Similar presentations:

Taguchi Philosophy

1.

2. Overview (Lecture the 2nd)

HSE basisHazard / Risk

Taguchi Philosophy

3. HSE Basis

Policy - a set of ideas or a plan of what to do in particular situations that has beenagreed to officially by a group of people, a business organization

Procedure - is a document that is put together by groups within the organization,

and is used as a template when performing a particular task on the job.

Mission - defines the company’s business, its objectives and its approach to reach

those objectives, it focuses on today and what an organization does to achieve it.

Both are vital in directing goals

Vision - describes the desired future position of the company, it focuses on

tomorrow and what an organization wants to ultimately become

For example :

Mission: To attract and attain customers with high-valued products and services and

the most satisfying ownership experience in America.

Vision: To be the most successful and respected car company in America.

4. Hierarchy of Control

5.

6. Hazard / Risk

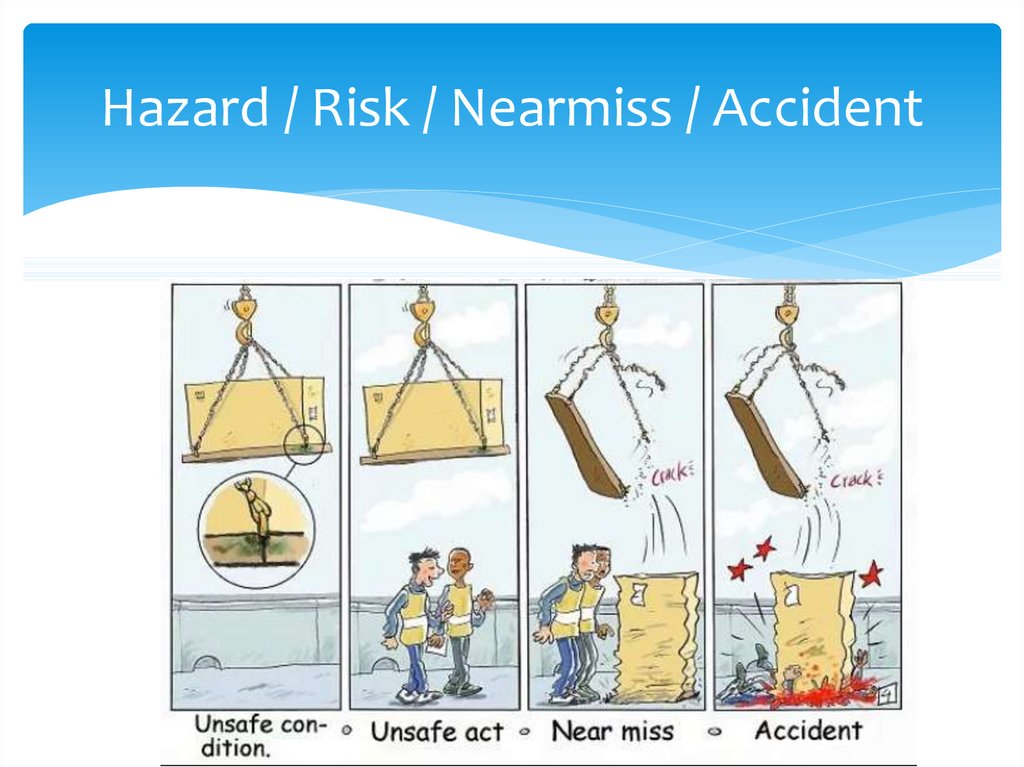

Hazard – any action or situation which has a potential source of harm oradverse health effect on asset, environment or person(s) health.

Risk – is probability (the chance), high or low, that somebody / something

could be harmed by these and other hazards

Hazard + Risk = Incident / accident

Types of incidents:

Incident - an unexpected event that may result in property damage, but does

not result in an injury or illness

Accident - an unexpected event that may result in property damage, and does

result in an injury or illness to an employee. Bad event caused by error or by

chance

Nearmiss - is an unplanned event that has the potential to cause, but does not

actually result in human injury, environmental or equipment damage, or an

interruption to normal operation and didn’t face with worse case scenario.

7.

8. Hazard / Risk / Nearmiss / Accident

9.

10. Taguchi Philosophy

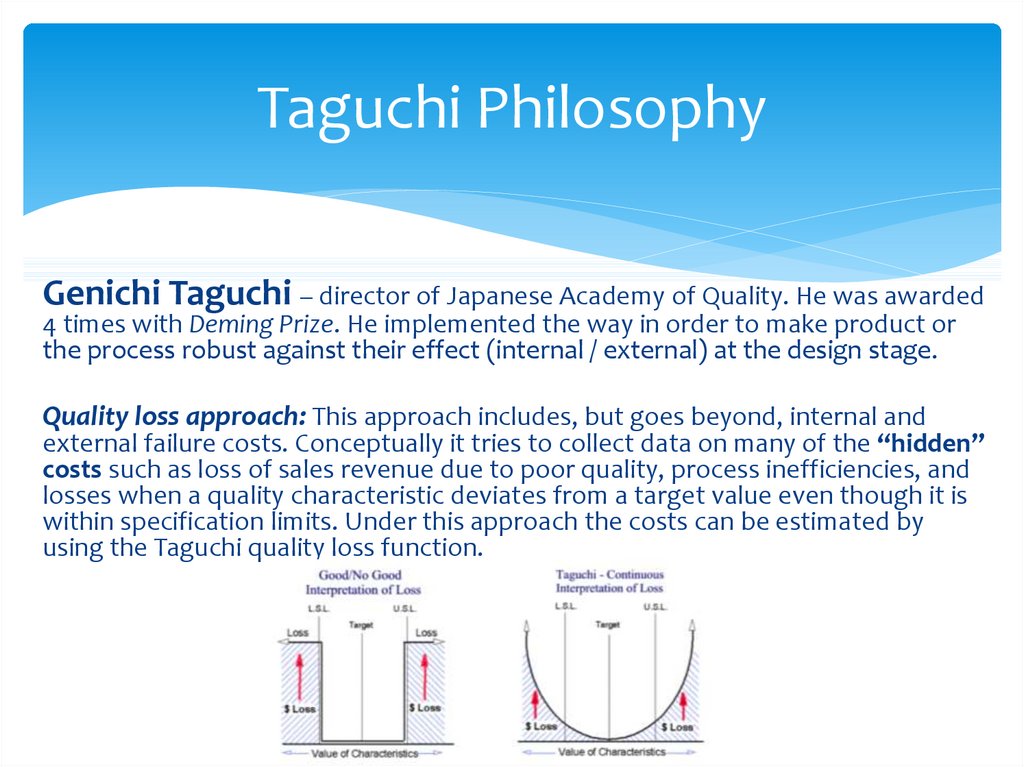

Genichi Taguchi – director of Japanese Academy of Quality. He was awarded4 times with Deming Prize. He implemented the way in order to make product or

the process robust against their effect (internal / external) at the design stage.

Quality loss approach: This approach includes, but goes beyond, internal and

external failure costs. Conceptually it tries to collect data on many of the “hidden”

costs such as loss of sales revenue due to poor quality, process inefficiencies, and

losses when a quality characteristic deviates from a target value even though it is

within specification limits. Under this approach the costs can be estimated by

using the Taguchi quality loss function.

11. Taguchi Philosophy

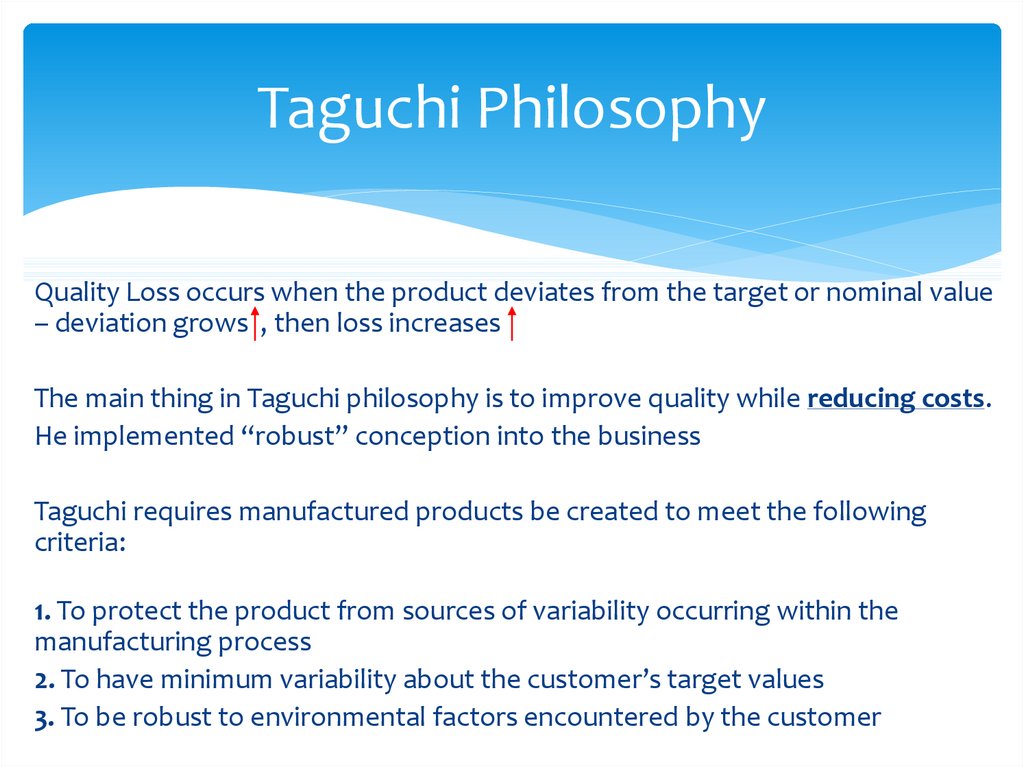

Quality Loss occurs when the product deviates from the target or nominal value– deviation grows , then loss increases

The main thing in Taguchi philosophy is to improve quality while reducing costs.

He implemented “robust” conception into the business

Taguchi requires manufactured products be created to meet the following

criteria:

1. To protect the product from sources of variability occurring within the

manufacturing process

2. To have minimum variability about the customer’s target values

3. To be robust to environmental factors encountered by the customer

12. Taguchi Philosophy

Taguchi formulated a number of principles, following which allows toensure the high quality of the products:

1. Losses - are damages caused to the consumer and the manufacturer

by deviation from the target value.

2. Quality needs to be planned, controlling the factors for reducing

scatter. For this, the concept of signal and noise is introduced. The

signal is the target value of the parameter, the noise is the deviation.

Noises are divided into external and internal. External noise is a variation

of the environment, characteristics of workers, wear. Internal noise production problems.

3. Eliminate losses best at the design stage and redesign.

4. Decisions that do not reduce costs are ignored.

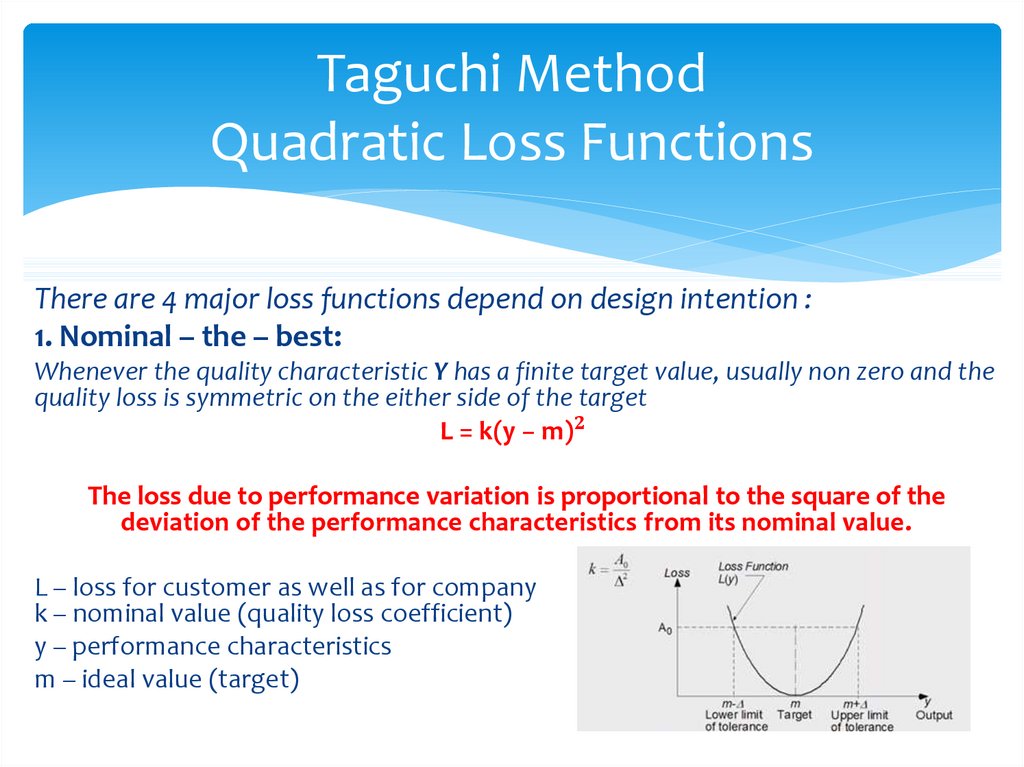

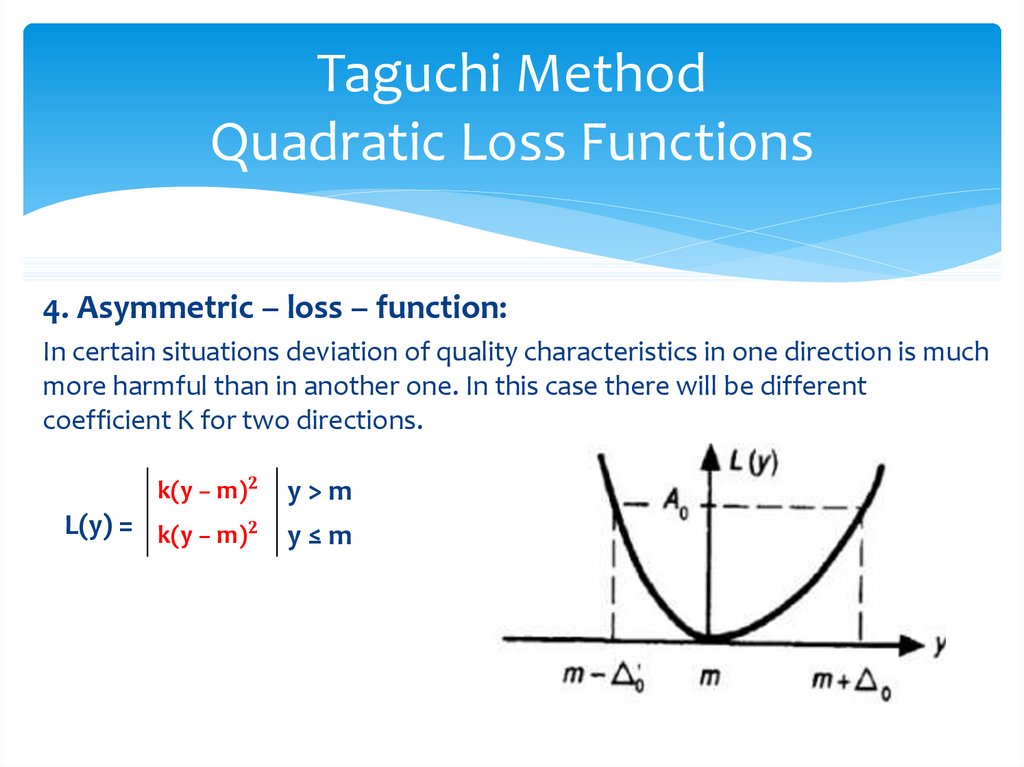

13. Taguchi Method Quadratic Loss Functions

There are 4 major loss functions depend on design intention :1. Nominal – the – best:

Whenever the quality characteristic Y has a finite target value, usually non zero and the

quality loss is symmetric on the either side of the target

L = k(y − m)

management

management