Similar presentations:

Ceramics research group

1.

2.

The MTM triangleStructure

Processing

Properties

Dept. Metallurgy and Materials Engineering, K.U.Leuven

3.

Ceramics research groupZAP (Professors):

ATP (Technical support):

Postdoctoral Researchers:

Visiting scientists:

PhD students:

PhD students:

Prof. Omer Van der Biest

Prof. Jef Vleugels

Dr.

Dr.

Dr.

Dr.

Dr.

Bernd Baufeld

Shuigen Huang

Kim Vanmeensel

Songlin Ran

Bram Neirinck

Tina Mattheys

Swarnakar Akhilesh Kumar

Li Zhang

Khuram Shahzad

Joop Vandeursen

Wout Veulemans

Olivier Van Roey

Mohammed Abid

Annabel Braem

Olivier Malek

Ezhil Jothinathan

Dept. Metallurgy and Materials Engineering, K.U.Leuven

4.

Activities ceramics research groupProcessing of ceramics

• Powder synthesis (sol-gel, carbo- and borothermal reduction)

• Powder metallurgical shaping

• Colloïdal shaping by electrophoretic deposition (EPD)

• Sintering (pressureless, hot pressing, microwave, SPS)

Microstructural analysis and functional properties

• Microstructural analysis (SEM, EPMA, XRD, TEM)

• Mechanical properties (hardness, toughness, strength, etc.)

• Elastic and damping properties at room and elevated temperature

• Chemical compatibility

Modelling

• Electrophoretic deposition (EPD)

• Functionally graded materials (FGM)

• Damping

• Field assisted sintering technology (FAST, SPS, PECS)

Dept. Metallurgy and Materials Engineering, K.U.Leuven

5.

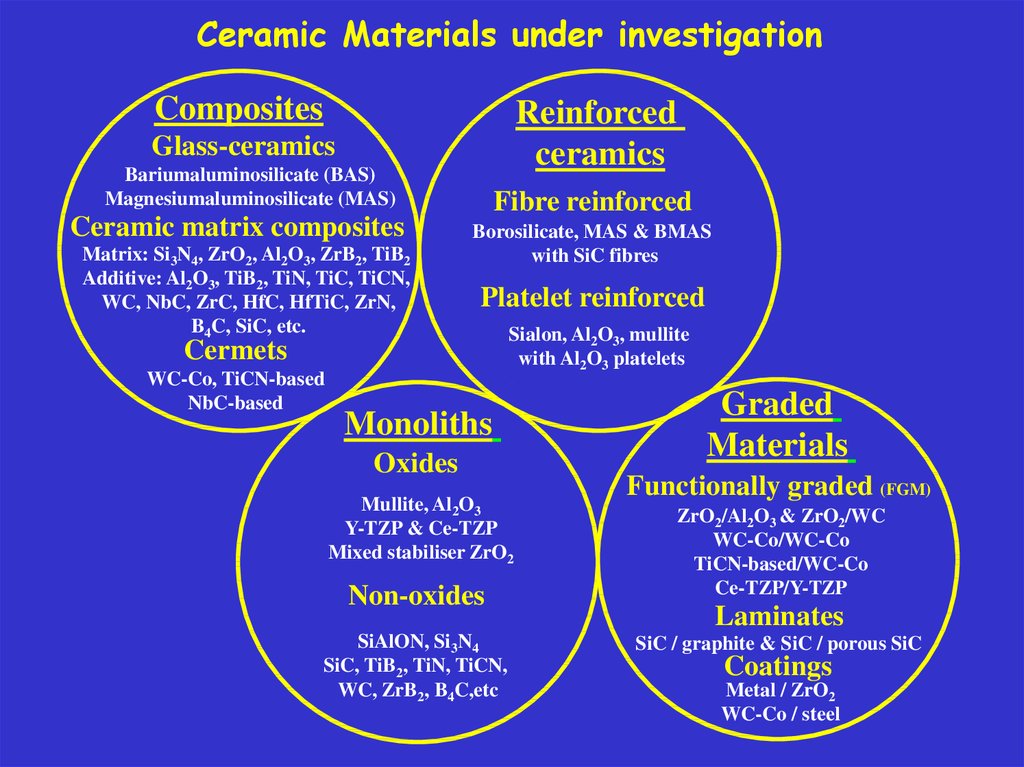

Ceramic Materials under investigationComposites

Reinforced

ceramics

Glass-ceramics

Bariumaluminosilicate (BAS)

Magnesiumaluminosilicate (MAS)

Ceramic matrix composites

Matrix: Si3N4, ZrO2, Al2O3, ZrB2, TiB2

Additive: Al2O3, TiB2, TiN, TiC, TiCN,

WC, NbC, ZrC, HfC, HfTiC, ZrN,

B4C, SiC, etc.

Fibre reinforced

Borosilicate, MAS & BMAS

with SiC fibres

Platelet reinforced

Cermets

WC-Co, TiCN-based

NbC-based

Sialon, Al2O3, mullite

with Al2O3 platelets

Composites

Reinforced ceramic

Ceramic matrix composites

Matrix: Y-TZP,Ce-TZP,Si3N4,Al2O3

Addition: Al2O3,TiB,TiN,TiCN,TiC,WC,...

2

Glass-ceramics

Bariumaluminosilicates (BAS)

Magnesiumaluminosilicates (MAS)

Cermets

Fibre-reinforced

Borosilicate, MAS and BMAS with

SiC fibres

Platelet-reinforced

SiAlON, mullite and Al2O3 with

Al2O3 platelets

WC/Co-based

Graded materials

Monoliths

Oxides

Mullite, Al2O3

Y-TZP & Ce-TZP

Mixed stabiliser ZrO2

Non-oxides

SiAlON, Si3N4

SiC, TiB2, TiN, TiCN,

WC, ZrB2, B4C,etc

Graded

Materials

Functionally graded (FGM)

ZrO2/Al2O3 & ZrO2/WC

WC-Co/WC-Co

TiCN-based/WC-Co

Ce-TZP/Y-TZP

Laminates

SiC / graphite & SiC / porous SiC

Coatings

Metal / ZrO2

WC-Co / steel

6.

Research Topics• Processing and characterisation of functionally graded materials (FGM)

• Colloidal processing by means of electrophoretic deposition (DC & AC-EPD)

• Development and characterisation of ceramic, CMC’s and cermets

• Modelling and application of field assisted sintering (FAST, SPS, PECS)

• Investigation of elastic and damping properties of materials

• Cutting tool development and chemical compatibility assessment

• Nanomaterials and nanocomposites (biomaterials, photovoltaics, batteries)

• Processing of Porous materials (ceramics, glass & metals)

• Mechanical alloying

Dept. Metallurgy and Materials Engineering, K.U.Leuven

7.

Cutting tool development and chemical compatibility studiesDEVELOPMENT OF NEW CUTTING MATERIALS, TOOLS, MACHINE CONCEPTS

AND TECHNOLOGIES FOR DRY HIGH SPEED CUTTING

• New composites

• Chemical wear assesment

• Gradient materials

Dept. Metallurgy and Materials Engineering, K.U.Leuven

8.

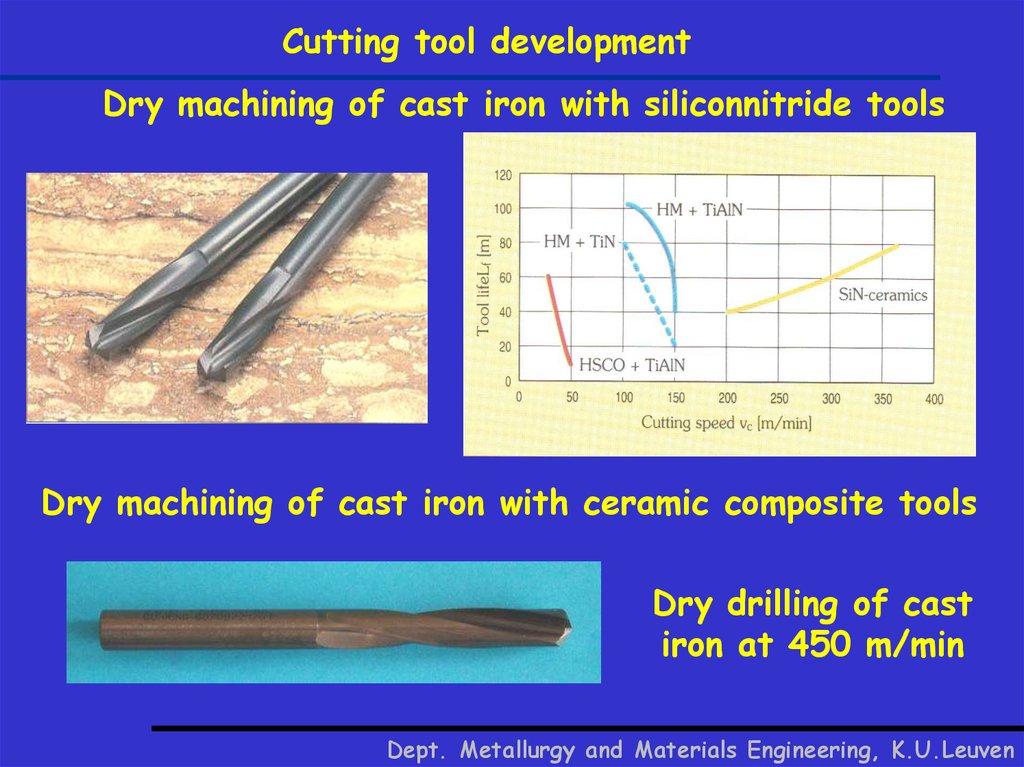

Cutting tool developmentDry machining of cast iron with siliconnitride tools

Dry machining of cast iron with ceramic composite tools

Dry drilling of cast

iron at 450 m/min

Dept. Metallurgy and Materials Engineering, K.U.Leuven

9.

Chemical compatibility assessmentNi-Cr or Ni-Al wire

Workpiece

material

Al2O3

Tool material

Experimental parameters

Temperature

Holding time

Mechanical load

Workpiece

Tool

Nimonic 105

Workpiece

Drill core

Coating

Fixed

Dept. Metallurgy and Materials Engineering, K.U.Leuven

10.

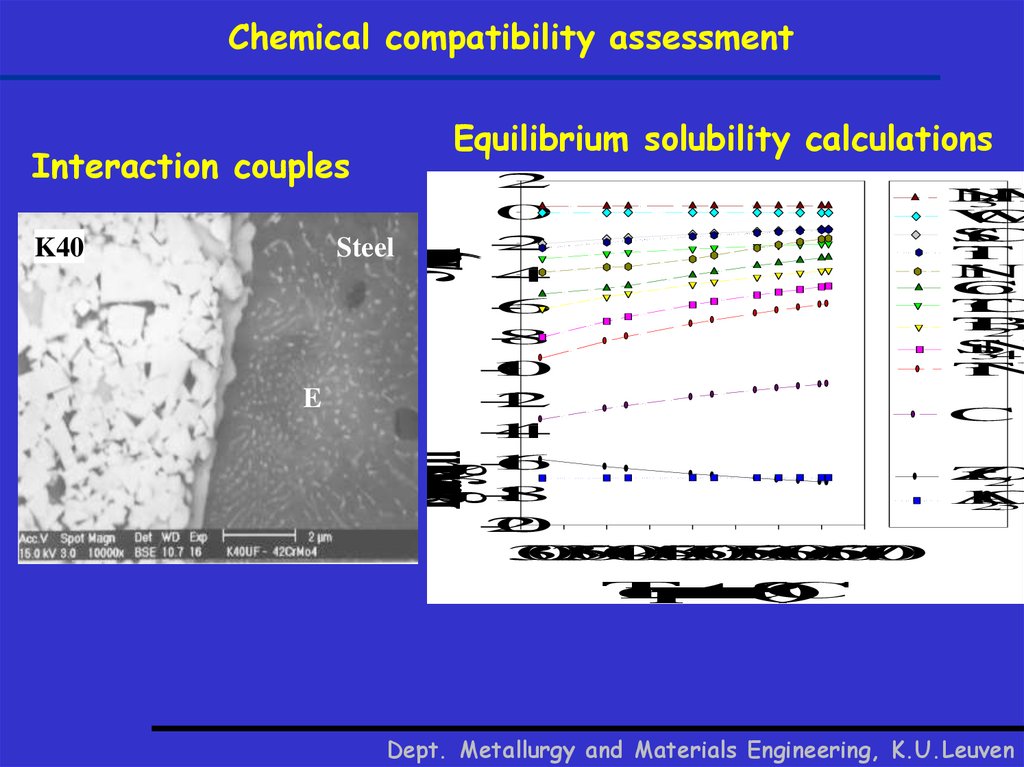

Chemical compatibility assessmentEquilibrium solubility calculations

Interaction couples

Steel

E

Logslubity(logcm

3/mole)

K40

2

0

2

4

6

8

1

0

1

2

1

4

1

6

1

8

2

0

3

0

0

3

5

0

4

0

0

4

5

0

5

0

0

5

5

0

6

0

0

6

5

0

7

0

0

N

i

A

l

3

W

C

S

i

C

T

i

N

i

C

o

T

i

C

T

i

B

2

S

i

N

3

4

T

i

N

C

Z

r

O

2

A

l

O

2

3

T

e

m

p

e

r

a

t

u

r

e

(

°

C

)

Dept. Metallurgy and Materials Engineering, K.U.Leuven

11.

Functionally graded materials (FGM)Thermal resistance

Wear resistance (Hardness)

To combine irreconcilable properties in the same component

by engineering a gradient in composition and concomitant properties

Fracture toughness

Dept. Metallurgy and Materials Engineering, K.U.Leuven

12.

Electrophoretic deposition (EPD)Colloidal processing technique in an electric field

+

_

V

+

+

• Particles are charged by interaction

with the solvent and additives

_

_

• Charged particles move under the

influence of an applied electric field

(electrophoresis)

+

_

_

+

+

electrode

• Partices form a growing deposit on

the deposition electrode (deposition)

_

suspension

electrode

Charged particles

+ Cations

_ Anions

Dept. Metallurgy and Materials Engineering, K.U.Leuven

13.

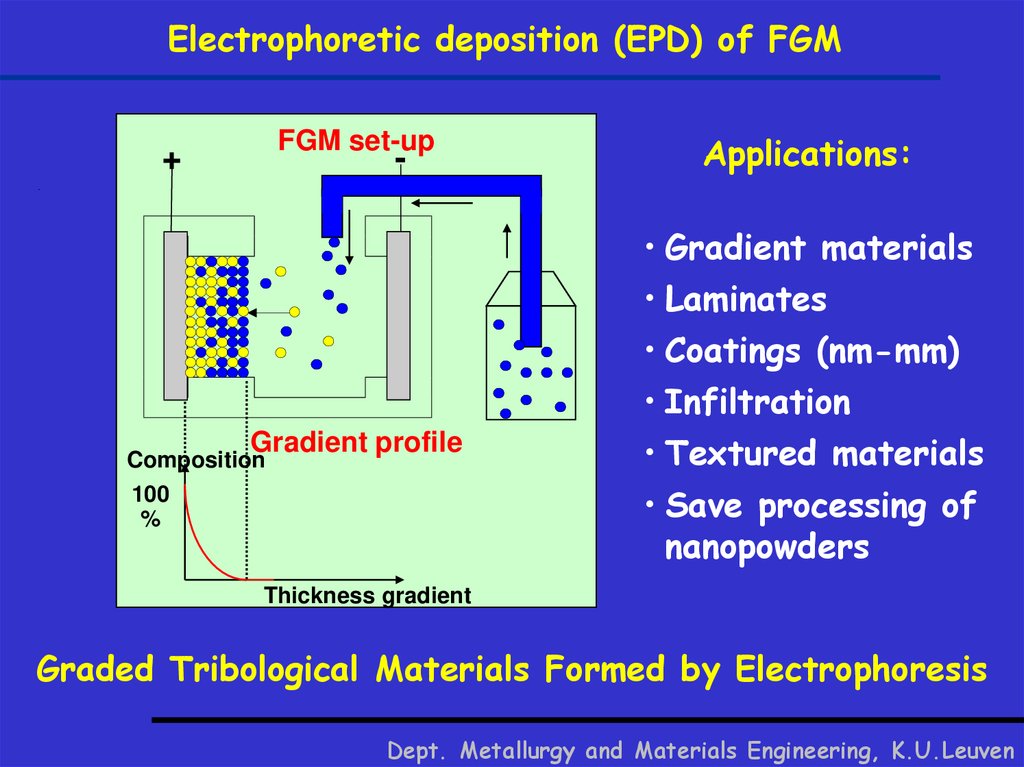

Electrophoretic deposition (EPD) of FGMFGM set-up

+

-

Applications:

• Gradient materials

• Laminates

• Coatings (nm-mm)

Gradient profile

Composition

• Infiltration

• Textured materials

• Save processing of

nanopowders

100

%

Thickness gradient

Graded Tribological Materials Formed by Electrophoresis

Dept. Metallurgy and Materials Engineering, K.U.Leuven

14.

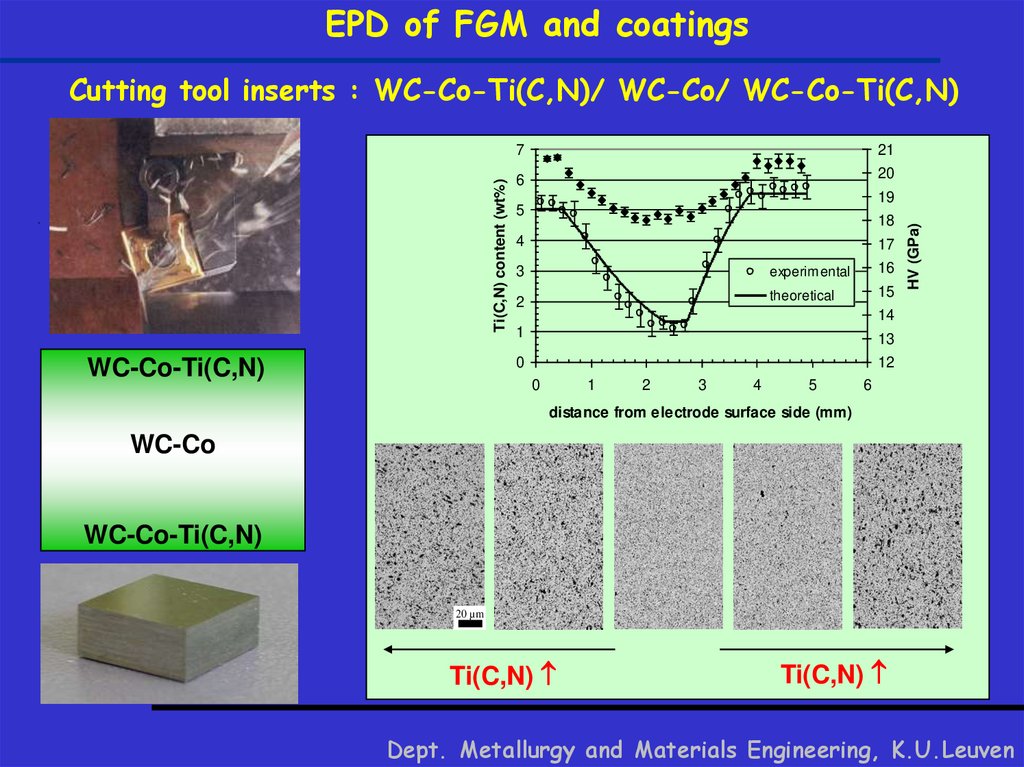

EPD of FGM and coatingsWC-Co-Ti(C,N)

7

21

6

20

19

5

18

4

17

3

experimental

16

2

theoretical

15

HV (GPa)

Ti(C,N) content (wt%)

Cutting tool inserts : WC-Co-Ti(C,N)/ WC-Co/ WC-Co-Ti(C,N)

14

1

13

0

12

0

1

2

3

4

5

6

distance from electrode surface side (mm)

WC-Co

WC-Co-Ti(C,N)

20 µm

Ti(C,N)

Ti(C,N)

Dept. Metallurgy and Materials Engineering, K.U.Leuven

15.

EPD of FGM and coatingsHSS substrate

EPD-coated

Sintered

Final machined

HSS taps with carbide

coating

Dept. Metallurgy and Materials Engineering, K.U.Leuven

16.

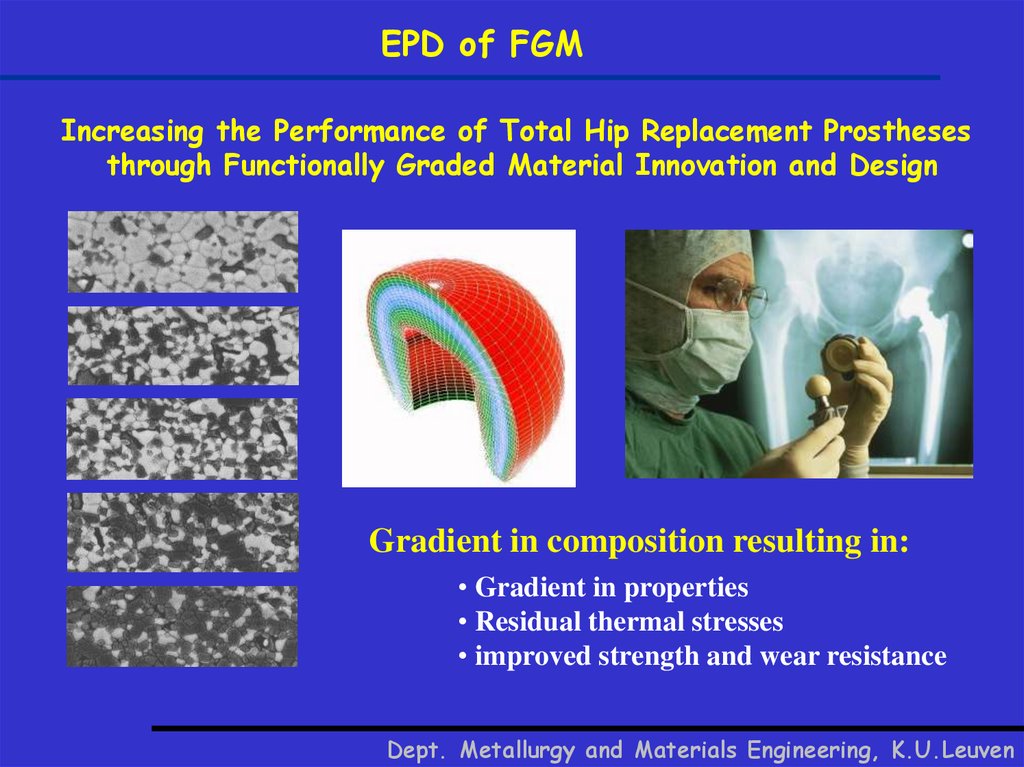

EPD of FGMIncreasing the Performance of Total Hip Replacement Prostheses

through Functionally Graded Material Innovation and Design

Gradient in composition resulting in:

• Gradient in properties

• Residual thermal stresses

• improved strength and wear resistance

Dept. Metallurgy and Materials Engineering, K.U.Leuven

17.

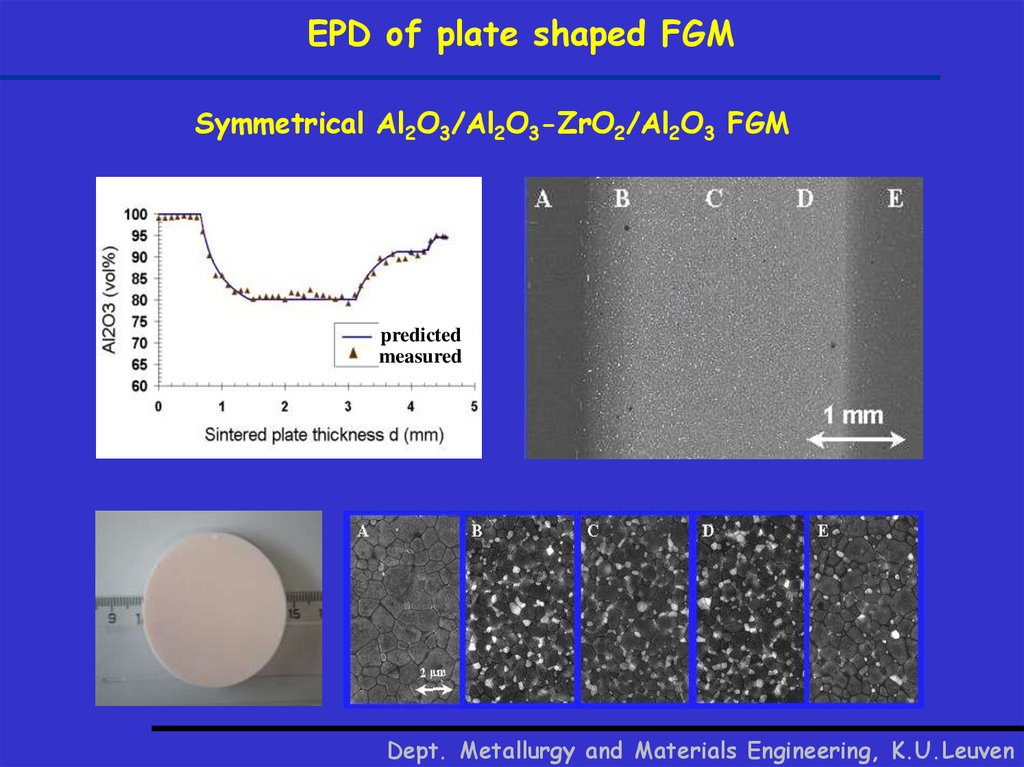

EPD of plate shaped FGMSymmetrical Al2O3/Al2O3-ZrO2/Al2O3 FGM

predicted

measured

Dept. Metallurgy and Materials Engineering, K.U.Leuven

18.

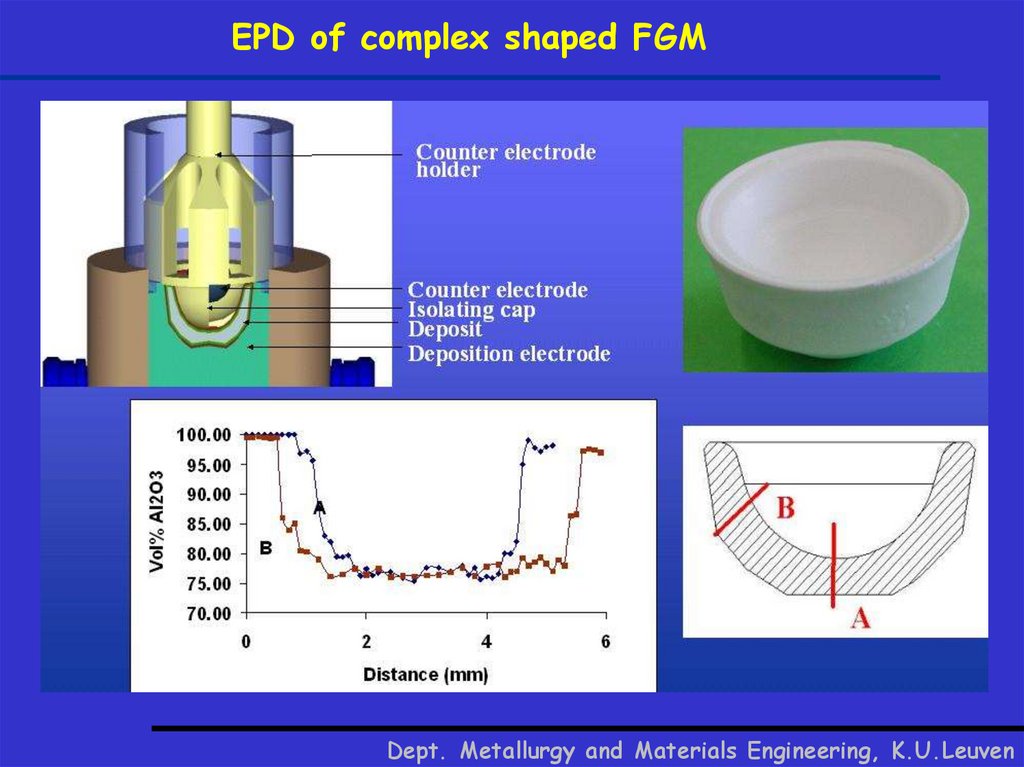

EPD of complex shaped FGMNear-net-shape processing (max + 100 µm)

Dept. Metallurgy and Materials Engineering, K.U.Leuven

19.

EPD of complex shaped FGMDept. Metallurgy and Materials Engineering, K.U.Leuven

20.

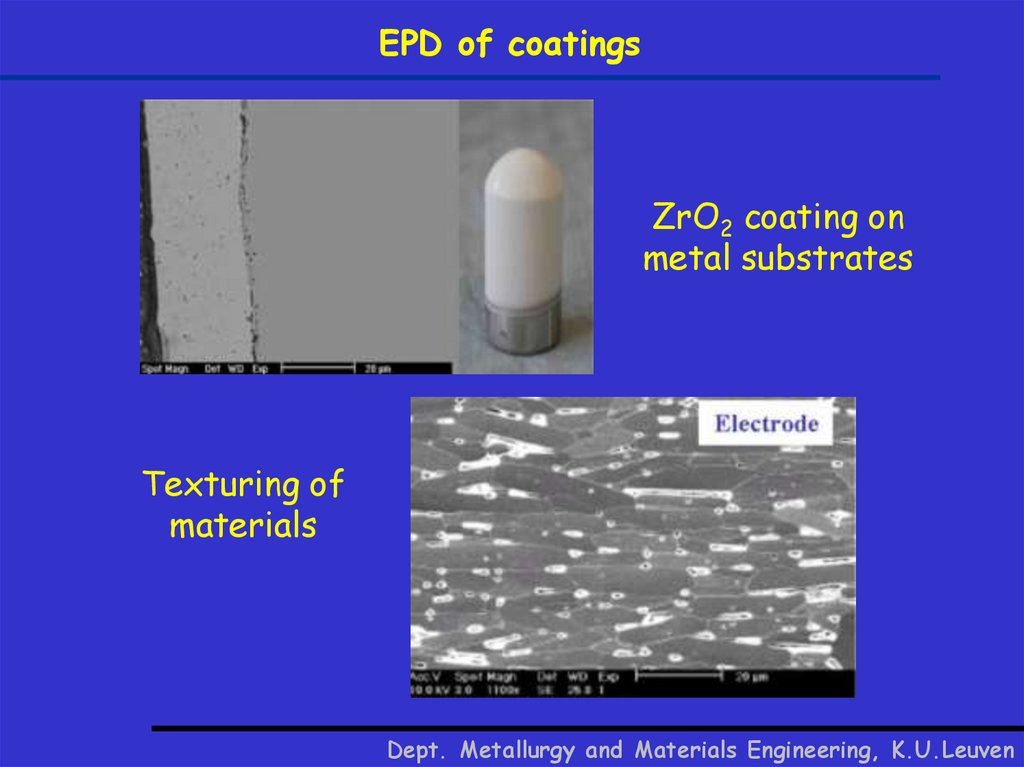

EPD of coatingsZrO2 coating on

metal substrates

Texturing of

materials

Dept. Metallurgy and Materials Engineering, K.U.Leuven

21.

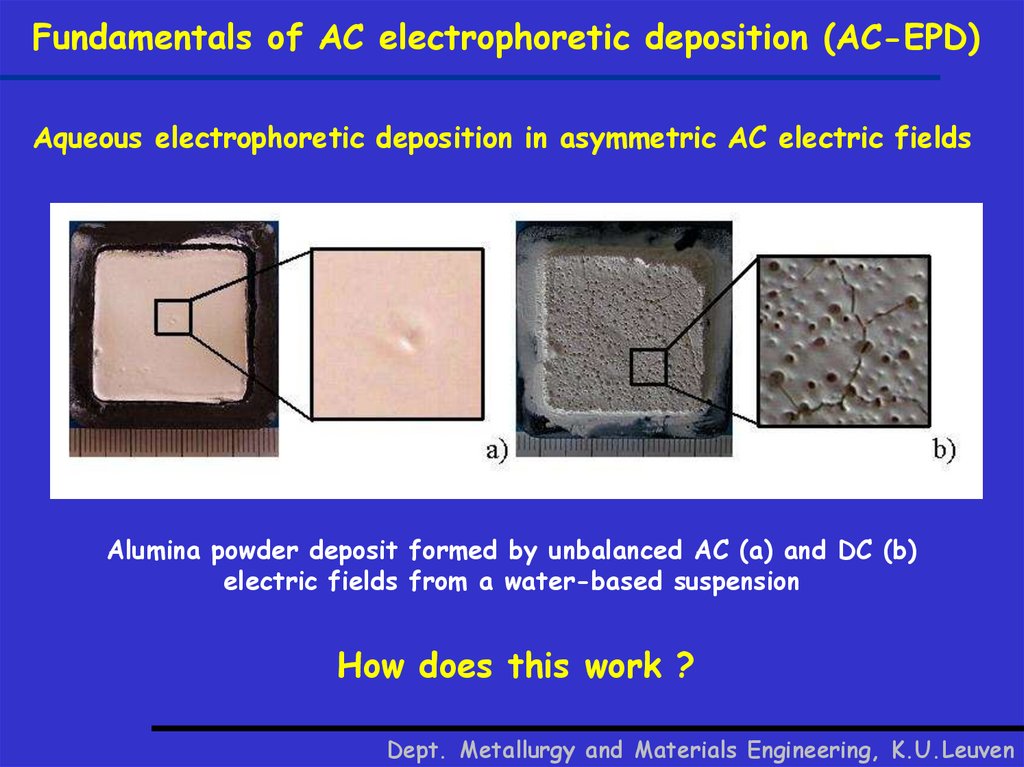

Fundamentals of AC electrophoretic deposition (AC-EPD)Aqueous electrophoretic deposition in asymmetric AC electric fields

Alumina powder deposit formed by unbalanced AC (a) and DC (b)

electric fields from a water-based suspension

How does this work ?

Dept. Metallurgy and Materials Engineering, K.U.Leuven

22.

Basic science on EPDElectrophoretic forming of functionally graded materials and coatings

Region of surface forces

+

_

Liquid flow

lines

_

+

• Electrophoretic mobility and zeta

potential measurements

• AFM of particle-electrode interaction

_

+

deposit

• Charging mechanisms and particleadditive interactions

• Study of the deposition process

+

_

• Suspension stability studies

Felectroforetic

Hydrodynamic layer

• Electrochemical reactions

• Fluid dynamic interactions during EPD

• Modelling of the EPD kinetics

GOA-TBA 2005-2008 K.U.Leuven

Dept. Metallurgy and Materials Engineering, K.U.Leuven

23.

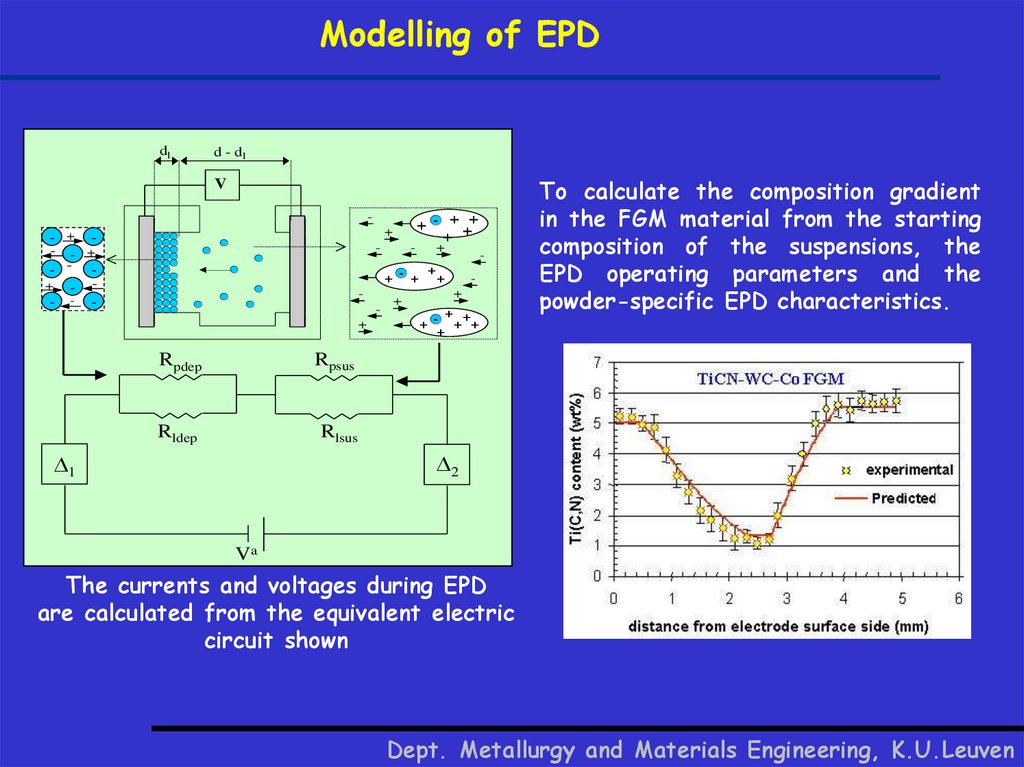

Modelling of EPDdl

d - dl

V

+

- + - - +

- - + - - - -

-

-

+ - + ++

+

+

-

+

+ - + +

+

Rpdep

Rpsus

Rldep

Rlsus

+

+

+ +

+ - + +

+

To calculate the composition gradient

in the FGM material from the starting

composition of the suspensions, the

EPD operating parameters and the

powder-specific EPD characteristics.

2

1

Va

The currents and voltages during EPD

are calculated from the equivalent electric

circuit shown

Dept. Metallurgy and Materials Engineering, K.U.Leuven

24.

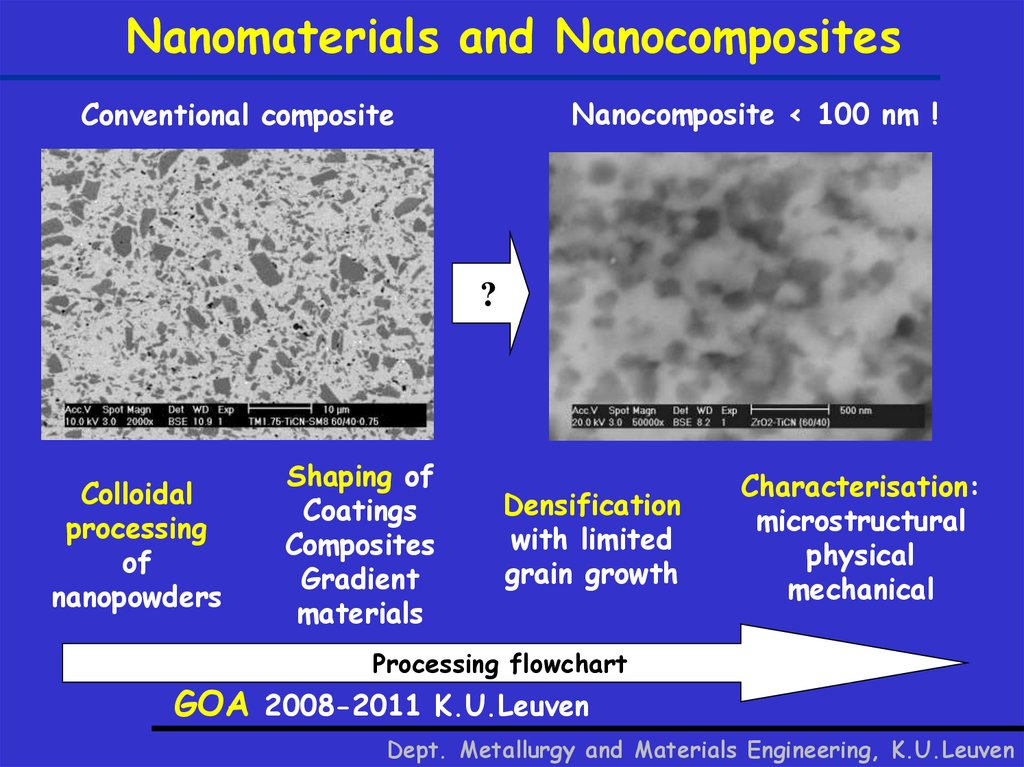

Nanomaterials and NanocompositesNanocomposite < 100 nm !

Conventional composite

?

Colloidal

processing

of

nanopowders

Shaping of

Coatings

Composites

Gradient

materials

Densification

with limited

grain growth

Characterisation:

microstructural

physical

mechanical

Processing

flowchart

GOA-TBA

2008-2011

K.U.Leuven

GOA 2008-2011 K.U.Leuven

Dept. Metallurgy and Materials Engineering, K.U.Leuven

25.

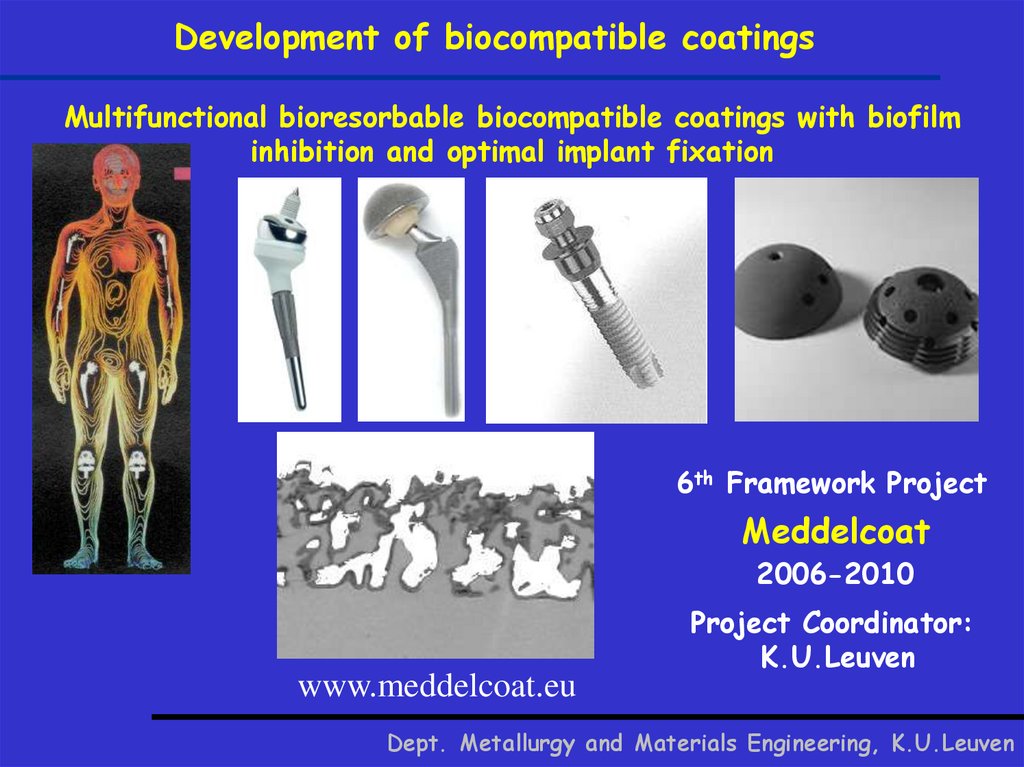

Development of biocompatible coatingsMultifunctional bioresorbable biocompatible coatings with biofilm

inhibition and optimal implant fixation

to be coated

6th Framework Project

Meddelcoat

2006-2010

www.meddelcoat.eu

Project Coordinator:

K.U.Leuven

Dept. Metallurgy and Materials Engineering, K.U.Leuven

26.

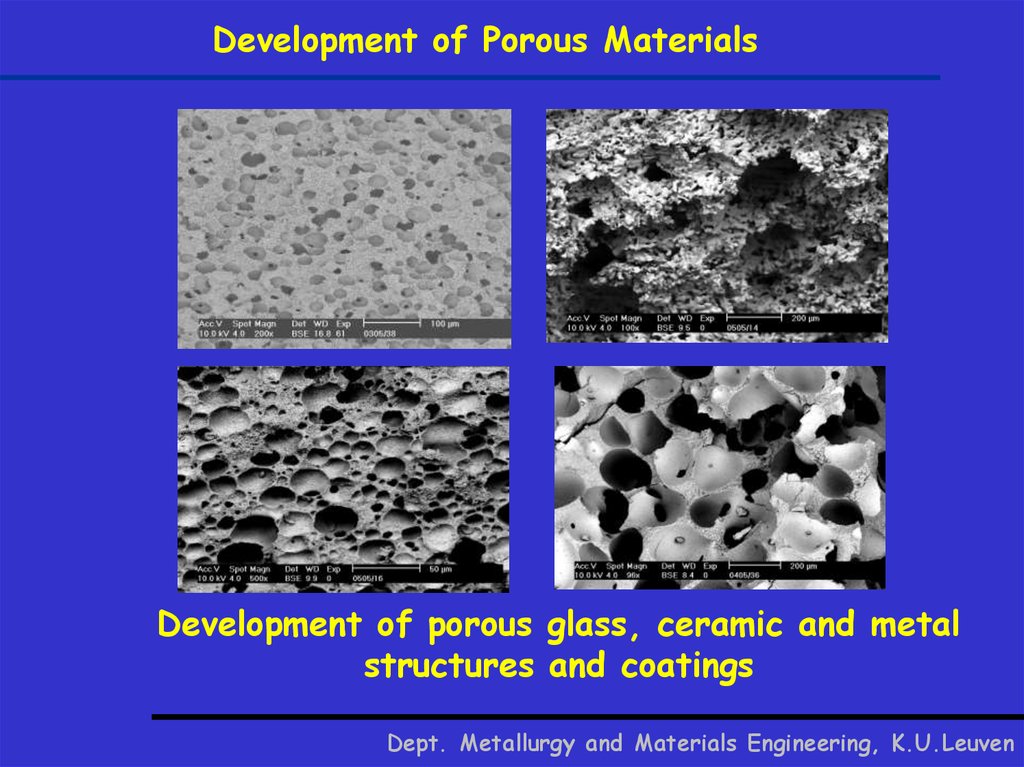

Development of Porous MaterialsDevelopment of porous glass, ceramic and metal

structures and coatings

Dept. Metallurgy and Materials Engineering, K.U.Leuven

27.

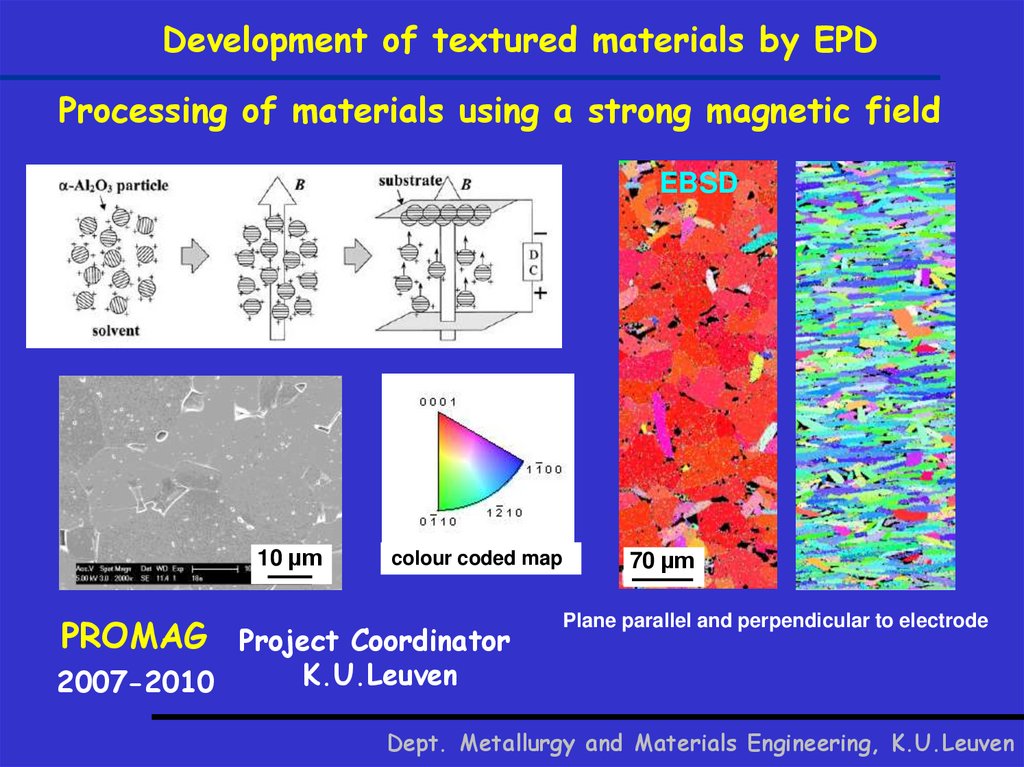

Development of textured materials by EPDProcessing of materials using a strong magnetic field

EBSD

SBO

10 µm

colour coded map

PROMAG Project Coordinator

2007-2010

70 µm

Plane parallel and perpendicular to electrode

K.U.Leuven

Dept. Metallurgy and Materials Engineering, K.U.Leuven

28.

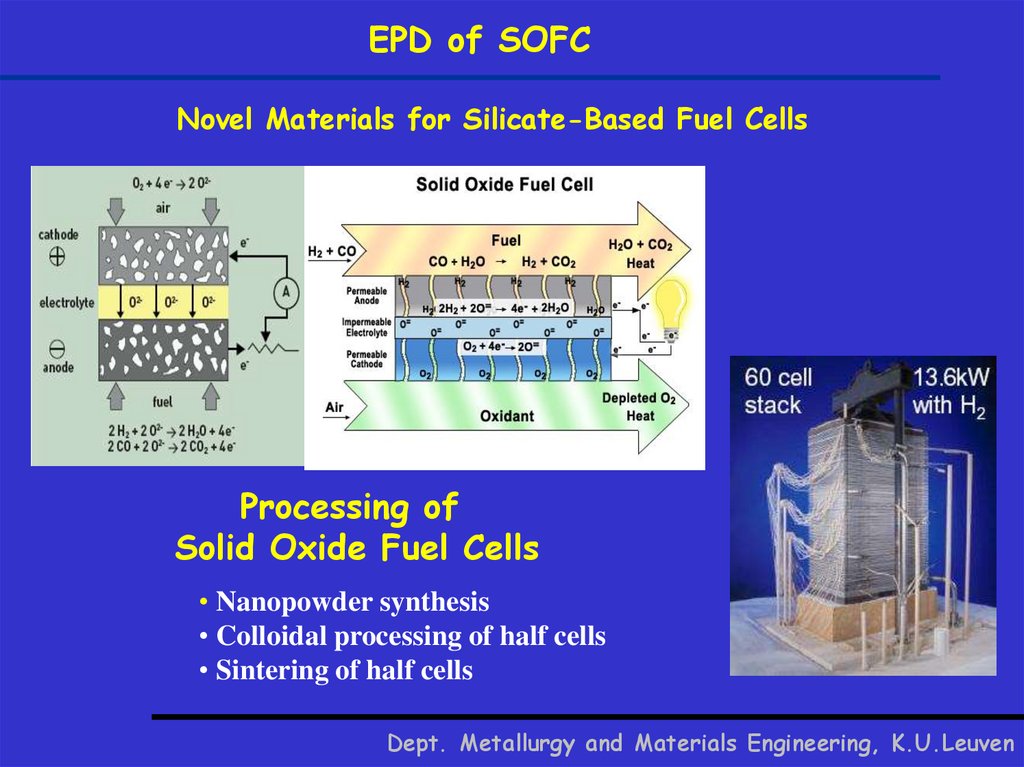

EPD of SOFCNovel Materials for Silicate-Based Fuel Cells

Processing of

Solid Oxide Fuel Cells

• Nanopowder synthesis

• Colloidal processing of half cells

• Sintering of half cells

Dept. Metallurgy and Materials Engineering, K.U.Leuven

29.

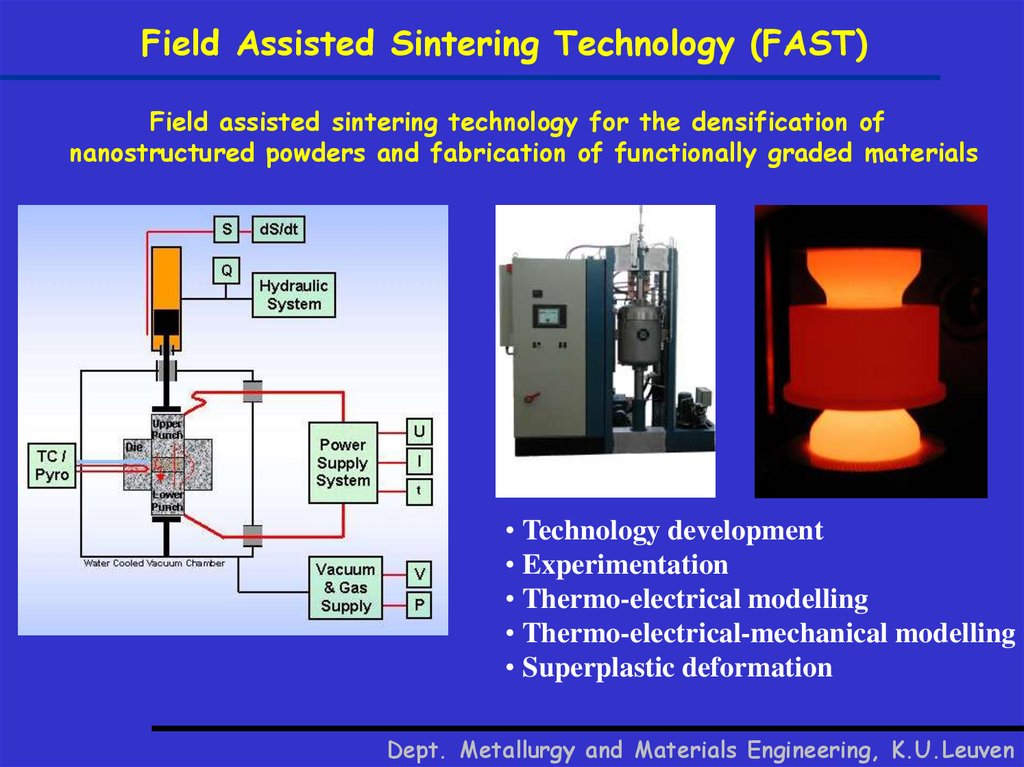

Field Assisted Sintering Technology (FAST)Field assisted sintering technology for the densification of

nanostructured powders and fabrication of functionally graded materials

• Technology development

• Experimentation

• Thermo-electrical modelling

• Thermo-electrical-mechanical modelling

• Superplastic deformation

Dept. Metallurgy and Materials Engineering, K.U.Leuven

30.

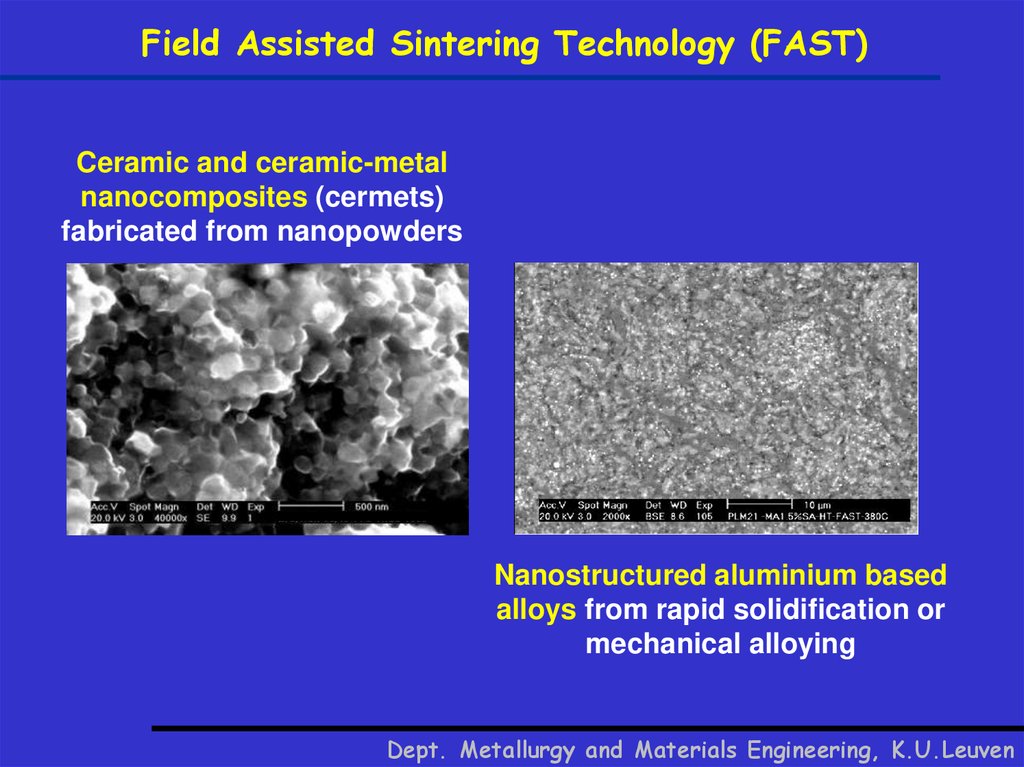

Field Assisted Sintering Technology (FAST)Ceramic and ceramic-metal

nanocomposites (cermets)

fabricated from nanopowders

Nanostructured aluminium based

alloys from rapid solidification or

mechanical alloying

Dept. Metallurgy and Materials Engineering, K.U.Leuven

31.

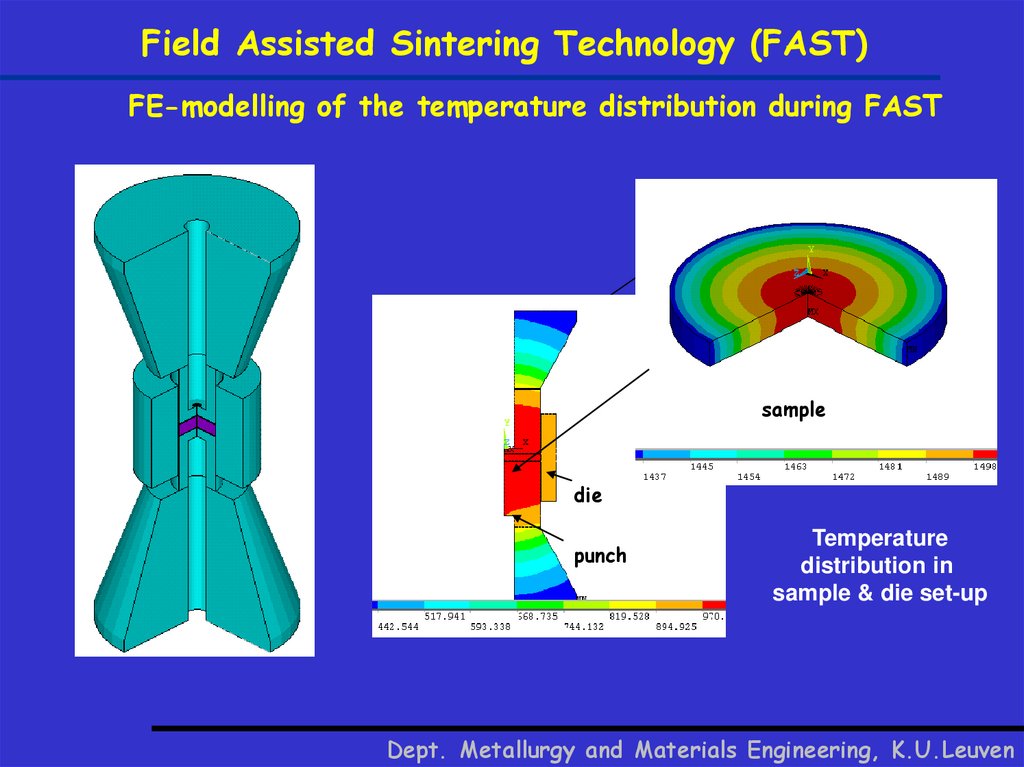

Field Assisted Sintering Technology (FAST)FE-modelling of the temperature distribution during FAST

sample

die

punch

Temperature

distribution in

sample & die set-up

Dept. Metallurgy and Materials Engineering, K.U.Leuven

32.

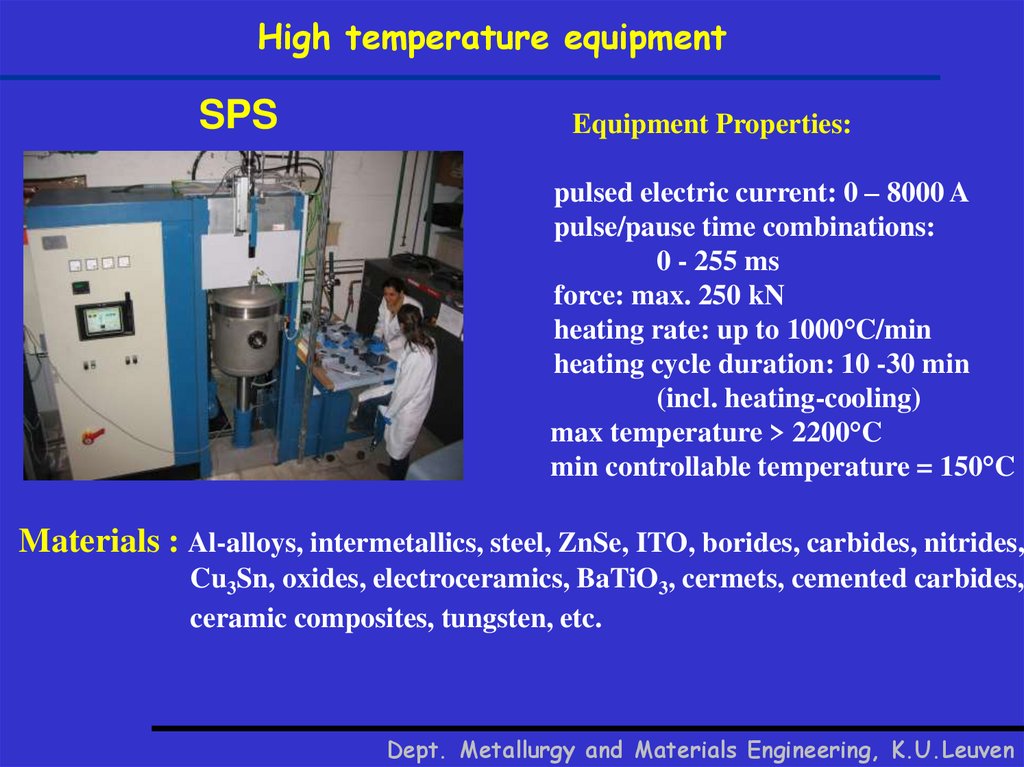

High temperature equipmentSPS

Equipment Properties:

pulsed electric current: 0 – 8000 A

pulse/pause time combinations:

0 - 255 ms

force: max. 250 kN

heating rate: up to 1000°C/min

heating cycle duration: 10 -30 min

(incl. heating-cooling)

max temperature > 2200°C

min controllable temperature = 150°C

Materials : Al-alloys, intermetallics, steel, ZnSe, ITO, borides, carbides, nitrides,

Cu3Sn, oxides, electroceramics, BaTiO3, cermets, cemented carbides,

ceramic composites, tungsten, etc.

Dept. Metallurgy and Materials Engineering, K.U.Leuven

33.

Electro-conductive ceramic compositesFor electrical discharge machining (EDM) and wear applications

http://www.mtm.kuleuven.be/Research/GBOU-IWT/spark/index.html

http://www.moncerat.org

Dept. Metallurgy and Materials Engineering, K.U.Leuven

34.

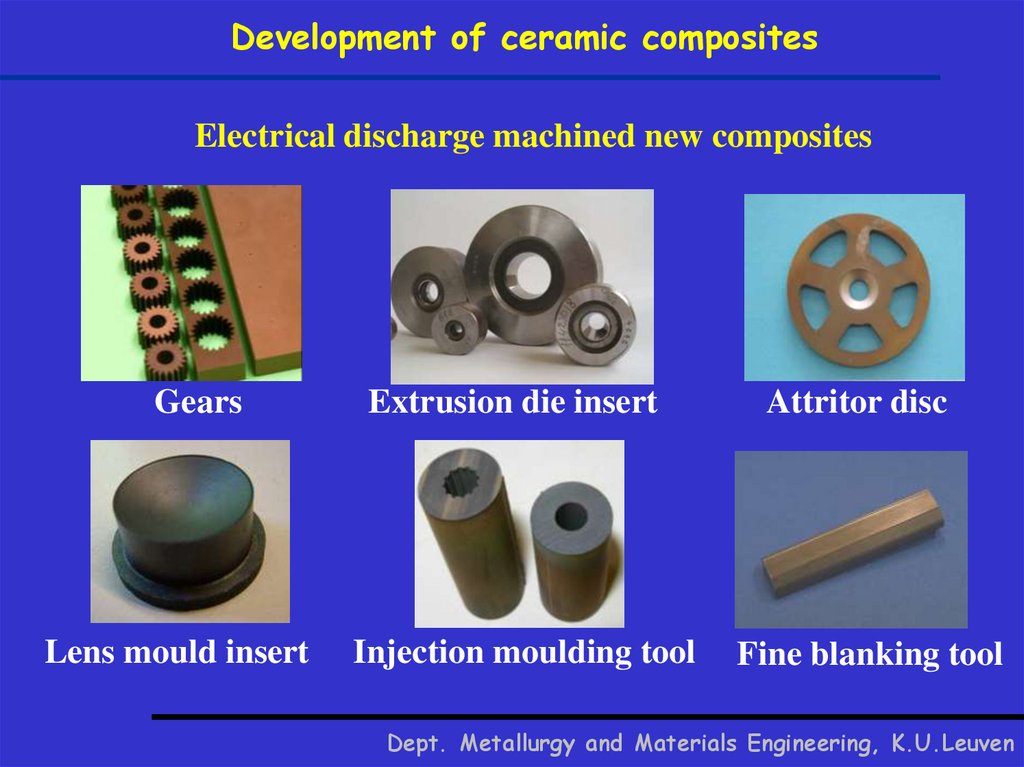

Development of ceramic compositesElectrical discharge machined new composites

Gears

Lens mould insert

Extrusion die insert

Injection moulding tool

Attritor disc

Fine blanking tool

Dept. Metallurgy and Materials Engineering, K.U.Leuven

35.

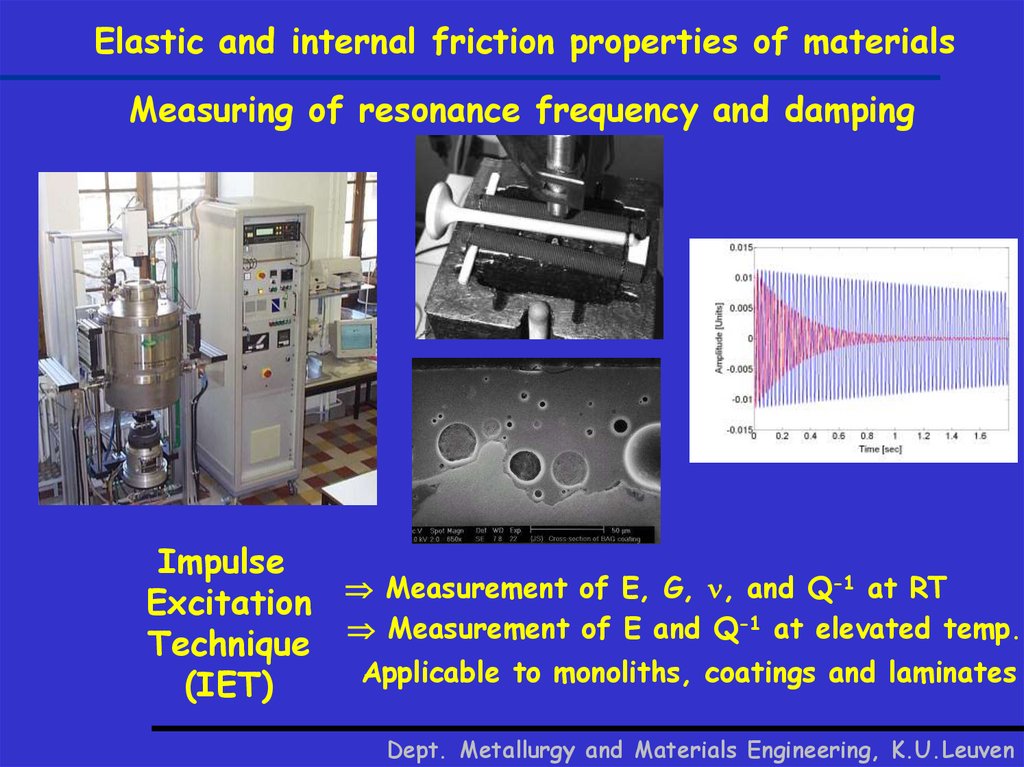

Elastic and internal friction properties of materialsMeasuring of resonance frequency and damping

Impulse

Measurement of E, G, , and Q-1 at RT

Excitation

Measurement of E and Q-1 at elevated temp.

Technique

Applicable to monoliths, coatings and laminates

(IET)

Dept. Metallurgy and Materials Engineering, K.U.Leuven

36.

Elastic and damping properties of materialsSchematic of an IET-furnace

Microphone

Furnace

Ceramic tube

Pneumatic

tapping device

310

0.1

280

0.08

250

0.06

Test in N2 (1 atm)

heating at 2°C/min

fr (25°C) = 8.7 kHz

220

190

160

0

200

400

0.04

0.02

Internal friction (Q-1)

Ceramic ball

Test specimen

Young's modulus (GPa)

Si3N4 result : fr or E (T) and Q-1(T)

0

600 800 1000 1200 1400

Temperature (°C)

Dept. Metallurgy and Materials Engineering, K.U.Leuven

37.

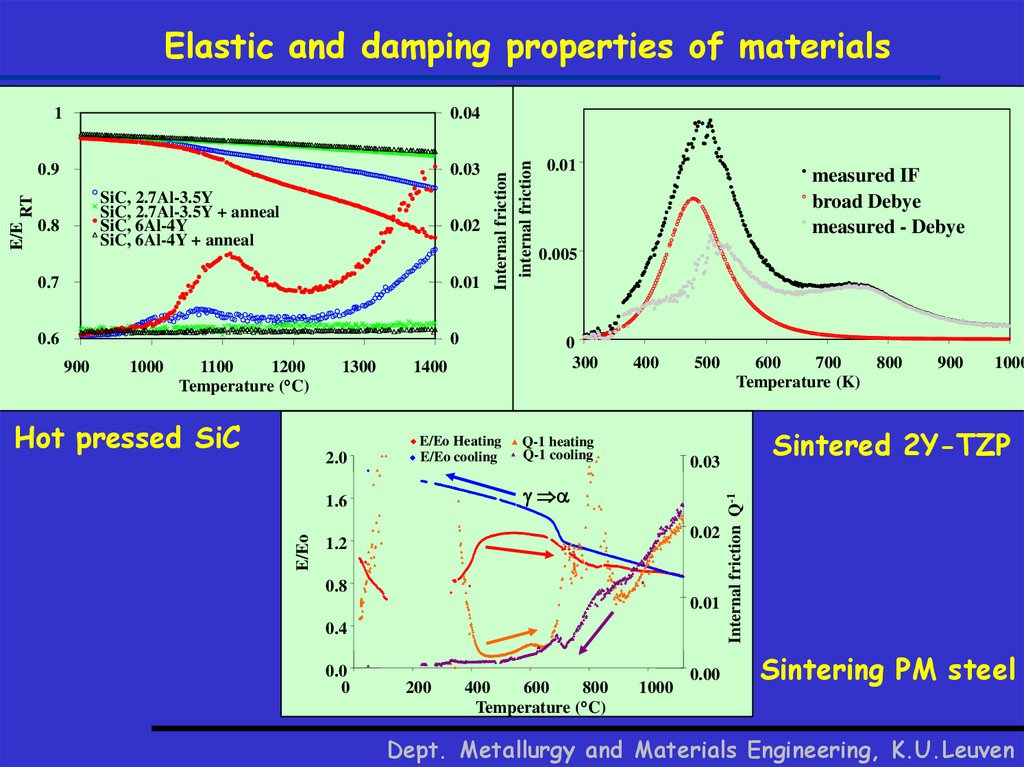

0.040.9

0.03

E/E

RT

SiC, 2.7Al-3.5Y

SiC, 2.7Al-3.5Y + anneal

SiC, 6Al-4Y

SiC, 6Al-4Y + anneal

0.8

0.02

0.7

0.01

0.6

0

900

1000

1100

1200

Temperature (°C)

Hot pressed SiC

1300

2.0

E/Eo Heating

E/Eo cooling

measured IF

broad Debye

measured - Debye

0.005

0

300

1400

400

Q-1 heating

Q-1 cooling

500

0.02

1.2

0.8

0.01

0.4

0.0

0

200

400

600

800

Temperature (°C)

600

700

800

Temperature (K)

1000

0.00

900

1000

Sintered 2Y-TZP

0.03

g a

1.6

E/Eo

0.01

Internal friction Q-1

1

Internal friction

internal friction

Elastic and damping properties of materials

Sintering PM steel

Dept. Metallurgy and Materials Engineering, K.U.Leuven

38.

Elastic and damping properties of materialsStructural Integrity of Ceramic Multilayers and Coatings”

Dept. Metallurgy and Materials Engineering, K.U.Leuven

39.

Selective laser sintering and meltingDirect rapid manufacturing of metallic and ceramic parts

SBO project: DiRaMaP (2008-2012)

Project Coordinator:

PMA, K.U.Leuven

Dept. Metallurgy and Materials Engineering, K.U.Leuven

40.

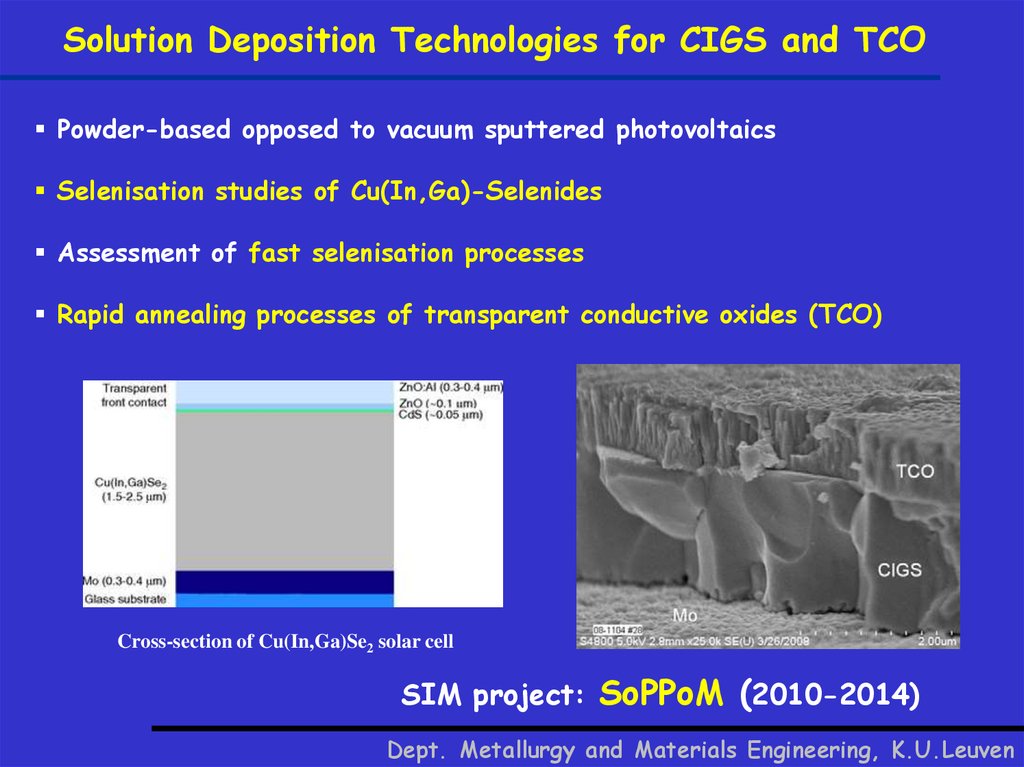

Solution Deposition Technologies for CIGS and TCOPowder-based opposed to vacuum sputtered photovoltaics

Selenisation studies of Cu(In,Ga)-Selenides

Assessment of fast selenisation processes

Rapid annealing processes of transparent conductive oxides (TCO)

Cross-section of Cu(In,Ga)Se2 solar cell

SIM project: SoPPoM (2010-2014)

Dept. Metallurgy and Materials Engineering, K.U.Leuven

41.

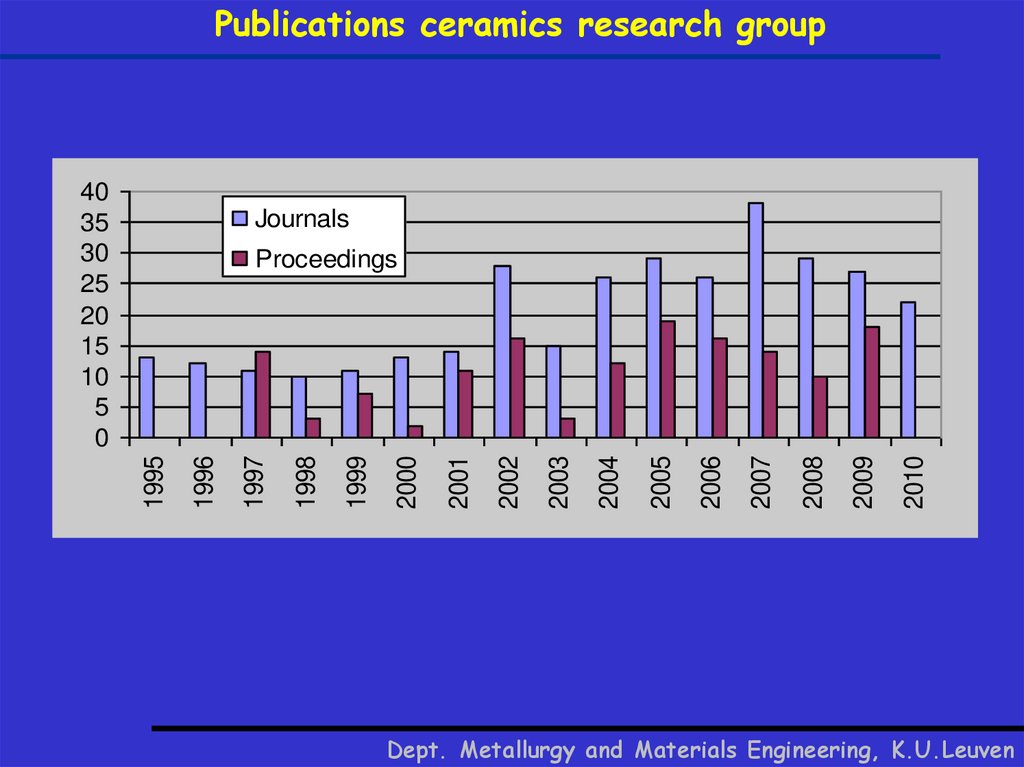

Publications ceramics research group40

35

30

25

20

15

10

5

0

Journals

2010

2009

2008

2007

2006

2005

2004

2003

2002

2001

2000

1999

1998

1997

1996

1995

Proceedings

Dept. Metallurgy and Materials Engineering, K.U.Leuven

42.

Ceramics research groupDept. Metallurgy and Materials Engineering, K.U.Leuven

industry

industry