Similar presentations:

Unipharma - professional pharmaceutical wholesale company

1. COMPANY INTRODUCTION for Evalar 08th October 2019

UNIPHARMA Introduction - 10th May 20182.

Company overviewSTRATEGY

UNIPHARMA - Professional pharmaceutical wholesale company which is driven by its

customer = pharmacist Is to keep the No.1 position in every well-run pharmacy

that means No.1 among the Slovak wholesale pharmaceutical distributors.

By continual achievement of following goals :

- having the best sortiment, service, seriousness, serveability, stability

-

keeping acceptable profitability for it´s shareholders

continuously building a company of more generations of and for pharmaceutists

UNIPHARMA Introduction - 20th February 2019

2

3.

Company overview – Company historyUNIPHARMA (UP) was established 11.11. 1992 as a pharmaceutical

company with main focus on the wholesale distribution of

pharmaceutical goods in Slovakia market

1992 – 1995 Unipharma Ltd.

Since 1995 is Unipharma joint stock company

CEO / Chairman of the board of directors RNDr. Tomislav Jurik, CSc.

Unipharma basic philosophy is to supports its clients – public

pharmaceutists, of whom many are at the same time shareholders (806)

of the company.

The founding

Unipharma

of Unipharma ltd.

is transformed to

Business started

a joint-stock

at very small building company, moving

in Kos rented by the

to bigger rented

(bunder - pharmacist

building

Mr. Tomislav Jurik

in Prievidza

(actual Chairman

of the board & CEO)

Unipharma

accomplished

building of its

very first own

Distribution Center

in Bojnice

Unipharma

accomplished

building of

an affiliate

Distribution Center

in Bratislava

Unipharma

bought the Hospital

Kosice-Saca as.

1st private

Unipharma

accomplished

building

of an affiliate

Distribution

Center

in Prešov

Unipharma

Unipharma bought

bought the

the Hospital

Hospital

Bánovce

Handlová - 2nd 3rd private hospital,

private hospital, ltd

ltd.

UNIPHARMA Introduction - 20th February 2019

Unipharma build

its

own Medical Diagnostic Centre

- Uniklinika of

Cardinal

Korec in Prievidza

YEARS

3

4.

Company overview – annual salesAnnual sales was 485,5 mil. EUR (2018)

UNIPHARMA Introduction - 20th February 2019

4

5.

Company overview – Company values = 5xSservice

sortiment

stability

seriousness

reliability

UNIPHARMA Introduction - 20th February 2019

5

6.

UNIPHARMA GROUPCentrála Unipharmy

ODS BOJNICE

UNIKLINIKA

kardinála Korca

Prievidza

ODS PREŠOV

APOTHEKE A.S.

Bratislava

UNIPOLIKLINIKA

Dubnica nad Váhom

UNICENTRUM

BOJNICE

ODS BRATISLAVA

UNIPHARMA Introduction - 20th February 2019

6

7.

UNIPHARMA IntroductionNational information center of

Slovak republic issued the

Certificate

„Reliable partner”

in public procurement

(2014 & 2016 & 2017)

UNIPHARMA Introduction - 20th February 2019

7

8.

PortfolioUNIPHARMA PORTFÓLIO PRODUKTOV

1.

Drugs : 6 618 SKU´s

2.

Additional products : 9 277 SKU´s

3.

Non-registered drugs: 157 SKU´s

4.

Medical devices : 8 754 SKU´s

5.

Veterinary drugs : 824 SKU´s

UNIPHARMA Proposal and Quotation details

8

9.

Marketing activities – „Lekárnik“Scientific magazine for pharmasists and UNIPHARMA clients

UNIPHARMA Introduction - 20th February 2019

9

10.

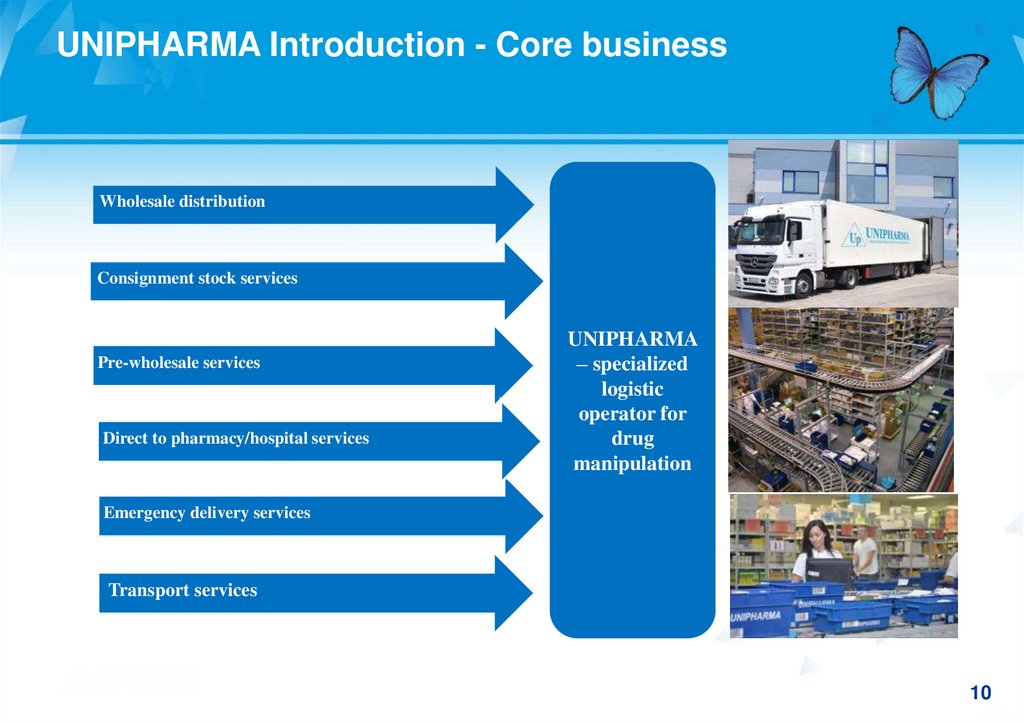

UNIPHARMA Introduction - Core businessWholesale distribution

Consignment stock services

Pre-wholesale services

Direct to pharmacy/hospital services

UNIPHARMA

– specialized

logistic

operator for

drug

manipulation

Emergency delivery services

Transport services

10

UNIPHARMA Introduction - 20th February 2019

10

11.

„Plus lekáreň“ associationNumber of partner pharmacies:

508

UNIPHARMA Introduction - 20th February 2019

11

12.

„Plus lekáreň“ associationUNIPHARMA Introduction - 20th February 2019

12

13.

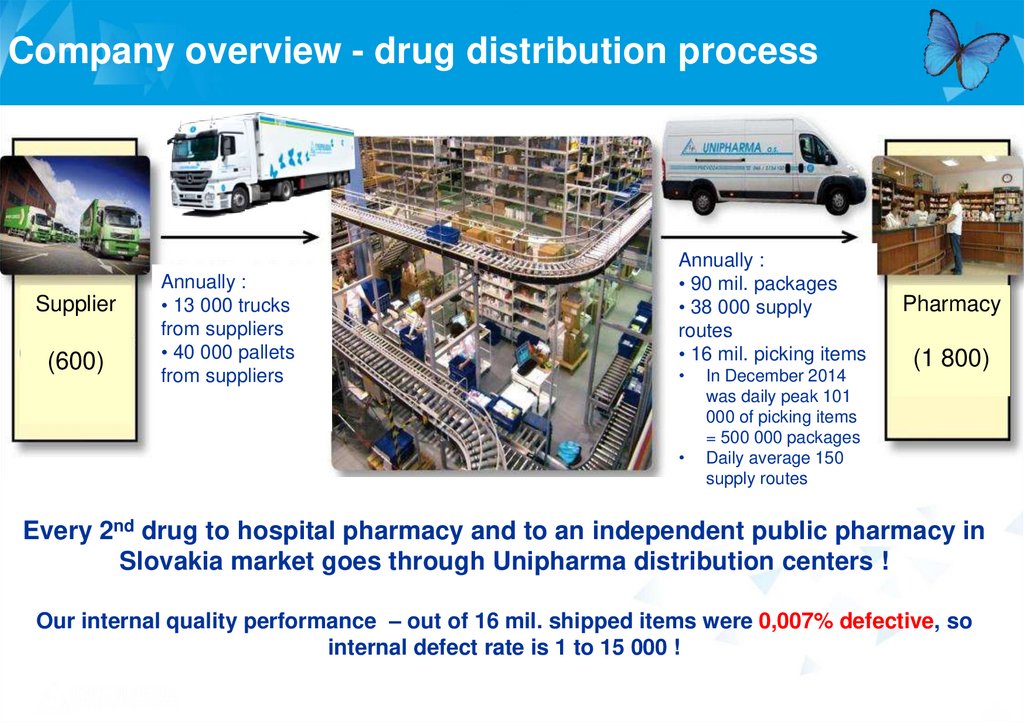

Company overview - drug distribution processSupplier

(600)

Annually :

• 13 000 trucks

from suppliers

• 40 000 pallets

from suppliers

Annually :

• 90 mil. packages

• 38 000 supply

routes

• 16 mil. picking items

In December 2014

was daily peak 101

000 of picking items

= 500 000 packages

Daily average 150

supply routes

Pharmacy

(1 800)

Every 2nd drug to hospital pharmacy and to an independent public pharmacy in

Slovakia market goes through Unipharma distribution centers !

Our internal quality performance – out of 16 mil. shipped items were 0,007% defective, so

internal defect rate is 1 to 15 000 !

UNIPHARMA Introduction - 20th February 2019

13

14.

Warehousing – Distribution centersRNDr. Igor Šuňal, PhD.

Distribution division director &

ODS Bojnice

Headquarters UNIPHARMA ODS Bojnice (1999)

PharmDr. Ondrej

Takáč

ODS Prešov Director

Bc. Marcel Svrček

ODS Bratislava Director

Affiliate Bratislava (2002)

Affiliate Prešov (2004)

Total warehouses capacity : 13 000 pallets positions and 20 000 square metres.

UNIPHARMA Introduction - 20th February 2019

14

15.

NEW WAREHOUSE IN BOJNICEUNIPHARMA Introduction - 20th February 2019

15

15

16.

Warehousing – Smoooth process flowAVERAGE LEAD-TIME FROM RECEIVING CUSTOMER ORDER UNTIL SHIPMENT IS 40 MINUTES !

UNIPHARMA Introduction - 20th February 2019

16

17.

Warehousing – receiving inspection processGOODS-IN DOCK

TEMPERATURE

INSPECTION

VISUAL INSPECTION

Receiving inspection

• Warehouse operator performs receiving inspection and

together with driver of supplier check following :

• Basic data: supplier, type, quantity

• Temperature inspection and visual inspection (no

damages etc.)

• Release of received goods is performed by QP

UNIPHARMA Introduction - 20th February 2019

17

18.

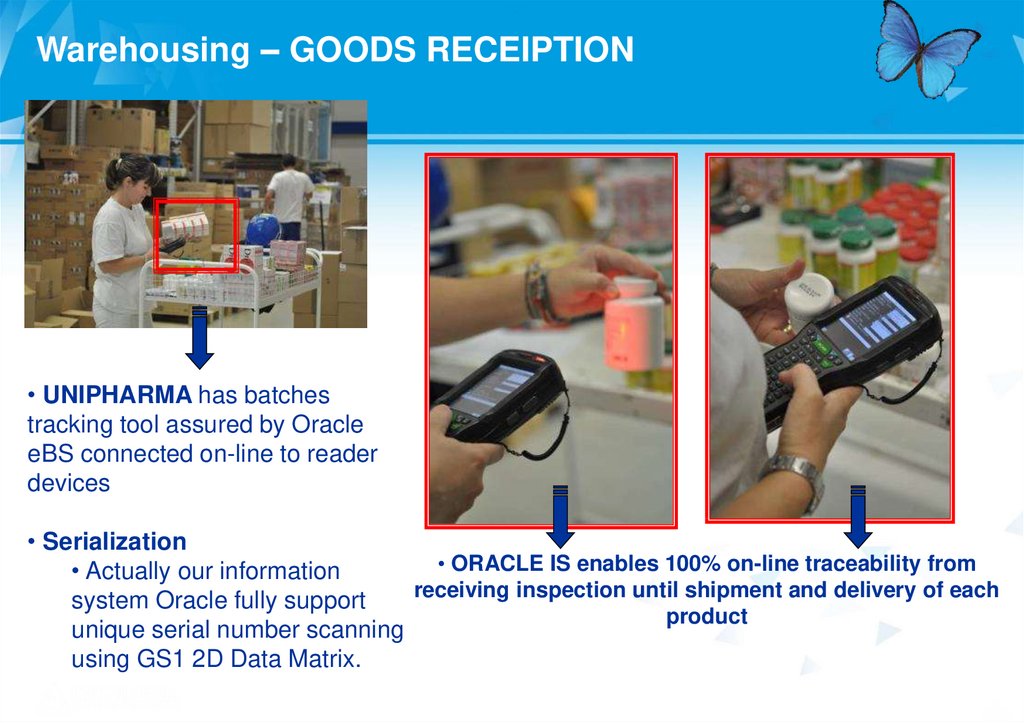

Warehousing – GOODS RECEIPTION• UNIPHARMA has batches

tracking tool assured by Oracle

eBS connected on-line to reader

devices

• Serialization

• ORACLE IS enables 100% on-line traceability from

• Actually our information

receiving inspection until shipment and delivery of each

system Oracle fully support

product

unique serial number scanning

using GS1 2D Data Matrix.

UNIPHARMA Introduction - 20th February 2019

18

19.

Warehousing – MODERN DISTRIBUTION CENTERSUNIPHARMA Introduction - 20th February 2019

19

20.

Warehousing – Employees periodical GDP testing & traningWarehouse operators and drivers are periodically trained, educated and tested

according to GDP + SOP´s requirements.

UNIPHARMA Introduction - 20th February 2019

20

21.

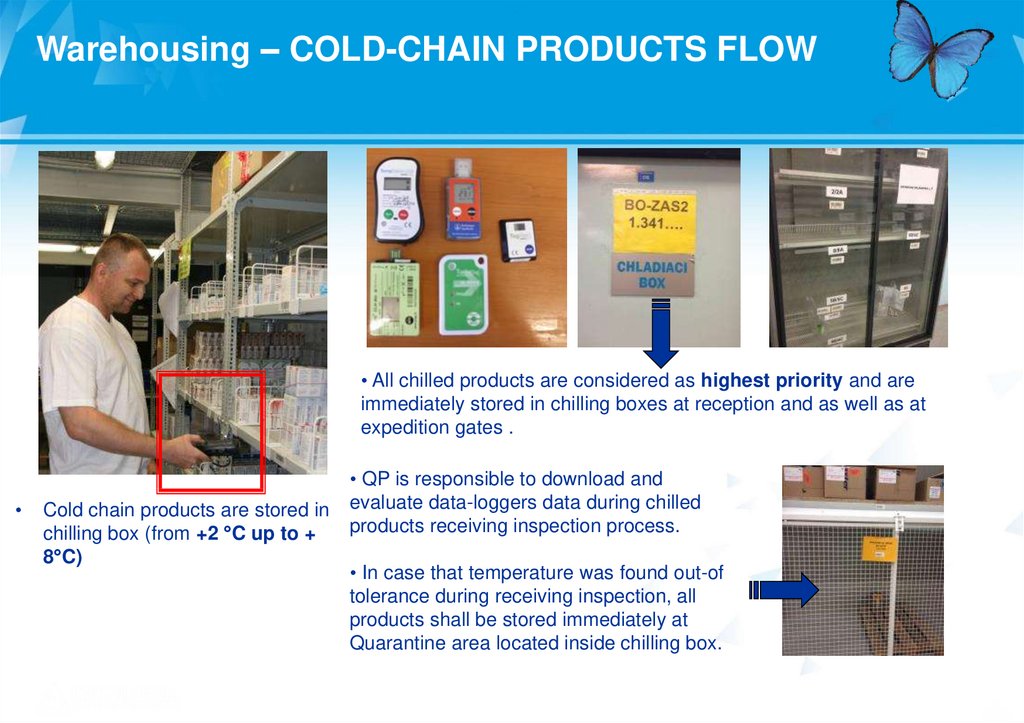

Warehousing – COLD-CHAIN PRODUCTS FLOW• All chilled products are considered as highest priority and are

immediately stored in chilling boxes at reception and as well as at

expedition gates .

Cold chain products are stored in

chilling box (from +2 °C up to +

8°C)

• QP is responsible to download and

evaluate data-loggers data during chilled

products receiving inspection process.

• In case that temperature was found out-of

tolerance during receiving inspection, all

products shall be stored immediately at

Quarantine area located inside chilling box.

UNIPHARMA Introduction - 20th February 2019

21

22.

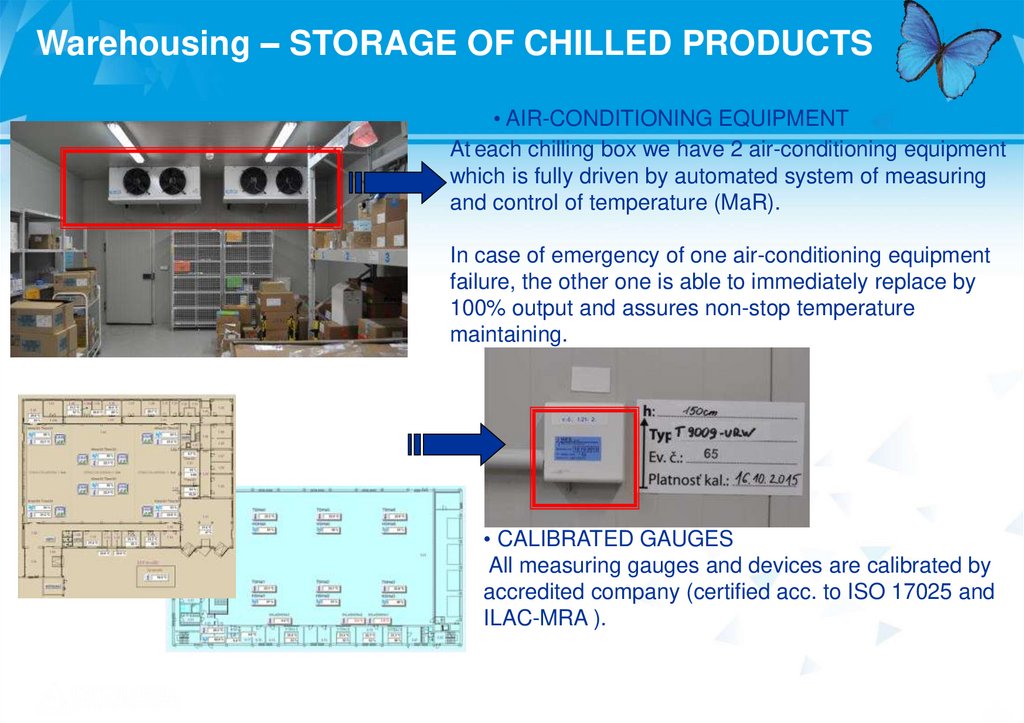

Warehousing – STORAGE OF CHILLED PRODUCTS• AIR-CONDITIONING EQUIPMENT

At each chilling box we have 2 air-conditioning equipment

which is fully driven by automated system of measuring

and control of temperature (MaR).

In case of emergency of one air-conditioning equipment

failure, the other one is able to immediately replace by

100% output and assures non-stop temperature

maintaining.

• CALIBRATED GAUGES

All measuring gauges and devices are calibrated by

accredited company (certified acc. to ISO 17025 and

ILAC-MRA ).

UNIPHARMA Introduction - 20th February 2019

22

23.

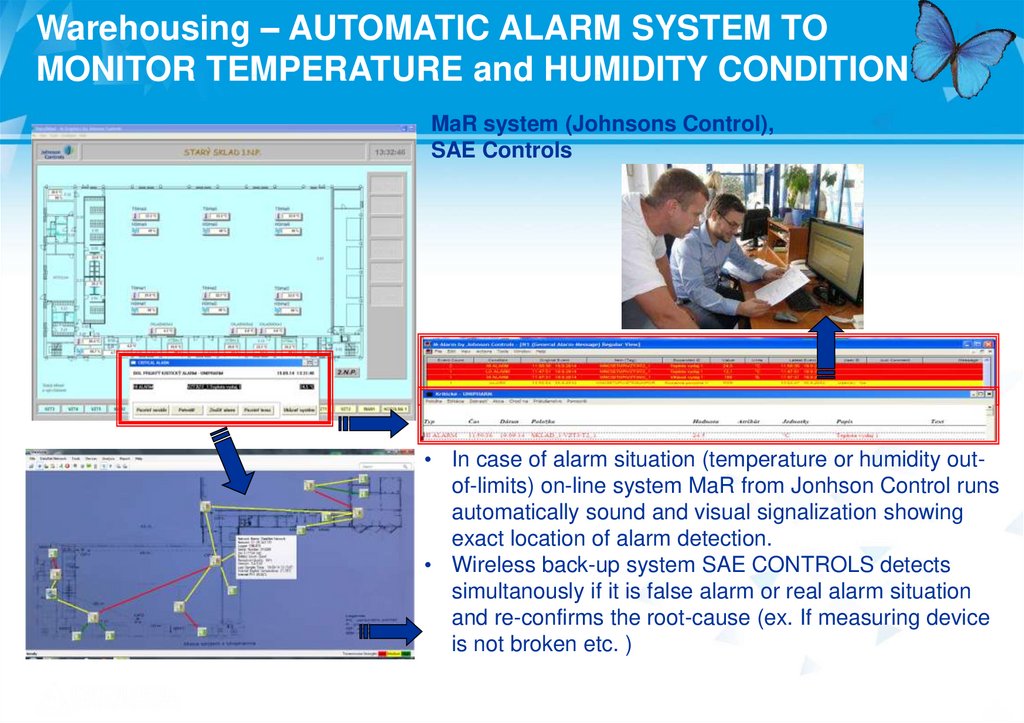

Warehousing – AUTOMATIC ALARM SYSTEM TOMONITOR TEMPERATURE and HUMIDITY CONDITION

MaR system (Johnsons Control),

SAE Controls

• In case of alarm situation (temperature or humidity outof-limits) on-line system MaR from Jonhson Control runs

automatically sound and visual signalization showing

exact location of alarm detection.

• Wireless back-up system SAE CONTROLS detects

simultanously if it is false alarm or real alarm situation

and re-confirms the root-cause (ex. If measuring device

is not broken etc. )

UNIPHARMA Introduction - 20th February 2019

23

24.

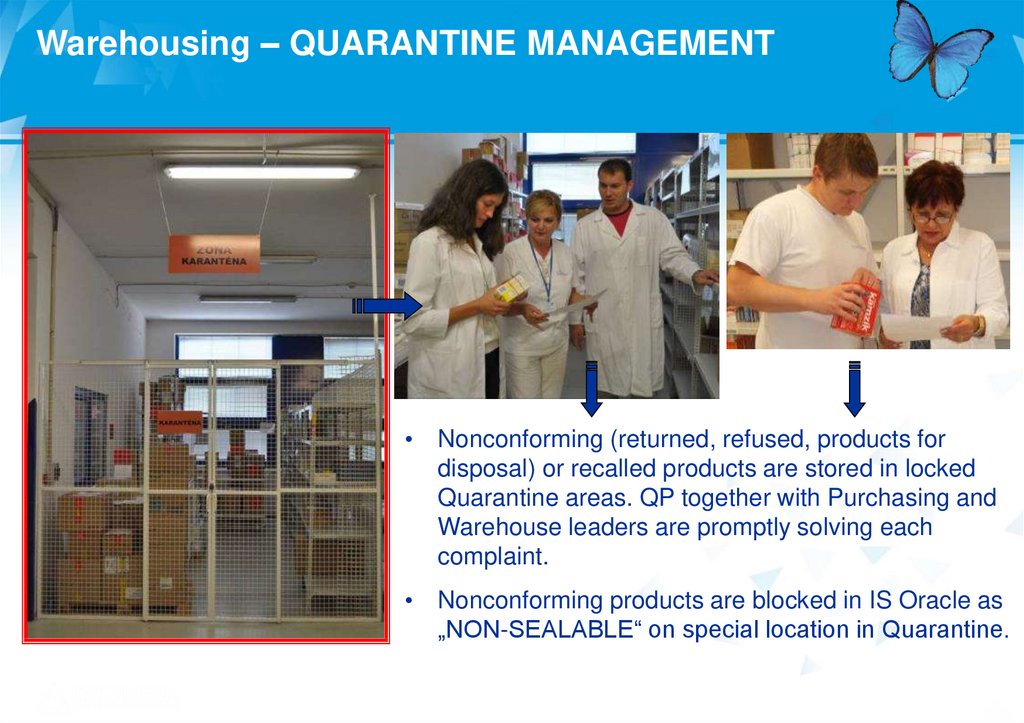

Warehousing – QUARANTINE MANAGEMENT• Nonconforming (returned, refused, products for

disposal) or recalled products are stored in locked

Quarantine areas. QP together with Purchasing and

Warehouse leaders are promptly solving each

complaint.

• Nonconforming products are blocked in IS Oracle as

„NON-SEALABLE“ on special location in Quarantine.

UNIPHARMA Introduction - 20th February 2019

24

25.

Warehousing – CLEANING / SANITATIONQualified Unipharma personnel performs sanitation of all warehouse

premises and returnable packages for pharmacies.

UNIPHARMA Introduction - 20th February 2019

25

26.

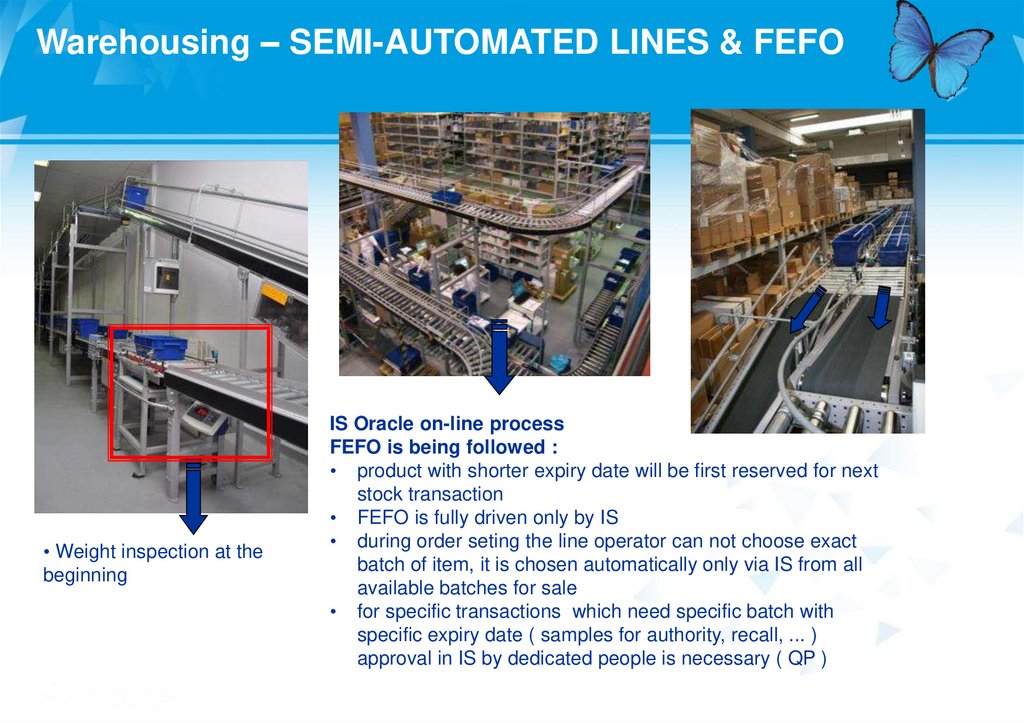

Warehousing – SEMI-AUTOMATED LINES & FEFO• Weight inspection at the

beginning

IS Oracle on-line process

FEFO is being followed :

• product with shorter expiry date will be first reserved for next

stock transaction

• FEFO is fully driven only by IS

• during order seting the line operator can not choose exact

batch of item, it is chosen automatically only via IS from all

available batches for sale

• for specific transactions which need specific batch with

specific expiry date ( samples for authority, recall, ... )

approval in IS by dedicated people is necessary ( QP )

UNIPHARMA Introduction - 20th February 2019

26

27.

Warehousing – SEMI-AUTOMATED LINE PROCESSEach product has dedicated

specific location

UNIPHARMA Introduction - 20th February 2019

27

28.

Warehousing – SEMI-AUTOMATED LINE PROCESSBar-code-reader

automatically

detects failures

for ex. wrong

location of picked

product of wrong

product type

UNIPHARMA Introduction - 20th February 2019

28

29.

Warehousing – FINAL INSPECTION PROCESS• Each comleted package goes through

automated weight inspection which

automatically detects any discrepancy.

• In case of weight nonconformity detection,

manual re-inspection is performed by

inspector.

UNIPHARMA Introduction - 20th February 2019

29

30.

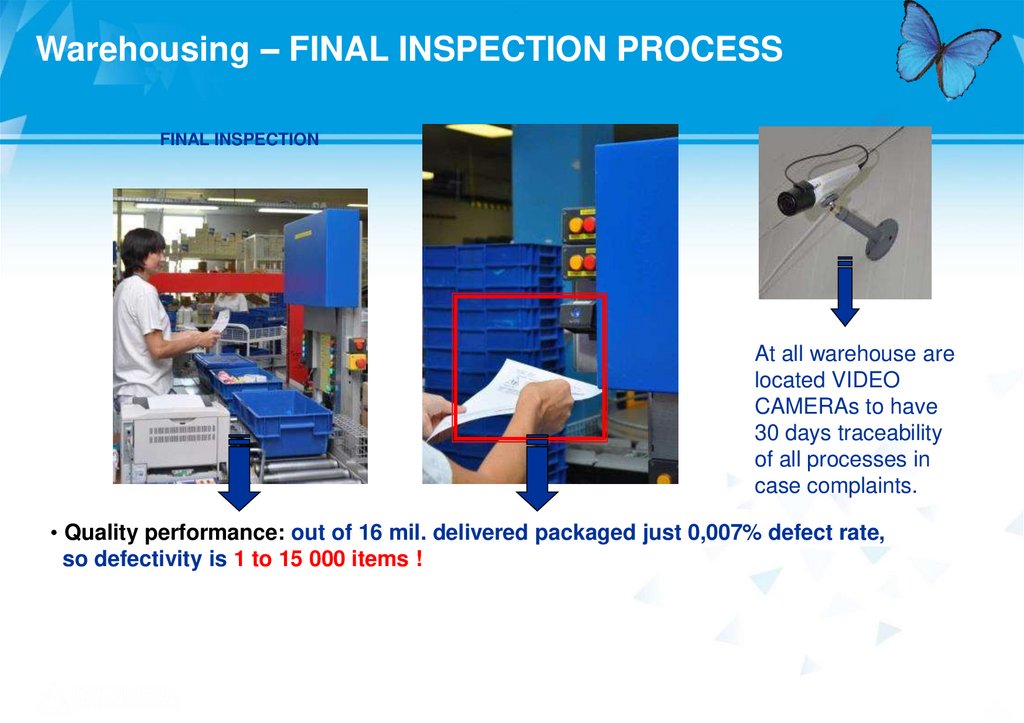

Warehousing – FINAL INSPECTION PROCESSFINAL INSPECTION

At all warehouse are

located VIDEO

CAMERAs to have

30 days traceability

of all processes in

case complaints.

• Quality performance: out of 16 mil. delivered packaged just 0,007% defect rate,

so defectivity is 1 to 15 000 items !

UNIPHARMA Introduction - 20th February 2019

30

31.

EXPEDITION (PICK & PACK)Released and packed packages are moved to expedition gate

UNIPHARMA Introduction - 20th February 2019

31

32.

Warehousing– description of Warehouse Management System

Dedicated location at expedition

goods-out gate

Shipment loading

• Drivers also use bar-code-reader to automatically

check completion of each delivery

• In case of missing boxes or incorrect supply route, IS

will automatically stop the transaction and shows

„ALERT“ message through bar-code-reader, so driver

can not continue transaction as long as mistake is not

being corrected

UNIPHARMA Introduction - 20th February 2019

32

32

33.

Warehousing– description of Warehouse Management System

Delivery to customers

Automated bar-code reader device

connected to IS Oracle assures mistakeproof system during loading process. In

ca of missing package, delivery route can

not be closed.

TERMOBOX with calibrated

gauge connected to GPS online software for safe

transportation of cold chain

products

UNIPHARMA Introduction - 20th February 2019

33

33

34.

Warehousing– description of Warehouse Management System

Delivery to customers

• All UNIPHARMA vehicles are equipped by automatic locking system

which assures locking of the vehicle during delivery to each pharmacy

UNIPHARMA Introduction - 20th February 2019

34

34

35.

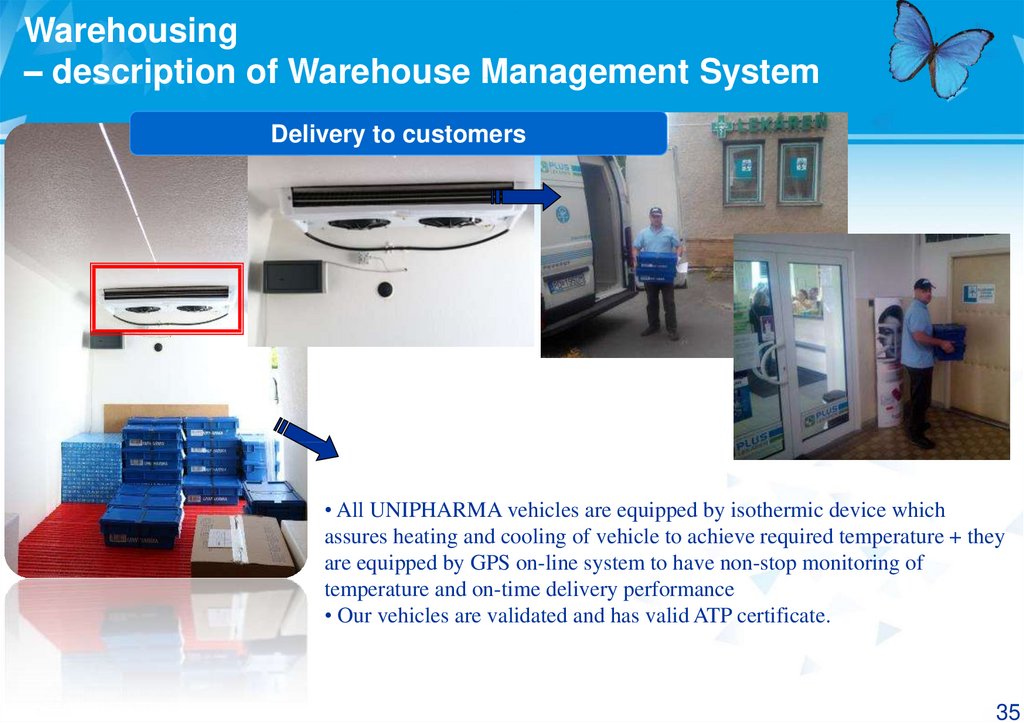

Warehousing– description of Warehouse Management System

Delivery to customers

• All UNIPHARMA vehicles are equipped by isothermic device which

assures heating and cooling of vehicle to achieve required temperature + they

are equipped by GPS on-line system to have non-stop monitoring of

temperature and on-time delivery performance

• Our vehicles are validated and has valid ATP certificate.

UNIPHARMA Introduction - 20th February 2019

35

35

36.

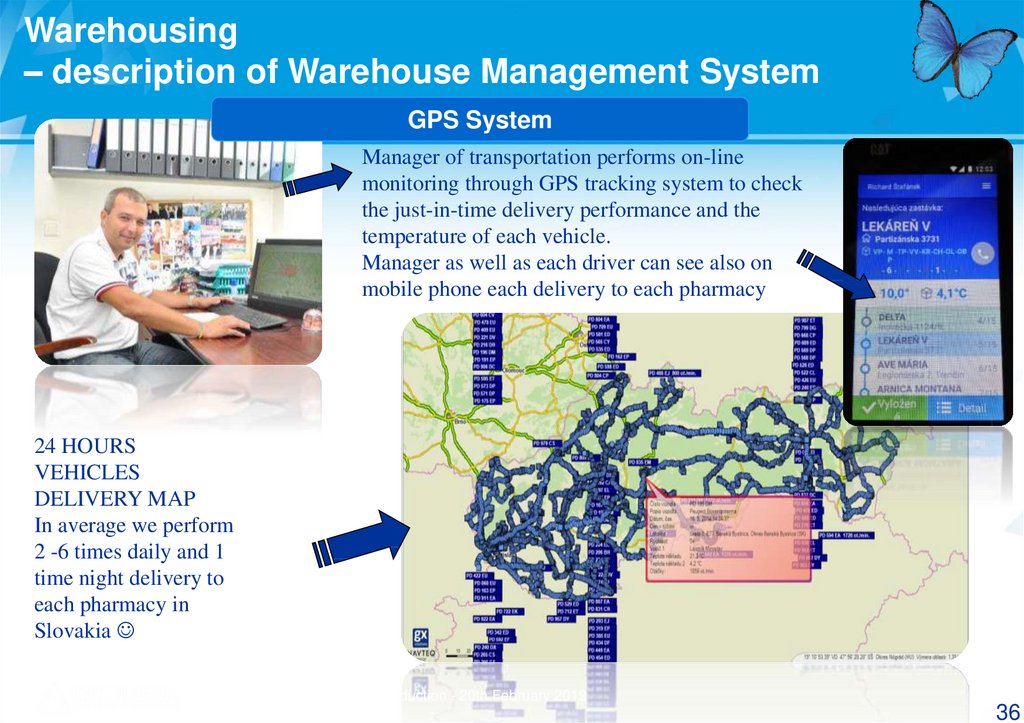

Warehousing– description of Warehouse Management System

GPS System

Manager of transportation performs on-line

monitoring through GPS tracking system to check

the just-in-time delivery performance and the

temperature of each vehicle.

Manager as well as each driver can see also on

mobile phone each delivery to each pharmacy

24 HOURS

VEHICLES

DELIVERY MAP

In average we perform

2 -6 times daily and 1

time night delivery to

each pharmacy in

Slovakia

UNIPHARMA Introduction - 20th February 2019

36

36

marketing

marketing medicine

medicine