Similar presentations:

“Nafen” alumina nanofibers as support for “Iriotec” antistatic pigments

1.

“Nafen” alumina nanofibers as support for“Iriotec” antistatic pigments

VERSION 2.0 @ 28.12.2016

2.

Available antistatic solutions-

discrete carbon fibers (chopped/milled)

color; difficult incorporation

-

carbon nanotubes (CNTs)

high dosage

(high percolation threshold)

-

Iriotec (Minatec) core-shell pigments

-

inorganic nanoparticles – transparent conductive oxides

(ITO/ATO++)

-

surfactants / quaternary ammonium salts (QAS)

-

conductive polymers (ICP)

-

metal salts; ionic liquids (RTIL), blends

-

other / exotic

(usually) color;

difficult incorporation

HIGH

price

non-permanent;

sensitive to

humidity

(often) insufficient

performance level

SUMMARY:

industry still seeks for GOOD

ESD solution

2

3.

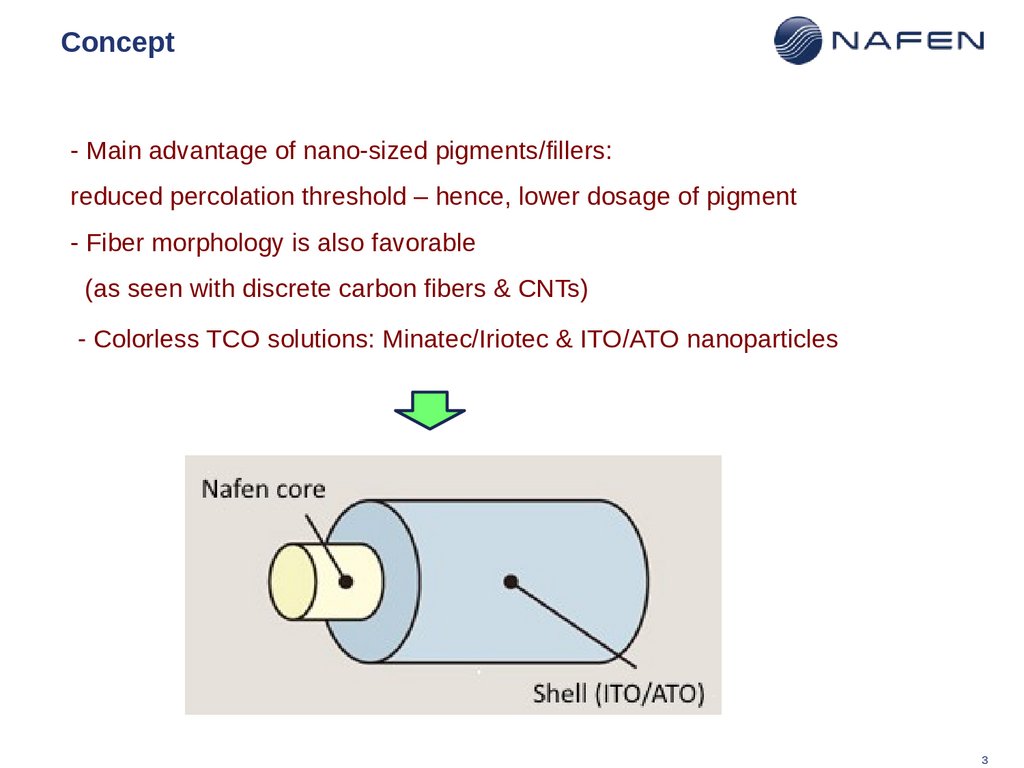

Concept- Main advantage of nano-sized pigments/fillers:

reduced percolation threshold – hence, lower dosage of pigment

- Fiber morphology is also favorable

(as seen with discrete carbon fibers & CNTs)

- Colorless TCO solutions: Minatec/Iriotec & ITO/ATO nanoparticles

3

4.

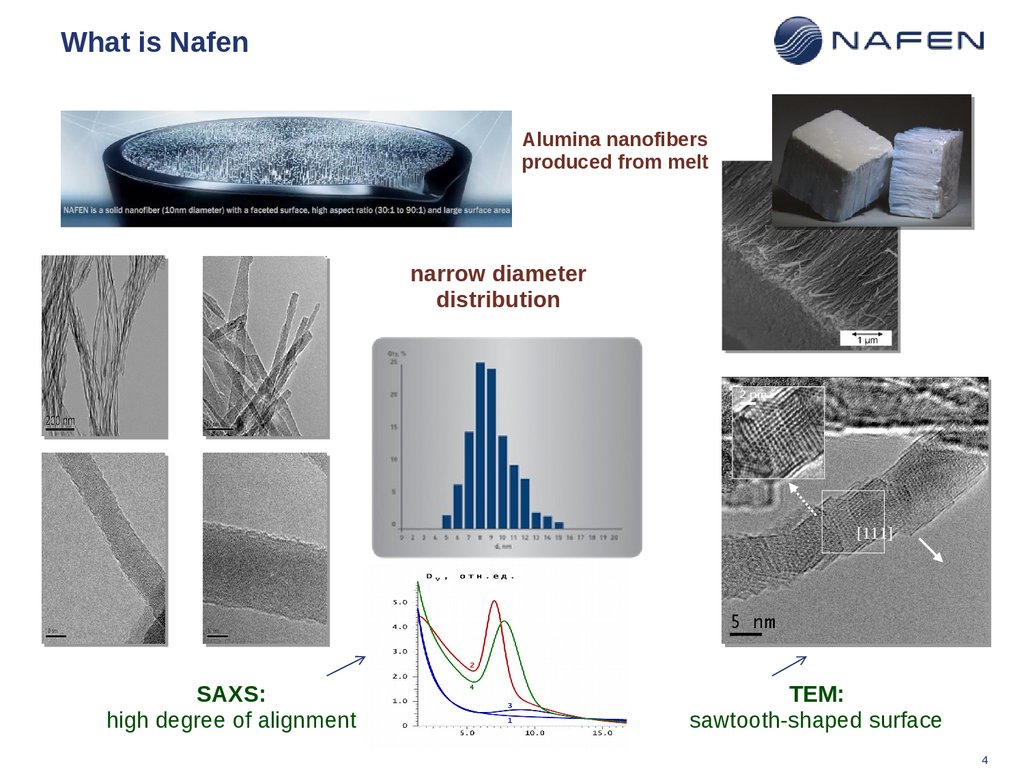

What is NafenAlumina nanofibers

produced from melt

narrow diameter

distribution

[111]

[111]

Рис.

Рис.5.8.

5.8.Ориентация

Ориентацияфасеток

фасетокувеличенного

увеличенногоразмера

размера(5(5нм

нмииболее).

более).

SAXS:

high degree of alignment

TEM:

sawtooth-shaped surface

4

5.

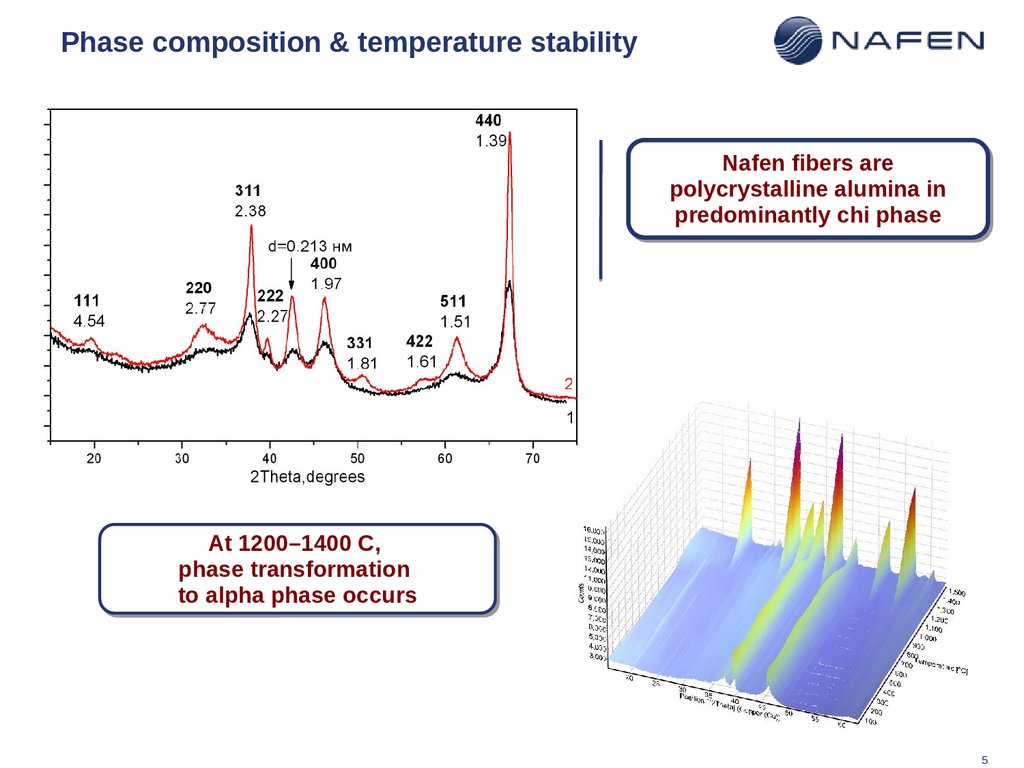

Phase composition & temperature stabilityNafen

Nafen fibers

fibers are

are

polycrystalline

polycrystalline alumina

alumina in

in

predominantly

predominantly chi

chi phase

phase

High-Temperature XRD

At

At 1200–1400

1200–1400 C,

C,

phase

phase transformation

transformation

to

to alpha

alpha phase

phase occurs

occurs

5

6.

Nafen dispersionsPre-dispersed “Nafen“

can be used

in various liquid

(e.g. sol-gel) processes

Ultrasonic dispersion and/or

targeted surface treatment

(functionalization) allows good

(almost to single fiber) level of

dispersion

6

7.

Nafen as support for functional pigments1) nanometer size (diameter) and fiber morphology : allows to

reach low percolation threshold

2) Al2O3: high chemical/UV stability

3) relatively high SSA and “sawtooth-shaped” surface:

allows easy anchoring of active components (ITO/ATO)

4) white: no effect on color of coatings

5) surface chemistry can be tailored:

- three subtypes of Nafen available

- functionalization is possible –

e.g. to enhance adhesion to ITO coating

6) ready masterbatches for liquid medium processes (sol-gel)

can be produced

7) “bonus” reinforcement effect in polymers

7

8.

Future possibilities: hybrid fillers?CNT (ITO@Nafen)

main pigment

(“regular” Minatec)

(polymer) matrix)

concept used in thermally conductive materials:

e.g. Ai-jie Ma , Weixing Chen & Yonggang Hou (2012) Enhanced Thermal Conductivity of Epoxy

Composites with MWCNTs/AlN Hybrid Filler, Polymer-Plastics Technology and Engineering, 51:15, 1578-1582

8

9.

Thank You for Attention9

chemistry

chemistry