Similar presentations:

Porous Type Anodic Oxide Film

1.

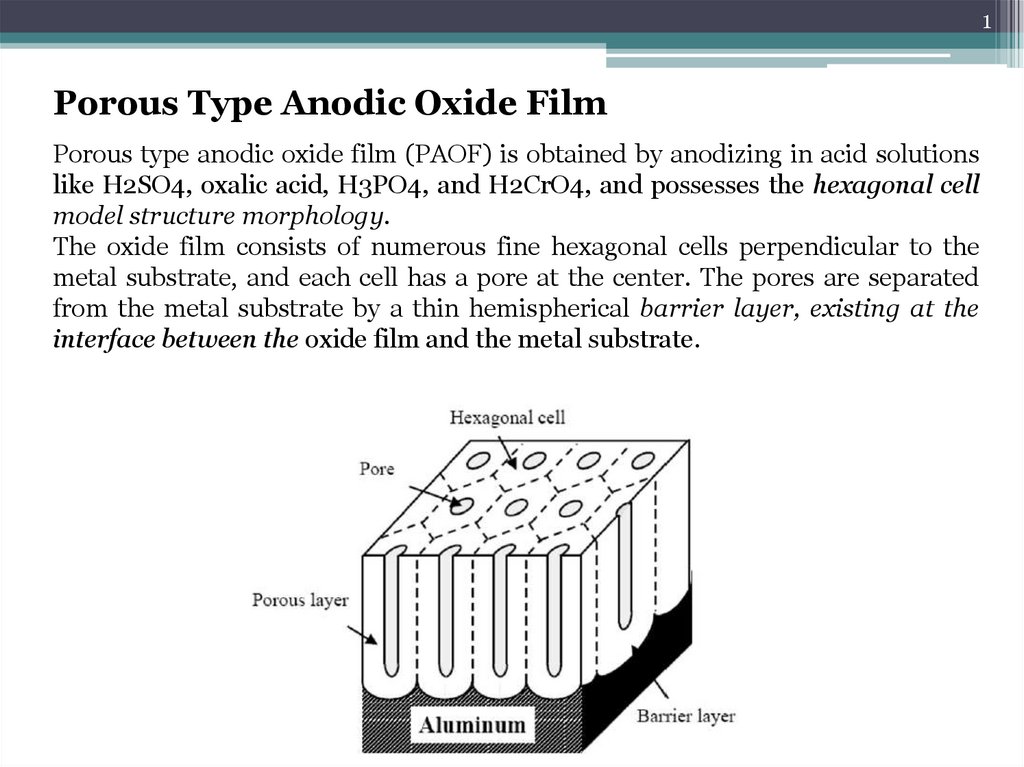

1Porous Type Anodic Oxide Film

Porous type anodic oxide film (PAOF) is obtained by anodizing in acid solutions

like H2SO4, oxalic acid, H3PO4, and H2CrO4, and possesses the hexagonal cell

model structure morphology.

The oxide film consists of numerous fine hexagonal cells perpendicular to the

metal substrate, and each cell has a pore at the center. The pores are separated

from the metal substrate by a thin hemispherical barrier layer, existing at the

interface between the oxide film and the metal substrate.

2.

2Nanoporous anodic alumina was discovered during the first decades of the

twentieth century and widely used in industry for:

•corrosion protection,

•car industry,

•metal decoration purposes,

•optics and photonics,

•electronics,

•membrane science,

•materials science,

•engineering,

•medicine,

•industry.

More than 3000 journal papers on nanoporous anodic alumina were published in

last 20 years.

3.

34.

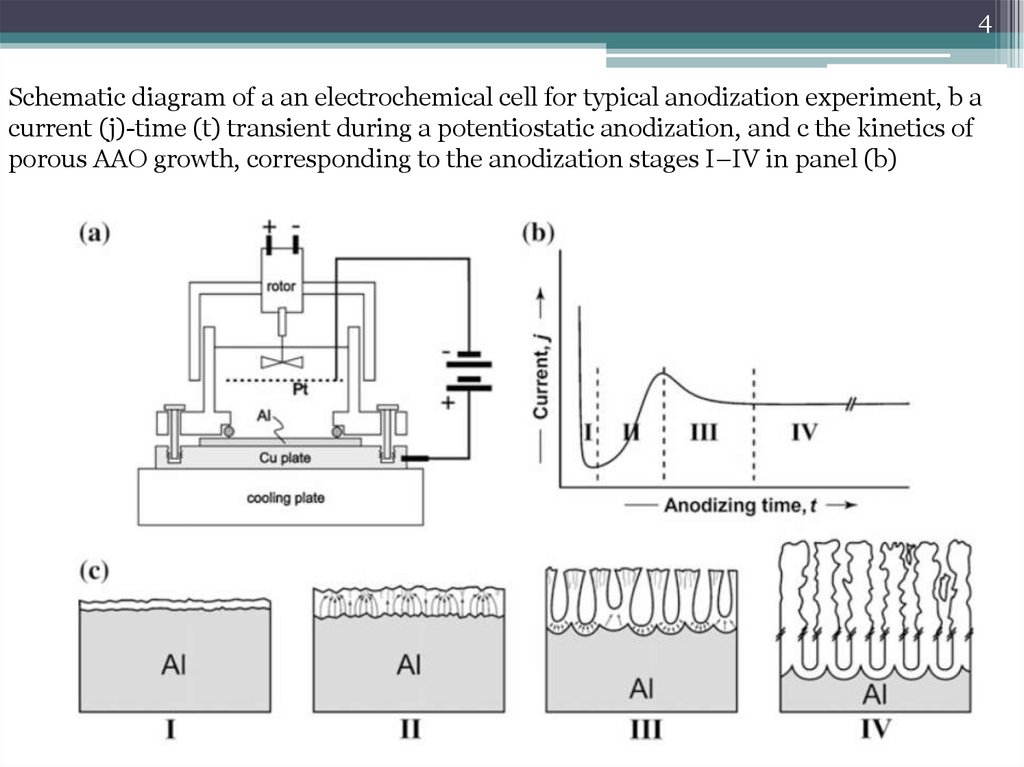

4Schematic diagram of a an electrochemical cell for typical anodization experiment, b a

current (j)-time (t) transient during a potentiostatic anodization, and c the kinetics of

porous AAO growth, corresponding to the anodization stages I–IV in panel (b)

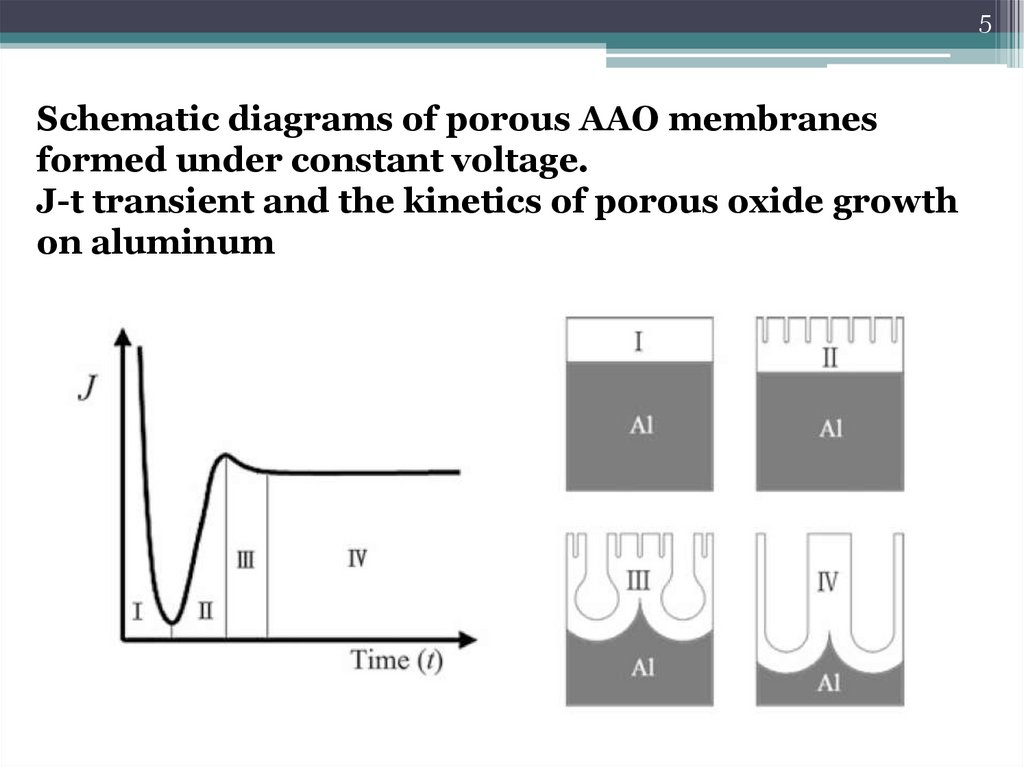

5.

5Schematic diagrams of porous AAO membranes

formed under constant voltage.

J-t transient and the kinetics of porous oxide growth

on aluminum

6.

6Stage I

At the moment after applying a constant U, the J will reach a

high value quickly, which can be attributed to the occurrence of

electrolytic process of water.

Immediately, a thin compact oxide barrier layer begins to form

on the aluminum surface which in contact with the electrolyte.

At this stage, the thickness of the oxide barrier layer increases

rapidly, which means that the total resistance will increase

correspondingly. Therefore, the J will decrease abruptly to

reach the minimum value under the potentiostatic mode, when

the barrier layer thickness increases to a certain value

7.

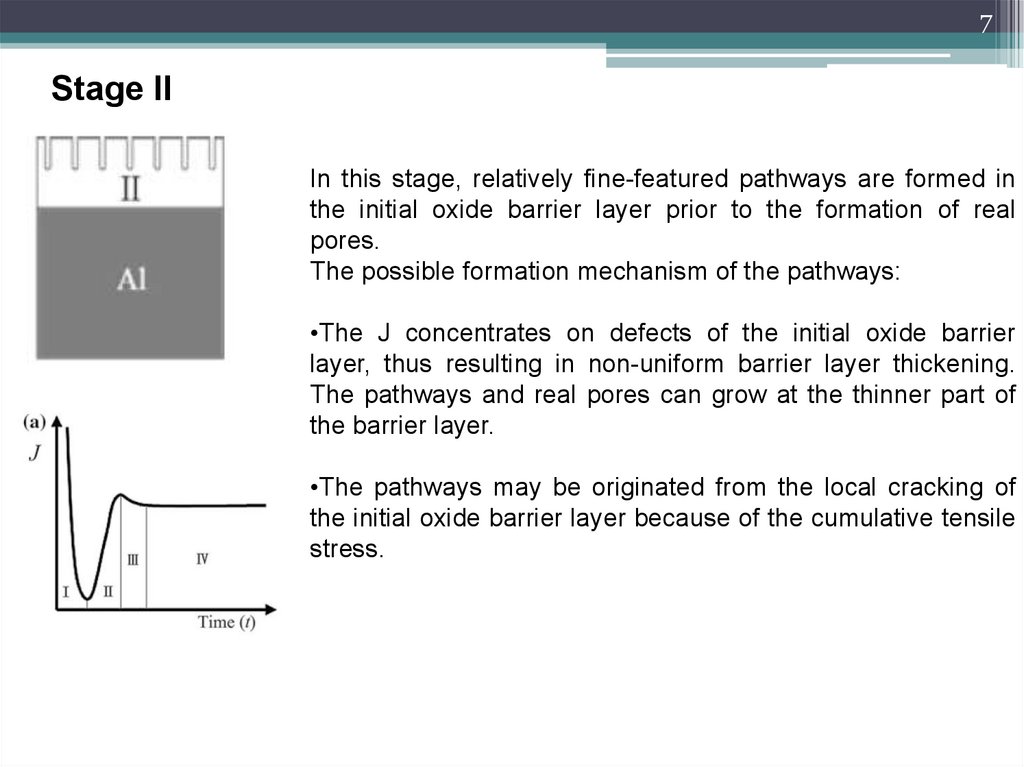

7Stage II

In this stage, relatively fine-featured pathways are formed in

the initial oxide barrier layer prior to the formation of real

pores.

The possible formation mechanism of the pathways:

•The J concentrates on defects of the initial oxide barrier

layer, thus resulting in non-uniform barrier layer thickening.

The pathways and real pores can grow at the thinner part of

the barrier layer.

•The pathways may be originated from the local cracking of

the initial oxide barrier layer because of the cumulative tensile

stress.

8.

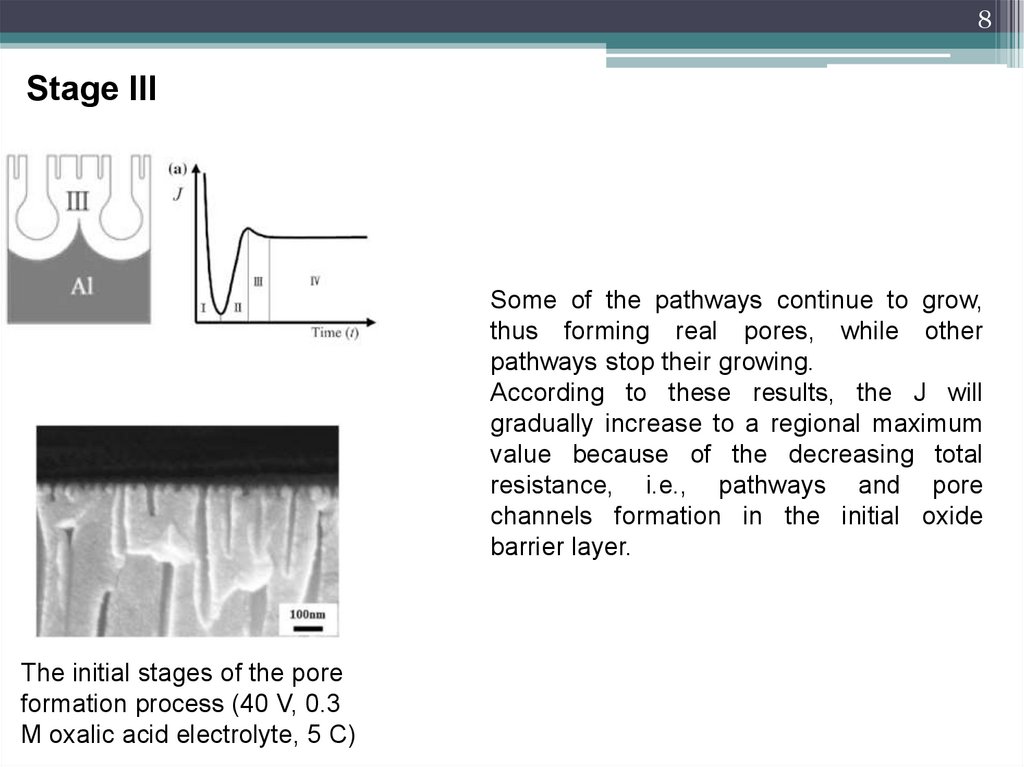

8Stage III

Some of the pathways continue to grow,

thus forming real pores, while other

pathways stop their growing.

According to these results, the J will

gradually increase to a regional maximum

value because of the decreasing total

resistance, i.e., pathways and pore

channels formation in the initial oxide

barrier layer.

The initial stages of the pore

formation process (40 V, 0.3

M oxalic acid electrolyte, 5 C)

9.

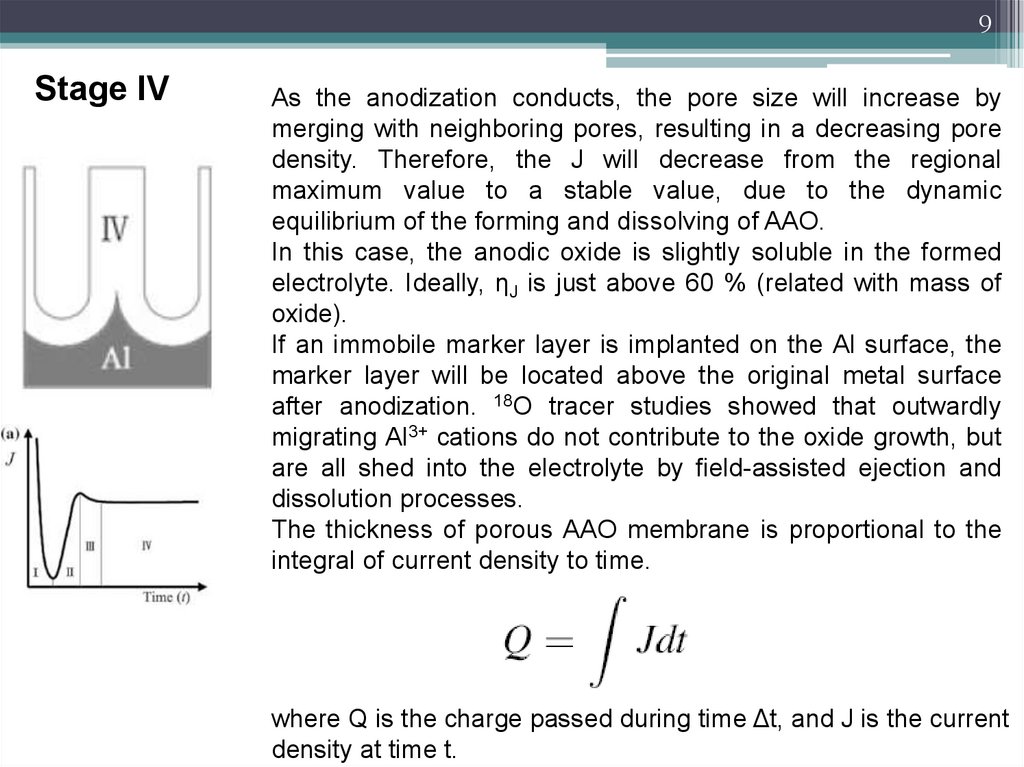

9Stage IV

As the anodization conducts, the pore size will increase by

merging with neighboring pores, resulting in a decreasing pore

density. Therefore, the J will decrease from the regional

maximum value to a stable value, due to the dynamic

equilibrium of the forming and dissolving of AAO.

In this case, the anodic oxide is slightly soluble in the formed

electrolyte. Ideally, ηJ is just above 60 % (related with mass of

oxide).

If an immobile marker layer is implanted on the Al surface, the

marker layer will be located above the original metal surface

after anodization. 18O tracer studies showed that outwardly

migrating Al3+ cations do not contribute to the oxide growth, but

are all shed into the electrolyte by field-assisted ejection and

dissolution processes.

The thickness of porous AAO membrane is proportional to the

integral of current density to time.

where Q is the charge passed during time Δt, and J is the current

density at time t.

10.

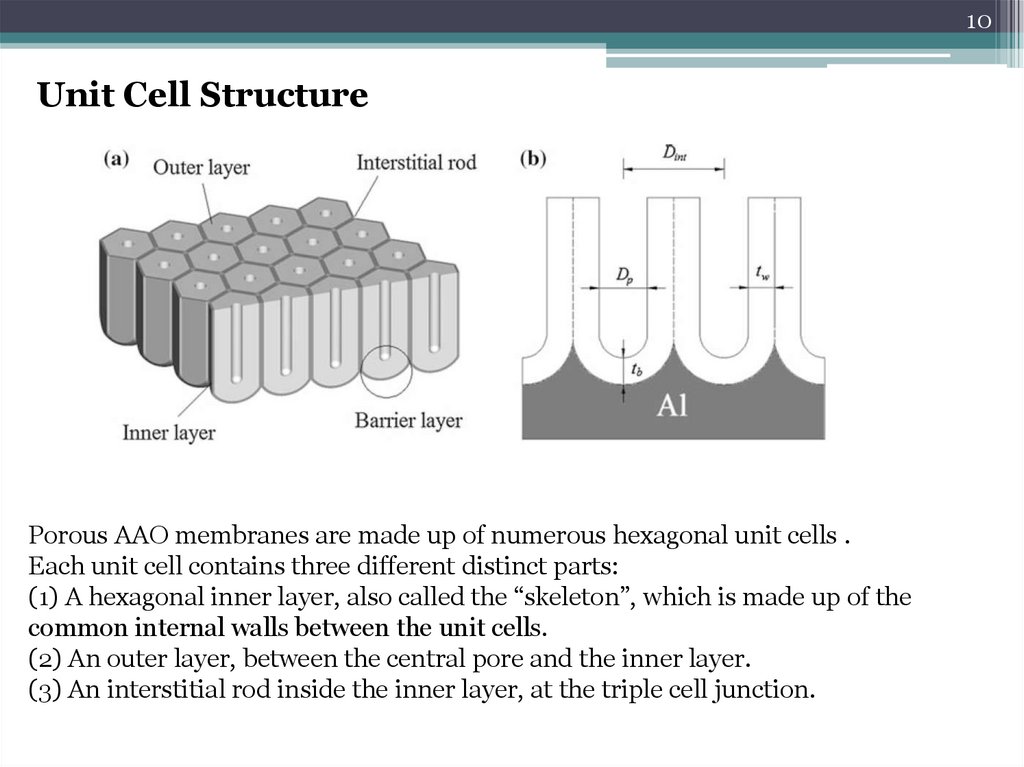

10Unit Cell Structure

Porous AAO membranes are made up of numerous hexagonal unit cells .

Each unit cell contains three different distinct parts:

(1) A hexagonal inner layer, also called the “skeleton”, which is made up of the

common internal walls between the unit cells.

(2) An outer layer, between the central pore and the inner layer.

(3) An interstitial rod inside the inner layer, at the triple cell junction.

11.

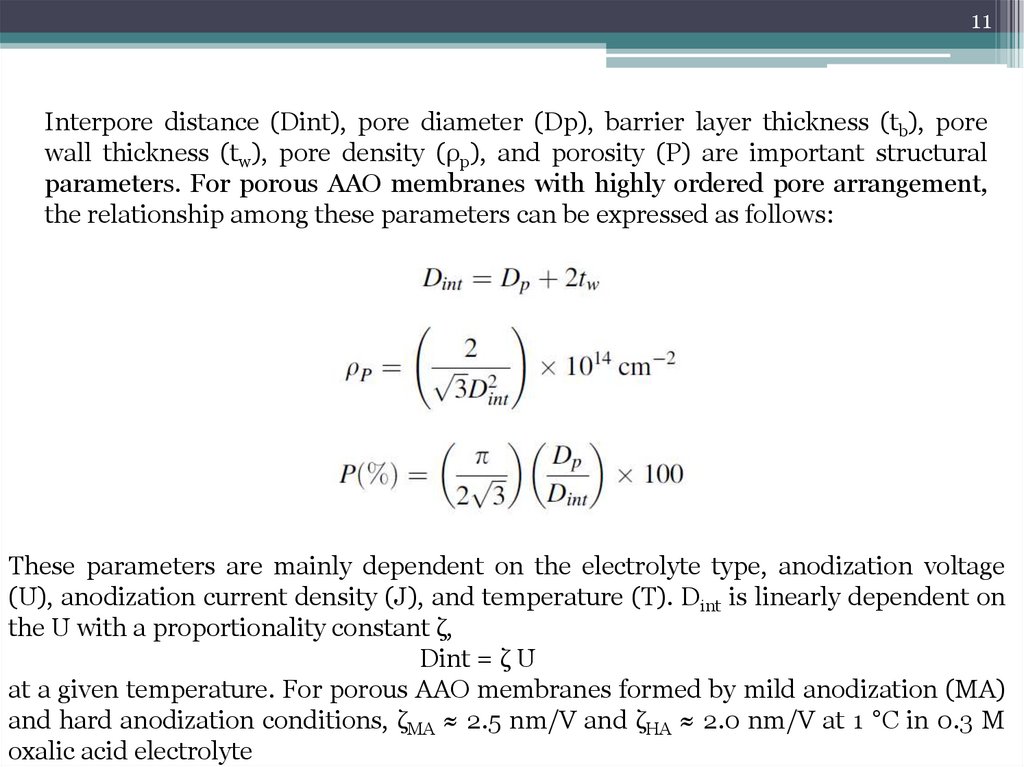

11Interpore distance (Dint), pore diameter (Dp), barrier layer thickness (tb), pore

wall thickness (tw), pore density (ρp), and porosity (P) are important structural

parameters. For porous AAO membranes with highly ordered pore arrangement,

the relationship among these parameters can be expressed as follows:

These parameters are mainly dependent on the electrolyte type, anodization voltage

(U), anodization current density (J), and temperature (T). Dint is linearly dependent on

the U with a proportionality constant ζ,

Dint = ζ U

at a given temperature. For porous AAO membranes formed by mild anodization (MA)

and hard anodization conditions, ζMA ≈ 2.5 nm/V and ζHA ≈ 2.0 nm/V at 1 °C in 0.3 M

oxalic acid electrolyte

12.

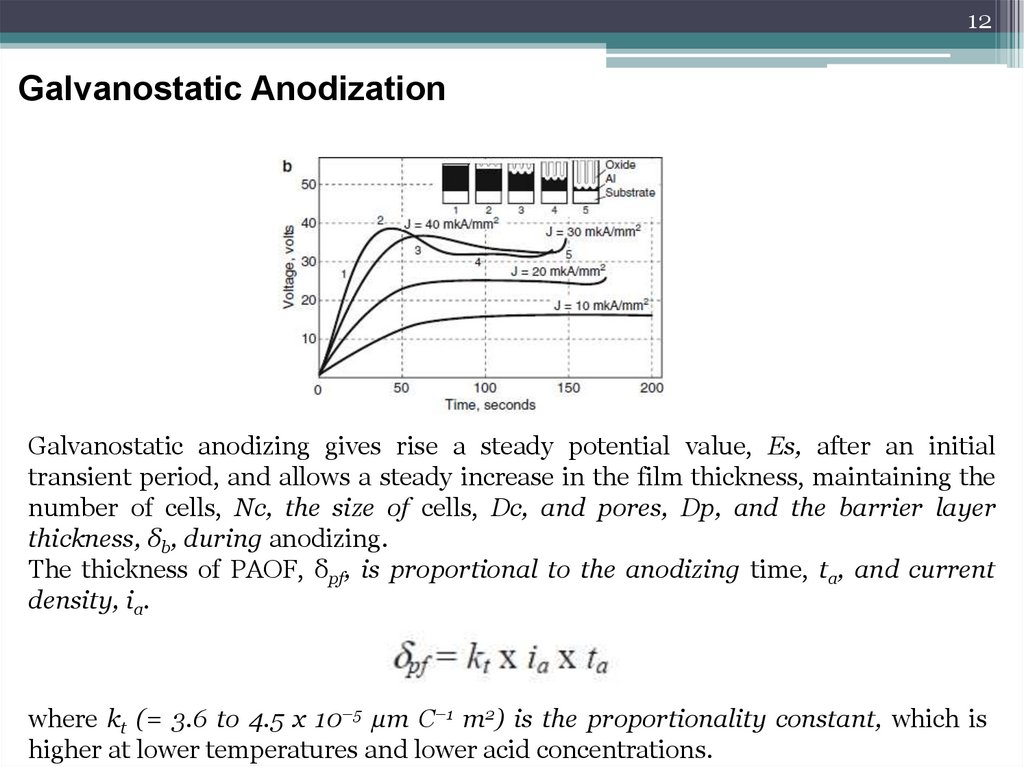

12Galvanostatic Anodization

Galvanostatic anodizing gives rise a steady potential value, Es, after an initial

transient period, and allows a steady increase in the film thickness, maintaining the

number of cells, Nc, the size of cells, Dc, and pores, Dp, and the barrier layer

thickness, δb, during anodizing.

The thickness of PAOF, δpf, is proportional to the anodizing time, ta, and current

density, ia.

where kt (= 3.6 to 4.5 x 10–5 μm C–1 m2) is the proportionality constant, which is

higher at lower temperatures and lower acid concentrations.

13.

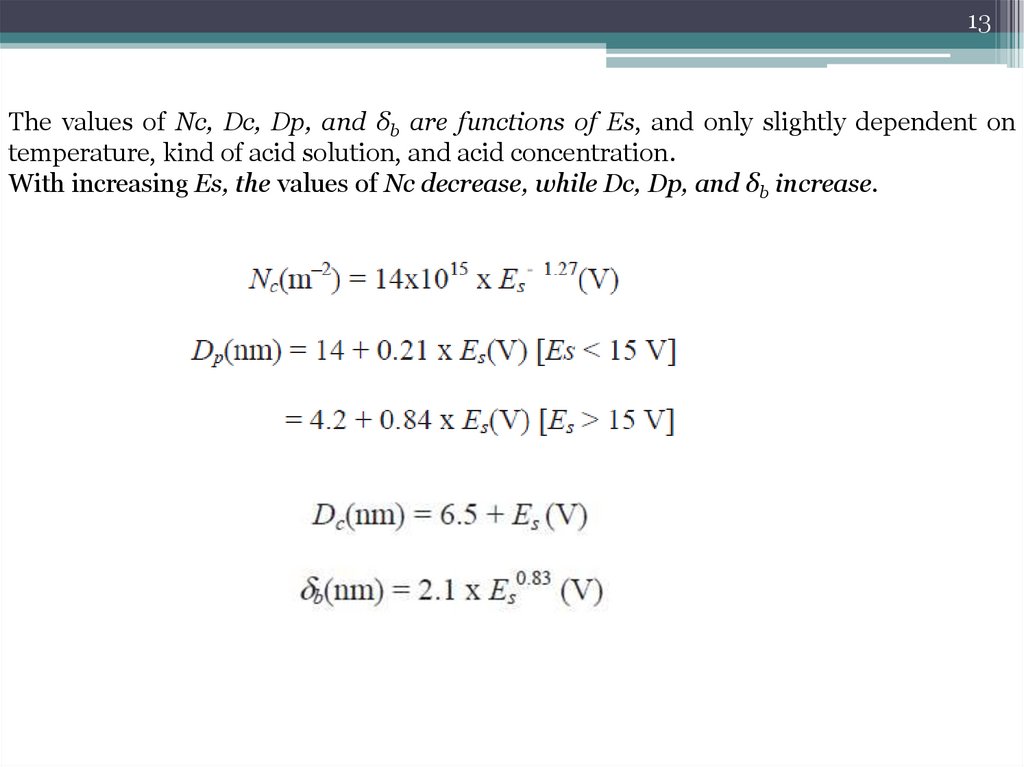

13The values of Nc, Dc, Dp, and δb are functions of Es, and only slightly dependent on

temperature, kind of acid solution, and acid concentration.

With increasing Es, the values of Nc decrease, while Dc, Dp, and δb increase.

14.

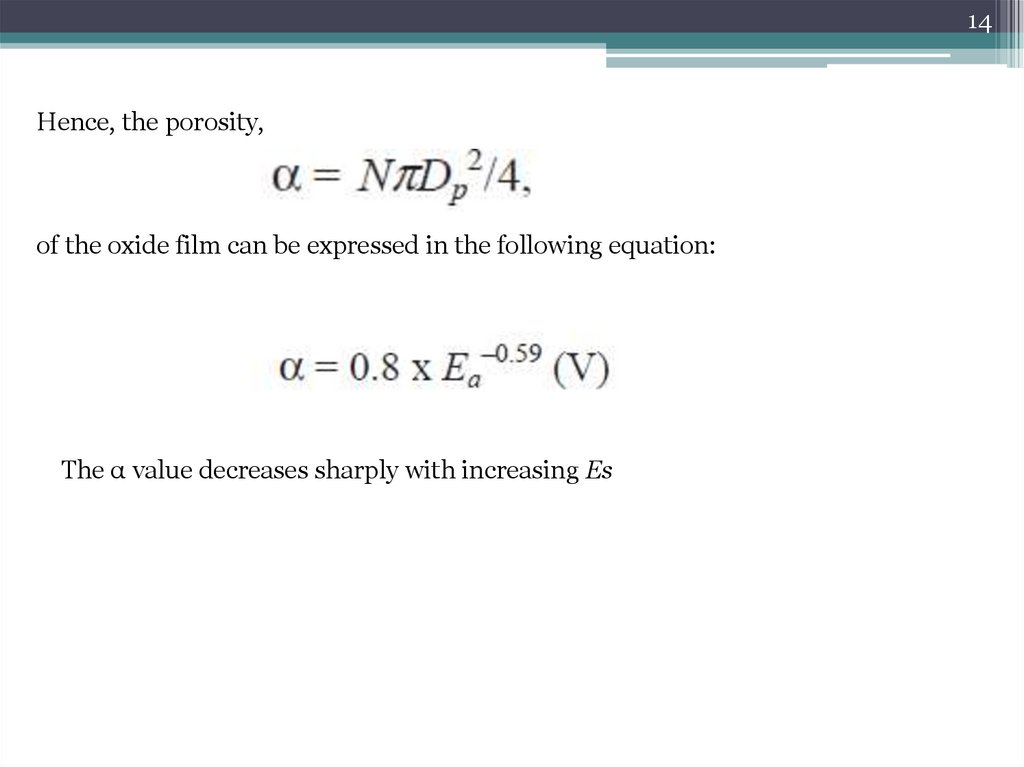

14Hence, the porosity,

of the oxide film can be expressed in the following equation:

The α value decreases sharply with increasing Es

english

english