Similar presentations:

Lubrication

1. Dia 1

sound2

2. Dia 2

The position of the drain tankis often in the double bottom.

Drain tank (or sump) with lubricant

2

3. Dia 3

Pumpsdraw the lubricant

from the drain tank.

2

4. Dia 4

The lubricant is led throughfilters

to the cooler (heat exchanger).

cooler

2

5. Dia 5

In the cooler the lubricant iscooled by fresh water or sea water.

cooler

sound

2

6. Dia 6

From the cooler the lube oil passesthrough the distribution branches in

the engine.

distribution branches

sound

2

7. Dia 7

sDistribution branches

8. Dia 8

In a crosshead engine oil bores run through thecrankshaft, crankwebs and crankpins,

9. Dia 9

so that the oil can flowfrom the main bearing to

the crank,

connecting rod,

crosshead,

crosshead guide shoes and

crosshead guides.

S

sound

10. Dia 10

The oil passes through the main lube-oil supply lineto the bearings.

11. Dia 11

In a trunk enginethe cylinder-lubrication

is done by the

oil mist

thrown up by the crank.

sound

12. Dia 12

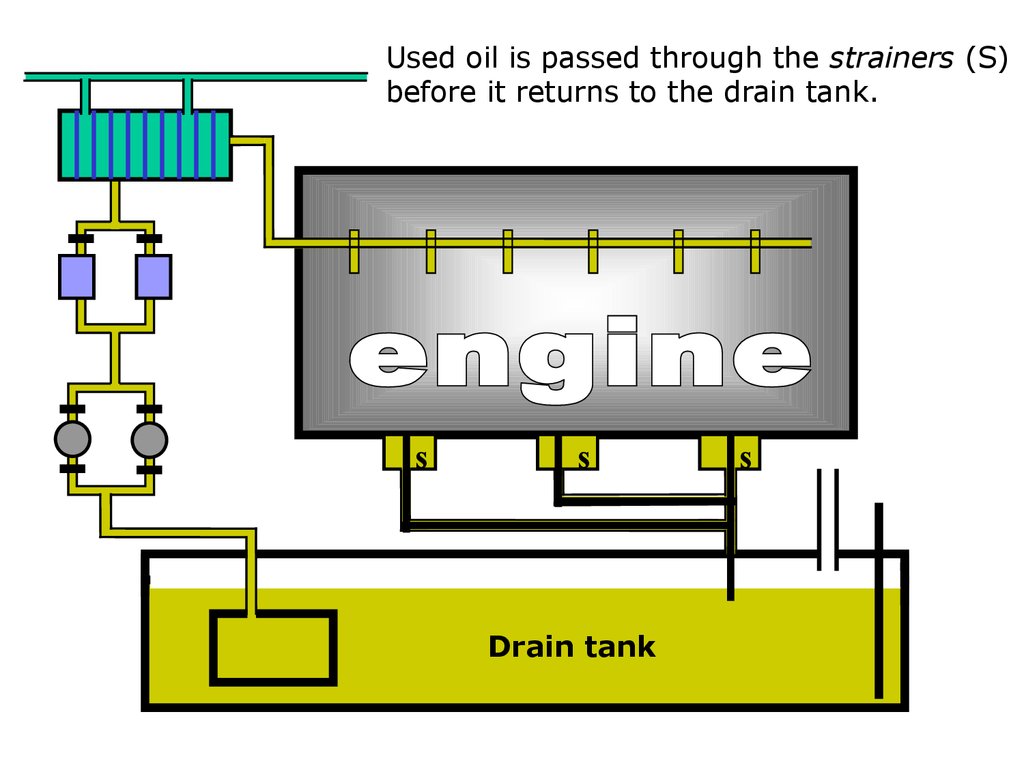

Used oil is passed through the strainers (S)before it returns to the drain tank.

s

s

s

Drain tank

sound

2

13. Dia 13

Before the lubricating oil is enteredinto the system again, it must be

purified by a strainer in the drain tank.

strainer

sound

2

14. Dia 14

Air in the drain tank can escapethrough the air vent (breather).

Air vent

(breather)

sound

2

15. Dia 15

The oil-level is indicated with a level gaugeand is measured through a sounding pipe.

Level gauge

Sounding

pipe

sound

2

16. Dia 16

TheInternational Maritime Language Programme – IMLP

C

The IMLP is an IMO-standard.

P.C. van Kluijven

mechanics

mechanics industry

industry