Similar presentations:

Leak and pressure tests in magnets production chain

1. Leak and pressure tests in magnets production chain

Galimov A.R.JINR-GSI meeting, 2018-12-02

2. Applied helium leak test methods

A) Enclosure test (integral leak detection);B) Spray technique (local leak detection);

С) Enclosure test (integral leak detection);

D) Sniffer technique (local leak detection)

E) Bubble test

Leak detectors:

ASM310

ASM380

HLT575

ASM340

Maximum sensitive:

5×10-13 Пам3/с (5×10-12 mbar•l/с)

3. Enclosure test

IsolatorsTubes

Parts of magnets (sometimes)

Sensitive: 5×10-13 Пам3/с

Summarize leak

4. Sniffer test

ConnectionsMagnets after cryogenic test

Magnets with problems

Sensitive: 5×10-9 Пам3/с

Place of leak;

Leak can be calculated

5. Spray technique

Parts of magnets before cryotestMagnets before cryotest

Another items for vacuum

Sensitive: 5×10-13 Пам3/с

Place of leak;

Leak can be calculated;

6. Enclosure test (main test for magnets)

MagnetsTubes

Another items with helium inside

Sensitive: 5×10-13 Пам3/с

Summarize leak;

7. Test bench for enclosure test

MagnetsTubes

Pressure test is done last leak test

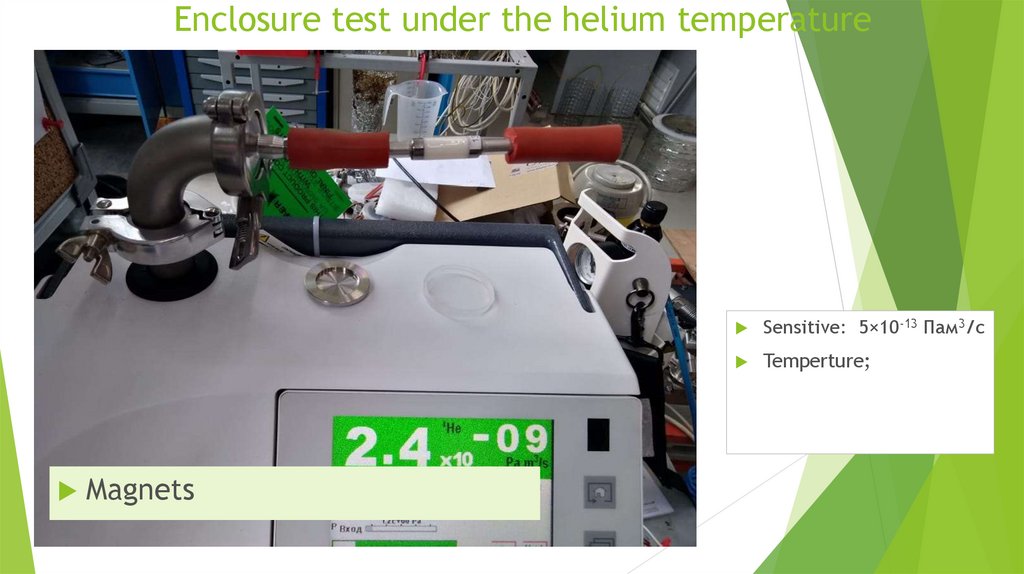

8. Enclosure test under the helium temperature

Theoret ical leak rat es of a t ubular leak of 8 0 nm diamet er and 1 mm longApplying law of Hagen-Poiseuille ( laminar f low, non-compressible f luides) , conservat ive approach

Temperat ure [ K]

1 .0 0 E+0 0

1 .0 0 E+0 1

1 .0 0 E+0 2

1 .0 0 E+0 3

1 .0 0 E-1 1

Gas 1 bar

Liquid 1 bar

3 .6 bar

1 .0 0 E-1 2

Molar flow rat e [ Mol/ s]

Operat ion t emperat ure at

highest operat ion pressure in LHC

1 .0 0 E-1 3

RT leak t est

at 2 5 bar

1 .0 0 E-1 4

1 .0 0 E-1 5

1 .0 0 E-1 6

9.

Enclosure test under the helium temperatureMagnets

Sensitive: 5×10-13 Пам3/с

Temperture;

industry

industry