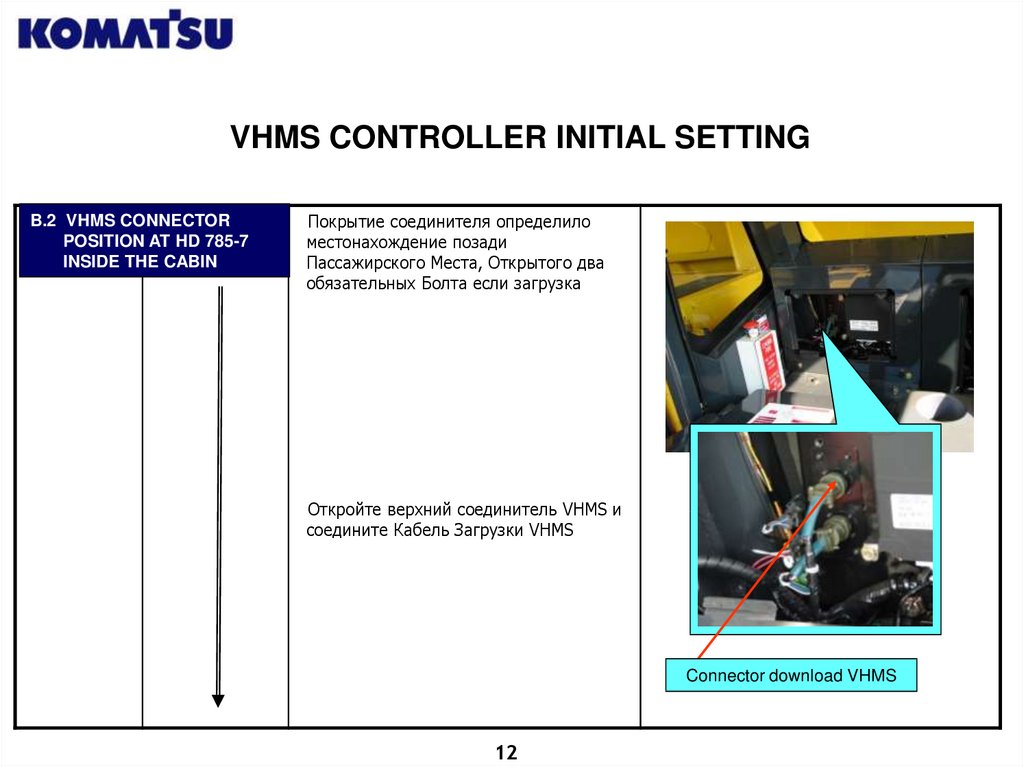

VHMS CONTROLLER INITIAL SETTINGB.2 VHMS CONNECTOR

POSITION AT HD 785-7

INSIDE THE CABIN

Покрытие соединителя определило

местонахождение позади

Пассажирского Места, Открытого два

обязательных Болта если загрузка

Откройте верхний соединитель VHMS и

соедините Кабель Загрузки VHMS

Connector download VHMS

12

13.

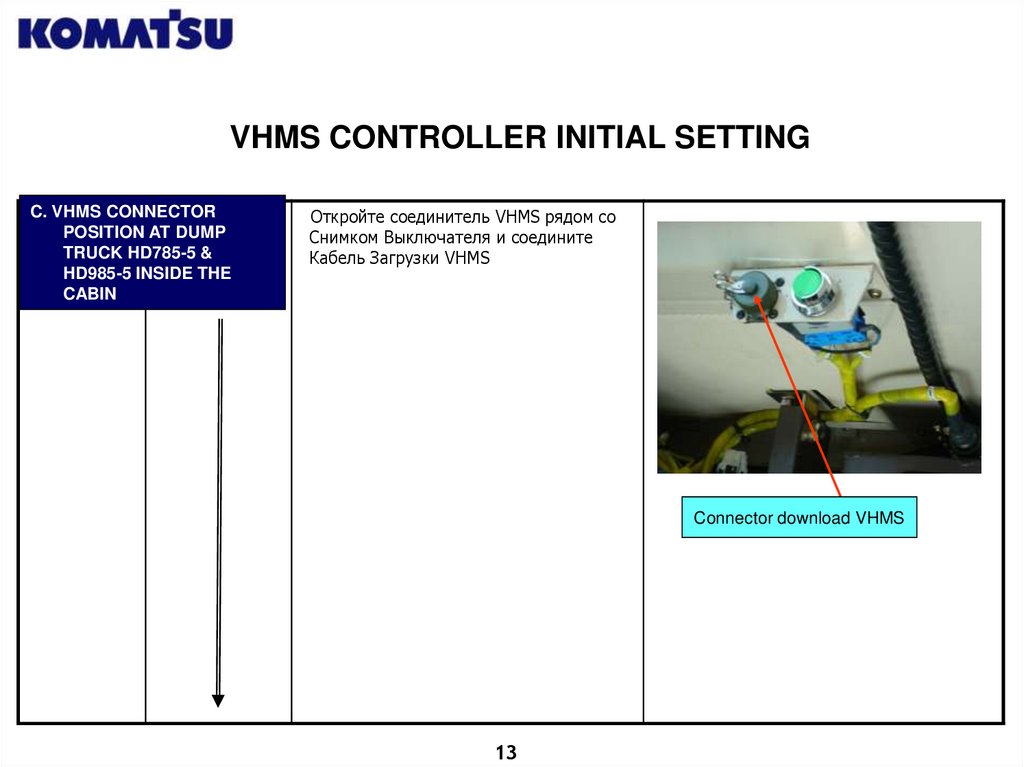

VHMS CONTROLLER INITIAL SETTINGC. VHMS CONNECTOR

POSITION AT DUMP

TRUCK HD785-5 &

HD985-5 INSIDE THE

CABIN

Откройте соединитель VHMS рядом со

Снимком Выключателя и соедините

Кабель Загрузки VHMS

Connector download VHMS

13

14.

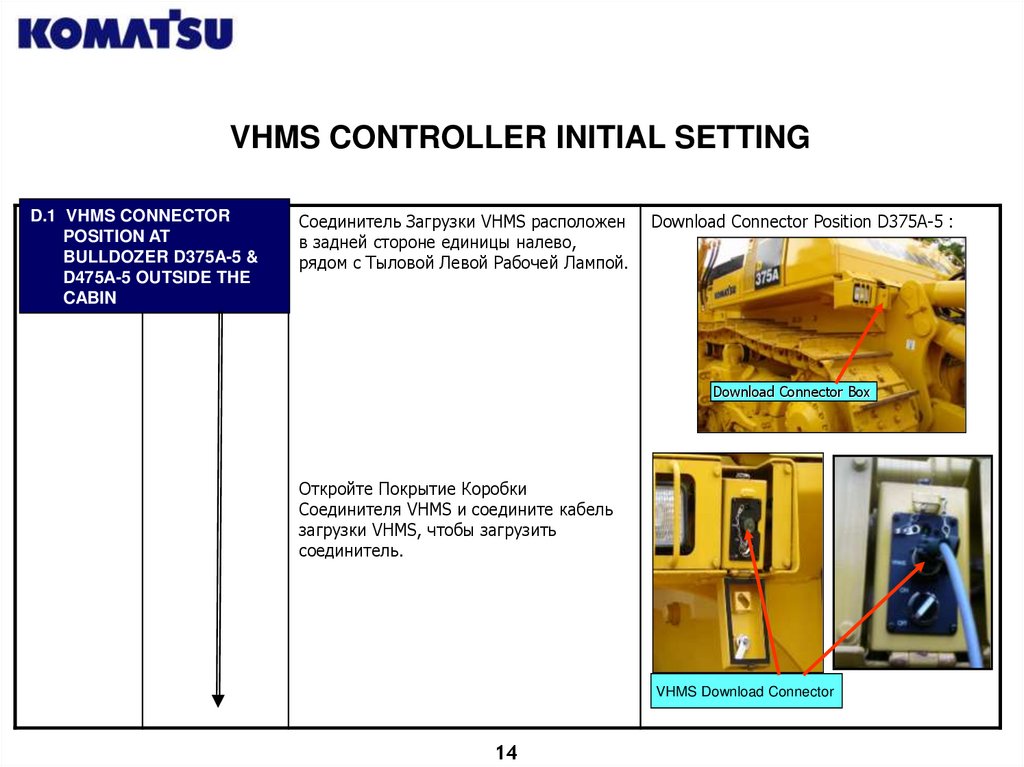

VHMS CONTROLLER INITIAL SETTINGD.1 VHMS CONNECTOR

POSITION AT

BULLDOZER D375A-5 &

D475A-5 OUTSIDE THE

CABIN

Соединитель Загрузки VHMS расположен

в задней стороне единицы налево,

рядом с Тыловой Левой Рабочей Лампой.

Download Connector Position D375A-5 :

Download Connector Box

Откройте Покрытие Коробки

Соединителя VHMS и соедините кабель

загрузки VHMS, чтобы загрузить

соединитель.

VHMS Download Connector

14

15.

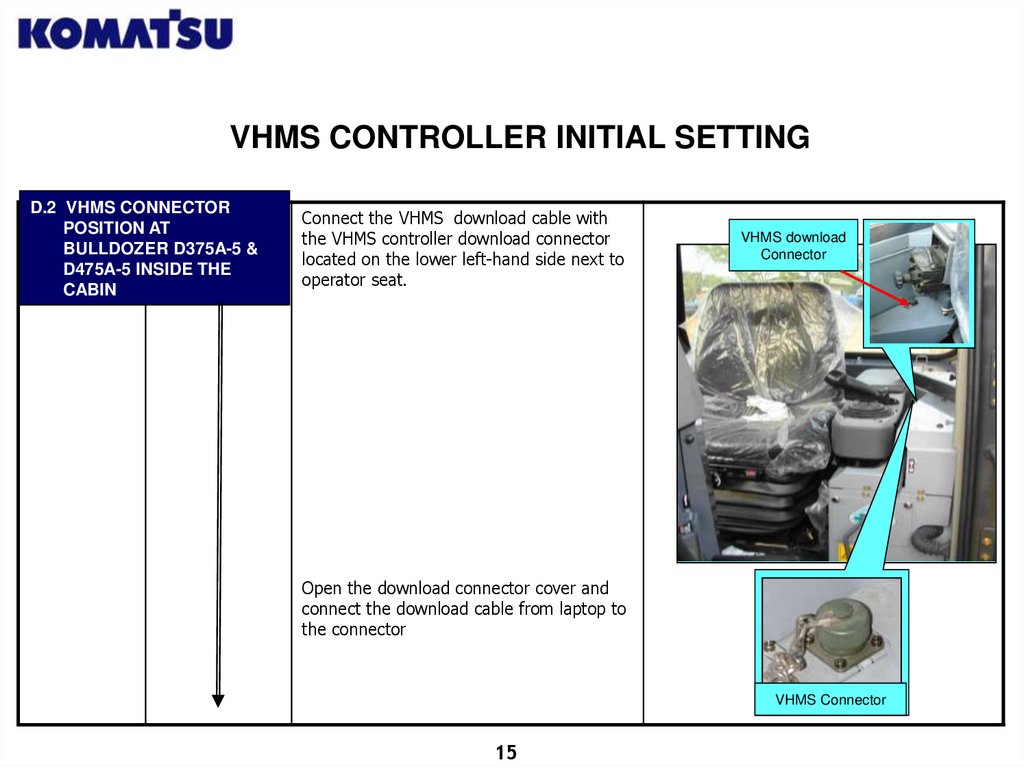

VHMS CONTROLLER INITIAL SETTINGD.2 VHMS CONNECTOR

POSITION AT

BULLDOZER D375A-5 &

D475A-5 INSIDE THE

CABIN

Connect the VHMS download cable with

the VHMS controller download connector

located on the lower left-hand side next to

operator seat.

VHMS download

Connector

Open the download connector cover and

connect the download cable from laptop to

the connector

VHMS Connector

15

16.

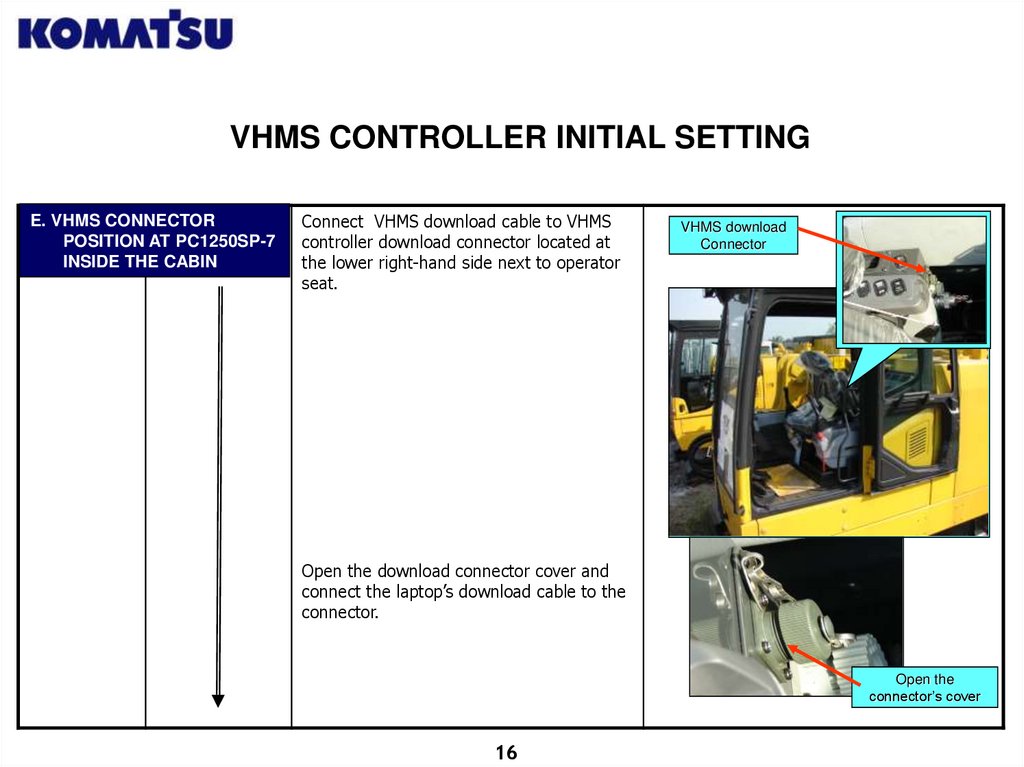

VHMS CONTROLLER INITIAL SETTINGE. VHMS CONNECTOR

POSITION AT PC1250SP-7

INSIDE THE CABIN

Connect VHMS download cable to VHMS

controller download connector located at

the lower right-hand side next to operator

seat.

VHMS download

Connector

Open the download connector cover and

connect the laptop’s download cable to the

connector.

Open the

connector’s cover

16

17.

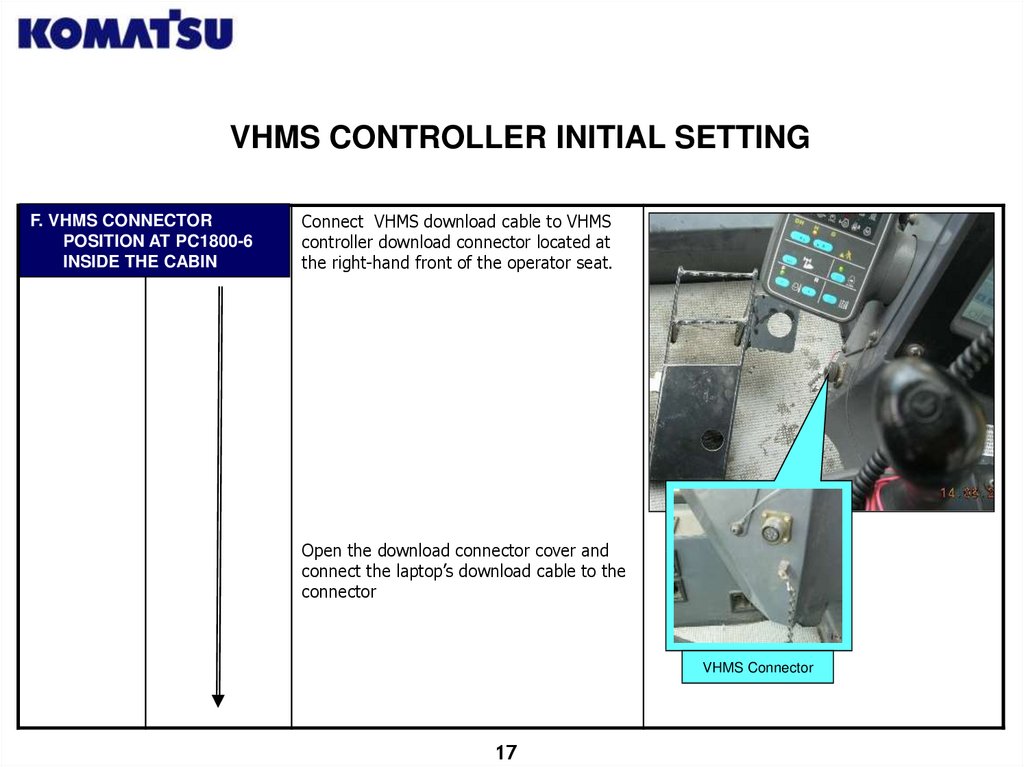

VHMS CONTROLLER INITIAL SETTINGF. VHMS CONNECTOR

POSITION AT PC1800-6

INSIDE THE CABIN

Connect VHMS download cable to VHMS

controller download connector located at

the right-hand front of the operator seat.

Open the download connector cover and

connect the laptop’s download cable to the

connector

VHMS Connector

17

18.

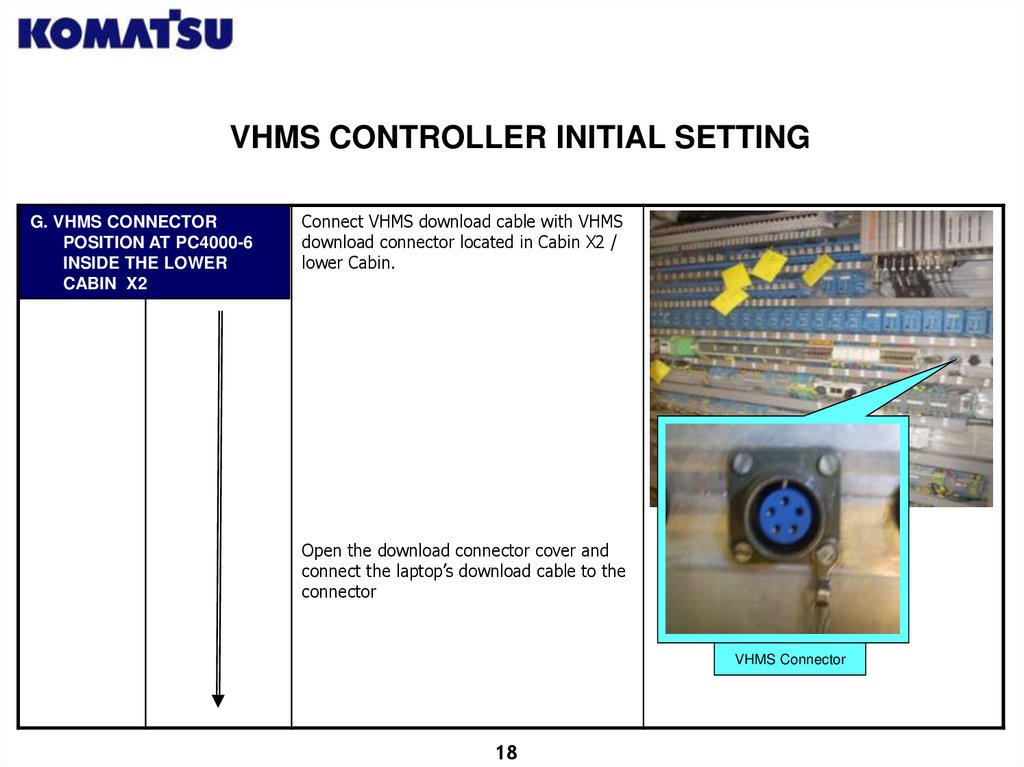

VHMS CONTROLLER INITIAL SETTINGG. VHMS CONNECTOR

POSITION AT PC4000-6

INSIDE THE LOWER

CABIN X2

Connect VHMS download cable with VHMS

download connector located in Cabin X2 /

lower Cabin.

Open the download connector cover and

connect the laptop’s download cable to the

connector

VHMS Connector

18

19.

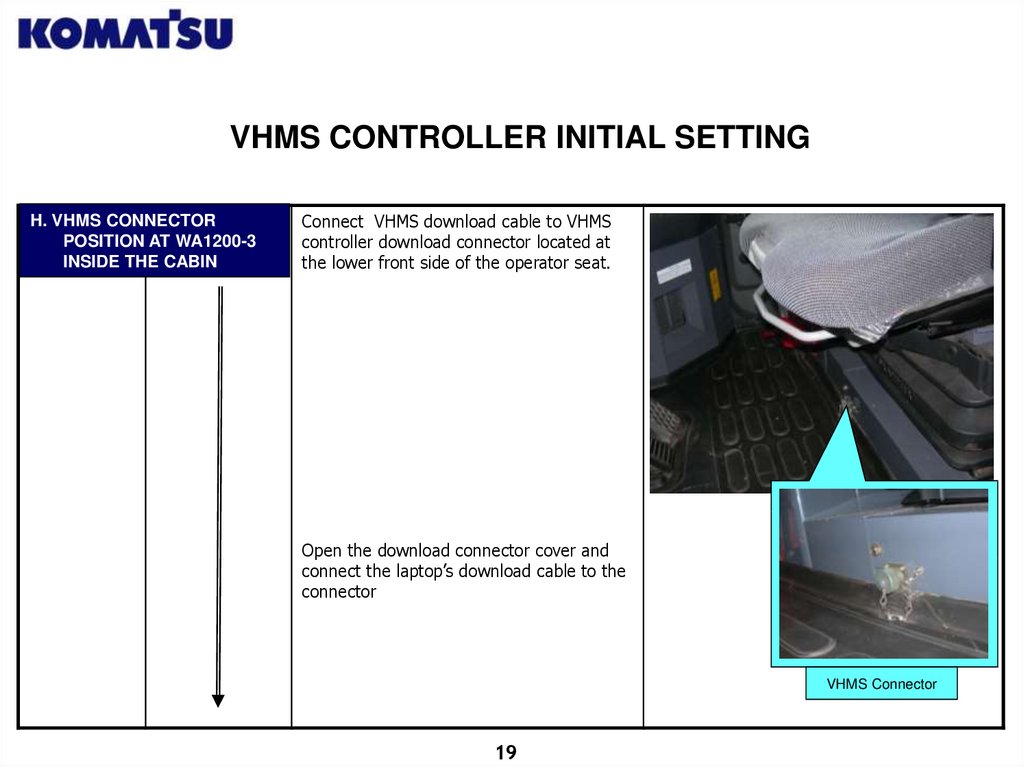

VHMS CONTROLLER INITIAL SETTINGH. VHMS CONNECTOR

POSITION AT WA1200-3

INSIDE THE CABIN

Connect VHMS download cable to VHMS

controller download connector located at

the lower front side of the operator seat.

Open the download connector cover and

connect the laptop’s download cable to the

connector

VHMS Connector

19

20.

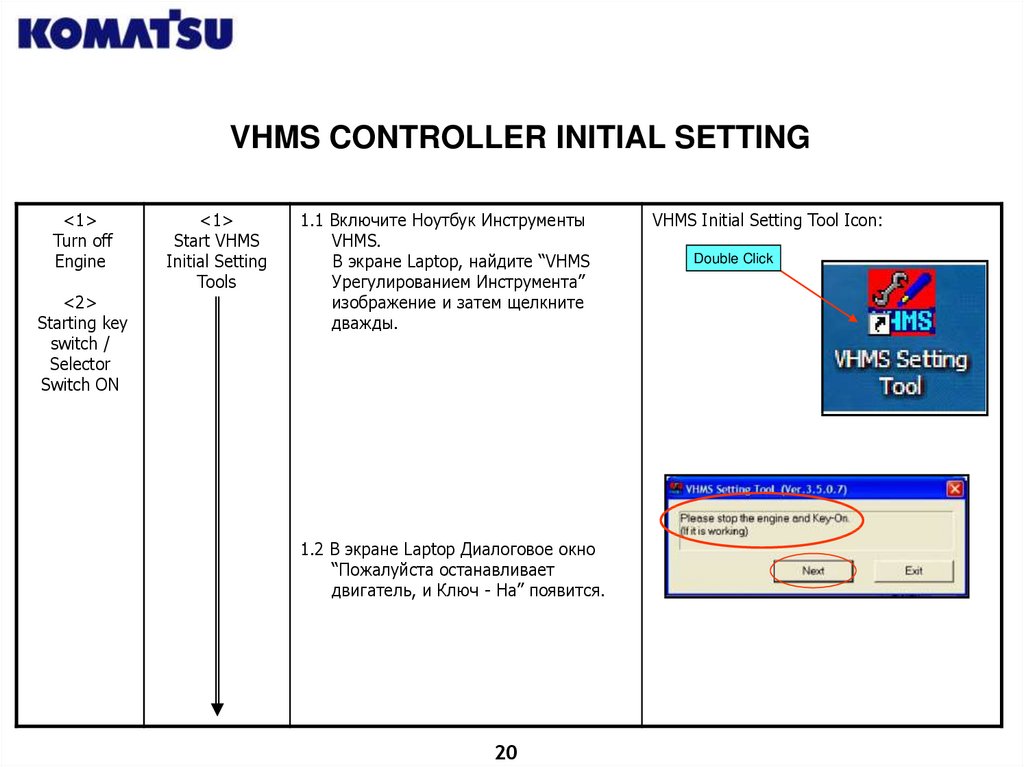

VHMS CONTROLLER INITIAL SETTING<1>

Turn off

Engine

<2>

Starting key

switch /

Selector

Switch ON

<1>

Start VHMS

Initial Setting

Tools

1.1 Включите Ноутбук Инструменты

VHMS.

В экране Laptop, найдите “VHMS

Урегулированием Инструмента”

изображение и затем щелкните

дважды.

1.2 В экране Laptop Диалоговое окно

“Пожалуйста останавливает

двигатель, и Ключ - На” появится.

20

VHMS Initial Setting Tool Icon:

Double Click

21.

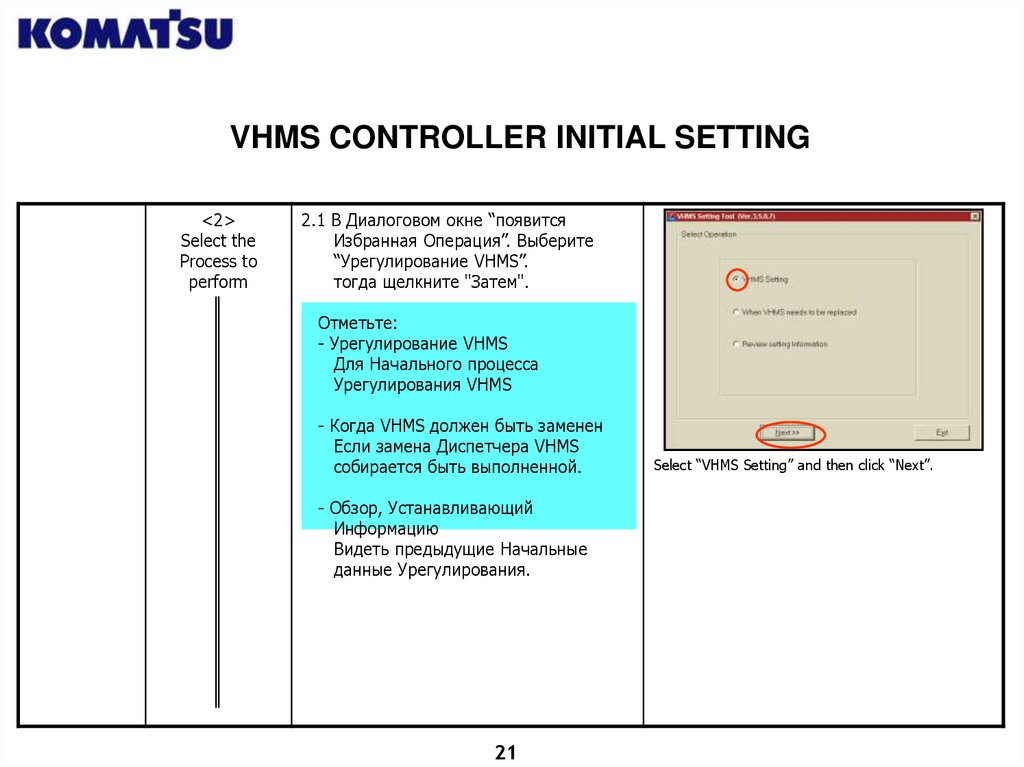

VHMS CONTROLLER INITIAL SETTING<2>

Select the

Process to

perform

2.1 В Диалоговом окне “появится

Избранная Операция”. Выберите

“Урегулирование VHMS”.

тогда щелкните "Затем".

Отметьте:

- Урегулирование VHMS

Для Начального процесса

Урегулирования VHMS

- Когда VHMS должен быть заменен

Если замена Диспетчера VHMS

собирается быть выполненной.

- Обзор, Устанавливающий

Информацию

Видеть предыдущие Начальные

данные Урегулирования.

21

Select “VHMS Setting” and then click “Next”.

22.

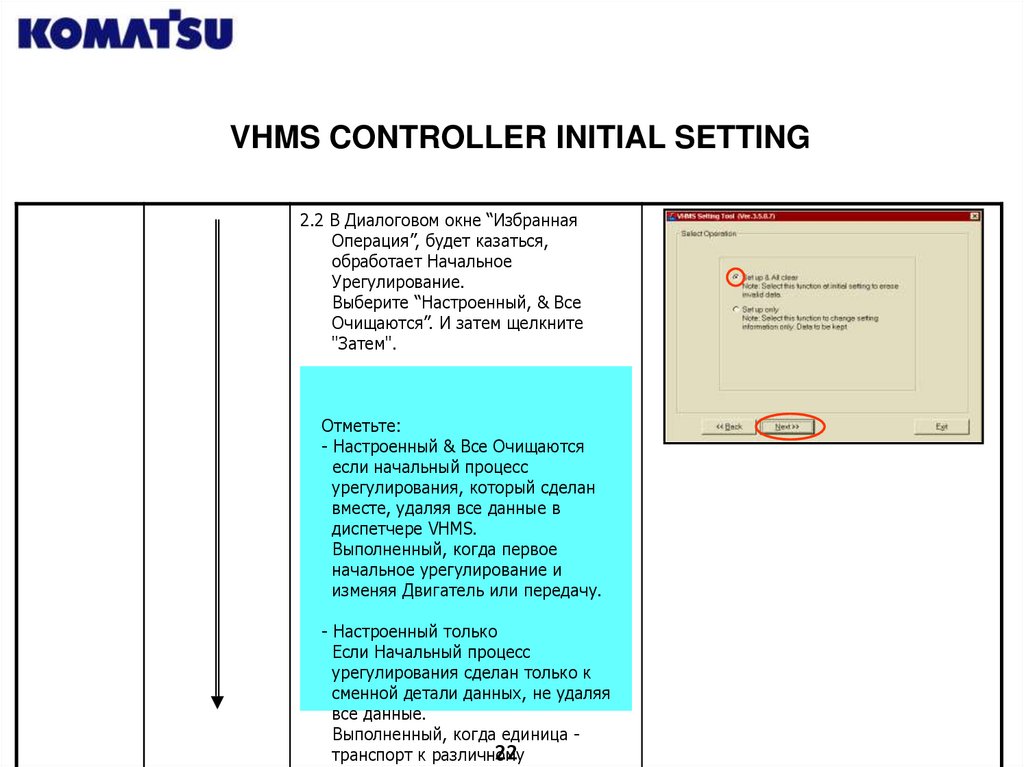

VHMS CONTROLLER INITIAL SETTING2.2 В Диалоговом окне “Избранная

Операция”, будет казаться,

обработает Начальное

Урегулирование.

Выберите “Настроенный, & Все

Очищаются”. И затем щелкните

"Затем".

Отметьте:

- Настроенный & Все Очищаются

если начальный процесс

урегулирования, который сделан

вместе, удаляя все данные в

диспетчере VHMS.

Выполненный, когда первое

начальное урегулирование и

изменяя Двигатель или передачу.

- Настроенный только

Если Начальный процесс

урегулирования сделан только к

сменной детали данных, не удаляя

все данные.

Выполненный, когда единица 22

транспорт к различному

23.

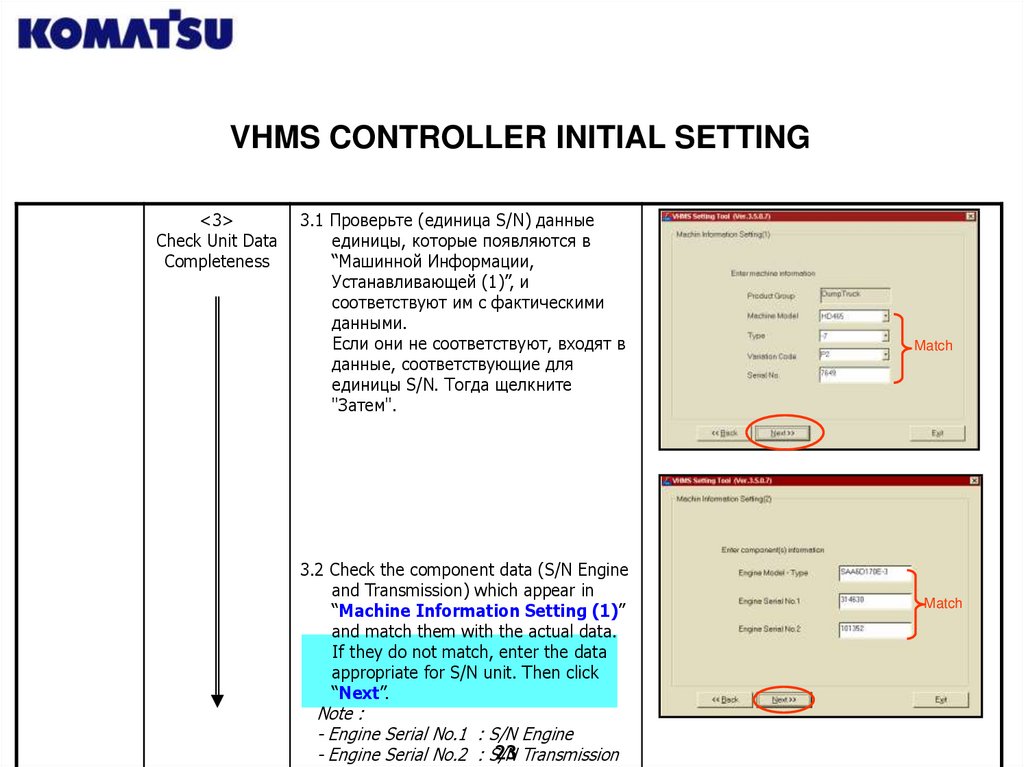

VHMS CONTROLLER INITIAL SETTING<3>

Check Unit Data

Completeness

3.1 Проверьте (единица S/N) данные

единицы, которые появляются в

“Машинной Информации,

Устанавливающей (1)”, и

соответствуют им с фактическими

данными.

Если они не соответствуют, входят в

данные, соответствующие для

единицы S/N. Тогда щелкните

"Затем".

3.2 Check the component data (S/N Engine

and Transmission) which appear in

“Machine Information Setting (1)”

and match them with the actual data.

If they do not match, enter the data

appropriate for S/N unit. Then click

“Next”.

Note :

- Engine Serial No.1 : S/N Engine

23 Transmission

- Engine Serial No.2 : S/N

Match

Match

24.

VHMS CONTROLLER INITIAL SETTING<4>

Setting Date

and Time Initial

Setting

4. In the Dialog Box “Date & Time

Setting” will appear

- Set “Time Zone” by clicking ” “ and

select “GMT + 08.00” (example for

Central Indonesian Time Zone).

- Set “Date (MM/DD/YYYY)” to suit

the local date when setting.

- Set “Time (Hour:Minute:Second)” to

suit the local time when setting.

If the data are already appropriate,

click “Next” for further process.

Time Zone Setting depends on the location where the

Unit will operate.

Time Zone :

- GMT + 07.00 : for Western Indonesia.

- GMT + 08.00 : for Central Indonesia.

- GMT + 09.00 : for Eastern Indonesia.

24

25.

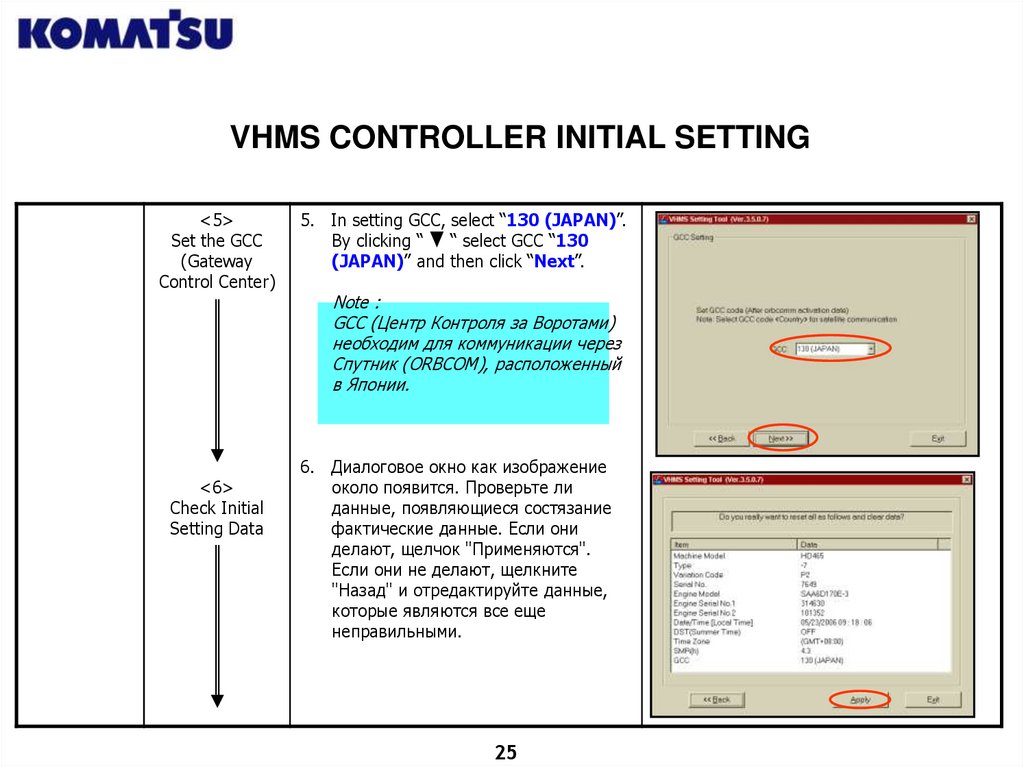

VHMS CONTROLLER INITIAL SETTING<5>

Set the GCC

(Gateway

Control Center)

<6>

Check Initial

Setting Data

5. In setting GCC, select “130 (JAPAN)”.

By clicking “

“ select GCC “130

(JAPAN)” and then click “Next”.

Note :

GCC (Центр Контроля за Воротами)

необходим для коммуникации через

Спутник (ORBCOM), расположенный

в Японии.

6. Диалоговое окно как изображение

около появится. Проверьте ли

данные, появляющиеся состязание

фактические данные. Если они

делают, щелчок "Применяются".

Если они не делают, щелкните

"Назад" и отредактируйте данные,

которые являются все еще

неправильными.

25

26.

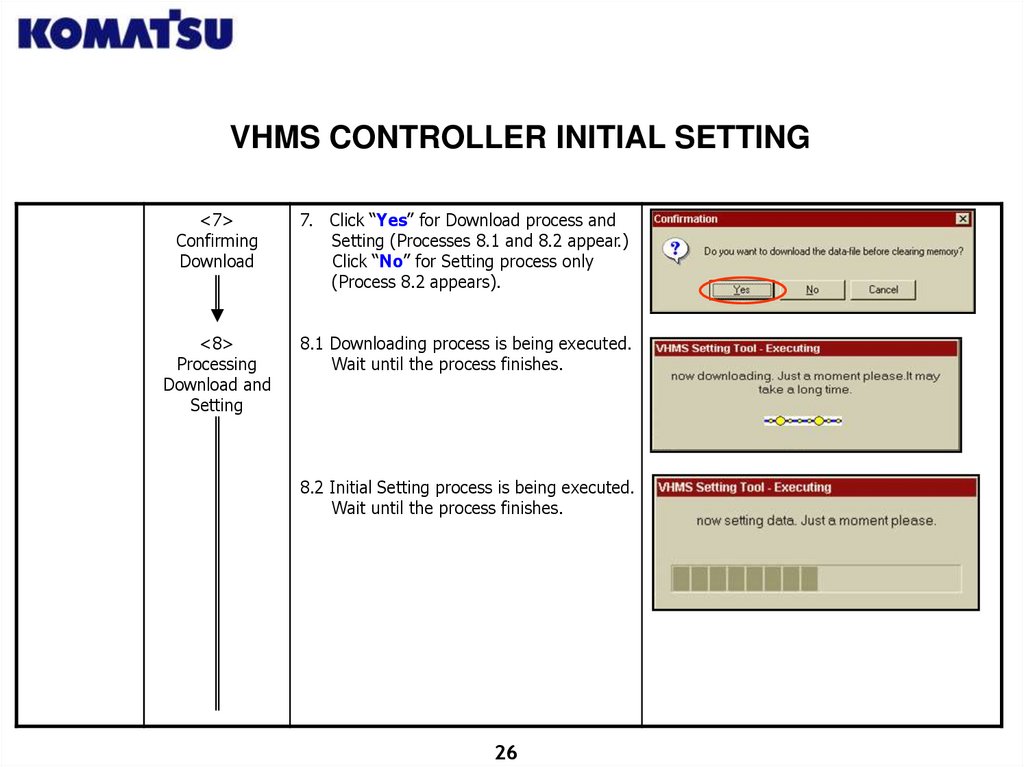

VHMS CONTROLLER INITIAL SETTING<7>

Confirming

Download

7. Click “Yes” for Download process and

Setting (Processes 8.1 and 8.2 appear.)

Click “No” for Setting process only

(Process 8.2 appears).

<8>

Processing

Download and

Setting

8.1 Downloading process is being executed.

Wait until the process finishes.

8.2 Initial Setting process is being executed.

Wait until the process finishes.

26

27.

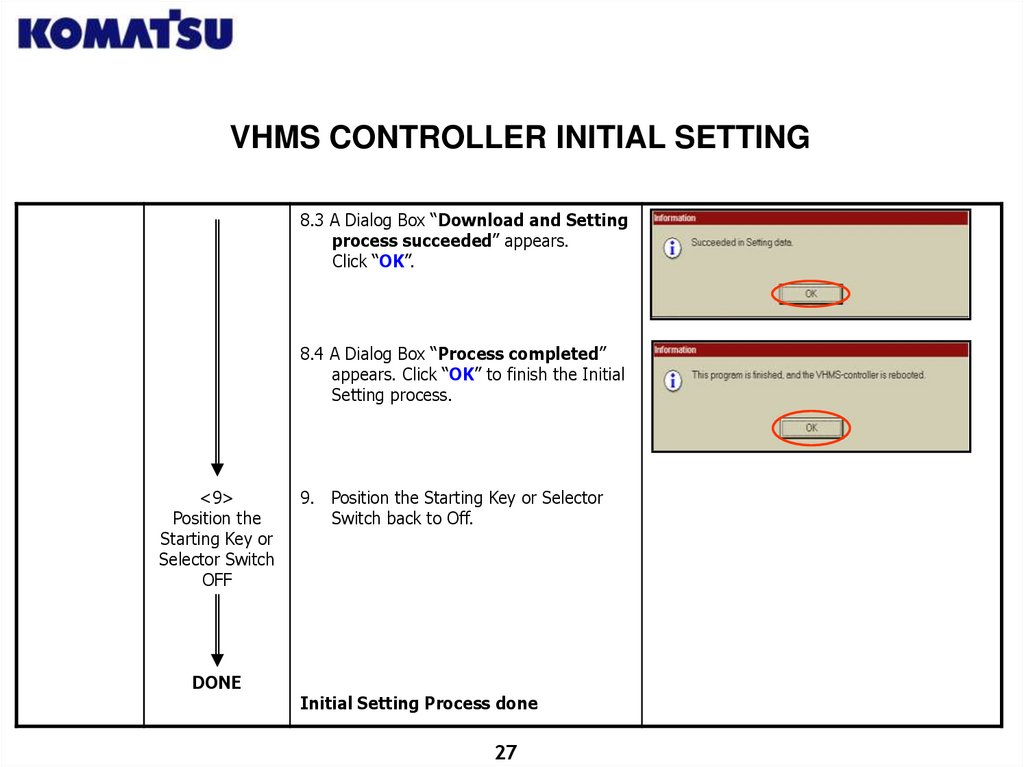

VHMS CONTROLLER INITIAL SETTING8.3 A Dialog Box “Download and Setting

process succeeded” appears.

Click “OK”.

8.4 A Dialog Box “Process completed”

appears. Click “OK” to finish the Initial

Setting process.

<9>

Position the

Starting Key or

Selector Switch

OFF

DONE

9. Position the Starting Key or Selector

Switch back to Off.

Initial Setting Process done

27

28.

VHMS DATA MANUAL DOWNLOAD28

29.

VHMS DATA MANUAL DOWNLOADVHMS Download Definition:

A process to copy data from VHMS Controller to Laptop.

General Objective:

To determine the data machine condition such as Trend Analysis data,

Fault History , PM-Clinic (manual snapshot), and Summary Payload

(specially for Dump Truck) & Operation Data Trend (specially for

Bulldozer).

29

30.

VHMS DATA MANUAL DOWNLOADEach Komatsu unit which is equipped with VHMS technology

instrument is always equipped with one or two special ports for

VHMS Data Download with different locations according to the

Machine Model described on the following page.

VHMS Data Manual Download can only be performed using

Komatsu P/N 799-688-3220 Download cable and Komatsu Download

Tools Software .

The validity of VHMS Data stored in VHMS Controller is determined

by the VHMS initial setting performance & Payload Meter II Data

Download.

30

31.

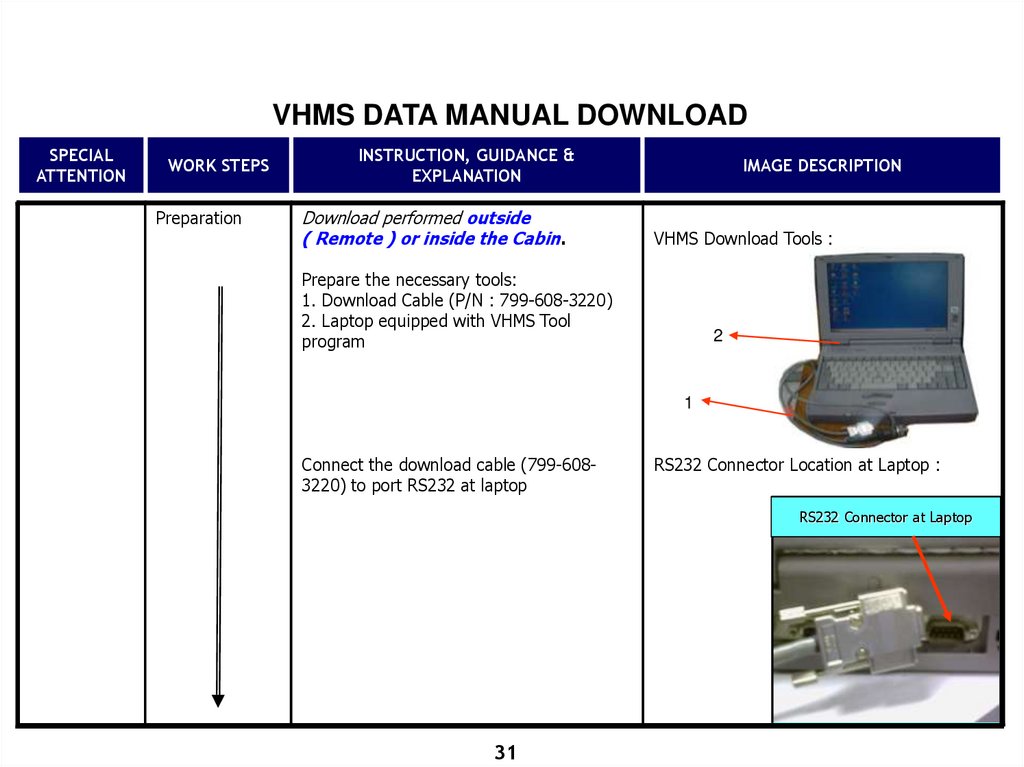

VHMS DATA MANUAL DOWNLOADSPECIAL

ATTENTION

WORK STEPS

Preparation

INSTRUCTION, GUIDANCE &

EXPLANATION

Download performed outside

( Remote ) or inside the Cabin.

IMAGE DESCRIPTION

VHMS Download Tools :

Prepare the necessary tools:

1. Download Cable (P/N : 799-608-3220)

2. Laptop equipped with VHMS Tool

program

2

1

Connect the download cable (799-6083220) to port RS232 at laptop

RS232 Connector Location at Laptop :

RS232 Connector at Laptop

31

32.

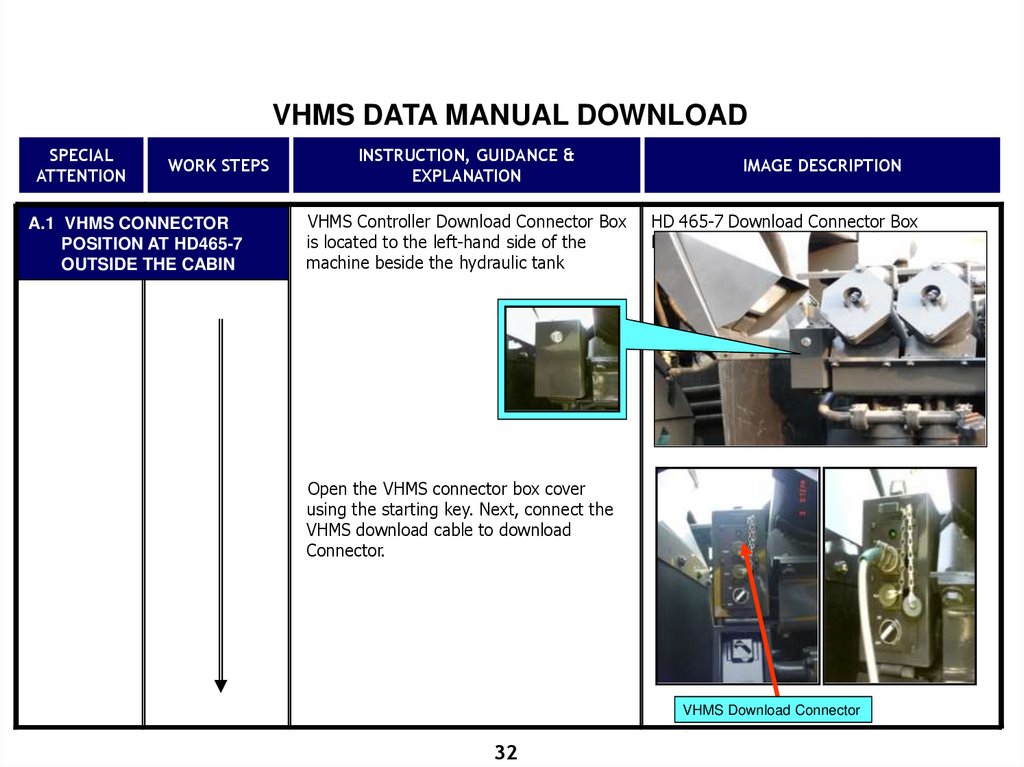

VHMS DATA MANUAL DOWNLOADSPECIAL

ATTENTION

WORK STEPS

A.1 VHMS CONNECTOR

POSITION AT HD465-7

OUTSIDE THE CABIN

INSTRUCTION, GUIDANCE &

EXPLANATION

VHMS Controller Download Connector Box

is located to the left-hand side of the

machine beside the hydraulic tank

IMAGE DESCRIPTION

HD 465-7 Download Connector Box

Location:

Open the VHMS connector box cover

using the starting key. Next, connect the

VHMS download cable to download

Connector.

VHMS Download Connector

32

33.

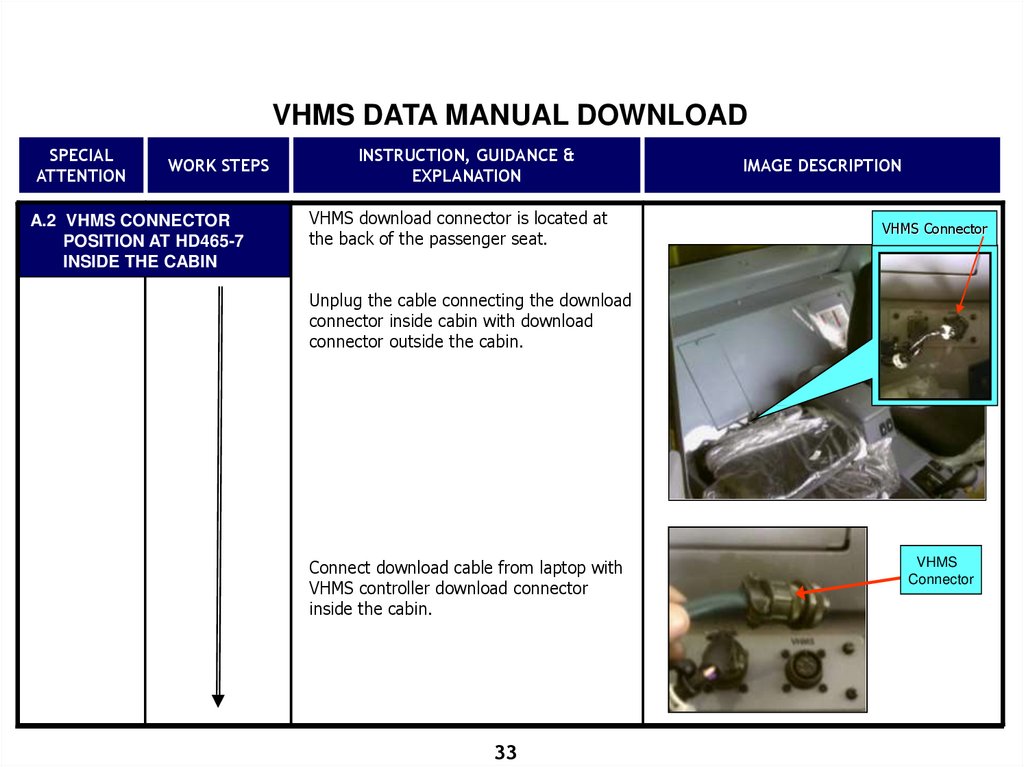

VHMS DATA MANUAL DOWNLOADSPECIAL

ATTENTION

WORK STEPS

A.2 VHMS CONNECTOR

POSITION AT HD465-7

INSIDE THE CABIN

INSTRUCTION, GUIDANCE &

EXPLANATION

VHMS download connector is located at

the back of the passenger seat.

IMAGE DESCRIPTION

VHMS Connector

Unplug the cable connecting the download

connector inside cabin with download

connector outside the cabin.

Connect download cable from laptop with

VHMS controller download connector

inside the cabin.

33

VHMS

Connector

34.

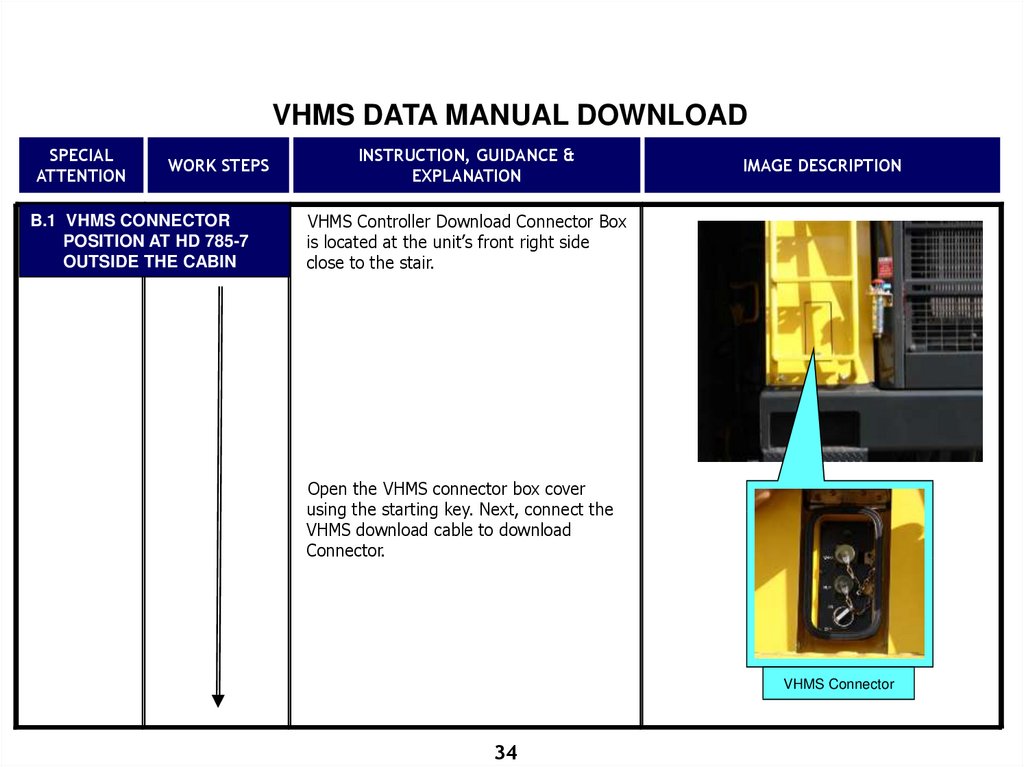

VHMS DATA MANUAL DOWNLOADSPECIAL

ATTENTION

WORK STEPS

B.1 VHMS CONNECTOR

POSITION AT HD 785-7

OUTSIDE THE CABIN

INSTRUCTION, GUIDANCE &

EXPLANATION

IMAGE DESCRIPTION

VHMS Controller Download Connector Box

is located at the unit’s front right side

close to the stair.

Open the VHMS connector box cover

using the starting key. Next, connect the

VHMS download cable to download

Connector.

VHMS Connector

34

35.

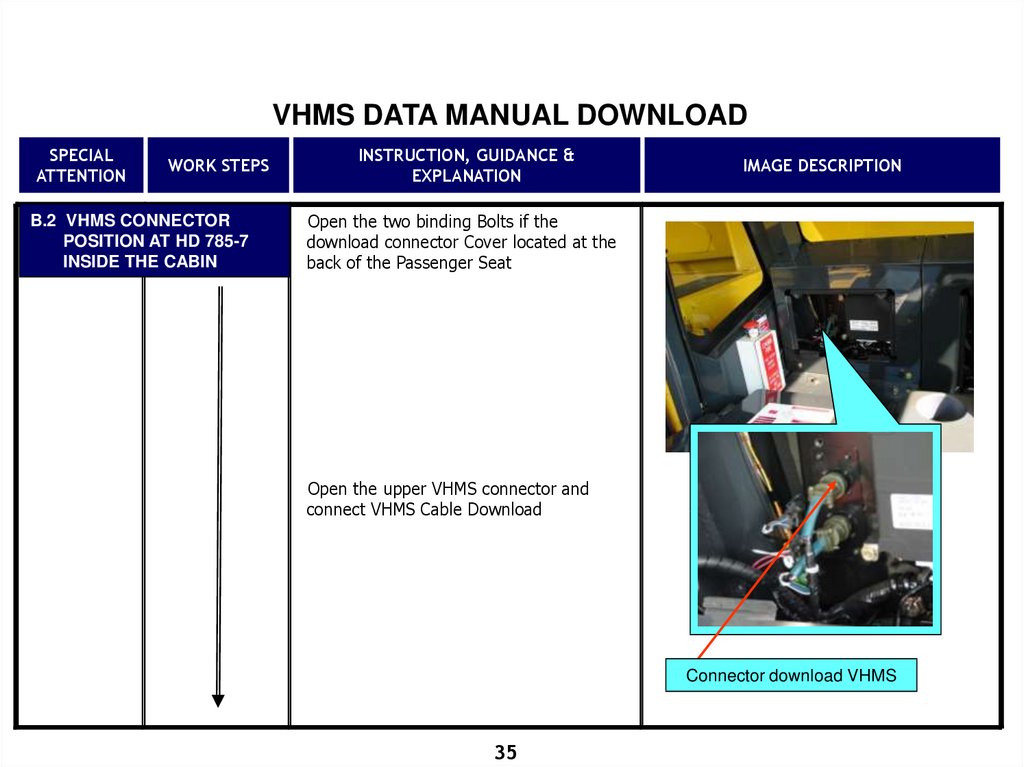

VHMS DATA MANUAL DOWNLOADSPECIAL

ATTENTION

WORK STEPS

B.2 VHMS CONNECTOR

POSITION AT HD 785-7

INSIDE THE CABIN

INSTRUCTION, GUIDANCE &

EXPLANATION

IMAGE DESCRIPTION

Open the two binding Bolts if the

download connector Cover located at the

back of the Passenger Seat

Open the upper VHMS connector and

connect VHMS Cable Download

Connector download VHMS

35

36.

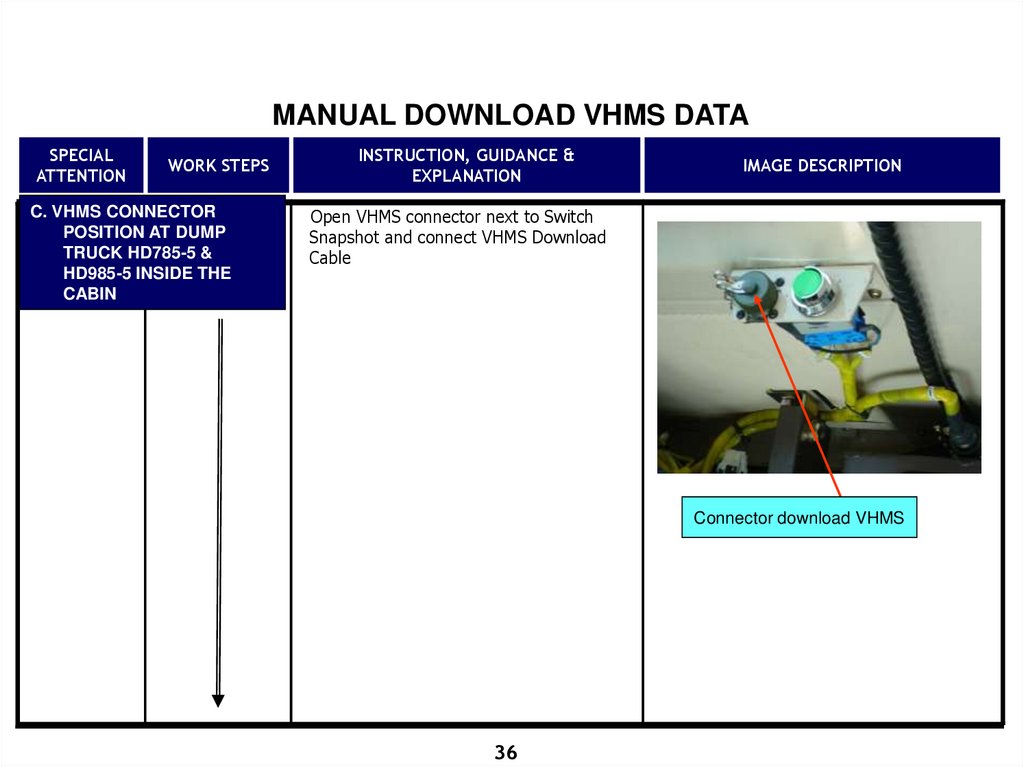

MANUAL DOWNLOAD VHMS DATASPECIAL

ATTENTION

WORK STEPS

C. VHMS CONNECTOR

POSITION AT DUMP

TRUCK HD785-5 &

HD985-5 INSIDE THE

CABIN

INSTRUCTION, GUIDANCE &

EXPLANATION

IMAGE DESCRIPTION

Open VHMS connector next to Switch

Snapshot and connect VHMS Download

Cable

Connector download VHMS

36

37.

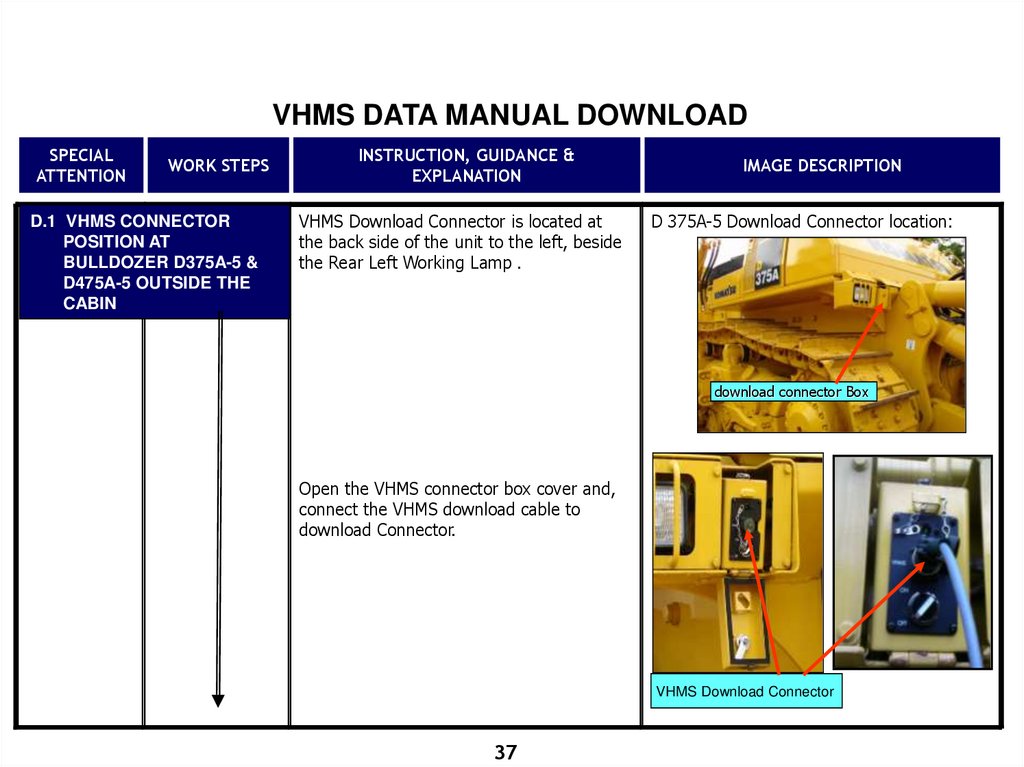

VHMS DATA MANUAL DOWNLOADSPECIAL

ATTENTION

WORK STEPS

D.1 VHMS CONNECTOR

POSITION AT

BULLDOZER D375A-5 &

D475A-5 OUTSIDE THE

CABIN

INSTRUCTION, GUIDANCE &

EXPLANATION

VHMS Download Connector is located at

the back side of the unit to the left, beside

the Rear Left Working Lamp .

IMAGE DESCRIPTION

D 375A-5 Download Connector location:

download connector Box

Open the VHMS connector box cover and,

connect the VHMS download cable to

download Connector.

VHMS Download Connector

37

38.

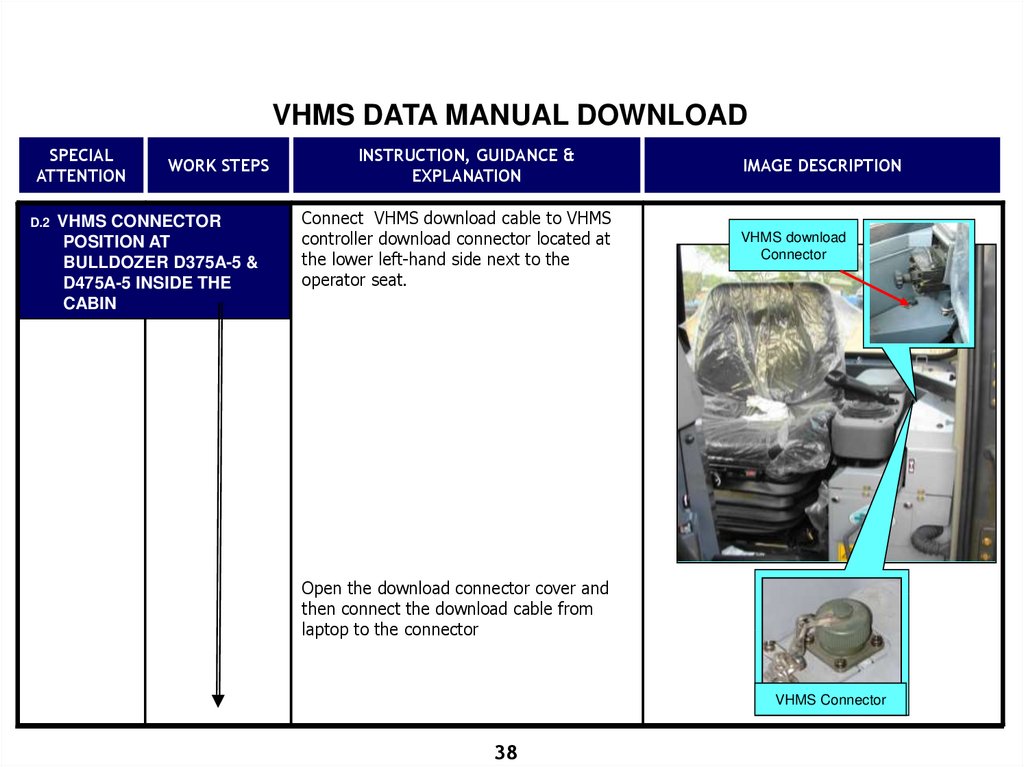

VHMS DATA MANUAL DOWNLOADSPECIAL

ATTENTION

D.2

WORK STEPS

VHMS CONNECTOR

POSITION AT

BULLDOZER D375A-5 &

D475A-5 INSIDE THE

CABIN

INSTRUCTION, GUIDANCE &

EXPLANATION

Connect VHMS download cable to VHMS

controller download connector located at

the lower left-hand side next to the

operator seat.

IMAGE DESCRIPTION

VHMS download

Connector

Open the download connector cover and

then connect the download cable from

laptop to the connector

VHMS Connector

38

39.

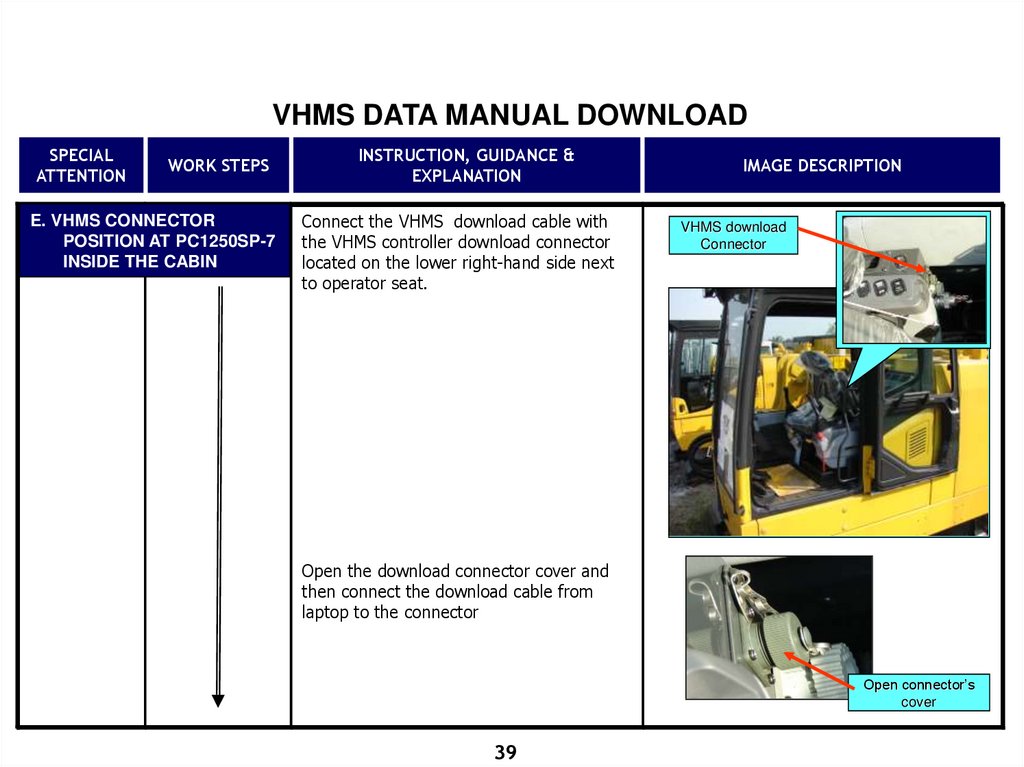

VHMS DATA MANUAL DOWNLOADSPECIAL

ATTENTION

WORK STEPS

E. VHMS CONNECTOR

POSITION AT PC1250SP-7

INSIDE THE CABIN

INSTRUCTION, GUIDANCE &

EXPLANATION

Connect the VHMS download cable with

the VHMS controller download connector

located on the lower right-hand side next

to operator seat.

IMAGE DESCRIPTION

VHMS download

Connector

Open the download connector cover and

then connect the download cable from

laptop to the connector

Open connector’s

cover

39

40.

VHMS DATA MANUAL DOWNLOADSPECIAL

ATTENTION

WORK STEPS

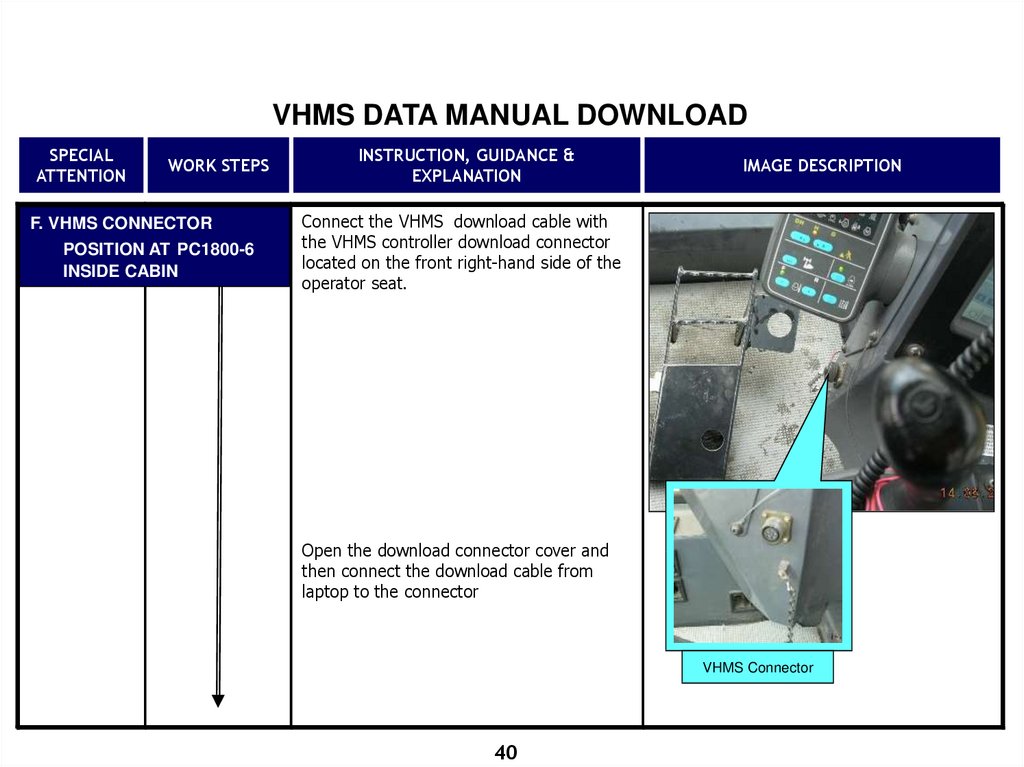

F. VHMS CONNECTOR

POSITION AT PC1800-6

INSIDE CABIN

INSTRUCTION, GUIDANCE &

EXPLANATION

IMAGE DESCRIPTION

Connect the VHMS download cable with

the VHMS controller download connector

located on the front right-hand side of the

operator seat.

Open the download connector cover and

then connect the download cable from

laptop to the connector

VHMS Connector

40

41.

VHMS DATA MANUAL DOWNLOADSPECIAL

ATTENTION

WORK STEPS

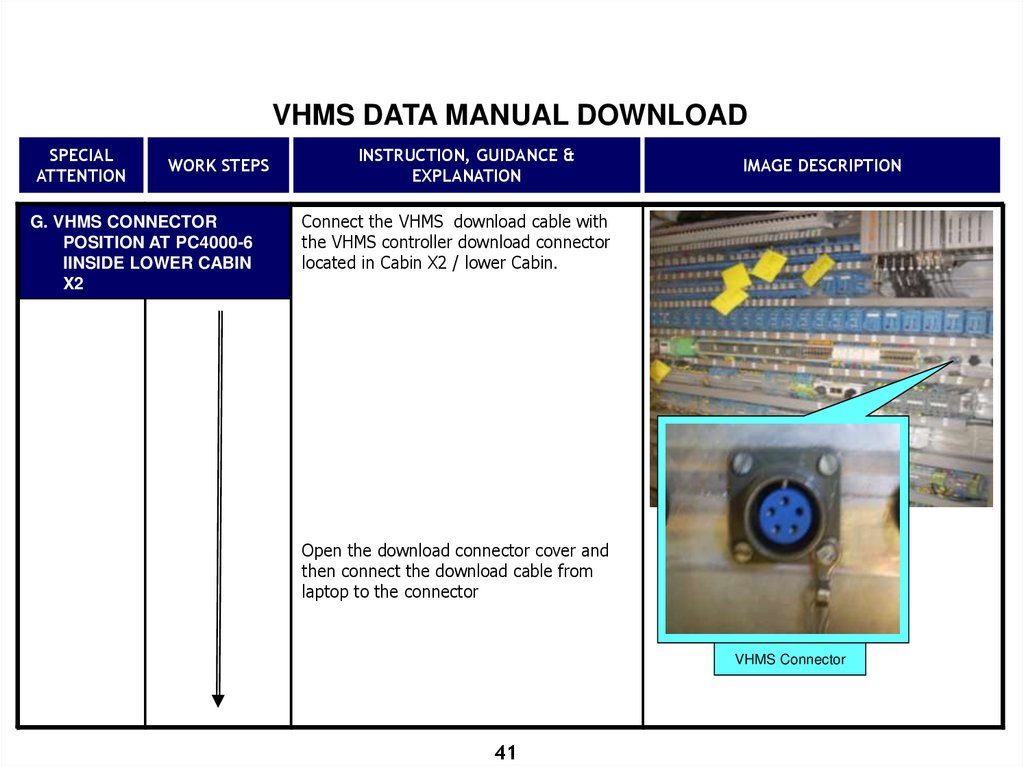

G. VHMS CONNECTOR

POSITION AT PC4000-6

IINSIDE LOWER CABIN

X2

INSTRUCTION, GUIDANCE &

EXPLANATION

IMAGE DESCRIPTION

Connect the VHMS download cable with

the VHMS controller download connector

located in Cabin X2 / lower Cabin.

Open the download connector cover and

then connect the download cable from

laptop to the connector

VHMS Connector

41

42.

VHMS DATA MANUAL DOWNLOADSPECIAL

ATTENTION

WORK STEPS

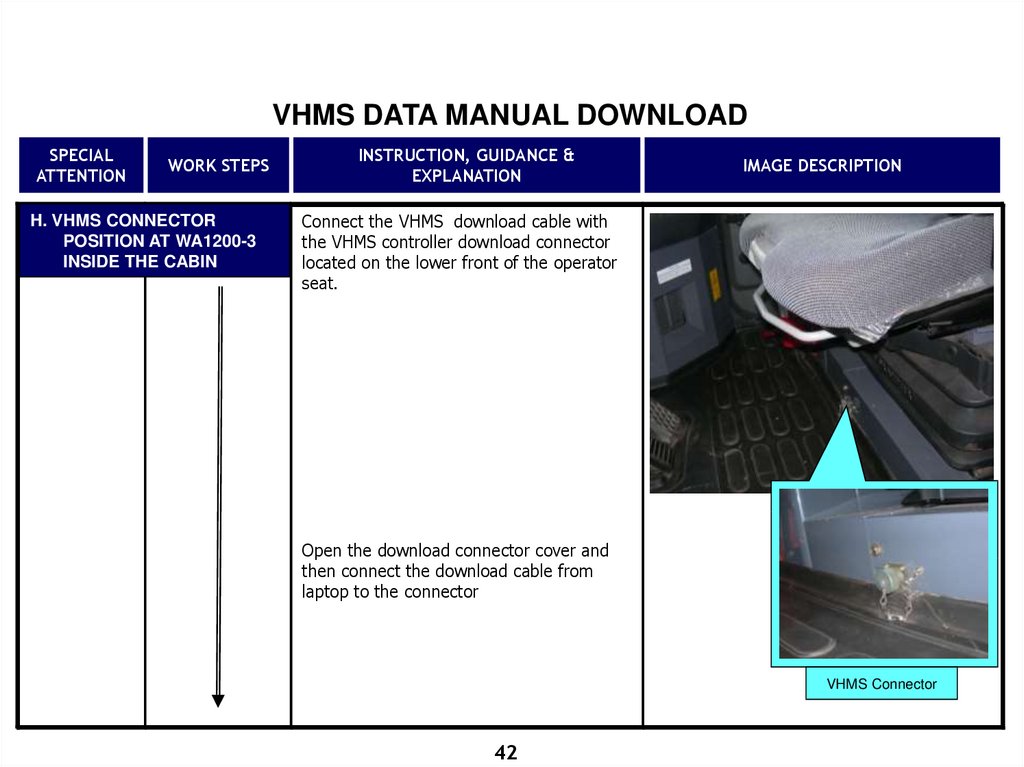

H. VHMS CONNECTOR

POSITION AT WA1200-3

INSIDE THE CABIN

INSTRUCTION, GUIDANCE &

EXPLANATION

IMAGE DESCRIPTION

Connect the VHMS download cable with

the VHMS controller download connector

located on the lower front of the operator

seat.

Open the download connector cover and

then connect the download cable from

laptop to the connector

VHMS Connector

42

43.

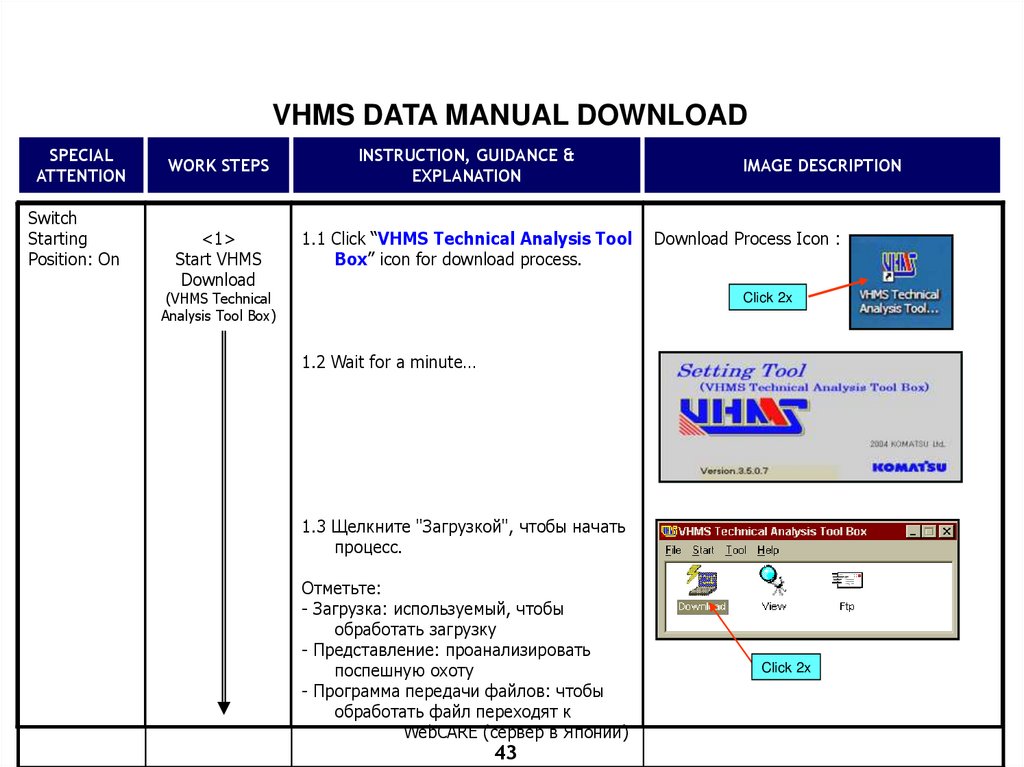

VHMS DATA MANUAL DOWNLOADSPECIAL

ATTENTION

Switch

Starting

Position: On

WORK STEPS

<1>

Start VHMS

Download

INSTRUCTION, GUIDANCE &

EXPLANATION

1.1 Click “VHMS Technical Analysis Tool

Box” icon for download process.

(VHMS Technical

Analysis Tool Box)

IMAGE DESCRIPTION

Download Process Icon :

Click 2x

1.2 Wait for a minute…

1.3 Щелкните "Загрузкой", чтобы начать

процесс.

Отметьте:

- Загрузка: используемый, чтобы

обработать загрузку

- Представление: проанализировать

поспешную охоту

- Программа передачи файлов: чтобы

обработать файл переходят к

WebCARE (сервер в Японии)

43

Click 2x

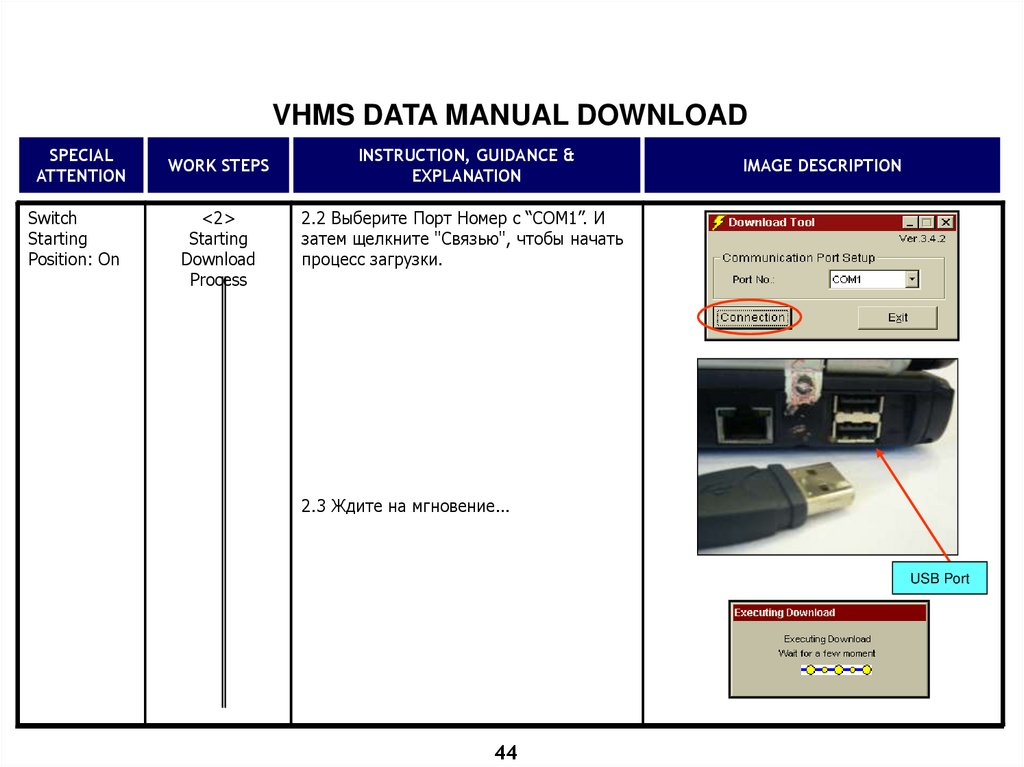

44.

VHMS DATA MANUAL DOWNLOADSPECIAL

ATTENTION

Switch

Starting

Position: On

WORK STEPS

<2>

Starting

Download

Process

INSTRUCTION, GUIDANCE &

EXPLANATION

IMAGE DESCRIPTION

2.2 Выберите Порт Номер с “COM1”. И

затем щелкните "Связью", чтобы начать

процесс загрузки.

2.3 Ждите на мгновение...

USB Port

44

45.

VHMS DATA MANUAL DOWNLOADSPECIAL

ATTENTION

WORK STEPS

INSTRUCTION, GUIDANCE &

EXPLANATION

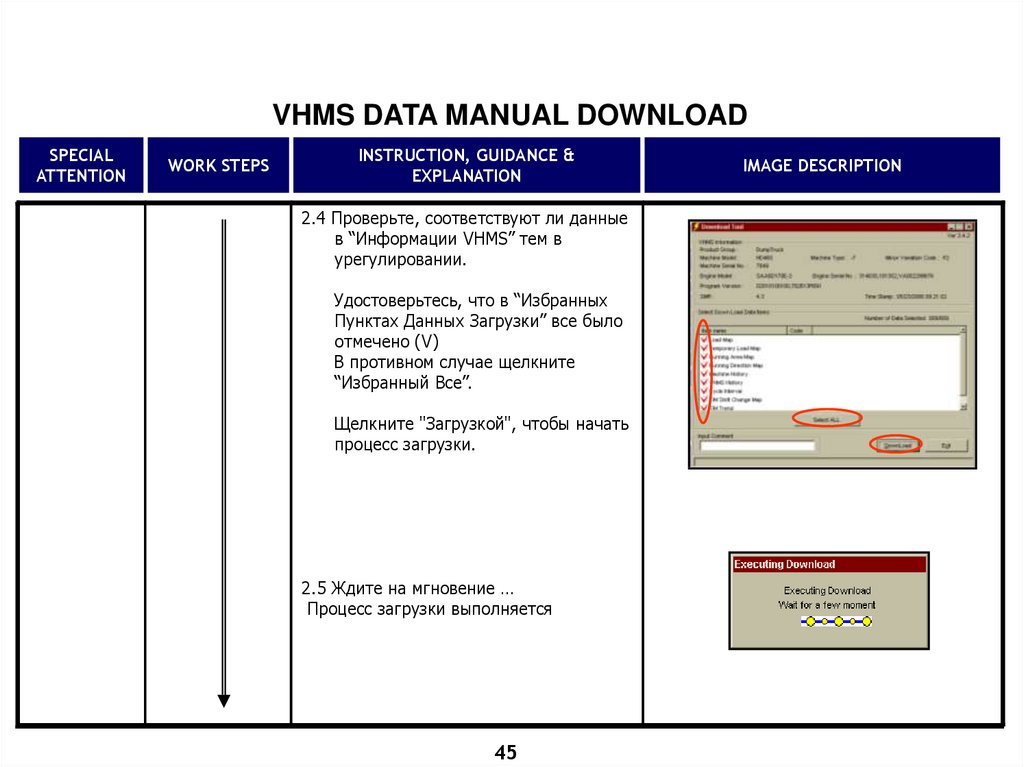

2.4 Проверьте, соответствуют ли данные

в “Информации VHMS” тем в

урегулировании.

Удостоверьтесь, что в “Избранных

Пунктах Данных Загрузки” все было

отмечено (V)

В противном случае щелкните

“Избранный Все”.

Щелкните "Загрузкой", чтобы начать

процесс загрузки.

2.5 Ждите на мгновение …

Процесс загрузки выполняется

45

IMAGE DESCRIPTION

46.

VHMS DATA MANUAL DOWNLOADSPECIAL

ATTENTION

Switch

Starting

Position: On

WORK STEPS

INSTRUCTION, GUIDANCE &

EXPLANATION

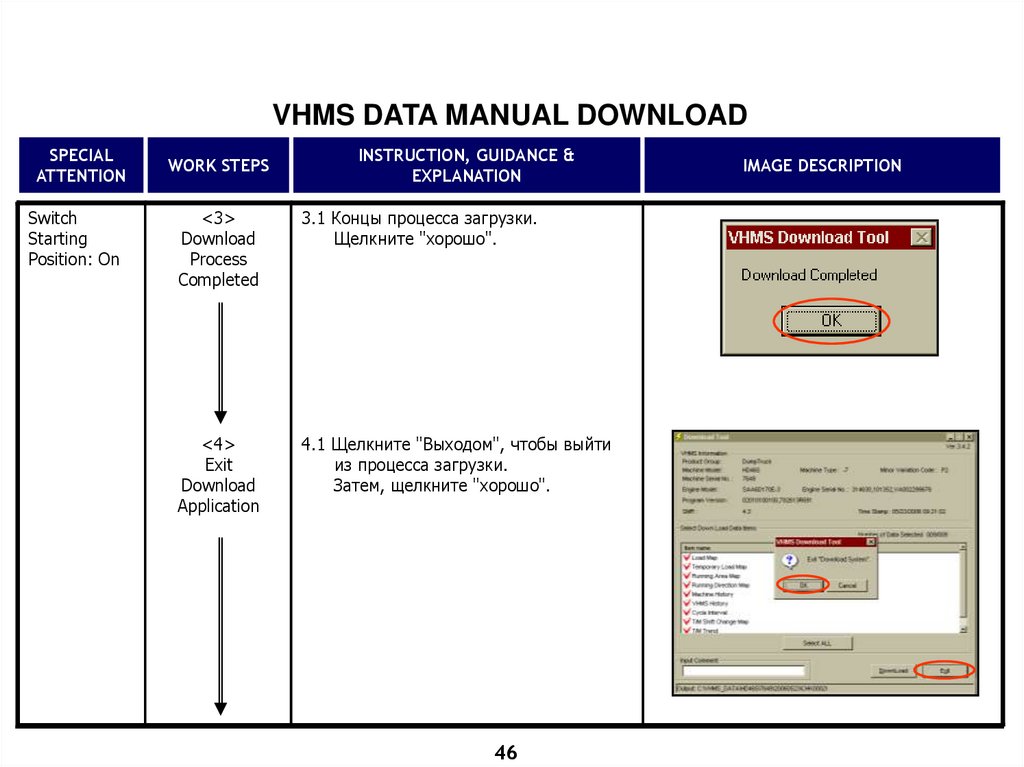

<3>

Download

Process

Completed

3.1 Концы процесса загрузки.

Щелкните "хорошо".

<4>

Exit

Download

Application

4.1 Щелкните "Выходом", чтобы выйти

из процесса загрузки.

Затем, щелкните "хорошо".

46

IMAGE DESCRIPTION

47.

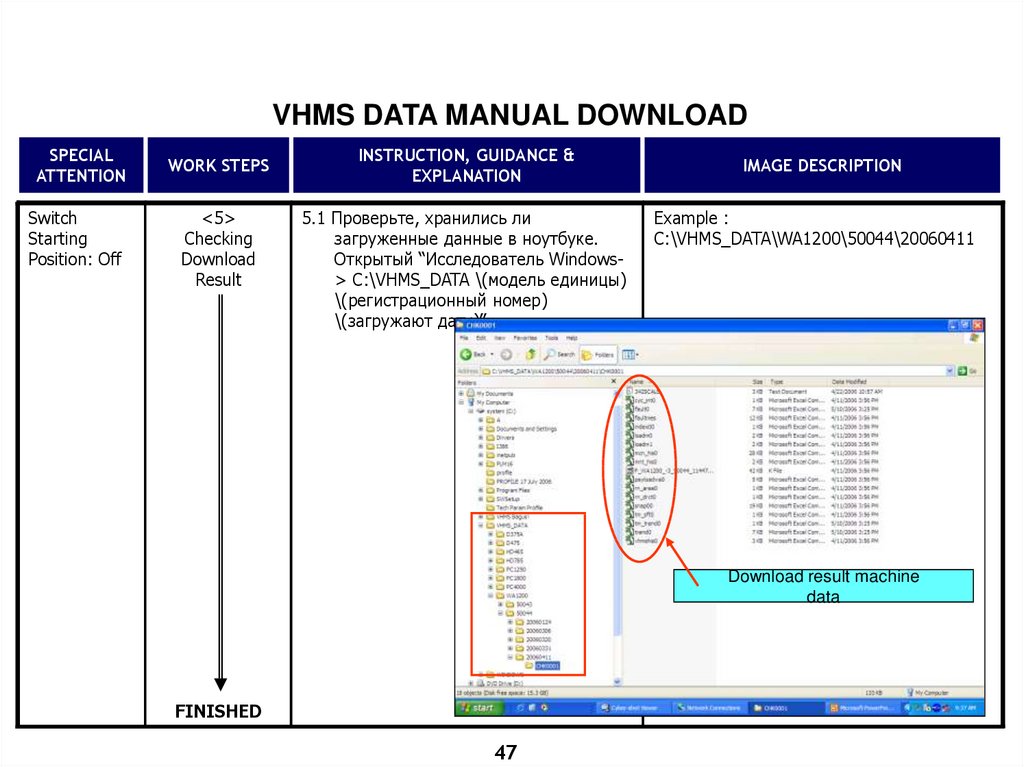

VHMS DATA MANUAL DOWNLOADSPECIAL

ATTENTION

Switch

Starting

Position: Off

WORK STEPS

<5>

Checking

Download

Result

INSTRUCTION, GUIDANCE &

EXPLANATION

5.1 Проверьте, хранились ли

загруженные данные в ноутбуке.

Открытый “Исследователь Windows> C:\VHMS_DATA \(модель единицы)

\(регистрационный номер)

\(загружают дату)”.

IMAGE DESCRIPTION

Example :

C:\VHMS_DATA\WA1200\50044\20060411

Download result machine

data

FINISHED

47

48.

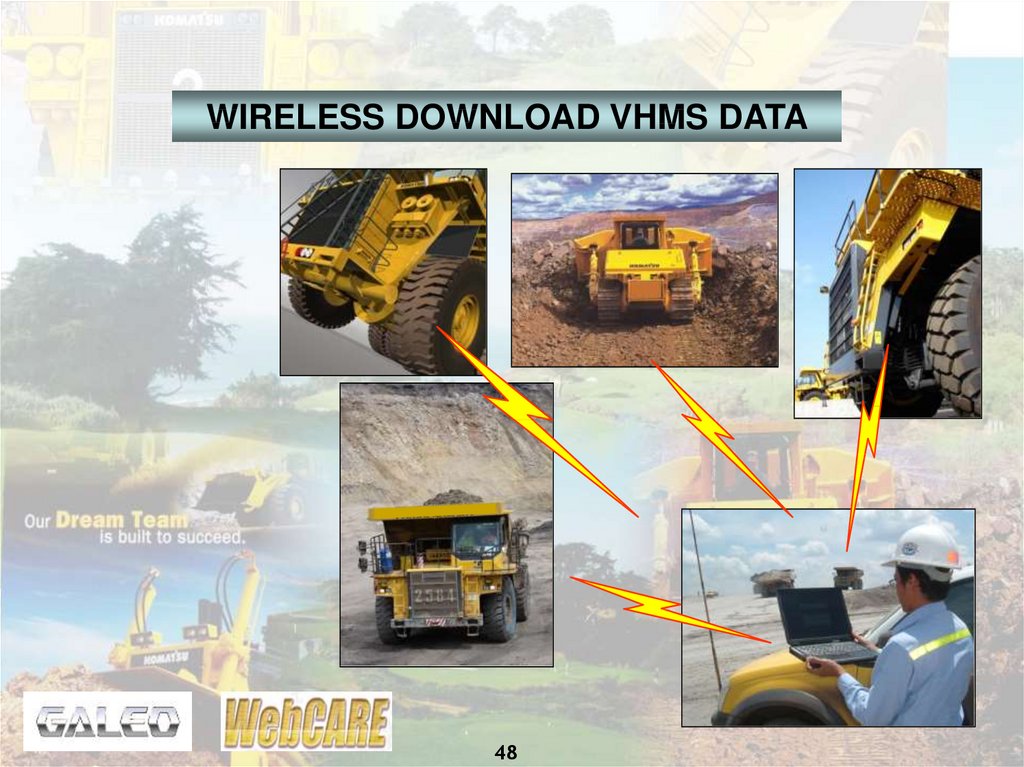

WIRELESS DOWNLOAD VHMS DATA48

49.

ЗАГРУЗКА РАДИО ДАННЫХ VHMSЗагрузка Радио ДАННЫХ VHMS - процесс загрузки ДАННЫХ VHMS от

Беспроводной Единицы, используя Беспроводное Средство Сети,

доступное в книге Примечания PC с максимальным диапазоном 150

метров и который не должен быть затруднен Металлами и или Холмы.

Чтобы позволить Беспроводную Загрузку ДАННЫХ VHMS, каждая

Единица со связанным упоминает ниже, будет во-первых

оборудованный беспроводным инструментом (модем).

Единицами Komatsu’s, которые были развиты и оборудованы

Беспроводным Типом Диспетчер VHMS, является HD465-7, HD785/9855, HD785-7, PC1250SP-7 & D375A-5 в машинах со

специфическим/самым новым Регистрационным номером.

49

50.

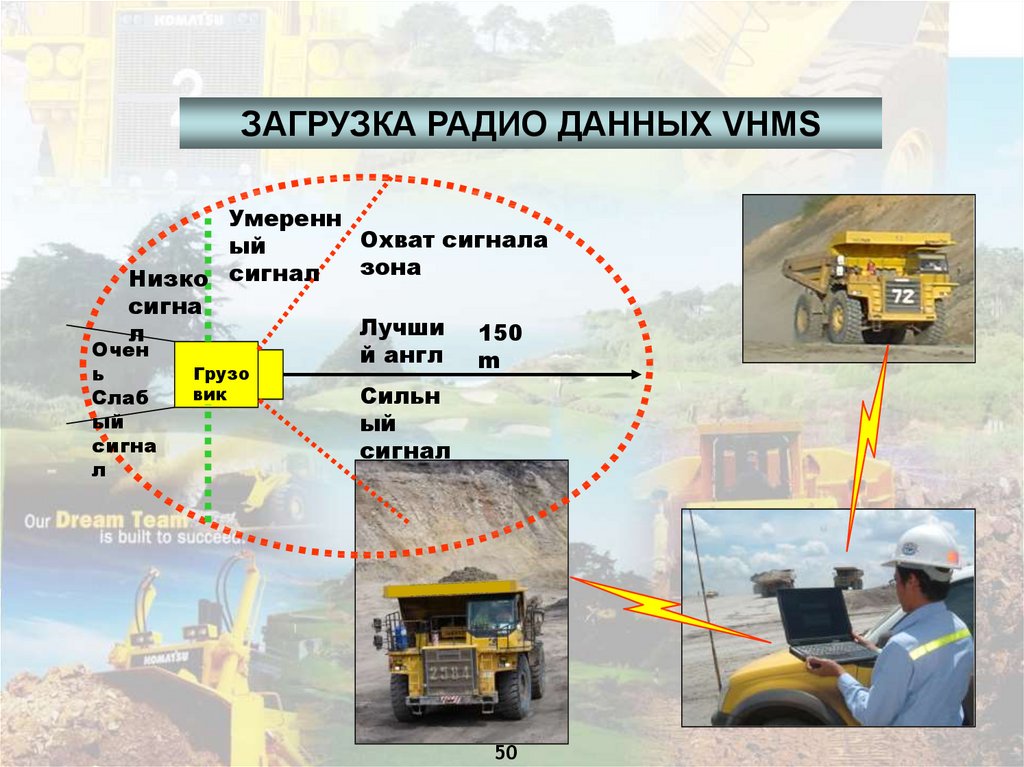

ЗАГРУЗКА РАДИО ДАННЫХ VHMSУмеренн

Охват сигнала

ый

зона

Низко сигнал

сигна

Лучши 150

л

Очен

й англ

m

Грузо

ь

Слаб

ый

сигна

л

вик

Сильн

ый

сигнал

50

51.

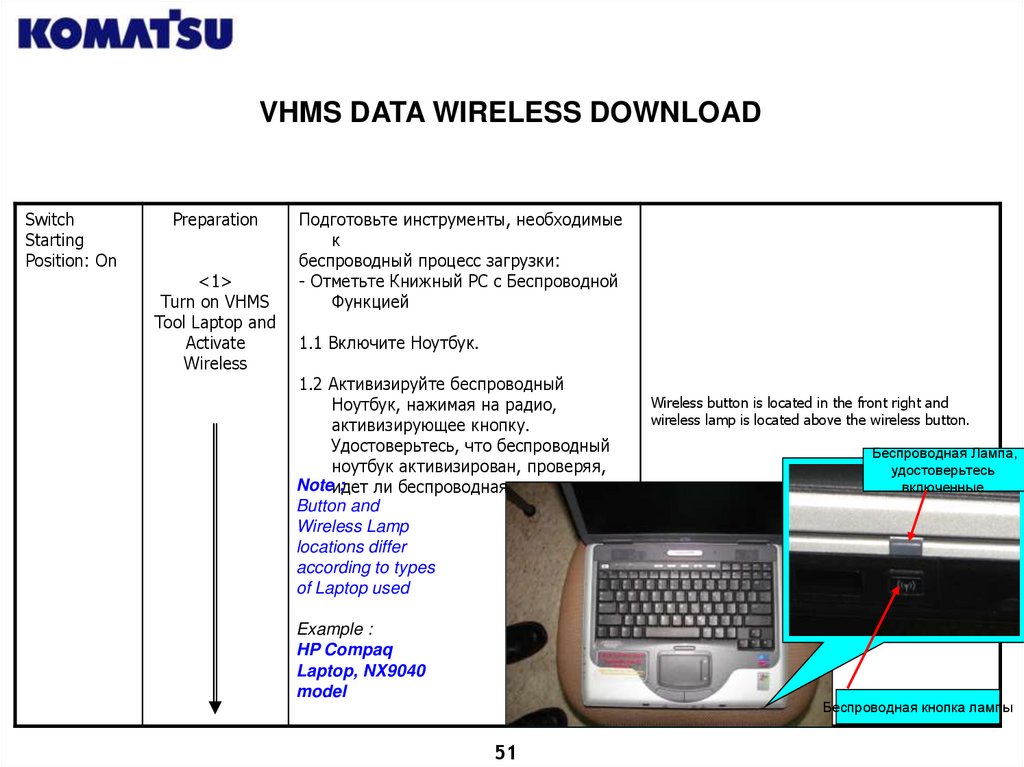

VHMS DATA WIRELESS DOWNLOADSwitch

Starting

Position: On

Preparation

<1>

Turn on VHMS

Tool Laptop and

Activate

Wireless

Подготовьте инструменты, необходимые

к

беспроводный процесс загрузки:

- Отметьте Книжный PC с Беспроводной

Функцией

1.1 Включите Ноутбук.

1.2 Активизируйте беспроводный

Ноутбук, нажимая на радио,

активизирующее кнопку.

Удостоверьтесь, что беспроводный

ноутбук активизирован, проверяя,

Noteидет

:

ли беспроводная лампа или нет.

Button and

Wireless Lamp

locations differ

according to types

of Laptop used

Example :

HP Compaq

Laptop, NX9040

model

Wireless button is located in the front right and

wireless lamp is located above the wireless button.

Беспроводная Лампа,

удостоверьтесь

включенные

Беспроводная кнопка лампы

51

52.

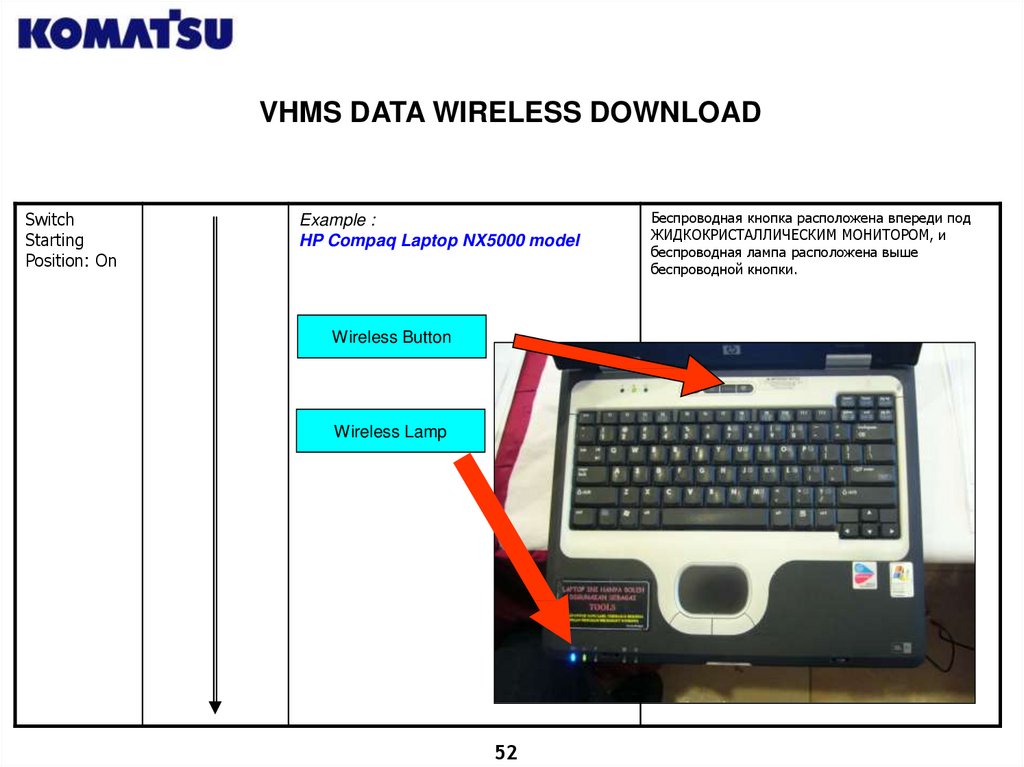

VHMS DATA WIRELESS DOWNLOADSwitch

Starting

Position: On

Example :

HP Compaq Laptop NX5000 model

Wireless Button

Wireless Lamp

52

Беспроводная кнопка расположена впереди под

ЖИДКОКРИСТАЛЛИЧЕСКИМ МОНИТОРОМ, и

беспроводная лампа расположена выше

беспроводной кнопки.

53.

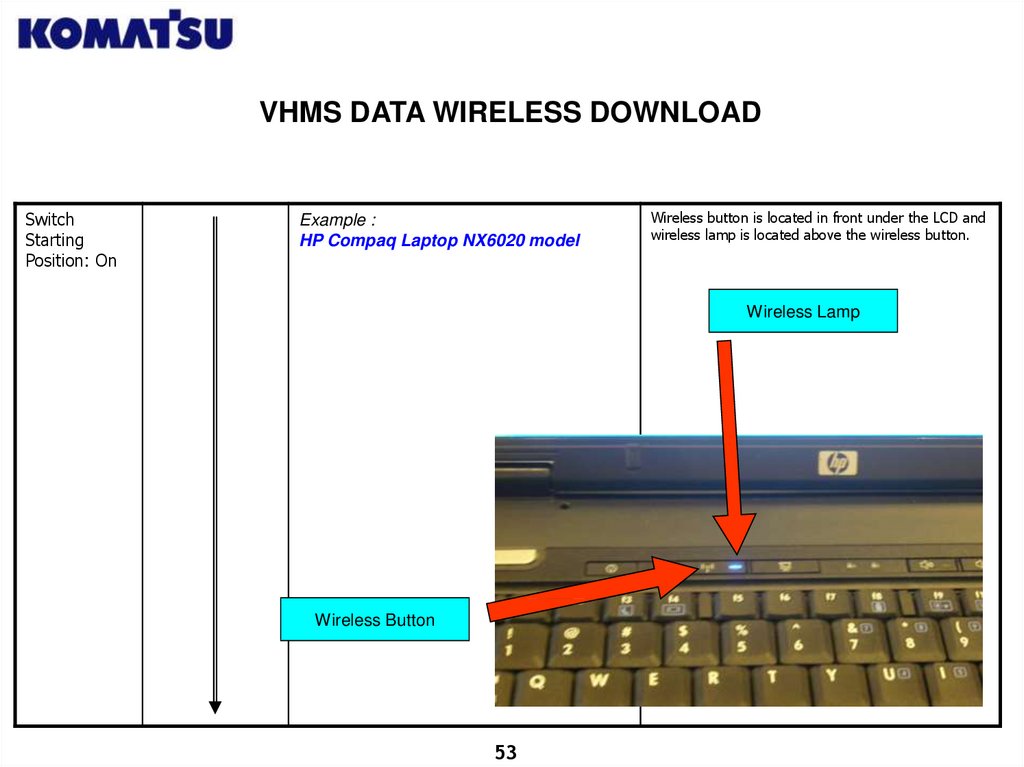

VHMS DATA WIRELESS DOWNLOADSwitch

Starting

Position: On

Example :

HP Compaq Laptop NX6020 model

Wireless button is located in front under the LCD and

wireless lamp is located above the wireless button.

Wireless Lamp

Wireless Button

53

54.

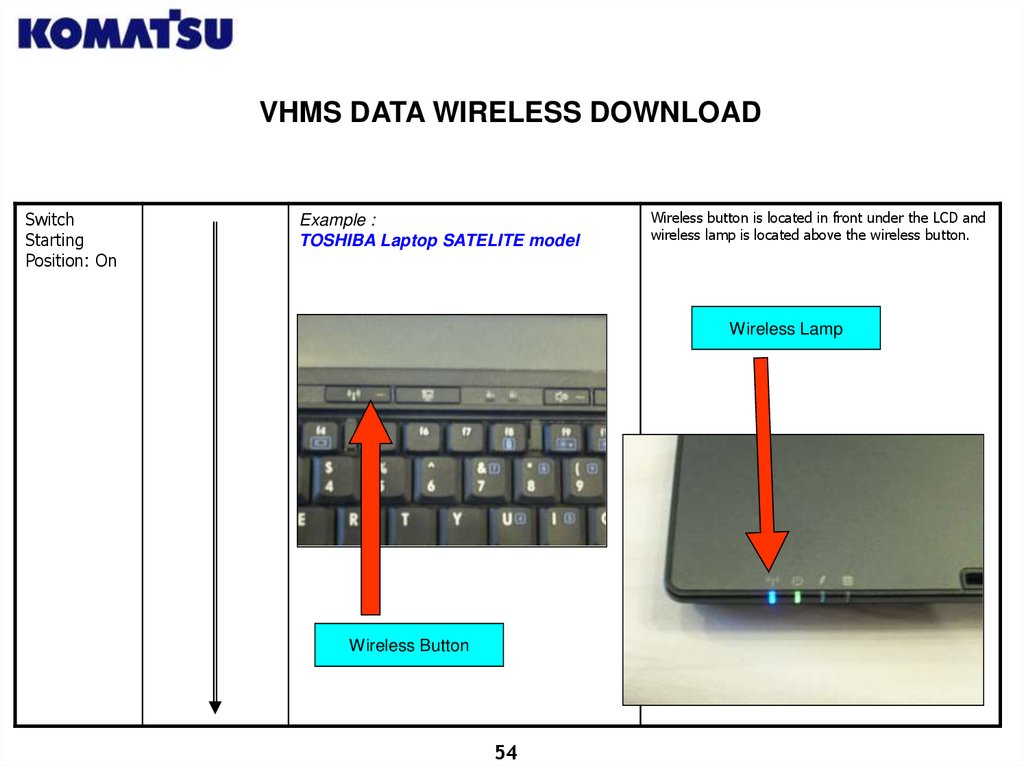

VHMS DATA WIRELESS DOWNLOADSwitch

Starting

Position: On

Example :

TOSHIBA Laptop SATELITE model

Wireless button is located in front under the LCD and

wireless lamp is located above the wireless button.

Wireless Lamp

Wireless Button

54

55.

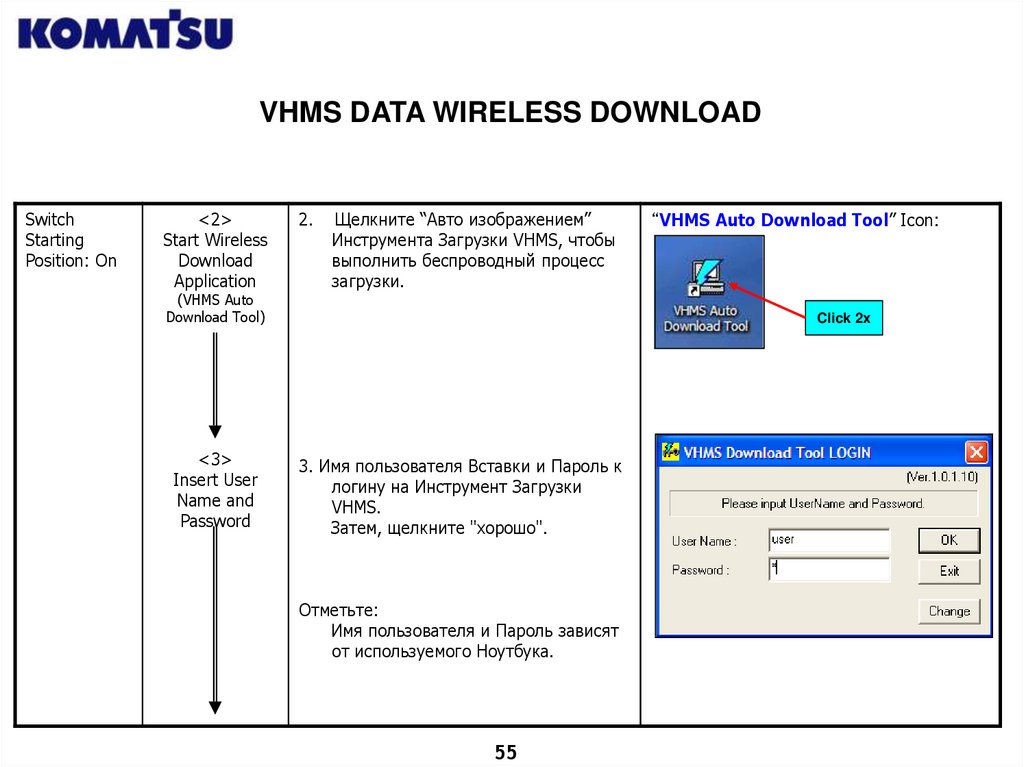

VHMS DATA WIRELESS DOWNLOADSwitch

Starting

Position: On

<2>

Start Wireless

Download

Application

2.

Щелкните “Авто изображением”

Инструмента Загрузки VHMS, чтобы

выполнить беспроводный процесс

загрузки.

(VHMS Auto

Download Tool)

<3>

Insert User

Name and

Password

“VHMS Auto Download Tool” Icon:

Click 2x

3. Имя пользователя Вставки и Пароль к

логину на Инструмент Загрузки

VHMS.

Затем, щелкните "хорошо".

Отметьте:

Имя пользователя и Пароль зависят

от используемого Ноутбука.

55

56.

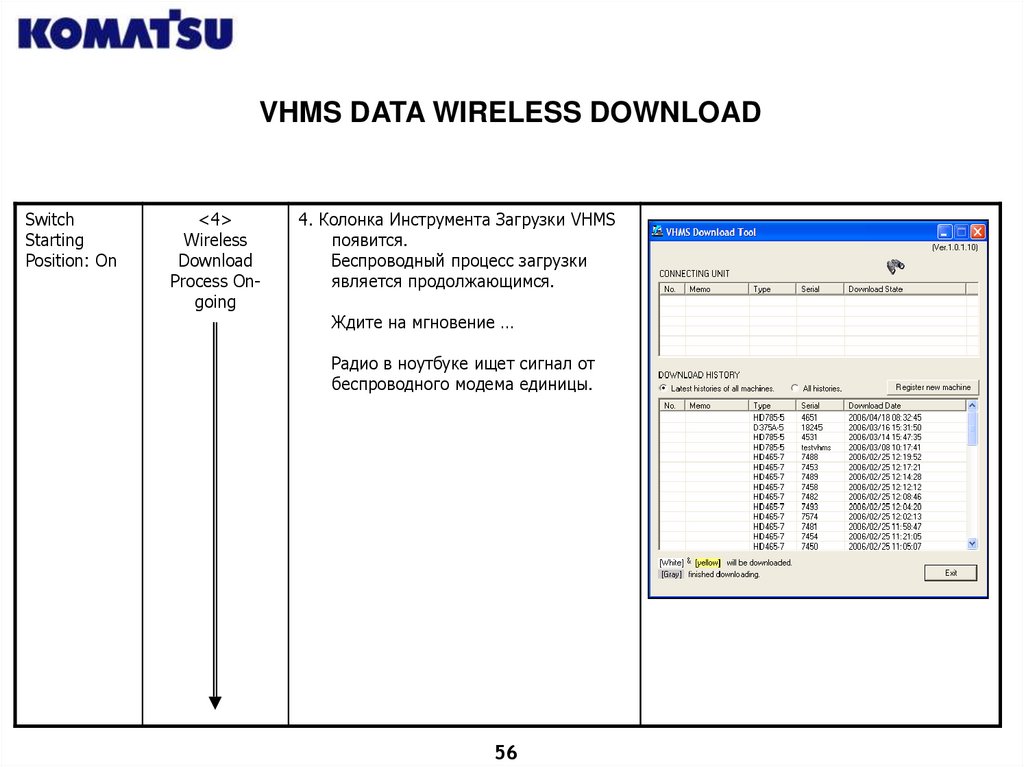

VHMS DATA WIRELESS DOWNLOADSwitch

Starting

Position: On

<4>

Wireless

Download

Process Ongoing

4. Колонка Инструмента Загрузки VHMS

появится.

Беспроводный процесс загрузки

является продолжающимся.

Ждите на мгновение …

Радио в ноутбуке ищет сигнал от

беспроводного модема единицы.

56

57.

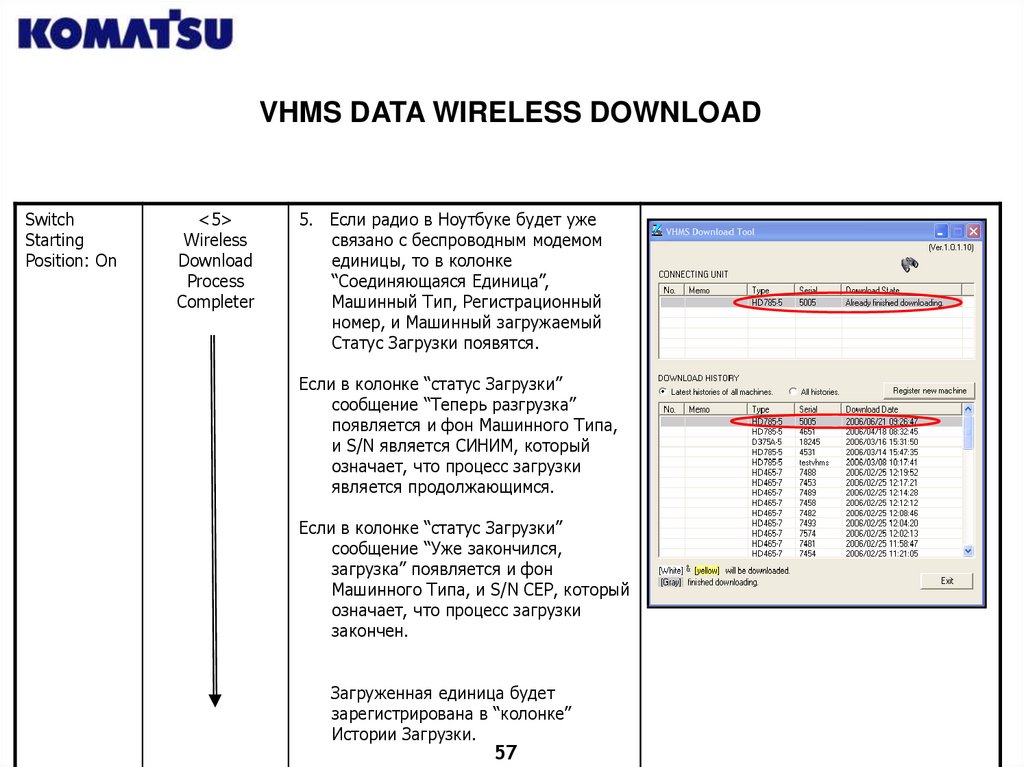

VHMS DATA WIRELESS DOWNLOADSwitch

Starting

Position: On

<5>

Wireless

Download

Process

Completer

5. Если радио в Ноутбуке будет уже

связано с беспроводным модемом

единицы, то в колонке

“Соединяющаяся Единица”,

Машинный Тип, Регистрационный

номер, и Машинный загружаемый

Статус Загрузки появятся.

Если в колонке “статус Загрузки”

сообщение “Теперь разгрузка”

появляется и фон Машинного Типа,

и S/N является СИНИМ, который

означает, что процесс загрузки

является продолжающимся.

Если в колонке “статус Загрузки”

сообщение “Уже закончился,

загрузка” появляется и фон

Машинного Типа, и S/N СЕР, который

означает, что процесс загрузки

закончен.

Загруженная единица будет

зарегистрирована в “колонке”

Истории Загрузки.

57

58.

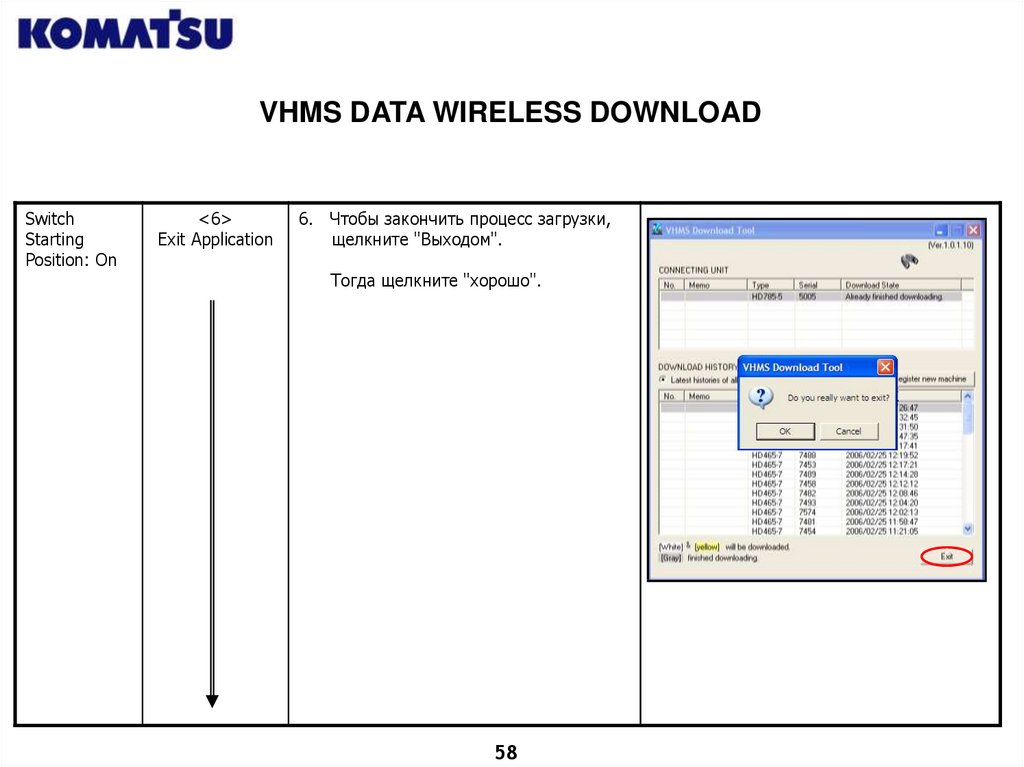

VHMS DATA WIRELESS DOWNLOADSwitch

Starting

Position: On

<6>

Exit Application

6. Чтобы закончить процесс загрузки,

щелкните "Выходом".

Тогда щелкните "хорошо".

58

59.

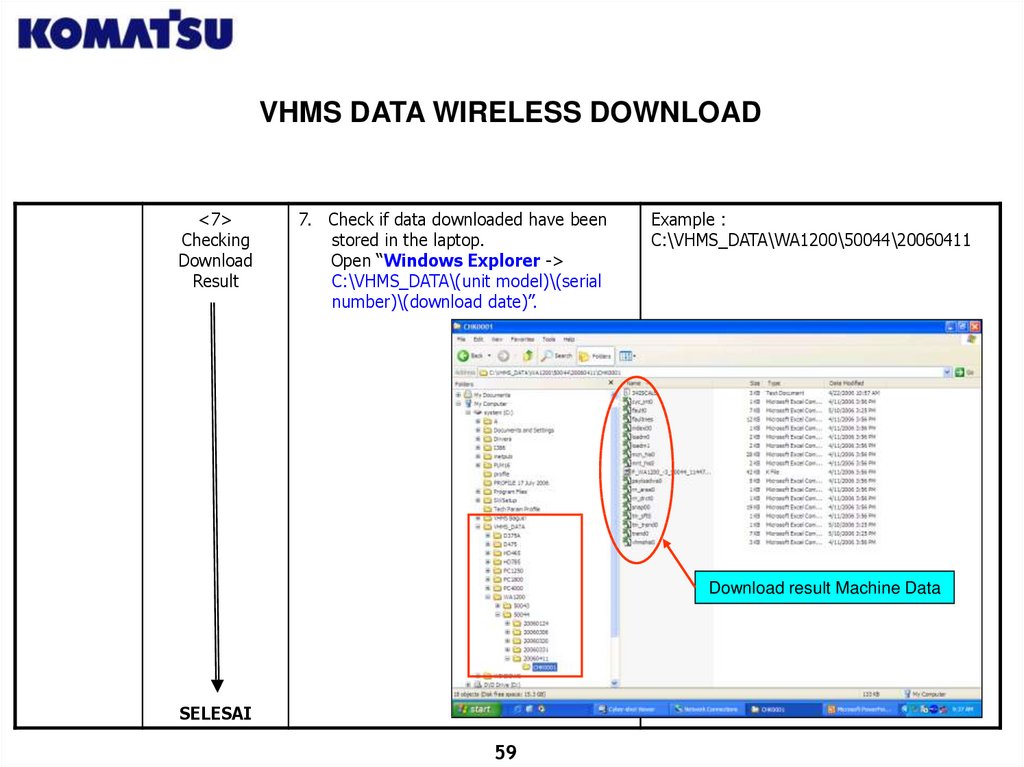

VHMS DATA WIRELESS DOWNLOAD<7>

Checking

Download

Result

7. Check if data downloaded have been

stored in the laptop.

Open “Windows Explorer ->

C:\VHMS_DATA\(unit model)\(serial

number)\(download date)”.

Example :

C:\VHMS_DATA\WA1200\50044\20060411

Download result Machine Data

SELESAI

59

60.

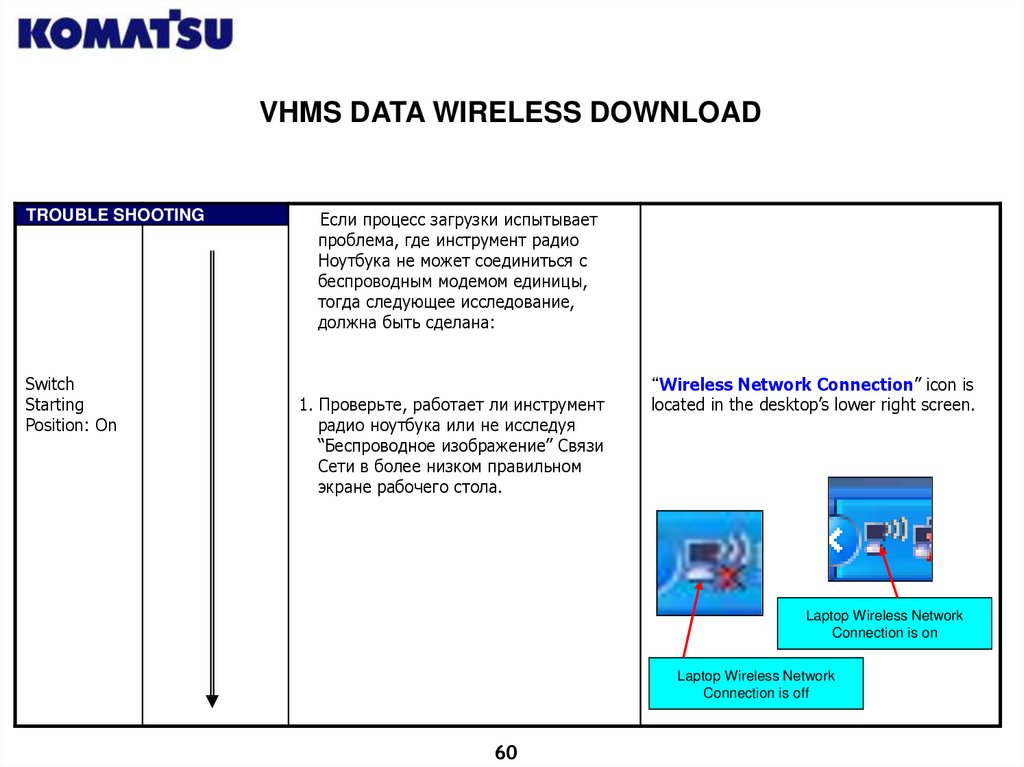

VHMS DATA WIRELESS DOWNLOADTROUBLE SHOOTING

Switch

Starting

Position: On

Если процесс загрузки испытывает

проблема, где инструмент радио

Ноутбука не может соединиться с

беспроводным модемом единицы,

тогда следующее исследование,

должна быть сделана:

1. Проверьте, работает ли инструмент

радио ноутбука или не исследуя

“Беспроводное изображение” Связи

Сети в более низком правильном

экране рабочего стола.

“Wireless Network Connection” icon is

located in the desktop’s lower right screen.

Laptop Wireless Network

Connection is on

Laptop Wireless Network

Connection is off

60

61.

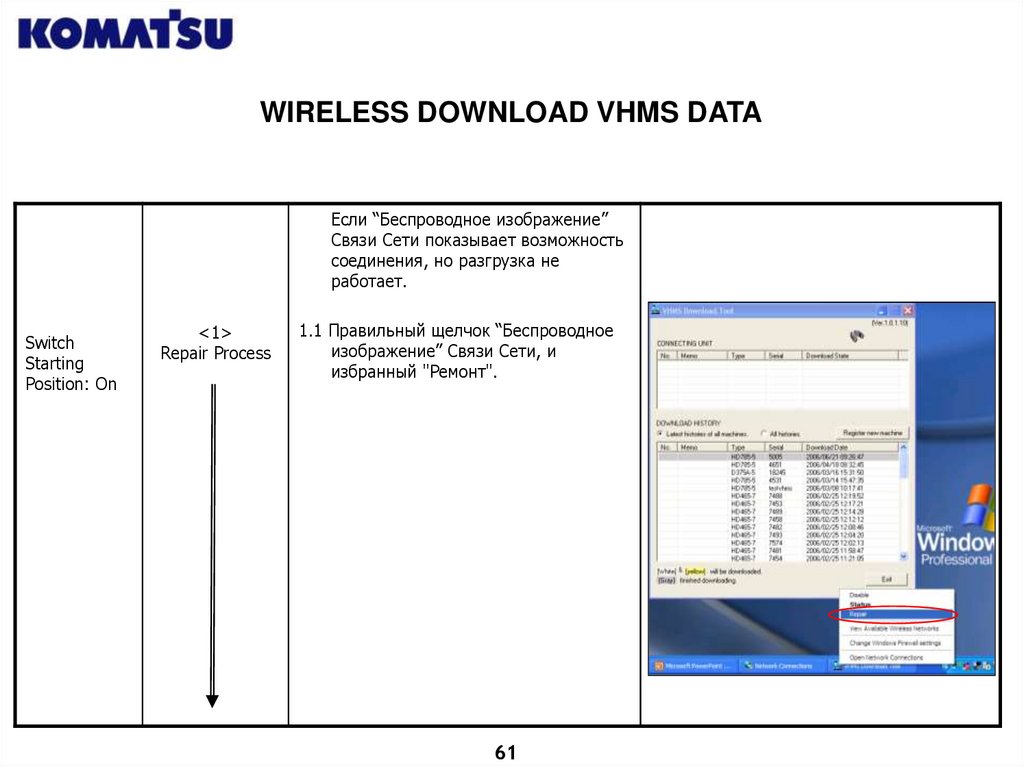

WIRELESS DOWNLOAD VHMS DATAЕсли “Беспроводное изображение”

Связи Сети показывает возможность

соединения, но разгрузка не

работает.

Switch

Starting

Position: On

<1>

Repair Process

1.1 Правильный щелчок “Беспроводное

изображение” Связи Сети, и

избранный "Ремонт".

61

62.

WIRELESS DOWNLOAD VHMS DATAStarting

Switch

Position: ON

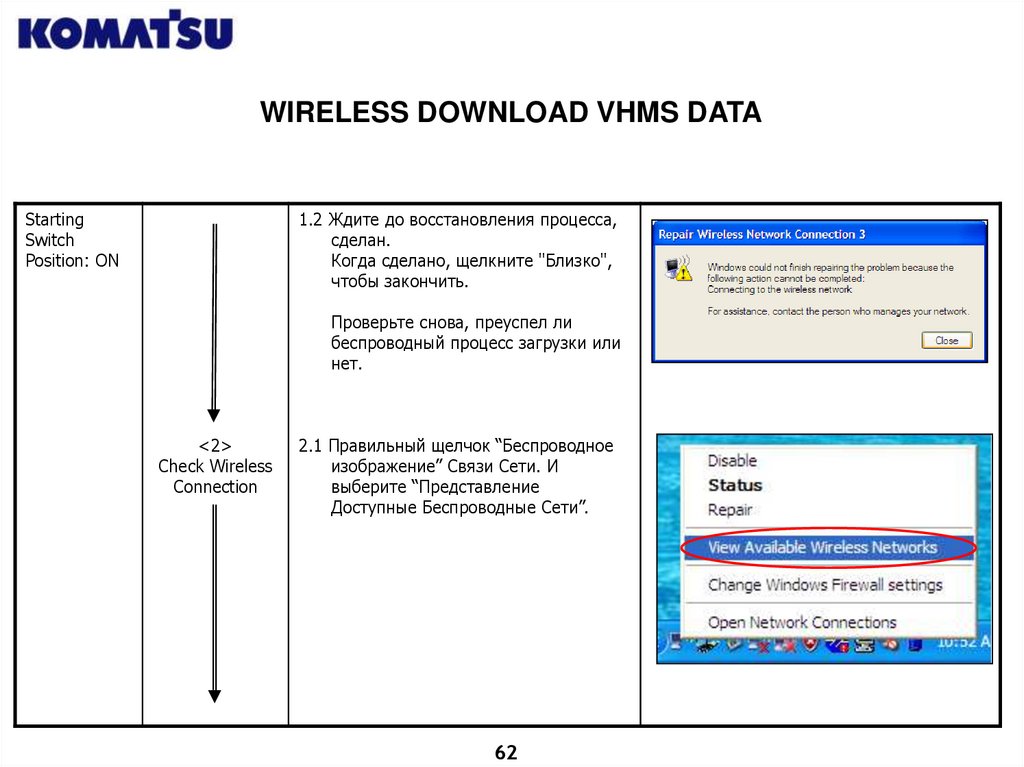

1.2 Ждите до восстановления процесса,

сделан.

Когда сделано, щелкните "Близко",

чтобы закончить.

Проверьте снова, преуспел ли

беспроводный процесс загрузки или

нет.

<2>

Check Wireless

Connection

2.1 Правильный щелчок “Беспроводное

изображение” Связи Сети. И

выберите “Представление

Доступные Беспроводные Сети”.

62

63.

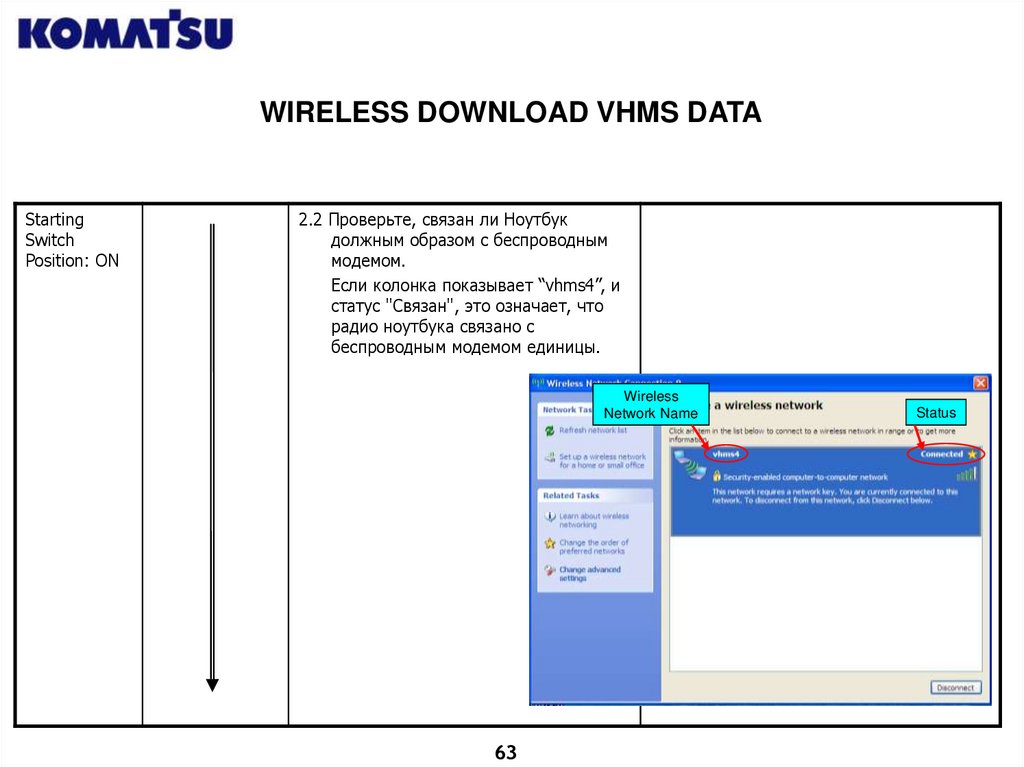

WIRELESS DOWNLOAD VHMS DATAStarting

Switch

Position: ON

2.2 Проверьте, связан ли Ноутбук

должным образом с беспроводным

модемом.

Если колонка показывает “vhms4”, и

статус "Связан", это означает, что

радио ноутбука связано с

беспроводным модемом единицы.

Wireless

Network Name

63

Status

64.

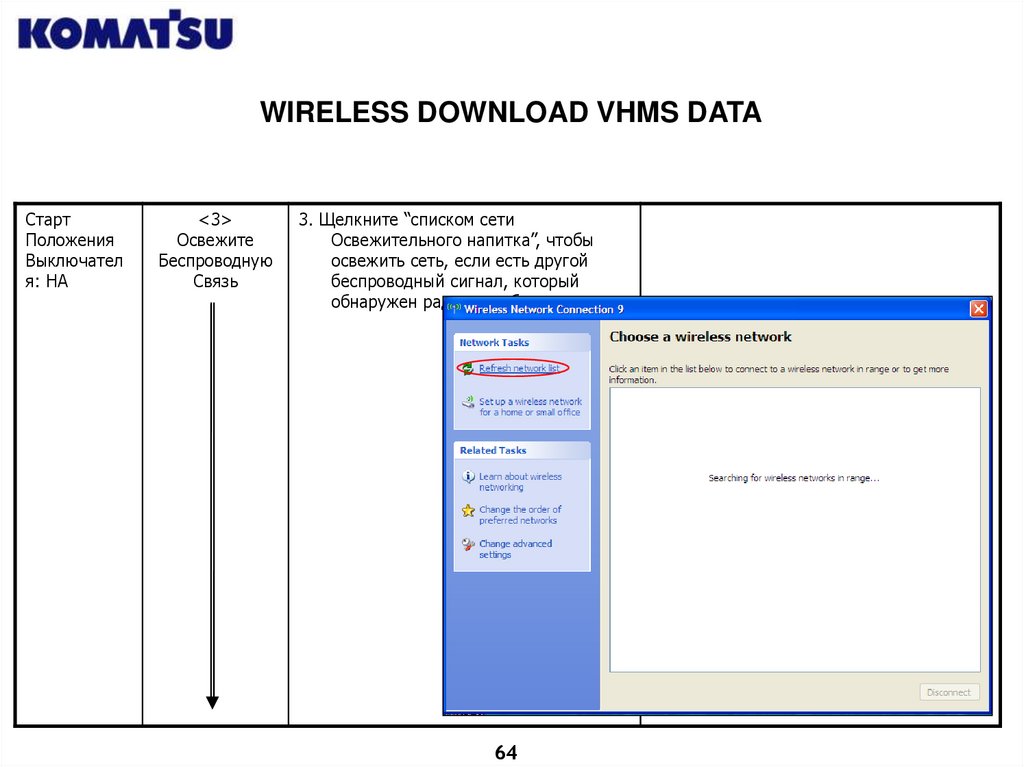

WIRELESS DOWNLOAD VHMS DATAСтарт

Положения

Выключател

я: НА

<3>

Освежите

Беспроводную

Связь

3. Щелкните “списком сети

Освежительного напитка”, чтобы

освежить сеть, если есть другой

беспроводный сигнал, который

обнаружен радио ноутбука.

64

65.

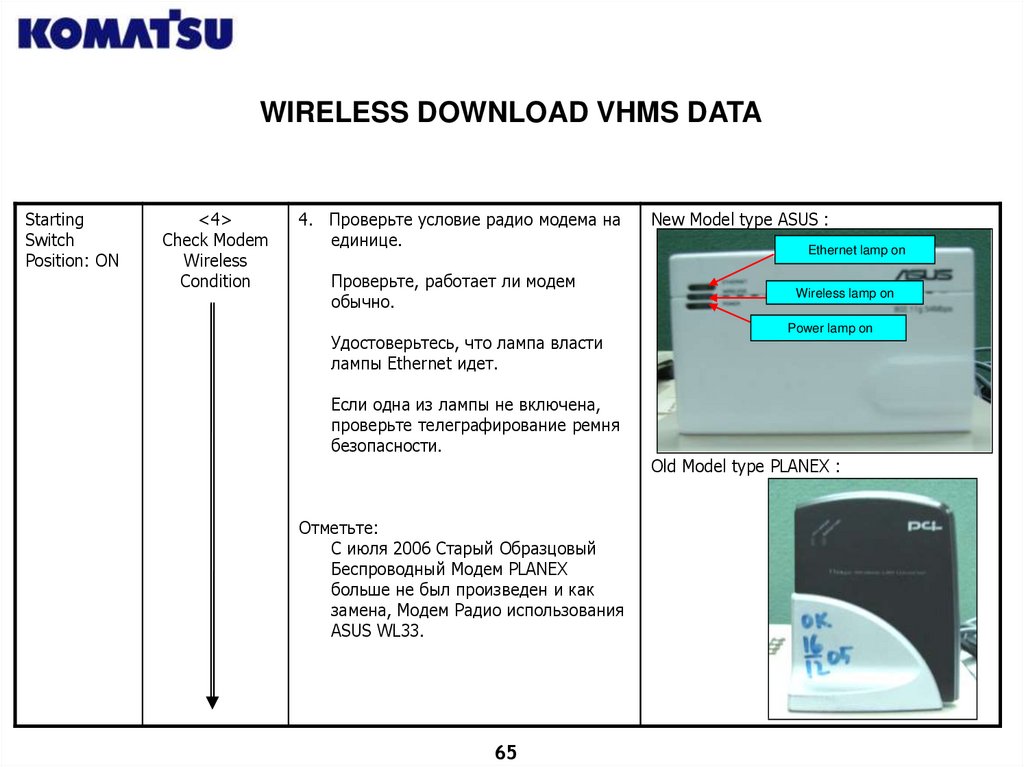

WIRELESS DOWNLOAD VHMS DATAStarting

Switch

Position: ON

<4>

Check Modem

Wireless

Condition

4. Проверьте условие радио модема на

единице.

Проверьте, работает ли модем

обычно.

Удостоверьтесь, что лампа власти

лампы Ethernet идет.

Если одна из лампы не включена,

проверьте телеграфирование ремня

безопасности.

Отметьте:

С июля 2006 Старый Образцовый

Беспроводный Модем PLANEX

больше не был произведен и как

замена, Модем Радио использования

ASUS WL33.

65

New Model type ASUS :

Ethernet lamp on

Wireless lamp on

Power lamp on

Old Model type PLANEX :

66.

VHMS BAGUS SOFTWARE66

67.

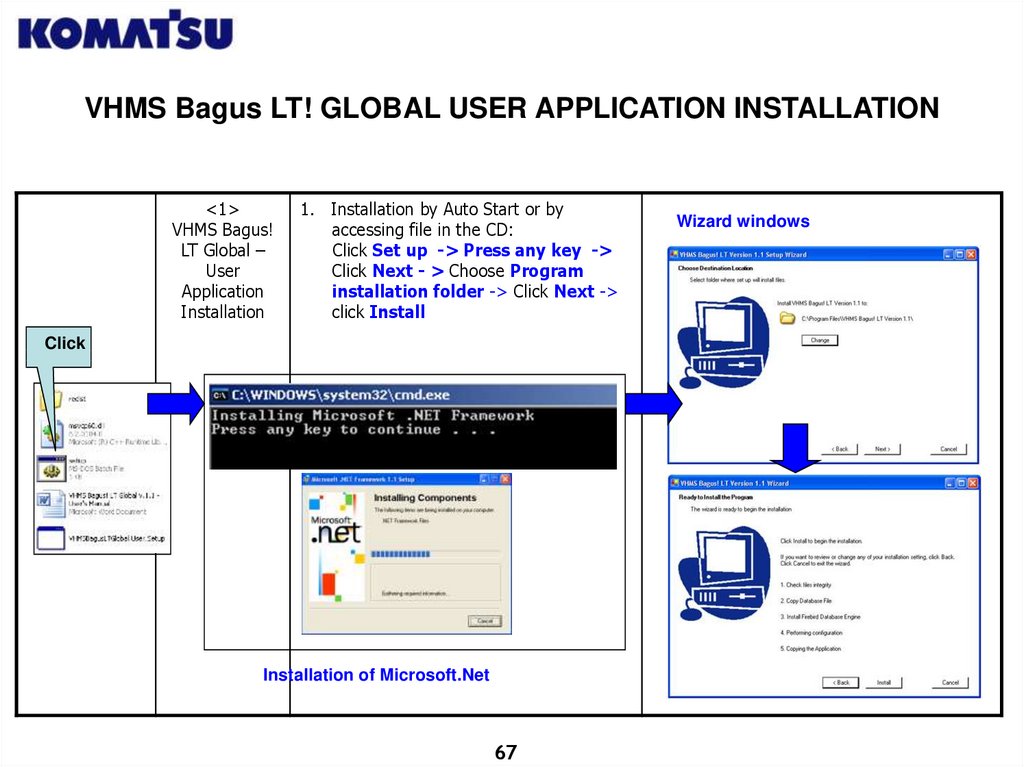

VHMS Bagus LT! GLOBAL USER APPLICATION INSTALLATION<1>

VHMS Bagus!

LT Global –

User

Application

Installation

1. Installation by Auto Start or by

accessing file in the CD:

Click Set up -> Press any key ->

Click Next - > Choose Program

installation folder -> Click Next ->

click Install

Click

Installation of Microsoft.Net

67

Wizard windows

68.

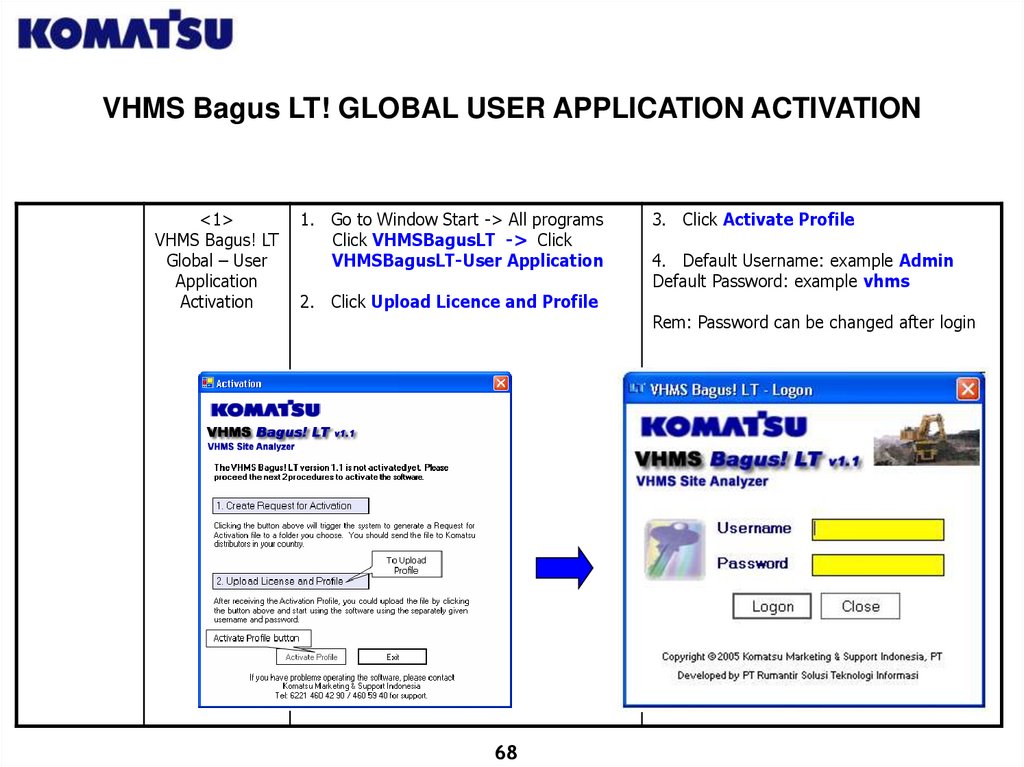

VHMS Bagus LT! GLOBAL USER APPLICATION ACTIVATION<1>

VHMS Bagus! LT

Global – User

Application

Activation

1. Go to Window Start -> All programs

Click VHMSBagusLT -> Click

VHMSBagusLT-User Application

2. Click Upload Licence and Profile

68

3. Click Activate Profile

4. Default Username: example Admin

Default Password: example vhms

Rem: Password can be changed after login

69.

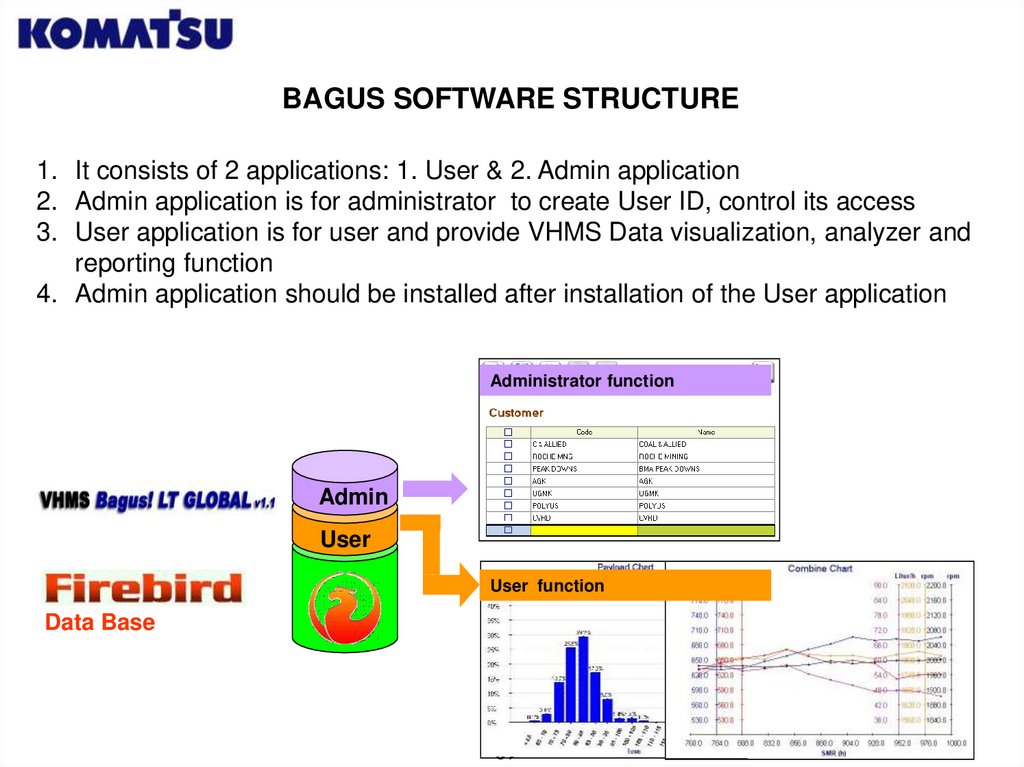

BAGUS SOFTWARE STRUCTURE1. It consists of 2 applications: 1. User & 2. Admin application

2. Admin application is for administrator to create User ID, control its access

3. User application is for user and provide VHMS Data visualization, analyzer and

reporting function

4. Admin application should be installed after installation of the User application

Administrator function

Admin

User

User function

Data Base

69

70.

VHMS BAGUS LT! GLOBAL USER APPLICATIONADDING NEW CUSTOMER

<1>

VHMS Bagus! LT

Global – User

Application

1. Go to Configuration :

Click Customer List

2. Click Edit -> Create double click

Code (yellow) & enter Customer

Code (Max 10 character) -> double

click Name and enter Customer

name (max 40 character)

Click Edit

3. Click Create and redo no 2

to enter new job site

4. Click Save

Click Create

Input Customer

70

71.

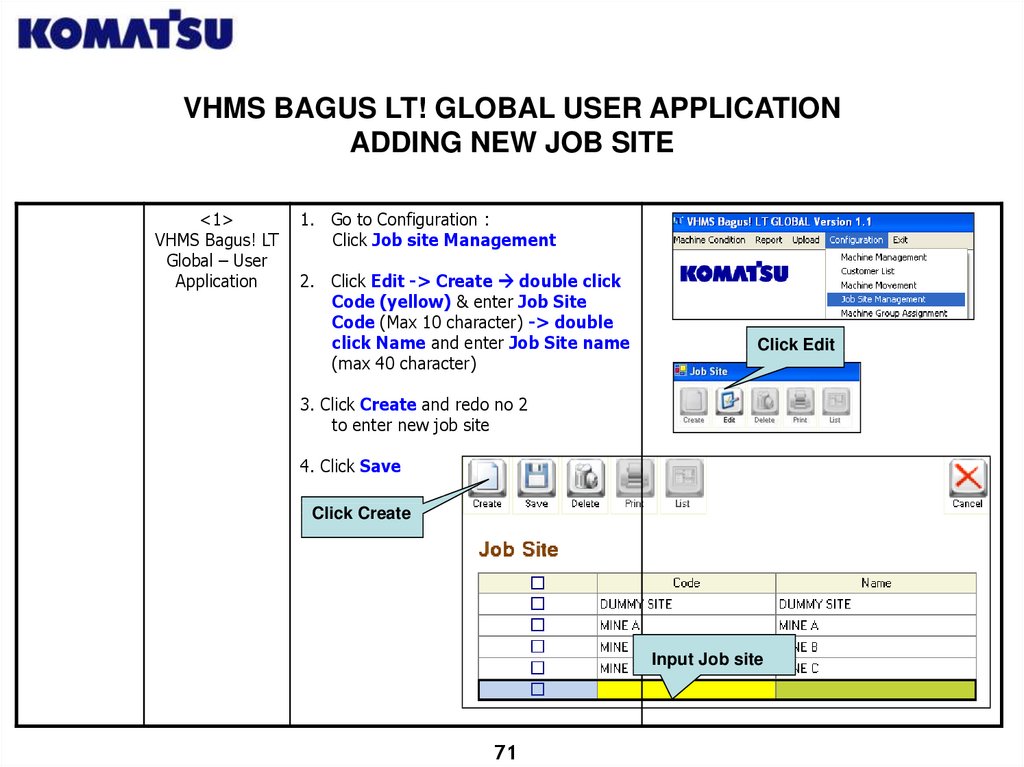

VHMS BAGUS LT! GLOBAL USER APPLICATIONADDING NEW JOB SITE

<1>

VHMS Bagus! LT

Global – User

Application

1. Go to Configuration :

Click Job site Management

2. Click Edit -> Create double click

Code (yellow) & enter Job Site

Code (Max 10 character) -> double

click Name and enter Job Site name

(max 40 character)

Click Edit

3. Click Create and redo no 2

to enter new job site

4. Click Save

Click Create

Input Job site

71

72.

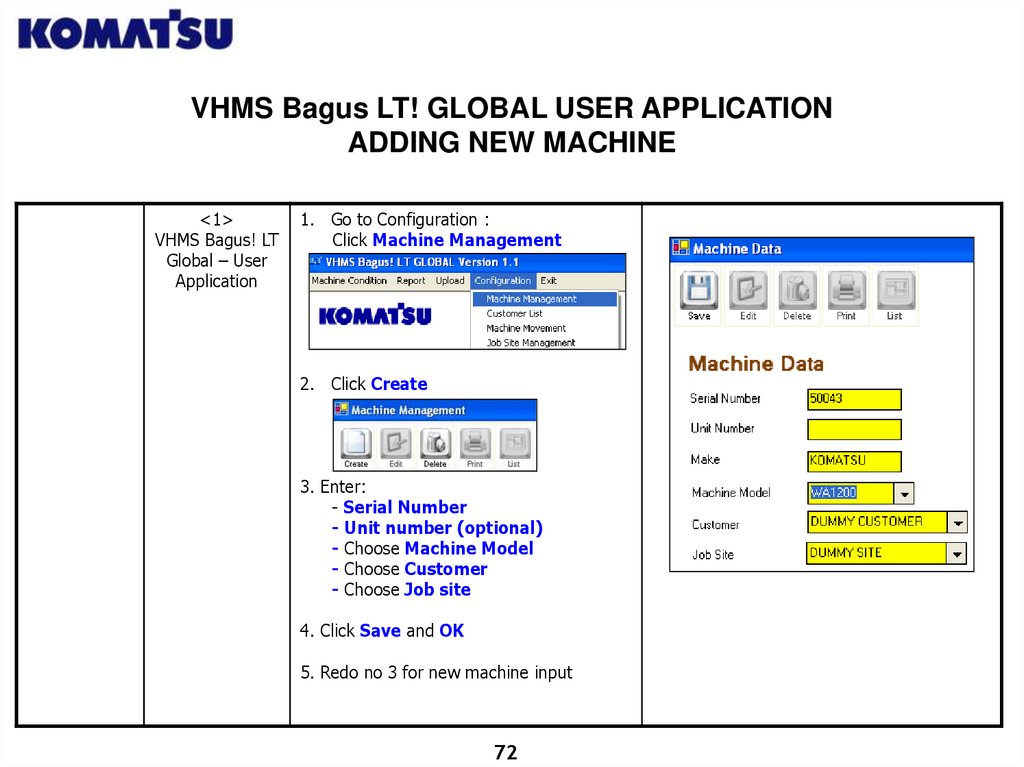

VHMS Bagus LT! GLOBAL USER APPLICATIONADDING NEW MACHINE

<1>

VHMS Bagus! LT

Global – User

Application

1. Go to Configuration :

Click Machine Management

2. Click Create

3. Enter:

- Serial Number

- Unit number (optional)

- Choose Machine Model

- Choose Customer

- Choose Job site

4. Click Save and OK

5. Redo no 3 for new machine input

72

73.

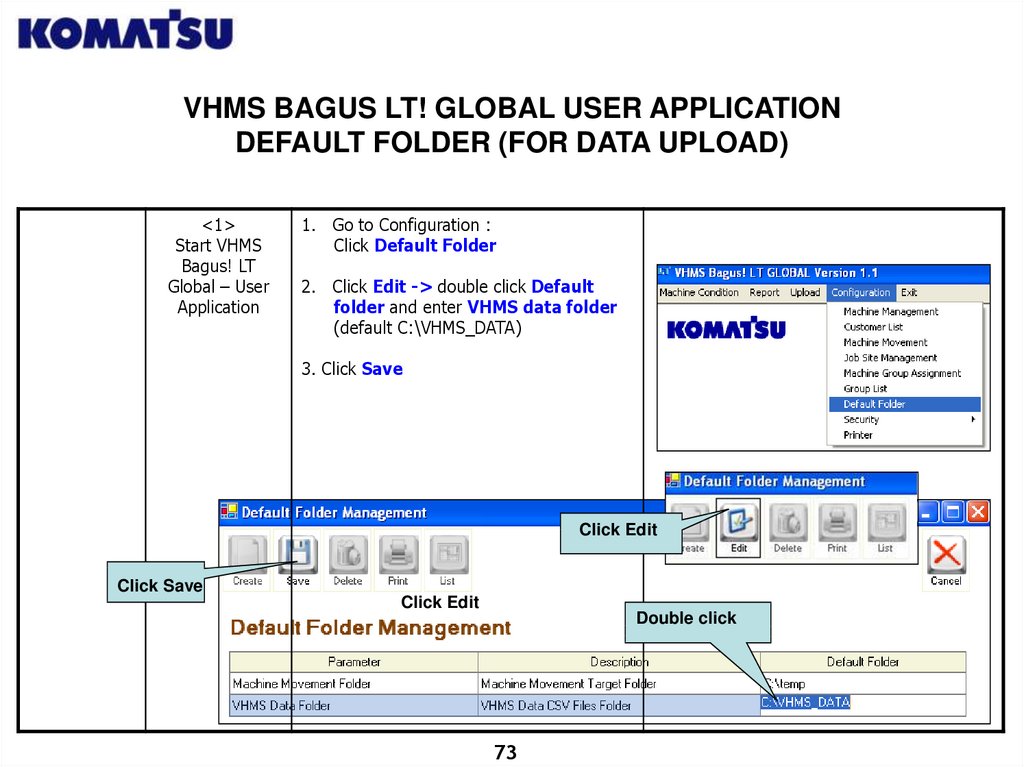

VHMS BAGUS LT! GLOBAL USER APPLICATIONDEFAULT FOLDER (FOR DATA UPLOAD)

<1>

Start VHMS

Bagus! LT

Global – User

Application

1. Go to Configuration :

Click Default Folder

2. Click Edit -> double click Default

folder and enter VHMS data folder

(default C:\VHMS_DATA)

3. Click Save

ClickEdit

Edit

Click

Click Save

Click Edit

Double click

73

74.

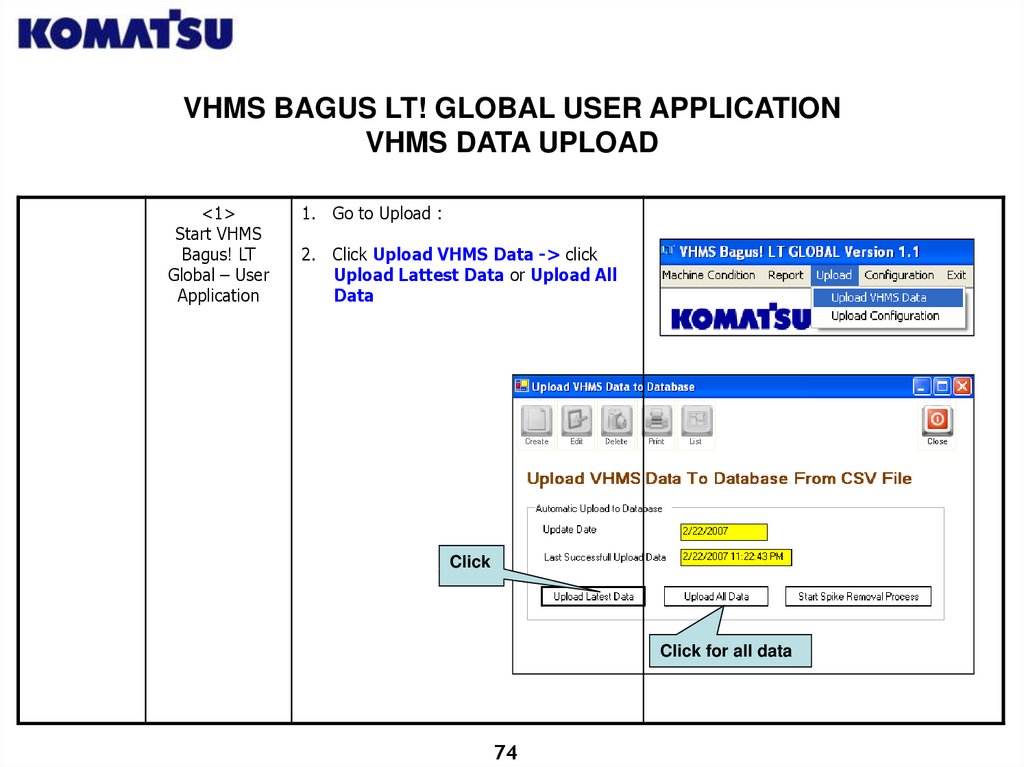

VHMS BAGUS LT! GLOBAL USER APPLICATIONVHMS DATA UPLOAD

<1>

Start VHMS

Bagus! LT

Global – User

Application

1. Go to Upload :

2. Click Upload VHMS Data -> click

Upload Lattest Data or Upload All

Data

Click

Click for all data

74

75.

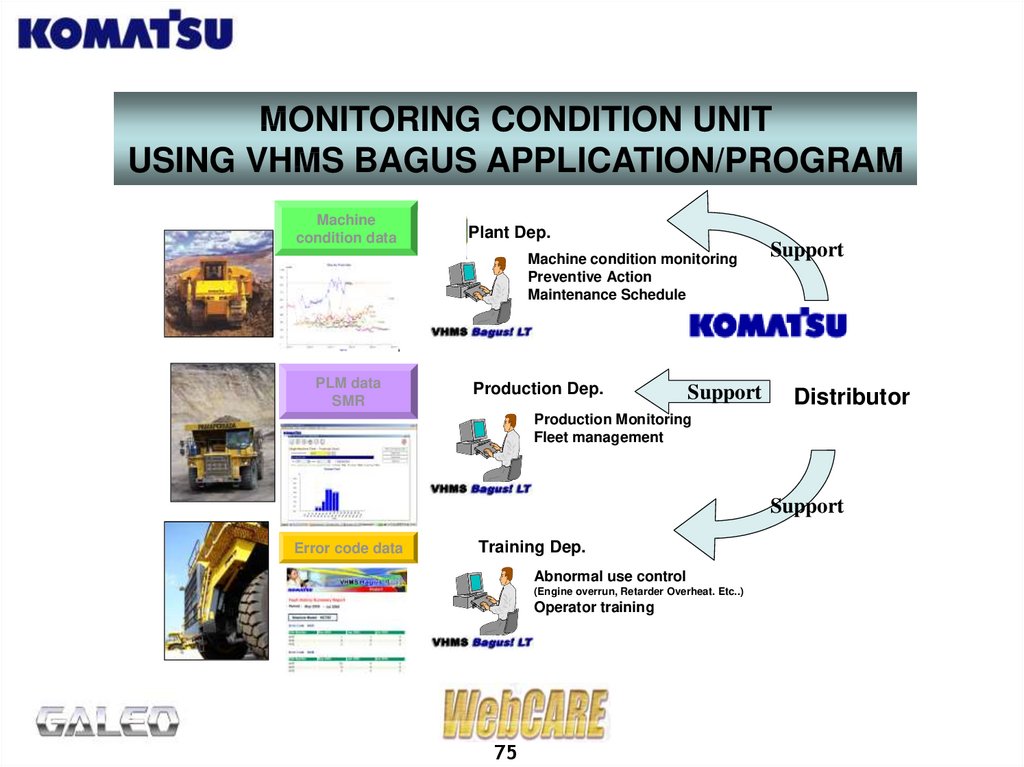

MONITORING CONDITION UNITUSING VHMS BAGUS APPLICATION/PROGRAM

Machine

condition data

Plant Dep.

Machine condition monitoring

Preventive Action

Maintenance Schedule

PLM data

SMR

Production Dep.

Support

Support

Distributor

Production Monitoring

Fleet management

Support

Error code data

Training Dep.

Abnormal use control

(Engine overrun, Retarder Overheat. Etc..)

Operator training

75

76.

MONITORING CONDITION UNITUSING VHMS BAGUS APPLICATION

Definition:

VHMS Bagus is an application or software name which functions as a

supporting tool in changing the original download VHMS Data (CSV File) of the

unit to an easier-to-read display data (XML File).

Objective:

To make unit condition analysis quickly and accurately become easier after

downloading.

Advantages of VHMS Bagus among others:

1. Can display Trend Analysis from various parameter and choices according to

the unit / component's working hours suitable with user’s need in planning

maintenance preventive activities.

2. Can display Fault History originating from the unit / component according to

incident time and frequency to minimize and analyze the unit’s damage caused

by human error factor.

3. Can display Summary Payload Meter (for dump truck) which is integrated with

PLM II according to the time and number, so that data of whether a unit is

operating in an under-load or overload condition within one period can be

quickly attained.

76

77.

MONITORING CONDITION UNITUSING VHMS BAGUS APPLICATION

4. Can display data from unit including Customer name, Location, SMR, Warning

Message, Machine Status, etc.

5. Generally VHMS Bagus role can reduce the implementation frequency of PMClinic or PPM Manual so that it can reduce the unit’s Down Time and the

mechanic’s extra effort.

VHMS Bagus Application limitations:

- Mechanical component damage without sensor cannot be detected by VHMS

Bagus.

- VHMS Bagus display data accuracy is influenced by the consistency of

Periodical Maintenance of the unit’s VHMS System.

- Payload Meter Summary data is influenced by PLM II memory condition.

77

78.

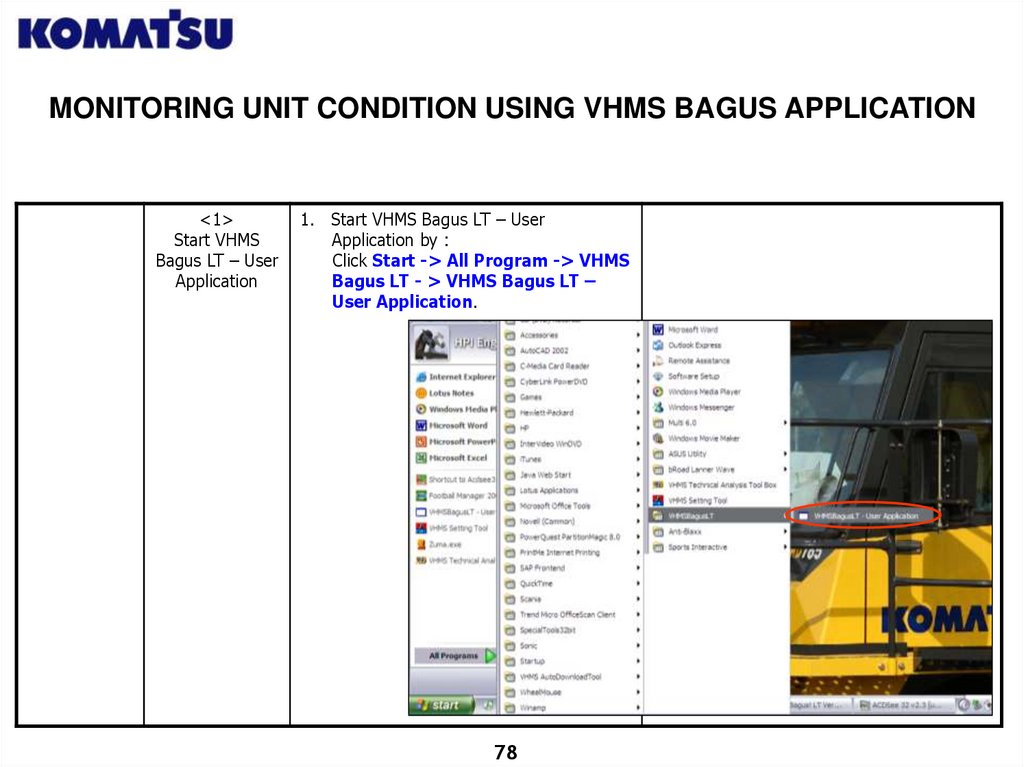

MONITORING UNIT CONDITION USING VHMS BAGUS APPLICATION<1>

Start VHMS

Bagus LT – User

Application

1. Start VHMS Bagus LT – User

Application by :

Click Start -> All Program -> VHMS

Bagus LT - > VHMS Bagus LT –

User Application.

78

79.

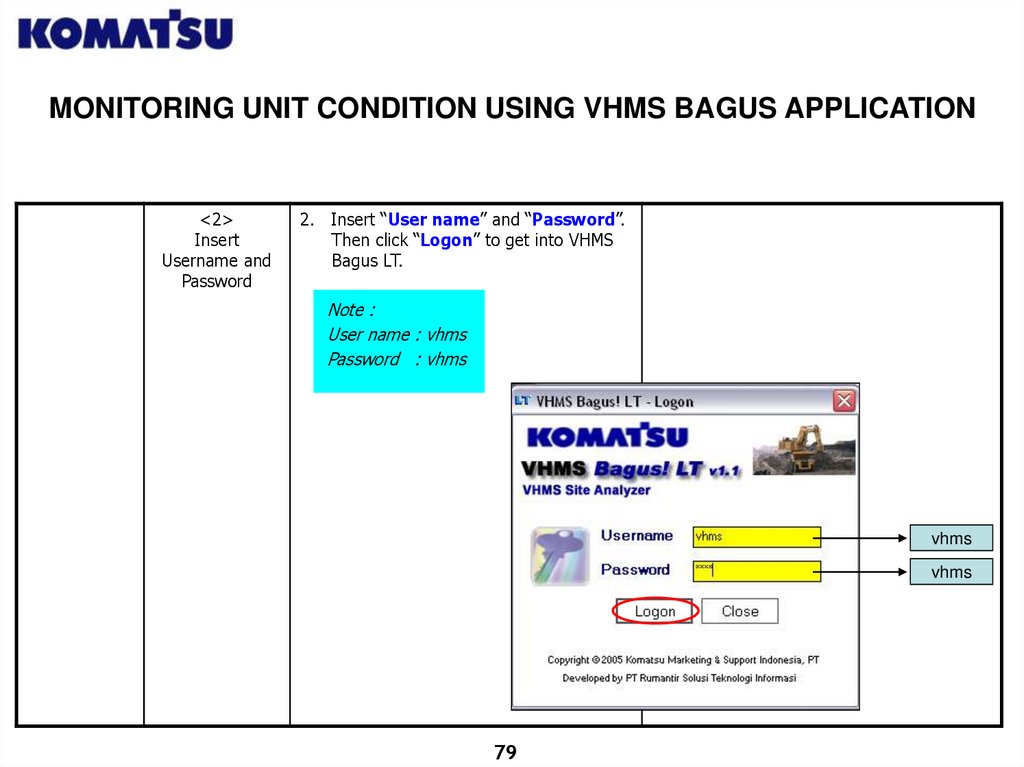

MONITORING UNIT CONDITION USING VHMS BAGUS APPLICATION<2>

Insert

Username and

Password

2. Insert “User name” and “Password”.

Then click “Logon” to get into VHMS

Bagus LT.

Note :

User name : vhms

Password : vhms

vhms

vhms

79

80.

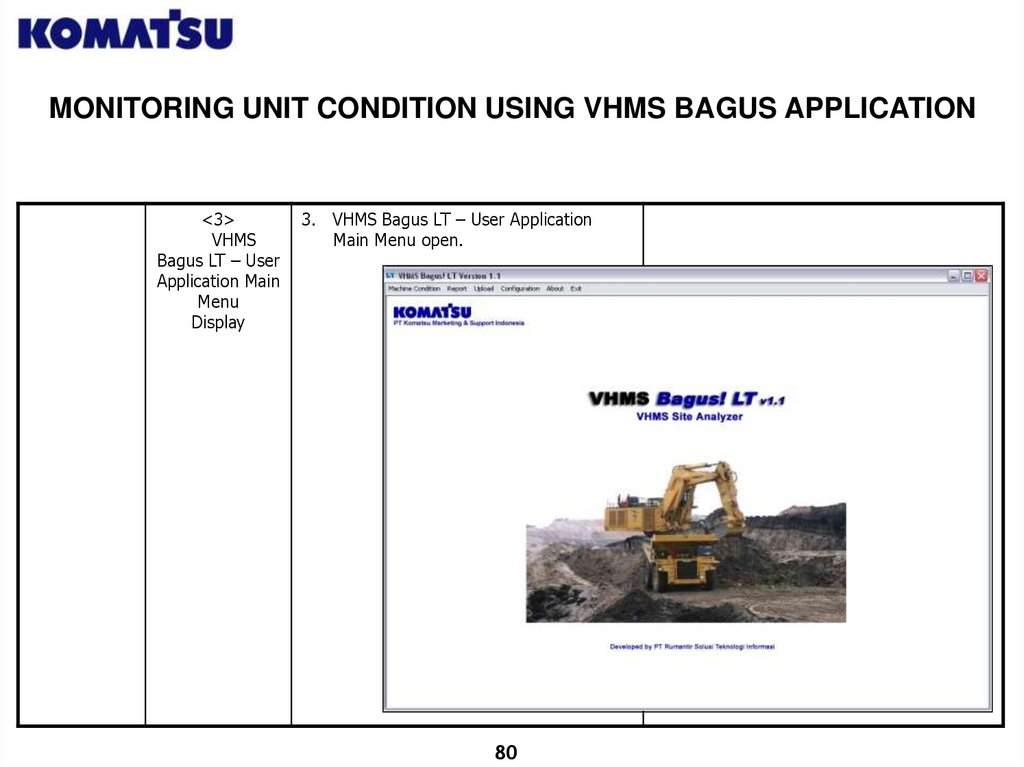

MONITORING UNIT CONDITION USING VHMS BAGUS APPLICATION<3>

VHMS

Bagus LT – User

Application Main

Menu

Display

3. VHMS Bagus LT – User Application

Main Menu open.

80

81.

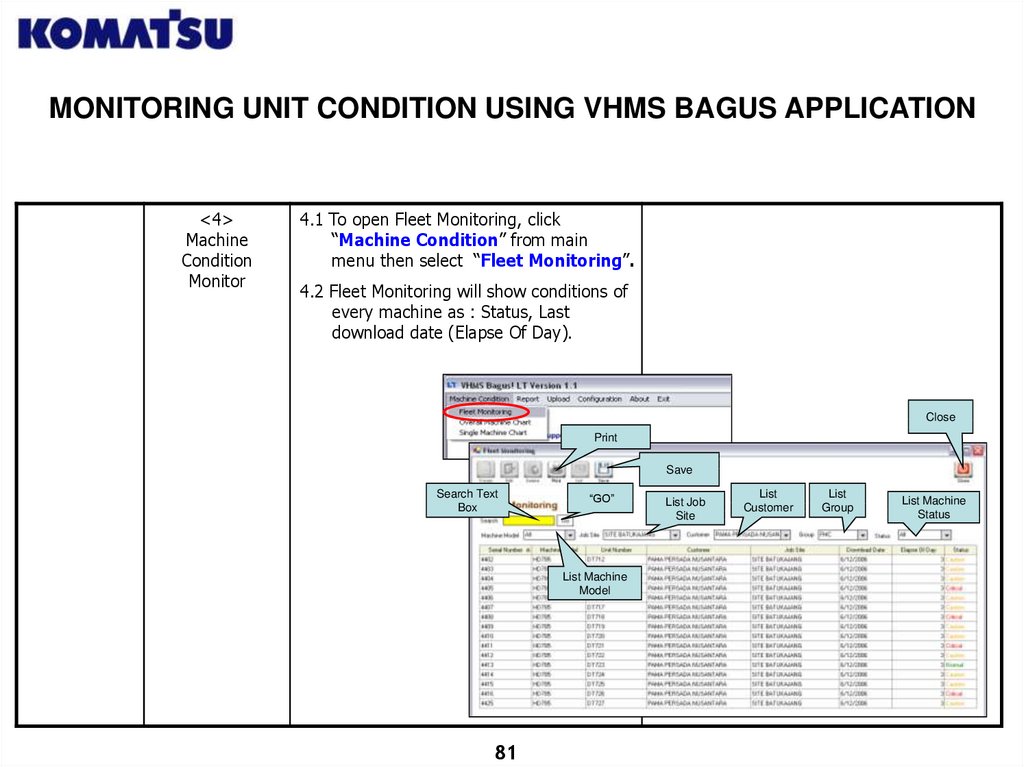

MONITORING UNIT CONDITION USING VHMS BAGUS APPLICATION<4>

Machine

Condition

Monitor

4.1 To open Fleet Monitoring, click

“Machine Condition” from main

menu then select “Fleet Monitoring”.

4.2 Fleet Monitoring will show conditions of

every machine as : Status, Last

download date (Elapse Of Day).

Close

Save

Search Text

Box

“GO”

List Machine

Model

81

List Job

Site

List

Customer

List

Group

List Machine

Status

82.

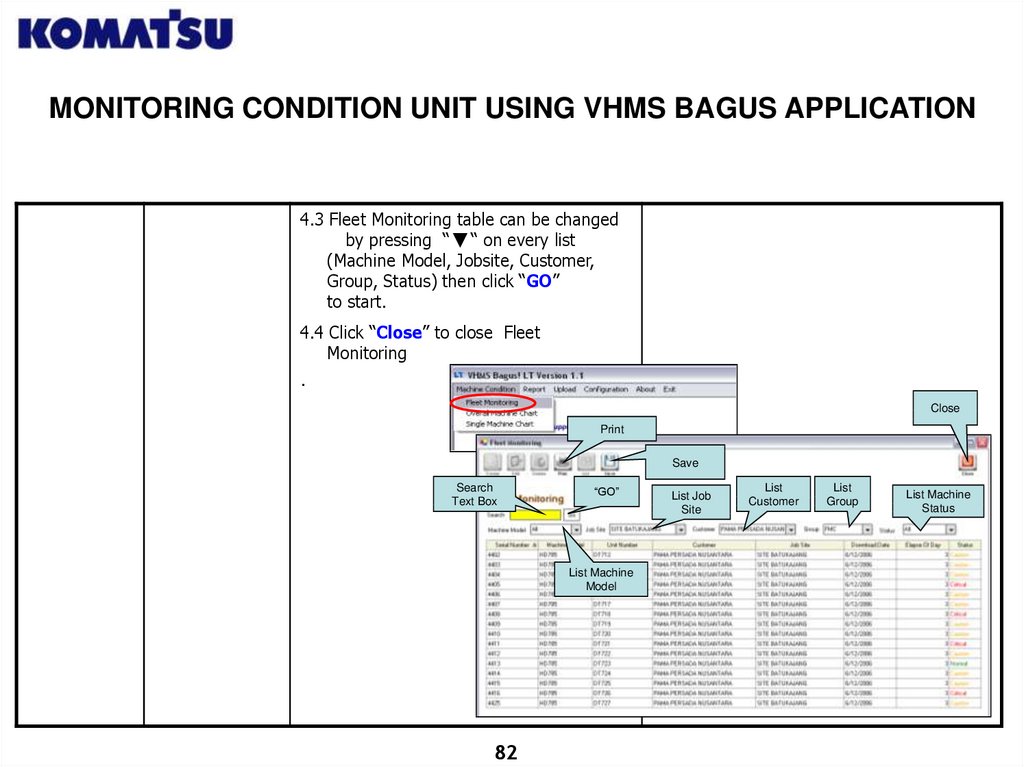

MONITORING CONDITION UNIT USING VHMS BAGUS APPLICATION4.3 Fleet Monitoring table can be changed

by pressing “ “ on every list

(Machine Model, Jobsite, Customer,

Group, Status) then click “GO”

to start.

4.4 Click “Close” to close Fleet

Monitoring

.

Close

Save

Search

Text Box

“GO”

List Machine

Model

82

List Job

Site

List

Customer

List

Group

List Machine

Status

83.

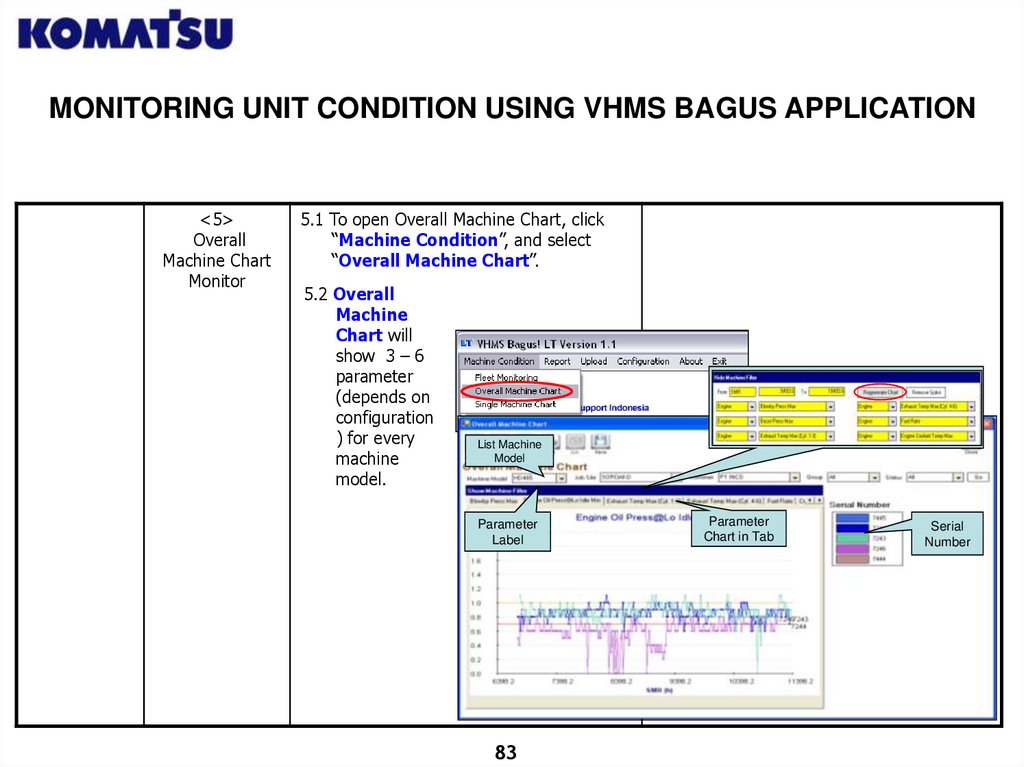

MONITORING UNIT CONDITION USING VHMS BAGUS APPLICATION<5>

Overall

Machine Chart

Monitor

5.1 To open Overall Machine Chart, click

“Machine Condition”, and select

“Overall Machine Chart”.

5.2 Overall

Machine

Chart will

show 3 – 6

parameter

(depends on

configuration

) for every

machine

model.

List Machine

Model

Parameter

Label

83

Parameter

Chart in Tab

Serial

Number

84.

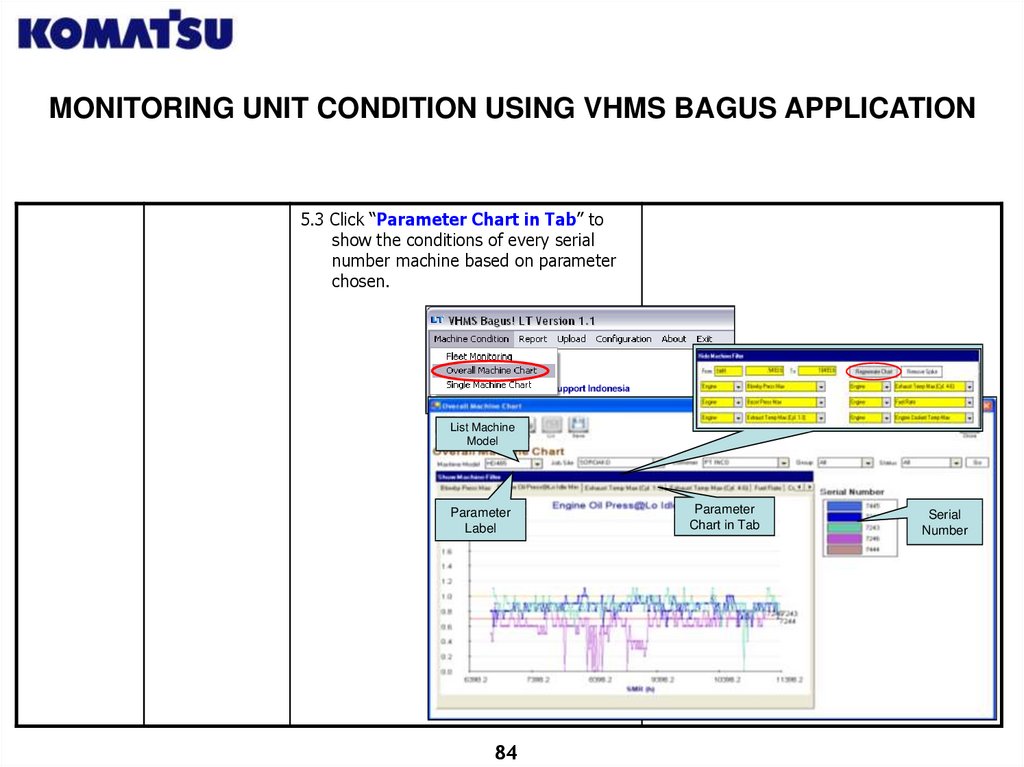

MONITORING UNIT CONDITION USING VHMS BAGUS APPLICATION5.3 Click “Parameter Chart in Tab” to

show the conditions of every serial

number machine based on parameter

chosen.

List Machine

Model

Parameter

Label

84

Parameter

Chart in Tab

Serial

Number

85.

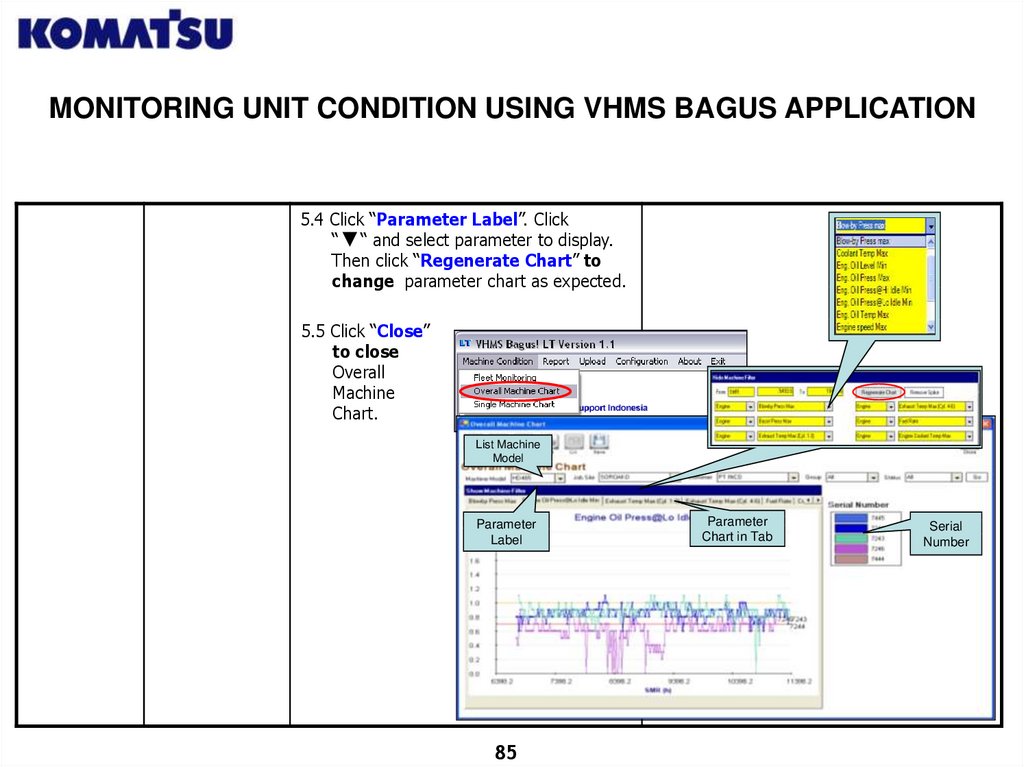

MONITORING UNIT CONDITION USING VHMS BAGUS APPLICATION5.4 Click “Parameter Label”. Click

“ “ and select parameter to display.

Then click “Regenerate Chart” to

change parameter chart as expected.

5.5 Click “Close”

to close

Overall

Machine

Chart.

List Machine

Model

Parameter

Label

85

Parameter

Chart in Tab

Serial

Number

86.

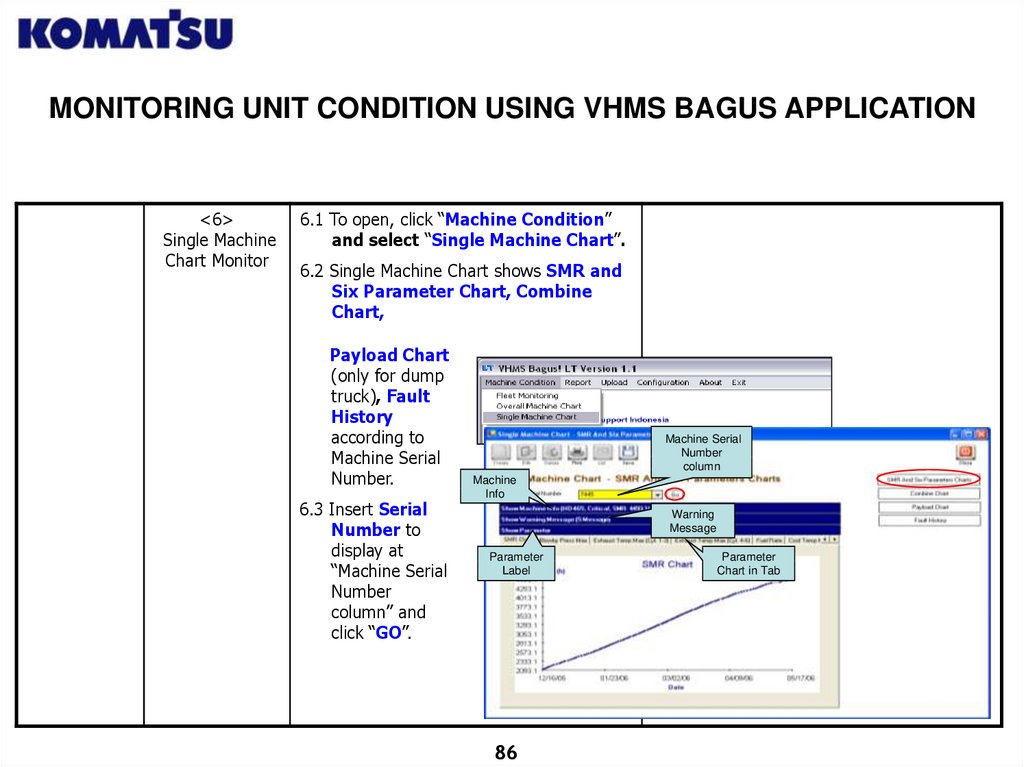

MONITORING UNIT CONDITION USING VHMS BAGUS APPLICATION<6>

Single Machine

Chart Monitor

6.1 To open, click “Machine Condition”

and select “Single Machine Chart”.

6.2 Single Machine Chart shows SMR and

Six Parameter Chart, Combine

Chart,

Payload Chart

(only for dump

truck), Fault

History

according to

Machine Serial

Number.

6.3 Insert Serial

Number to

display at

“Machine Serial

Number

column” and

click “GO”.

Machine Serial

Number

column

Machine

Info

Warning

Message

Parameter

Label

86

Parameter

Chart in Tab

87.

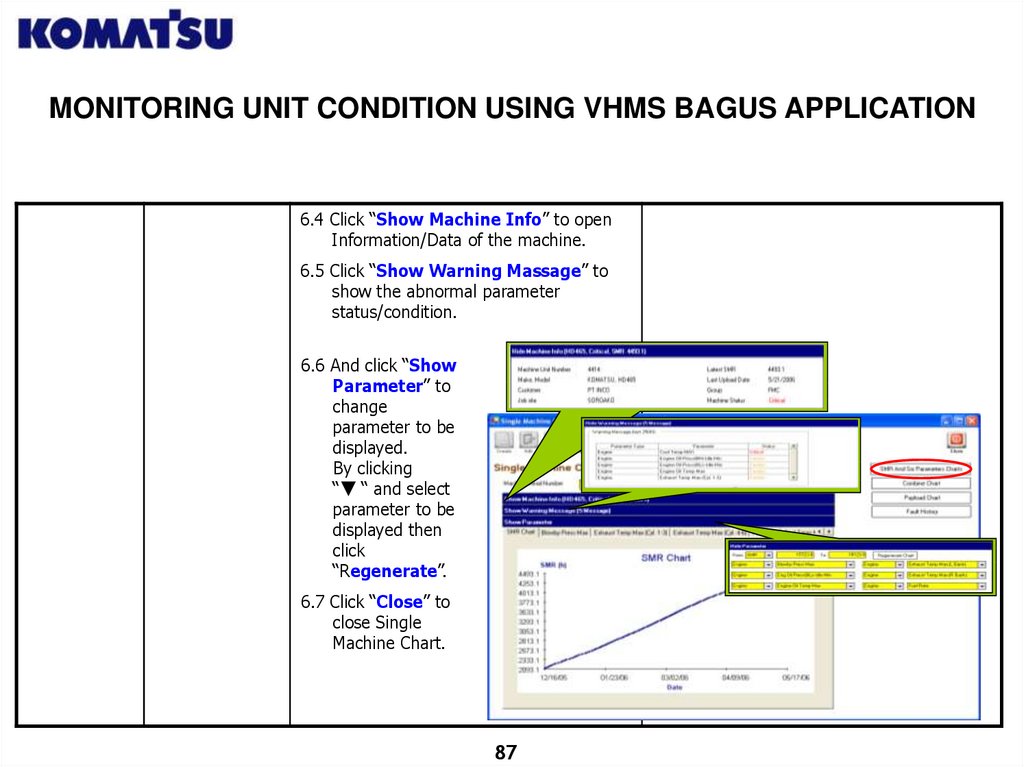

MONITORING UNIT CONDITION USING VHMS BAGUS APPLICATION6.4 Click “Show Machine Info” to open

Information/Data of the machine.

6.5 Click “Show Warning Massage” to

show the abnormal parameter

status/condition.

6.6 And click “Show

Parameter” to

change

parameter to be

displayed.

By clicking

“ “ and select

parameter to be

displayed then

click

“Regenerate”.

6.7 Click “Close” to

close Single

Machine Chart.

87

88.

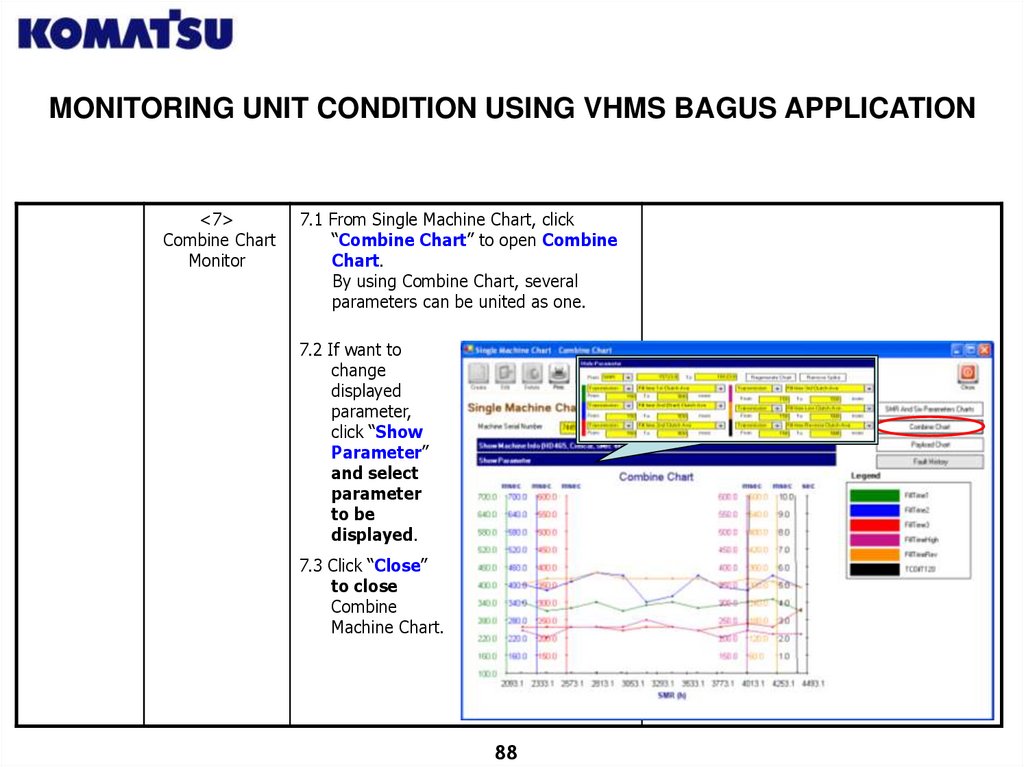

MONITORING UNIT CONDITION USING VHMS BAGUS APPLICATION<7>

Combine Chart

Monitor

7.1 From Single Machine Chart, click

“Combine Chart” to open Combine

Chart.

By using Combine Chart, several

parameters can be united as one.

7.2 If want to

change

displayed

parameter,

click “Show

Parameter”

and select

parameter

to be

displayed.

7.3 Click “Close”

to close

Combine

Machine Chart.

88

89.

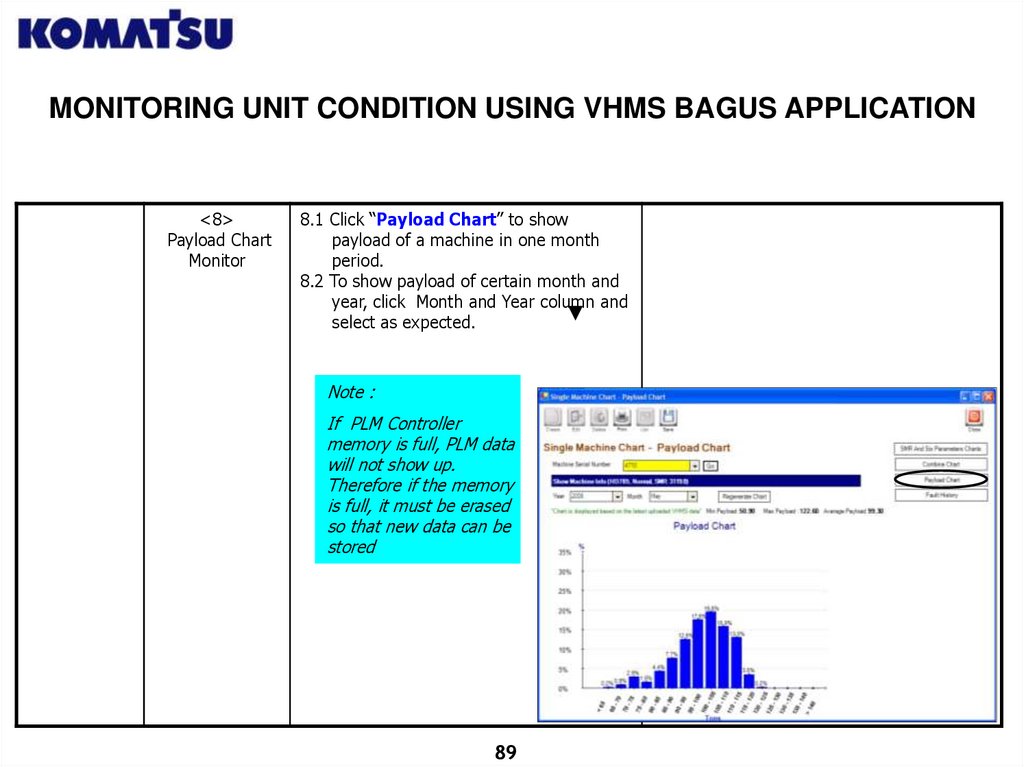

MONITORING UNIT CONDITION USING VHMS BAGUS APPLICATION<8>

Payload Chart

Monitor

8.1 Click “Payload Chart” to show

payload of a machine in one month

period.

8.2 To show payload of certain month and

year, click Month and Year column and

select as expected.

Note :

If PLM Controller

memory is full, PLM data

will not show up.

Therefore if the memory

is full, it must be erased

so that new data can be

stored

89

90.

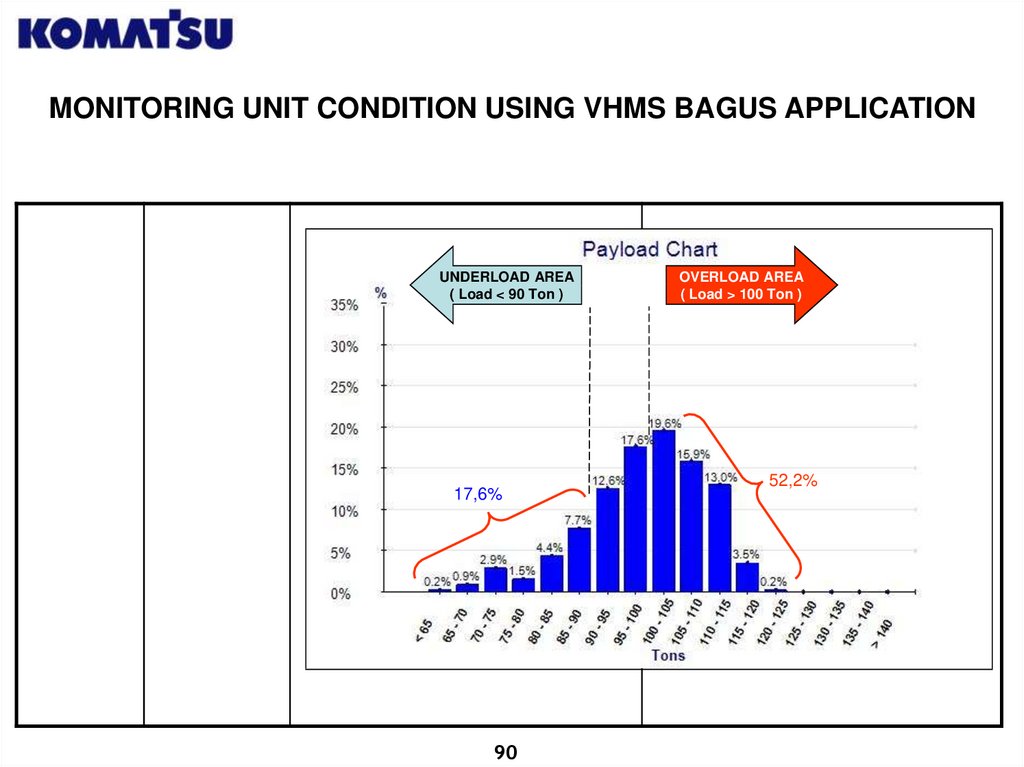

MONITORING UNIT CONDITION USING VHMS BAGUS APPLICATIONUNDERLOAD AREA

( Load < 90 Ton )

17,6%

90

OVERLOAD AREA

( Load > 100 Ton )

52,2%

91.

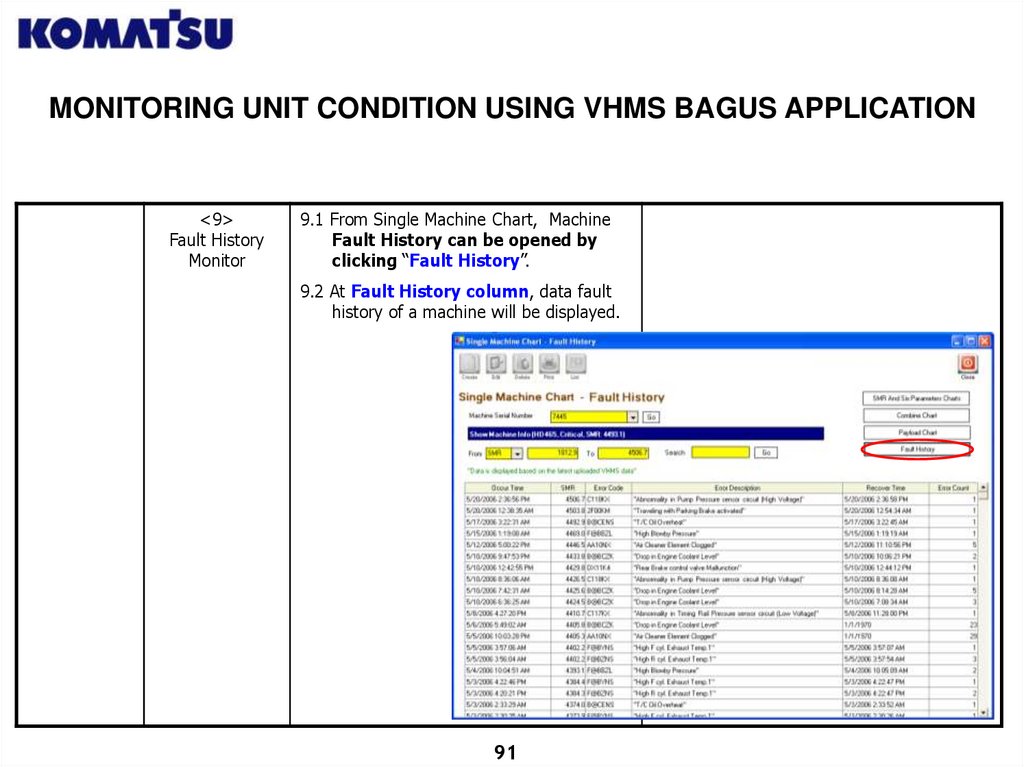

MONITORING UNIT CONDITION USING VHMS BAGUS APPLICATION<9>

Fault History

Monitor

9.1 From Single Machine Chart, Machine

Fault History can be opened by

clicking “Fault History”.

9.2 At Fault History column, data fault

history of a machine will be displayed.

91

92.

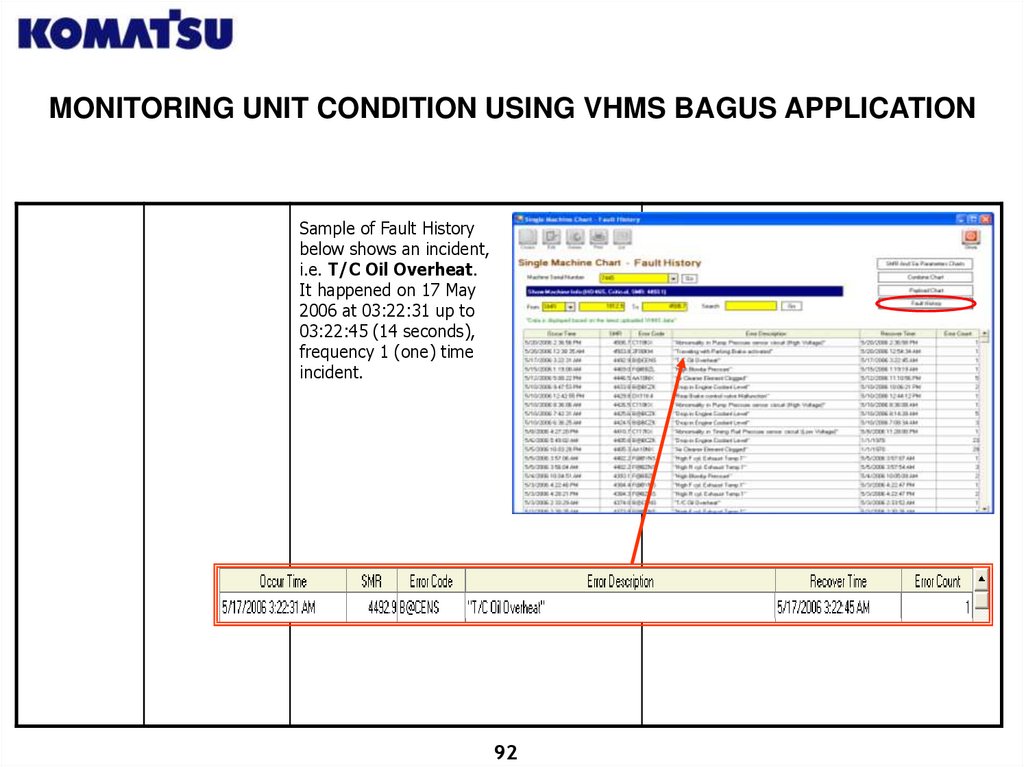

MONITORING UNIT CONDITION USING VHMS BAGUS APPLICATIONSample of Fault History

below shows an incident,

i.e. T/C Oil Overheat.

It happened on 17 May

2006 at 03:22:31 up to

03:22:45 (14 seconds),

frequency 1 (one) time

incident.

92

93.

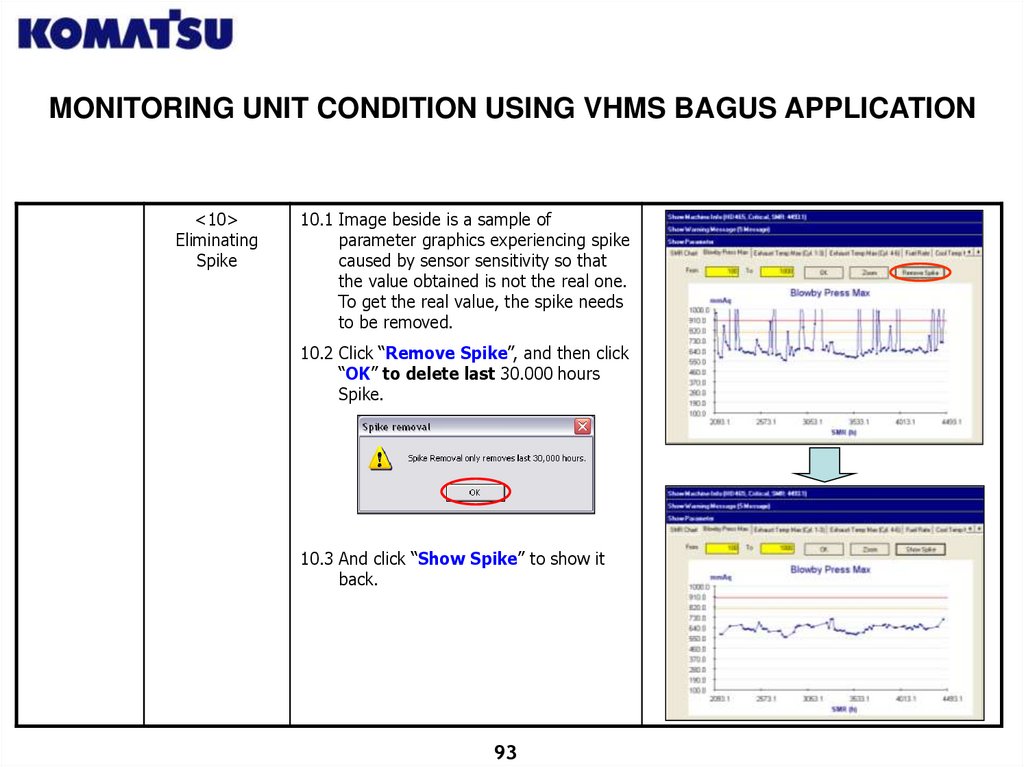

MONITORING UNIT CONDITION USING VHMS BAGUS APPLICATION<10>

Eliminating

Spike

10.1 Image beside is a sample of

parameter graphics experiencing spike

caused by sensor sensitivity so that

the value obtained is not the real one.

To get the real value, the spike needs

to be removed.

10.2 Click “Remove Spike”, and then click

“OK” to delete last 30.000 hours

Spike.

10.3 And click “Show Spike” to show it

back.

93

94.

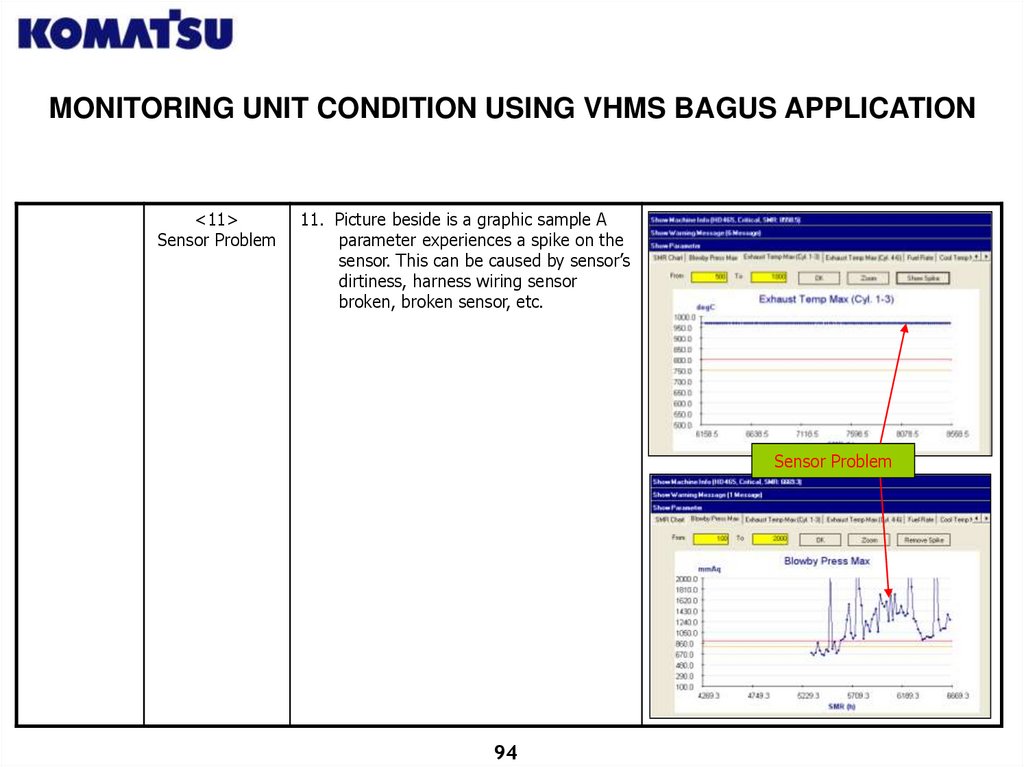

MONITORING UNIT CONDITION USING VHMS BAGUS APPLICATION<11>

Sensor Problem

11. Picture beside is a graphic sample A

parameter experiences a spike on the

sensor. This can be caused by sensor’s

dirtiness, harness wiring sensor

broken, broken sensor, etc.

Sensor Problem

94

95.

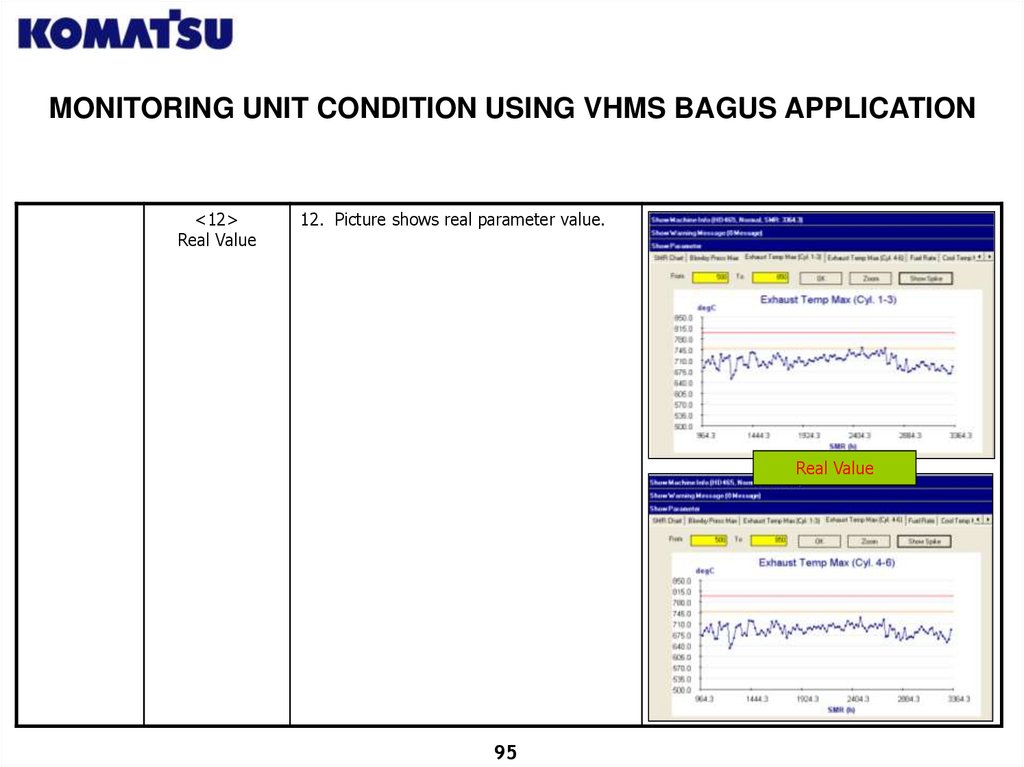

MONITORING UNIT CONDITION USING VHMS BAGUS APPLICATION<12>

Real Value

12. Picture shows real parameter value.

Real Value

95

96.

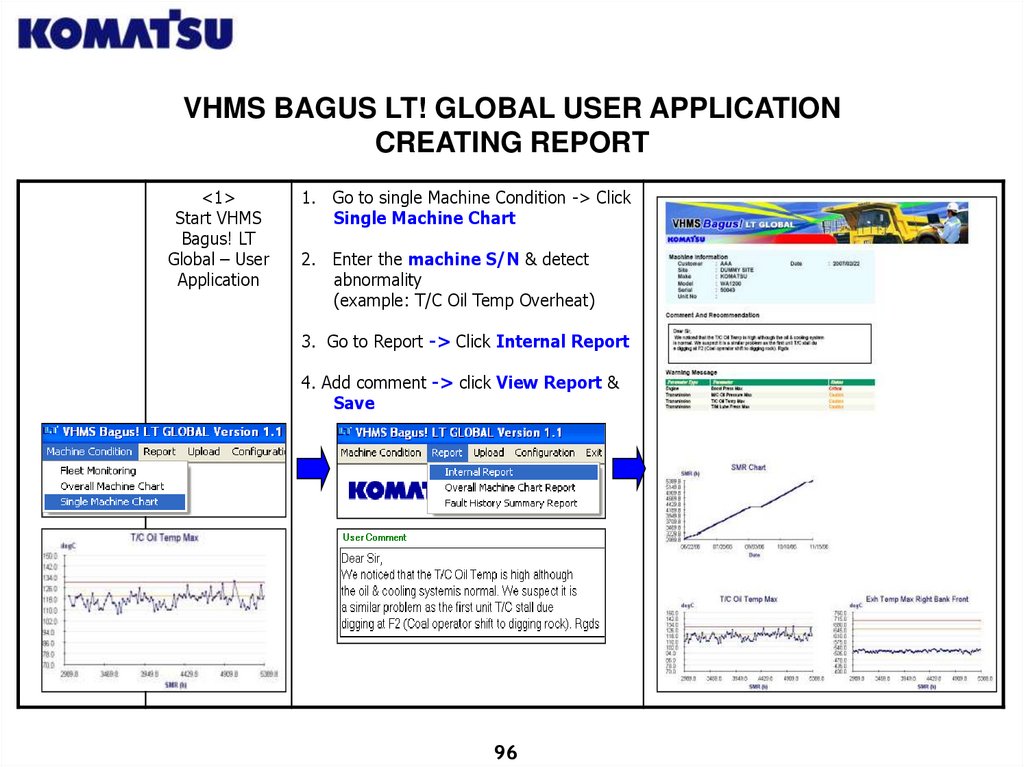

VHMS BAGUS LT! GLOBAL USER APPLICATIONCREATING REPORT

<1>

Start VHMS

Bagus! LT

Global – User

Application

1. Go to single Machine Condition -> Click

Single Machine Chart

2. Enter the machine S/N & detect

abnormality

(example: T/C Oil Temp Overheat)

3. Go to Report -> Click Internal Report

4. Add comment -> click View Report &

Save

96

97.

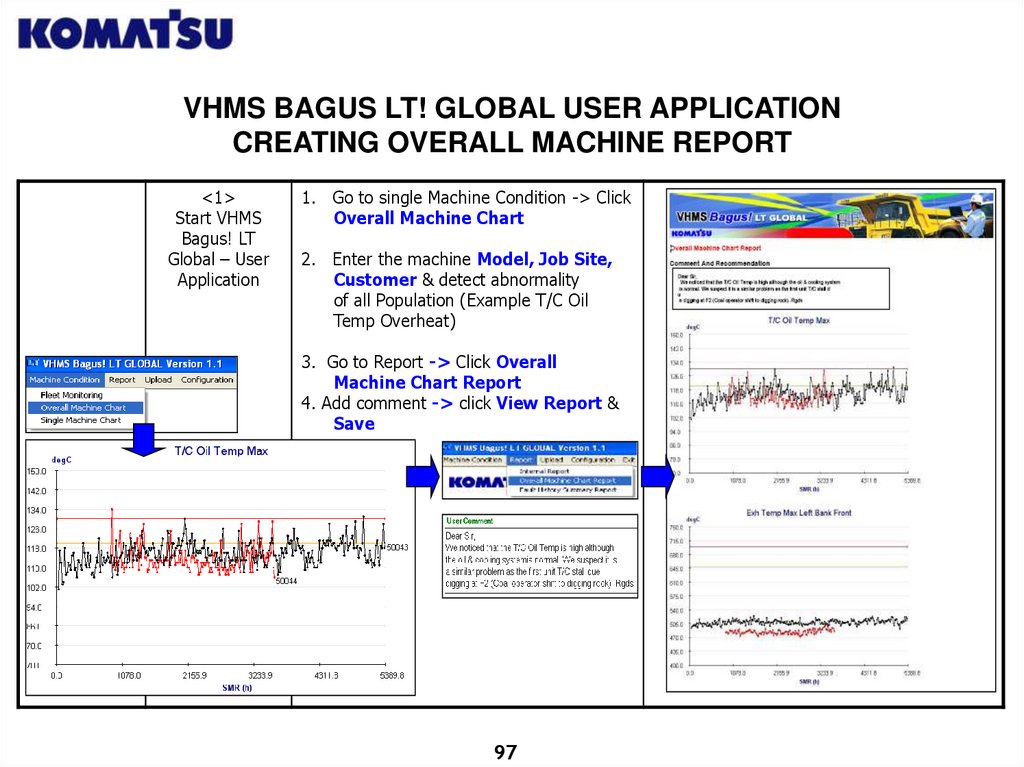

VHMS BAGUS LT! GLOBAL USER APPLICATIONCREATING OVERALL MACHINE REPORT

<1>

Start VHMS

Bagus! LT

Global – User

Application

1. Go to single Machine Condition -> Click

Overall Machine Chart

2. Enter the machine Model, Job Site,

Customer & detect abnormality

of all Population (Example T/C Oil

Temp Overheat)

3. Go to Report -> Click Overall

Machine Chart Report

4. Add comment -> click View Report &

Save

97

98.

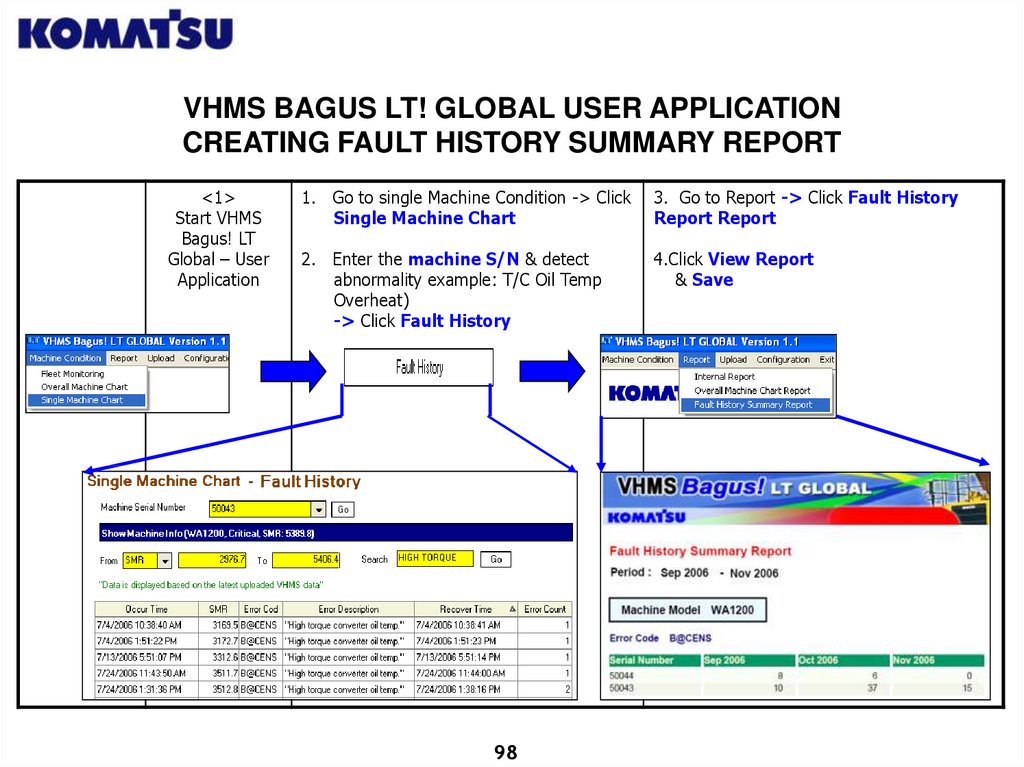

VHMS BAGUS LT! GLOBAL USER APPLICATIONCREATING FAULT HISTORY SUMMARY REPORT

<1>

Start VHMS

Bagus! LT

Global – User

Application

1. Go to single Machine Condition -> Click

Single Machine Chart

3. Go to Report -> Click Fault History

Report Report

2. Enter the machine S/N & detect

abnormality example: T/C Oil Temp

Overheat)

-> Click Fault History

4.Click View Report

& Save

98

99.

CHAPTER IIIVHMS Bagus! LT GLOBAL ADMIN

FUNCTION AND DATABASE

MAINTENANCE

99

100.

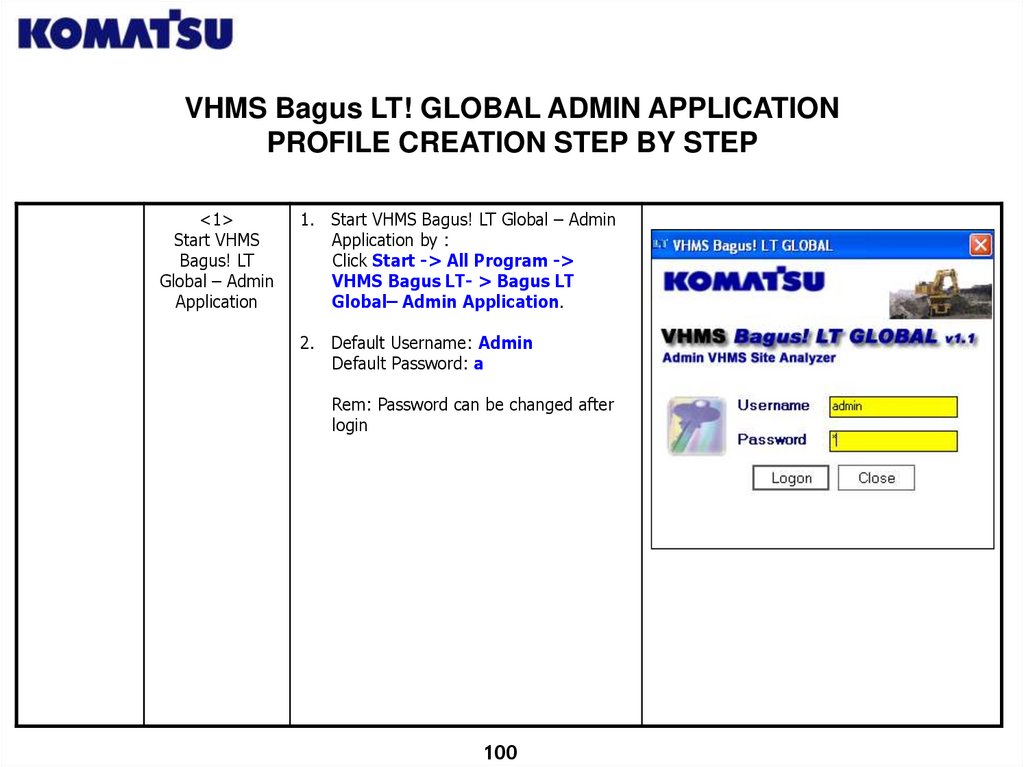

VHMS Bagus LT! GLOBAL ADMIN APPLICATIONPROFILE CREATION STEP BY STEP

<1>

Start VHMS

Bagus! LT

Global – Admin

Application

1. Start VHMS Bagus! LT Global – Admin

Application by :

Click Start -> All Program ->

VHMS Bagus LT- > Bagus LT

Global– Admin Application.

2. Default Username: Admin

Default Password: a

Rem: Password can be changed after

login

100

101.

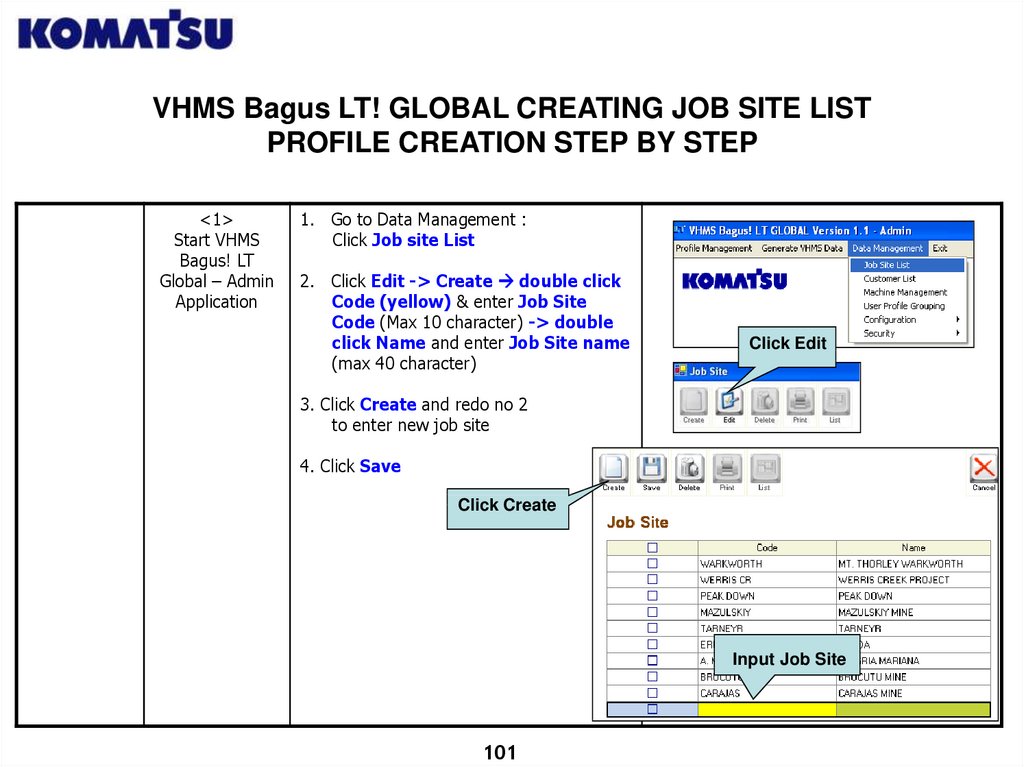

VHMS Bagus LT! GLOBAL CREATING JOB SITE LISTPROFILE CREATION STEP BY STEP

<1>

Start VHMS

Bagus! LT

Global – Admin

Application

1. Go to Data Management :

Click Job site List

2. Click Edit -> Create double click

Code (yellow) & enter Job Site

Code (Max 10 character) -> double

click Name and enter Job Site name

(max 40 character)

Click Edit

3. Click Create and redo no 2

to enter new job site

4. Click Save

Click Create

Input Job Site

101

102.

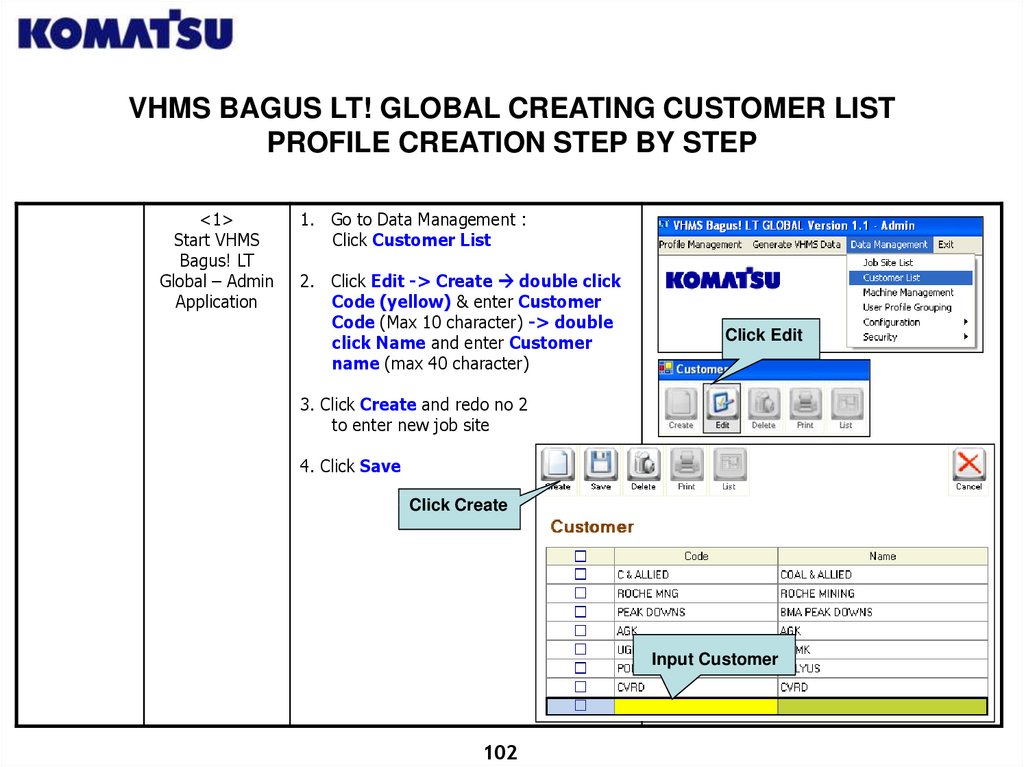

VHMS BAGUS LT! GLOBAL CREATING CUSTOMER LISTPROFILE CREATION STEP BY STEP

<1>

Start VHMS

Bagus! LT

Global – Admin

Application

1. Go to Data Management :

Click Customer List

2. Click Edit -> Create double click

Code (yellow) & enter Customer

Code (Max 10 character) -> double

click Name and enter Customer

name (max 40 character)

Click Edit

3. Click Create and redo no 2

to enter new job site

4. Click Save

Click Create

Input Customer

102

103.

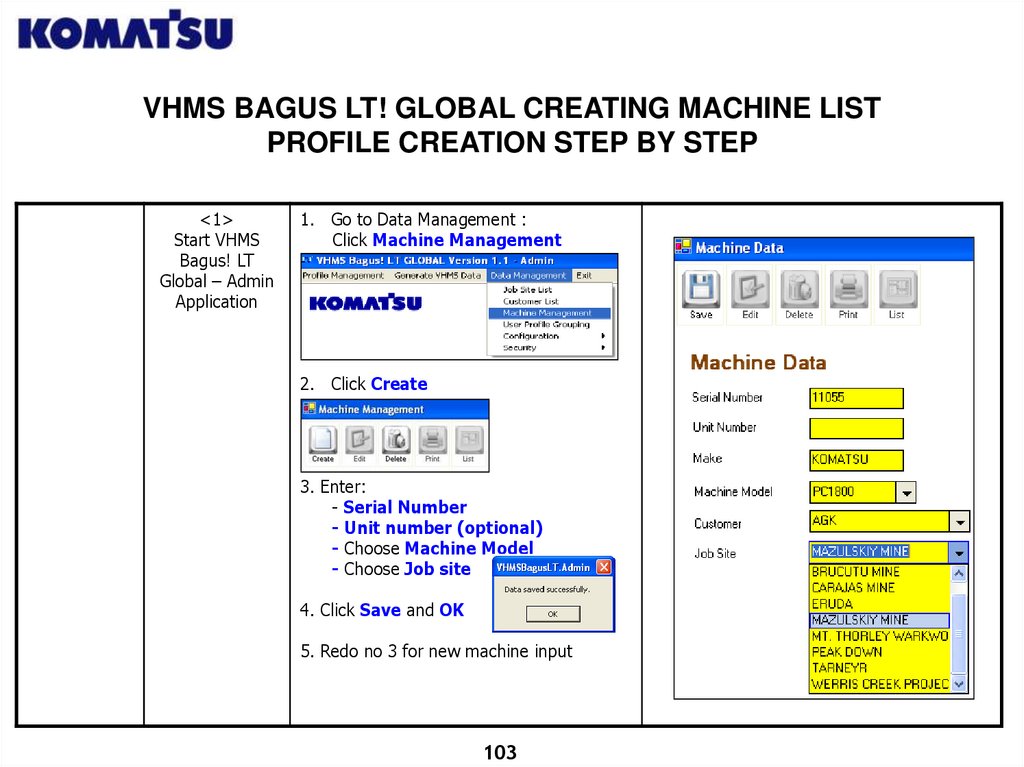

VHMS BAGUS LT! GLOBAL CREATING MACHINE LISTPROFILE CREATION STEP BY STEP

<1>

Start VHMS

Bagus! LT

Global – Admin

Application

1. Go to Data Management :

Click Machine Management

2. Click Create

3. Enter:

- Serial Number

- Unit number (optional)

- Choose Machine Model

- Choose Job site

4. Click Save and OK

5. Redo no 3 for new machine input

103

104.

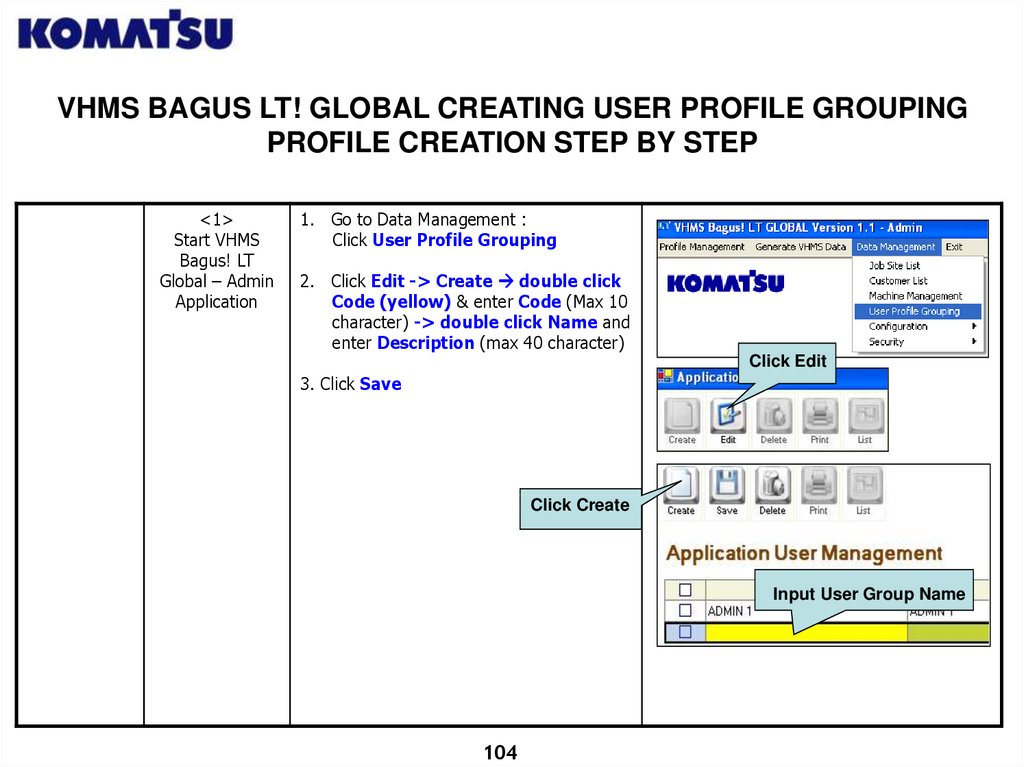

VHMS BAGUS LT! GLOBAL CREATING USER PROFILE GROUPINGPROFILE CREATION STEP BY STEP

<1>

Start VHMS

Bagus! LT

Global – Admin

Application

1. Go to Data Management :

Click User Profile Grouping

2. Click Edit -> Create double click

Code (yellow) & enter Code (Max 10

character) -> double click Name and

enter Description (max 40 character)

Click Edit

3. Click Save

Click Create

Input User Group Name

104

105.

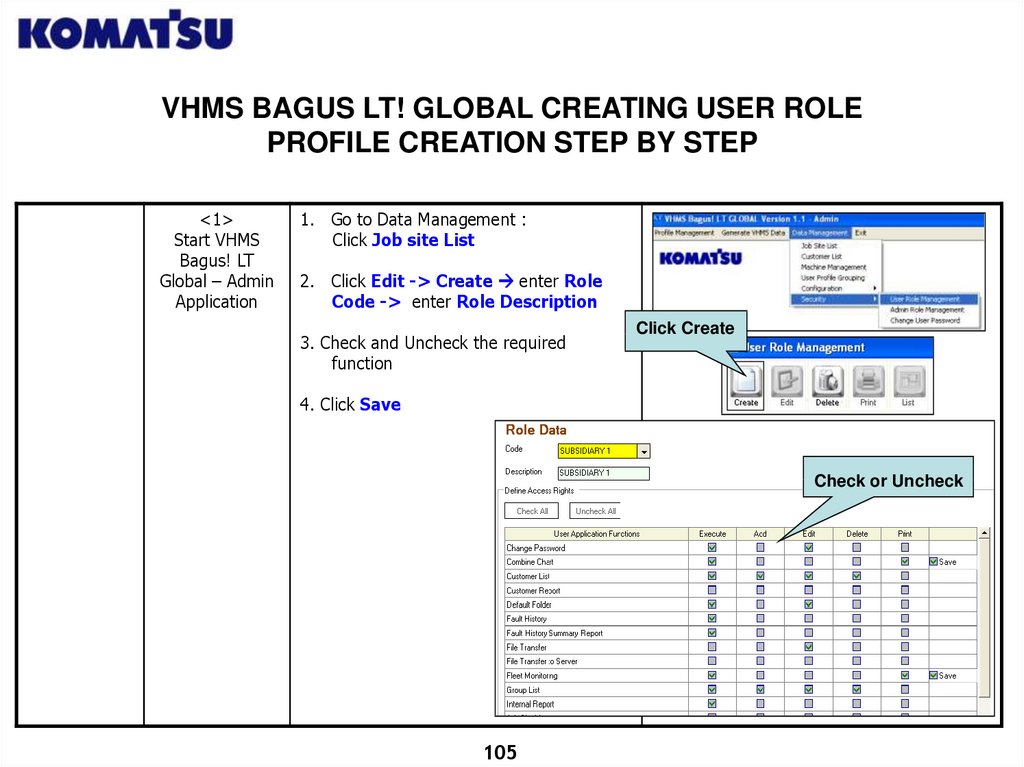

VHMS BAGUS LT! GLOBAL CREATING USER ROLEPROFILE CREATION STEP BY STEP

<1>

Start VHMS

Bagus! LT

Global – Admin

Application

1. Go to Data Management :

Click Job site List

2. Click Edit -> Create enter Role

Code -> enter Role Description

3. Check and Uncheck the required

function

Click Create

4. Click Save

Check or Uncheck

105

106.

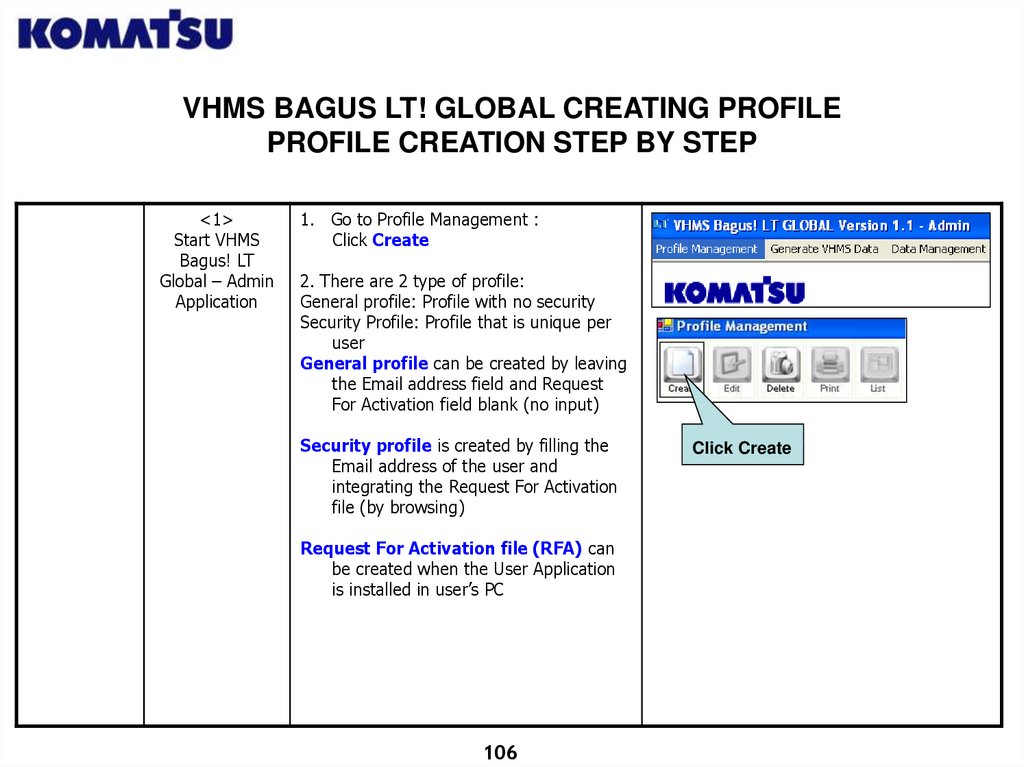

VHMS BAGUS LT! GLOBAL CREATING PROFILEPROFILE CREATION STEP BY STEP

<1>

Start VHMS

Bagus! LT

Global – Admin

Application

1. Go to Profile Management :

Click Create

2. There are 2 type of profile:

General profile: Profile with no security

Security Profile: Profile that is unique per

user

General profile can be created by leaving

the Email address field and Request

For Activation field blank (no input)

Security profile is created by filling the

Email address of the user and

integrating the Request For Activation

file (by browsing)

Request For Activation file (RFA) can

be created when the User Application

is installed in user’s PC

106

Click Create

107.

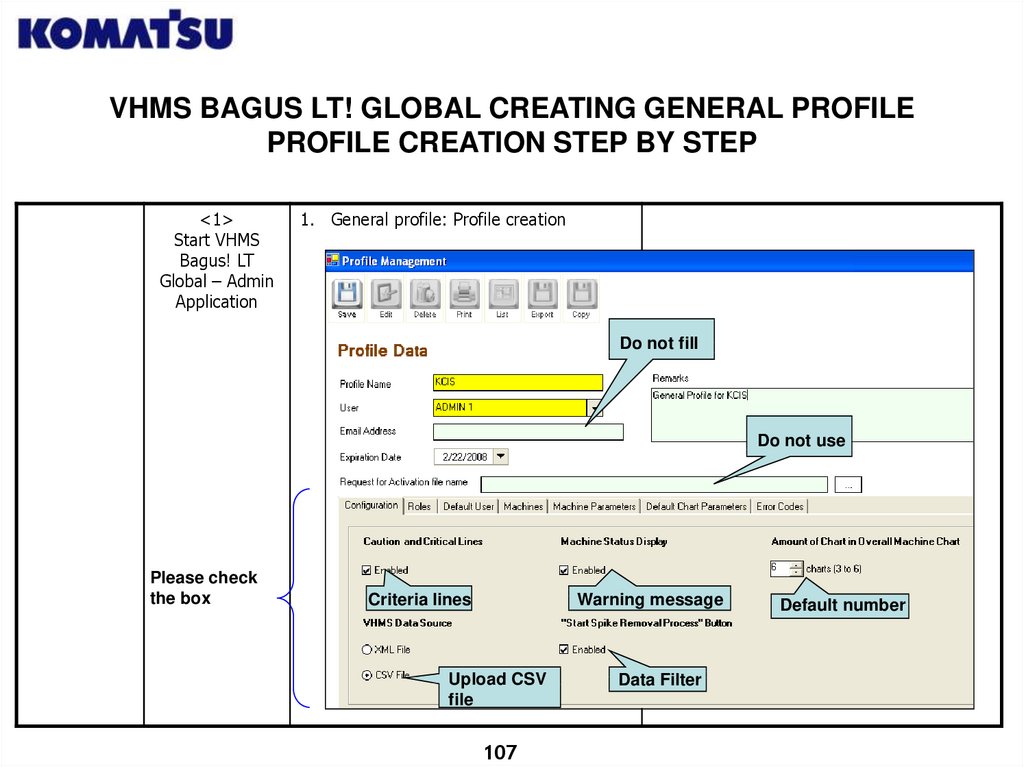

VHMS BAGUS LT! GLOBAL CREATING GENERAL PROFILEPROFILE CREATION STEP BY STEP

<1>

Start VHMS

Bagus! LT

Global – Admin

Application

1. General profile: Profile creation

Do not fill

Do not use

Please check

the box

Criteria lines

Warning message

Upload CSV

file

107

Data Filter

Default number

108.

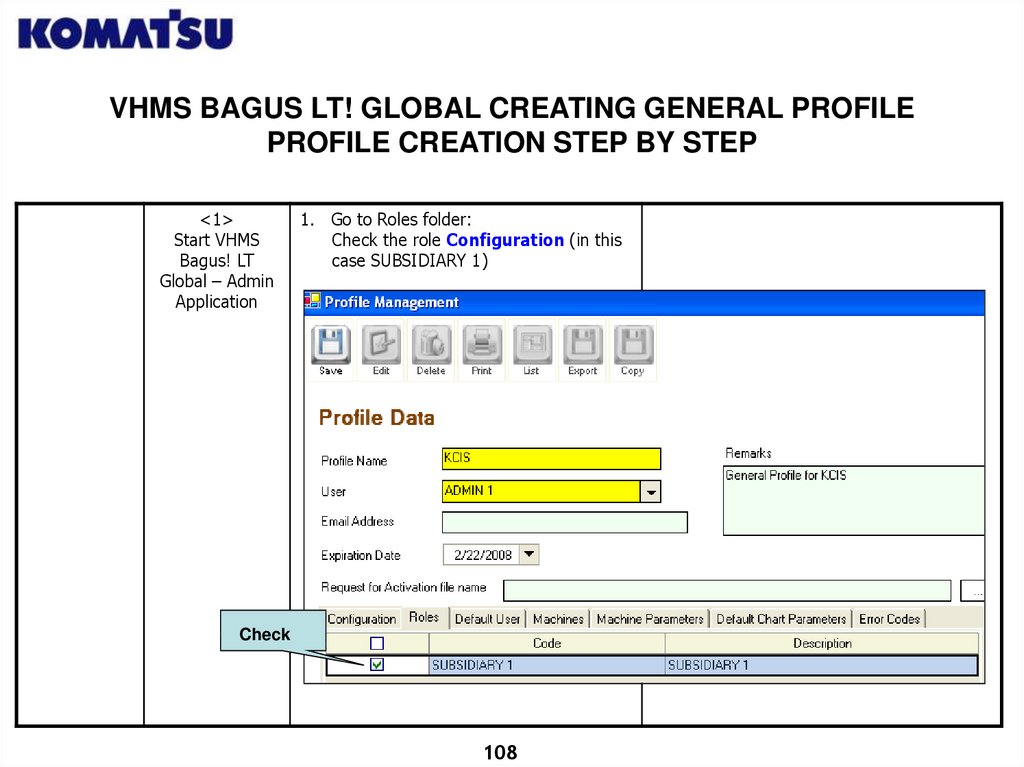

VHMS BAGUS LT! GLOBAL CREATING GENERAL PROFILEPROFILE CREATION STEP BY STEP

<1>

Start VHMS

Bagus! LT

Global – Admin

Application

1. Go to Roles folder:

Check the role Configuration (in this

case SUBSIDIARY 1)

Check

108

109.

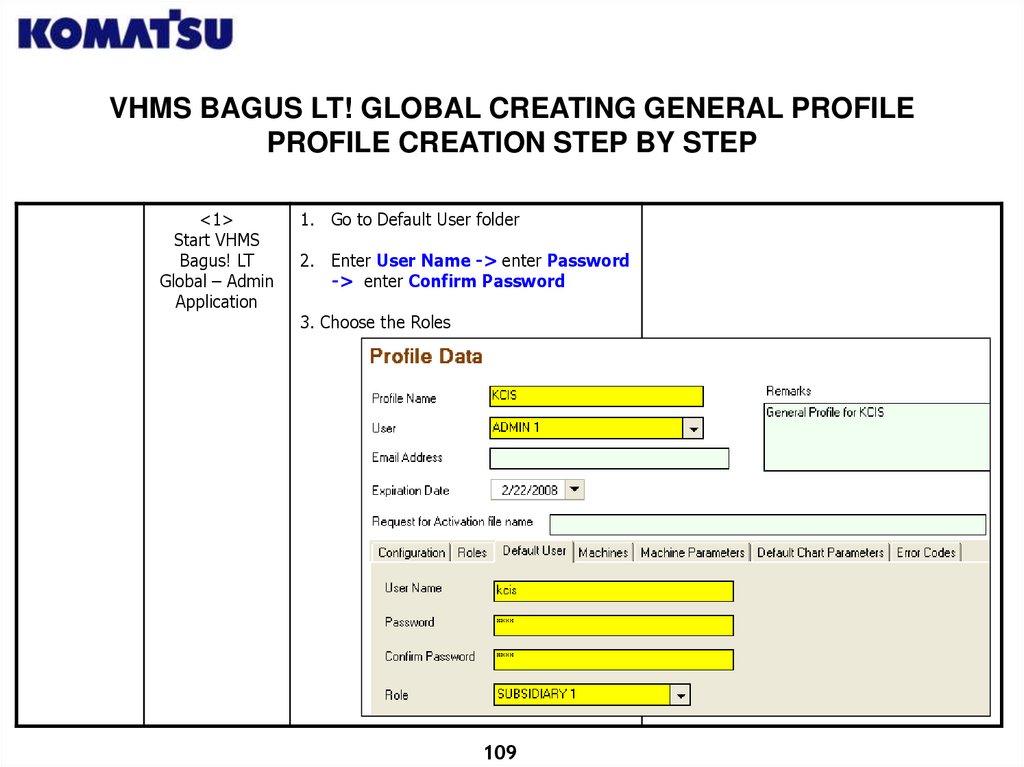

VHMS BAGUS LT! GLOBAL CREATING GENERAL PROFILEPROFILE CREATION STEP BY STEP

<1>

Start VHMS

Bagus! LT

Global – Admin

Application

1. Go to Default User folder

2. Enter User Name -> enter Password

-> enter Confirm Password

3. Choose the Roles

109

110.

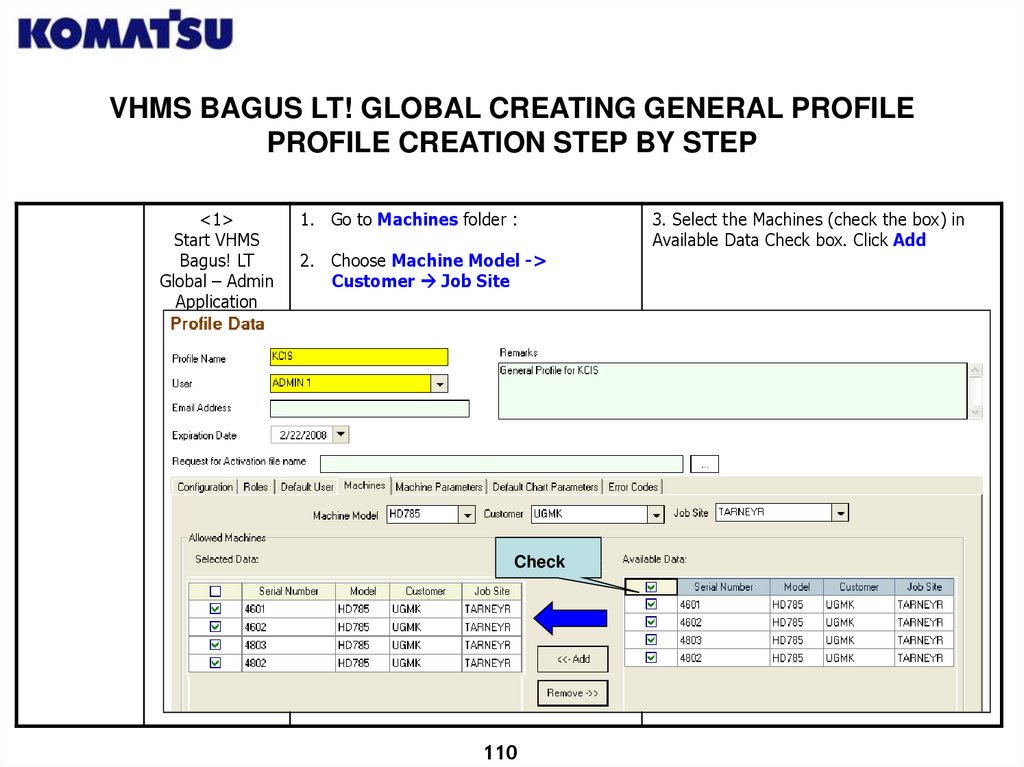

VHMS BAGUS LT! GLOBAL CREATING GENERAL PROFILEPROFILE CREATION STEP BY STEP

<1>

Start VHMS

Bagus! LT

Global – Admin

Application

1. Go to Machines folder :

2. Choose Machine Model ->

Customer Job Site

Check

110

3. Select the Machines (check the box) in

Available Data Check box. Click Add

111.

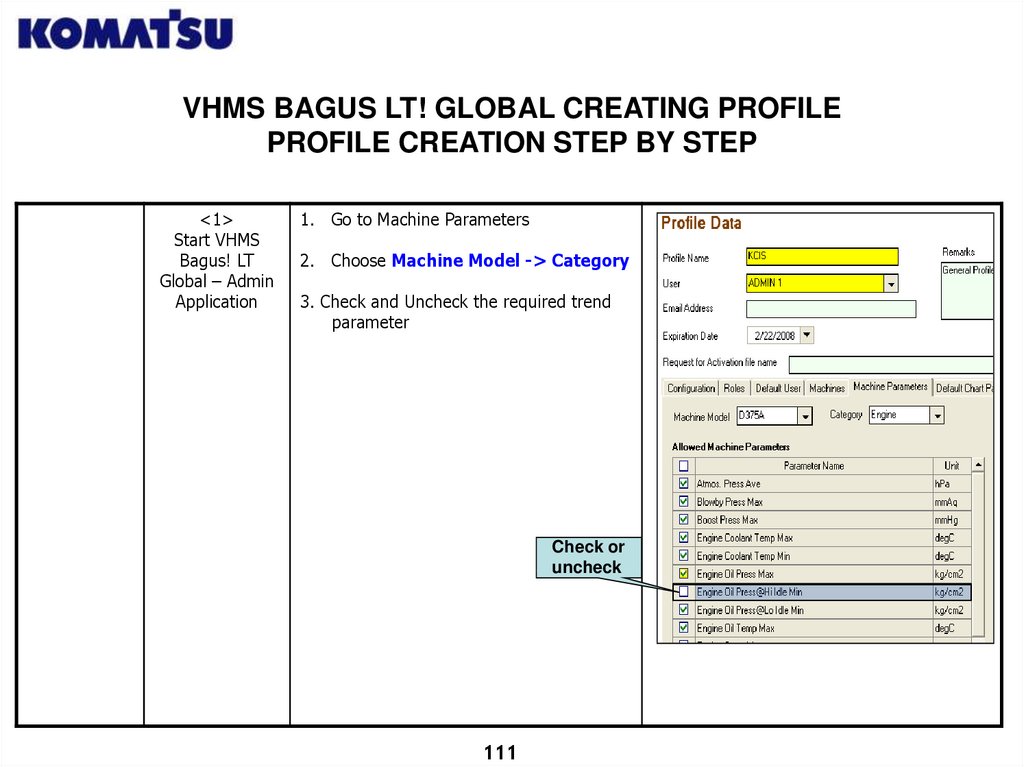

VHMS BAGUS LT! GLOBAL CREATING PROFILEPROFILE CREATION STEP BY STEP

<1>

Start VHMS

Bagus! LT

Global – Admin

Application

1. Go to Machine Parameters

2. Choose Machine Model -> Category

3. Check and Uncheck the required trend

parameter

Check or

uncheck

111

112.

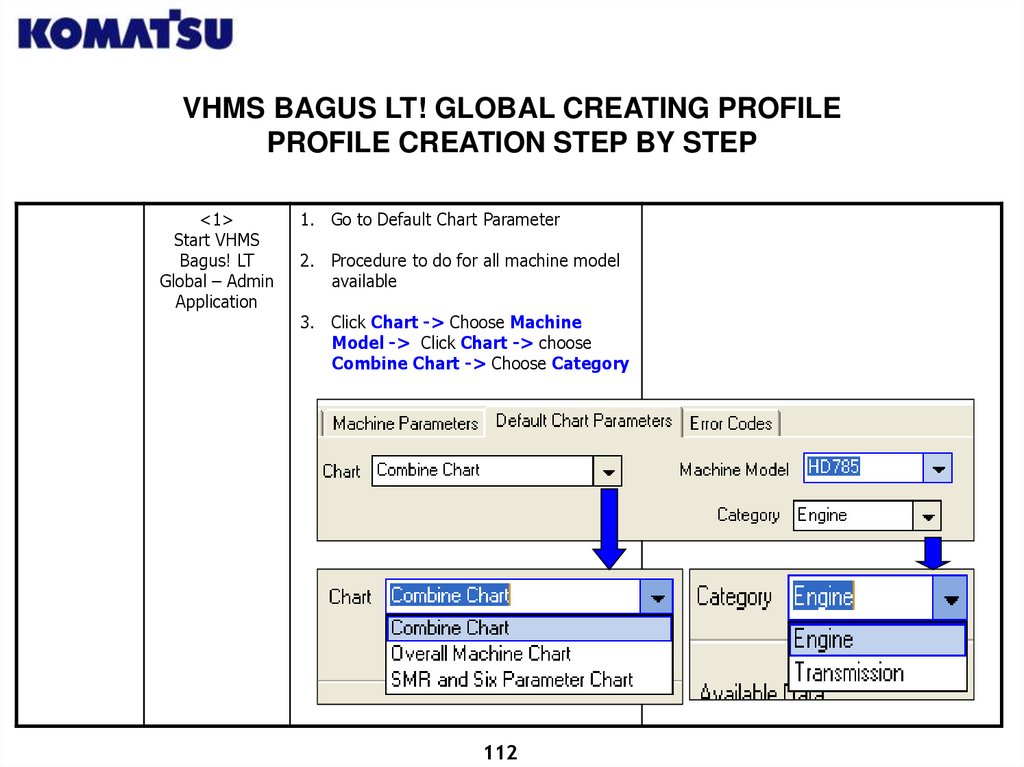

VHMS BAGUS LT! GLOBAL CREATING PROFILEPROFILE CREATION STEP BY STEP

<1>

Start VHMS

Bagus! LT

Global – Admin

Application

1. Go to Default Chart Parameter

2. Procedure to do for all machine model

available

3. Click Chart -> Choose Machine

Model -> Click Chart -> choose

Combine Chart -> Choose Category

112

113.

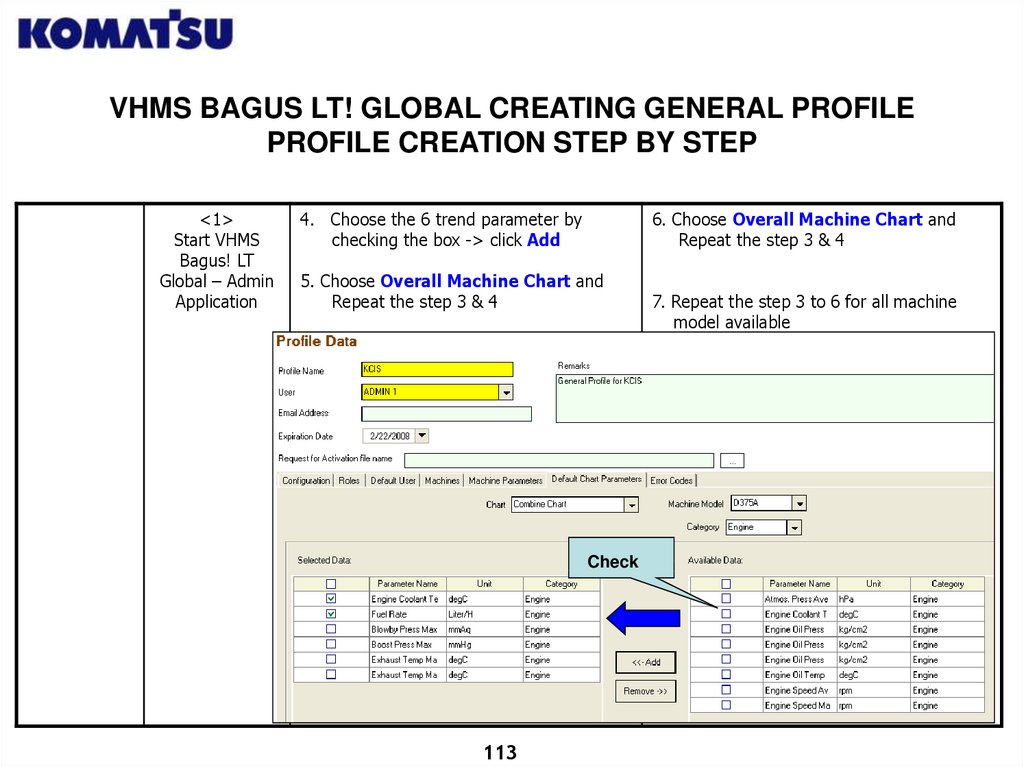

VHMS BAGUS LT! GLOBAL CREATING GENERAL PROFILEPROFILE CREATION STEP BY STEP

<1>

Start VHMS

Bagus! LT

Global – Admin

Application

4. Choose the 6 trend parameter by

checking the box -> click Add

6. Choose Overall Machine Chart and

Repeat the step 3 & 4

5. Choose Overall Machine Chart and

Repeat the step 3 & 4

Check

113

7. Repeat the step 3 to 6 for all machine

model available

114.

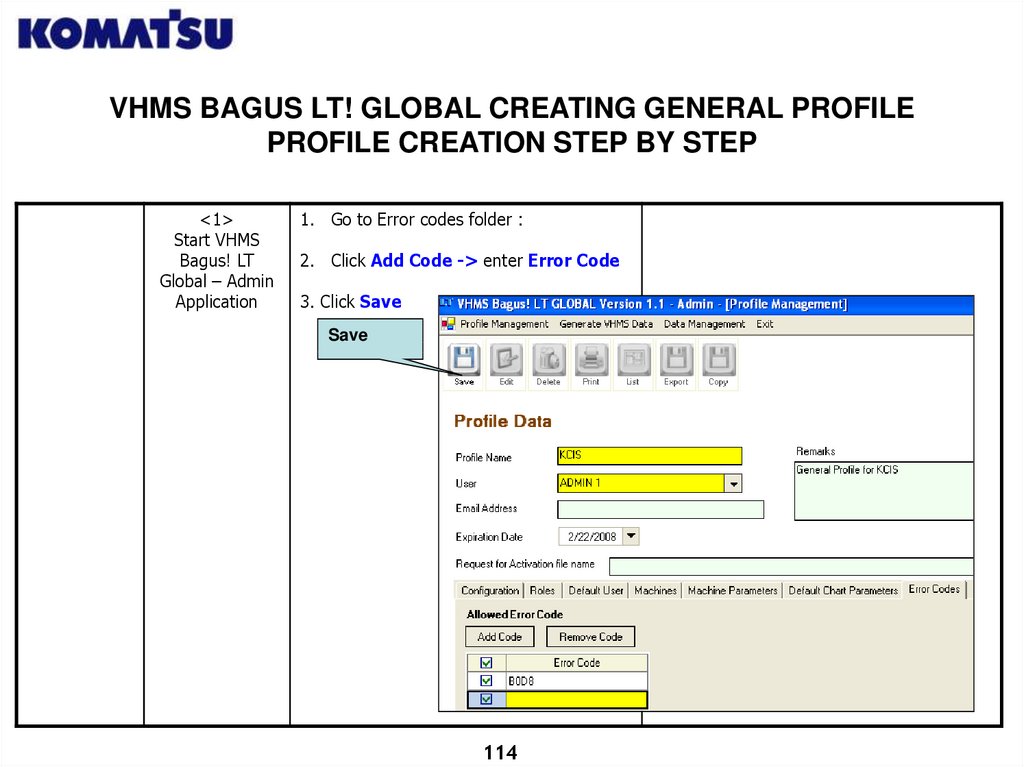

VHMS BAGUS LT! GLOBAL CREATING GENERAL PROFILEPROFILE CREATION STEP BY STEP

<1>

Start VHMS

Bagus! LT

Global – Admin

Application

1. Go to Error codes folder :

2. Click Add Code -> enter Error Code

3. Click Save

Save

114

115.

UPDATE USER PROFILE AND TECHNICAL PARAMETER TOVHMS BAGUS DATABASE

VHMS Bagus LT User Profile & Technical Parameter Process Update is

performed when changes happen to VHMS Bagus LT – User Application

user profile and technical parameter.

Changes to User Profile :

1. Population change

2. User Role change

Changes to Technical Parameter :

1. Caution and Critical Line Value change

2. Quantity of machine parameter change

This change will be done by VHMS LT Administrator. Afterwards

Administrator will send an Update Profile / Technical Parameter File to

each VHMS LT User. Each User is obliged to upload the file into VHMS LT

User application.

115

116.

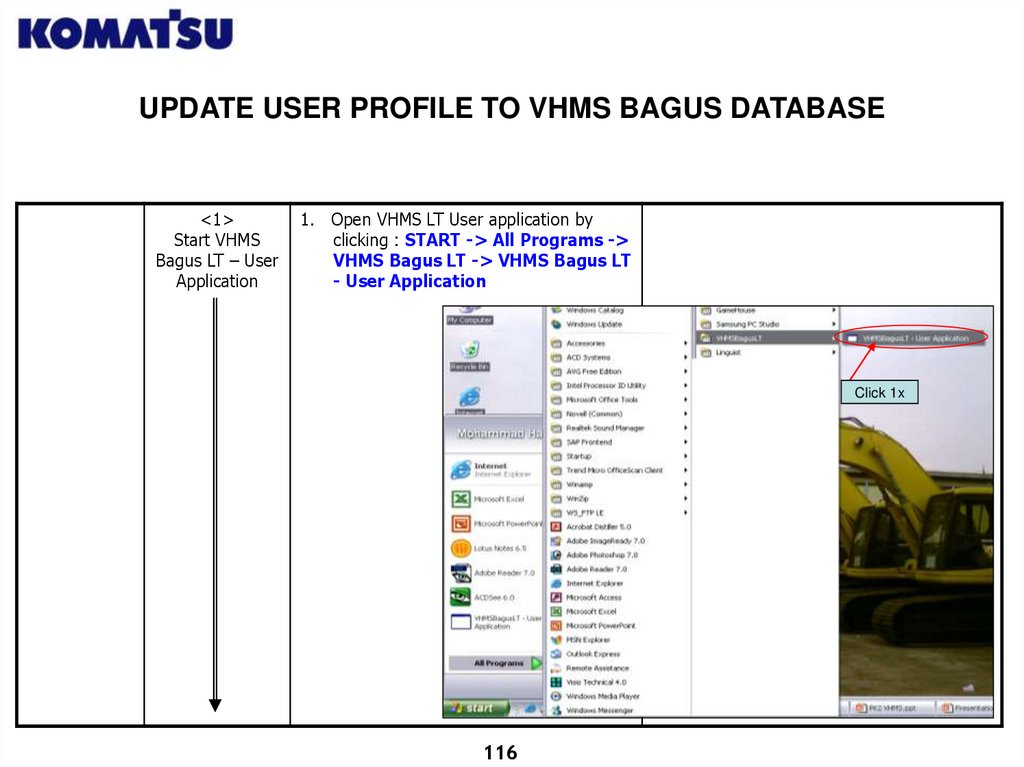

UPDATE USER PROFILE TO VHMS BAGUS DATABASE<1>

Start VHMS

Bagus LT – User

Application

1. Open VHMS LT User application by

clicking : START -> All Programs ->

VHMS Bagus LT -> VHMS Bagus LT

- User Application

Click 1x

116

117.

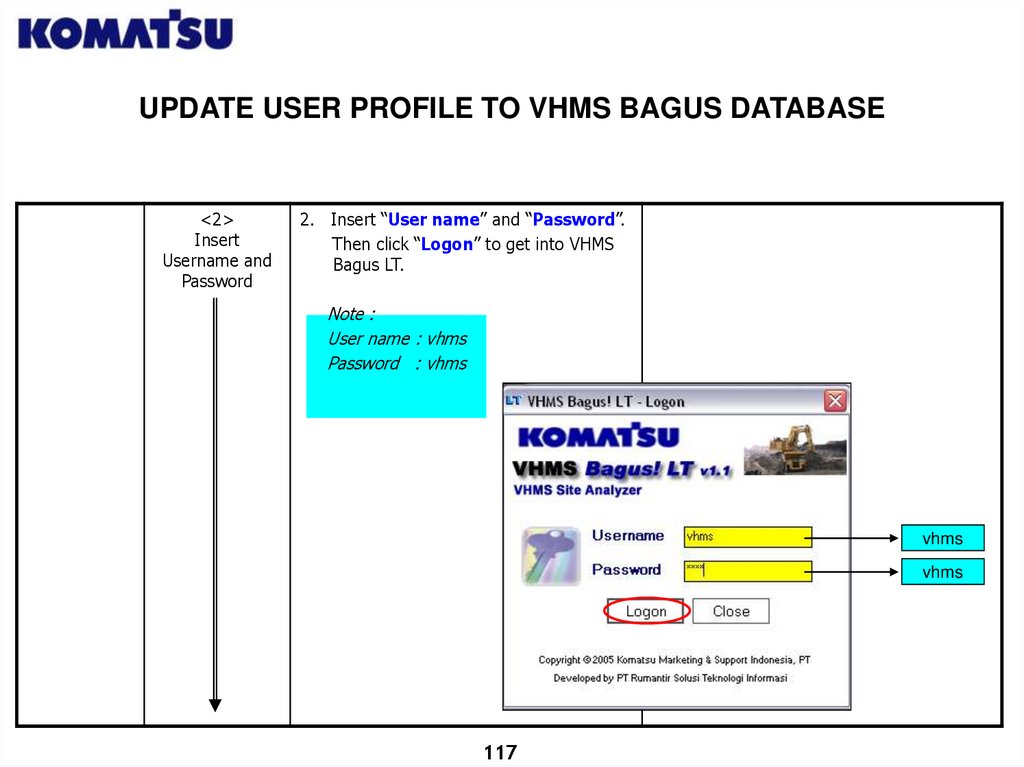

UPDATE USER PROFILE TO VHMS BAGUS DATABASE<2>

Insert

Username and

Password

2. Insert “User name” and “Password”.

Then click “Logon” to get into VHMS

Bagus LT.

Note :

User name : vhms

Password : vhms

vhms

vhms

117

118.

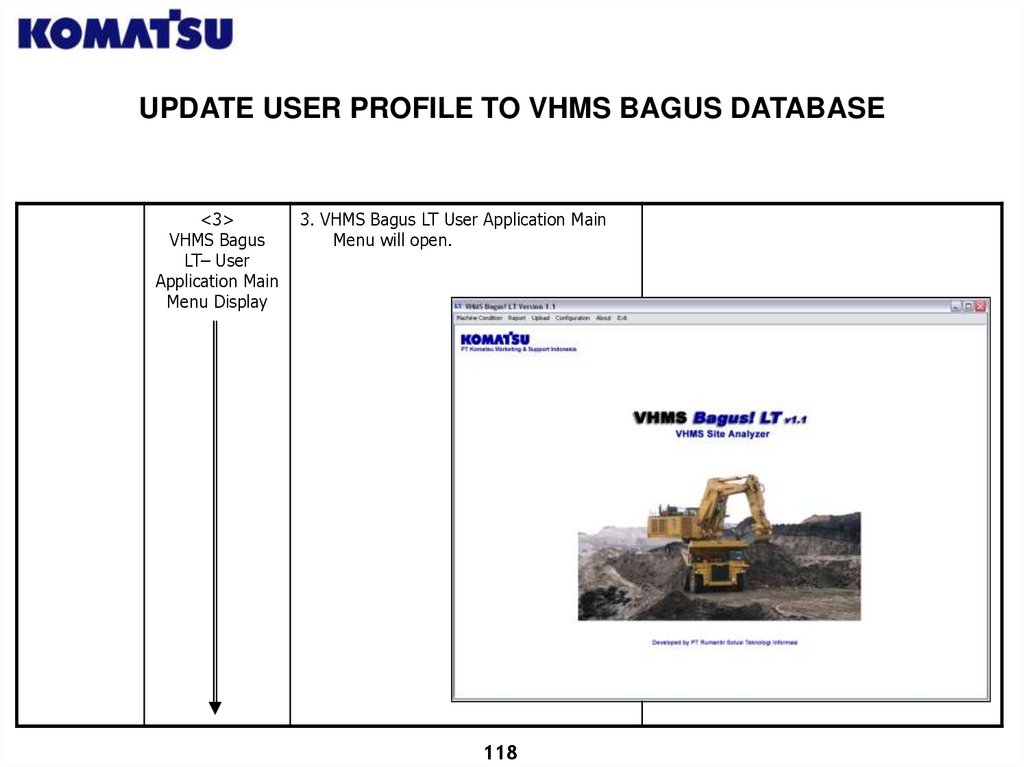

UPDATE USER PROFILE TO VHMS BAGUS DATABASE<3>

VHMS Bagus

LT– User

Application Main

Menu Display

3. VHMS Bagus LT User Application Main

Menu will open.

118

119.

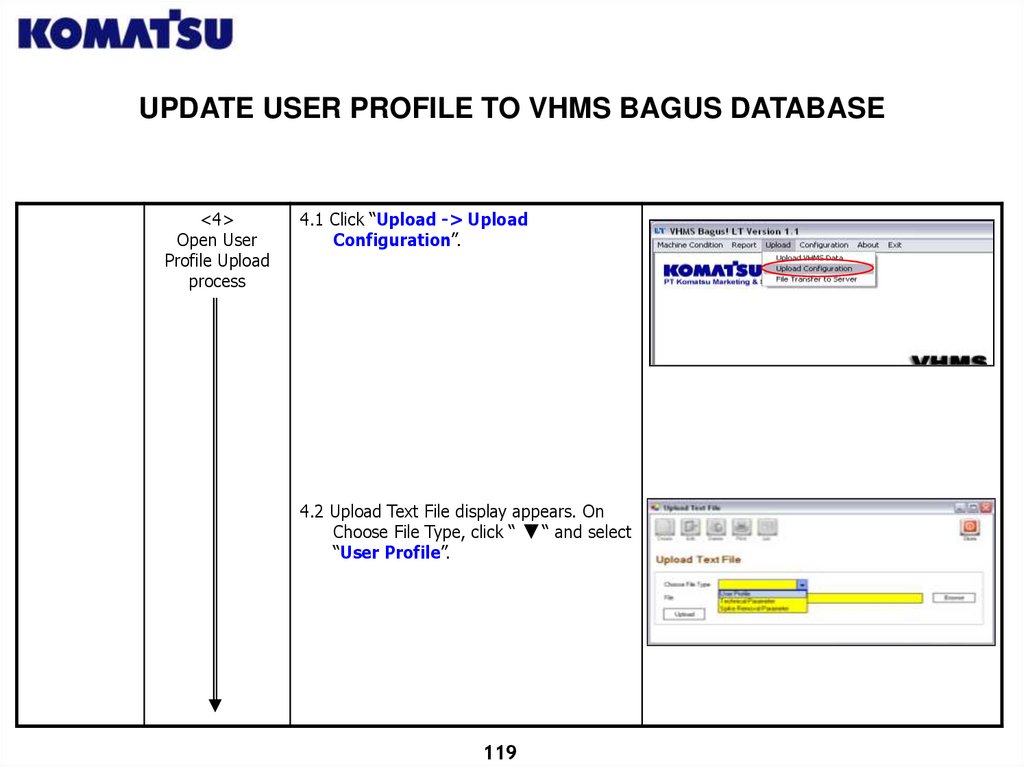

UPDATE USER PROFILE TO VHMS BAGUS DATABASE<4>

Open User

Profile Upload

process

4.1 Click “Upload -> Upload

Configuration”.

4.2 Upload Text File display appears. On

Choose File Type, click “

“ and select

“User Profile”.

119

120.

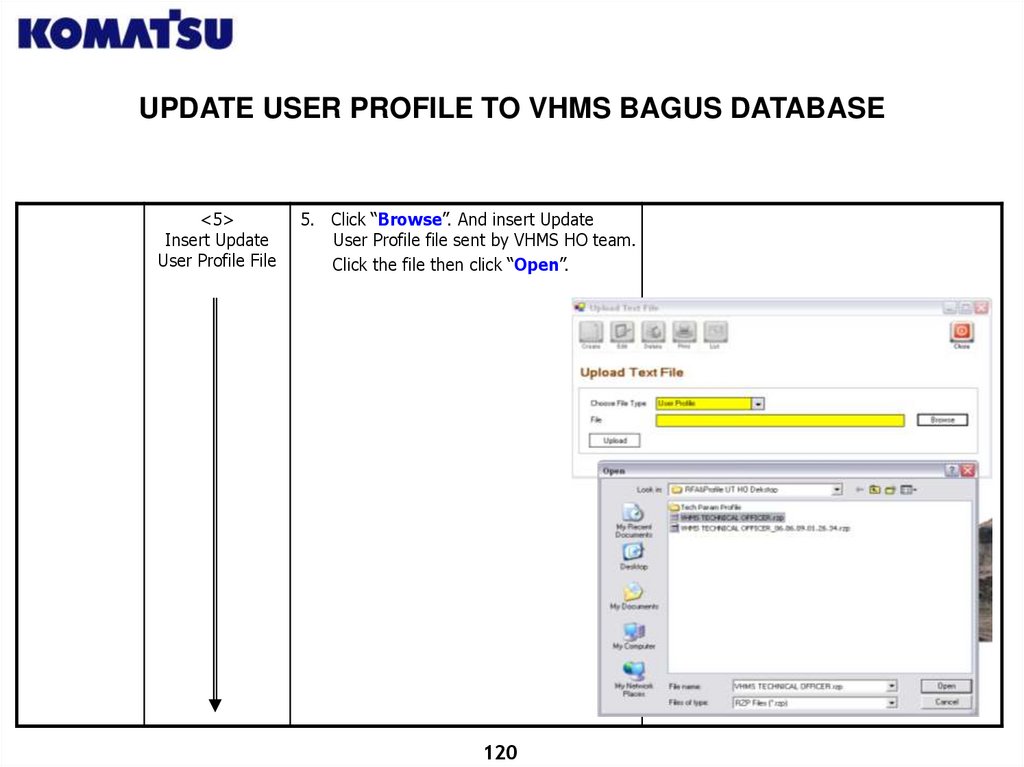

UPDATE USER PROFILE TO VHMS BAGUS DATABASE<5>

Insert Update

User Profile File

5. Click “Browse”. And insert Update

User Profile file sent by VHMS HO team.

Click the file then click “Open”.

120

121.

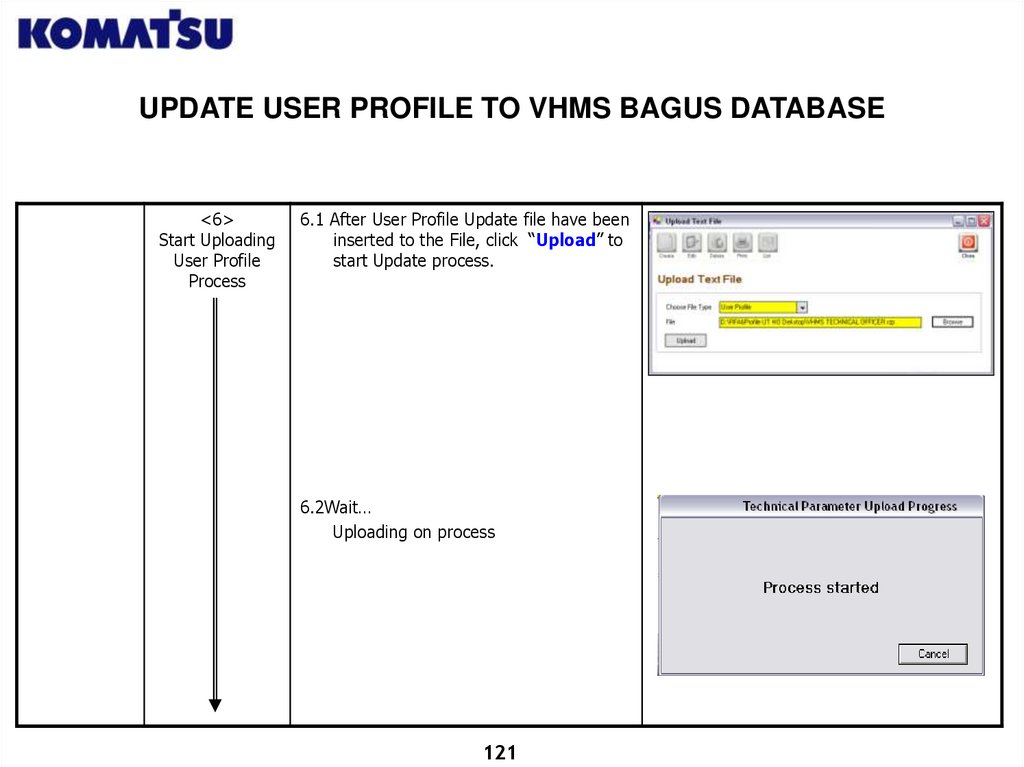

UPDATE USER PROFILE TO VHMS BAGUS DATABASE<6>

Start Uploading

User Profile

Process

6.1 After User Profile Update file have been

inserted to the File, click “Upload” to

start Update process.

6.2Wait…

Uploading on process

121

122.

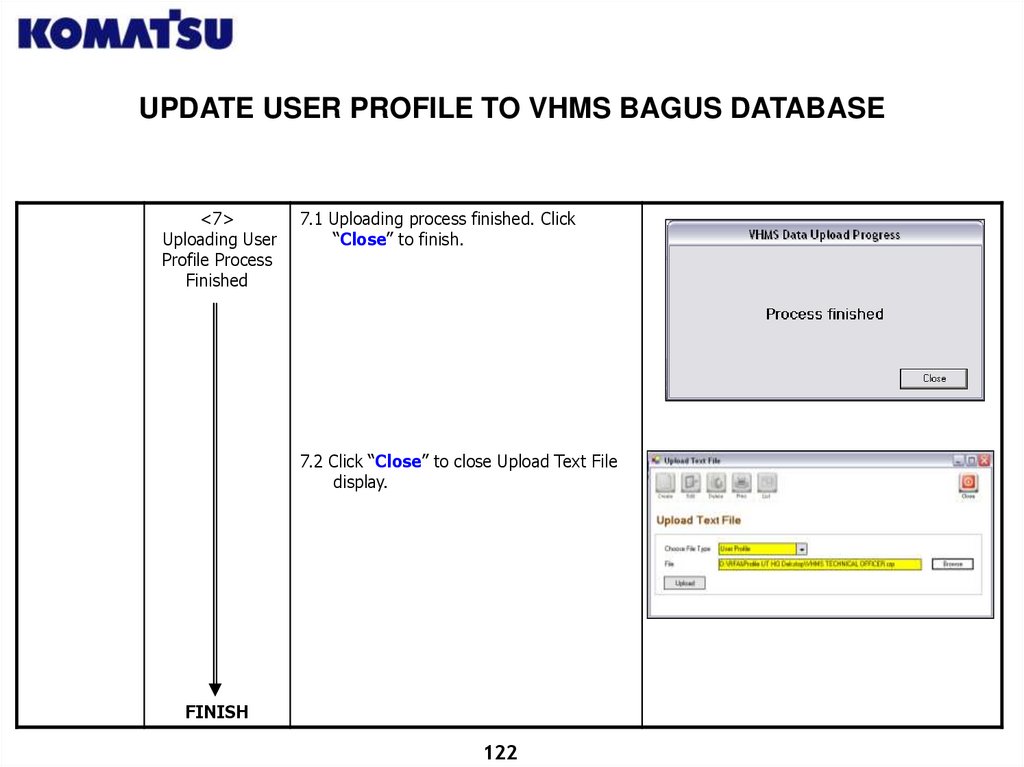

UPDATE USER PROFILE TO VHMS BAGUS DATABASE<7>

Uploading User

Profile Process

Finished

7.1 Uploading process finished. Click

“Close” to finish.

7.2 Click “Close” to close Upload Text File

display.

FINISH

122

123.

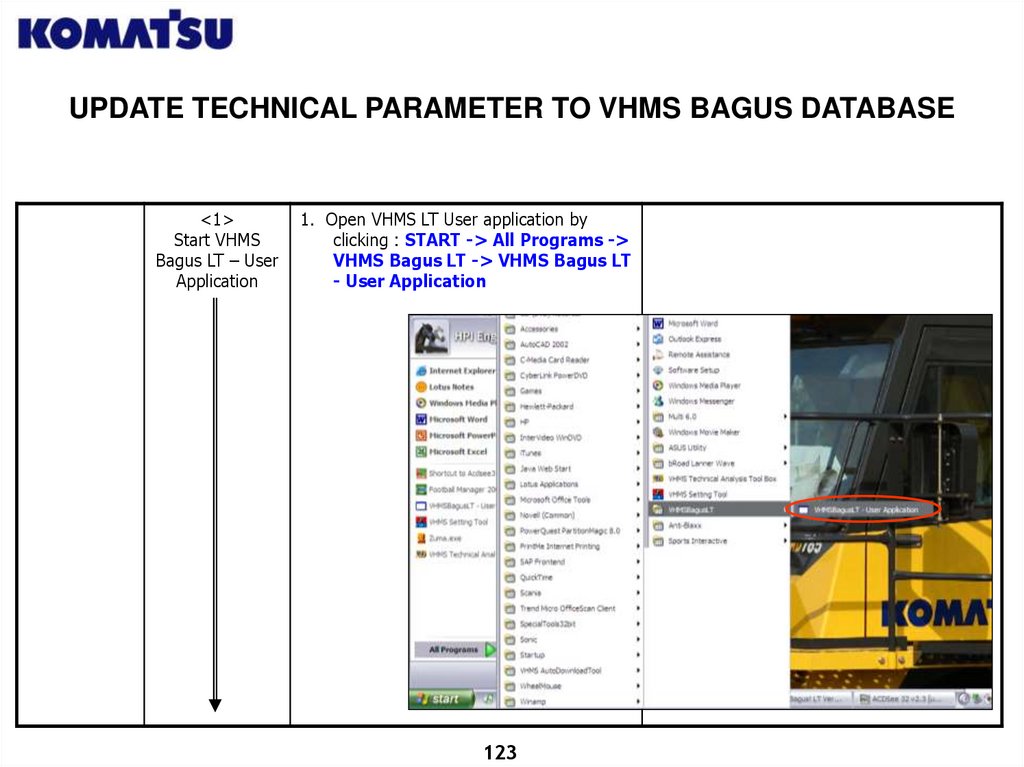

UPDATE TECHNICAL PARAMETER TO VHMS BAGUS DATABASE<1>

Start VHMS

Bagus LT – User

Application

1. Open VHMS LT User application by

clicking : START -> All Programs ->

VHMS Bagus LT -> VHMS Bagus LT

- User Application

123

124.

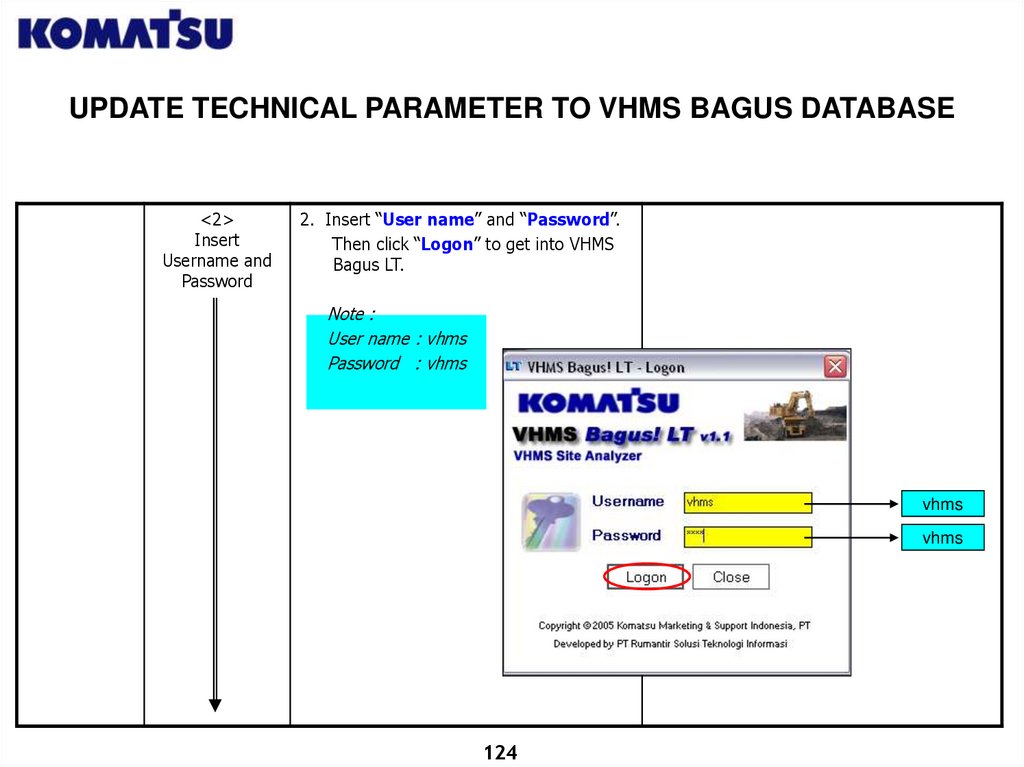

UPDATE TECHNICAL PARAMETER TO VHMS BAGUS DATABASE<2>

Insert

Username and

Password

2. Insert “User name” and “Password”.

Then click “Logon” to get into VHMS

Bagus LT.

Note :

User name : vhms

Password : vhms

vhms

vhms

124

125.

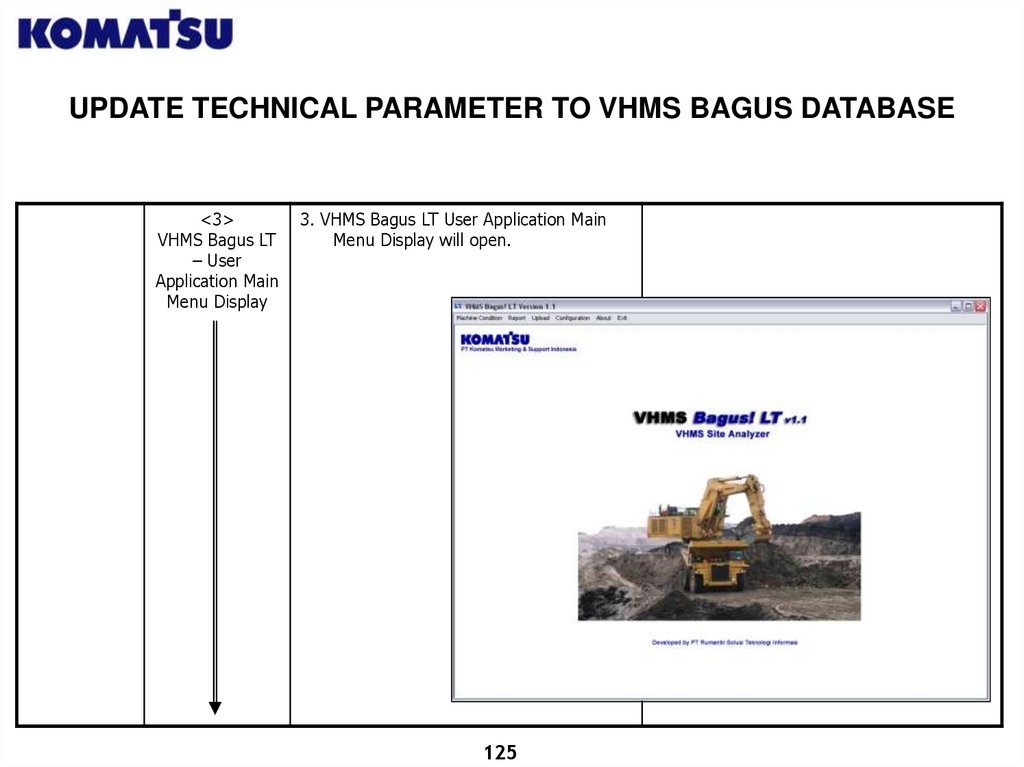

UPDATE TECHNICAL PARAMETER TO VHMS BAGUS DATABASE<3>

VHMS Bagus LT

– User

Application Main

Menu Display

3. VHMS Bagus LT User Application Main

Menu Display will open.

125

126.

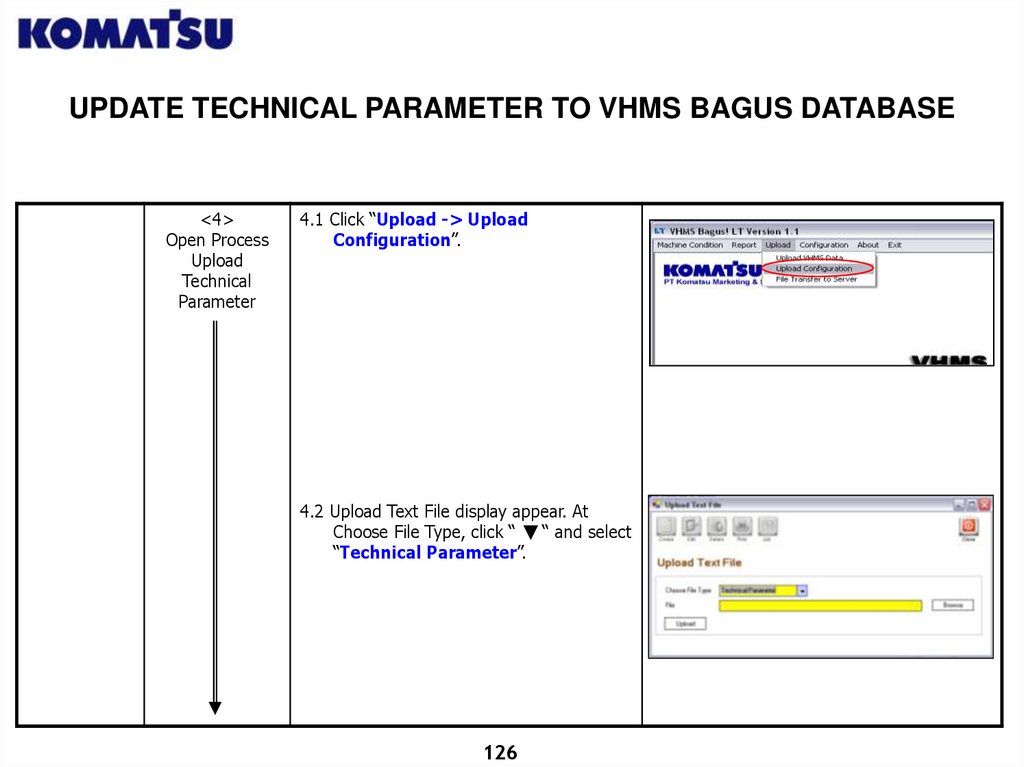

UPDATE TECHNICAL PARAMETER TO VHMS BAGUS DATABASE<4>

Open Process

Upload

Technical

Parameter

4.1 Click “Upload -> Upload

Configuration”.

4.2 Upload Text File display appear. At

Choose File Type, click “

“ and select

“Technical Parameter”.

126

127.

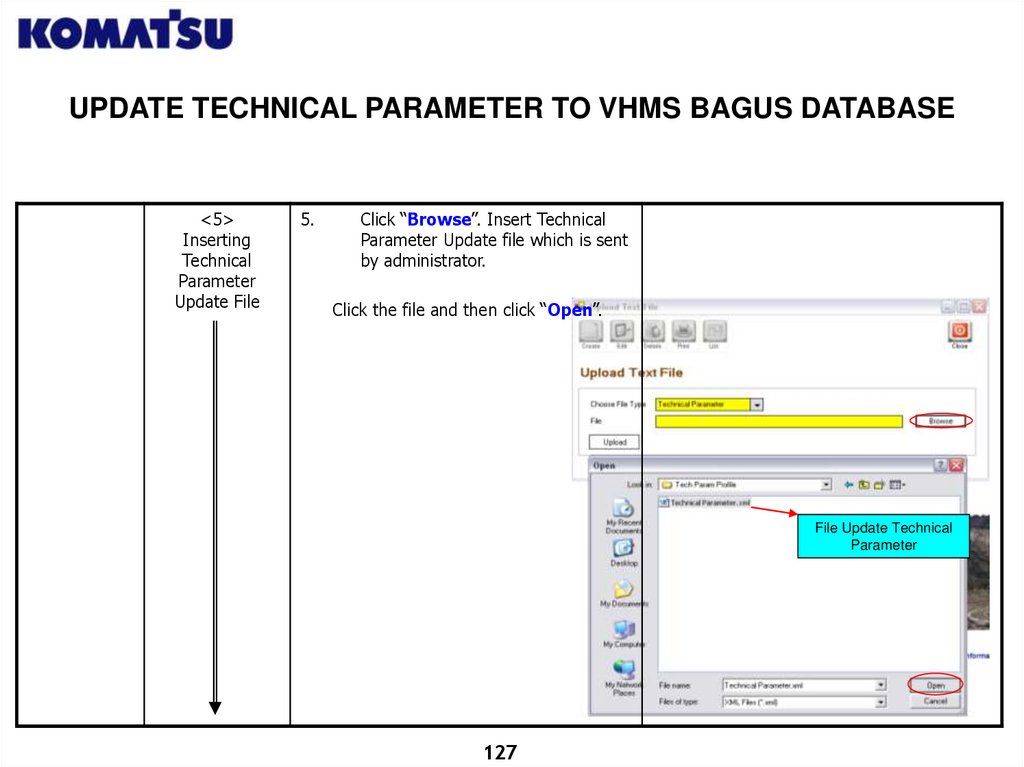

UPDATE TECHNICAL PARAMETER TO VHMS BAGUS DATABASE<5>

Inserting

Technical

Parameter

Update File

5.

Click “Browse”. Insert Technical

Parameter Update file which is sent

by administrator.

Click the file and then click “Open”.

File Update Technical

Parameter

127

128.

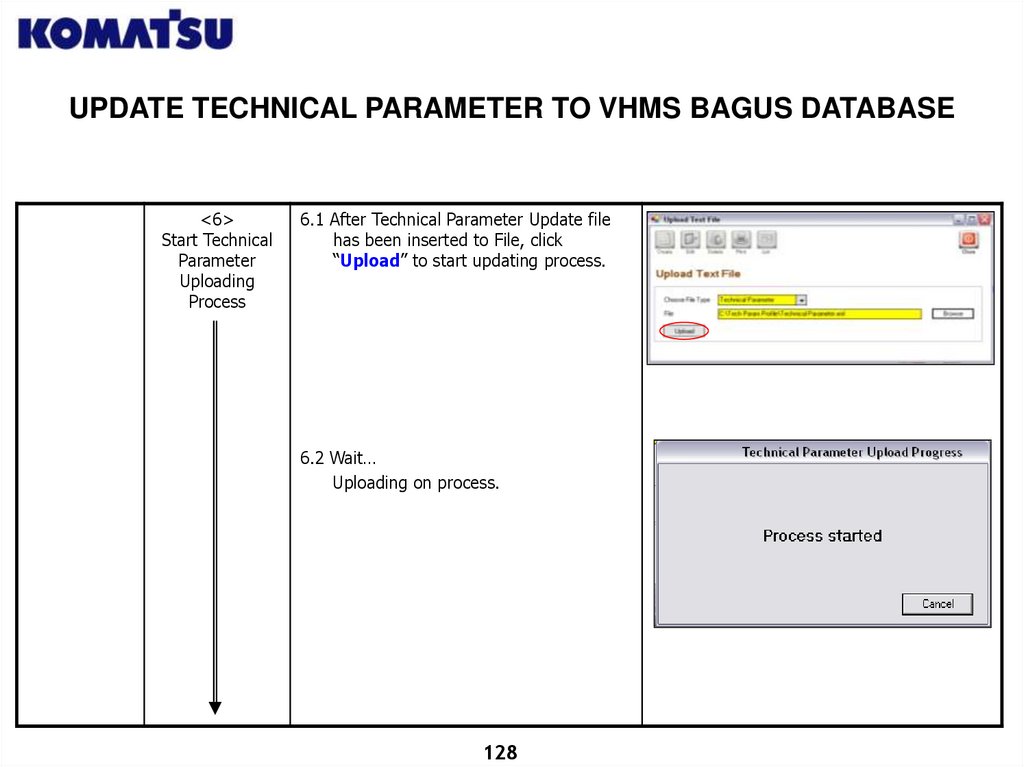

UPDATE TECHNICAL PARAMETER TO VHMS BAGUS DATABASE<6>

Start Technical

Parameter

Uploading

Process

6.1 After Technical Parameter Update file

has been inserted to File, click

“Upload” to start updating process.

6.2 Wait…

Uploading on process.

128

129.

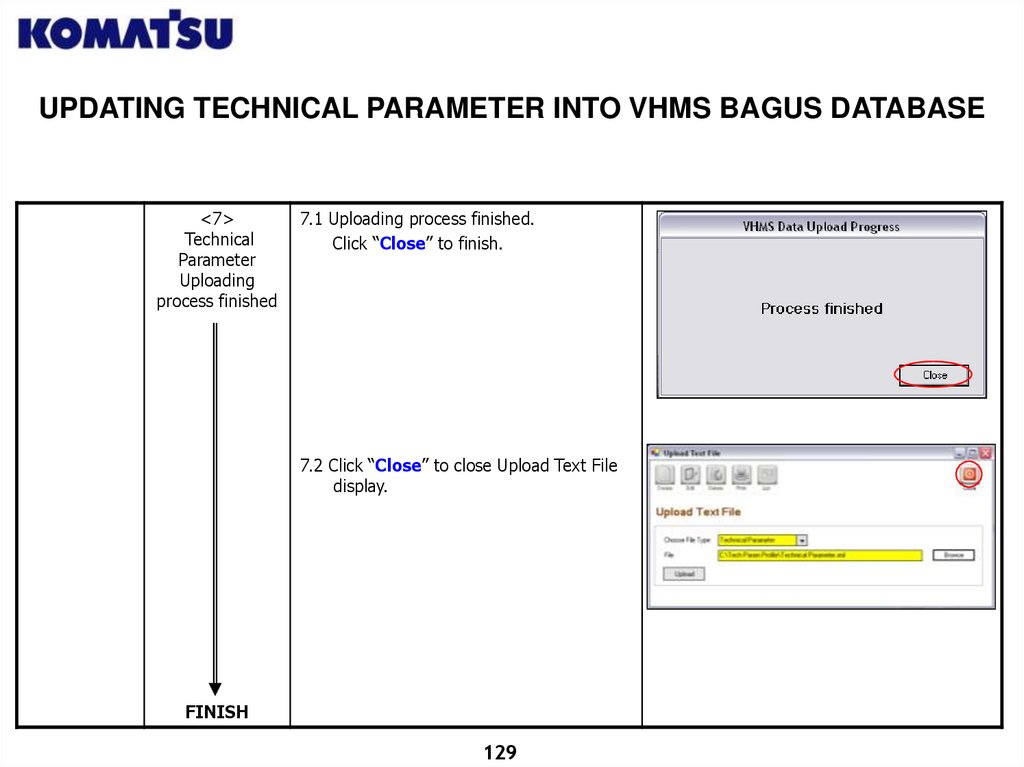

UPDATING TECHNICAL PARAMETER INTO VHMS BAGUS DATABASE<7>

Technical

Parameter

Uploading

process finished

7.1 Uploading process finished.

Click “Close” to finish.

7.2 Click “Close” to close Upload Text File

display.

FINISH

129

130.

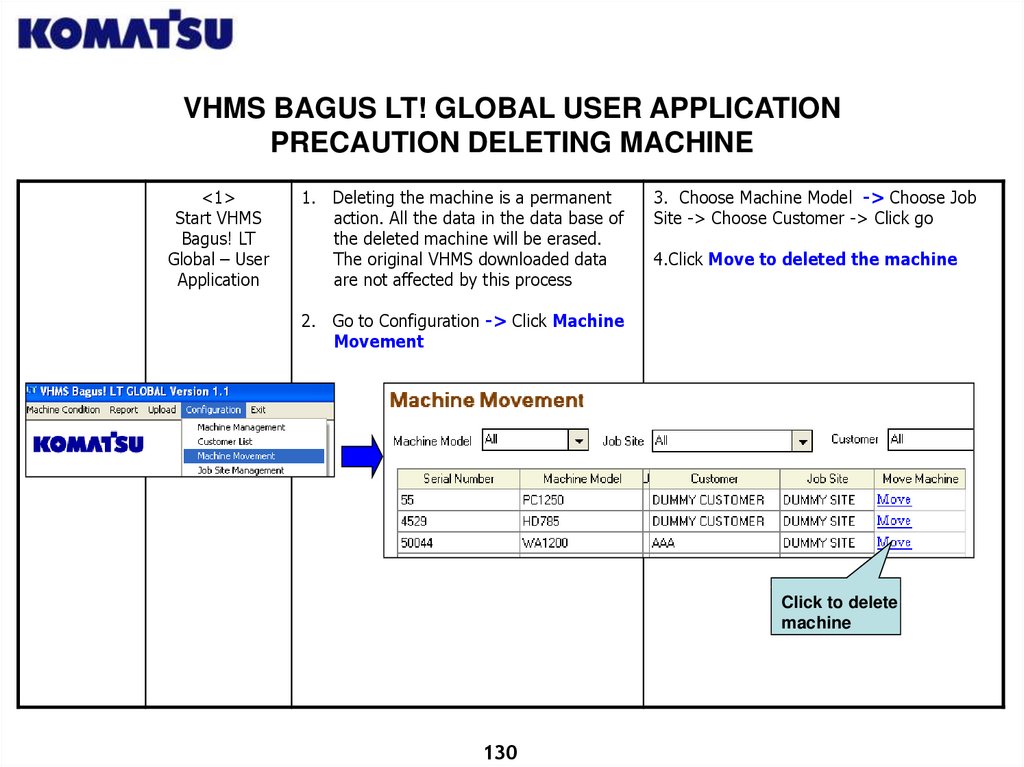

VHMS BAGUS LT! GLOBAL USER APPLICATIONPRECAUTION DELETING MACHINE

<1>

Start VHMS

Bagus! LT

Global – User

Application

1. Deleting the machine is a permanent

action. All the data in the data base of

the deleted machine will be erased.

The original VHMS downloaded data

are not affected by this process

3. Choose Machine Model -> Choose Job

Site -> Choose Customer -> Click go

4.Click Move to deleted the machine

2. Go to Configuration -> Click Machine

Movement

Click to delete

machine

130

131.

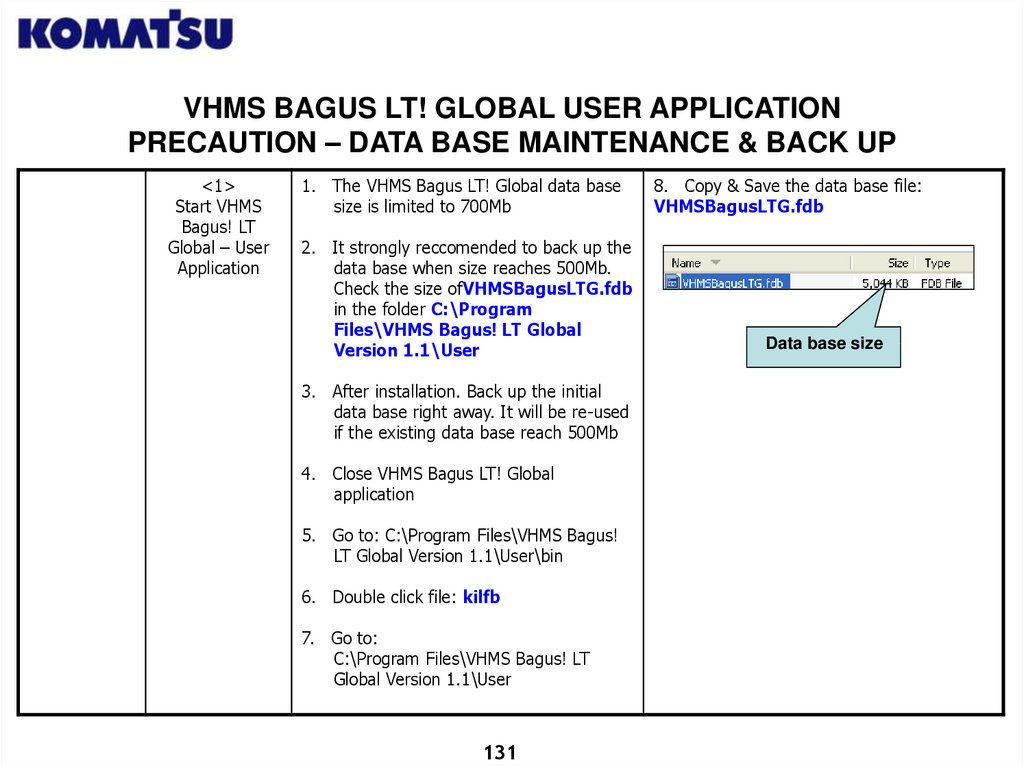

VHMS BAGUS LT! GLOBAL USER APPLICATIONPRECAUTION – DATA BASE MAINTENANCE & BACK UP

<1>

Start VHMS

Bagus! LT

Global – User

Application

1. The VHMS Bagus LT! Global data base

size is limited to 700Mb

2. It strongly reccomended to back up the

data base when size reaches 500Mb.

Check the size ofVHMSBagusLTG.fdb

in the folder C:\Program

Files\VHMS Bagus! LT Global

Version 1.1\User

3. After installation. Back up the initial

data base right away. It will be re-used

if the existing data base reach 500Mb

4. Close VHMS Bagus LT! Global

application

5. Go to: C:\Program Files\VHMS Bagus!

LT Global Version 1.1\User\bin

6. Double click file: kilfb

7. Go to:

C:\Program Files\VHMS Bagus! LT

Global Version 1.1\User

131

8. Copy & Save the data base file:

VHMSBagusLTG.fdb

Data base size

132.

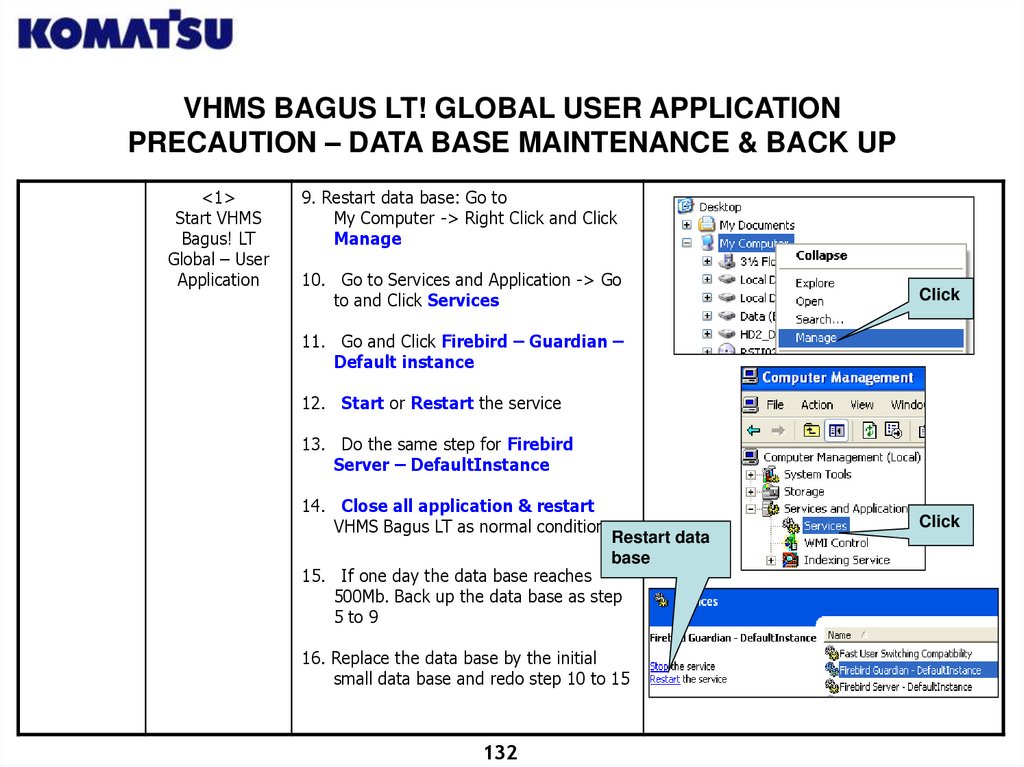

VHMS BAGUS LT! GLOBAL USER APPLICATIONPRECAUTION – DATA BASE MAINTENANCE & BACK UP

<1>

Start VHMS

Bagus! LT

Global – User

Application

9. Restart data base: Go to

My Computer -> Right Click and Click

Manage

10. Go to Services and Application -> Go

to and Click Services

Click

11. Go and Click Firebird – Guardian –

Default instance

12. Start or Restart the service

13. Do the same step for Firebird

Server – DefaultInstance

14. Close all application & restart

VHMS Bagus LT as normal condition

Click

Restart data

base

15. If one day the data base reaches

500Mb. Back up the data base as step

5 to 9

16. Replace the data base by the initial

small data base and redo step 10 to 15

132

133.

CHAPTER IVPLM II

133

134.

DOWN LOAD PAYLOAD METER134

135.

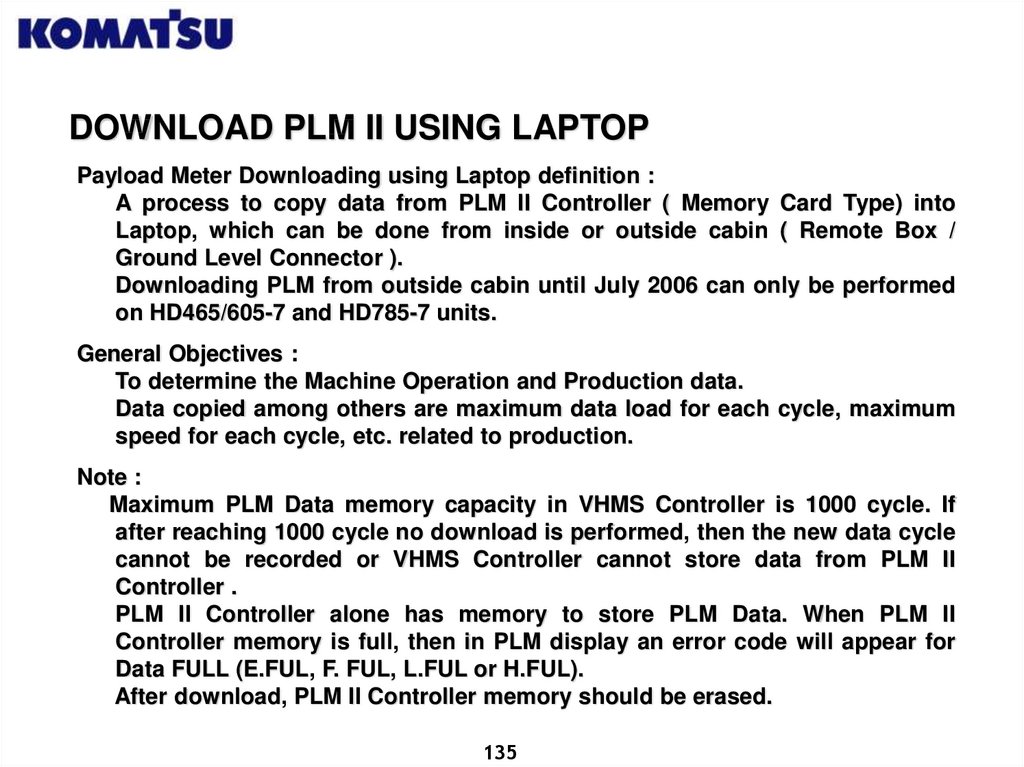

DOWNLOAD PLM II USING LAPTOPPayload Meter Downloading using Laptop definition :

A process to copy data from PLM II Controller ( Memory Card Type) into

Laptop, which can be done from inside or outside cabin ( Remote Box /

Ground Level Connector ).

Downloading PLM from outside cabin until July 2006 can only be performed

on HD465/605-7 and HD785-7 units.

General Objectives :

To determine the Machine Operation and Production data.

Data copied among others are maximum data load for each cycle, maximum

speed for each cycle, etc. related to production.

Note :

Maximum PLM Data memory capacity in VHMS Controller is 1000 cycle. If

after reaching 1000 cycle no download is performed, then the new data cycle

cannot be recorded or VHMS Controller cannot store data from PLM II

Controller .

PLM II Controller alone has memory to store PLM Data. When PLM II

Controller memory is full, then in PLM display an error code will appear for

Data FULL (E.FUL, F. FUL, L.FUL or H.FUL).

After download, PLM II Controller memory should be erased.

135

136.

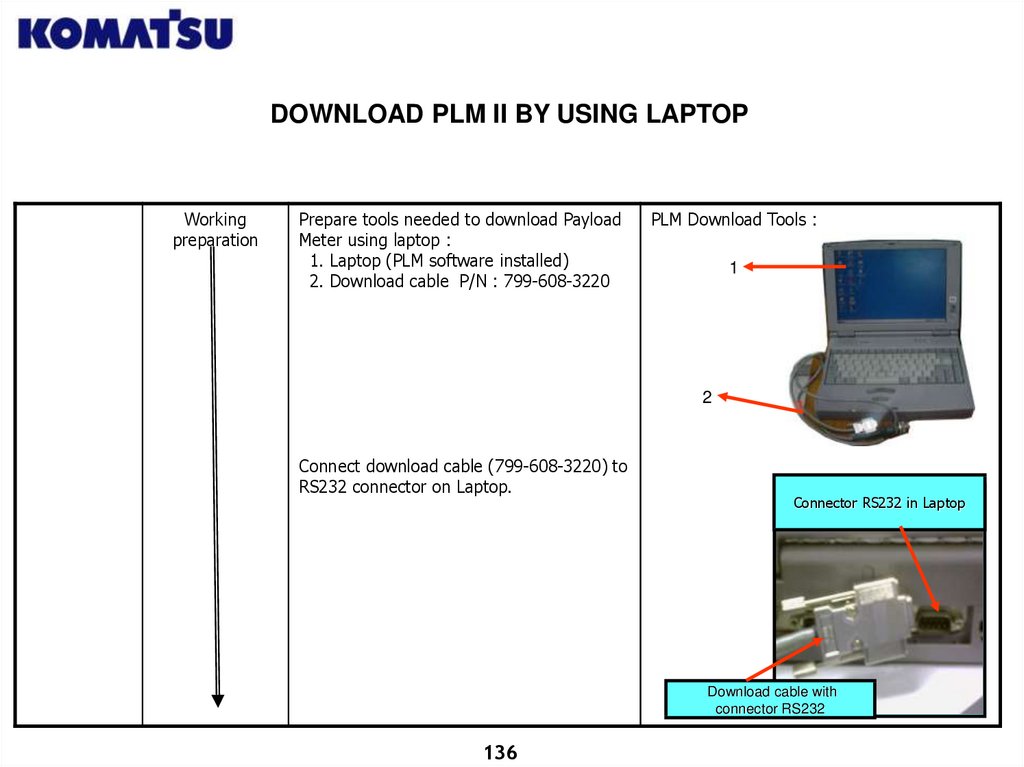

DOWNLOAD PLM II BY USING LAPTOPWorking

preparation

Prepare tools needed to download Payload

Meter using laptop :

1. Laptop (PLM software installed)

2. Download cable P/N : 799-608-3220

PLM Download Tools :

1

2

Connect download cable (799-608-3220) to

RS232 connector on Laptop.

Connector RS232 in Laptop

Download cable with

connector RS232

136

137.

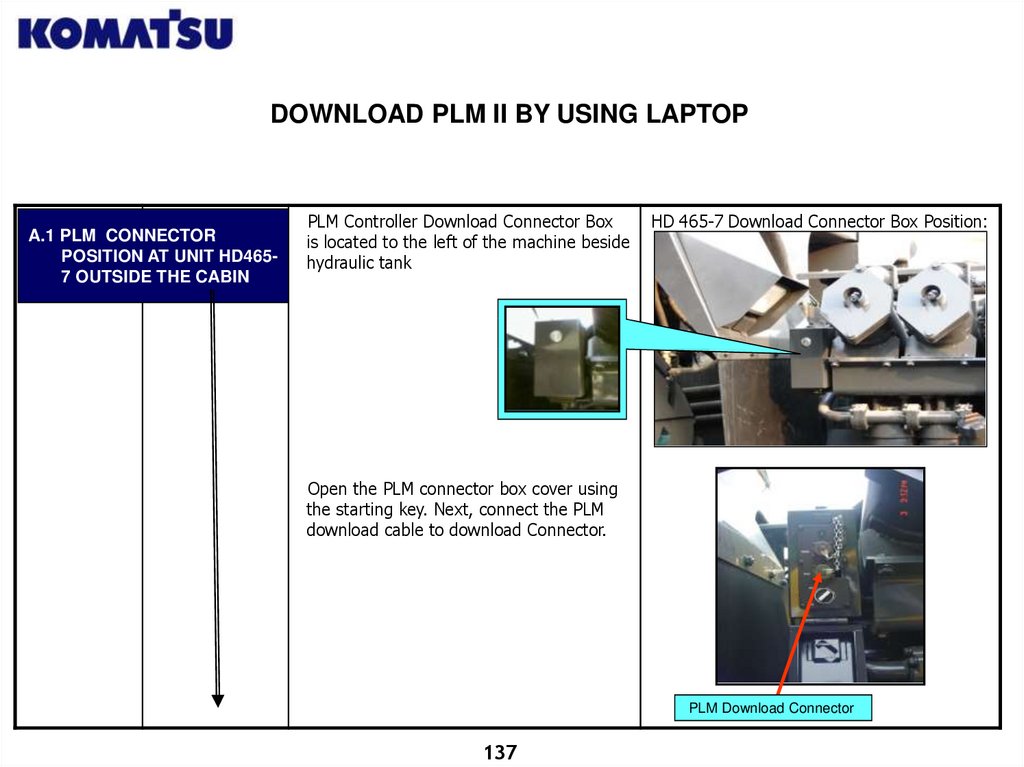

DOWNLOAD PLM II BY USING LAPTOPA.1 PLM CONNECTOR

POSITION AT UNIT HD4657 OUTSIDE THE CABIN

PLM Controller Download Connector Box

is located to the left of the machine beside

hydraulic tank

HD 465-7 Download Connector Box Position:

Open the PLM connector box cover using

the starting key. Next, connect the PLM

download cable to download Connector.

PLM Download Connector

137

138.

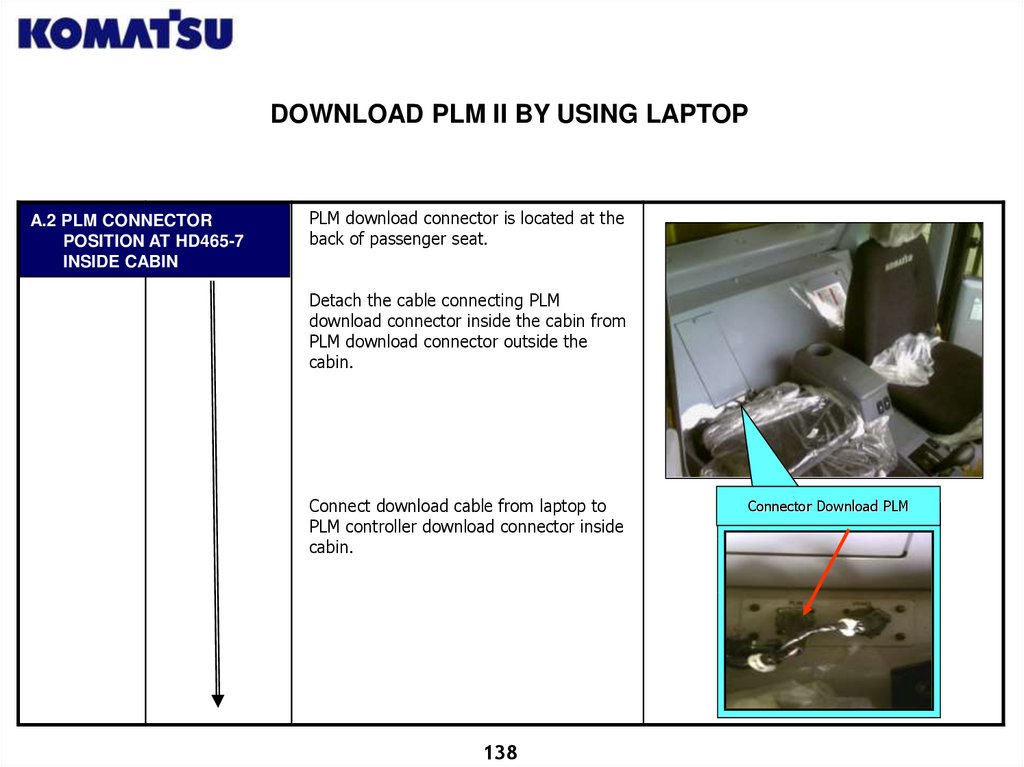

DOWNLOAD PLM II BY USING LAPTOPA.2 PLM CONNECTOR

POSITION AT HD465-7

INSIDE CABIN

PLM download connector is located at the

back of passenger seat.

Detach the cable connecting PLM

download connector inside the cabin from

PLM download connector outside the

cabin.

Connect download cable from laptop to

PLM controller download connector inside

cabin.

138

Connector Download PLM

139.

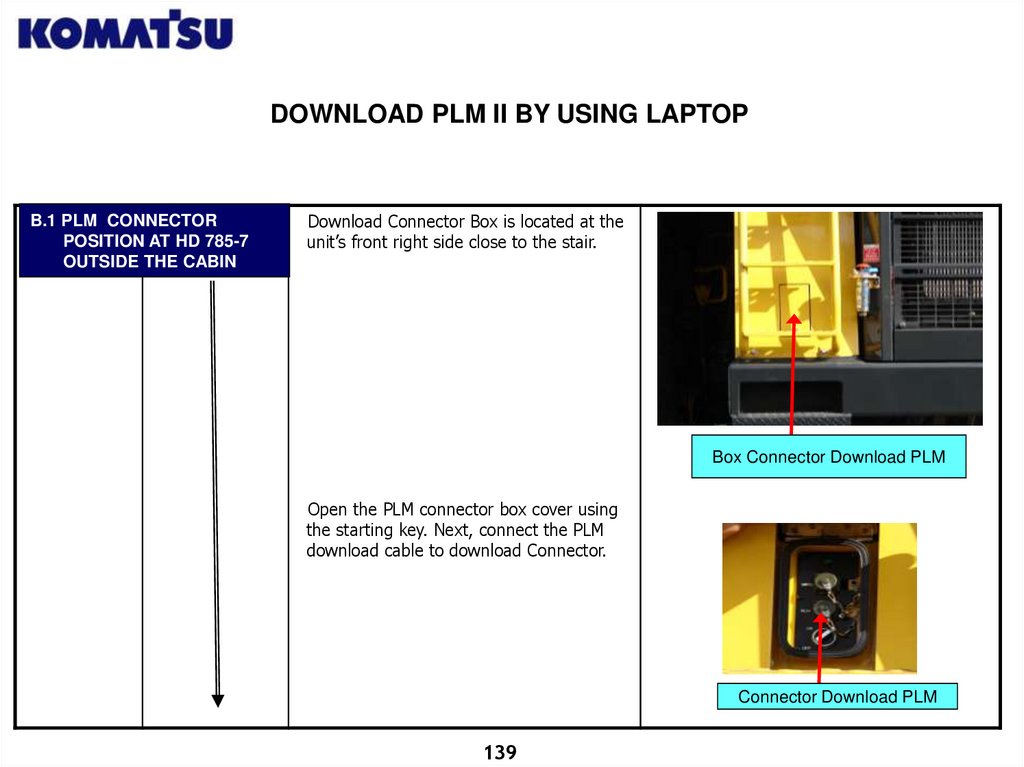

DOWNLOAD PLM II BY USING LAPTOPB.1 PLM CONNECTOR

POSITION AT HD 785-7

OUTSIDE THE CABIN

Download Connector Box is located at the

unit’s front right side close to the stair.

Box Connector Download PLM

Open the PLM connector box cover using

the starting key. Next, connect the PLM

download cable to download Connector.

Connector Download PLM

139

140.

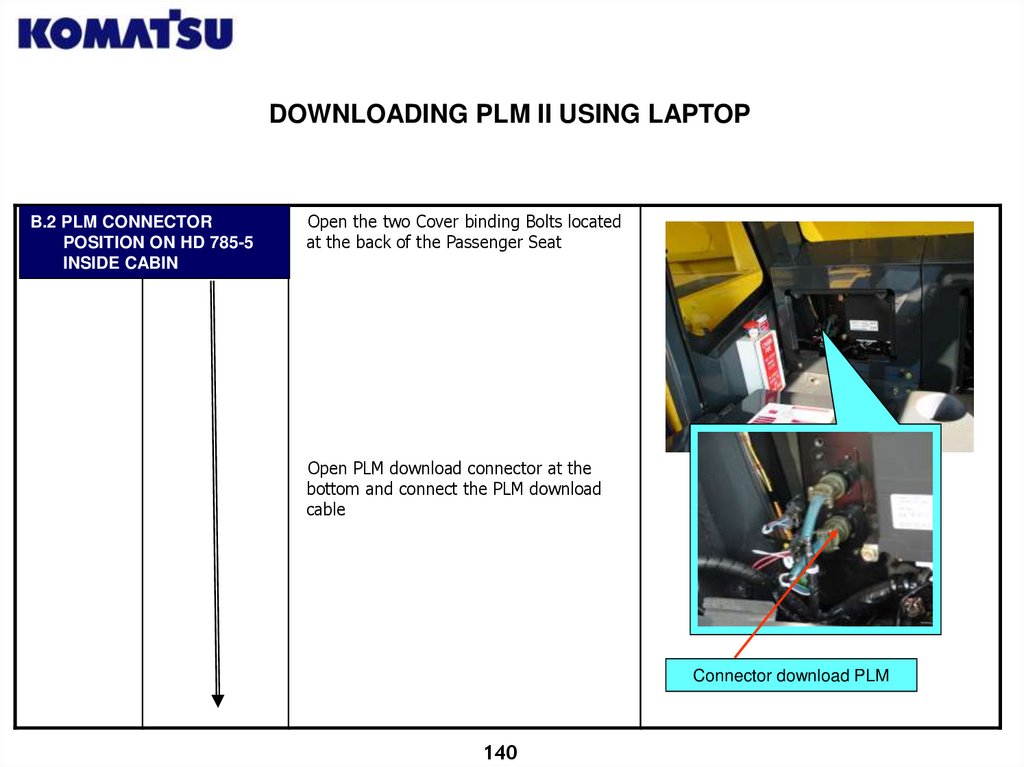

DOWNLOADING PLM II USING LAPTOPB.2 PLM CONNECTOR

POSITION ON HD 785-5

INSIDE CABIN

Open the two Cover binding Bolts located

at the back of the Passenger Seat

Open PLM download connector at the

bottom and connect the PLM download

cable

Connector download PLM

140

141.

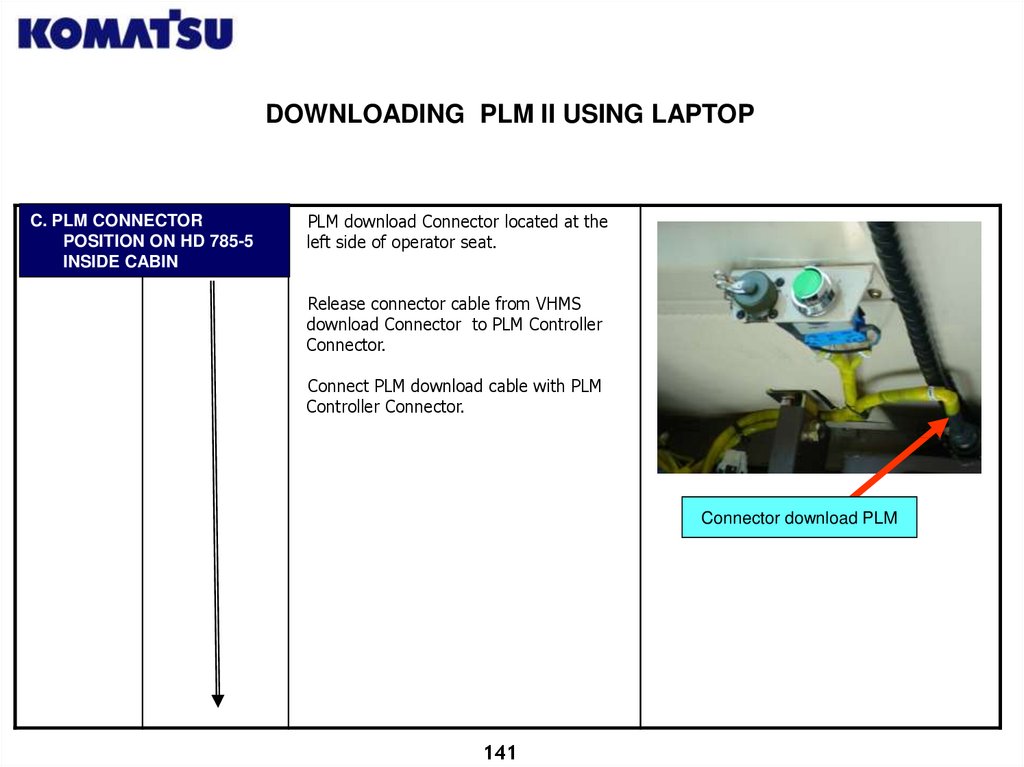

DOWNLOADING PLM II USING LAPTOPC. PLM CONNECTOR

POSITION ON HD 785-5

INSIDE CABIN

PLM download Connector located at the

left side of operator seat.

Release connector cable from VHMS

download Connector to PLM Controller

Connector.

Connect PLM download cable with PLM

Controller Connector.

Connector download PLM

141

142.

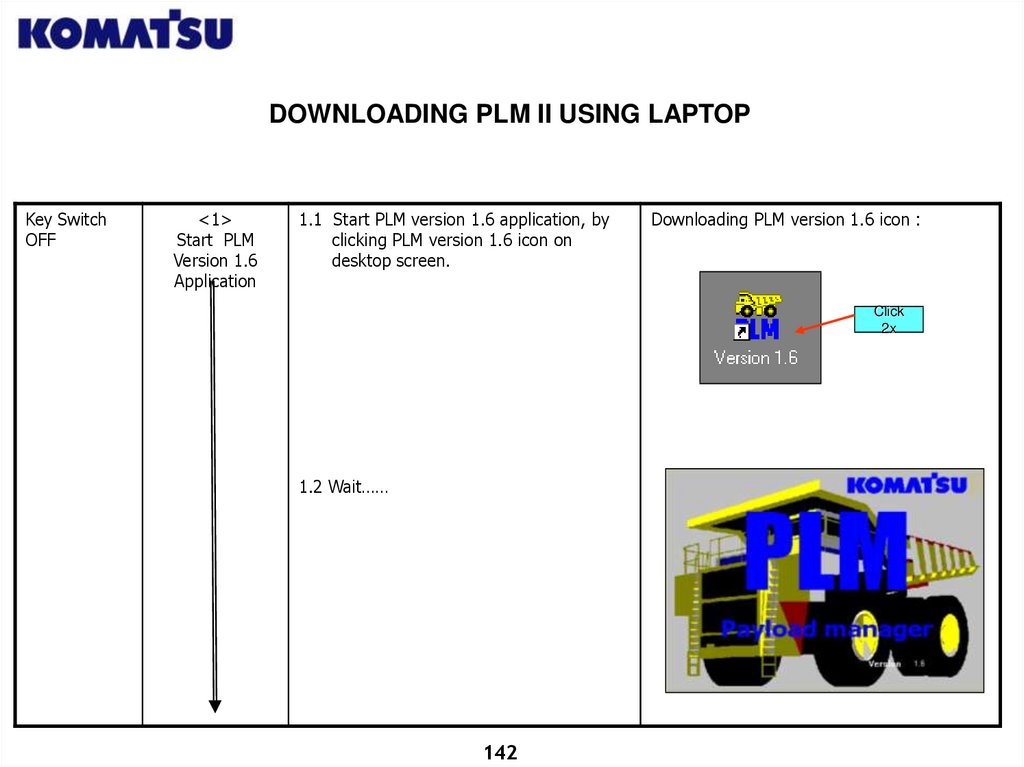

DOWNLOADING PLM II USING LAPTOPKey Switch

OFF

<1>

Start PLM

Version 1.6

Application

1.1 Start PLM version 1.6 application, by

clicking PLM version 1.6 icon on

desktop screen.

Downloading PLM version 1.6 icon :

Click

2x

1.2 Wait……

142

143.

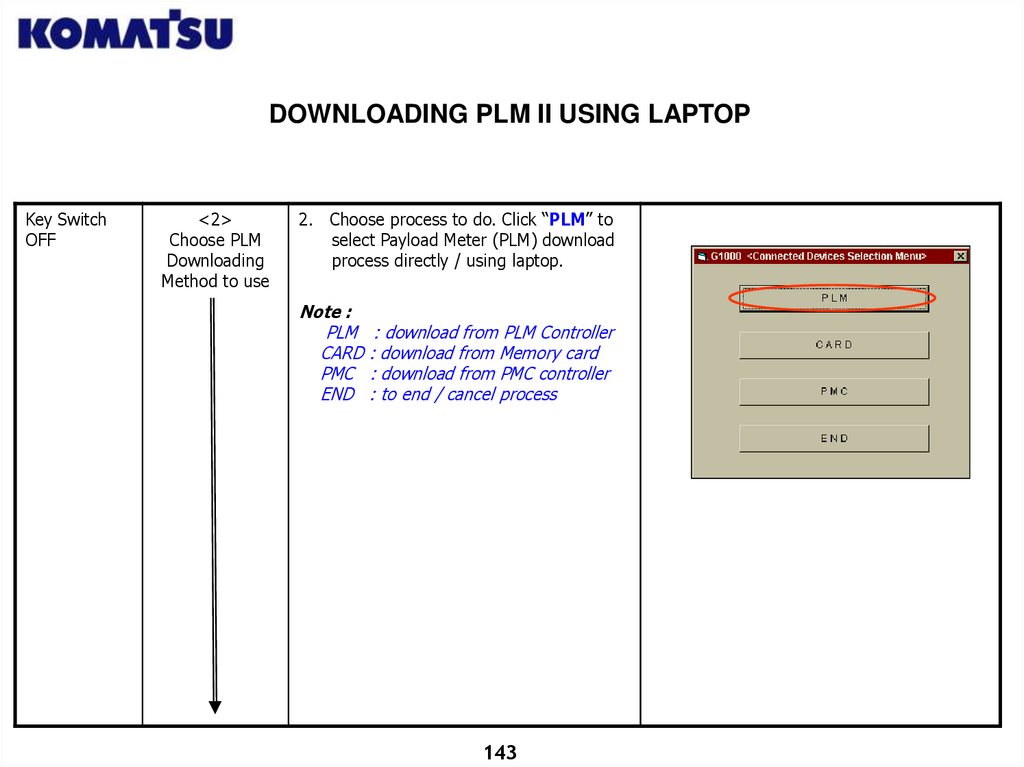

DOWNLOADING PLM II USING LAPTOPKey Switch

OFF

<2>

Choose PLM

Downloading

Method to use

2. Choose process to do. Click “PLM” to

select Payload Meter (PLM) download

process directly / using laptop.

Note :

PLM

CARD

PMC

END

: download from PLM Controller

: download from Memory card

: download from PMC controller

: to end / cancel process

143

144.

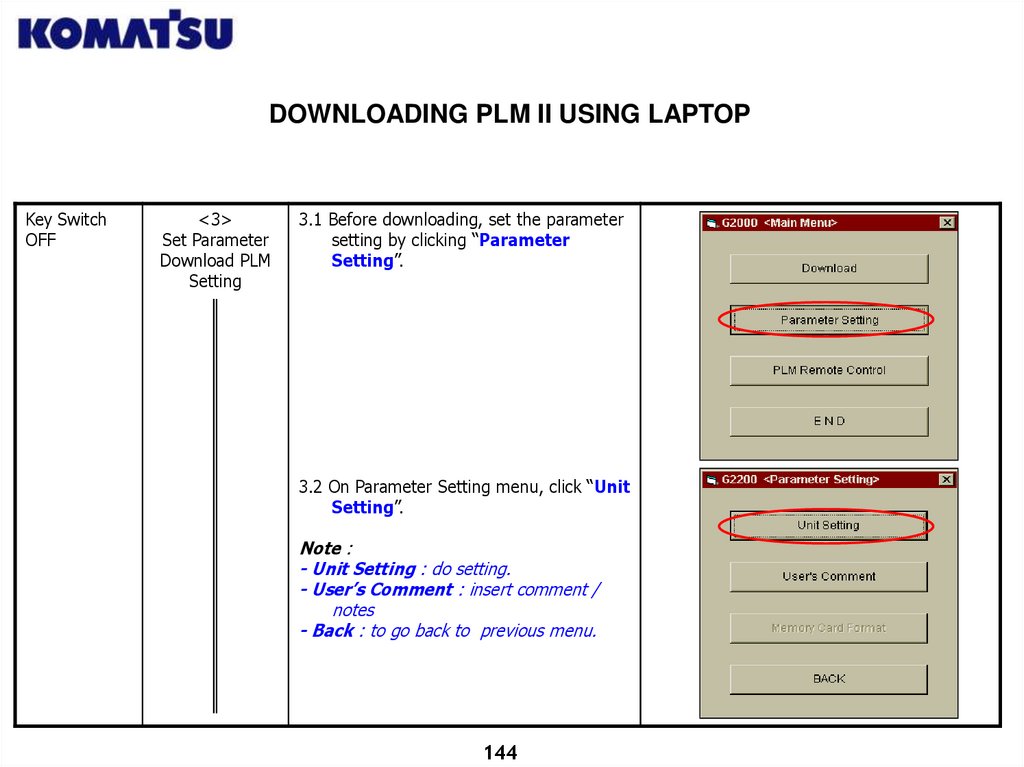

DOWNLOADING PLM II USING LAPTOPKey Switch

OFF

<3>

Set Parameter

Download PLM

Setting

3.1 Before downloading, set the parameter

setting by clicking “Parameter

Setting”.

3.2 On Parameter Setting menu, click “Unit

Setting”.

Note :

- Unit Setting : do setting.

- User’s Comment : insert comment /

notes

- Back : to go back to previous menu.

144

145.

DOWNLOAD PLM II BY USING LAPTOPKey Switch

OFF

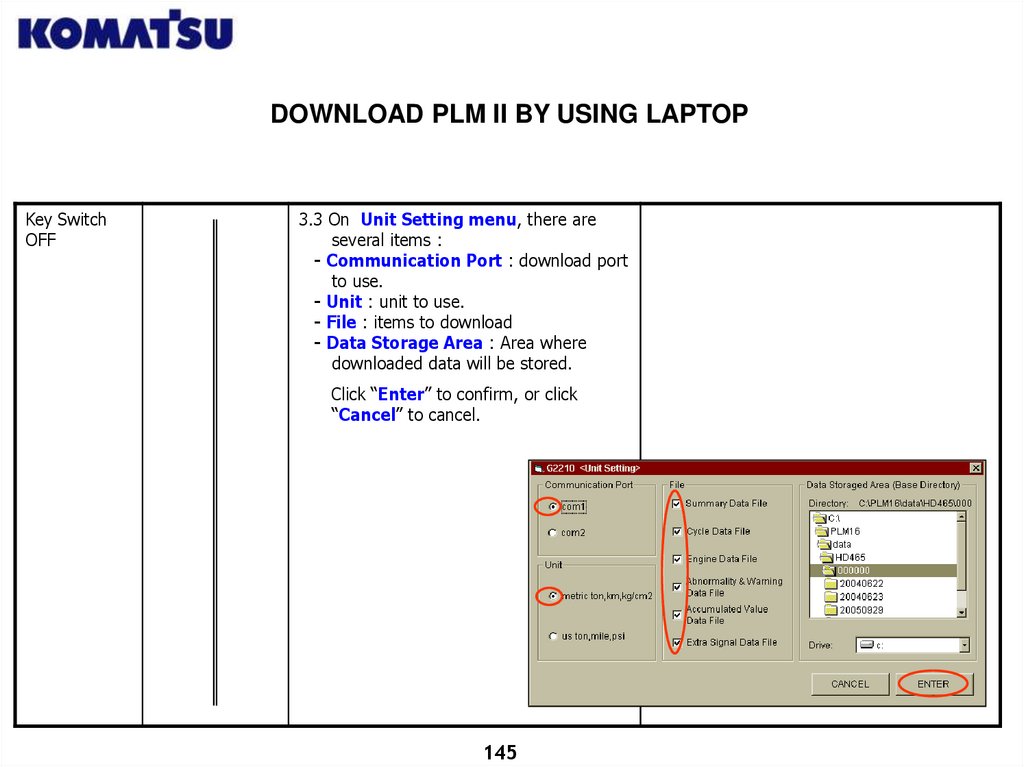

3.3 On Unit Setting menu, there are

several items :

- Communication Port : download port

to use.

- Unit : unit to use.

- File : items to download

- Data Storage Area : Area where

downloaded data will be stored.

Click “Enter” to confirm, or click

“Cancel” to cancel.

145

146.

DOWNLOADING PLM II USING LAPTOPKey Switch

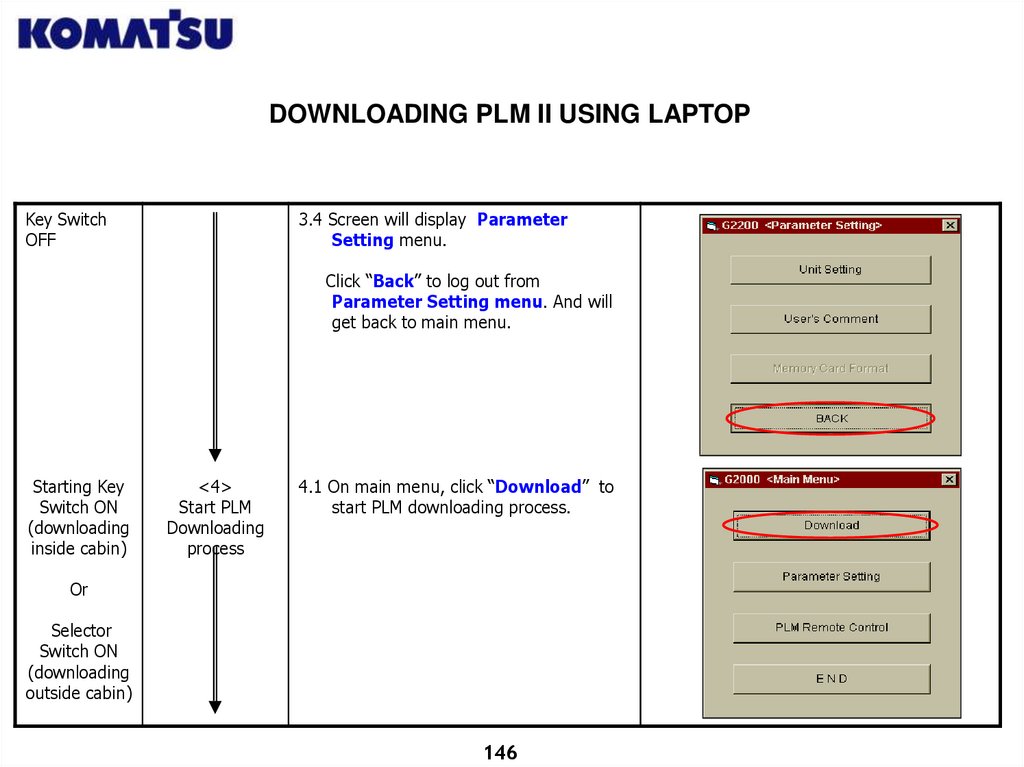

OFF

3.4 Screen will display Parameter

Setting menu.

Click “Back” to log out from

Parameter Setting menu. And will

get back to main menu.

Starting Key

Switch ON

(downloading

inside cabin)

<4>

Start PLM

Downloading

process

4.1 On main menu, click “Download” to

start PLM downloading process.

Or

Selector

Switch ON

(downloading

outside cabin)

146

147.

DOWNLOADING PLM II USING LAPTOPStarting Key

Switch ON

(downloading

inside cabin)

Or

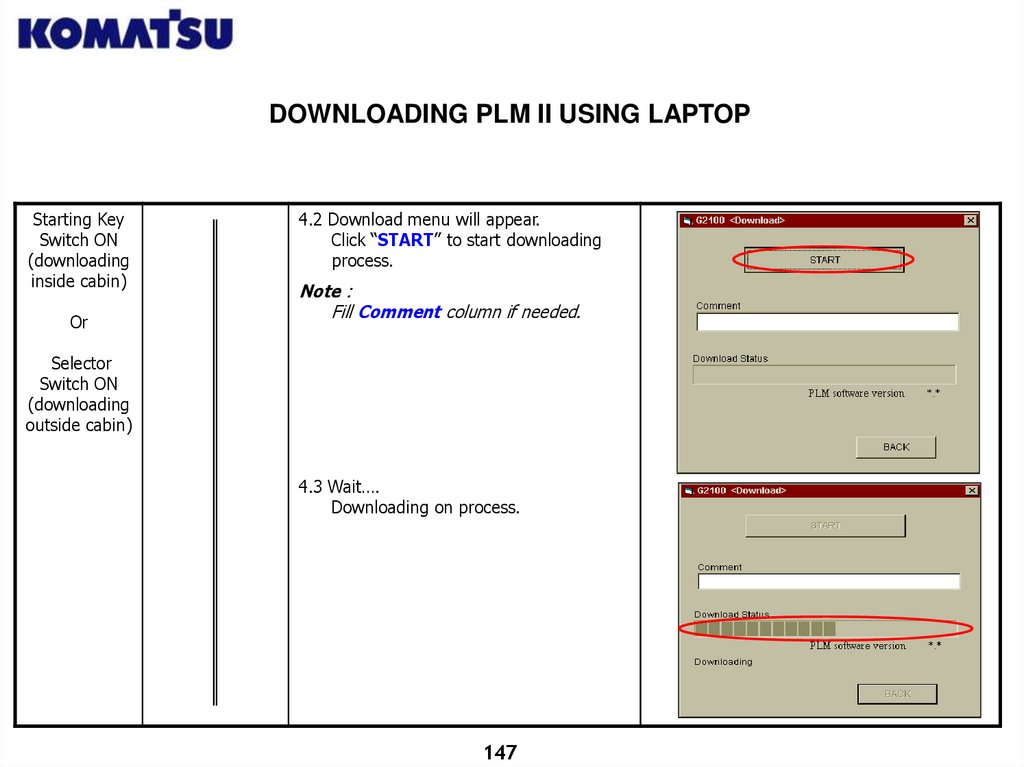

4.2 Download menu will appear.

Click “START” to start downloading

process.

Note :

Fill Comment column if needed.

Selector

Switch ON

(downloading

outside cabin)

4.3 Wait….

Downloading on process.

147

148.

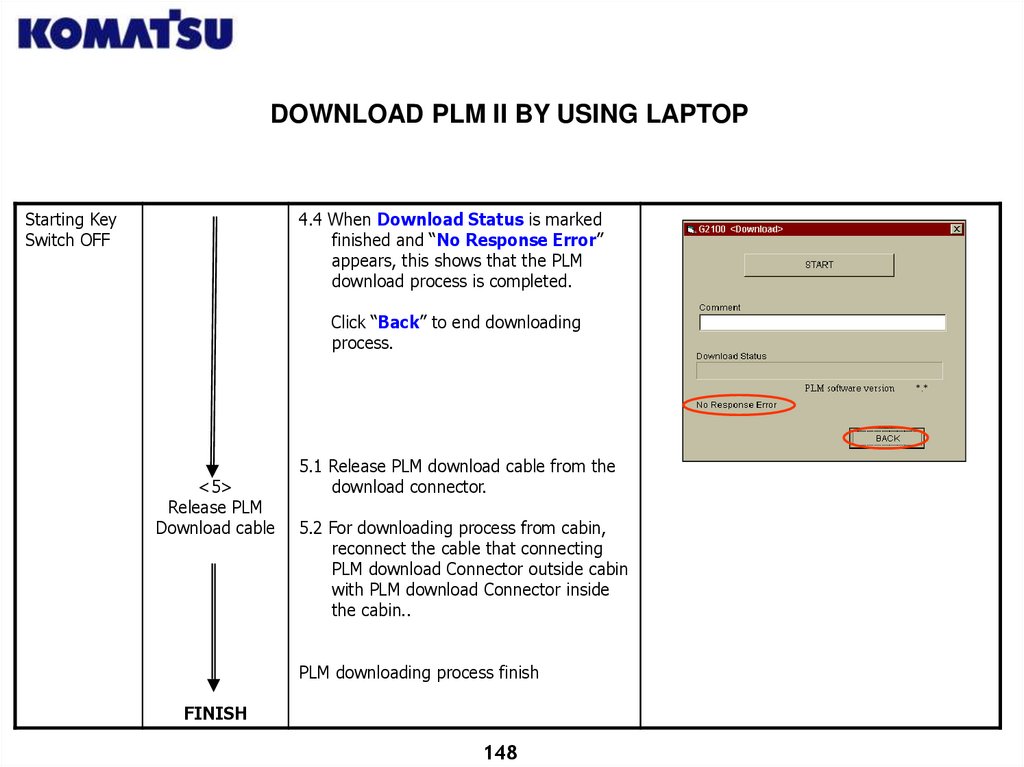

DOWNLOAD PLM II BY USING LAPTOPStarting Key

Switch OFF

4.4 When Download Status is marked

finished and “No Response Error”

appears, this shows that the PLM

download process is completed.

Click “Back” to end downloading

process.

<5>

Release PLM

Download cable

5.1 Release PLM download cable from the

download connector.

5.2 For downloading process from cabin,

reconnect the cable that connecting

PLM download Connector outside cabin

with PLM download Connector inside

the cabin..

PLM downloading process finish

FINISH

148

149.

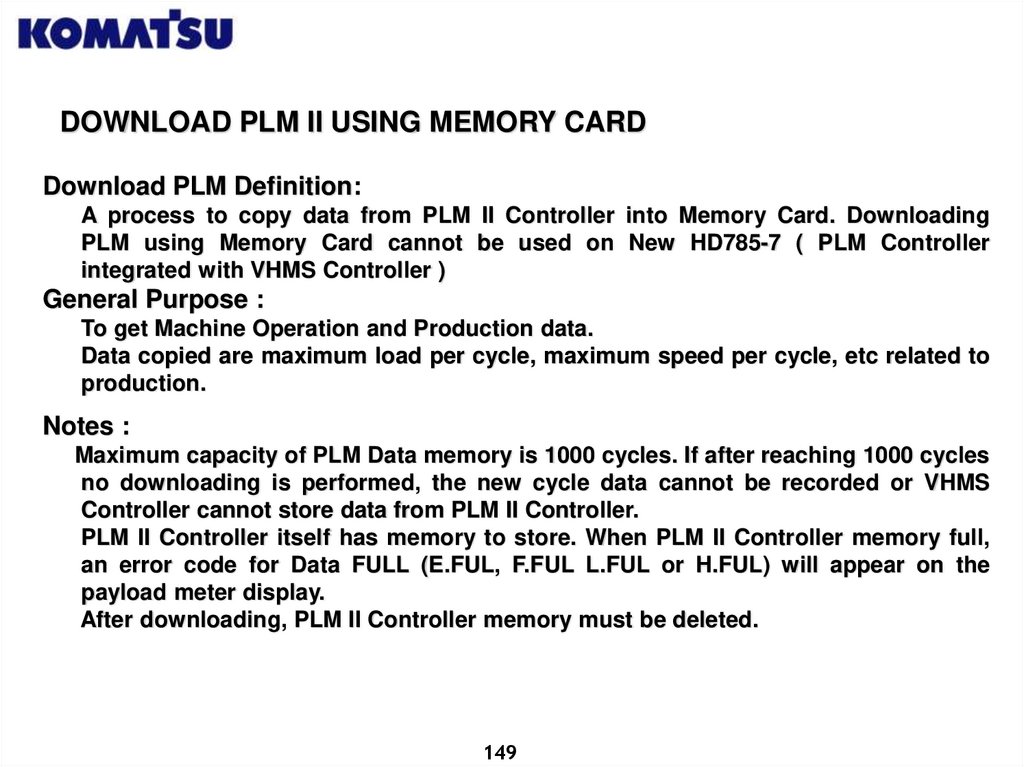

DOWNLOAD PLM II USING MEMORY CARDDownload PLM Definition:

A process to copy data from PLM II Controller into Memory Card. Downloading

PLM using Memory Card cannot be used on New HD785-7 ( PLM Controller

integrated with VHMS Controller )

General Purpose :

To get Machine Operation and Production data.

Data copied are maximum load per cycle, maximum speed per cycle, etc related to

production.

Notes :

Maximum capacity of PLM Data memory is 1000 cycles. If after reaching 1000 cycles

no downloading is performed, the new cycle data cannot be recorded or VHMS

Controller cannot store data from PLM II Controller.

PLM II Controller itself has memory to store. When PLM II Controller memory full,

an error code for Data FULL (E.FUL, F.FUL L.FUL or H.FUL) will appear on the

payload meter display.

After downloading, PLM II Controller memory must be deleted.

149

150.

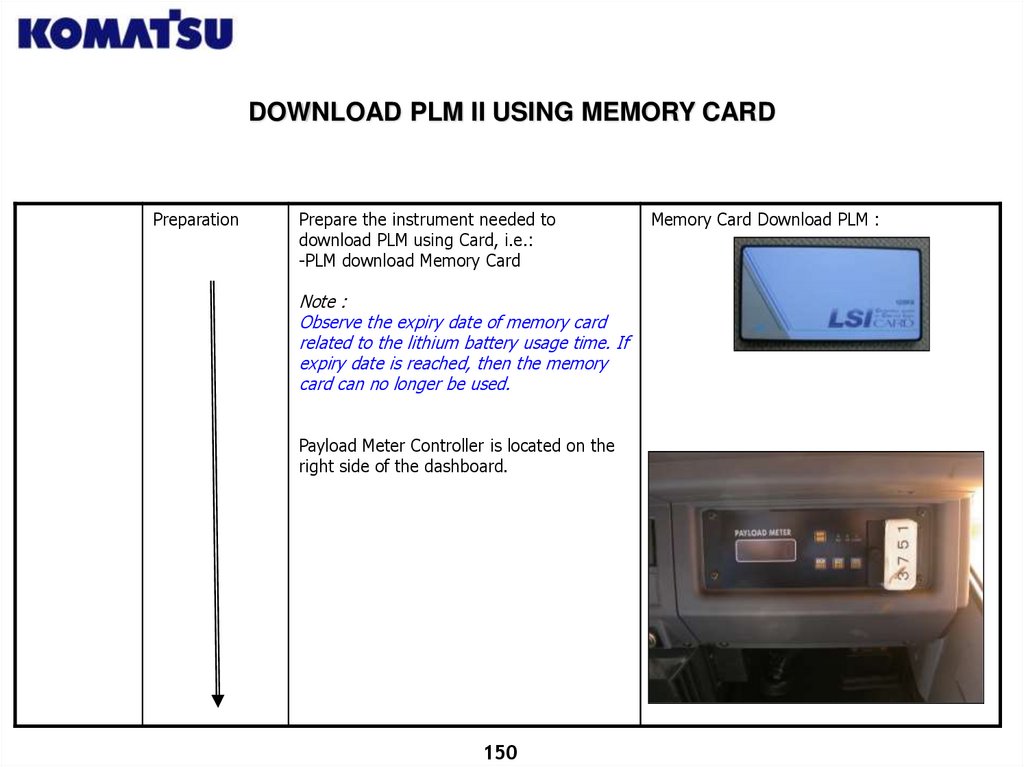

DOWNLOAD PLM II USING MEMORY CARDPreparation

Prepare the instrument needed to

download PLM using Card, i.e.:

-PLM download Memory Card

Note :

Observe the expiry date of memory card

related to the lithium battery usage time. If

expiry date is reached, then the memory

card can no longer be used.

Payload Meter Controller is located on the

right side of the dashboard.

150

Memory Card Download PLM :

151.

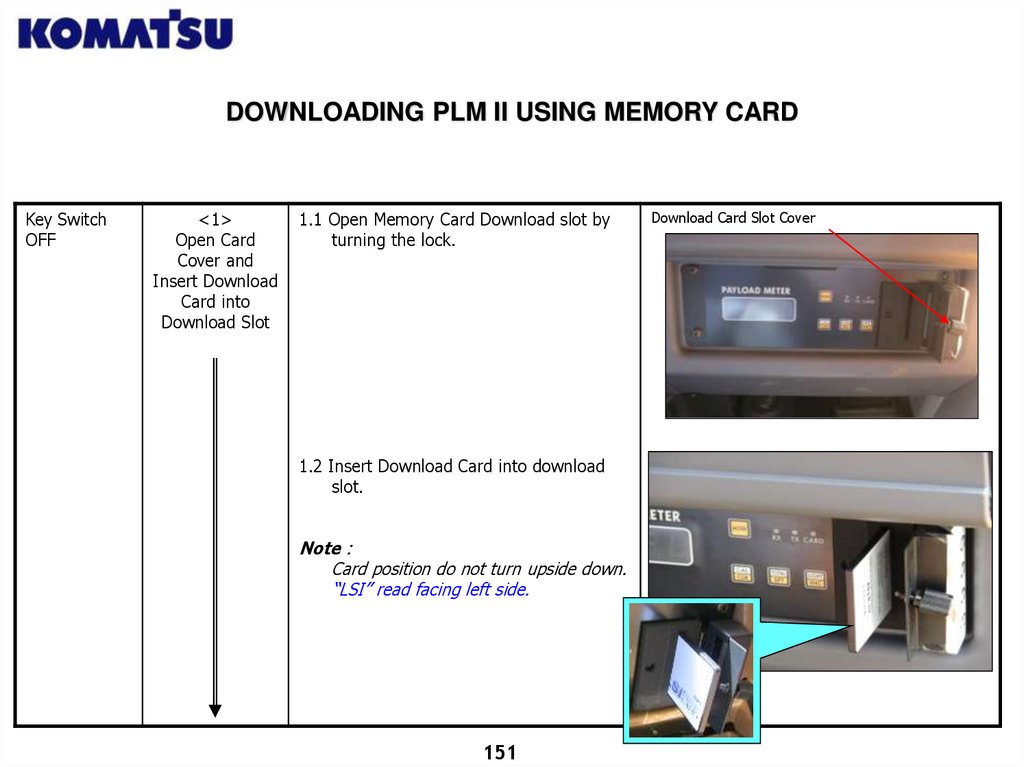

DOWNLOADING PLM II USING MEMORY CARDKey Switch

OFF

<1>

Open Card

Cover and

Insert Download

Card into

Download Slot

1.1 Open Memory Card Download slot by

turning the lock.

1.2 Insert Download Card into download

slot.

Note :

Card position do not turn upside down.

“LSI” read facing left side.

151

Download Card Slot Cover

152.

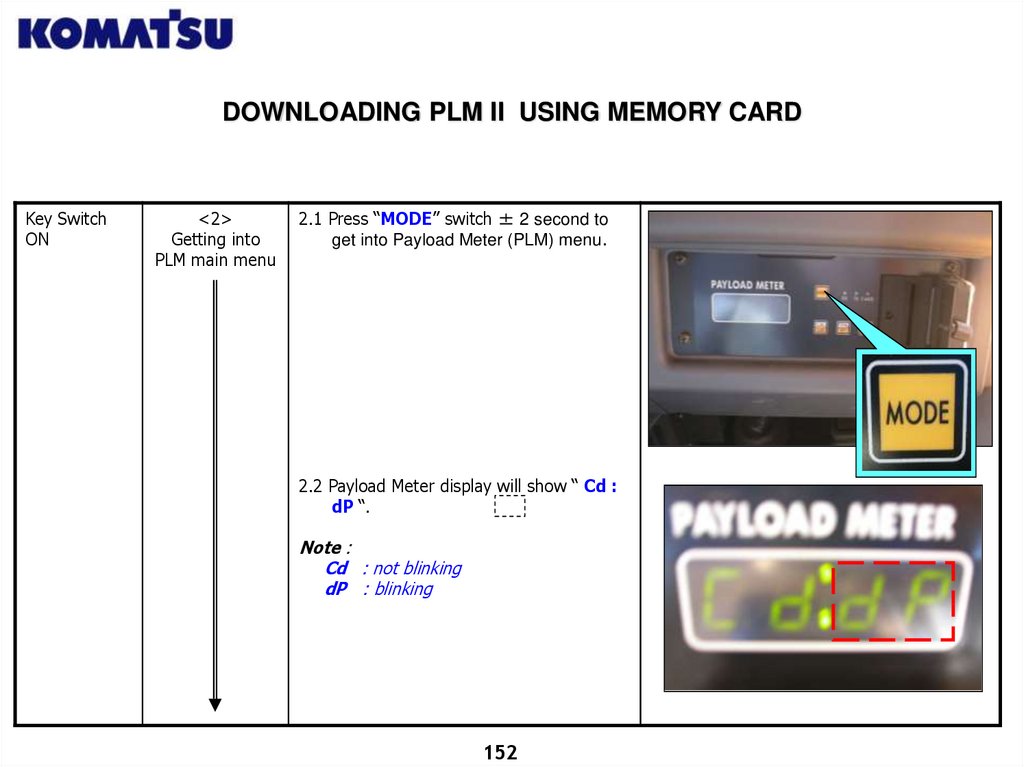

DOWNLOADING PLM II USING MEMORY CARDKey Switch

ON

<2>

Getting into

PLM main menu

2.1 Press “MODE” switch ± 2 second to

get into Payload Meter (PLM) menu.

2.2 Payload Meter display will show “ Cd :

dP “.

Note :

Cd : not blinking

dP : blinking

152

153.

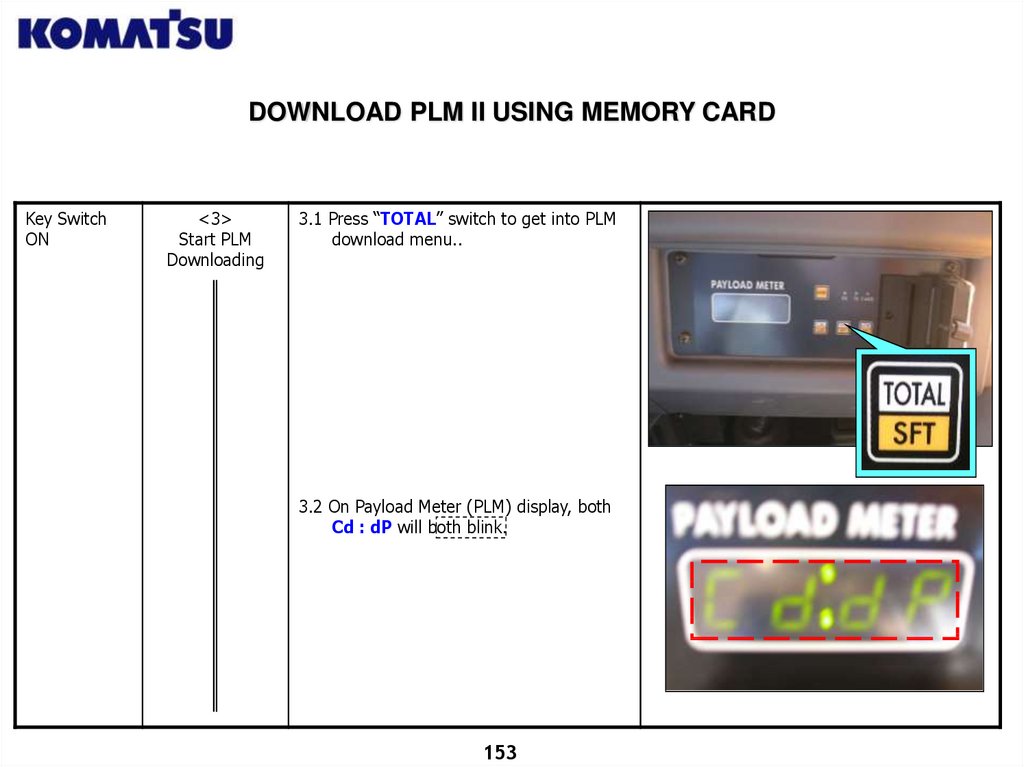

DOWNLOAD PLM II USING MEMORY CARDKey Switch

ON

<3>

Start PLM

Downloading

3.1 Press “TOTAL” switch to get into PLM

download menu..

3.2 On Payload Meter (PLM) display, both

Cd : dP will both blink.

153

154.

DOWNLOAD PLM II USING MEMORY CARDKey Switch

ON

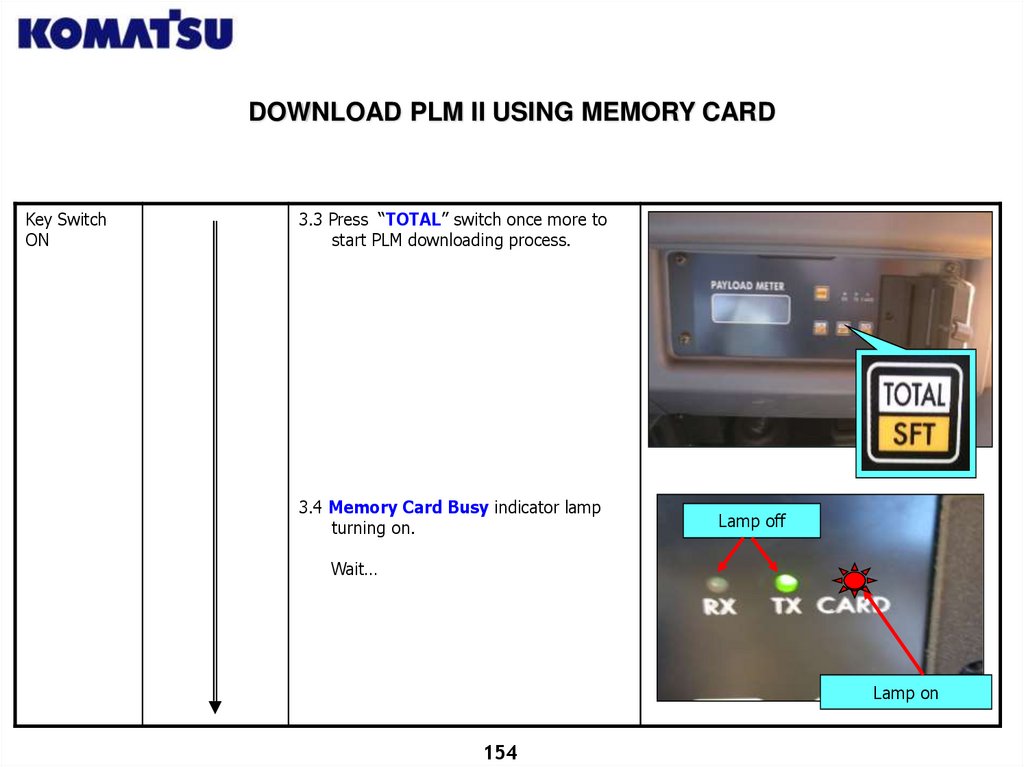

3.3 Press “TOTAL” switch once more to

start PLM downloading process.

3.4 Memory Card Busy indicator lamp

turning on.

Lamp off

Wait…

Lamp on

154

155.

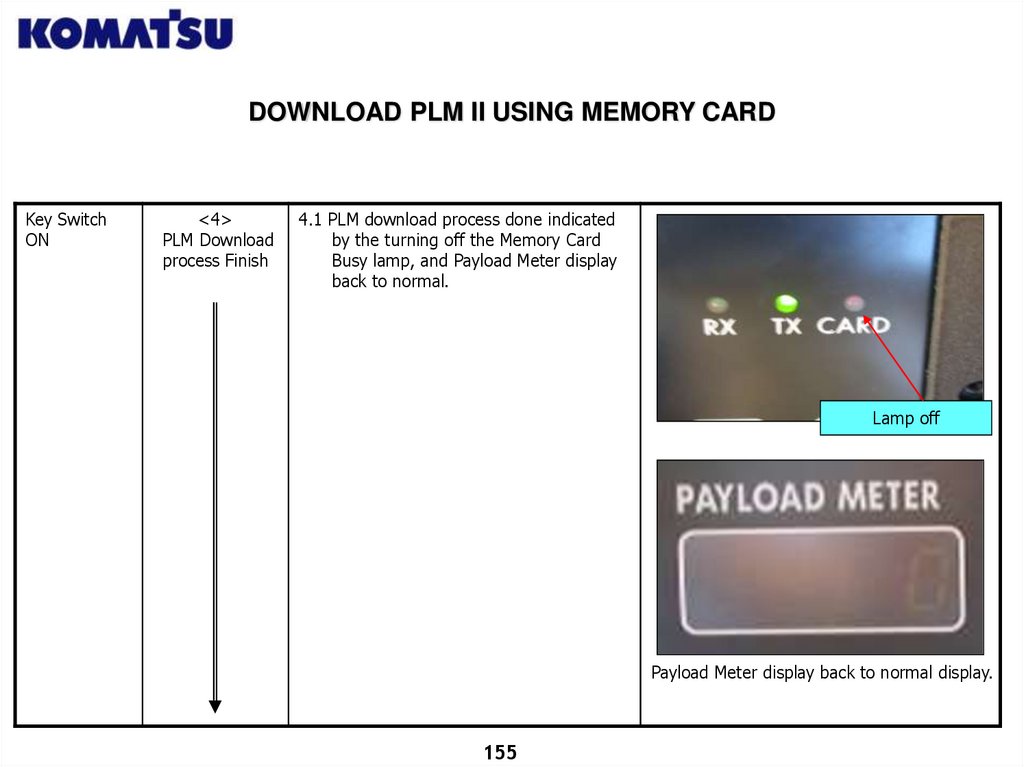

DOWNLOAD PLM II USING MEMORY CARDKey Switch

ON

<4>

PLM Download

process Finish

4.1 PLM download process done indicated

by the turning off the Memory Card

Busy lamp, and Payload Meter display

back to normal.

Lamp off

Payload Meter display back to normal display.

155

156.

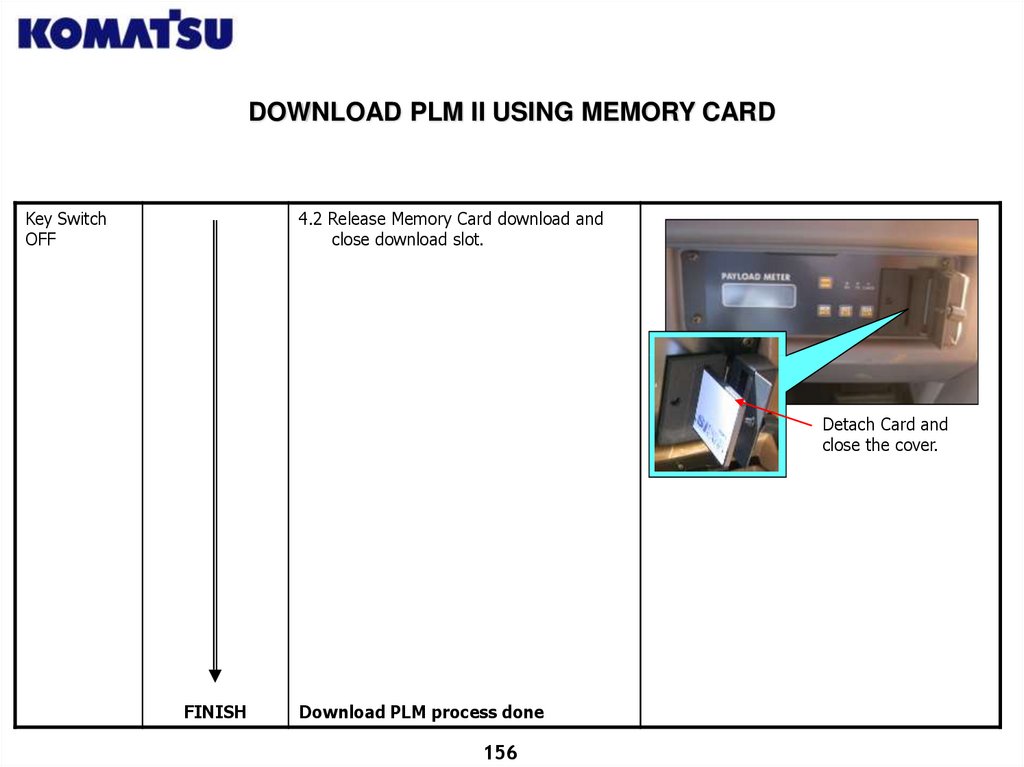

DOWNLOAD PLM II USING MEMORY CARDKey Switch

OFF

4.2 Release Memory Card download and

close download slot.

Detach Card and

close the cover.

FINISH

Download PLM process done

156

157.

DOWNLOADING PLM DATA FROM MEMORY CARD TO LAPTOP/DESKTOPUSING CARD READER

Download PLM from Memory Card definition:

A process to copy data from LSI KOMATSU Memory Card into

Laptop or Desktop using KOMATSU Card Reader tools.

General Purpose :

To get machine operation and production data.

Data copied is maximum load data per cycle, maximum speed per

cycle, etc which connected with production.

Note :

LSI Komatsu Memory Card capacity is only 128 kb, so one Memory

Card is only effective for only one unit.

KOMATSU Card Reader & KOMATSU LSI Memory Card (built in

lithium battery with expired date ) is a patent of KOMATSU .

This method is not applicable if PLM set to the unit is PLM I (printer

type) .

157

158.

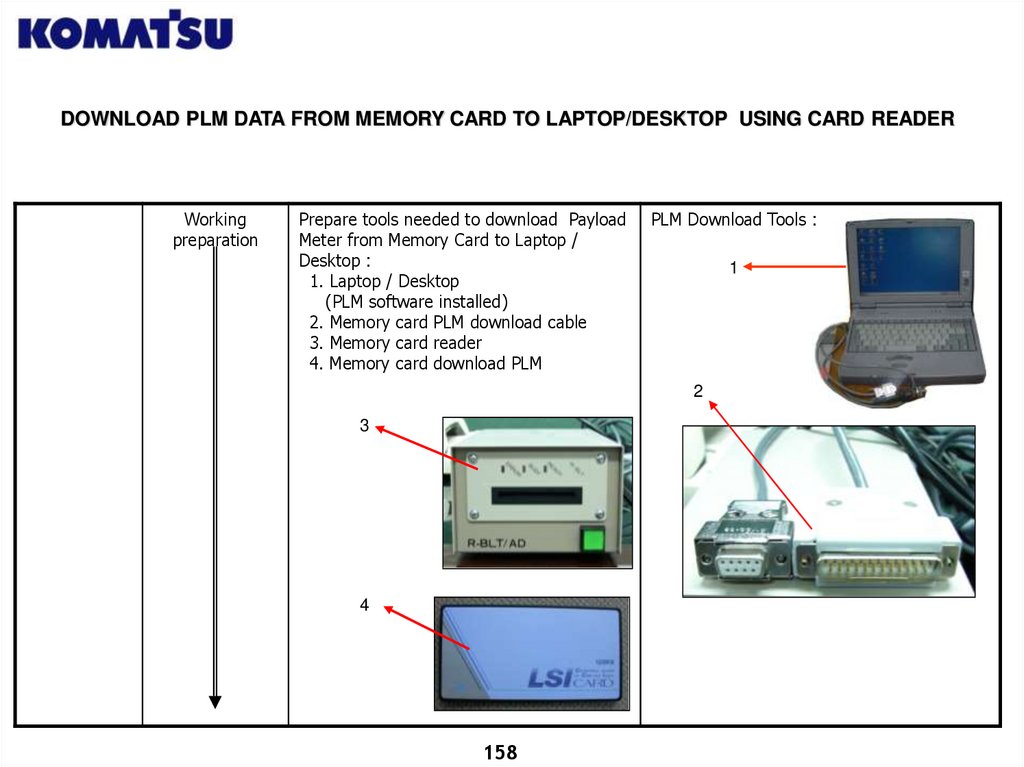

DOWNLOAD PLM DATA FROM MEMORY CARD TO LAPTOP/DESKTOP USING CARD READERWorking

preparation

Prepare tools needed to download Payload

Meter from Memory Card to Laptop /

Desktop :

1. Laptop / Desktop

(PLM software installed)

2. Memory card PLM download cable

3. Memory card reader

4. Memory card download PLM

PLM Download Tools :

1

2

3

4

158

159.

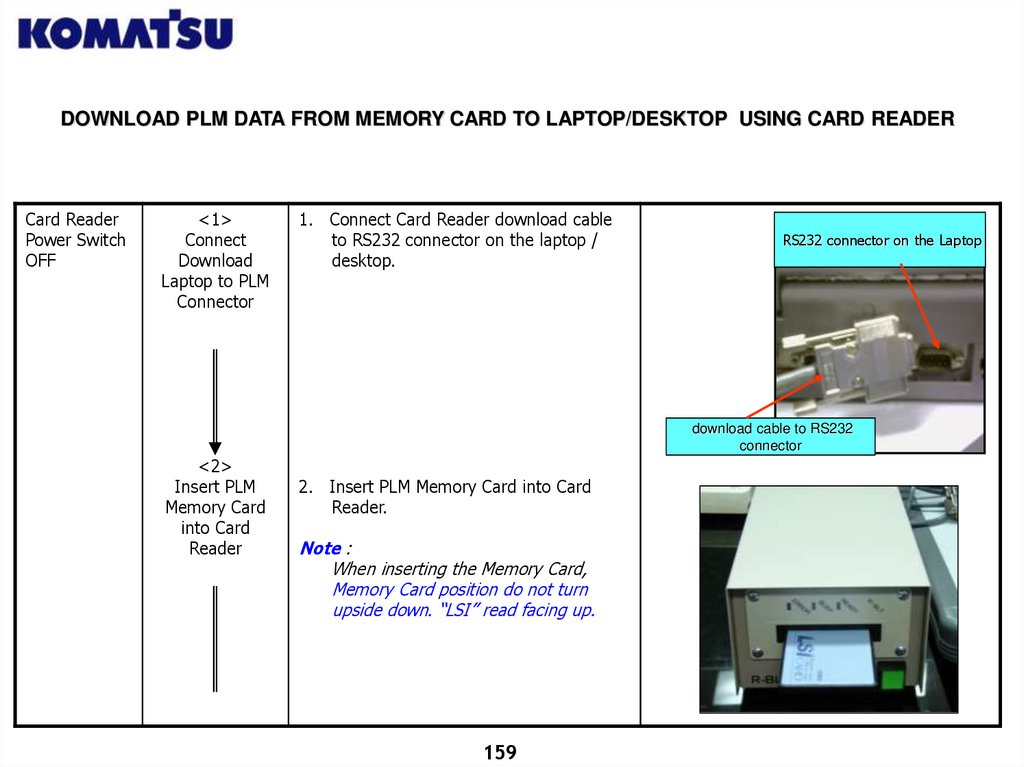

DOWNLOAD PLM DATA FROM MEMORY CARD TO LAPTOP/DESKTOP USING CARD READERCard Reader

Power Switch

OFF

<1>

Connect

Download

Laptop to PLM

Connector

1. Connect Card Reader download cable

to RS232 connector on the laptop /

desktop.

RS232 connector on the Laptop

download cable to RS232

connector

<2>

Insert PLM

Memory Card

into Card

Reader

2. Insert PLM Memory Card into Card

Reader.

Note :

When inserting the Memory Card,

Memory Card position do not turn

upside down. “LSI” read facing up.

159

160.

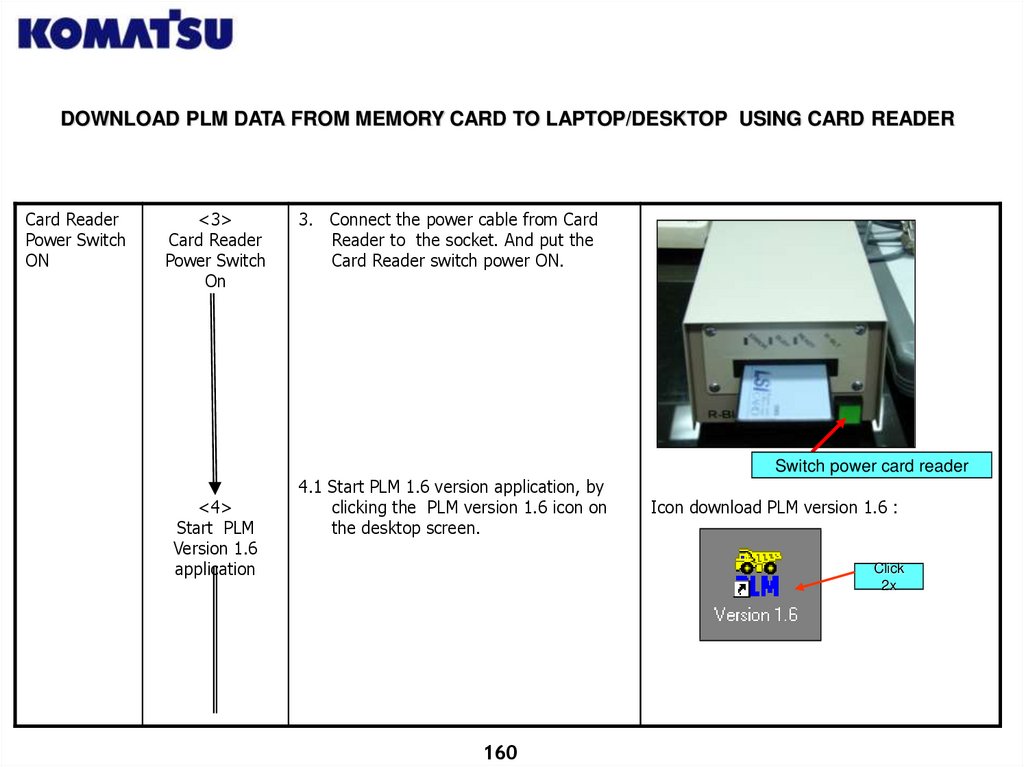

DOWNLOAD PLM DATA FROM MEMORY CARD TO LAPTOP/DESKTOP USING CARD READERCard Reader

Power Switch

ON

<3>

Card Reader

Power Switch

On

3. Connect the power cable from Card

Reader to the socket. And put the

Card Reader switch power ON.

Switch power card reader

<4>

Start PLM

Version 1.6

application

4.1 Start PLM 1.6 version application, by

clicking the PLM version 1.6 icon on

the desktop screen.

Icon download PLM version 1.6 :

Click

2x

160

161.

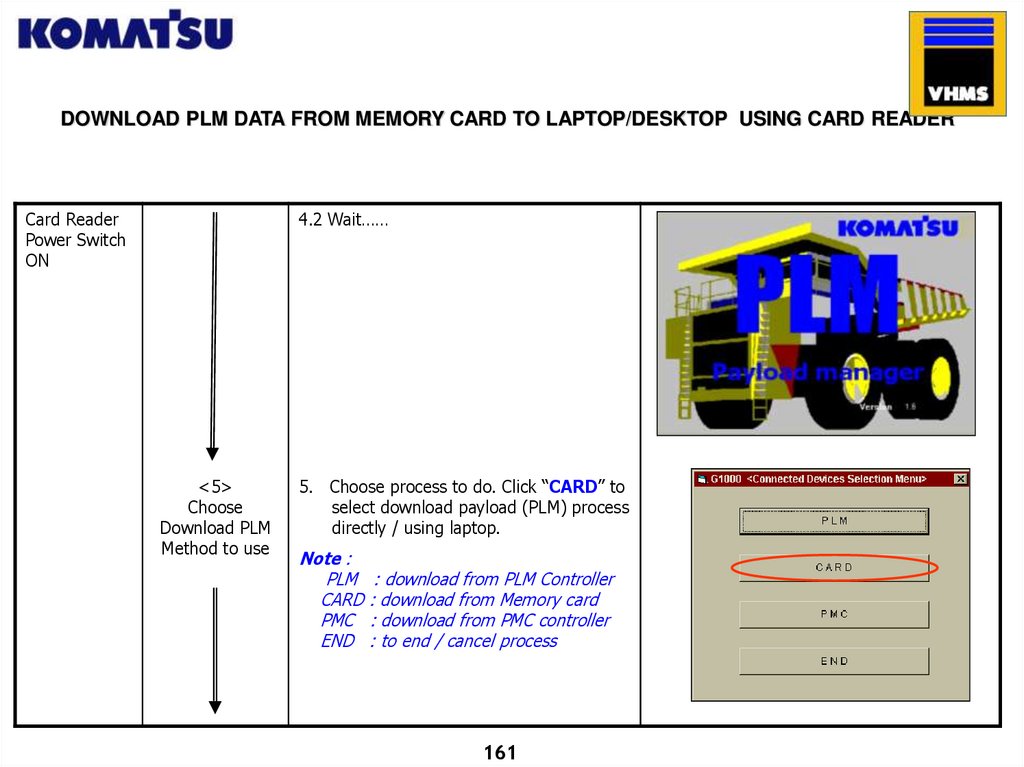

DOWNLOAD PLM DATA FROM MEMORY CARD TO LAPTOP/DESKTOP USING CARD READERCard Reader

Power Switch

ON

4.2 Wait……

<5>

Choose

Download PLM

Method to use

5. Choose process to do. Click “CARD” to

select download payload (PLM) process

directly / using laptop.

Note :

PLM

CARD

PMC

END

: download from PLM Controller

: download from Memory card

: download from PMC controller

: to end / cancel process

161

162.

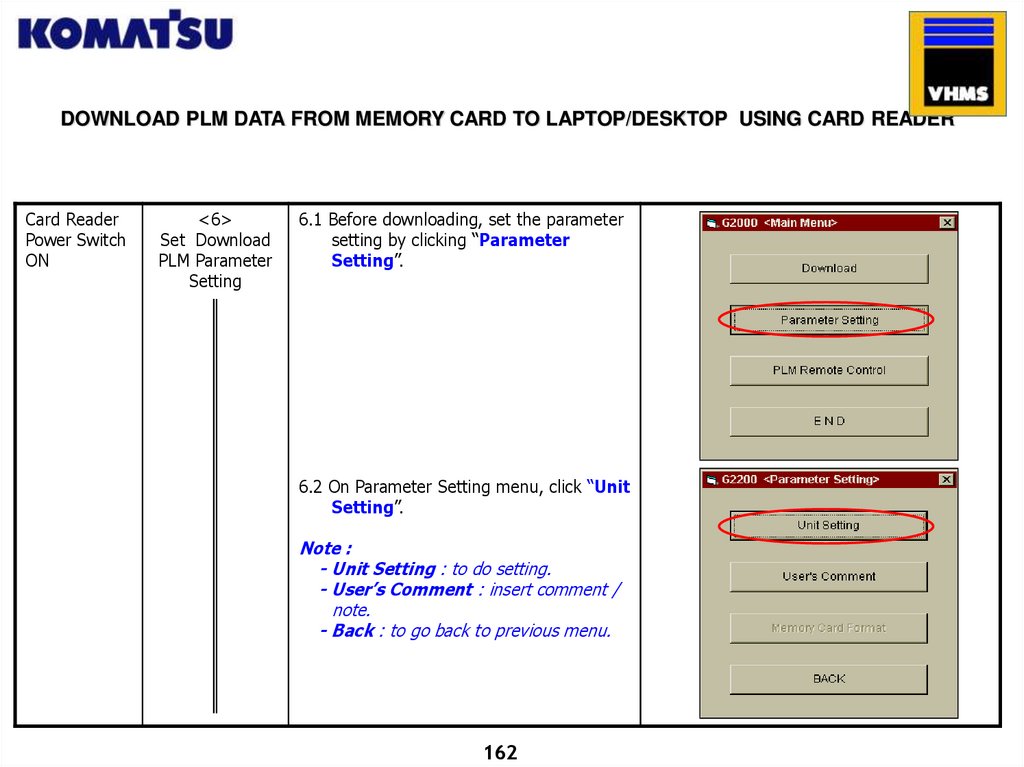

DOWNLOAD PLM DATA FROM MEMORY CARD TO LAPTOP/DESKTOP USING CARD READERCard Reader

Power Switch

ON

<6>

Set Download

PLM Parameter

Setting

6.1 Before downloading, set the parameter

setting by clicking “Parameter

Setting”.

6.2 On Parameter Setting menu, click “Unit

Setting”.

Note :

- Unit Setting : to do setting.

- User’s Comment : insert comment /

note.

- Back : to go back to previous menu.

162

163.

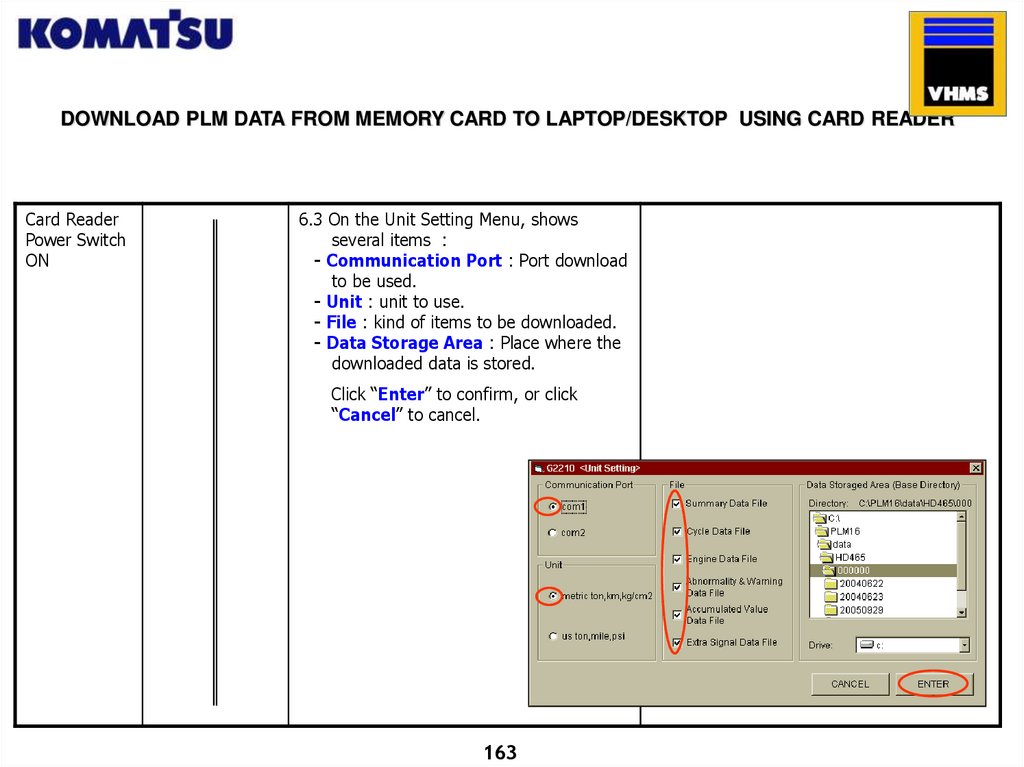

DOWNLOAD PLM DATA FROM MEMORY CARD TO LAPTOP/DESKTOP USING CARD READERCard Reader

Power Switch

ON

6.3 On the Unit Setting Menu, shows

several items :

- Communication Port : Port download

to be used.

- Unit : unit to use.

- File : kind of items to be downloaded.

- Data Storage Area : Place where the

downloaded data is stored.

Click “Enter” to confirm, or click

“Cancel” to cancel.

163

164.

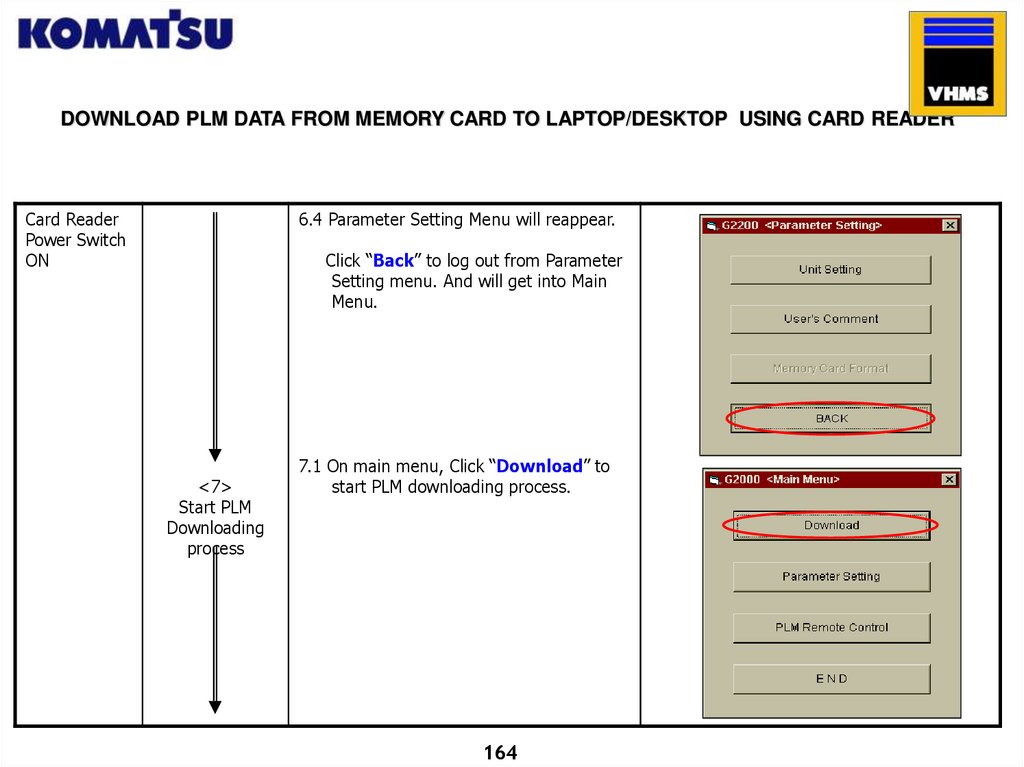

DOWNLOAD PLM DATA FROM MEMORY CARD TO LAPTOP/DESKTOP USING CARD READERCard Reader

Power Switch

ON

6.4 Parameter Setting Menu will reappear.

Click “Back” to log out from Parameter

Setting menu. And will get into Main

Menu.

<7>

Start PLM

Downloading

process

7.1 On main menu, Click “Download” to

start PLM downloading process.

164

165.

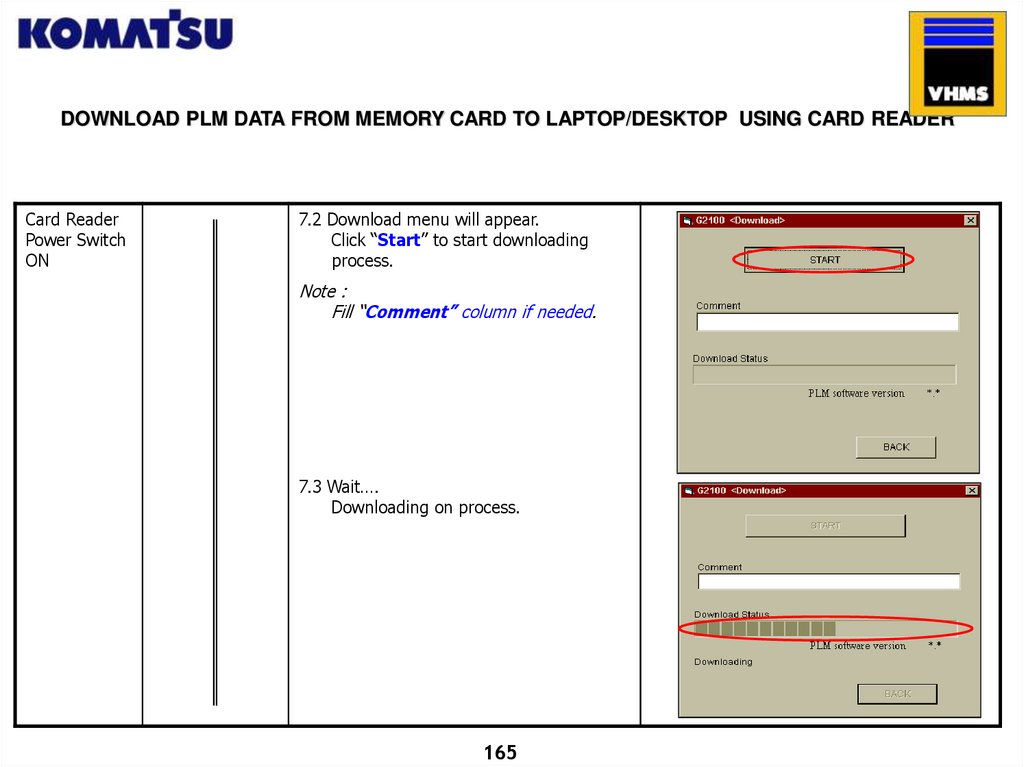

DOWNLOAD PLM DATA FROM MEMORY CARD TO LAPTOP/DESKTOP USING CARD READERCard Reader

Power Switch

ON

7.2 Download menu will appear.

Click “Start” to start downloading

process.

Note :

Fill “Comment” column if needed.

7.3 Wait….

Downloading on process.

165

166.

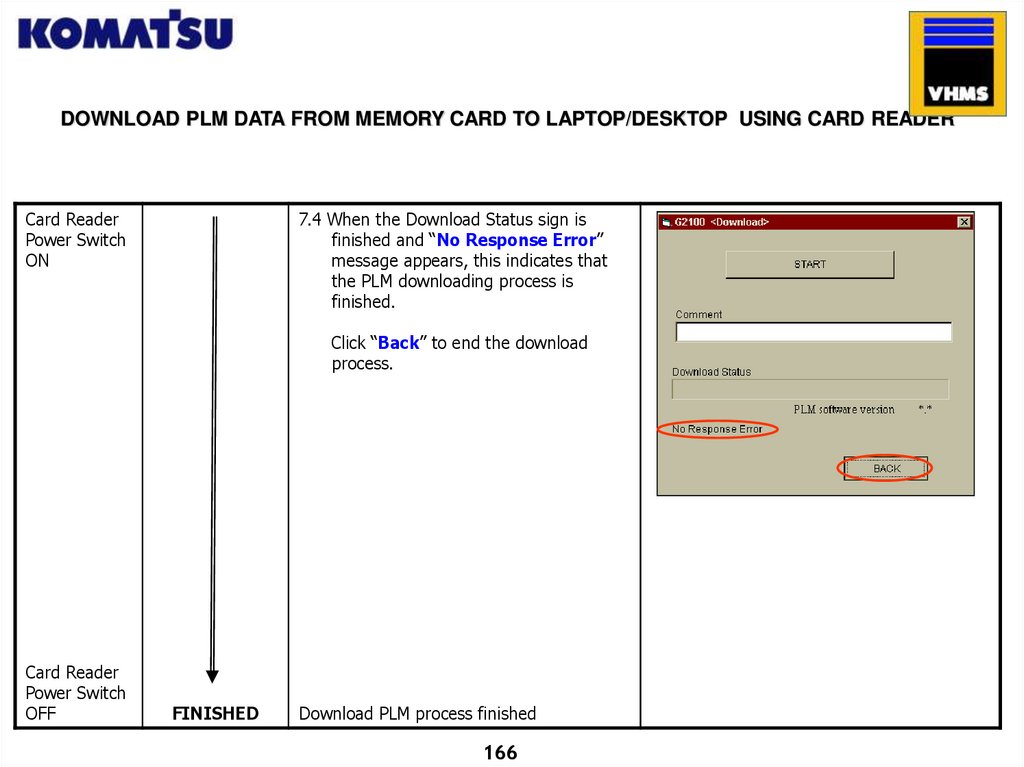

DOWNLOAD PLM DATA FROM MEMORY CARD TO LAPTOP/DESKTOP USING CARD READERCard Reader

Power Switch

ON

7.4 When the Download Status sign is

finished and “No Response Error”

message appears, this indicates that

the PLM downloading process is

finished.

Click “Back” to end the download

process.

Card Reader

Power Switch

OFF

FINISHED

Download PLM process finished

166

167.

POSTSCRIPTThis guidebook is originally prepared

by PT. United Tractors, Komatsu

distributor in Indonesia and reviewed

by PT. Komatsu Marketing & Support

Indonesia, in order to share our

experience of VHMS system among

Komatsu subsidiaries and distributors

in the world.

PT UNITED TRACTORS Tbk.

SERVICE DIVISION

This book describes in details the work

process starting from Down Load

process up to Technical Analysis

process.

With the launching of this book, it is

expected that every mechanic is able

to optimally utilize all benefits from

Pay Load Meter instrument & VHMS

Technology.

In line with the fast growing

technology reflected by Komatsu’s

newest products and Application

Improvement, we welcome inputs and

findings in the Continuous

Improvement and Mechanic’s

Competencies acceleration schemes.